Combined Substrate Holder for Microwave Plasma Chemical Vapor Deposition Equipment

A technology of chemical vapor deposition and microwave plasma, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of microwave power, temperature, air pressure, unstable air flow, and samples falling under the equipment lifting platform , affecting the use of molybdenum brackets, etc., to achieve the effects of improving accuracy and reliability, reducing production costs, and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

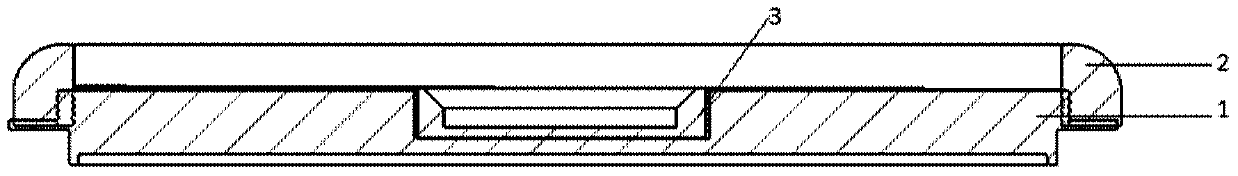

[0031] According to the general inventive concept of the present invention, a combined substrate base for microwave plasma chemical vapor deposition equipment is provided, including:

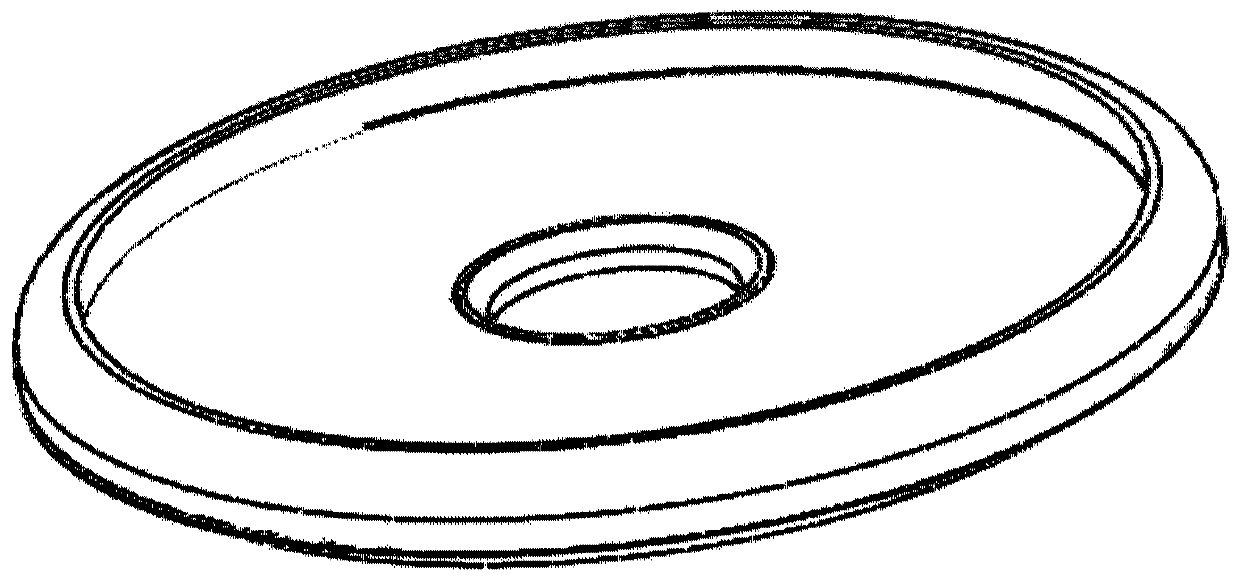

[0032] The main body of the tray is a disc structure, the outer side of the disc has external threads, and the center of the disc has a groove;

[0033] The outer edge part is a ring structure, and the inner side of the ring has an internal thread matched with the external thread. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com