Multi-coating cutting tool deposited in periodicity and preparation method thereof

A periodic, multi-coating technology, applied in lathe tools, turning equipment, manufacturing tools, etc., can solve problems such as low bonding strength, achieve low equipment requirements, simple process, high temperature oxidation resistance and high temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

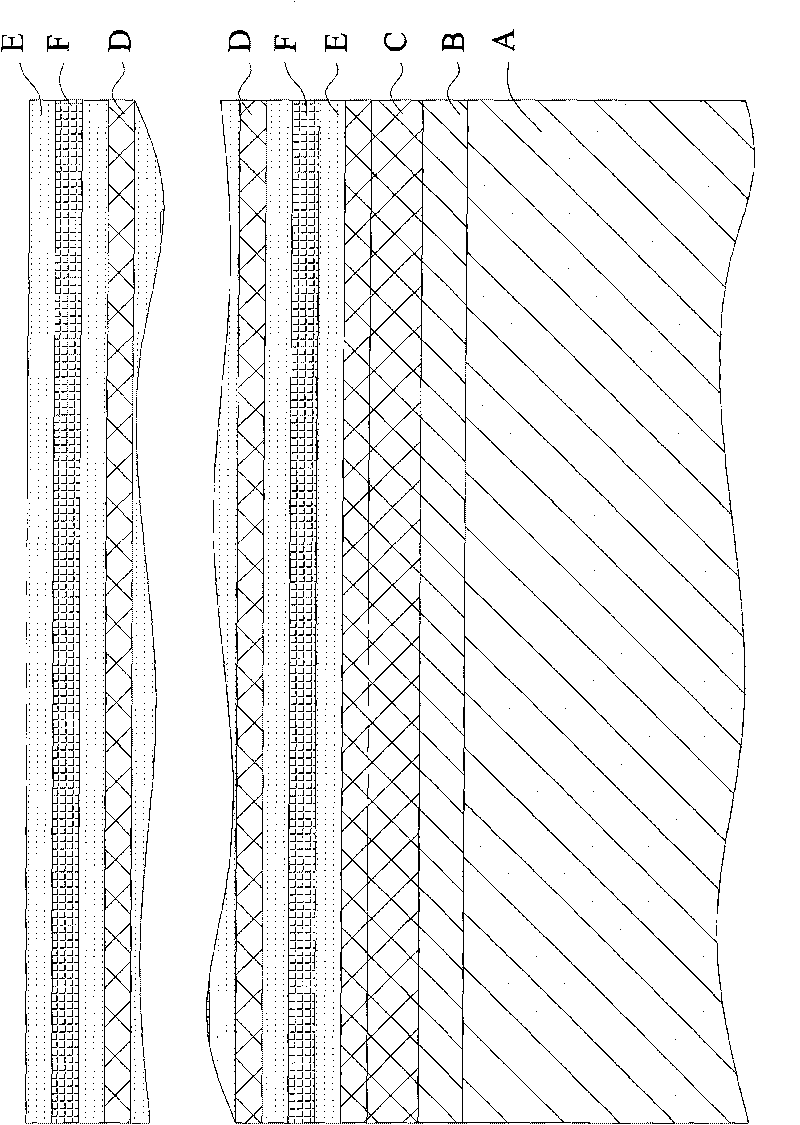

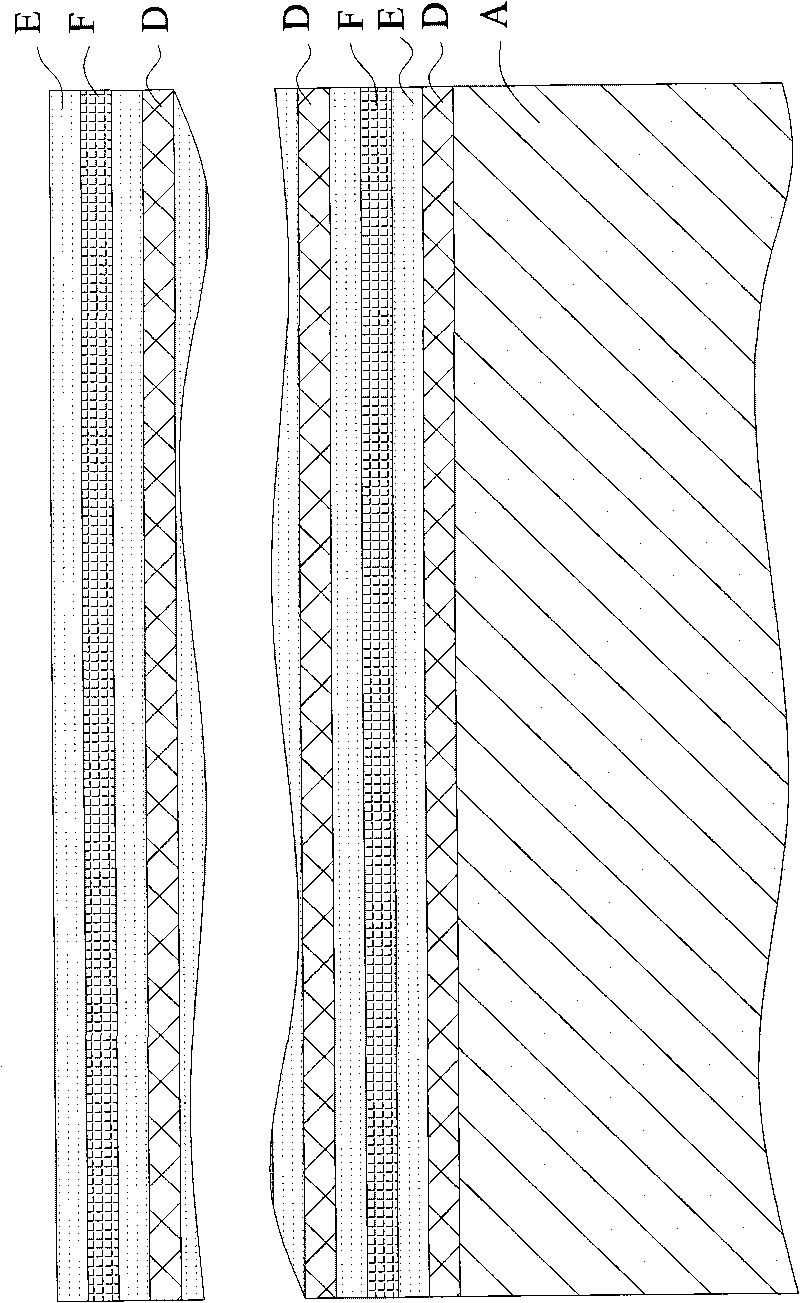

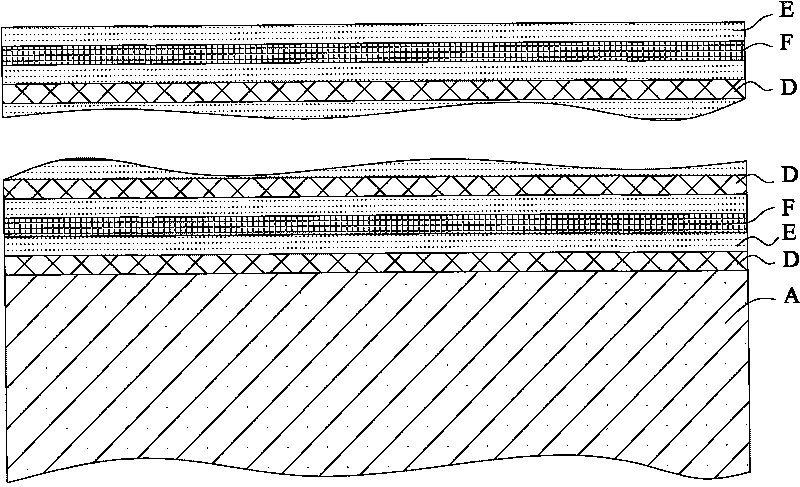

[0023] A kind of periodically deposited multi-coated cutting tool of the present invention comprises a cutting tool substrate and a coating deposited on the cutting tool substrate. Composed of TiAlSiN layer, the composite coating is based on the surface of the tool substrate and presents a multi-periodical change trend with a period of "TiN layer to TiSiN layer to TiAlSiN layer to TiSiN layer" as a cycle.

[0024]The above-mentioned multi-coated cutting tool is prepared by the following physical vapor deposition process:

[0025] The technical solution for realizing the present invention is described below by taking the cemented carbide substrate as an example: first, the tool substrate is subjected to pretreatments such as surface cleaning and Ar etching, and then a layer of physical vapor deposition is first sequentially deposited on the pretreated cutter substrate. A Ti metal layer with a thickness of 20nm~30nm and a TiN transition layer with a thickness of 20nm~40nm, and t...

Embodiment 2

[0028] The cemented carbide blade of model CNMG120408 and the cemented carbide blade of model SEET12T3 were respectively used as the tool substrate, and the surface cleaning, Ar etching and other pretreatments were performed on the aforementioned tool substrate, and then physical The gas phase multi-target deposition method alternately deposits multi-cycle coatings on the surface of the tool substrate with "TiN layer to TiSiN layer to TiAlSiN layer to TiSiN layer" as the modulation cycle. After 40 cycles, two coatings with different substrates but the same coating are obtained. Multi-coated cutting tools according to the invention. The obtained two kinds of multi-coated cutting tools all contain a composite coating, such as figure 1 As shown, the composite coating is based on the surface of the tool substrate and presents a "TiN layer to TiN layer 92 Si 8 N layer to Ti 46 Al 46 Si 8 N layer to Ti 92 Si 8 "N layer" is a multi-periodic change trend of a period, in which t...

Embodiment 3

[0034] Use the cemented carbide blade of the model CNMG120408 as the tool substrate, firstly carry out surface cleaning, Ar etching and other pretreatments on the aforementioned tool substrate, and then use the physical vapor phase multi-target deposition method on the surface of the tool substrate alternately on the pretreated tool substrate Deposit a multi-period coating with the modulation cycle of "TiN layer to TiSiN layer to TiAlSiN layer to TiSiN layer", and obtain the multi-coated tool of the present invention after 90 cycles. The multi-coated tool contains a composite coating, which is based on the surface of the tool substrate and presents a "TiN layer to TiN layer 92 Si 8 N layer to Ti 46 Al 46 Si 8 N layer to Ti 92 Si 8 "N layer" is a multi-periodic change trend of a period, in which the content of Ti, Al and Si elements is controlled by adjusting the composition of each target. The total thickness of the composite coating is about 3 μm, of which TiN, Ti 92 Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com