Centrifugal sintering method for functionally graded material of thin-wall pipe fitting

A technology of functionally graded materials and sintering methods, which is applied in the field of powder metallurgy and composite materials, can solve the problems of high energy consumption, difficulty in preparing samples with complex shapes, small size of materials, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

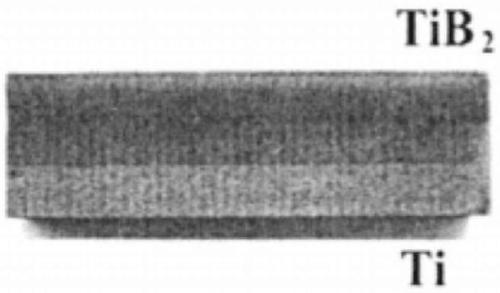

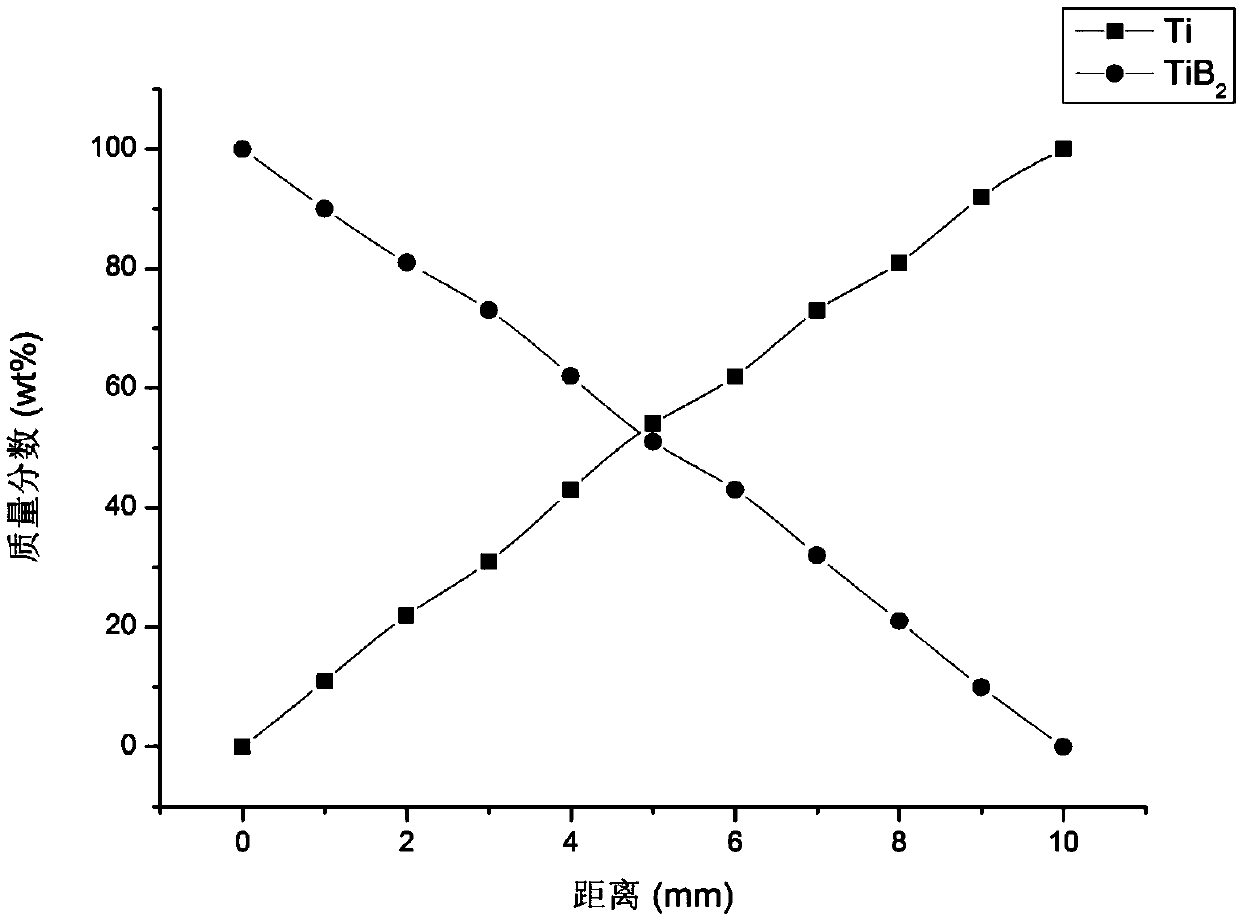

[0035] TiB with a three-layer gradient 2 -Ti slurry as an example, namely (25%Ti-75TiB 2 / 50%Ti-50%TiB 2 / 75%Ti-25%TiB 2 ).

[0036] This embodiment provides a method for centrifugal sintering of functionally graded materials for thin-walled pipes, including the following steps:

[0037] 1) Convert TiB 2 Ceramic powder and Ti metal powder are mixed according to a predetermined ratio to achieve uniform distribution;

[0038] 2) The uniformly distributed TiB 2 Ceramic powder, Ti metal powder are mixed with solvent and dispersant, stirred in the air and degassed by vacuum to form a uniform slurry;

[0039] 3) Put the slurry into the spraying machine, then extend the nozzle into the substrate in the centrifuge, adjust the pressure of the spraying machine, and move the position of the nozzle from top to bottom and bottom to top, so that The slurry can be evenly sprayed on the inner wall of the substrate, and then moved out of the nozzle;

[0040] 4) Change TiB 2 The relati...

Embodiment 2

[0046] Take the three-layer gradient C-SiC slurry as an example (20%C-80%SiC / 40%C-60%SiC / 60%C-40%SiC).

[0047] This embodiment provides a method for centrifugal sintering of functionally graded materials for thin-walled pipes, including the following steps:

[0048] 1) Mix SiC powder and C powder according to a predetermined ratio to achieve uniform distribution;

[0049] 2) Mix the evenly distributed SiC powder and C powder with solvent and dispersant, stir in the air, and form a uniform slurry after vacuum degassing;

[0050] 3) Put the slurry into the spraying machine, then extend the nozzle into the substrate in the centrifuge, adjust the pressure of the spraying machine, and move the position of the nozzle from top to bottom and bottom to top, so that The slurry can be evenly sprayed on the inner wall of the substrate, and then moved out of the nozzle;

[0051] 4) changing the relative volume percentage of SiC powder and C powder, re-preparing the slurry, and spraying ...

Embodiment 3

[0057] Take the three-layer gradient Mo-ZrC slurry (25%Mo-75%SiC / 50%Mo-50%ZrC / 75%Mo-ZrC) as an example.

[0058] This embodiment provides a method for centrifugal sintering of functionally graded materials for thin-walled pipes, including the following steps:

[0059] 1) Mix ZrC powder and Mo powder according to a predetermined ratio to achieve uniform distribution;

[0060] 2) Mix evenly distributed ZrC powder, Mo powder with solvent and dispersant, stir in the air and form a uniform slurry after vacuum degassing;

[0061] 3) Put the slurry into the spraying machine, then extend the nozzle into the substrate in the centrifuge, adjust the pressure of the spraying machine, and move the position of the nozzle from top to bottom and bottom to top, so that The slurry can be evenly sprayed on the inner wall of the substrate, and then moved out of the nozzle;

[0062] 4) changing the relative volume percentage of ZrC powder and Mo powder, re-preparing the slurry, and spraying the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com