Ultra-thin plate type heater and manufacturing method thereof

A heater and ultra-thin plate technology, used in ohmic resistance heating, electric heating devices, manufacturing stator/rotor bodies, etc., can solve problems such as inapplicability, and achieve the effects of fast heating, not easy to bend, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

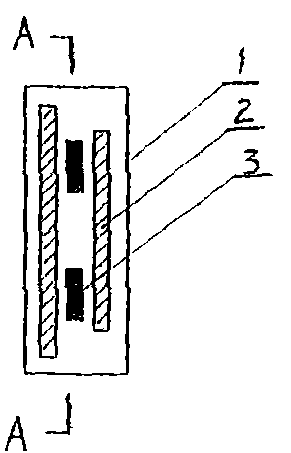

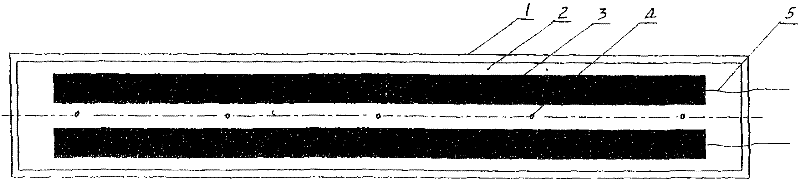

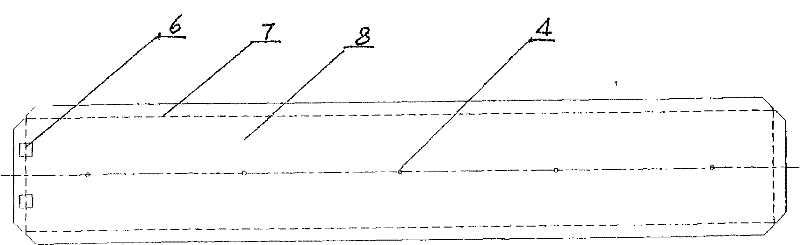

[0024] The invention relates to an ultra-thin plate heater and a manufacturing method thereof. The heater includes lead wires 5, and is characterized in that the heater is provided with a rectangular thin-plate casing 1 whose length and width match the air flow groove of the hydroelectric generator rotor, and two thin silicon wafers are arranged vertically on both sides of the casing. 2. Between the two silicon wafers, on both sides of the longitudinal center line, two thin heating elements 3 are arranged symmetrically in parallel, and the total thickness of the ultra-thin plate heater is 4.2-4.8mm, and the thickness of the upper and lower plates of the shell is 0.5- 1.0 mm, the thickness of the heating element is 0.7-1.0 mm, and the thickness of the silicon wafer is 0.4-0.7 mm. In addition, in order to increase the strength, riveting holes 4 are evenly distributed on the longitudinal centerline of the rectangular thin-plate housing 1 .

[0025] The manufacturing method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com