Superlattice heat-resistant ceramic core and preparation method thereof

A superlattice, ceramic core technology, applied in tobacco and other directions, can solve the problems of low heating rate, low user experience, poor reduction degree, etc., and achieve the effect of increasing heating rate, improving thermal efficiency, and promoting uniform temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

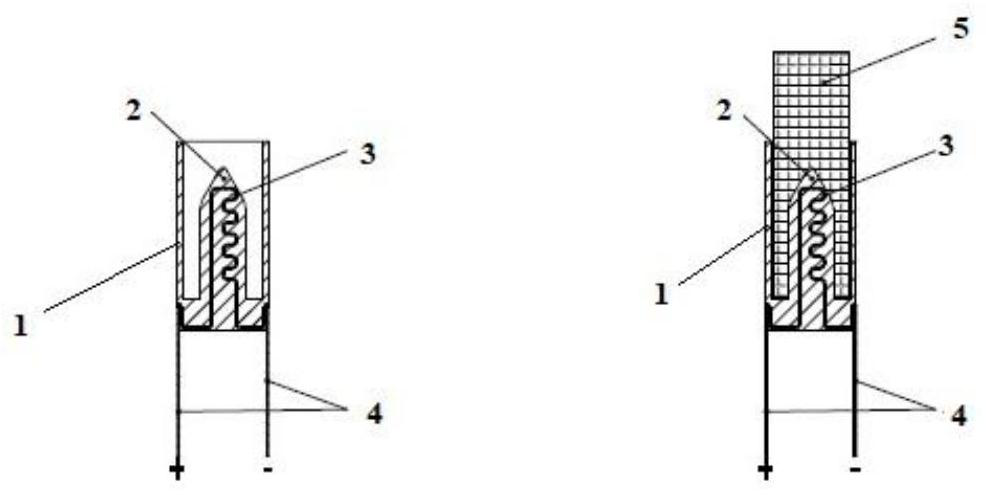

[0030] The method for preparing a superlattice heat-resistant ceramic core described above is characterized in that it comprises the following steps:

[0031] Step 1: making nickel-chromium heating wire 3;

[0032] Step 2: making a ceramic substrate, implanting the nickel-chromium heating wire 3 into the ceramic substrate 2, and pressing and forming the ceramic substrate 2 containing the nickel-chromium heating wire 3;

[0033] Step 3: Carrying out nano-superlattice coating 1 on the ceramic substrate;

[0034] Step 4: making silver-plated electrodes 4, and welding copper wires on the silver electrodes;

[0035] Step 5: Fix the ceramic core sealing base 5 with the ceramic base 2 through the slot to form a closure.

Embodiment 1

[0037] The resistance value of the nickel-chromium heating wire 3 is preferably 0.6Ω.

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, except that the resistance value of the nickel-chromium heating wire 3 is preferably 0.9Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com