Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Uniform temperature change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crispy fried stuffed bun, preparation method and pan dedicated therefor

InactiveCN1994095ASmall and exquisiteXuan soft and elasticBakery productsFood coatingFrying-pansFlavoring Agents

The invention relates to a method for producing fried bread, wherein said bread comprises skin and stuff. The stuff comprises 500g pork, 40-70g egg, 40-60g fecula, and 35-50g ginger, 70-85g flavoring agent, some green onion, and some water. The bottom of bread is thick with yellow skin. The invention also provides an aluminum pot, which can produce 300 breads at one time, with uniform temperature.

Owner:张友军

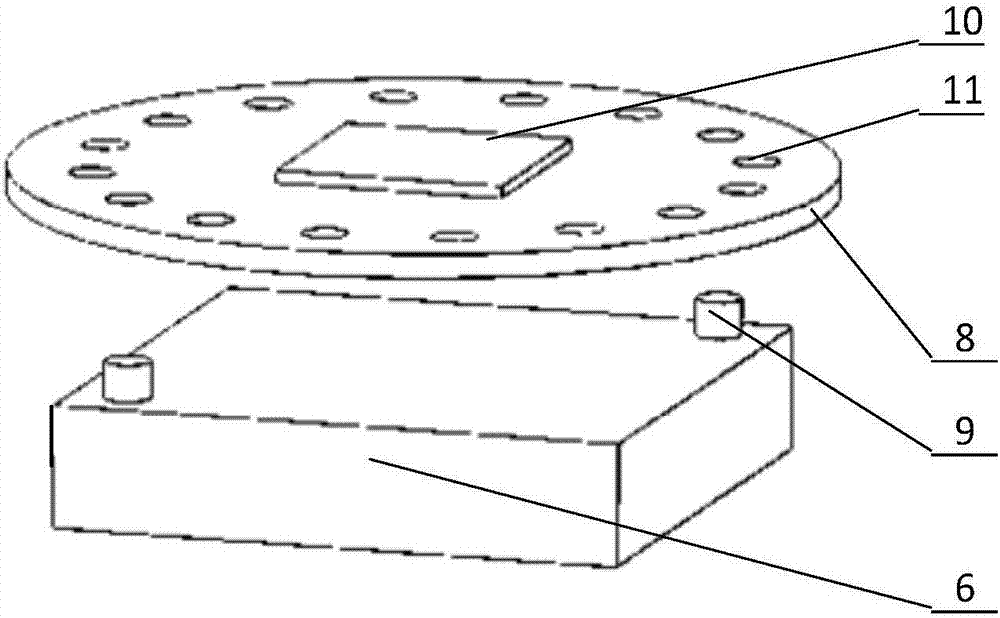

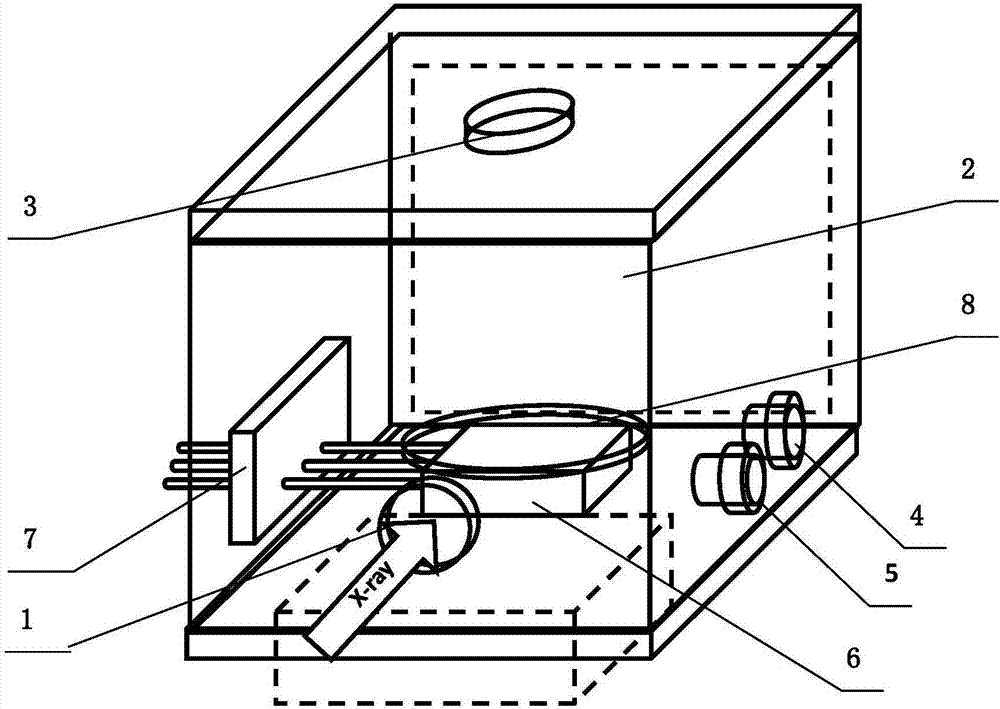

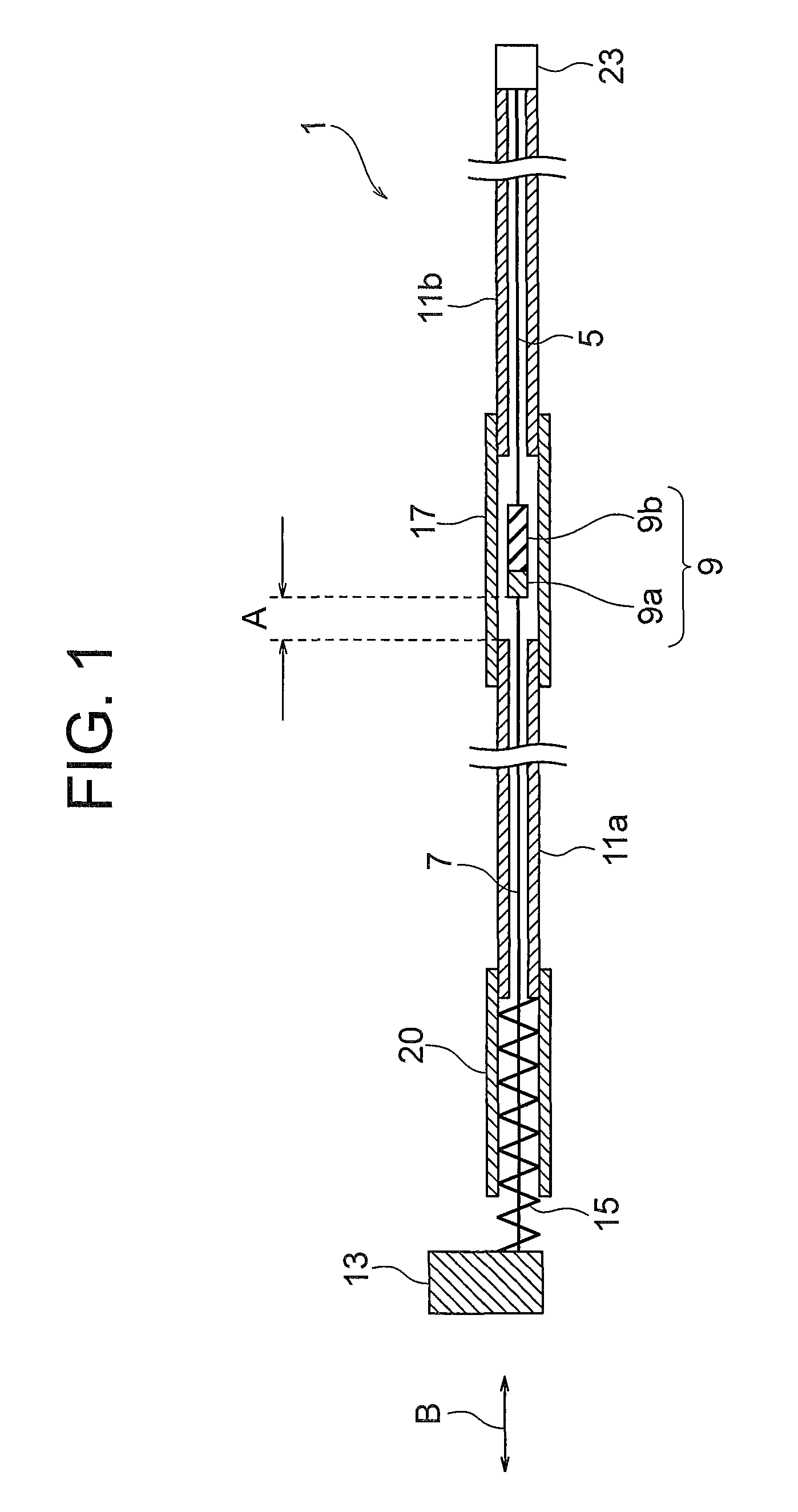

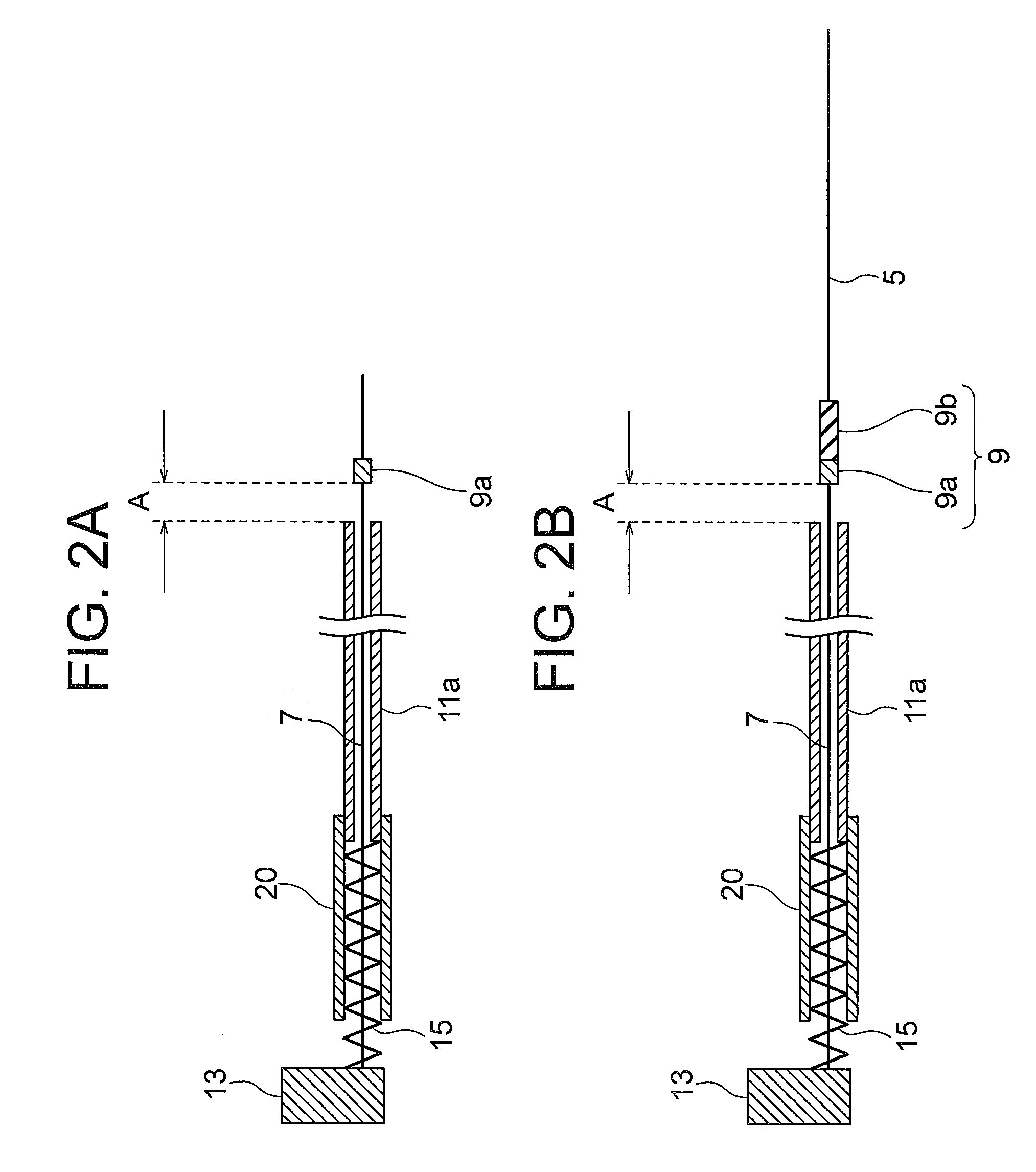

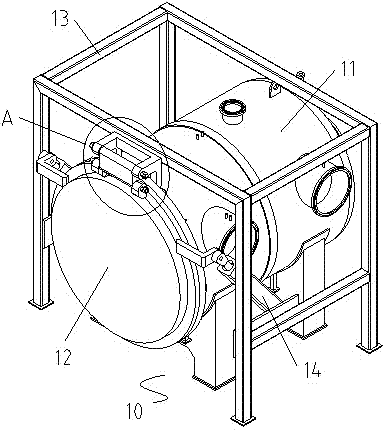

Vacuum cooling-heating stage for grazing incidence X-ray small-angle scattering experiment

PendingCN106979957AImprove reliabilityUniform temperature changeMaterial analysis using wave/particle radiationTemperature controlAngle of incidence

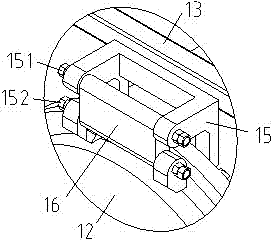

The invention relates to a vacuum cooling-heating stage for grazing incidence X-ray small-angle scattering experiment, comprising: a chamber providing a closed space; a vacuum connector communicated with the closed space; a variable temperature block disposed in the closed space, wherein a cable of the variable temperature block and a liquid nitrogen access pipeline pass through a variable temperature block fixing seal window to be connected with a temperature control device outside the closed space, and the top surface of the variable temperature block is provided with two raised screw heads; a sample tray for holding a sample, wherein a plurality of angle positioning holes in central symmetry are distributed in the sample tray and angularly mate with the raised screw heads; an incident seal window and an emergent seal window facing each other and fixed to the chamber, wherein X-ray passes through the incident seal window and irradiates to the sample at the grazing incidence angle of 0-2 DEG to produce scattering X-ray, and passes through the emergent seal window into a detector. The vacuum cooling-heating stage changes the temperature of a sample through the variable temperature block and the sample tray, uniform temperature variation is ensured for the sample, and in-plane rotational experiment of the sample can also be achieved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

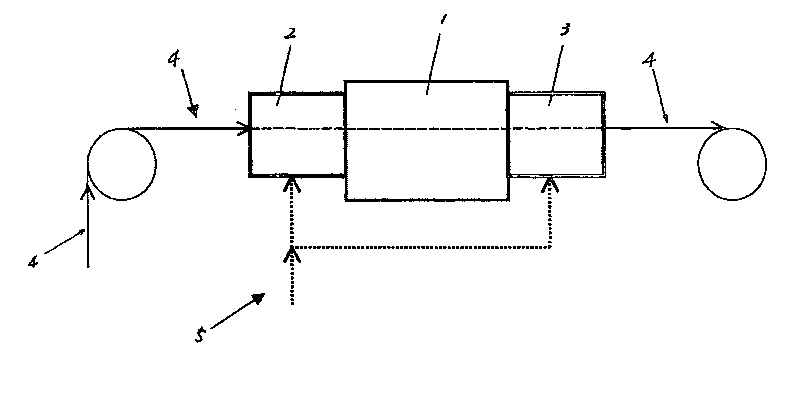

System and method for shutdown cooling of high-temperature gas cooled reactor nuclear power station

ActiveCN108278590AEasy to operateChange pressureLiquid degasificationNuclear energy generationNuclear powerInlet valve

The invention discloses a system and a method for shutdown cooling of a high-temperature gas cooled reactor nuclear power station. The system comprises an evaporator, an evaporator outlet valve set, asteam separator, an evaporator inlet valve set, a bypass valve set, a high-pressure heater, an auxiliary steam header, a condenser, a water feeding pump and a deaerator. The method comprises the following steps: 1) steam in the auxiliary steam header is introduced in a steam side of the high-pressure heater and the deaerator to increase the water feeding temperature in an inlet of the evaporator;2) the water feeding pressure in the inlet of the evaporator is adjusted by the water feeding pump; and the water injecting flow of the evaporator is controlled by an adjusting door in the inlet of the evaporator, so that the cooling speed of the evaporator is further controlled; and the pressure of the evaporator is controlled by an adjusting door in an outlet of the evaporator; 3) a working medium in the outlet of the evaporator is discharged into the steam separator; 4) the pressure of the steam separator is controlled by a bypass adjusting valve and auxiliary steam fed in the steam separator; and 5) water in the steam separator is recovered to the main deaerator to build a two-loop water cycle to cool the evaporator.

Owner:XIAN THERMAL POWER RES INST CO LTD

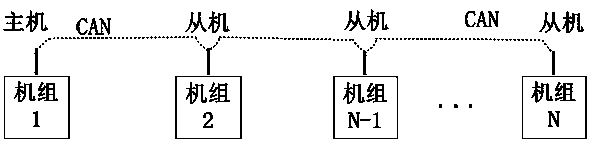

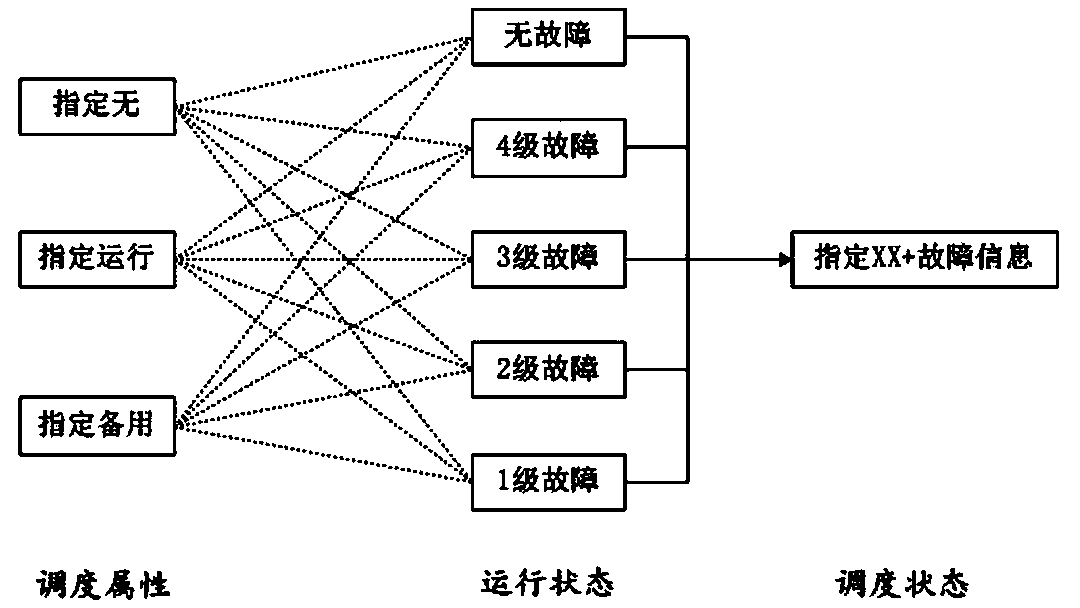

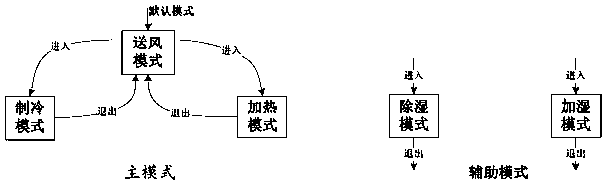

Air conditioning grouping system capable of improving reliability and grouping control method

InactiveCN109883006AUniform temperature changeAvoid race runsMechanical apparatusSpace heating and ventilation safety systemsOperation modeGroup operation

The invention discloses an air conditioning grouping system capable of improving reliability and a grouping control method. The grouping control method of an air conditioning comprises the steps thatthe operation status of units in a group is obtained by the group control end at intervals and is processed to obtain operation modes of the group; dispatching units and a dispatching order thereof are determined by the group control end according to dispatching attributes and the operation status of the units, and an issuing order is formulated according to a certain temperature order or a humidity order and the different operation modes in the dispatching order; and the group control end issues mode commands to the dispatching units for executing according to the issuing order. According tothe air conditioning grouping system capable of improving the reliability and the grouping control method, the competitive operation between slaves can be avoided, the temperature changes can furtherbe quickly responded, and the safety and the reliability of group operation are improved.

Owner:GREE ELECTRIC APPLIANCES INC

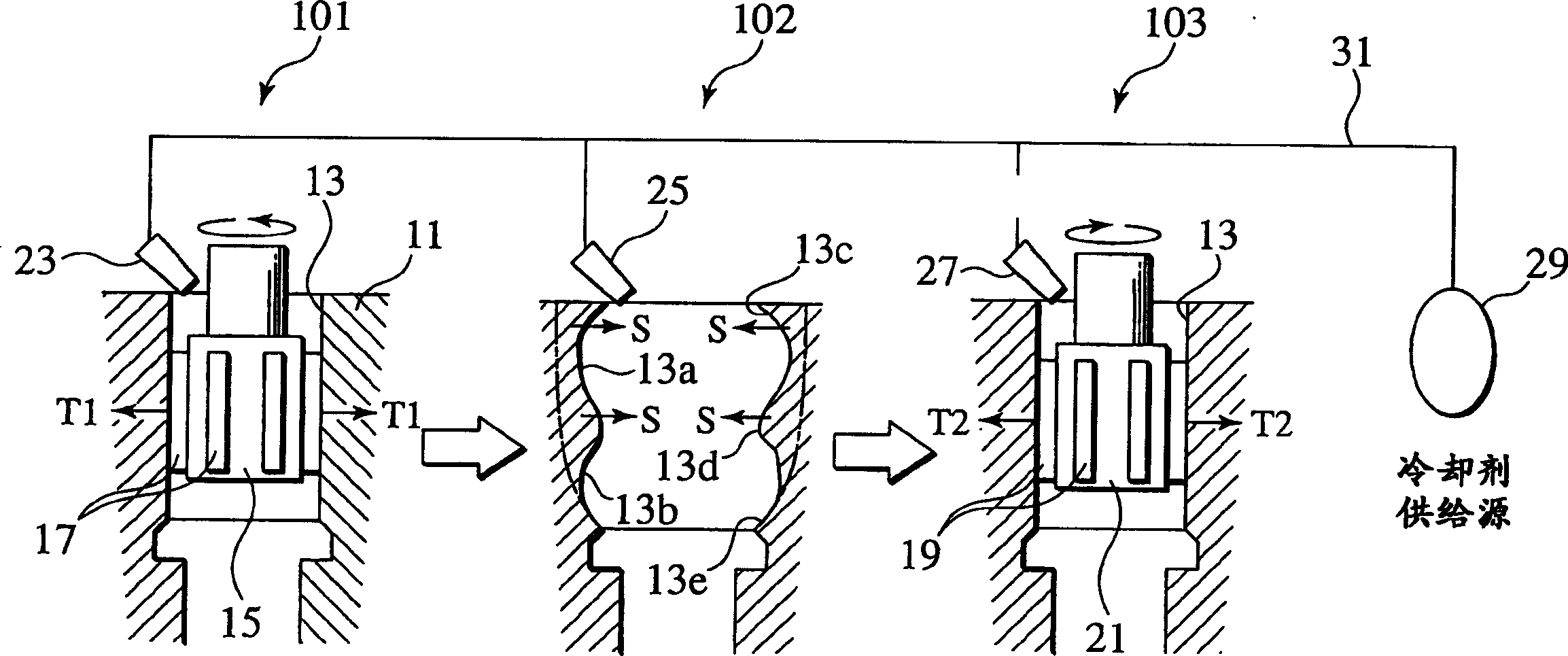

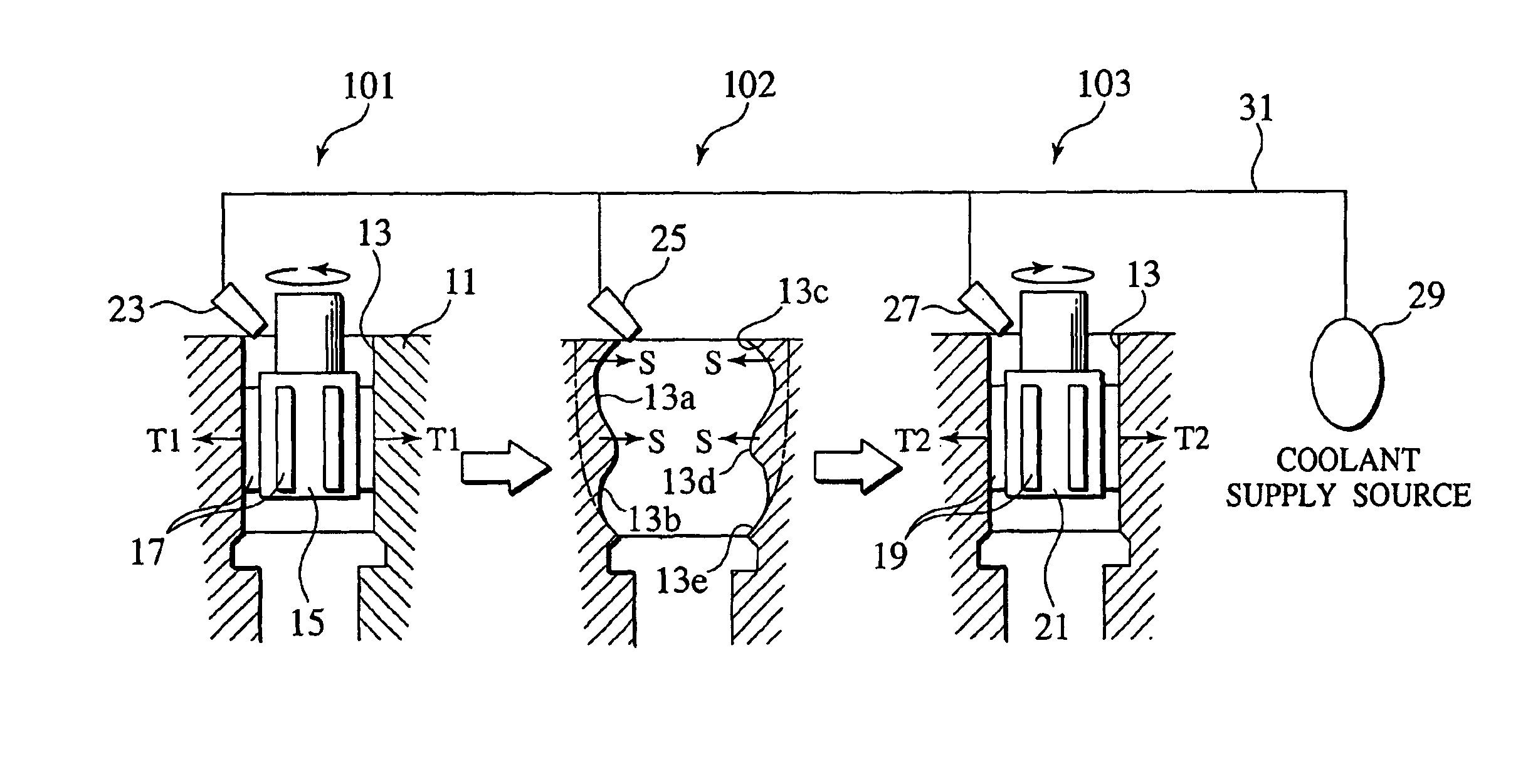

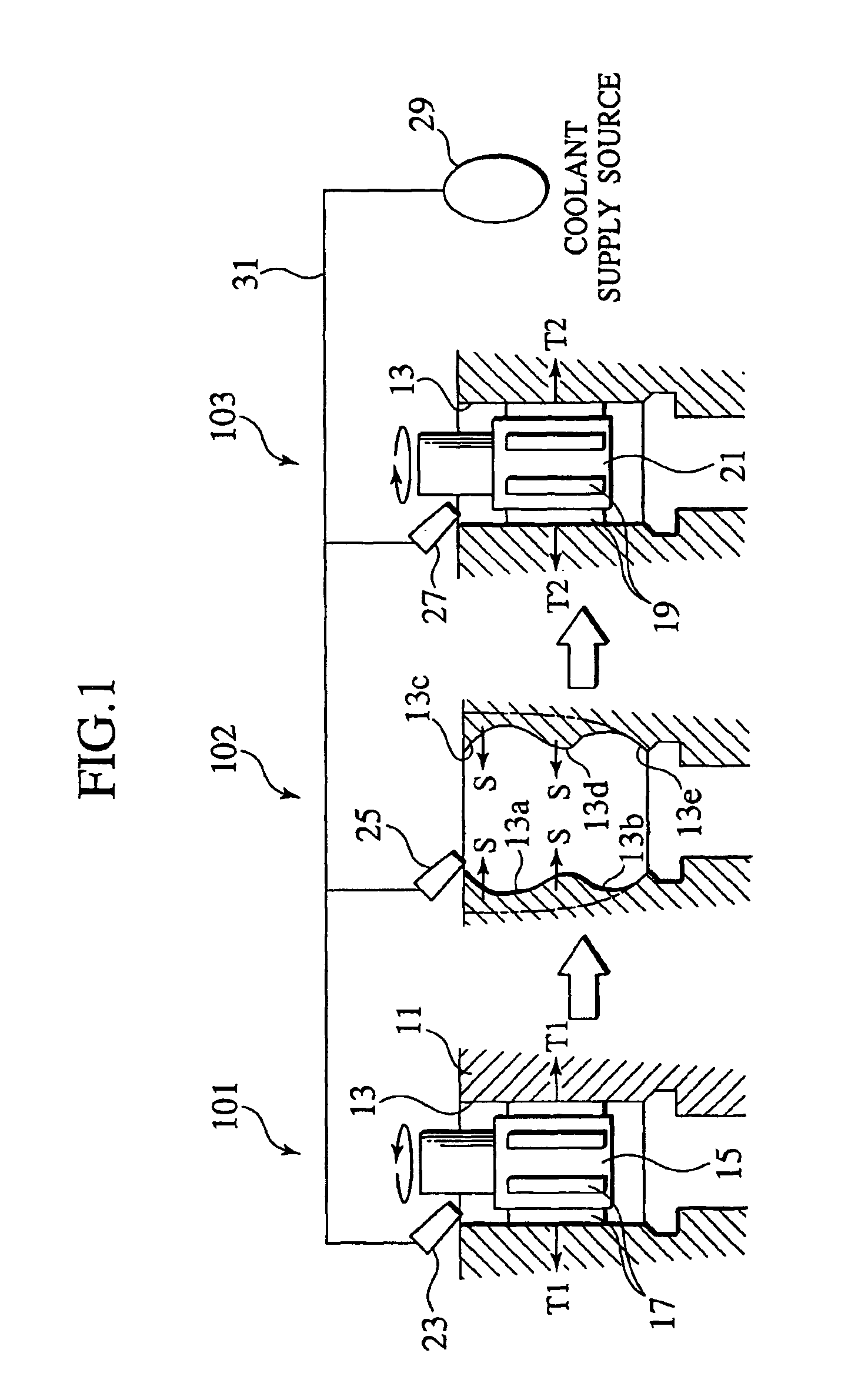

Honing method and honing equipment

Owner:NISSAN MOTOR CO LTD

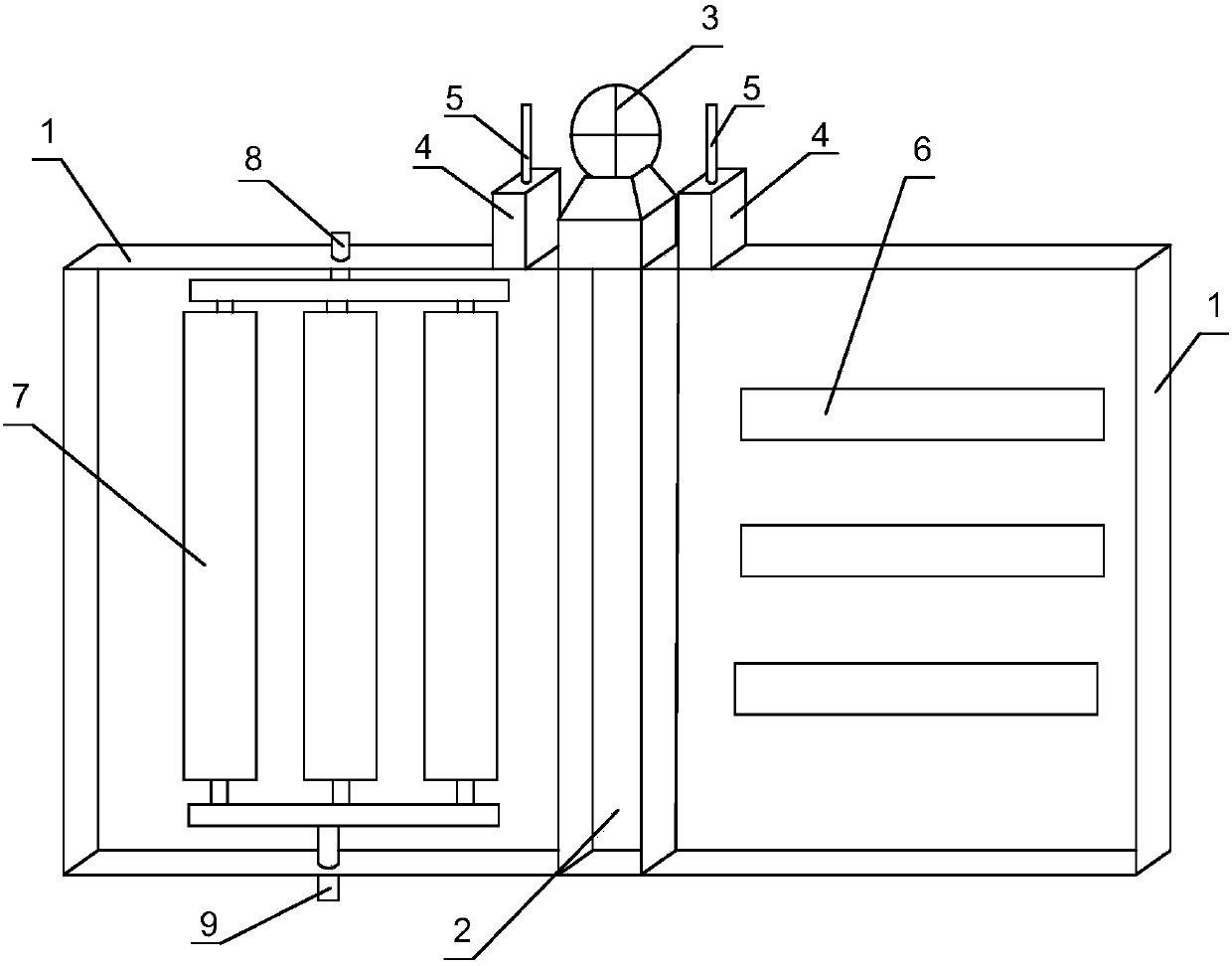

Glass rod material preparation method and preparation device

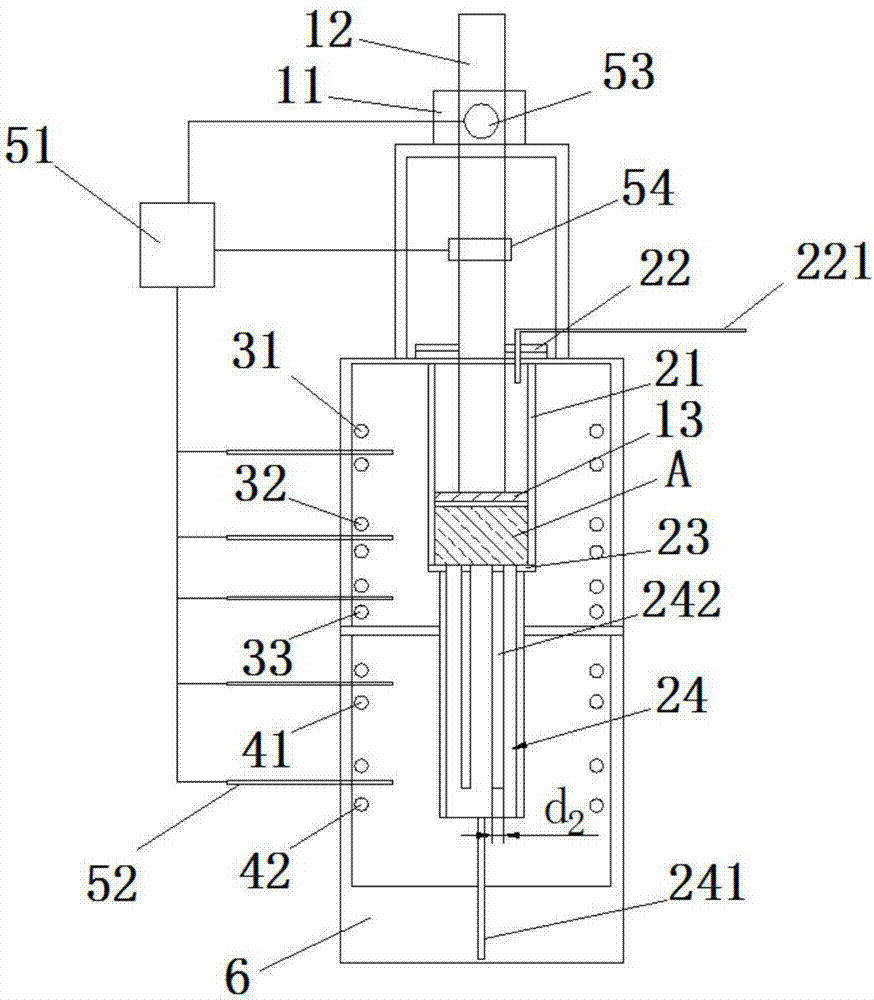

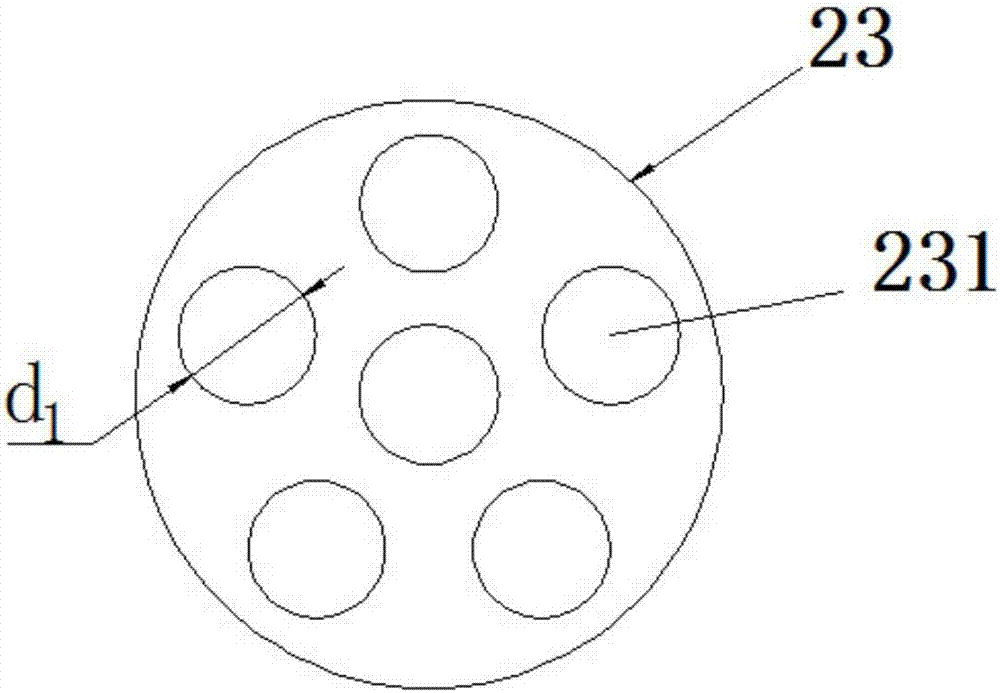

The invention relates to a glass rod material preparation method and a glass rod material preparation device. The glass rod material preparation method comprises the following steps: (a) putting a material into a material barrel; (b) feeding protection gas into the material barrel, a forming mold and a collimating mold; (c) controlling a heating unit to perform heating, preserving the heat till the temperature in the heating unit reaches softening temperature Ts of the material, controlling an annealing unit to be heated, and preserving the heat till the temperature in the annealing unit reaches annealing temperature of the material; (d) extruding the softened material, wherein after passing through the material barrel and being prepared into a rod material through the forming mold, the material enters the collimating mold; (e) enabling the heating unit to stop heating, naturally cooling the heating unit, preserving the heat of the annealing unit, and after the annealing unit is subjected to heat preservation for T, naturally cooling the annealing unit; and (f) after the annealing unit is cooled, taking out the material, and collimating and forming the material through the collimating mold, thus preparing the glass rod material. The forming mold is detachable, thus facilitating production of glass rod materials with different sizes; and furthermore, one forming mold can be provided with multiple through holes, so that the glass rod material production efficiency is improved.

Owner:NINGBO SUNNY INFRARED TECH COMPANY

Honing method and honing apparatus

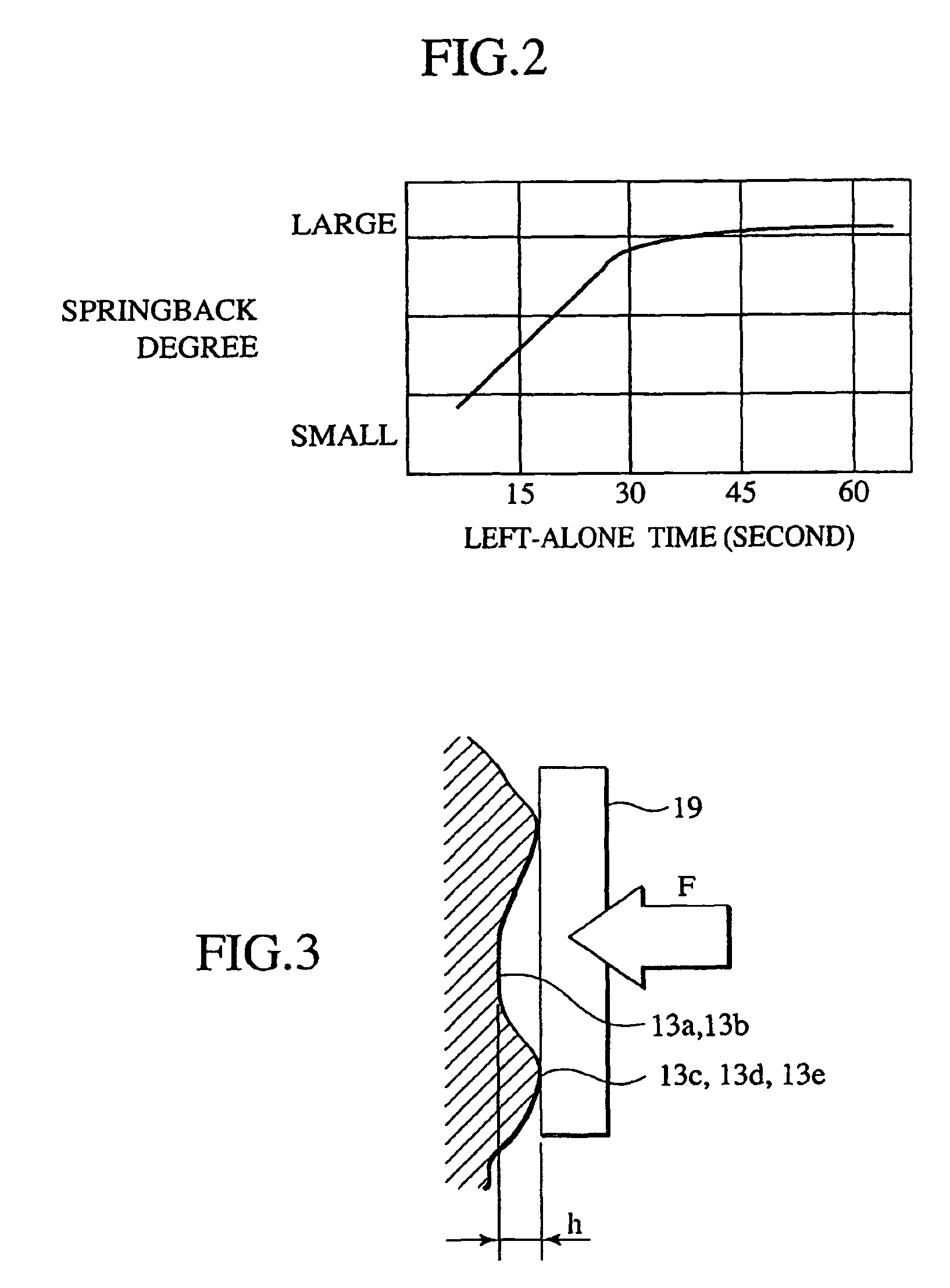

ActiveUS6910945B2Secured highly accuratelyExclude influenceEdge grinding machinesGrinding feed controlEngineeringNozzle

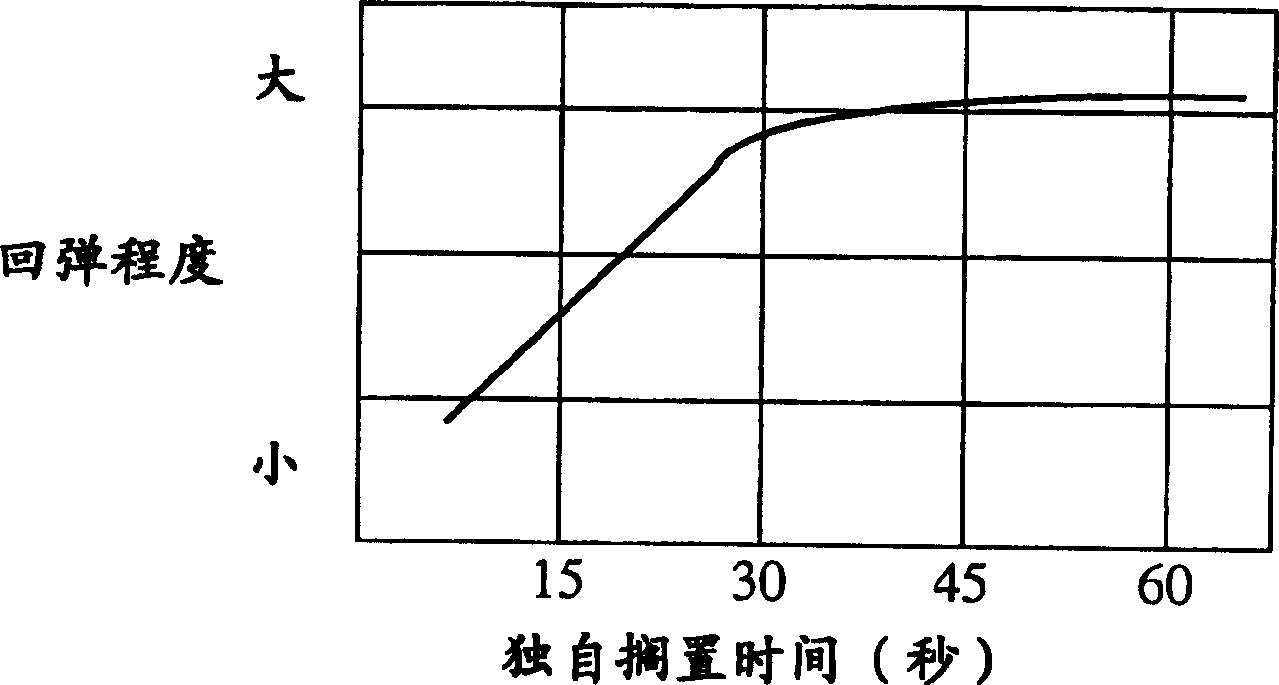

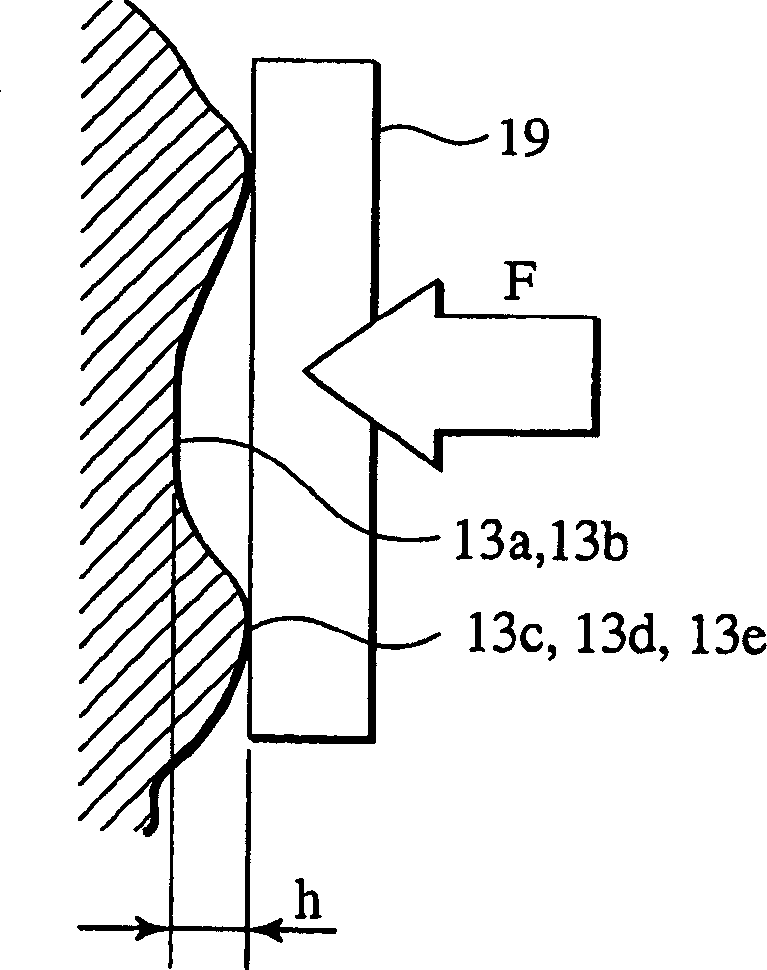

In a coarse honing step in a section (101), a honing head (15) provided with coarse honing hones (17) is inserted into a cylinder bore (13) of a cylinder block (11), the honing head 15 is rotated while axially moving it, and the inner peripheral surface of the cylinder bore (13) is thereby ground. In the next idling step in a section (102), the cylinder block (11) is left as it is for (60) seconds to generate a springback (S). In a subsequent finishing honing step in a section (103), a honing head (21) provided with finishing honing hones (19) is inserted into the cylinder bore (13), the honing head (21) is rotated in a reverse direction to a rotational direction in the coarse honing step while axially moving it, and the inner peripheral surface of the cylinder bore (13) is thereby ground. Further, a coolant is supplied to the sections of the coarse honing step, the idling step, and the finishing honing step from coolant nozzles (23), (25), and (27), respectively, using a common coolant supply source (29).

Owner:NISSAN MOTOR CO LTD

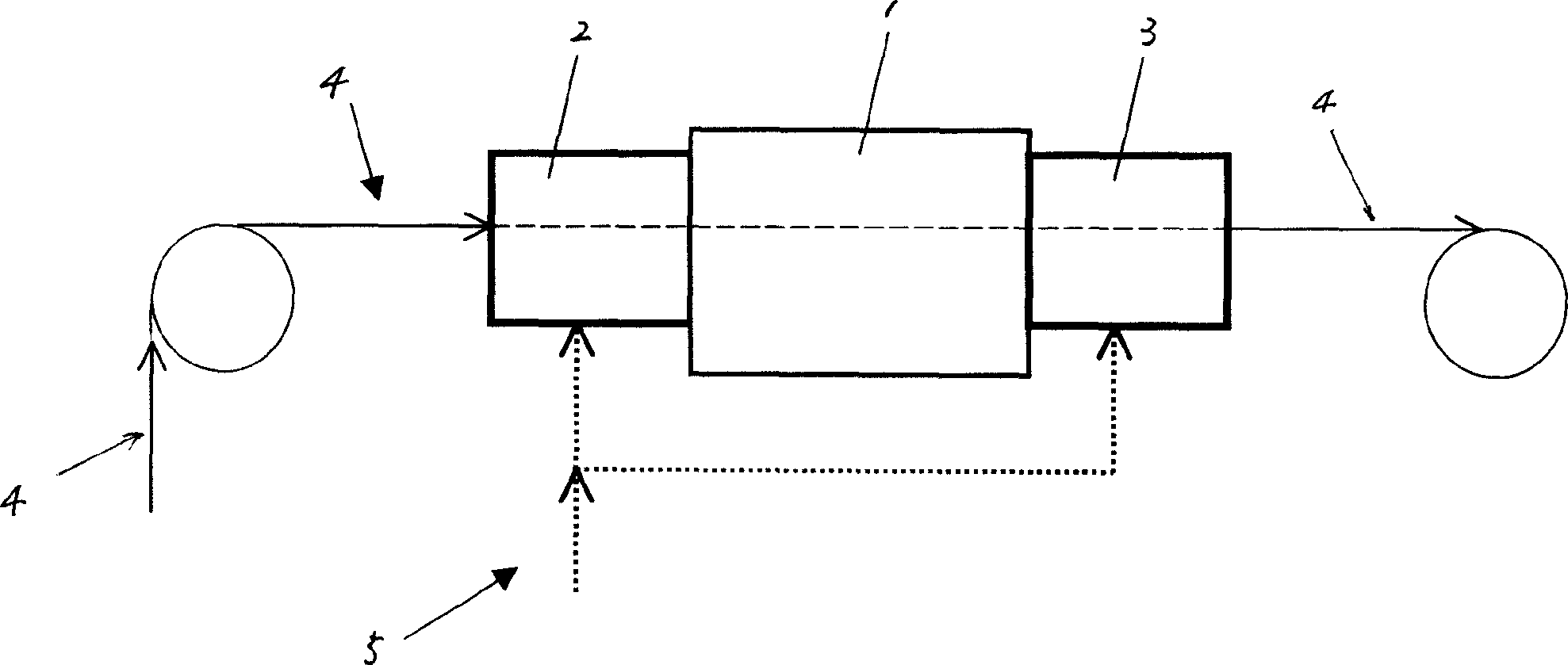

Furnace drying method for the strip steel surface coating

InactiveCN101116856AUniform temperature changeEliminate cracksPretreated surfacesCoatingsCoated surfaceProduction line

The invention discloses a drying method for surface coating of strip steel, the drying method includes the procedures as follows: after the strip steel being normally and continuously coated on the production line, the hot wind is used for preliminary drying the coat surface, simultaneously the electromagnetic induction is utilized to heat the inside of the strip steel for inner drying, then the hot wind is utilized again for the final drying the coat surface. The invention dries the coat of the strip steel by outside hot wind and inner heating, the temperature changes uniformly in the drying process of the coat, the invention can effectively eliminate coat crazing and can prevent uneven depth caused by the production accumulation of the coat; the invention utilizes simultaneous drying process for the outside and the inside of the coat, achieving the same effect; the invention can decrease the heating temperature for the electromagnetic induction the strip steel, thereby being useful to cool the production of the strip steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Method for controlling temperature of hot isobaric press and hot isobaric press

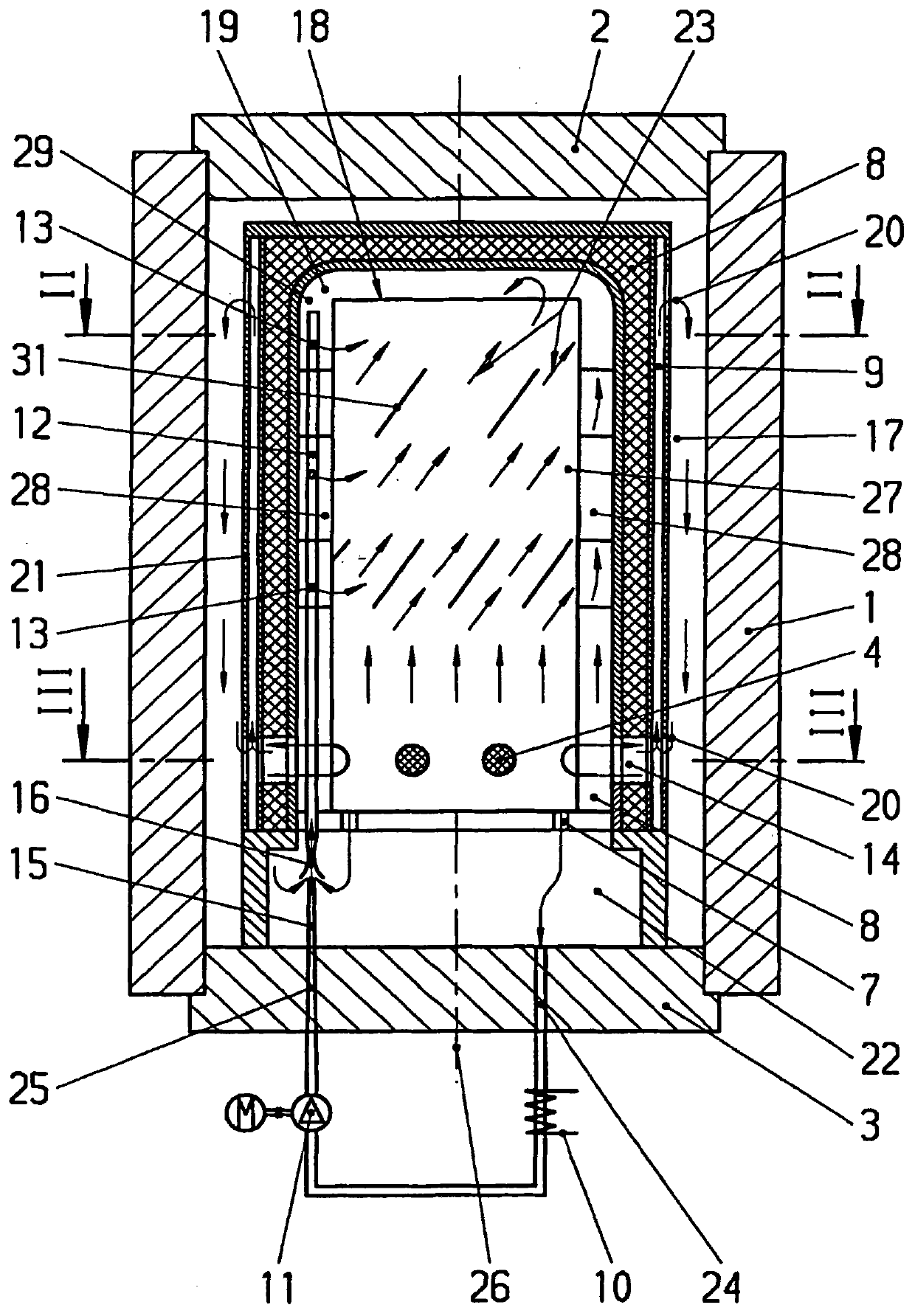

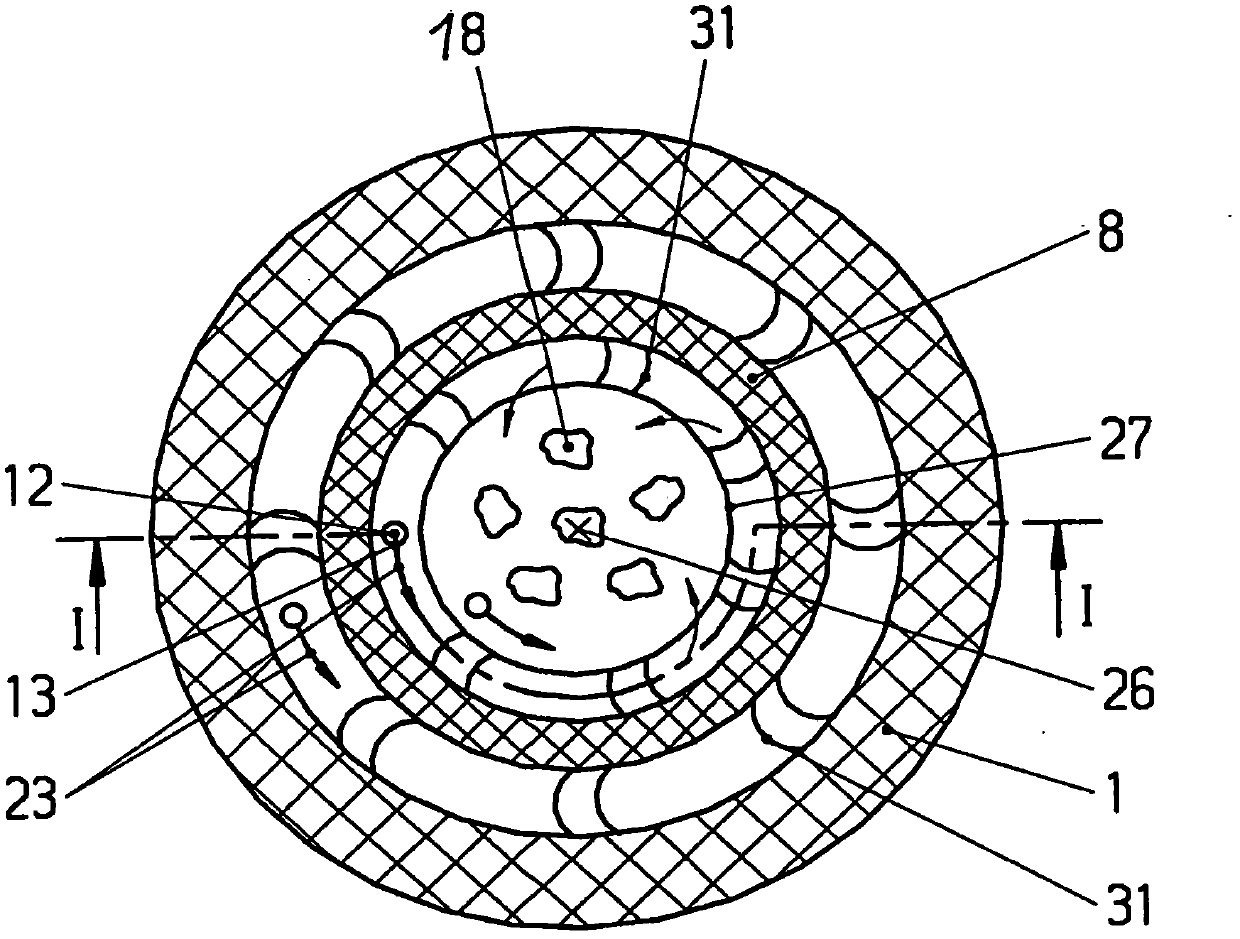

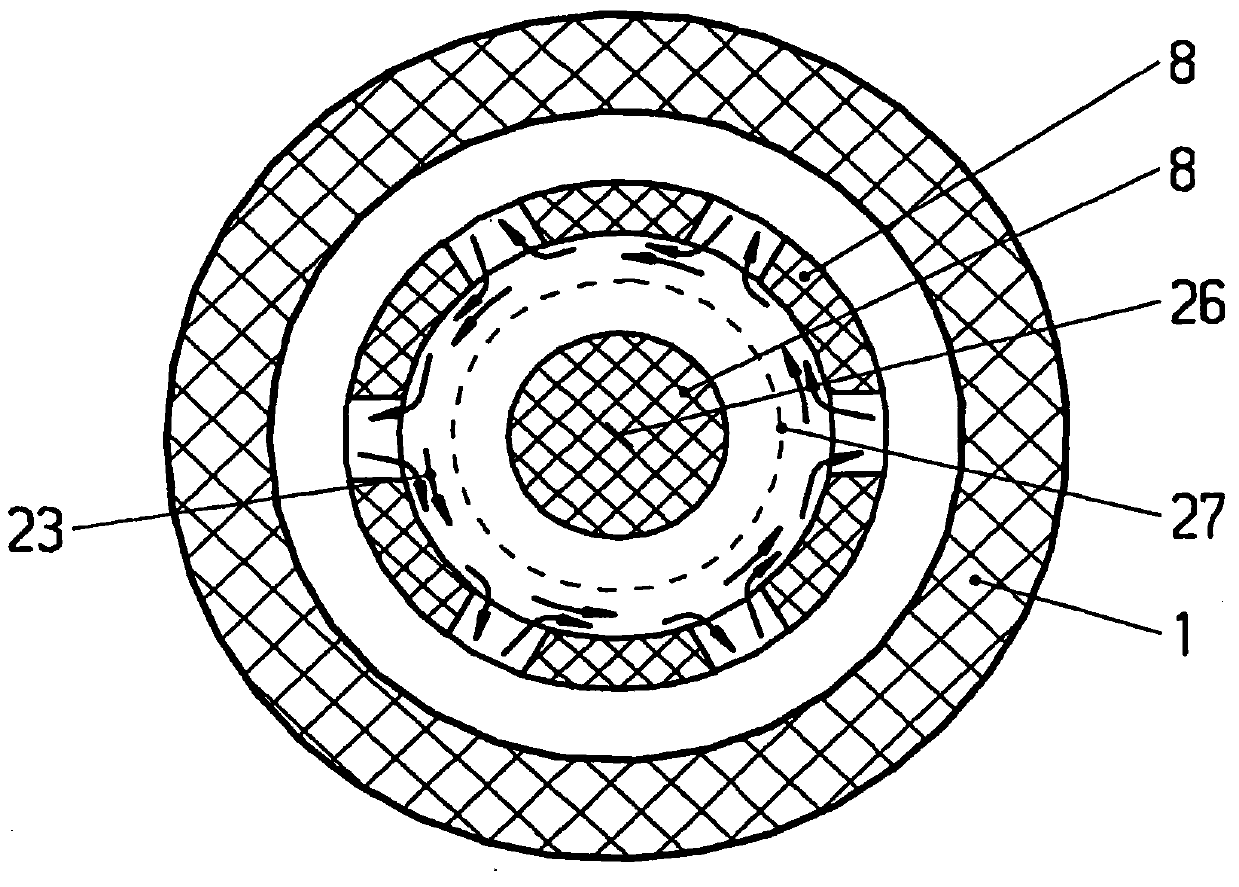

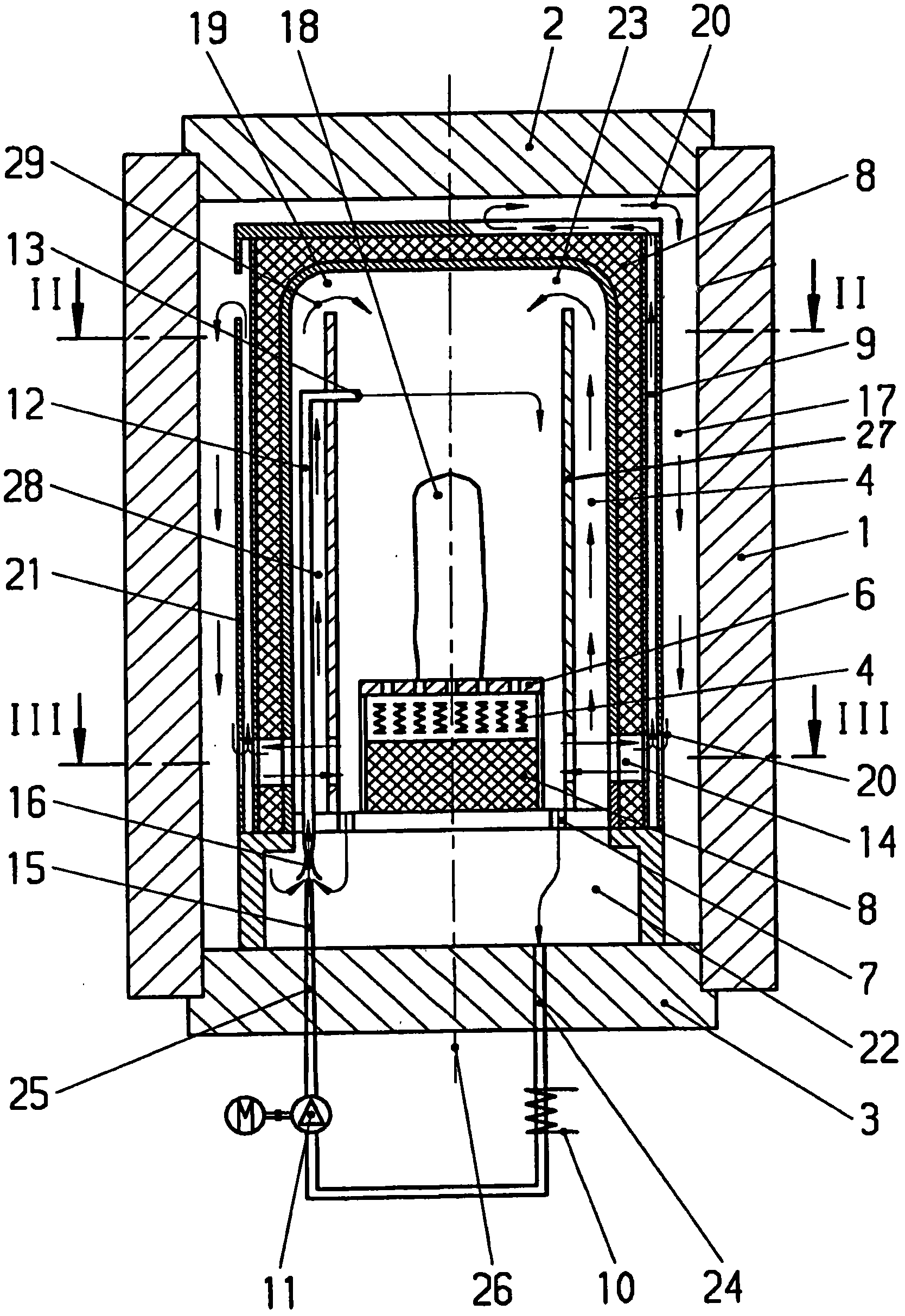

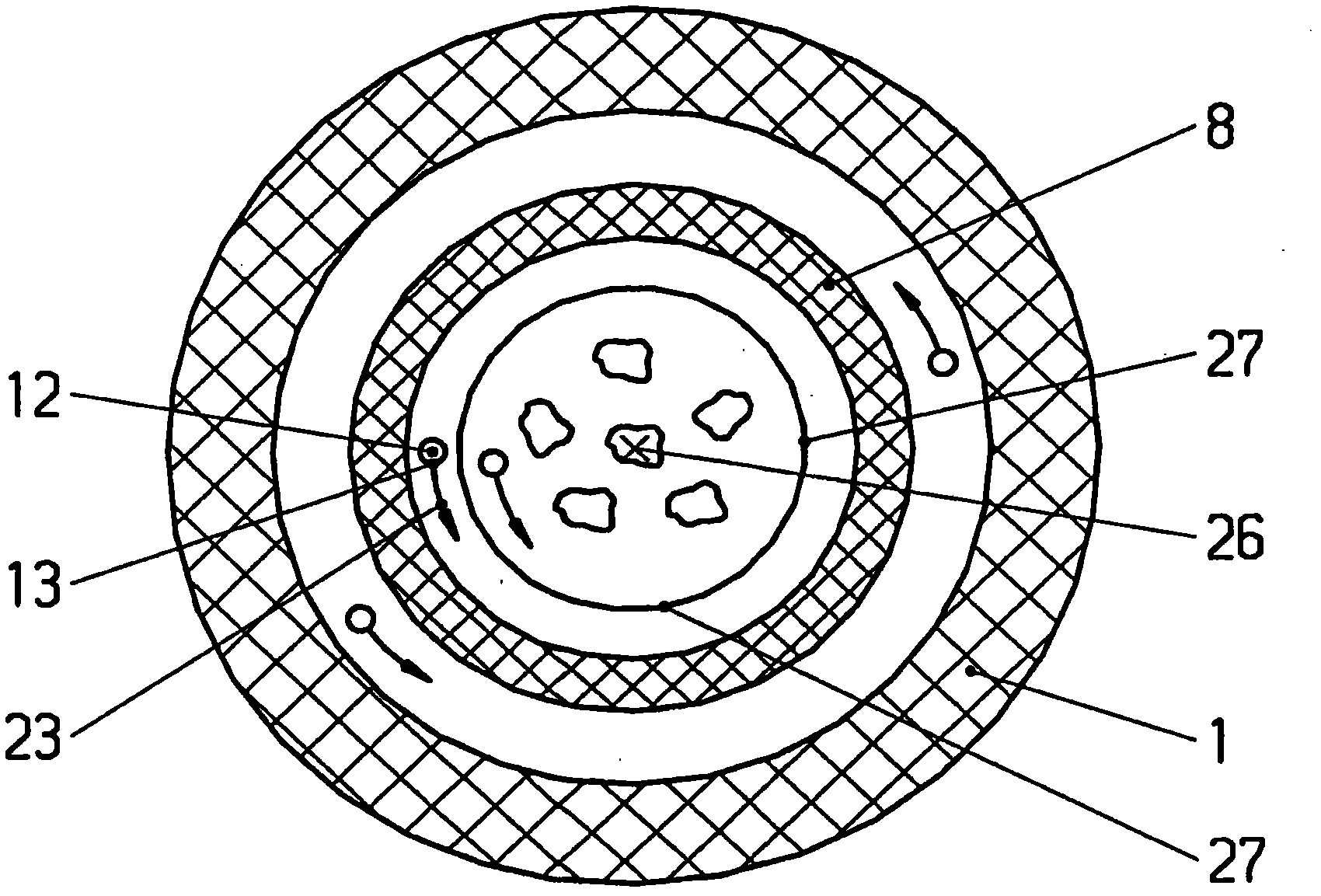

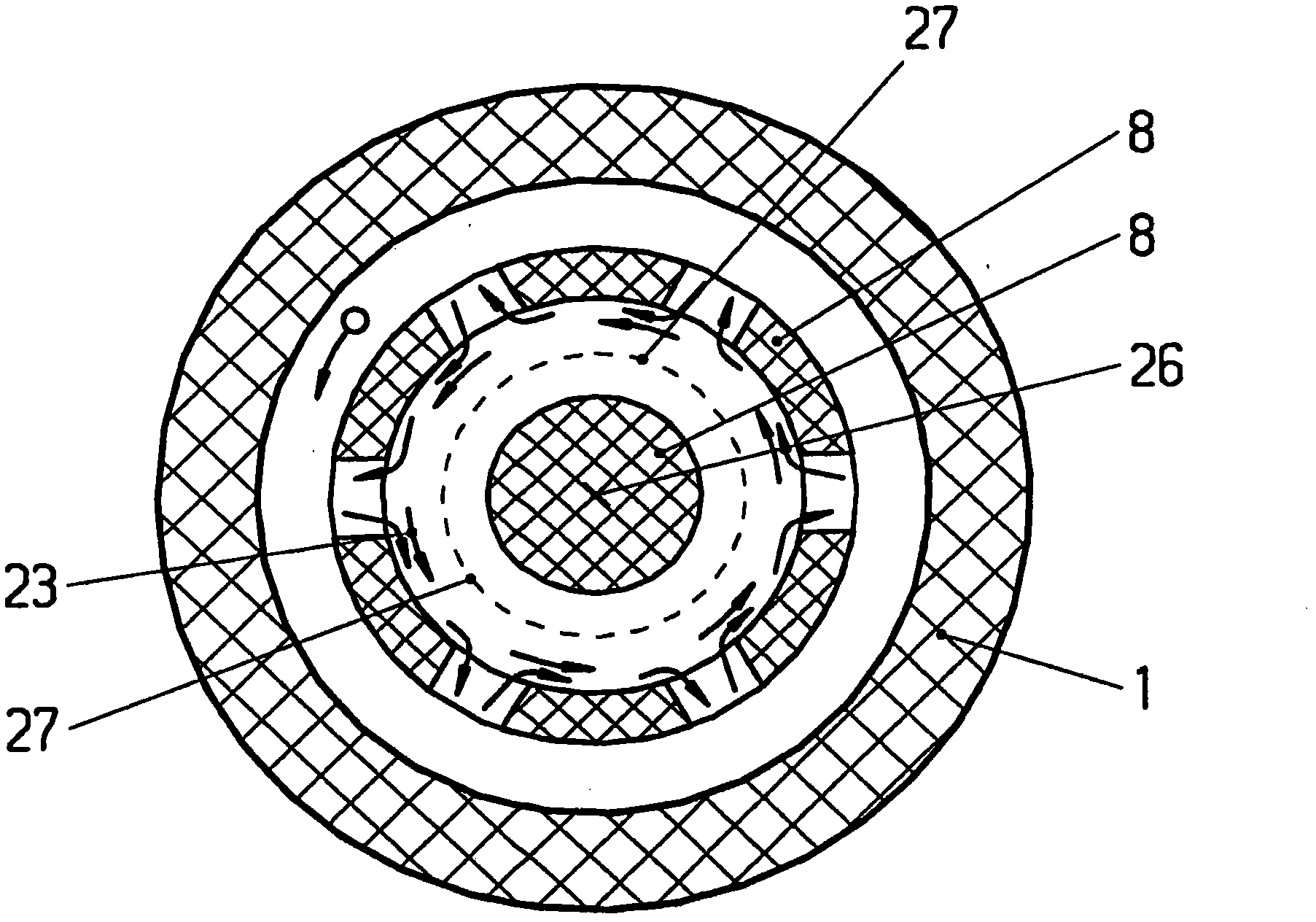

InactiveCN102282010APrecise process controlExcellent and uniform temperature changeMuffle furnacesRetort furnacesEngineeringHeating element

A method for controlling the temperature of a hot isobaric press comprising a pressure vessel (1) having a charging zone (19) located inside and being arranged between the charging zone and the pressure vessel The heat insulator (8) between them, wherein, the heating element (4) and the charging area (19) with the charging device (18) are arranged in the heat insulator (8). Therein, in addition to at least one existing natural or activated convection for heating or cooling or for maintaining the temperature level, at least one swirl (23) is actively or passively formed in the pressure vessel (1). An independent or also suitable hot isobaric press for this method is characterized in that in the pressure vessel (1) there are arranged active or passive means for forming a swirl (23) which occurs essentially at an angle to the convection device.

Owner:克莱默热处理设备公司

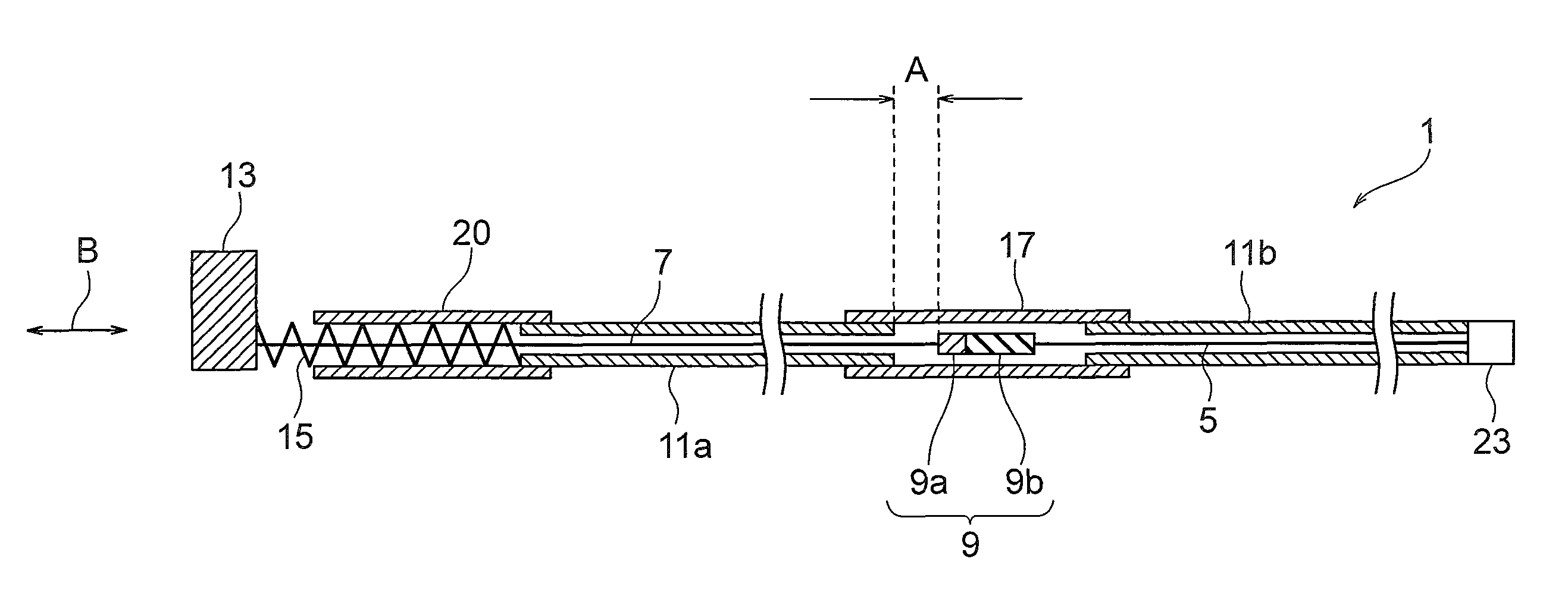

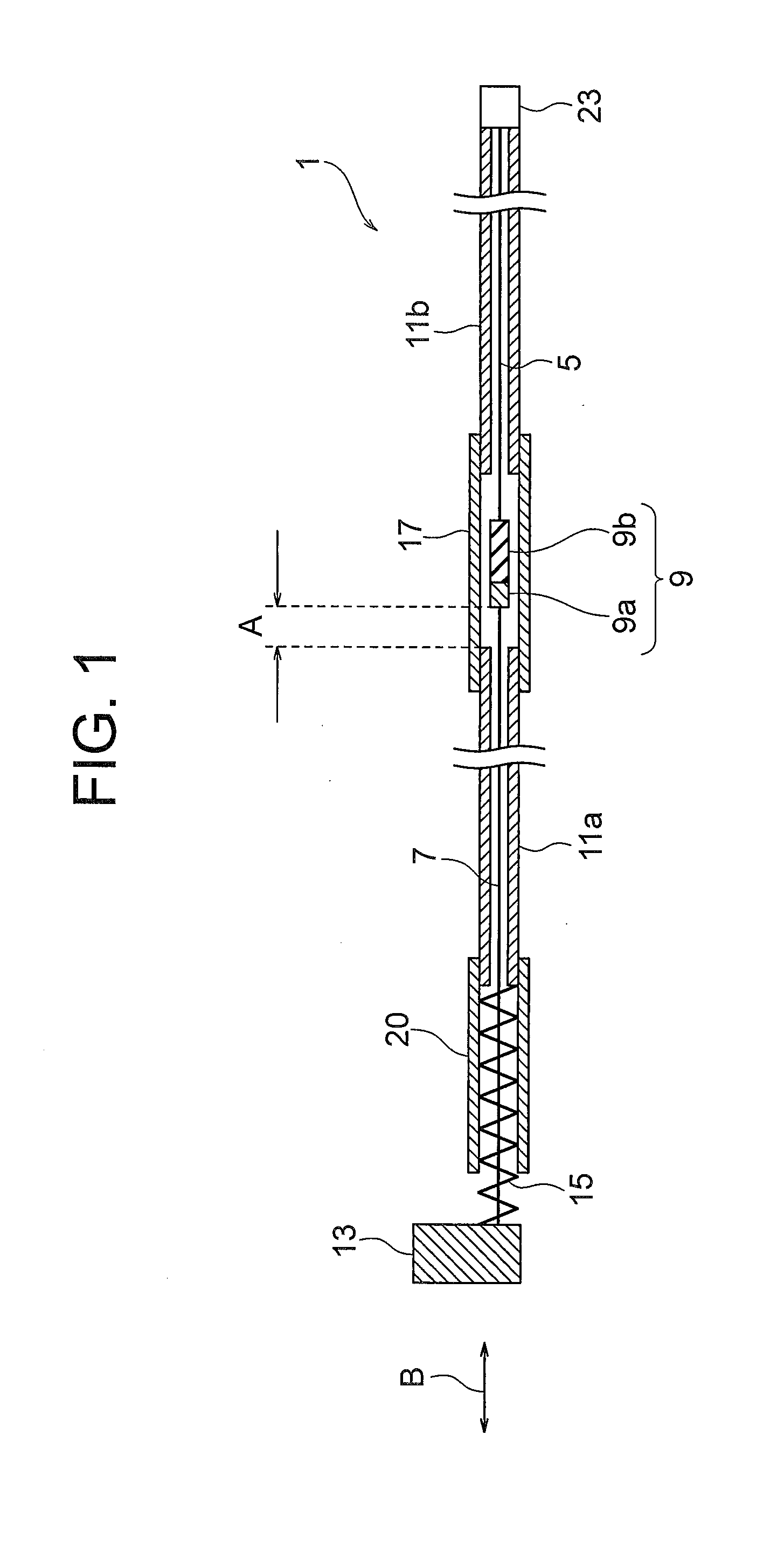

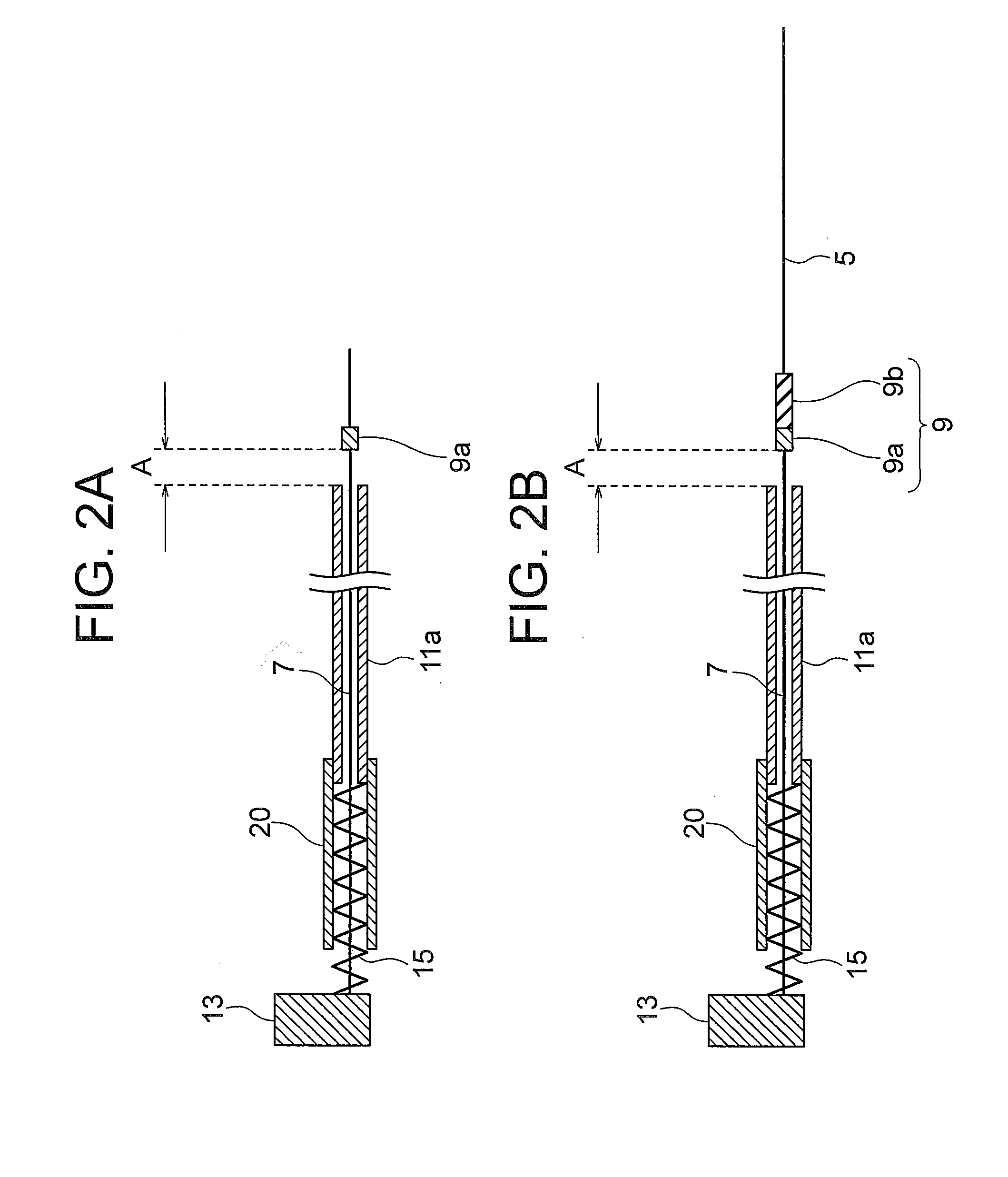

Shape memory alloy actuator

ActiveUS8800284B2Improve controllabilityHeat suppressionMechanical power devicesClosed-cycle gas positive displacement engine plantAlloyShape memory alloy actuators

A shape memory alloy actuator includes a wire portion which is inserted through a first tube member, a shape memory alloy wire portion which is inserted through a second tube member, a movable body which is movable in a direction in which, a length of the shape memory alloy wire portion changes, an elastic member which exerts an external force in a direction in which, the shape memory alloy wire portion elongates, and a fixing member to which, one end of the second tube member and one end of the shape memory alloy wire portion are fixed, and one end of the wire portion is connected to the movable body, and one end of the shape memory alloy wire portion and one end of the wire portion are joined to a joining portion, and the joining portion includes a plurality of crimp terminals.

Owner:OLYMPUS CORP

Method for preparing vacuum glass

ActiveCN104030557AShort heating timeQuality assuranceClimate change adaptationWindows/door improvementEnergy consumptionKiln

The invention relates to the field of vacuum glass and in particular relates to a method for preparing vacuum glass. The method comprises the following steps: (1) heating glass, gluing and curing; (2) arranging the glass; (3) heating the glass in a kiln; and (4) taking out the vacuum glass. The method is short in preparation time and high in sealing property, the energy consumption is reduced, and the vacuum glass manufactured by the method is uniform in bearing capacity.

Owner:青岛中腾志远真空玻璃科技发展有限公司

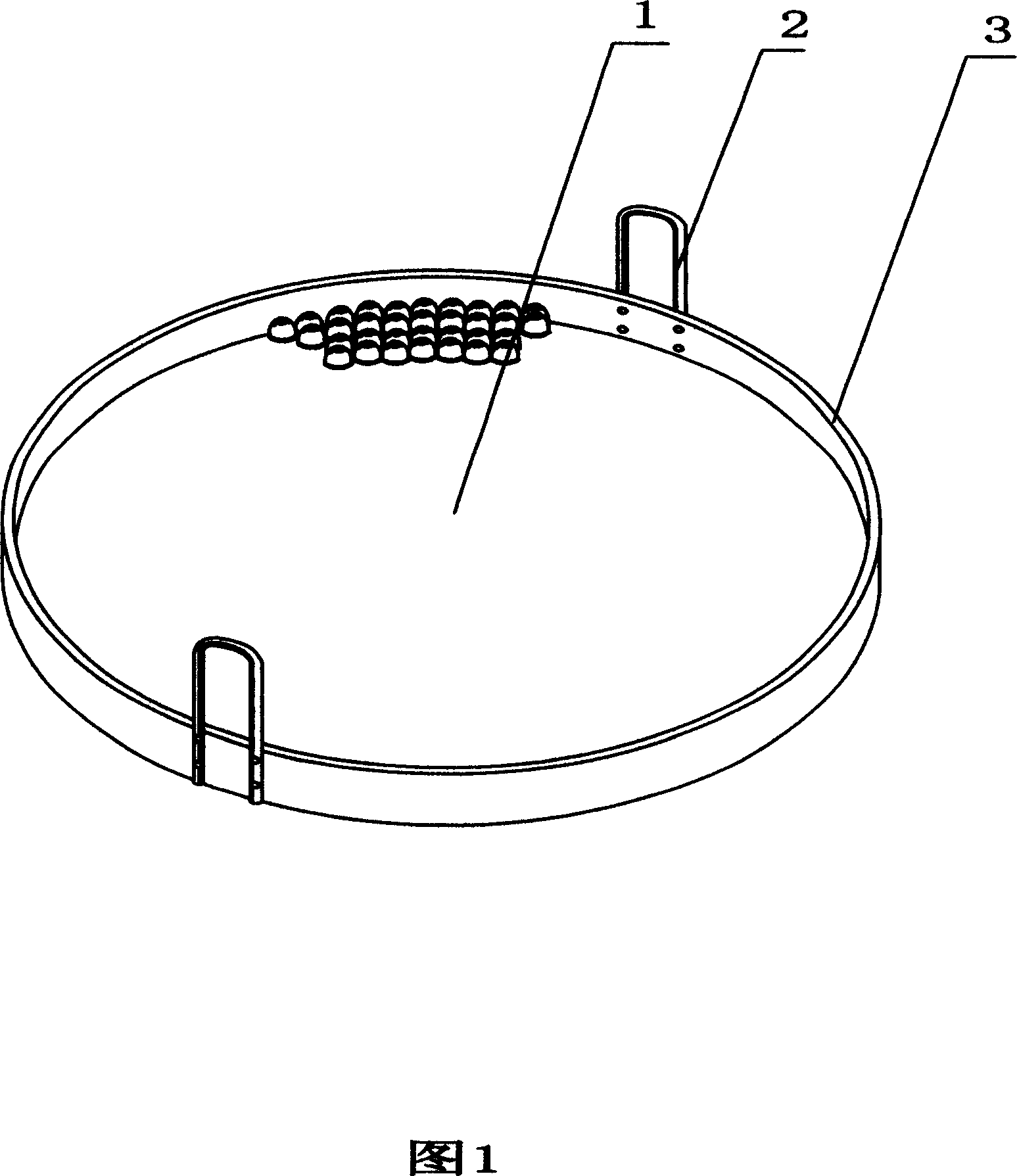

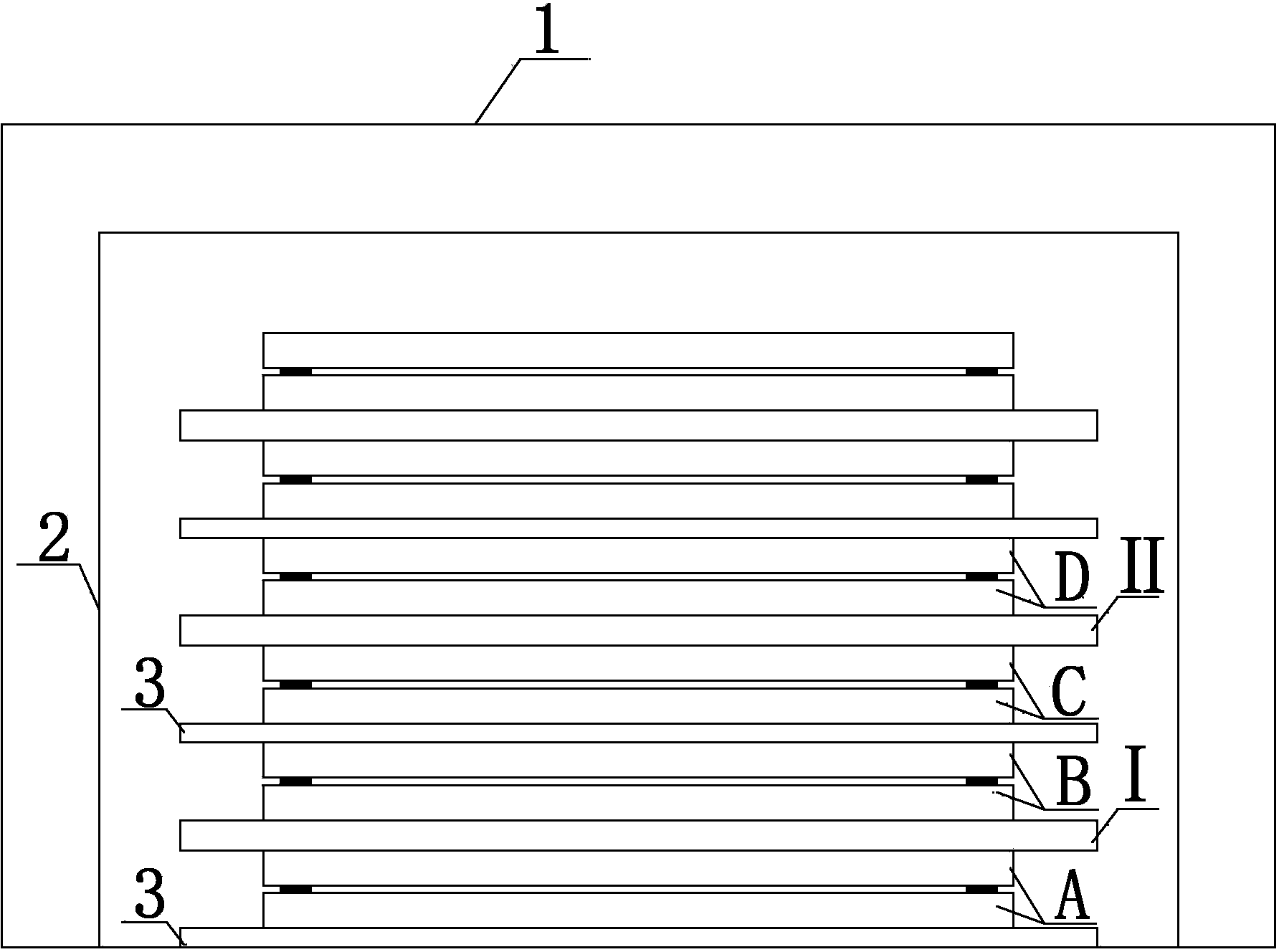

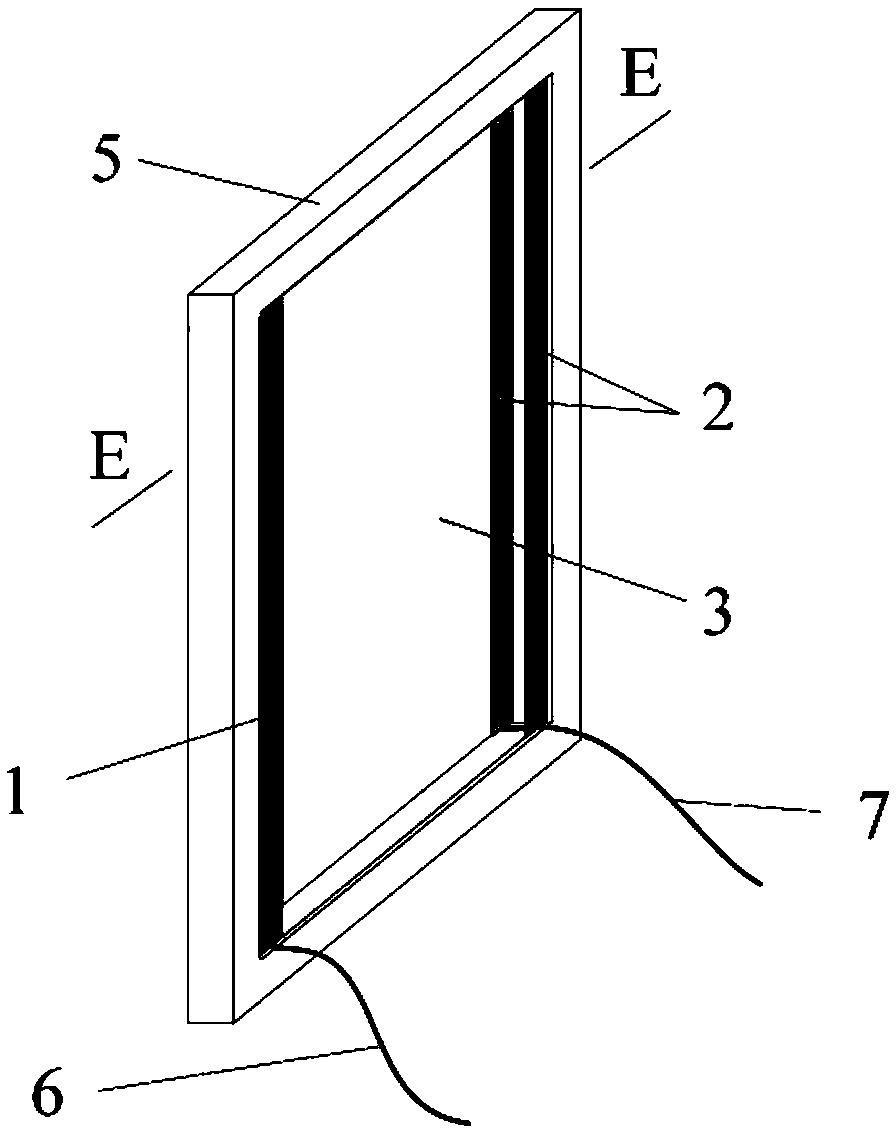

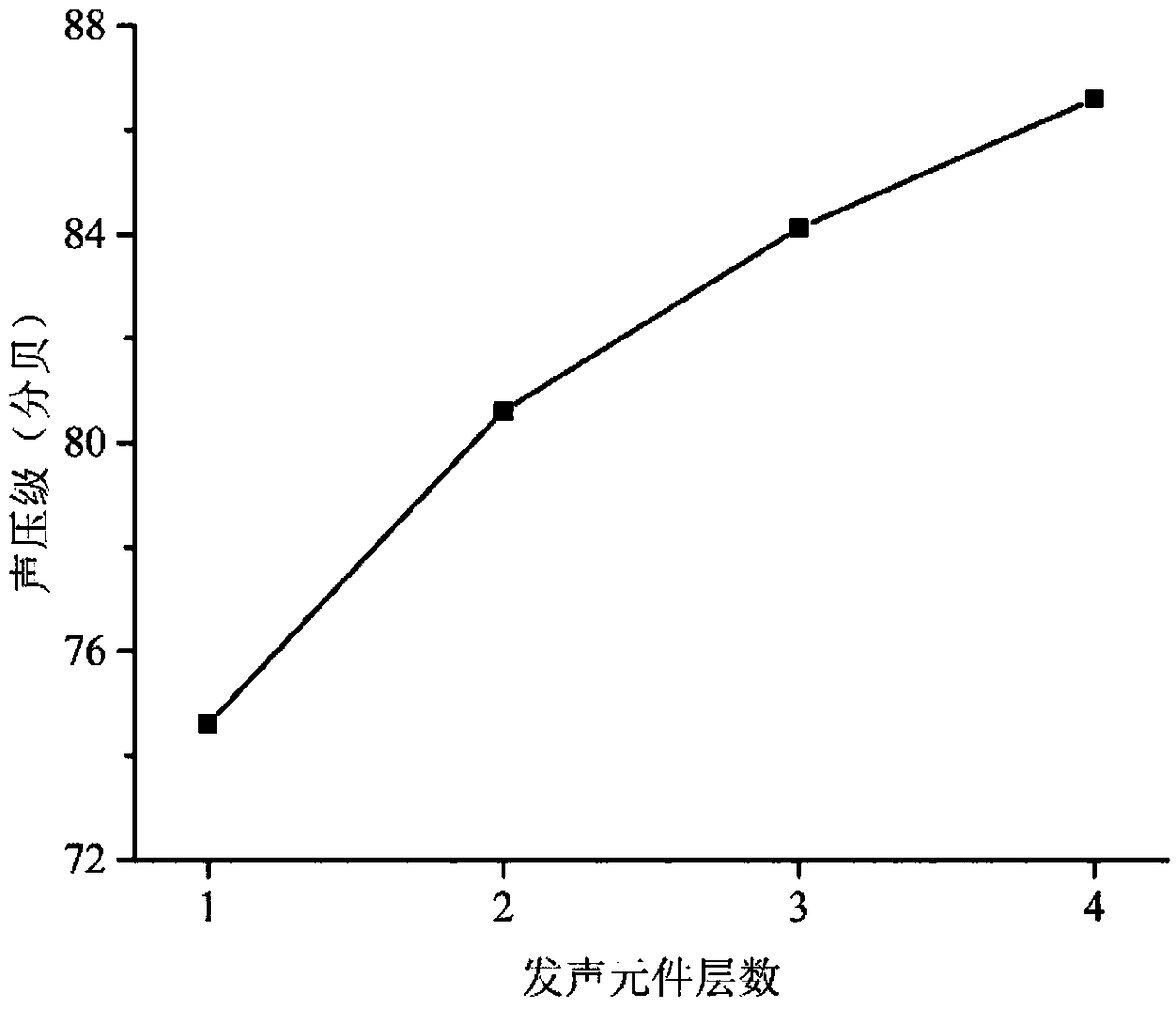

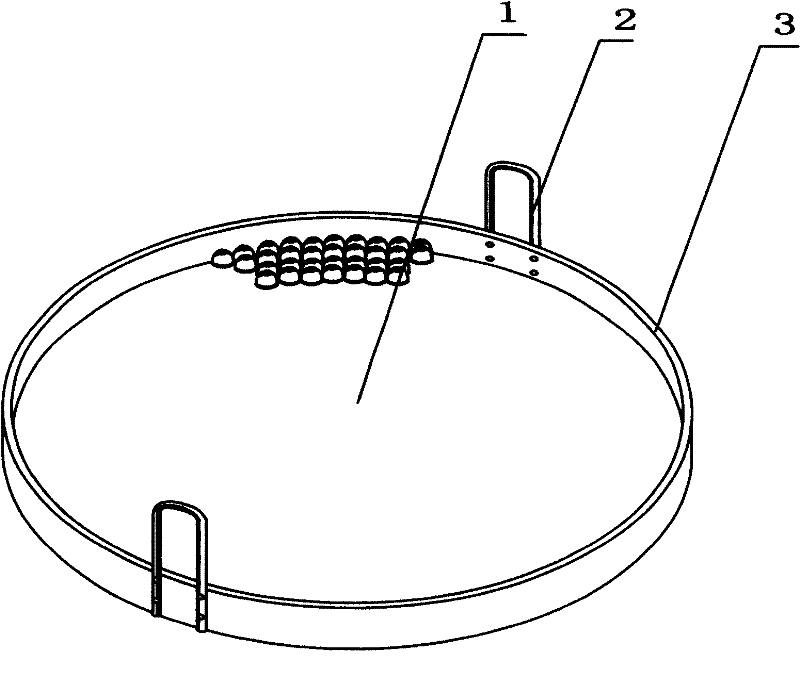

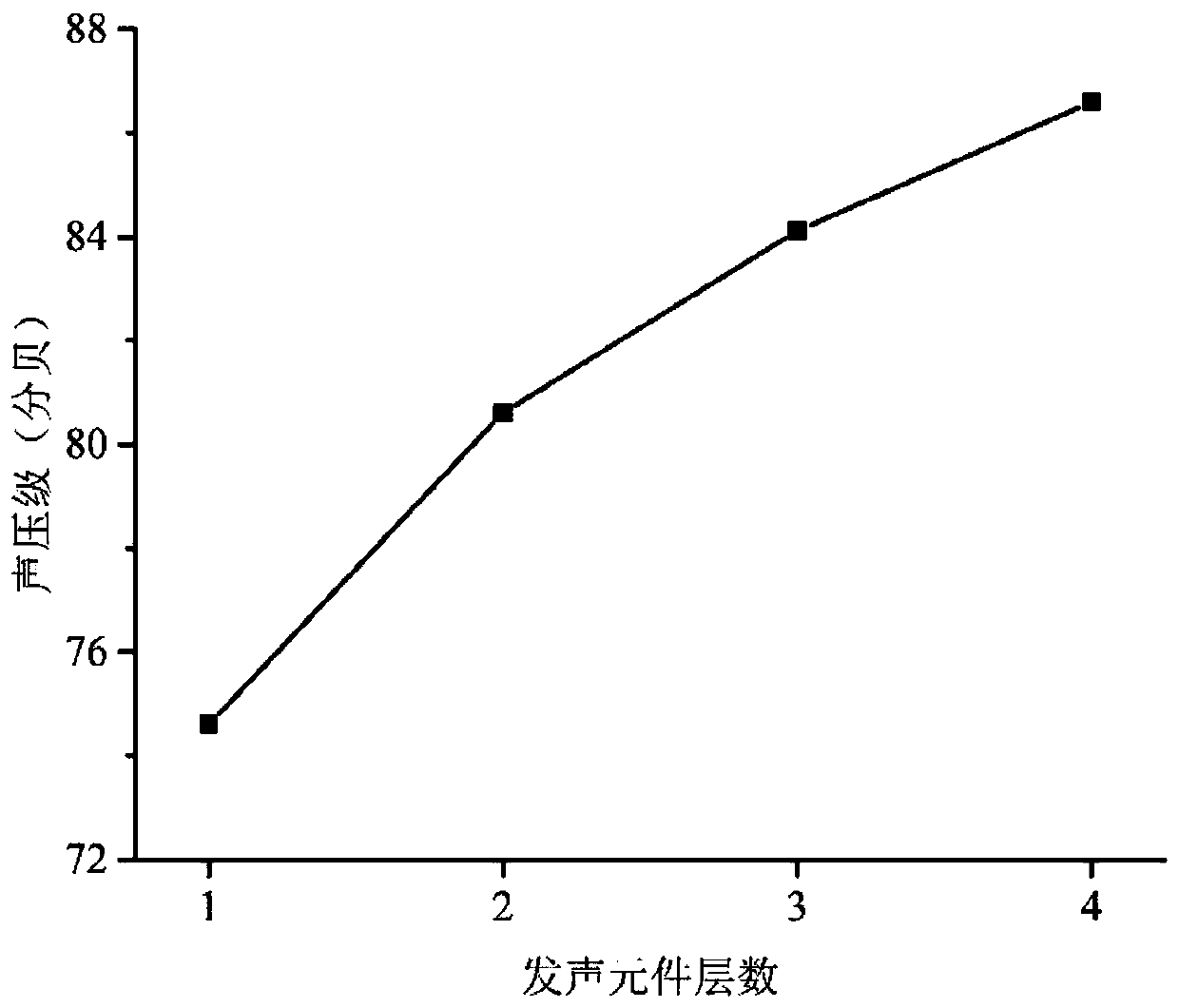

Multilayer carbon nano tube thin film stacked loudspeaker based on thermoacoustic effect

ActiveCN109195087ALow costNo resonanceElectrothermic-effect transistorCarbon nanotubeMetal electrodes

The present invention provides a multilayer carbon nano tube thin film stacked loudspeaker based on a thermoacoustic effect, belonging to the field of mechanical design. The loudspeaker comprises an outer frame and multiple layers of carbon nano tube thin films which are parallel to one another and connected in parallel, and the number of the layers is at least 2 and at most 4. The carbon nano tube thin films are formed by carbon nano tubes, the two ends of the carbon nano tube thin films are connected with metal electrodes which are fixed on the outer frame, the metal electrodes at the same side are connected with the same wire, and the metal electrodes connected with each layer of carbon nano tube thin film are not in contact. Sound production elements generate corresponding temperaturechange according to accessed audio signals to allow mediums around to rapidly expand and extract to emit sound waves. The loudspeaker provided by the invention has no a vibration part to avoid a resonance effect; the multilayer carbon nano tube thin film stacked loudspeaker is simple in structure and few in consumable items required by making, can be made to be any shape as required, and the soundfield medium is uniformly heat without a segmentation vibration phenomenon; and the loudspeaker provided by the invention can generate high-volume sound in an audible sound range, and can be appliedto audible sound devices such as a sound and a radio.

Owner:DALIAN UNIV OF TECH

Crispy fried stuffed bun, preparation method and pan dedicated therefor

InactiveCN1994095BSmall and exquisiteXuan soft and elasticFood coatingBakery productsFrying-pansFlavoring Agents

Owner:张友军

Drying method for the strip steel surface coating

InactiveCN101116856BUniform temperature changeEliminate cracksPretreated surfacesCoatingsProduction lineCoated surface

The invention discloses a drying method for surface coating of strip steel, the drying method includes the procedures as follows: after the strip steel being normally and continuously coated on the production line, the hot wind is used for preliminary drying the coat surface, simultaneously the electromagnetic induction is utilized to heat the inside of the strip steel for inner drying, then the hot wind is utilized again for the final drying the coat surface. The invention dries the coat of the strip steel by outside hot wind and inner heating, the temperature changes uniformly in the dryingprocess of the coat, the invention can effectively eliminate coat crazing and can prevent uneven depth caused by the production accumulation of the coat; the invention utilizes simultaneous drying process for the outside and the inside of the coat, achieving the same effect; the invention can decrease the heating temperature for the electromagnetic induction the strip steel, thereby being useful tocool the production of the strip steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

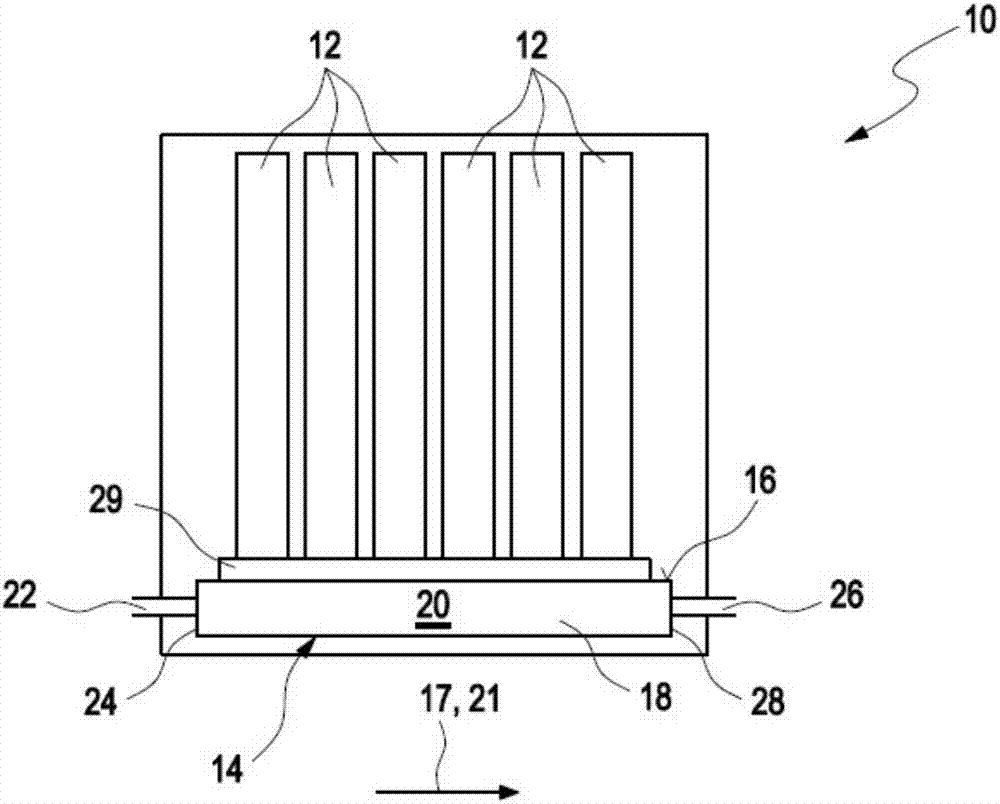

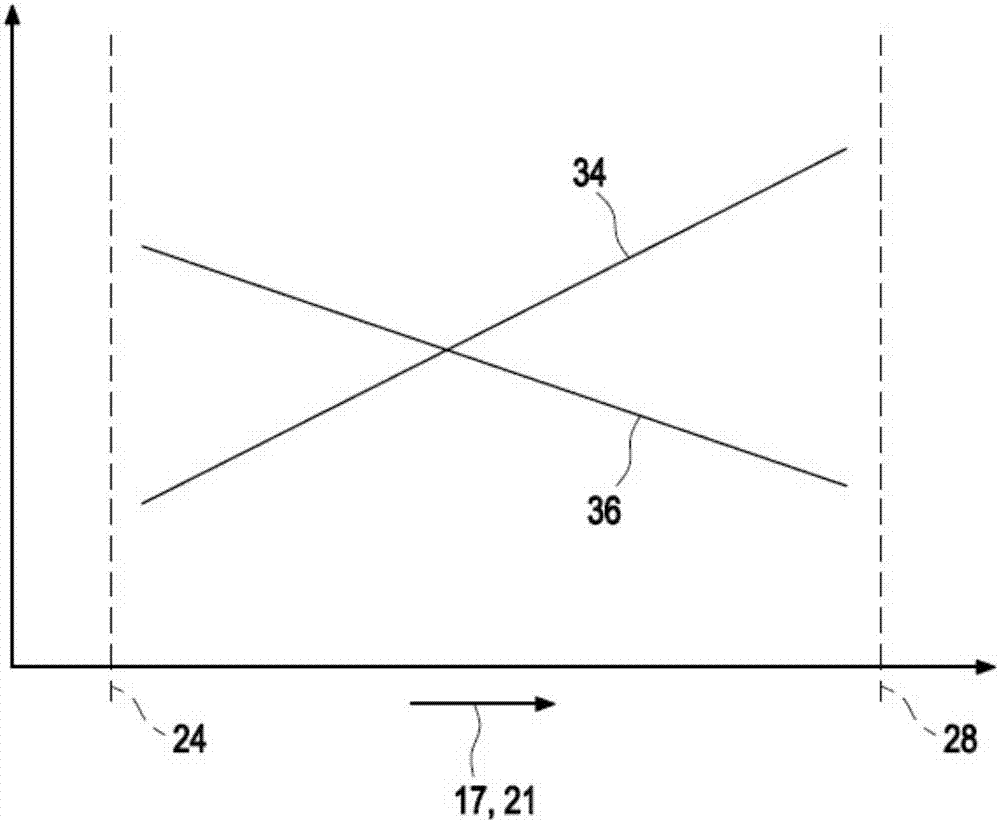

Heat exchanger for controlling the temperature of energy storage elements of an energy store

InactiveCN107078313AImpact ratioUniform temperature changeProtecting/adjusting hybrid/EDL capacitorCells cooling/heatingHeat conductingEngineering

The invention relates to a heat exchanger for controlling the temperature of energy storage elements (12) of an energy store (10) and / or of power electronics, for example of battery cells, having a heat exchange surface (16) which is placed on the energy store (10). Essential to the invention is the fact that the heat exchanger surface (16) is partially coated with a layer (29) comprising a heat-conducting material, and that the heat exchange surface (16) has contact regions (30) which are provided with the heat-conducting layer (29), and insulating regions (32) which are not provided with the heat-conducting layer (29). The invention further relates to an energy store and to the production thereof having energy storage elements (12) and at least one such heat exchanger (14), which rests on the energy storage elements (12) in order to control the temperature of the energy storage elements (12). Essential to the invention is the fact that a contact area between the energy storage elements (12) and the heat exchanger (14) is formed by the heat-conducting layer (29) applied to the heat exchanger (14).

Owner:MAHLE INT GMBH

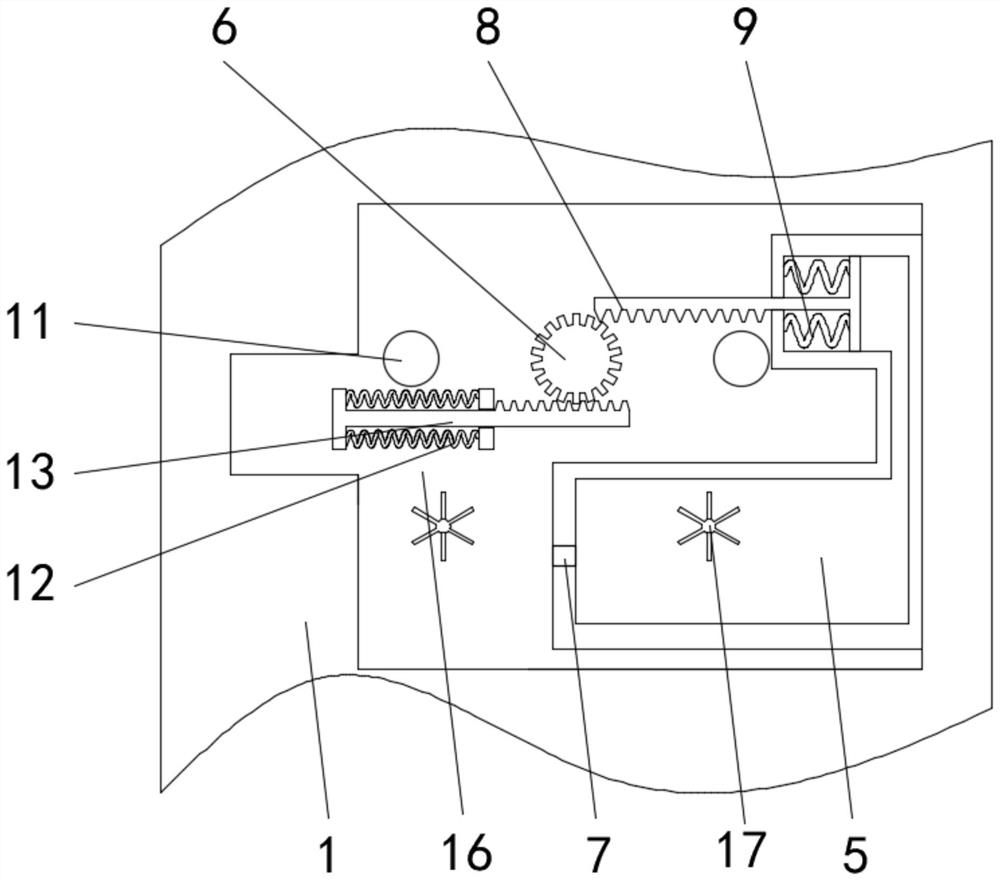

High-efficiency conveying mechanism for annealing processing of glass product

InactiveCN111792833AEvenly heatedUniform temperature changeGlass transportation apparatusRatchetGas passing

The invention relates to the technical field of glass manufacturing, and discloses a high-efficiency conveying mechanism for annealing processing of a glass product. The mechanism comprises a box body, wherein a material clamping cavity is formed in the middle part of the box body, a rotating frame is movably connected to the middle part of the material clamping cavity, and a lower fixing seat isfixedly connected to one side of the rotating frame. According to the invention, an automatic turnover mechanism is additionally arranged; when a to-be-treated glass tube is in a heating stage, a heatpreservation stage and a rapid cooling stage, gas passing through a gas pressure cavity has pressure changes due to different temperatures, and the gas pressure cavity is subjected to pressure reliefand negative pressure filling through gas outlet holes with small diameters, so an upper ratchet plate and a lower ratchet plate extend or retract under the action of the pressure changes; a rotatinggear rotates through a ratchet end, so a supporting frame drives the to-be-treated glass tube to turn over; and thus, the glass tube can be automatically turned over during temperature rise, the glass tube is heated uniformly, and can be turned over multiple times in the heat preservation stage and the rapid cooling stage, and the upper side and the lower side of the glass tube are heated more uniformly.

Owner:来安县华阳玻璃制品有限公司

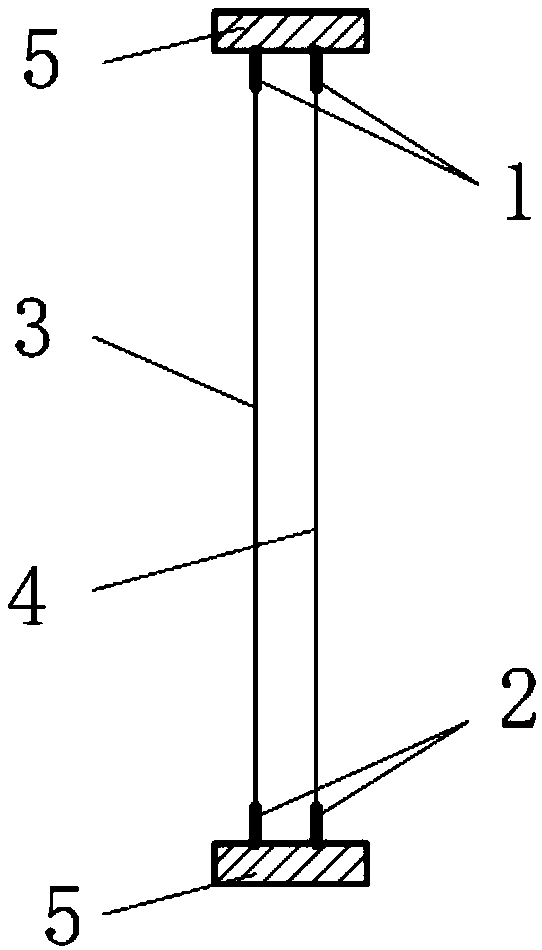

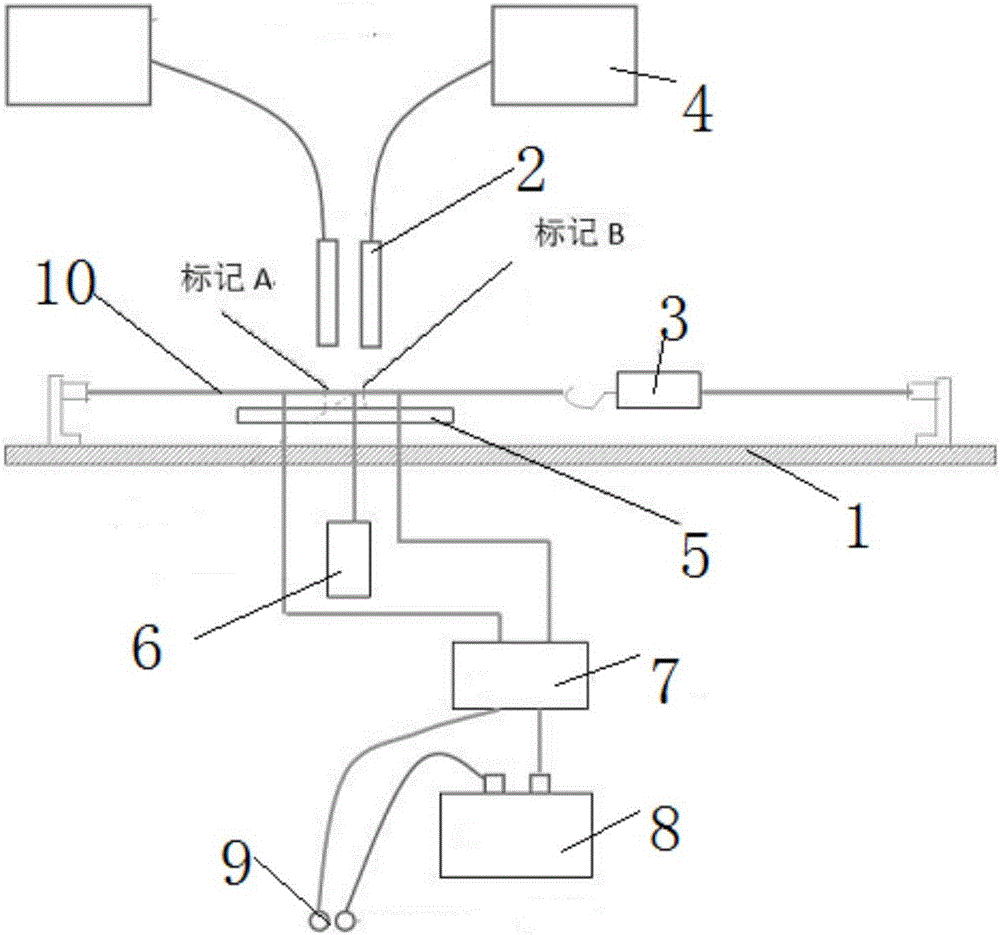

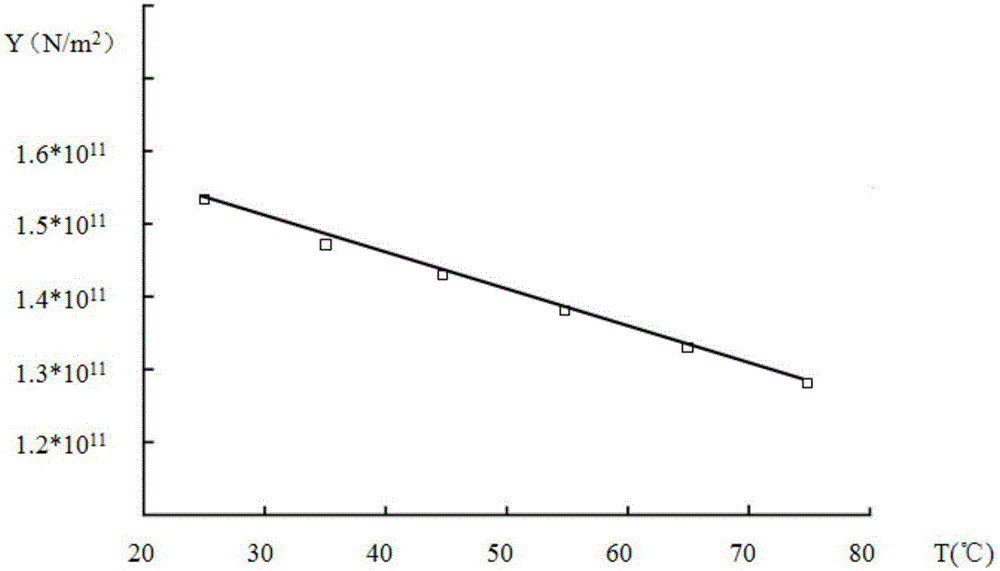

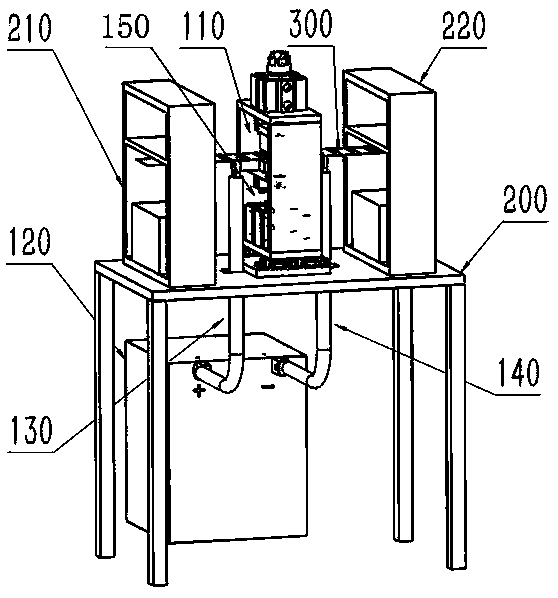

Temperature characteristic testing apparatus for Young modulus of metal wire and testing method thereof

PendingCN106198241AAchieve heatingRealize temperature changeMaterial strength using tensile/compressive forcesMetallic materialsDigital thermometers

The invention relates to a testing apparatus for a metal material, and particularly relates to a temperature characteristic testing apparatus for a Young modulus of a metal wire and a testing method thereof. The temperature characteristic testing apparatus comprises a fixing rack, wherein one end of the metal wire is fixedly arranged on one end of the fixing rack, while the other end of the metal wire is connected with an electronic portable scale; the electronic portable scale is connected with the other end of the fixing rack; the metal wire is stressed to be tightened; in an experimental area for the metal wire, the edges of the experimental area are provided with one digital microscope respectively; the digital microscopes are connected with a computer; a steel rule is also mounted in the experimental area; a probe of a two-channel digital thermometer is connected to the middle of the experimental area for the metal wire; the outer sides of two ends of the experimental area for the metal wire are connected onto a low-frequency alternating-current transformer respectively; the low-frequency alternating-current transformer is also connected with a power supply; a resistance changing box is connected in series between the low-frequency alternating-current transformer and the power supply. According to the temperature characteristic testing apparatus and the testing method thereof, a heating method of realizing impedance conversion by using the alternating-current transformer is provided; the temperature change of the metal wire is achieved by utilizing a current generating circuit; a numerical value which is accurately measured is obtained.

Owner:FUJIAN NORMAL UNIV

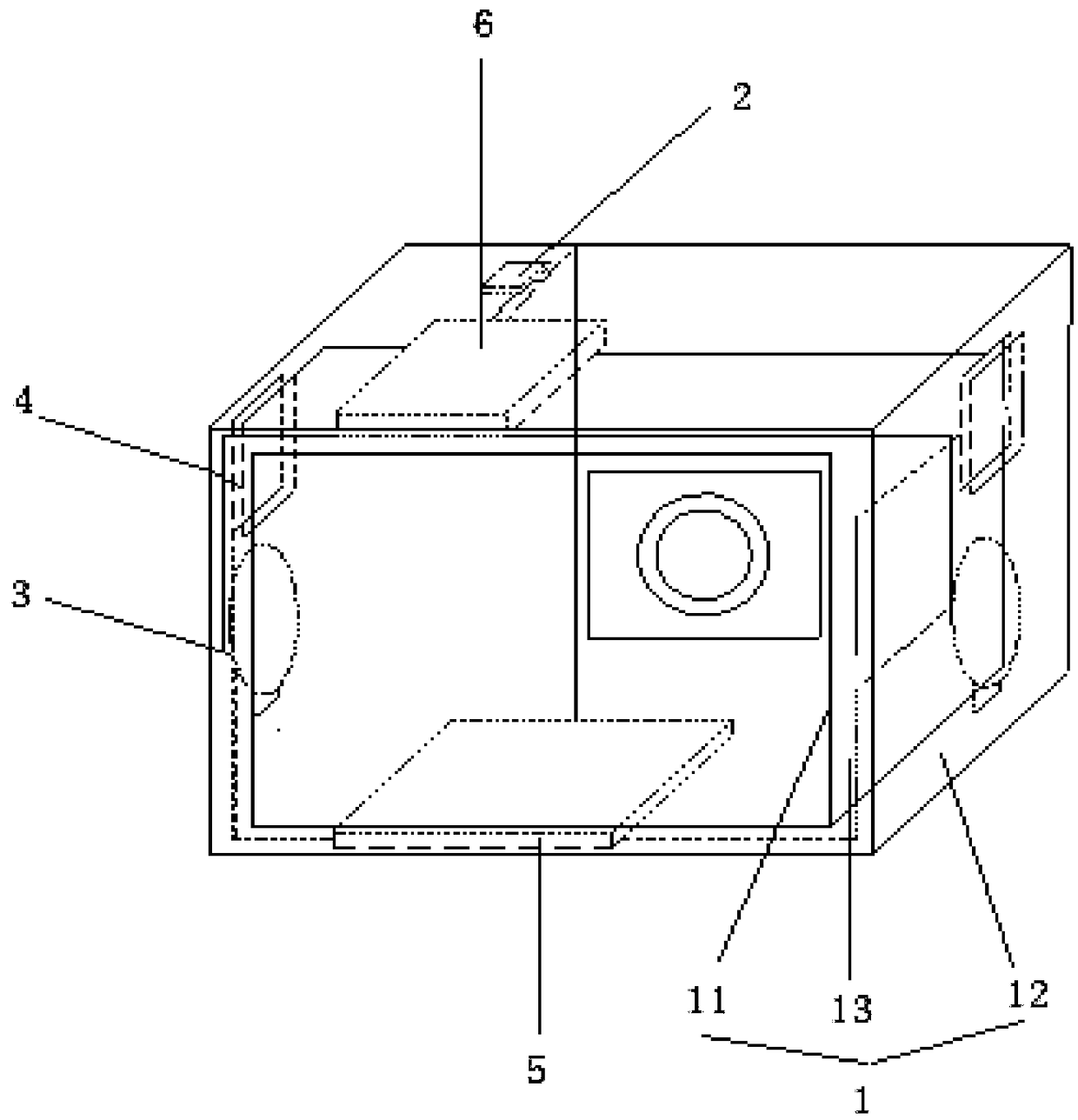

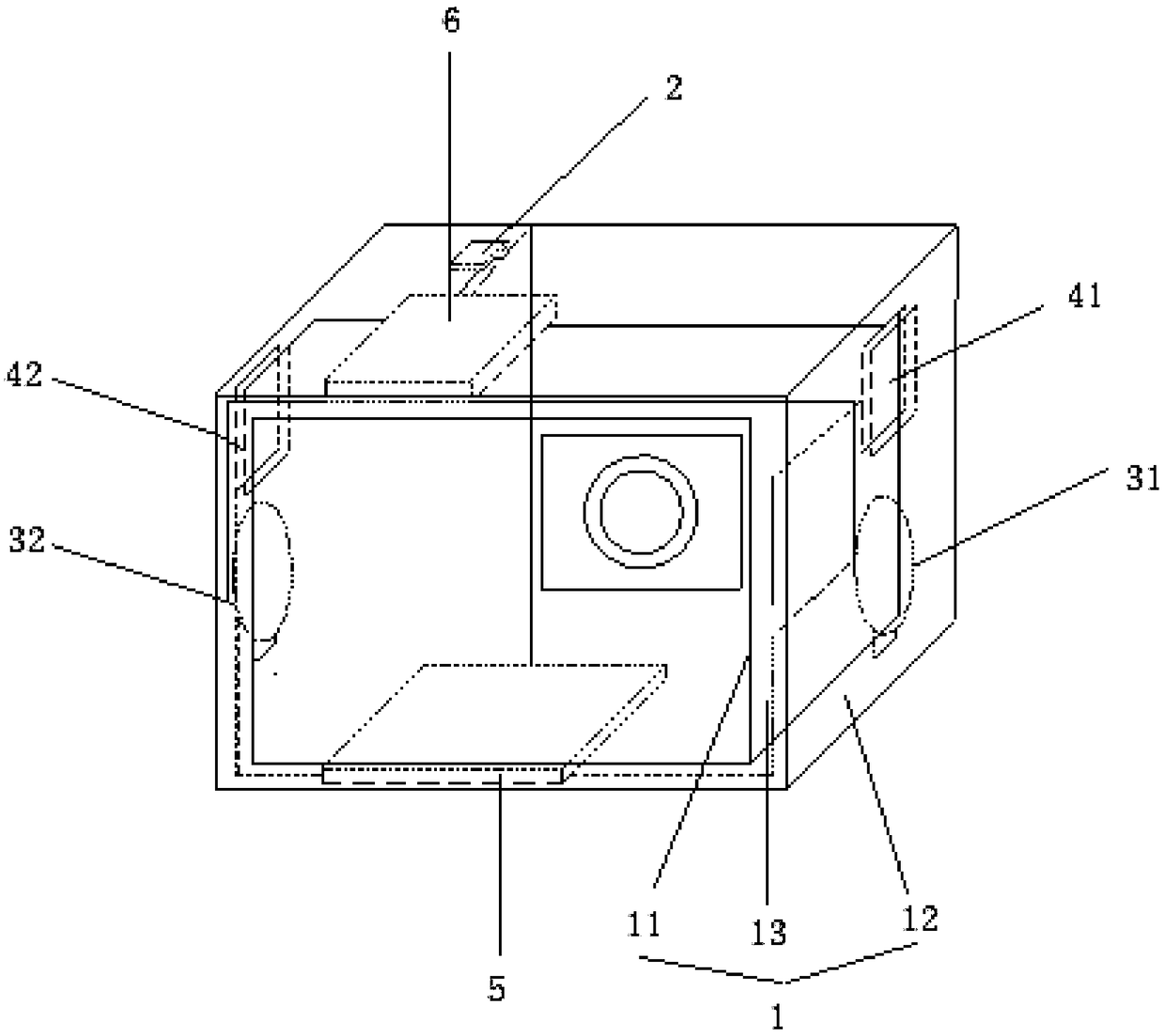

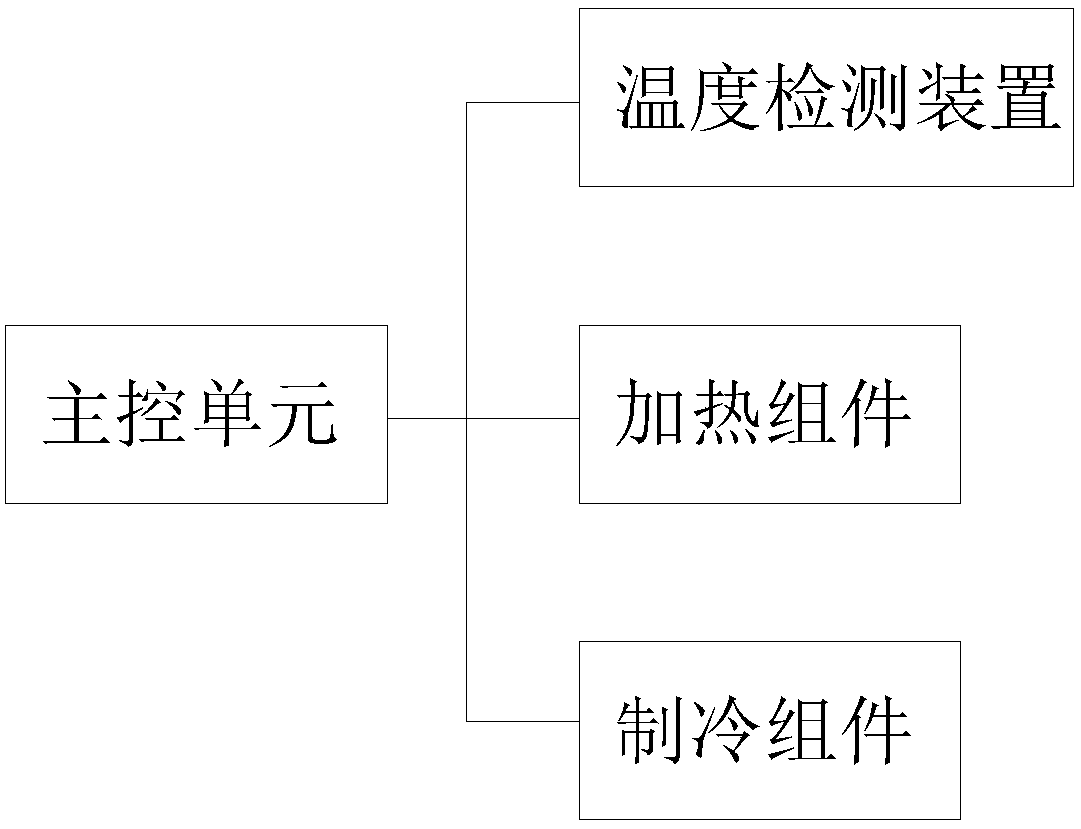

Electronic equipment and temperature control method thereof

InactiveCN108107947AExtended service lifeWill not be damagedTemperatue controlSubstation equipmentTemperature controlLower limit

The invention relates to the field of electronic equipment, and discloses a piece of electronic equipment and a temperature control method thereof. The electronic equipment comprises a housing, a temperature detection device, a heating component, a refrigeration component, and a main control unit. The housing consists of an inner wall and an outer wall arranged opposite to the inner wall, and an interlayer area is formed between the inner wall and the outer wall. The temperature detection device is arranged in the interlayer area, and detects the temperature in the interlayer area. The heatingcomponent is arranged in the interlayer area. The refrigeration component is arranged in the interlayer area. The main control unit is electrically connected with the temperature detection device, the heating component and the refrigeration component. The main control unit opens the refrigeration component when the temperature value received is higher than an upper limit threshold, and opens theheating component when the temperature value received is lower than a lower limit threshold. Compared with the prior art, the temperature in the electronic equipment can be controlled, so that the battery and other components are protected from damage, the service life of the electronic equipment is prolonged, it is ensured that the electronic equipment can work normally at different external temperatures, the user experience is enhanced, and the use range is increased.

Owner:SHANGHAI YUDE TECH CO LTD

Manufacturing method and manufacturing equipment of vacuum glass

InactiveCN107540248AAffect appearance qualityHigh bonding strengthGlass tempering apparatusVitreous BodiesWarming process

The invention provides a manufacturing method and manufacturing equipment of vacuum glass. The manufacturing method comprises the following steps of A, glue dotting on a first glass sheet; B, glue curing and glass tempering; C, placing of the glass sheet; D, vacuum sucking, heating, and sheet closing; E, fetching out. The manufacturing method has the advantages that while the first glass is tempered, the glass powder glue, blocking glue and fulcrum glue are cured, and the glass tempering and the glue curing are simultaneously completed, so that the technology steps are simplified, the preparation time is shortened, and the adhering strength between the glass powder glue, the blocking glue as well as the fulcrum glue and the first glass is improved; by respectively arranging heating bodiesat the upper part and lower part, the heating speed of each glass body is favorably improved; the heat is transferred to the glass in a contact heating way, so that the heat loss is reduced, and the energy-saving effect is realized; the uniform change of temperature at each part of the glass sheet is favorably guaranteed in the heating process; by arranging the blocking glue, the influence to theappearance quality of the vacuum glass due to the flowing of the melting glass power glue to the interior in a tempering furnace is avoided.

Owner:张艳乡

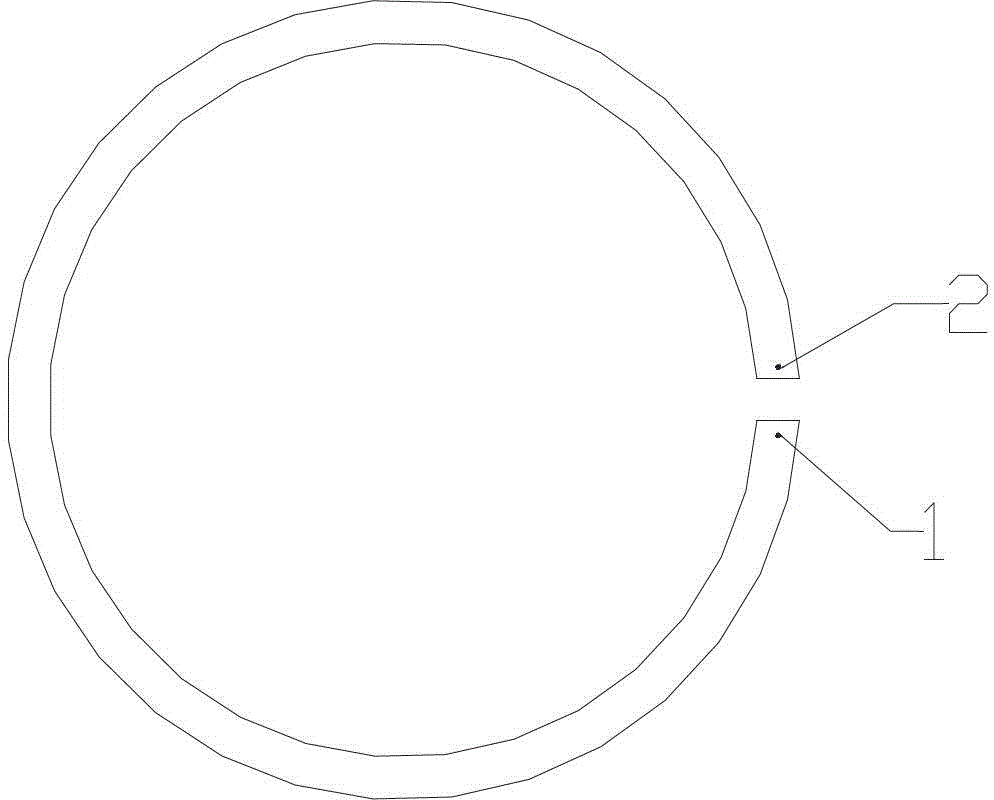

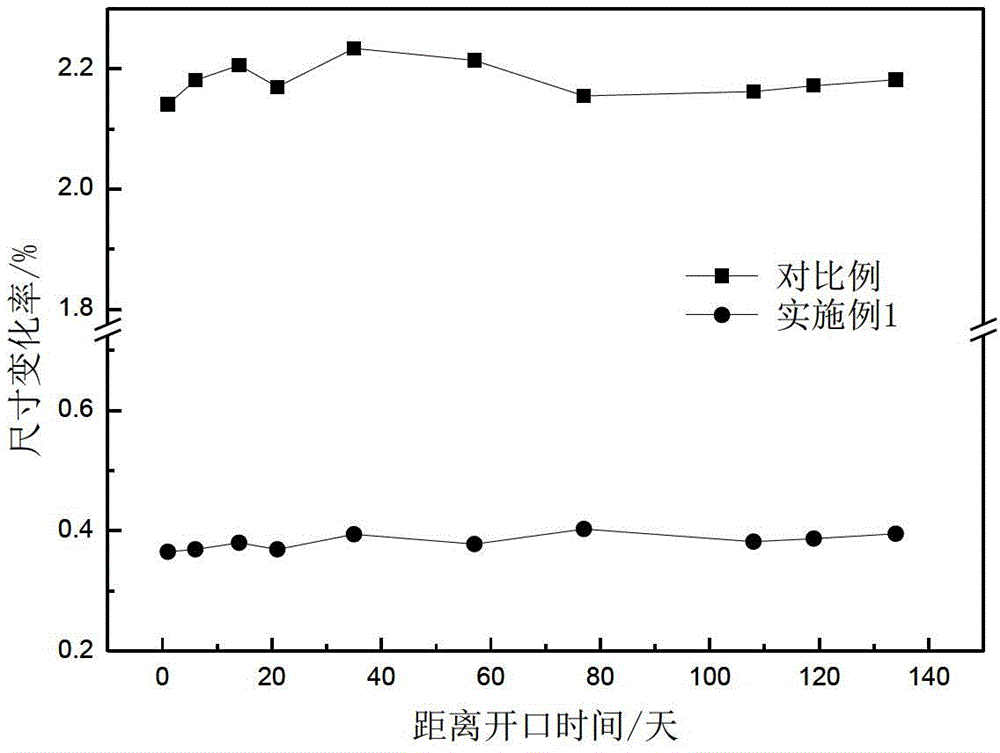

A cryogenic treatment method for improving the dimensional stability of gcr15 steel

ActiveCN103305669BUniform temperature changePrevent the phenomenon of temperature differences in different partsAfter treatmentRoom temperature

The invention discloses a cryogenic treatment method for improving dimensional stability of GCr15 steel. The method comprises the following steps of: cooling a GCr15 material after quenching to -80 DEG C- -100 DEG C at the rate of 2-5 DEG C / min, performing heat preservation for 0.5h-1h, continuously cooling to -180 DEG C- -190 DEG C after the end of heat preservation, and performing heat preservation for 2h-3h; and continuously heating to room temperature at the rate of 2-5 DEG C / min after the end of heat preservation, performing heat preservation for 0.5h-1h, and finally performing a normal tempering process, thereby ending the process. As for the GCr15 steel after treatment through the method disclosed by the invention, the surface hardness of the material is improved by 1.5HRC, and the dimensional variation ratio of an opening of a circular ring is obviously smaller than that without cryogenic treatment; and simultaneously, along with the prolongation of the opening time, the opening of the circular ring after cryogenic treatment has smaller fluctuation in the dimensional variation ratio of the opening of the circular ring and is more stable.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

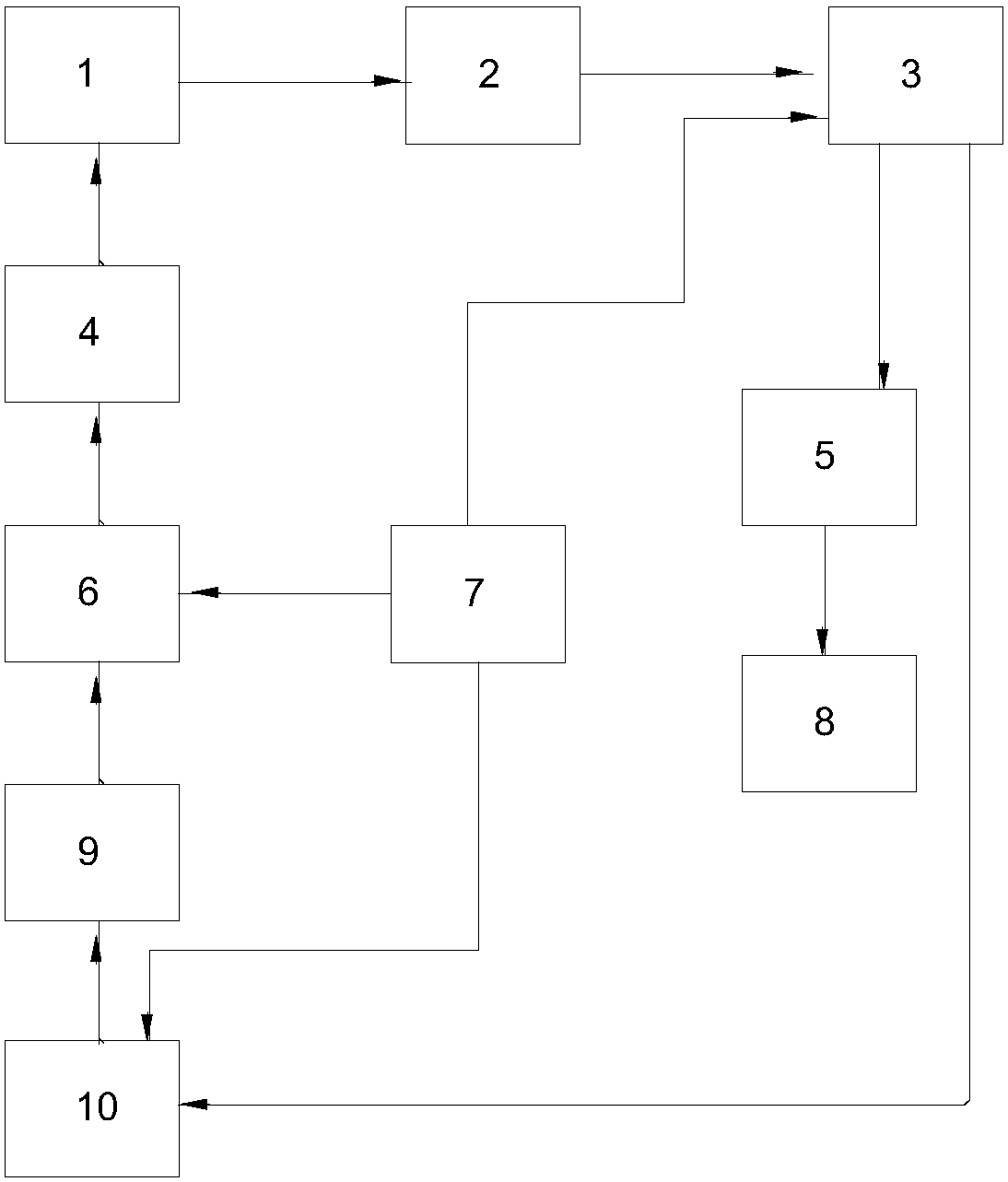

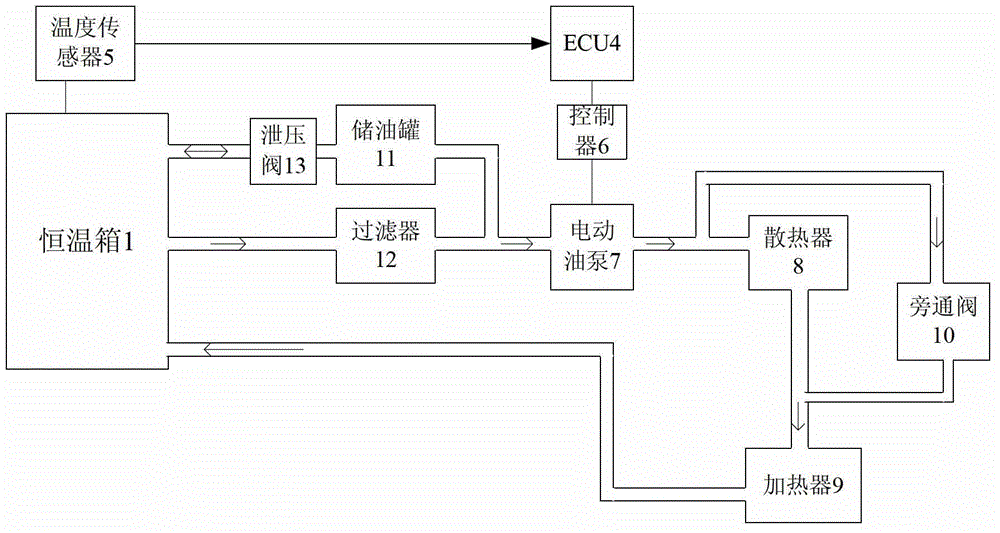

Temperature control system for battery packs

InactiveCN102832424BAdjustable temperatureGuaranteed work efficiencySecondary cellsCell component detailsTemperature controlWorking temperature

The invention discloses a temperature control system for battery packs. The temperature control system for the battery packs comprises the battery packs, an ECU (electronic control unit), a constant-temperature tank filled with insulated oil liquid, an oil liquid filter, a radiator, a heater, an oil pump controller and an oil pump. The constant-temperature tank is provided with an oil outlet and an oil inlet, a plurality of temperature sensors are arranged on the surface of the constant-temperature tank, the temperature sensors, the radiator, the heater and the oil pump controller are respectively electrically connected with the ECU, the oil pump is connected with the oil pump controller, the oil liquid filter is respectively communicated with the oil outlet of the constant-temperature tank and an oil inlet of the oil pump through pipelines, an oil outlet of the oil pump is communicated with the radiator through a pipeline, and the heater is respectively communicated with the oil inlet of the constant-temperature tank and the radiator through pipelines. The temperature control system for the battery packs has the advantages of simple structure, low cost, high safety and the like, the temperature of the battery packs can be constantly controlled within a normal working temperature range, working efficiency of the battery packs is effectively improved, and the service life of the battery packs is effectively prolonged.

Owner:SOUTH CHINA UNIV OF TECH

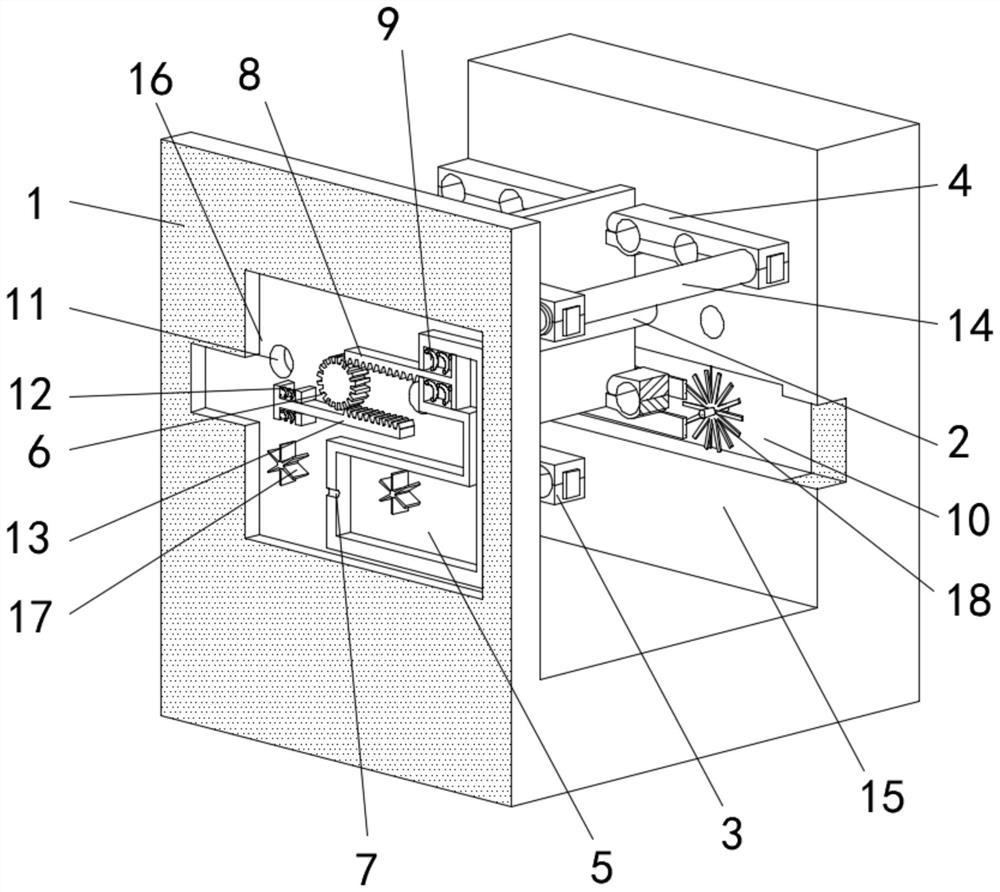

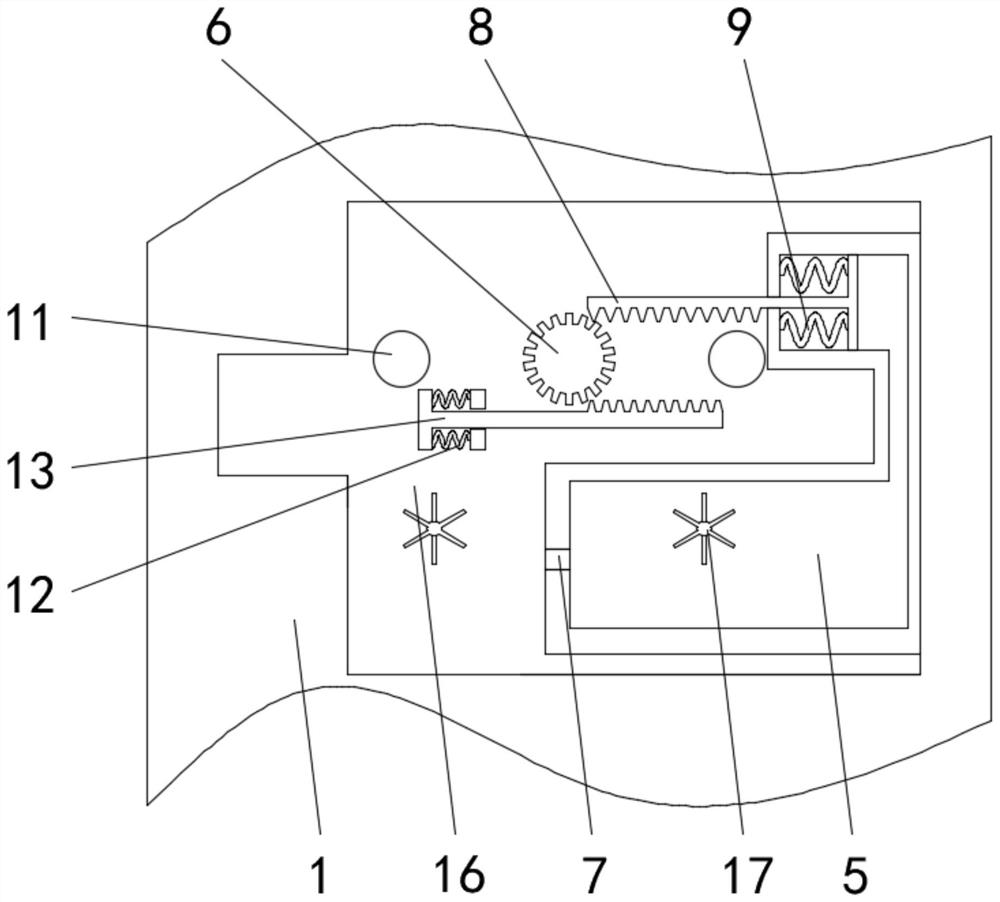

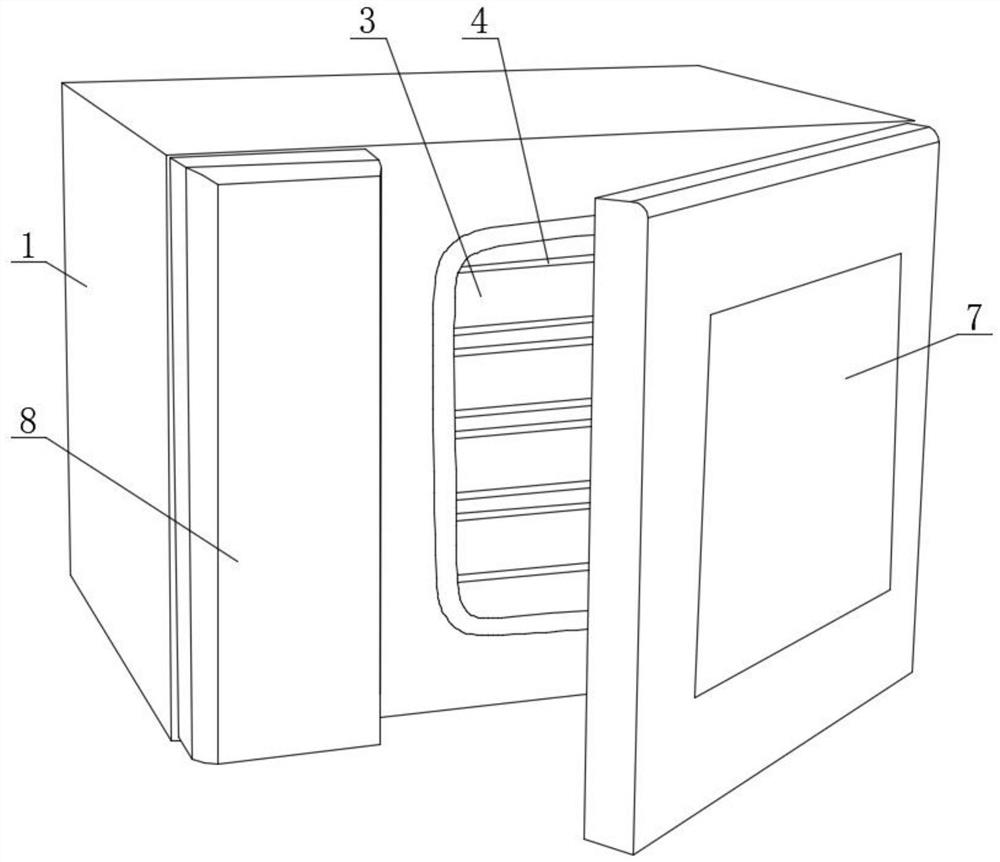

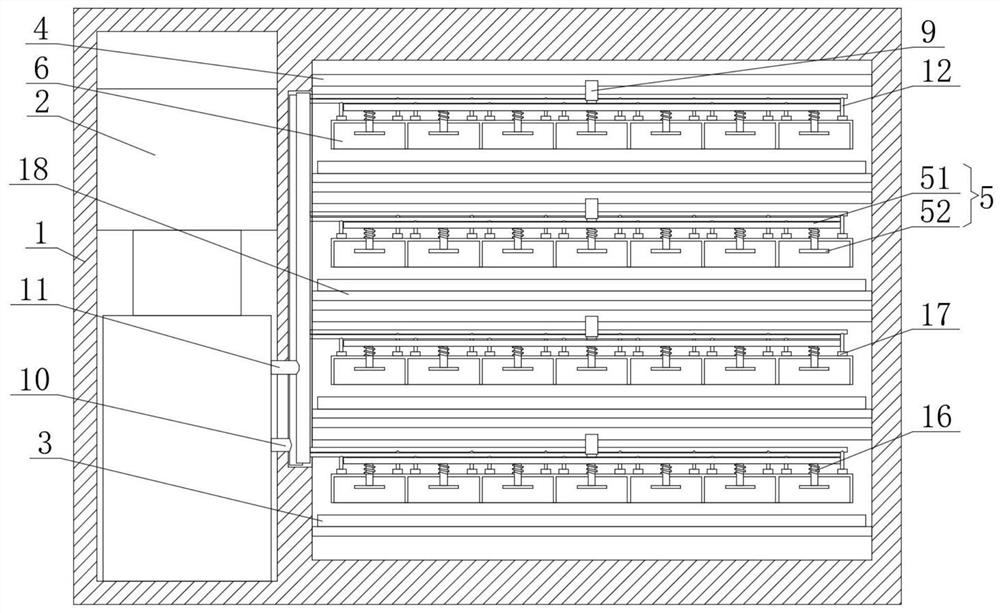

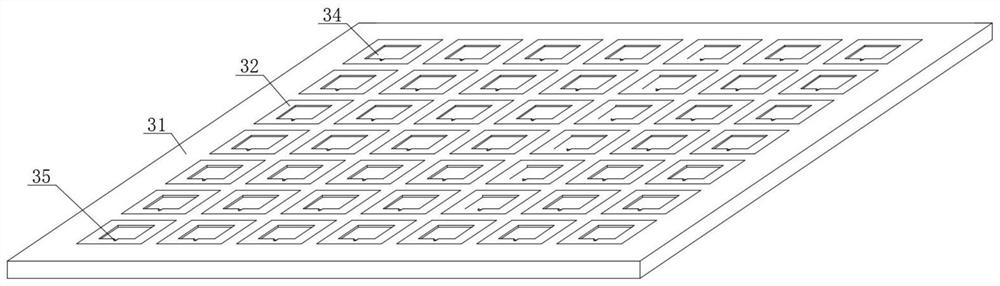

Temperature circulation box for chip security detection

PendingCN113960450AMeet testing needsPracticalElectronic circuit testingTemperature controlElectrical and Electronics engineering

The invention discloses a temperature circulation box for chip safety detection, and belongs to the field of chip safety detection. The technical key points are that the temperature circulation box comprises a circulation box and a temperature control mechanism, the temperature control mechanism is installed in the circulation box, and an air supply pipe and a recovery pipe are installed on the temperature control mechanism; the inner side of the circulation box is fixedly provided with shelving frames which are arranged at equal intervals, the shelving frames are provided with detection discs, the inner side of the circulation box is fixedly connected with detection plates which are arranged at equal intervals, the detection plates and the shelving frames are arranged in a staggered mode, and the bottoms of the detection plates are provided with thermoelectric refrigeration sheet groups. According to the invention, chips to be detected can be separated, the situation that other chips to be detected are influenced when the chips burst, and consequently the detection structure is not accurate is avoided, meanwhile, the interior of the temperature circulation detection box is protected, a temperature changing mode is selected according to the use requirements of a user, the test requirements are met, and the practicability is higher.

Owner:苏州杰裕恩信息技术有限公司

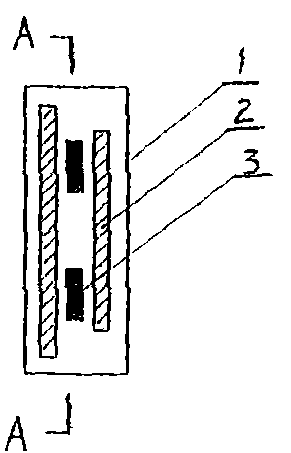

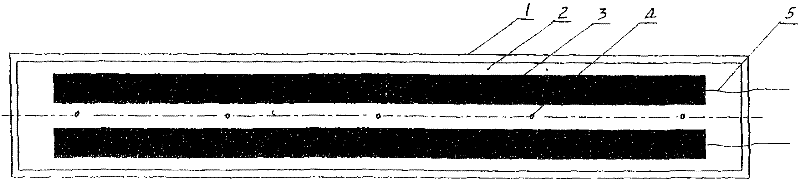

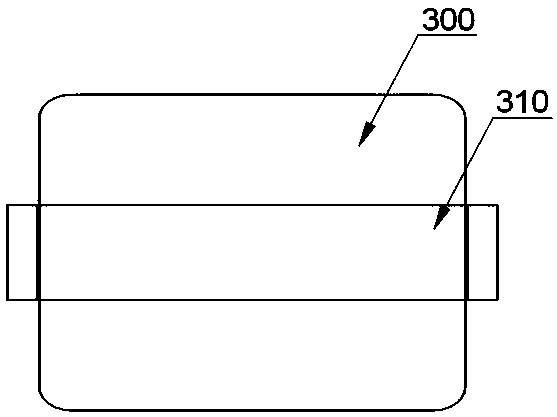

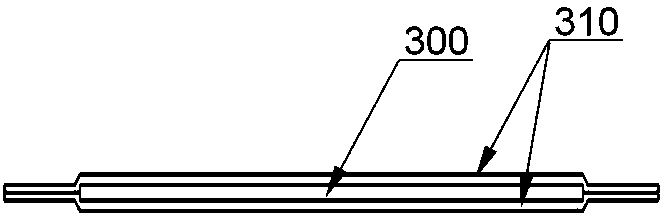

Ultra-thin plate type heater and manufacturing method thereof

ActiveCN101336014BUniform temperature changeFast heatingOhmic-resistance heatingManufacturing stator/rotor bodiesWaferingEngineering

The invention relates to a ultrathin plate type heater for performing scene shrink on a hydraulic generator rotor yoke, namely heating and a preparation method thereof. The heater is provided with a rectangle thin plate type case, and two thin silicon wafers are arranged vertically on two sides near the case. Two thin heating elements are arranged in parallel and symmetrically at the two sides ofa vertical center line between two silicon wafers. In the preparation of the invention, the case is composed of an upper plate and a lower plate, and flanges are arranged around the upper plate. First, the upper plate, the lower plate, the thin silicon wafers, the heating elements are cut out one by one according to the set sizes, then the silicon wafer, the heating elements, the silicon wafer are laid in turn on the lower plate. An educe wire is joined from one end of the heating element, the upper cover is covered and the flanges are folded. Riveting holes arranged along a center line equispacedly rivet the upper plate and the lower plate relatively one by one. Total thickness of the heater, thicknesses of the case, the heating element, the silicon wafers are controlled according to certain range.

Owner:JIANGSU YINONE ELECTRIC

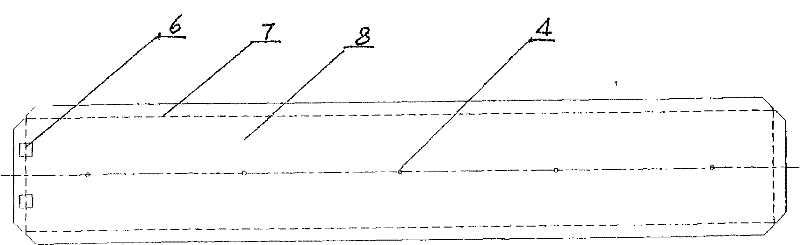

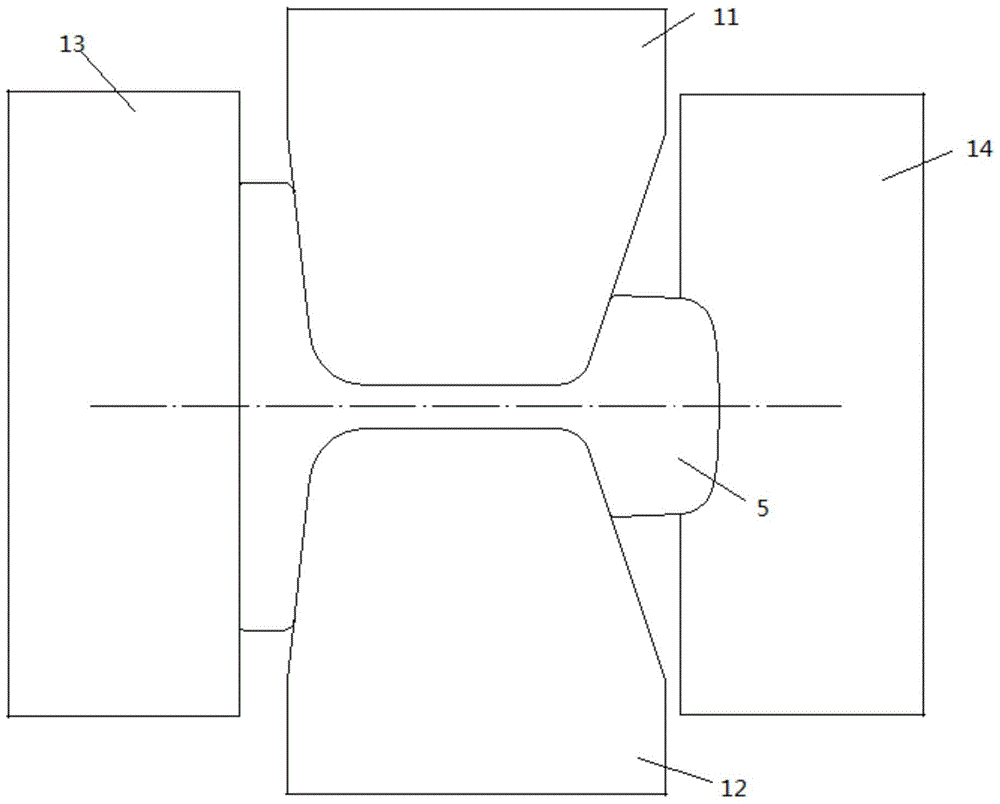

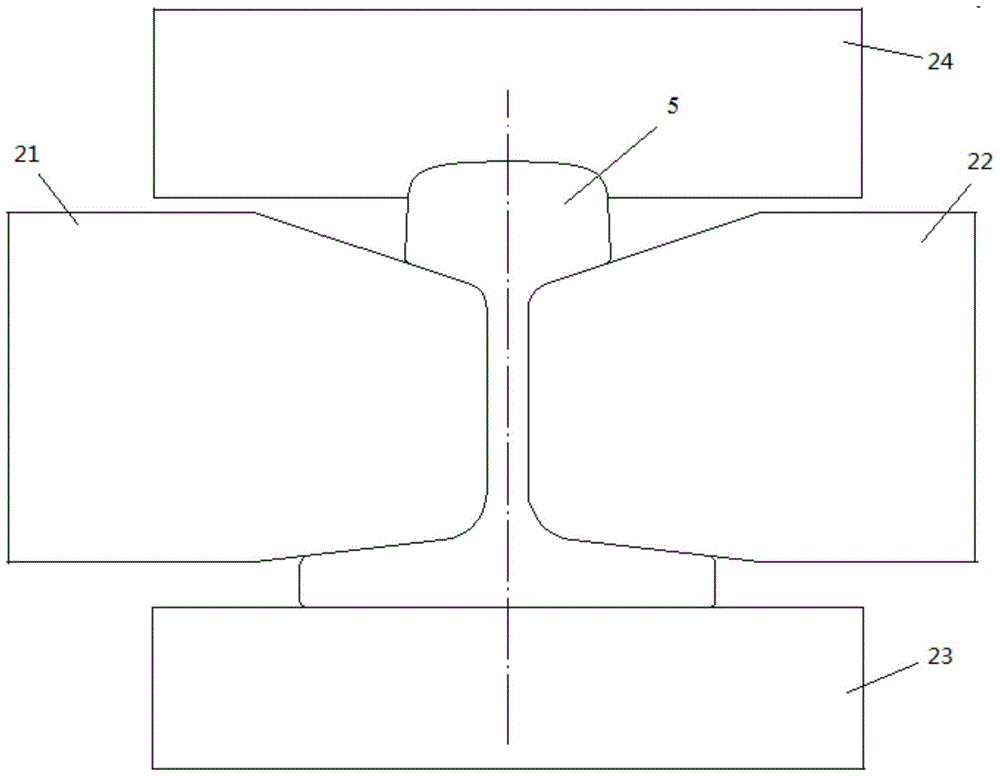

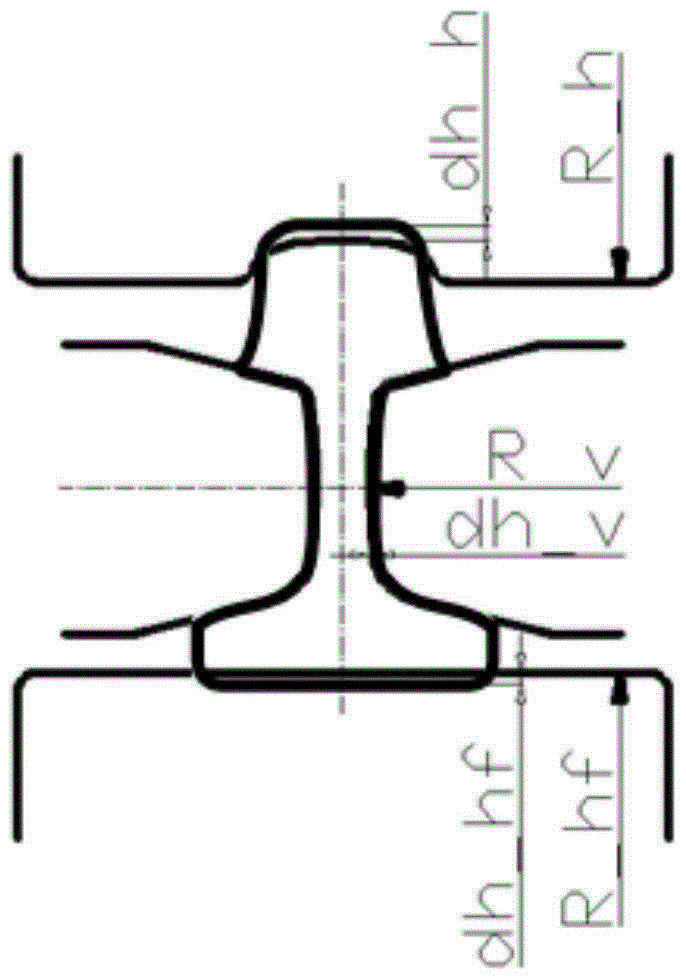

Rail vertical rolling method

ActiveCN104941998BEliminate the effects ofEliminate the effects of backlogRollsMetal rolling arrangementsEngineeringRolling mill

The invention discloses a vertical steel rail rolling method. Four-roller universal rolling mills are arranged. The method includes that both a steel-rail finished product frame and a finish rolling frame adopt a four-roller mode, are of a vertical structure and are configured with a single hole pattern, horizontal rollers are main driving rollers, and the diameter of each horizontal roller is 0.6-1.0 times of that of each vertical roller so as to guarantee that the horizontal rollers contact with a rolled piece firstly; each of the steel-rail finished product frame and the finish rolling frame is provided with an edging mill E; tilting is performed before the rolled piece enters the finish rolling frame; on the finish rolling frame, the railhead of the rolled piece is rolled vertically and upwardly, and the finish rolling frame cooperates with the edging mill to finish precision control on rail height size of the rolled piece; on the finished product frame, the rolled piece is trimmed on the edging mill E prior to being rolled in the universal vertical finish rolling machine UF to form a finished steel rail. By the method, the defects of water tank influence, gravity influence and the like in the prior art are eliminated, production difficulty is improved, product quality is improved, and production cost can be lowered effectively.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Tab molding mechanism, molding method and tab molding equipment

PendingCN109768209AImprove the heating effectIncrease productivityFinal product manufactureCell component detailsPower flowHot melt

The invention discloses a tab molding mechanism, molding method and tab molding equipment. The tab molding mechanism comprises a DC power supply, a laminating mechanism formed on a metal belt, and a conducting mechanism formed below the metal belt; the conducting mechanism comprises a first electrode and a second electrode arranged at the locations without tab sealant on the corresponding metal belt at two sides of the tab sealant; the positive electrode of the DC power supply is connected with the first electrode, and the negative electrode of the DC power supply is connected with the secondelectrode; in the thermal compounding, the laminating mechanism and the conducting mechanism are adhered at the metal belt locations at two sides of the tab sealant; a loop is formed among the positive electrode of the DC power supply, the first electrode, the metal belt, the second electrode and the negative electrode of the DC power supply; the DC power supply outputs the current, and the metalbelt between the first electrode and the second electrode are heated under the current thermal effect so that the tab sealant is hot-molten on the metal belt; the production efficiency is effectivelyimproved, the product quality is improved, and the energy loss is reduced.

Owner:深圳市鑫科高创科技有限公司

Method for controlling temperature of hot isobaric press and hot isobaric press

InactiveCN102282011BAvoid low temperature environmentImprove the heating effectMuffle furnacesRetort furnacesExit angleEngineering

A method for controlling the temperature of a hot isobaric press and a hot isobaric press comprising a pressure vessel (1) with a charging zone (19) located inside and arranged in An insulator (8) between the charging area and the pressure vessel, wherein a heating element (4) and a charging area (19) with a charging device (18) are arranged inside the insulating body (8), wherein for Forming a convection gap (28), at least the charging zone (19) is surrounded by a convection jacket (27), wherein fluid is injected via at least one nozzle (13) inside the pressure vessel (1) and / or the charging zone (19) to A swirl (23) is formed and this fluid mixes with the fluid there, and at the same time this fluid constitutes a circulation circuit (29) around said convection jacket (27) and enters said charging zone from said convection gap (28) (19). A hot isobaric press, wherein at least one conduit (12) is arranged in the pressure vessel (1) connected to at least one nozzle (13) inside the pressure vessel (1), wherein the exit angle of the nozzle (13) is suitable for A swirling flow (23) is formed in the charging zone (19) and conduits (12) are connected to regions of the pressure vessel (1) at different temperatures.

Owner:克莱默热处理设备公司

Doors and windows for regulating the temperature in a sunny house

ActiveCN107165546BAdjustable temperatureEasy to adjustVentilation arrangementUnits with parallel planesEngineeringGlass sheet

The invention discloses a door and window for adjusting the temperature in a sunshine house. The door and window comprises hollow glass plates, wherein the hollow glass plates are connected in order. A vent pipe is arranged between every two adjacent hollow glass plates, draught fans communicate with the tops of the vent pipes, and openings are formed in the two side walls of each vent pipe correspondingly; through holes communicating with the openings on the same sides are formed in the side walls, facing the vent pipes, of the hollow glass plates correspondingly, inserting plates used for blocking the through holes are inserted into the hollow glass plates correspondingly, and telescopic rods used for controlling the inserting plates to move up and down are connected with the tops of the inserting plates correspondingly; and a heating device is arranged in one of the two adjacent hollow glass plates, a condensing device is arranged in the other one of the two adjacent hollow glass plates, and vent holes are formed in inner glass plate bodies of the hollow glass plates. According to the door and window for adjusting the temperature in the sunshine house, the heating devices and the condensing devices are installed in the hollow glass plates correspondingly so that the temperature in the sunshine house can be extensively and rapidly adjusted.

Owner:四川爱斯兰特门窗科技有限公司

Door window for regulating temperature in sunshine room

InactiveCN107620426AImprove insulation effectFast heatingLighting and heating apparatusBuilding componentsGlass sheetLarge range

The invention discloses a door window for regulating the temperature in a sunshine room. The door window comprises hollow glass plates which are connected in sequence, ventilating pipes are arranged between the adjacent hollow glass plates, and fans communicate with the tops of the ventilating pipes; openings are formed in the two side walls of the ventilating pipes, and a through hole which communicates with the opening on the same side is formed in the side wall, facing towards the corresponding ventilating pipe, of each hollow glass plate; an inserting plate which blocks the corresponding through hole is inserted in each hollow glass plate; a telescopic rod which controls the corresponding inserting plate to move up and down is connected to the top of each inserting plate; a heating device is arranged inside one of the two adjacent hollow glass plates, and a condensing device is arranged inside the other hollow glass plate of the two adjacent hollow glass plates; and a ventilating hole is formed in an inner glass plate of each hollow glass plate. According to the door window for regulating the temperature in the sunshine room, the temperature in the sunshine room can be rapidlyadjusted in a large range by additionally mounting the heating devices and the condensing devices inside the hollow glass plates.

Owner:曾国春

Shape memory alloy actuator

ActiveUS20130174542A1Improve controllabilityReduce power consumptionMechanical power devicesClosed-cycle gas positive displacement engine plantAlloyShape memory alloy actuators

A shape memory alloy actuator includes a wire portion which is inserted through a first tube member, a shape memory alloy wire portion which is inserted through a second tube member, a movable body which is movable in a direction in which, a length of the shape memory alloy wire portion changes, an elastic member which exerts an external force in a direction in which, the shape memory alloy wire portion elongates, and a fixing member to which, one end of the second tube member and one end of the shape memory alloy wire portion are fixed, and one end of the wire portion is connected to the movable body, and one end of the shape memory alloy wire portion and one end of the wire portion are joined to a joining portion, and the joining portion includes a plurality of crimp terminals.

Owner:OLYMPUS CORP

A multi-layer carbon nanotube film stack loudspeaker based on thermoacoustic effect

ActiveCN109195087BLow costNo resonanceElectrothermic-effect transistorCarbon nanotubeMetal electrodes

The present invention provides a multilayer carbon nano tube thin film stacked loudspeaker based on a thermoacoustic effect, belonging to the field of mechanical design. The loudspeaker comprises an outer frame and multiple layers of carbon nano tube thin films which are parallel to one another and connected in parallel, and the number of the layers is at least 2 and at most 4. The carbon nano tube thin films are formed by carbon nano tubes, the two ends of the carbon nano tube thin films are connected with metal electrodes which are fixed on the outer frame, the metal electrodes at the same side are connected with the same wire, and the metal electrodes connected with each layer of carbon nano tube thin film are not in contact. Sound production elements generate corresponding temperaturechange according to accessed audio signals to allow mediums around to rapidly expand and extract to emit sound waves. The loudspeaker provided by the invention has no a vibration part to avoid a resonance effect; the multilayer carbon nano tube thin film stacked loudspeaker is simple in structure and few in consumable items required by making, can be made to be any shape as required, and the soundfield medium is uniformly heat without a segmentation vibration phenomenon; and the loudspeaker provided by the invention can generate high-volume sound in an audible sound range, and can be appliedto audible sound devices such as a sound and a radio.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com