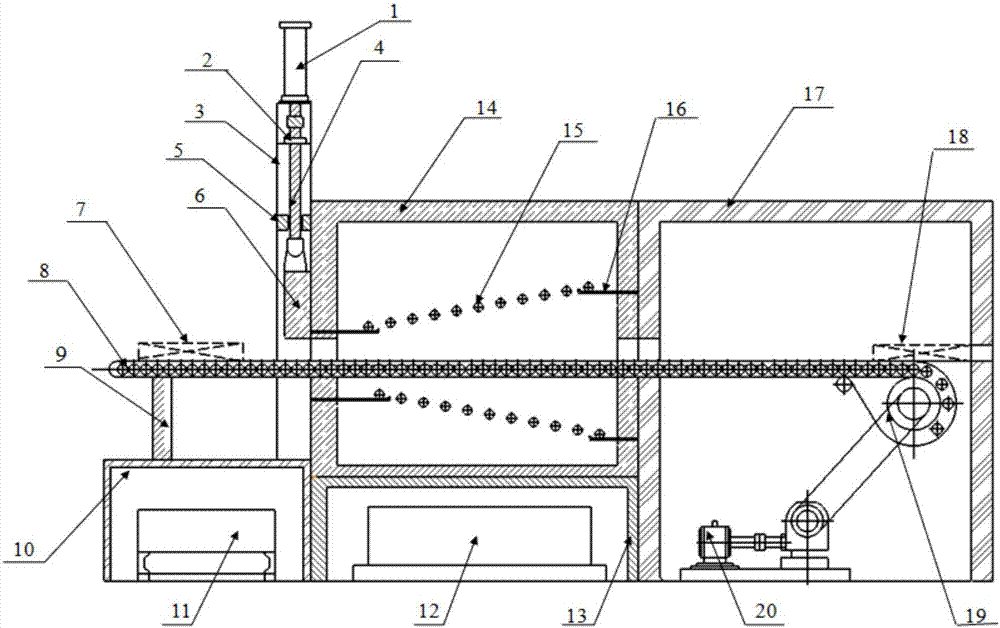

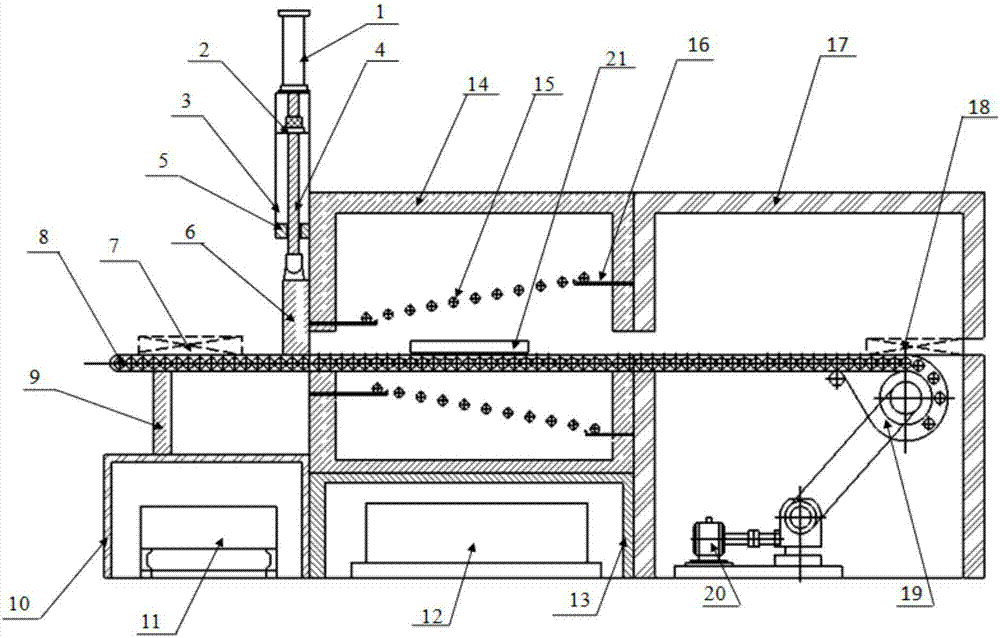

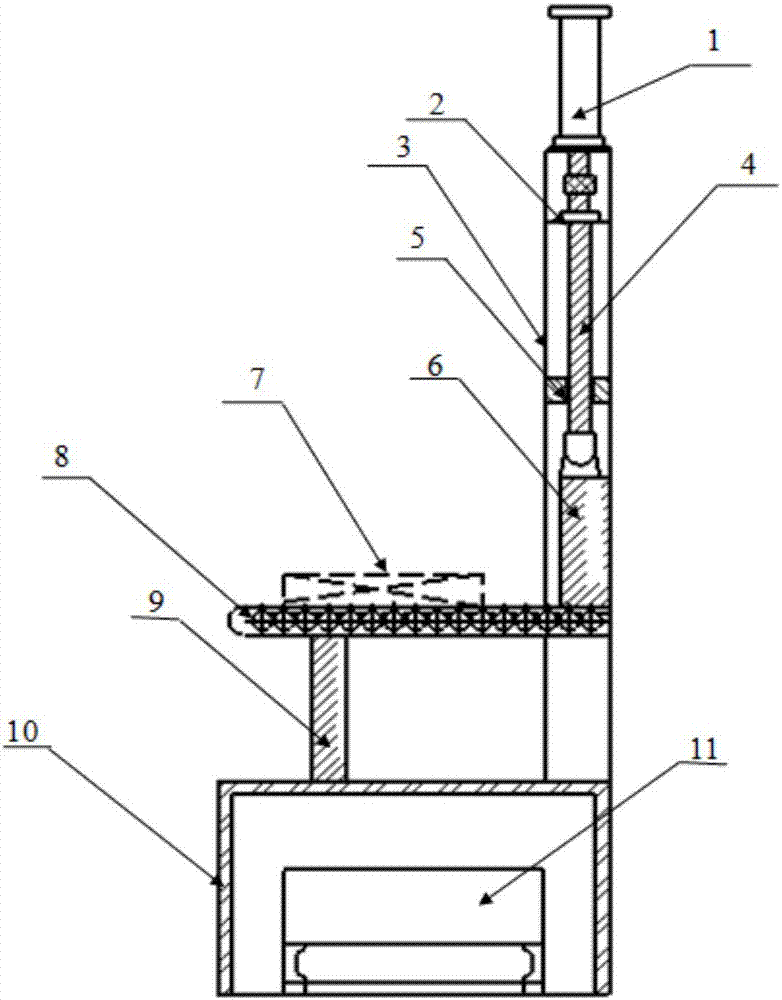

High-strength steel gradient induction heating device

An induction heating device, high-strength steel technology, applied in the direction of improving energy efficiency and process efficiency, can solve problems such as uncontrollability, large temperature error, unevenness, etc., to achieve uniform temperature gradient, uniform heating temperature gradient, no Effects of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Commonly used gradient induction heating conditions for parts

[0059] Take the gradient induction heating of a cuboid thin-walled metal part with a length of 300mm, a section size of 80mm×80mm, and a thickness of 8mm as an example:

[0060] 1. Presetting work: turn on the power, adjust the frequency conversion device 11, so that the maximum temperature that can be heated is 1000°C, and then set the expected maximum heating temperature to 950°C in the temperature gradient control panel 12, input the length of the part 300mm, and the temperature The gradient is 150°C, the temperature gradient control device records data and calculates the stop position of the transmission device, and the preset work is completed;

[0061] 2. Fix the parts on the part fixing device 7 of the feed inlet, open the furnace door 6 by using the furnace door telescopic device 4, start the transmission device, the transmission device will stop automatically at the preset position, at t...

Embodiment 2

[0066] Example 2: Special working conditions for gradient induction heating of parts

[0067] 1. Adjustment of temperature:

[0068] Take the gradient induction heating of a cuboid thin-walled metal part with a length of 300mm, a section size of 80mm×80mm, and a thickness of 8mm as an example:

[0069] (1) When the maximum heating temperature required by the parts rises from 950°C in Embodiment 1 to 1100°C, the frequency of the alternating current through the coil can be increased by adjusting the frequency conversion device 11 during the preset work, thereby increasing the generated alternating current. Change the magnetic field strength, increase the eddy current effect, and increase the maximum temperature that the parts can be heated, so that the maximum heating temperature can reach 1200 °C. Then through the adjustment of the temperature gradient control panel 12, the maximum temperature of the parts heated is 1100°C. (It can be realized by adjusting the frequency conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com