Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150 results about "Shape memory alloy actuators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Proportional valve with shape memory alloy actuator

InactiveUS6840257B2Limited sizeReduce weightTemperature control without auxillary powerOperating means/releasing devices for valvesClosed loopAlloy

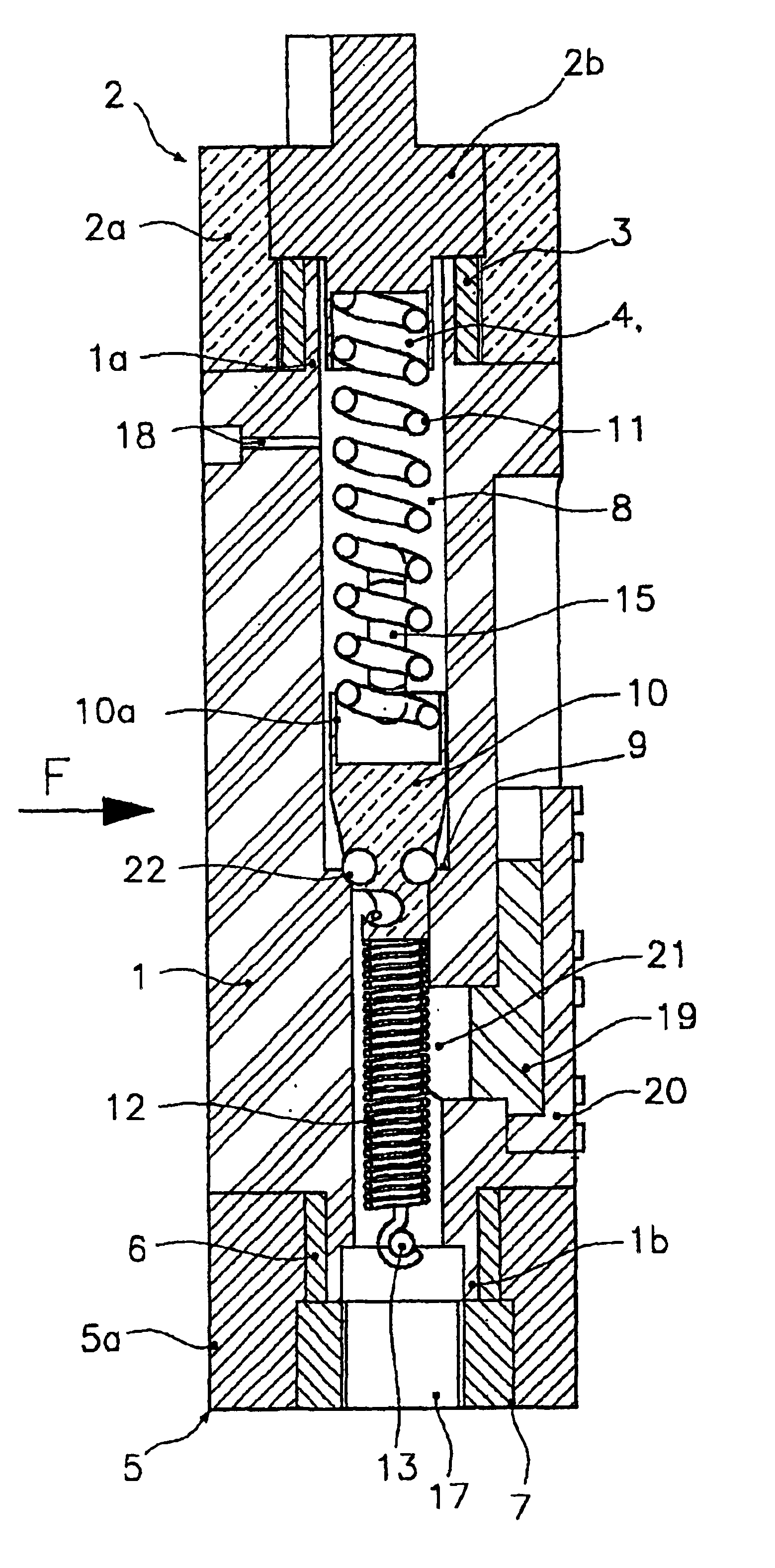

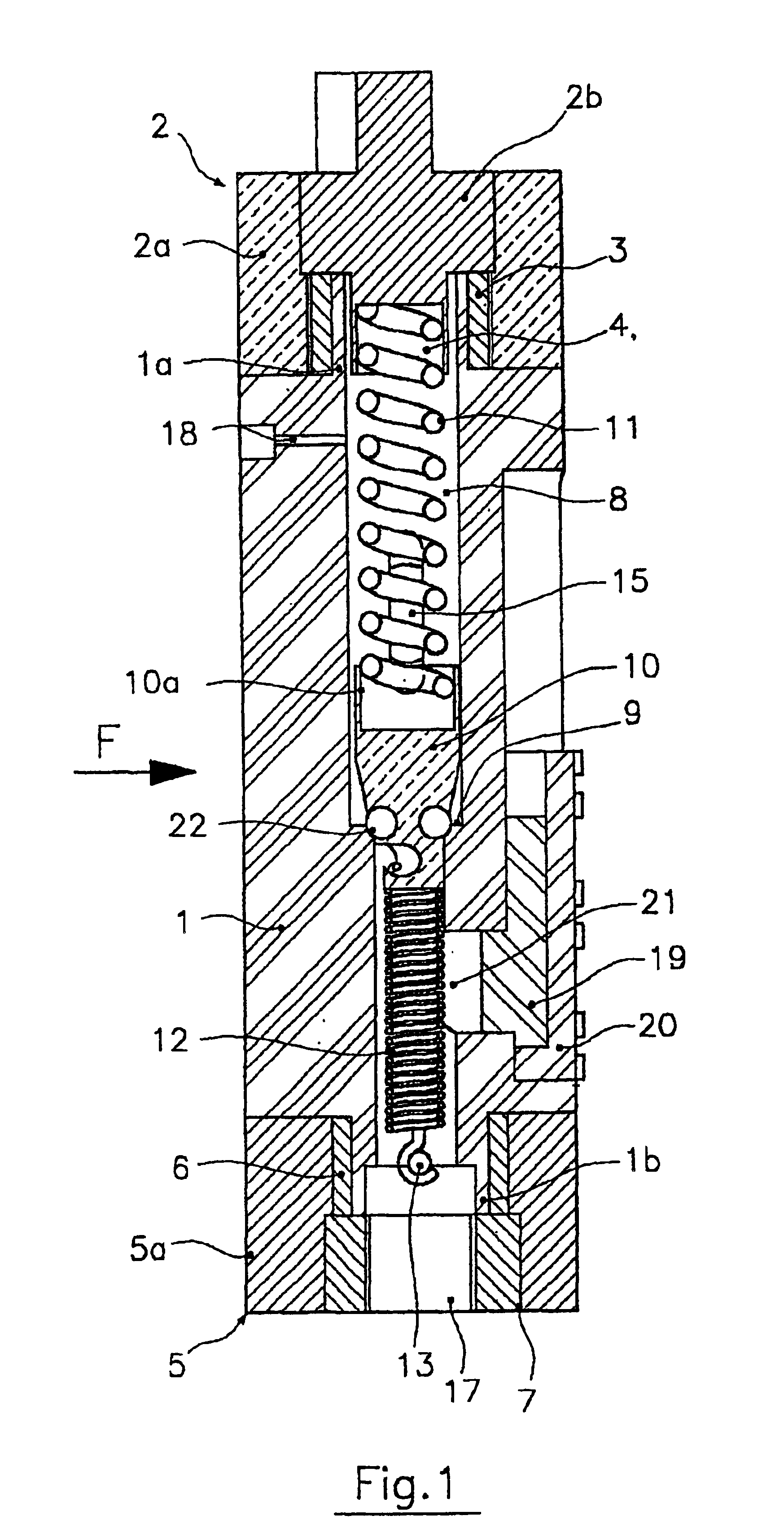

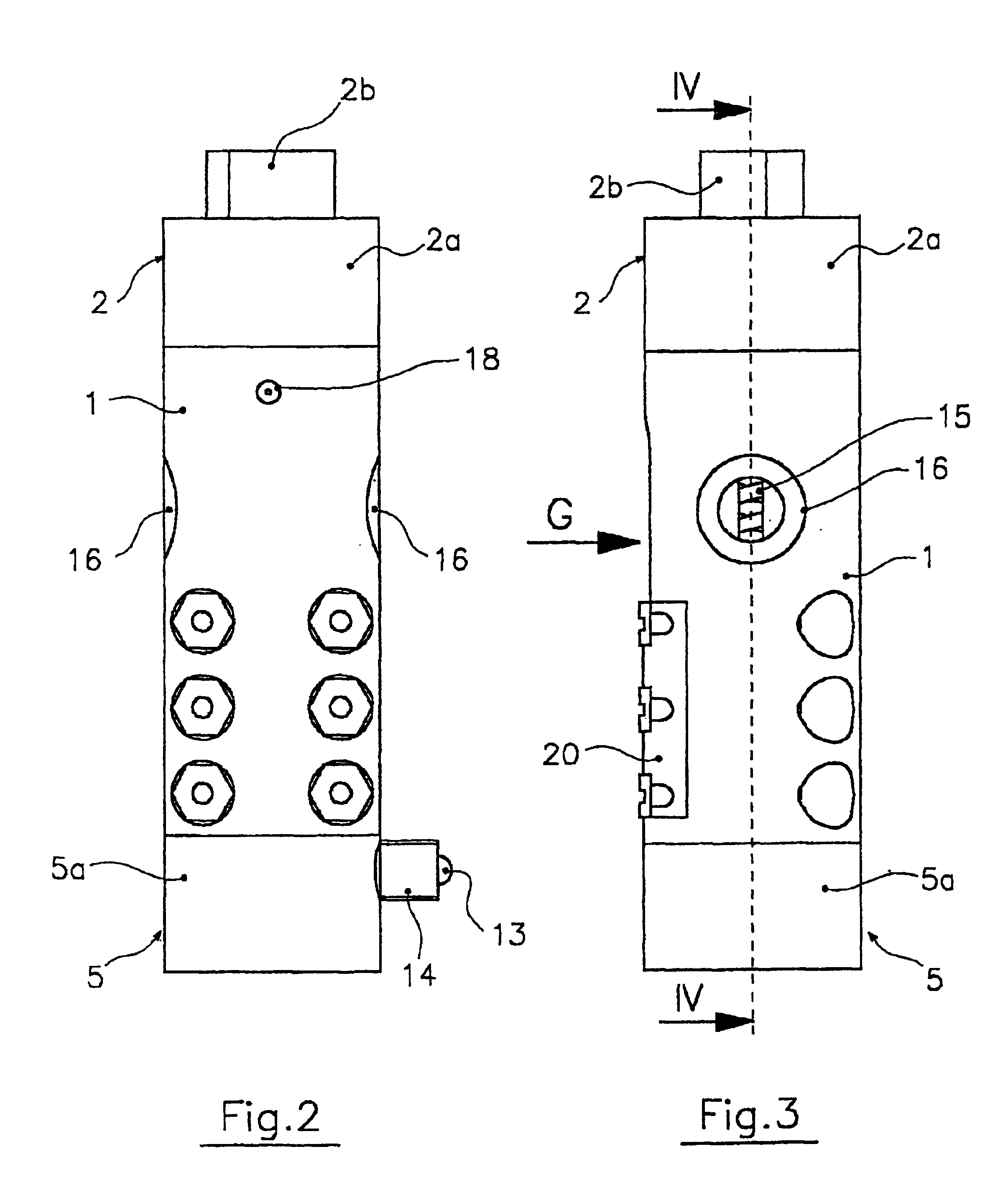

A proportional valve is disclosed for controlling the outlet pressure of a fluid flowing therethrough. The valve comprises a valve body having an inlet port and an outlet port for the fluid. The valve also has an inner chamber, within which there is formed a valve seat that may be opened and closed variably by a shutter axially movable from and towards the valve seat. Movement of the shutter is controlled by a shape memory alloy (SMA) actuating member operating antagonistically to an elastic member, the temperature of the fluid being lower than the transition temperature of the shape memory alloy. The actuating member and the elastic member are connected to the body valve at opposite sides relative to the valve seat. A power control circuit is also provided for circulating an electric current through the actuating member so as to heat the same by Joule effect from a temperature lower than the transition temperature to one that is higher. At least one vent hole is formed in the valve body for putting a portion of the chamber upstream of the valve seat into fluid communication with the outside or a collection network. The actuating member is housed in that portion of chamber corresponding to the inlet port of the fluid, whereby a continuous flow of fluid around the actuating member is ensured for accelerating the cooling process. A closed-loop control circuit for the power control circuit controls the circulating current as a function of a pressure signal generated by fluid pressure sensing means and in such a way as to offset the retarding effect produced by the fluid during heating of the actuating member.

Owner:ARENA ALBERTO +2

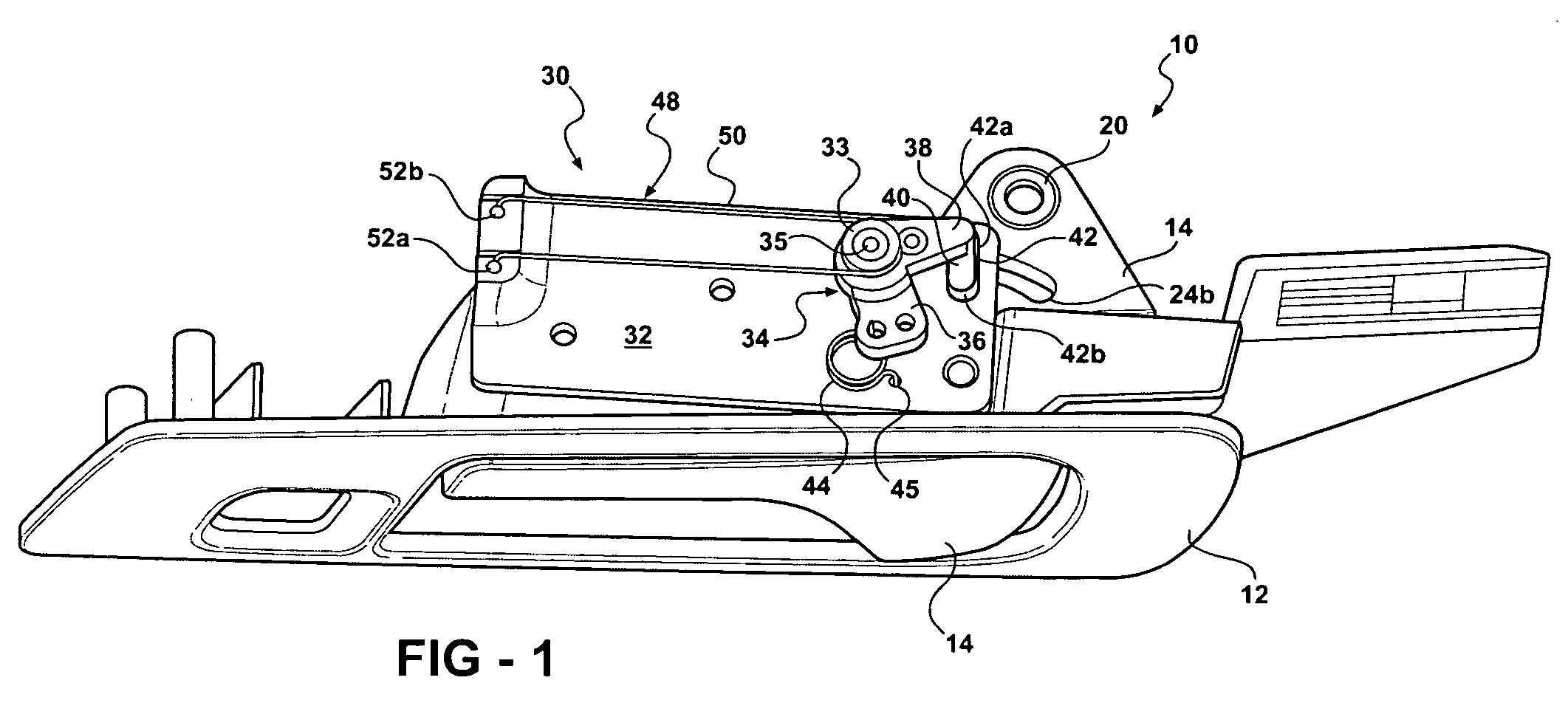

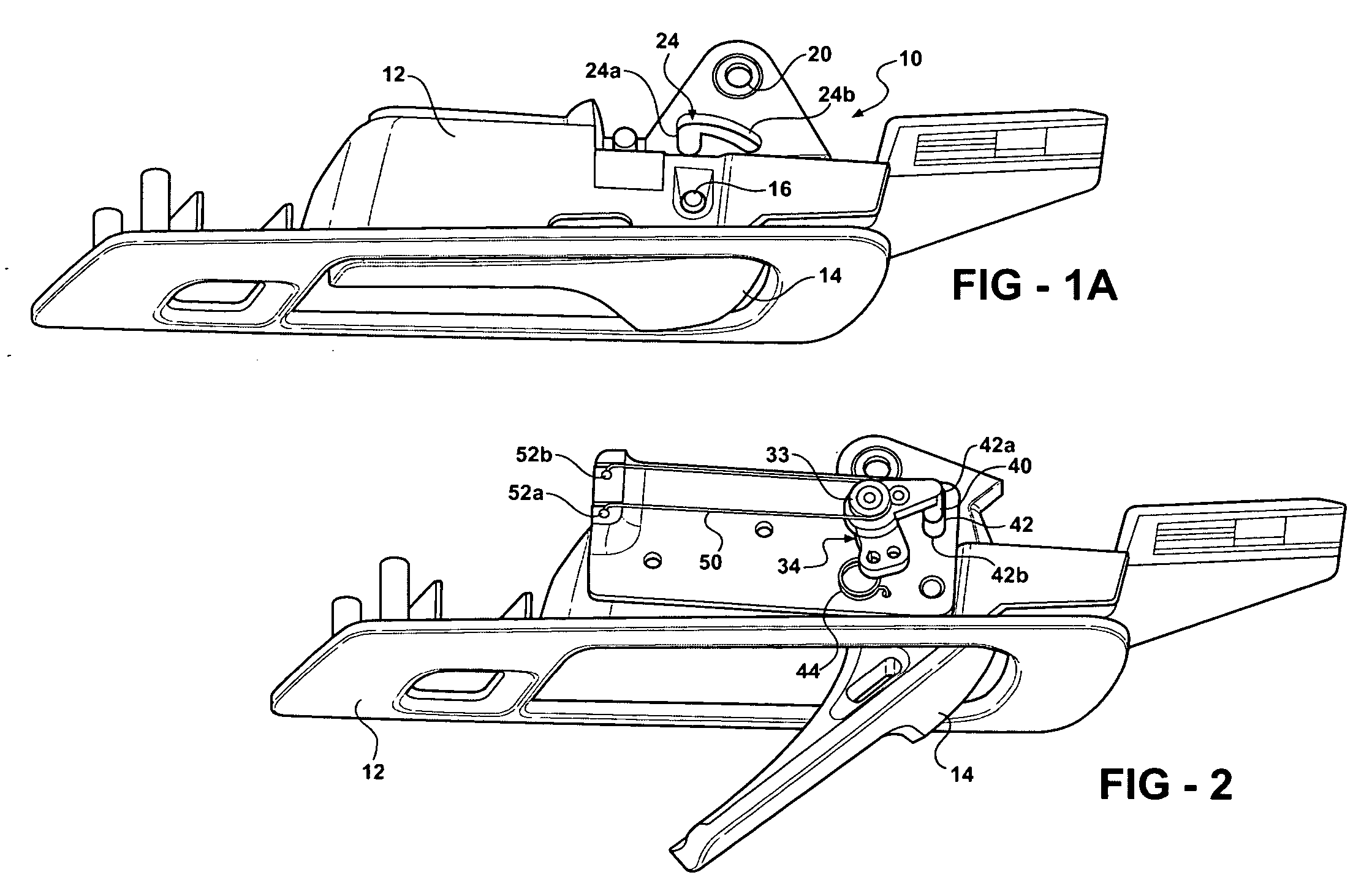

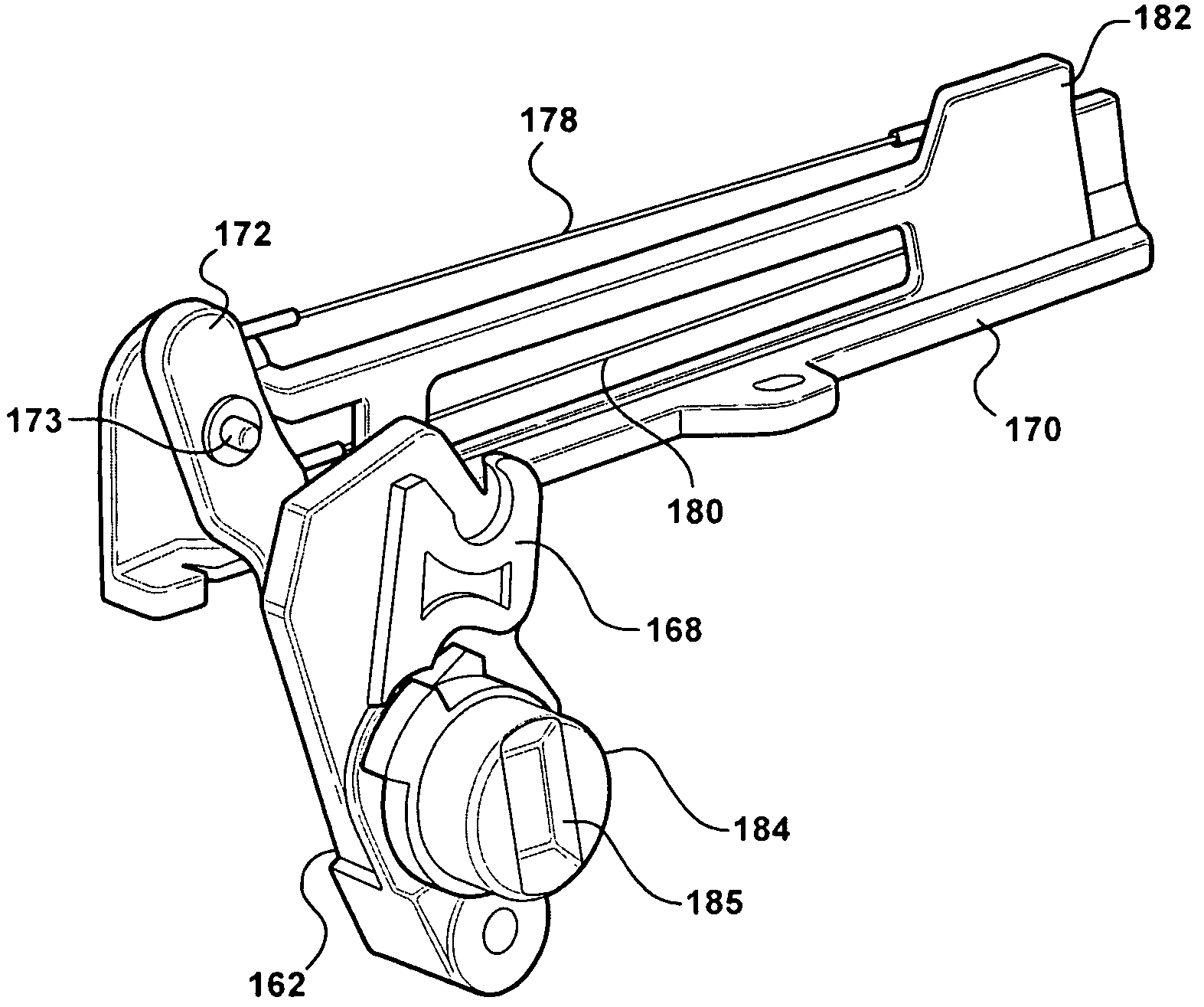

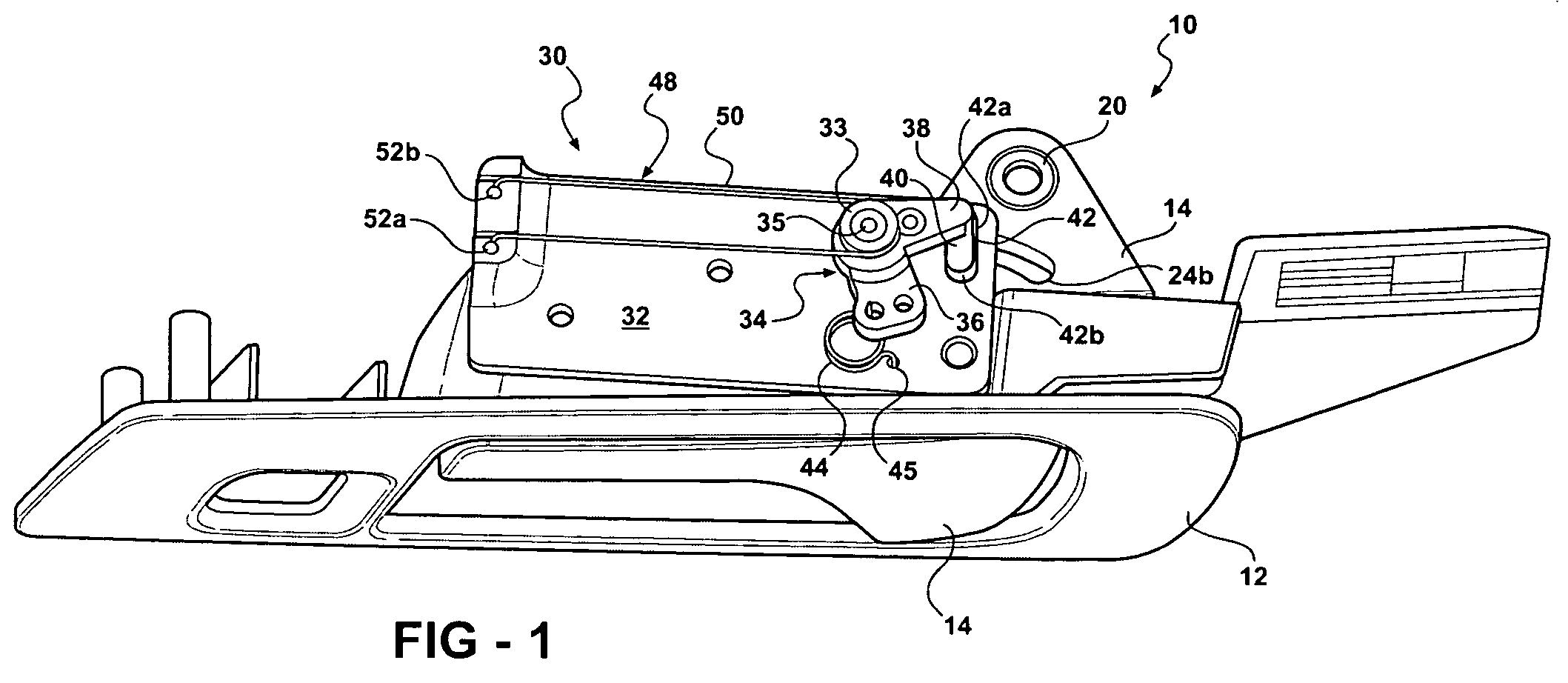

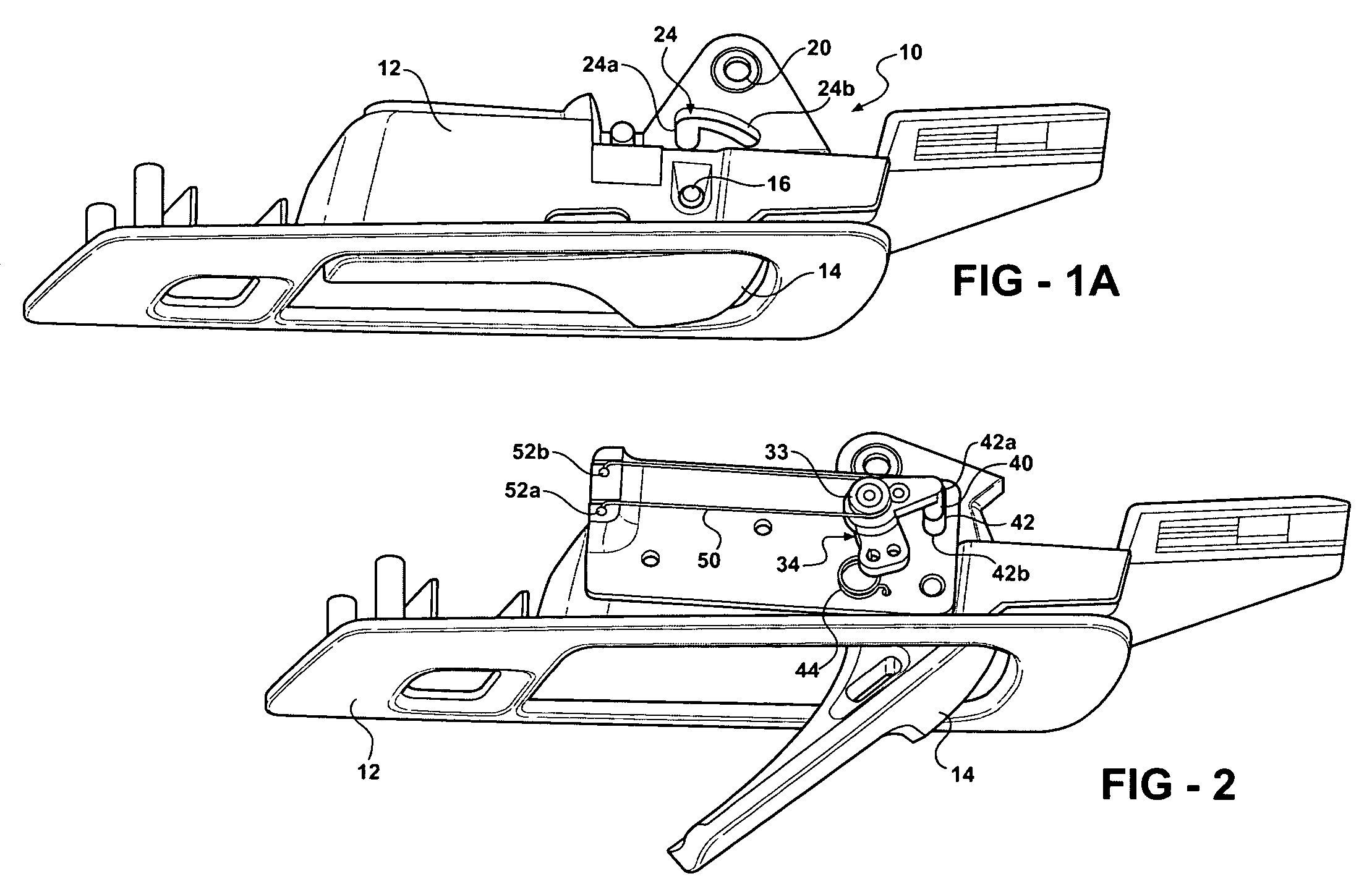

Vehicle lock controlled by a shape memory alloy actuator

InactiveUS20050146147A1Reduced packaging requirementsLow costNon-mechanical controlsConstruction fastening devicesControl theorySma actuator

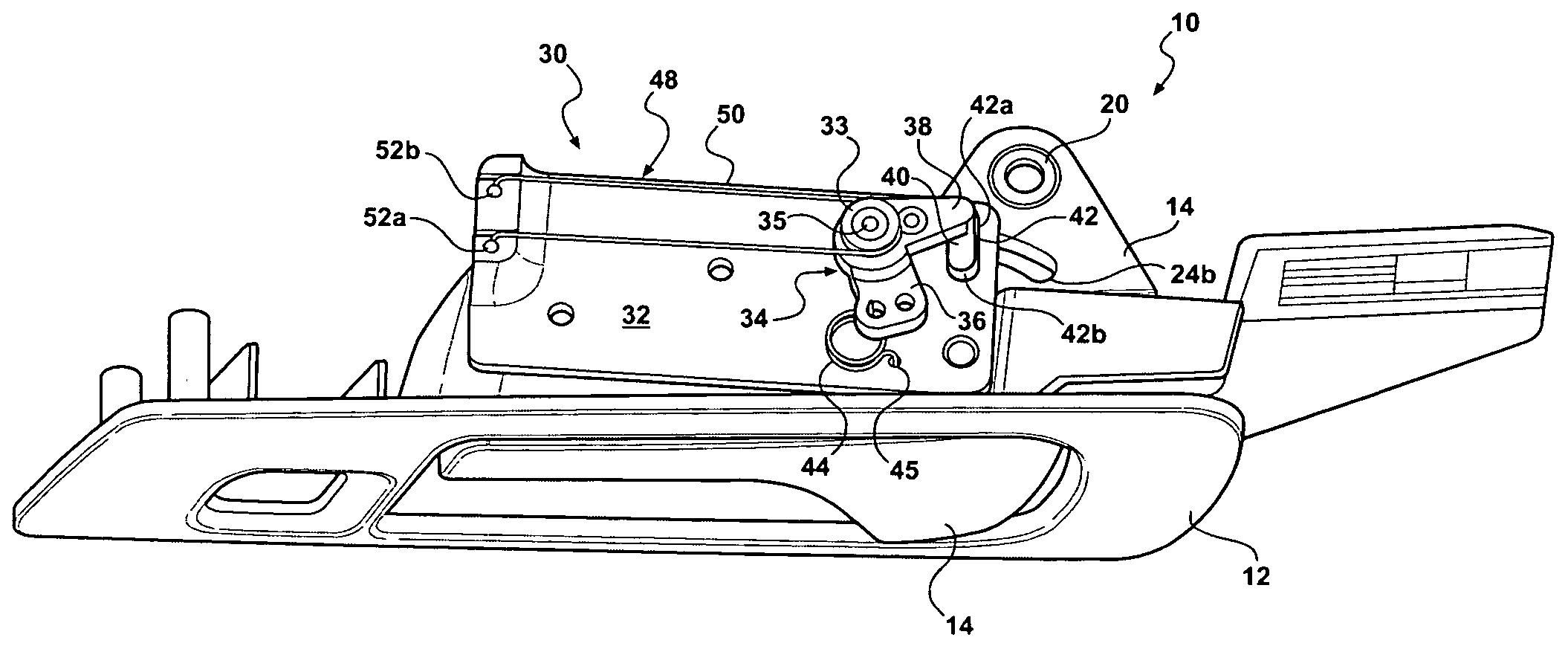

A contractible shape memory alloy (SMA) wire is used to throw a lever in a latch. The SMA actuator provides weight and space savings. In one embodiment, the SMA actuator is incorporated in the handle of the latch in order to provide a child lock or double lock function. The handle has a lever which includes a relatively short slot leg and a relatively long slot leg. A toggle sits in the slot. At least one SMA wire is connected to the toggle to move it between the relatively short slot leg, wherein the lever is prevented from pivoting, and the relatively long slot leg, where the lever is enabled to pivot. In another embodiment, the SMA actuator is embedded in the latch itself, and used to throw a lever that controls the child lock function.

Owner:INTIER AUTOMATIVE CLOSURES INC

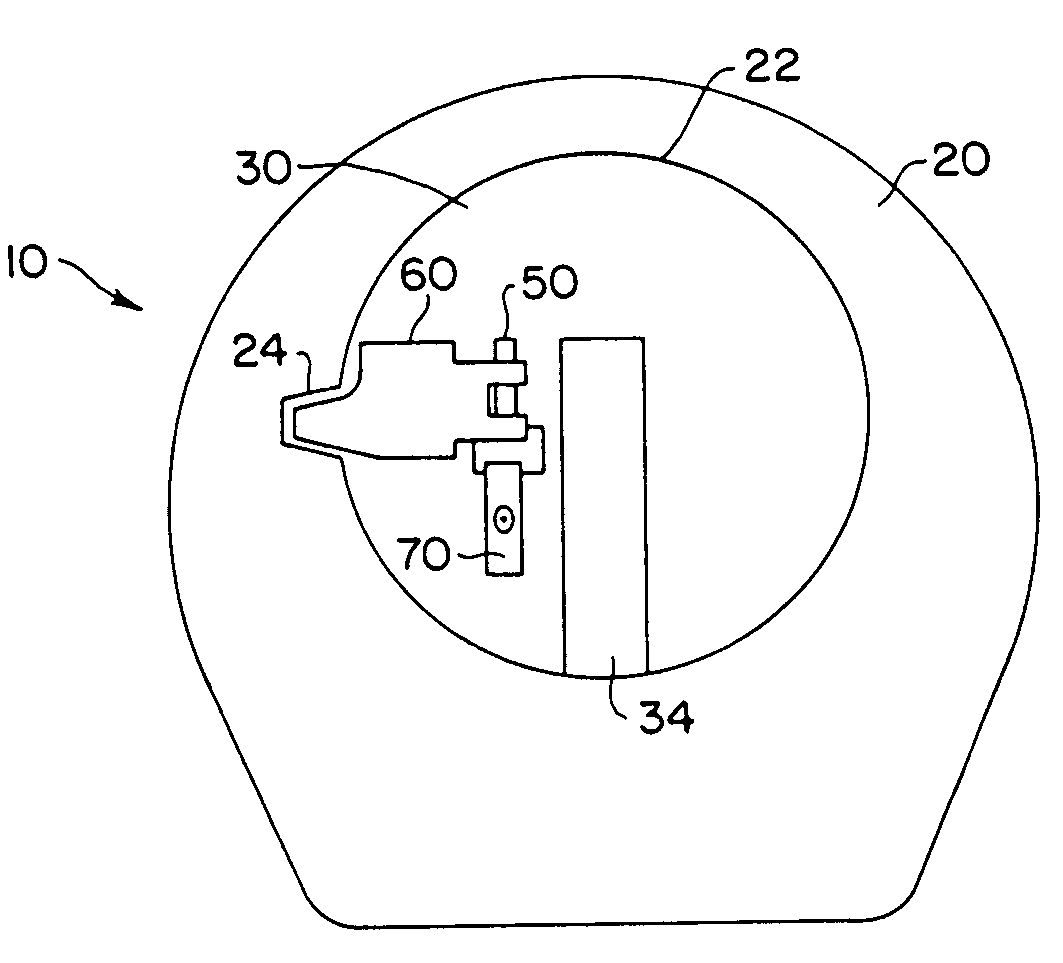

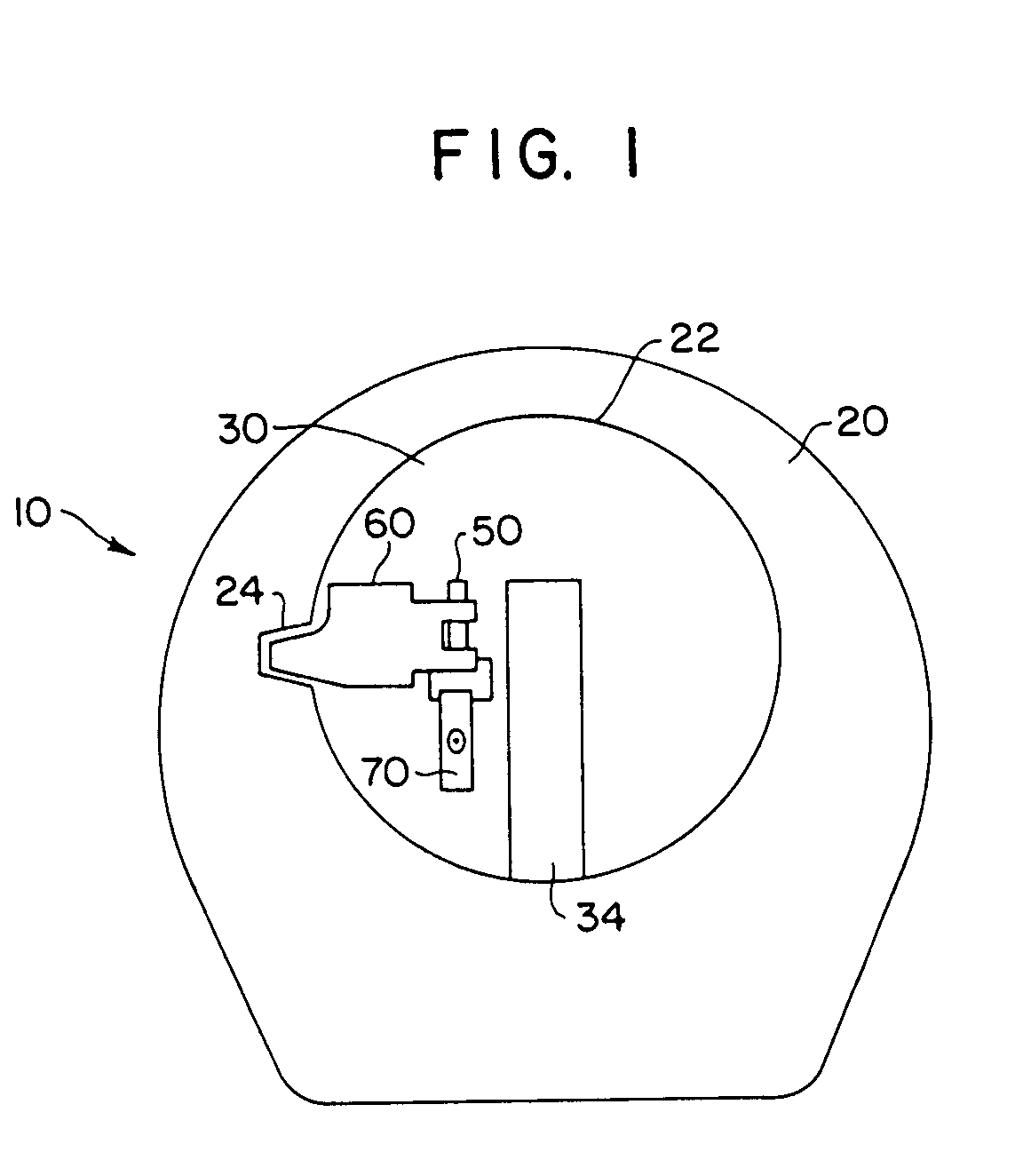

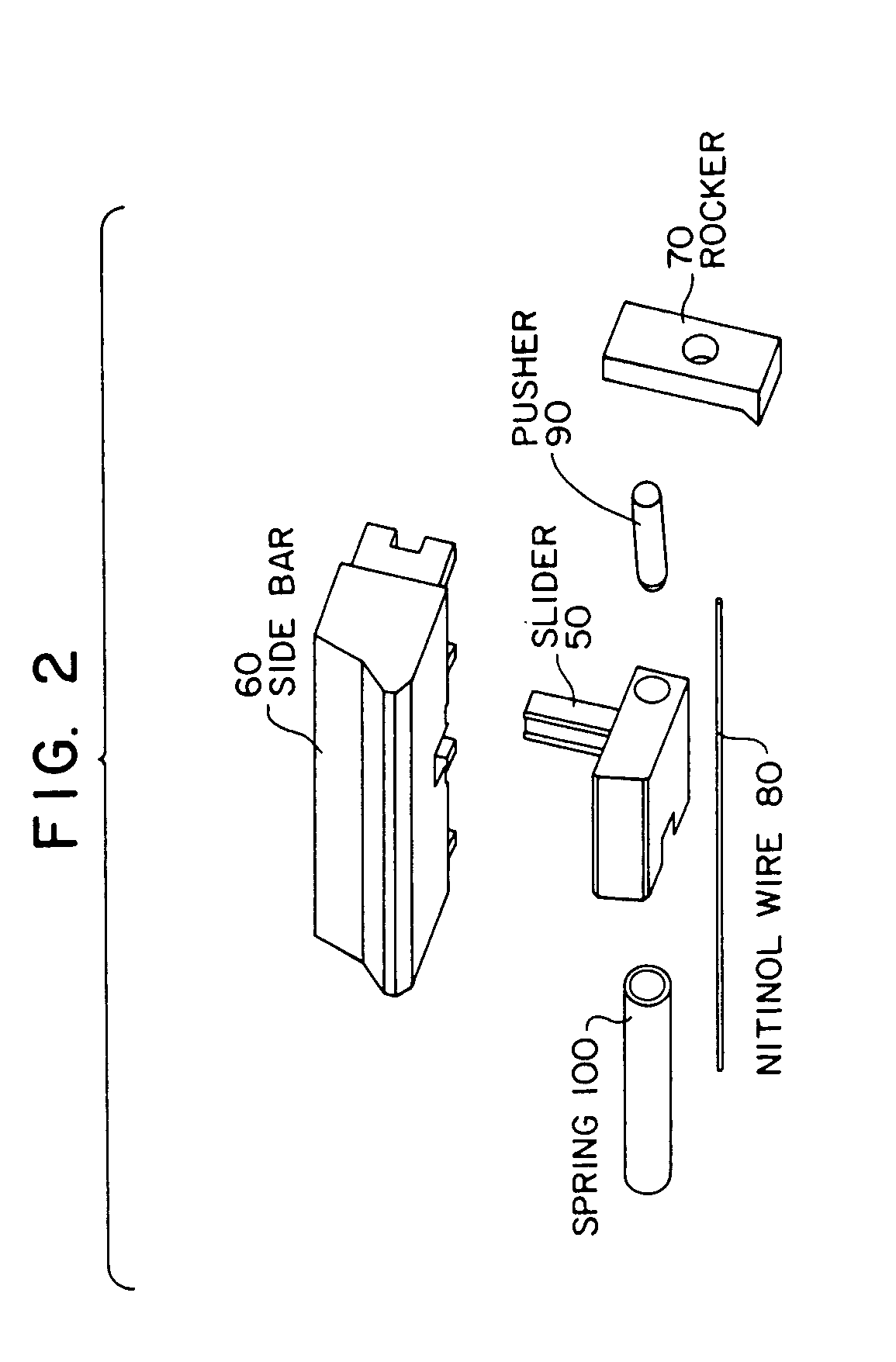

Electromechanical cylinder lock

InactiveUS7690231B1Good flexibilityAttempt have been hamperedShaftsNon-mechanical controlsEngineeringMechanical engineering

An electromechanical cylinder lock includes an outer lock shell and a rotatable lock barrel located therein which is controlled by dual locking features. A side bar or fence selectively blocks and permits rotation of the barrel with respect to the shell in response to insertion of a key into a keyway in the barrel. A slider bar is movable between a blocking position in which the side bar is prevented from permitting rotation of the barrel, and an unblocking position in which the side bar permits rotation of the barrel. Alternately, a blocking mechanism is provided to block motion of tumbler pins in the cylinder lock. A shape memory alloy actuator, such as a wire made of NITINOL disposed in the barrel is activated by an electric current in response to determination by an electronic control device whether an attempt to open the lock is authorized. Thermal interlock protection from external heating of the lock is also provided.

Owner:ASSA ABLOY HIGH SECURITY GRP INC

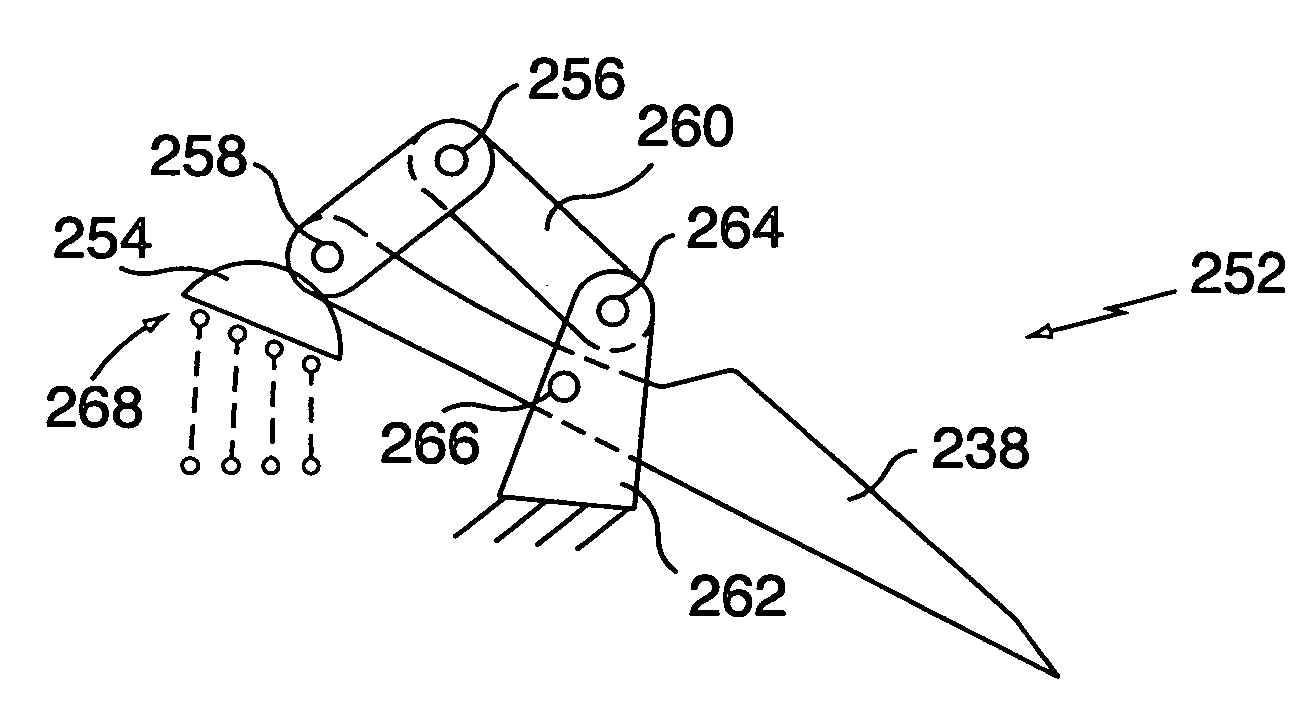

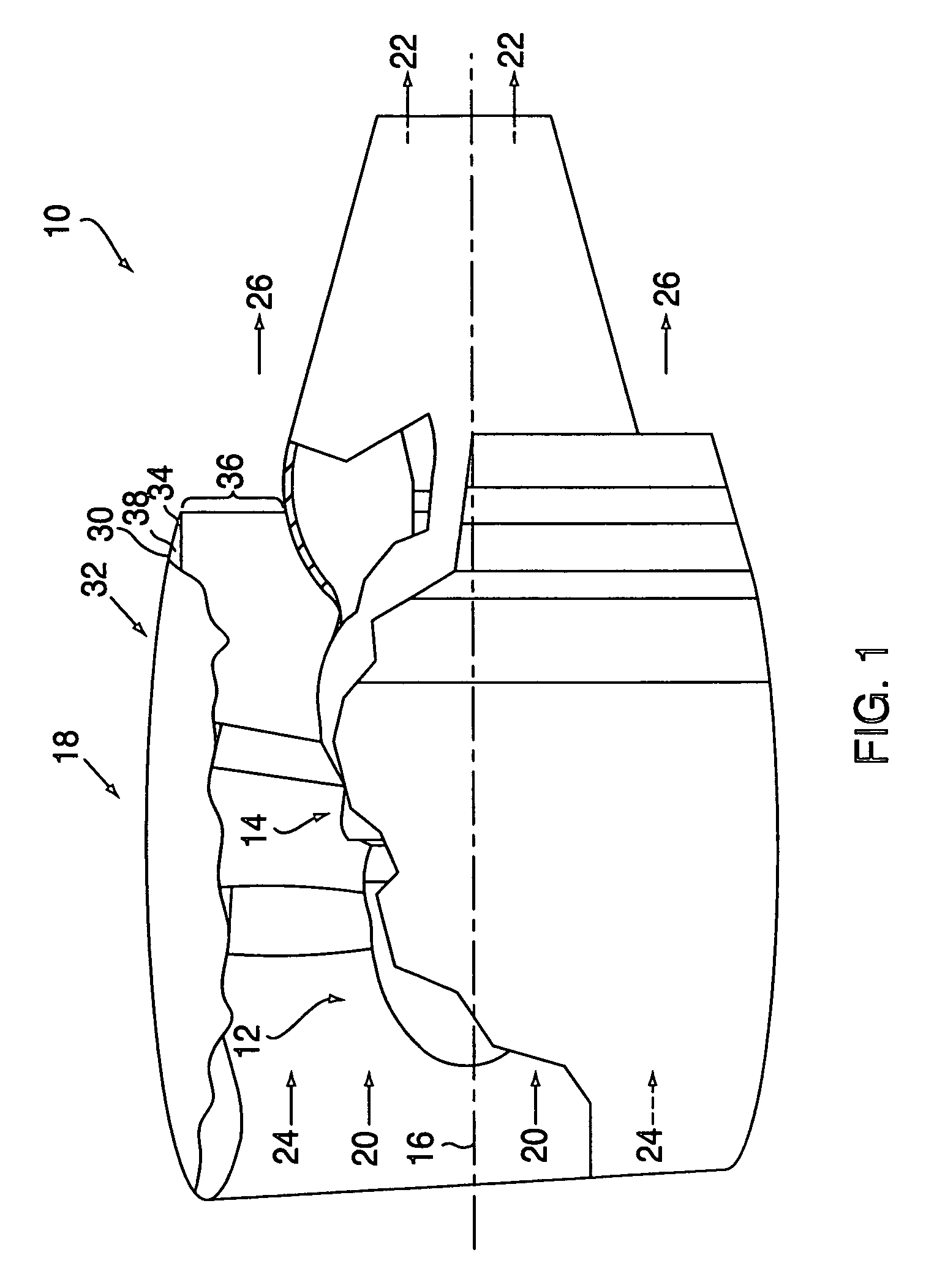

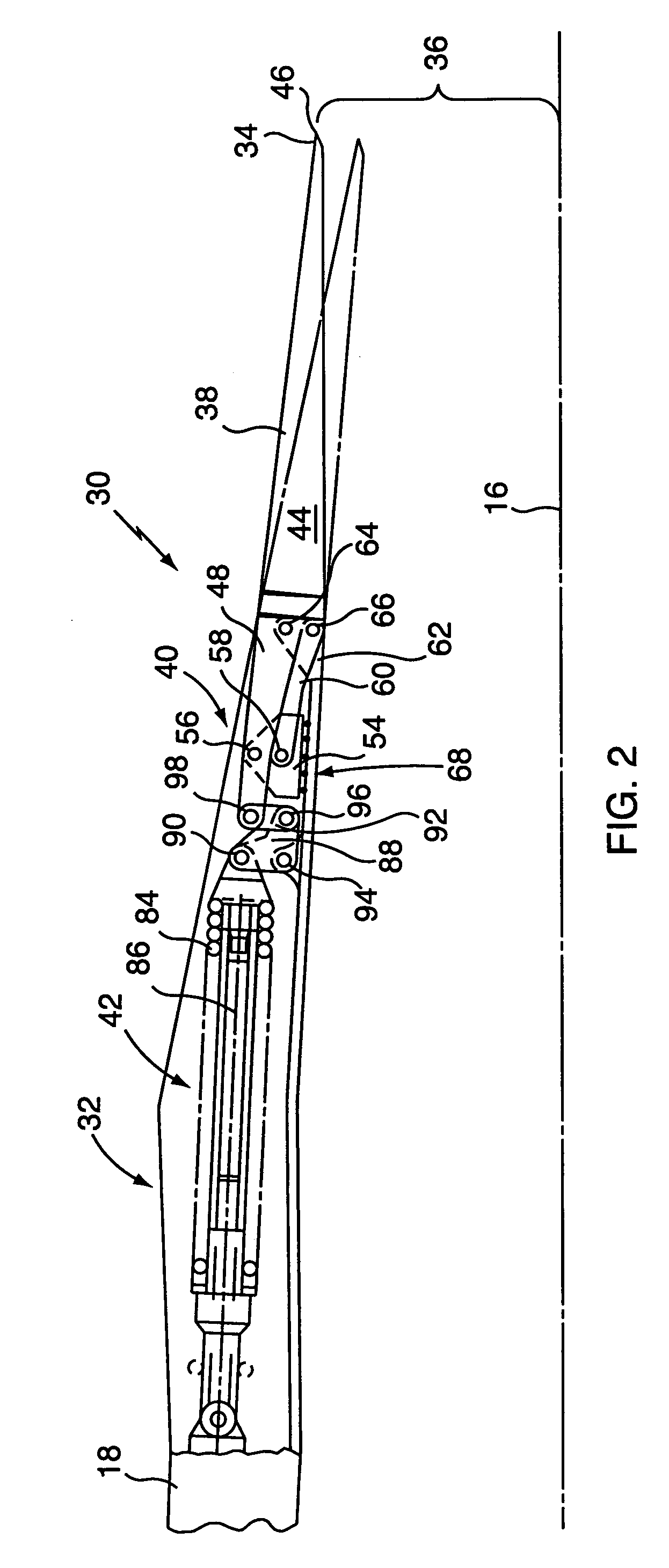

Variable area nozzle for gas turbine engines driven by shape memory alloy actuators

InactiveUS7004047B2Complex mechanismImprove efficiencyControlling membersPump componentsMartensiteControl theory

A gas turbine engine includes a variable area nozzle having a plurality of flaps. The flaps are actuated by a plurality of actuating mechanisms driven by shape memory alloy (SMA) actuators to vary fan exist nozzle area. The SMA actuator has a deformed shape in its martensitic state and a parent shape in its austenitic state. The SMA actuator is heated to transform from martensitic state to austenitic state generating a force output to actuate the flaps. The variable area nozzle also includes a plurality of return mechanisms deforming the SMA actuator when the SMA actuator is in its martensitic state.

Owner:RAYTHEON TECH CORP

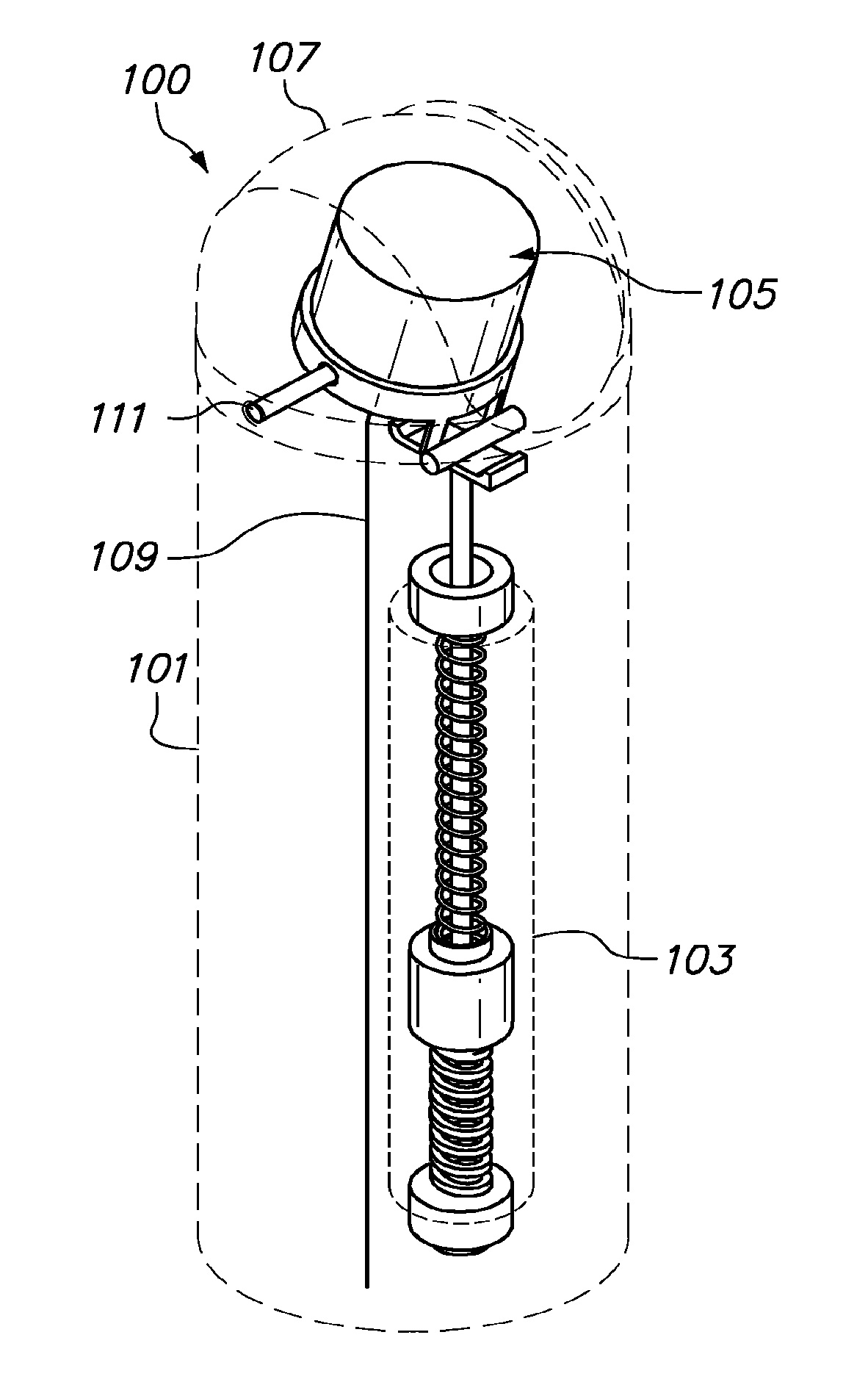

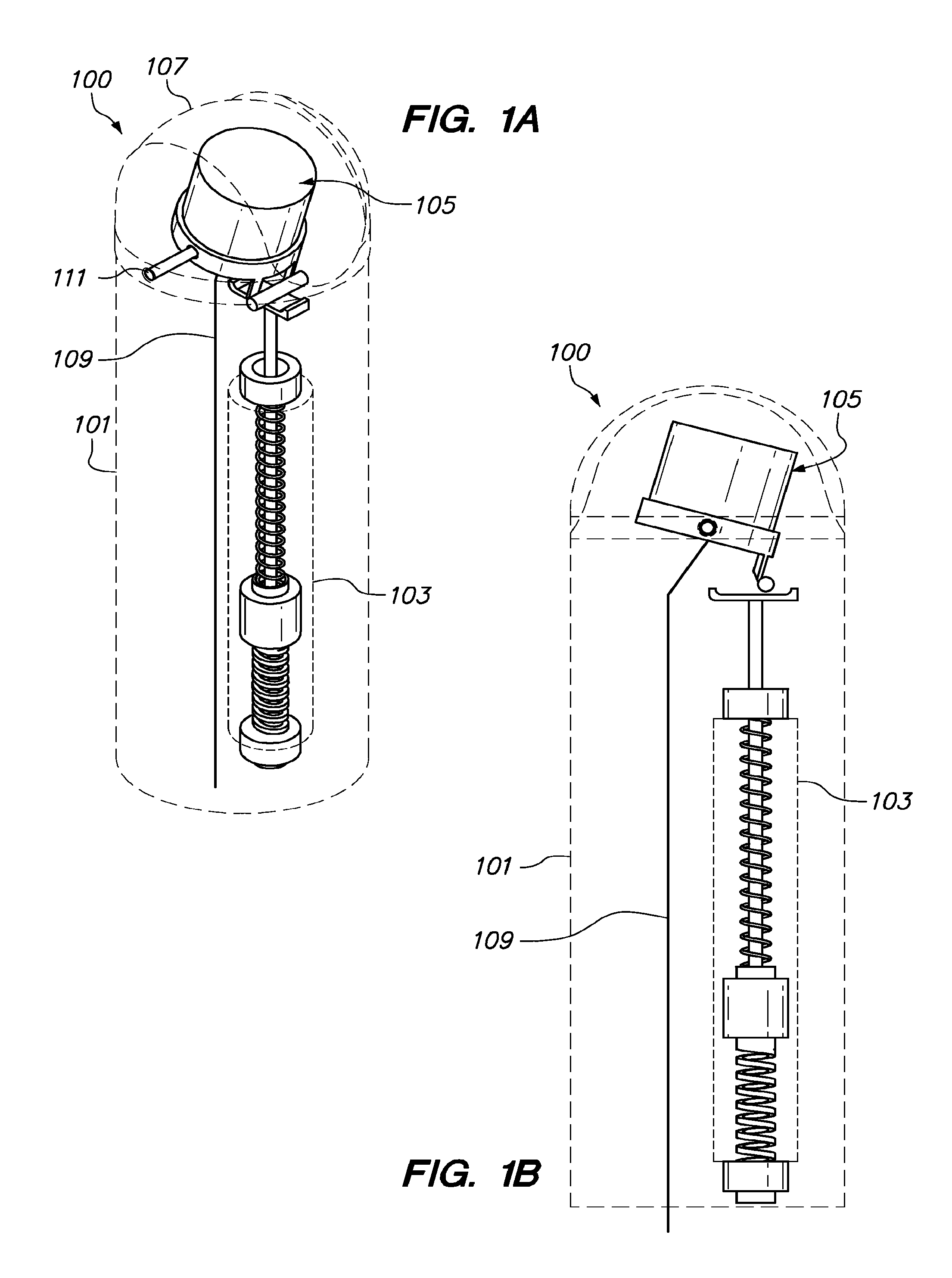

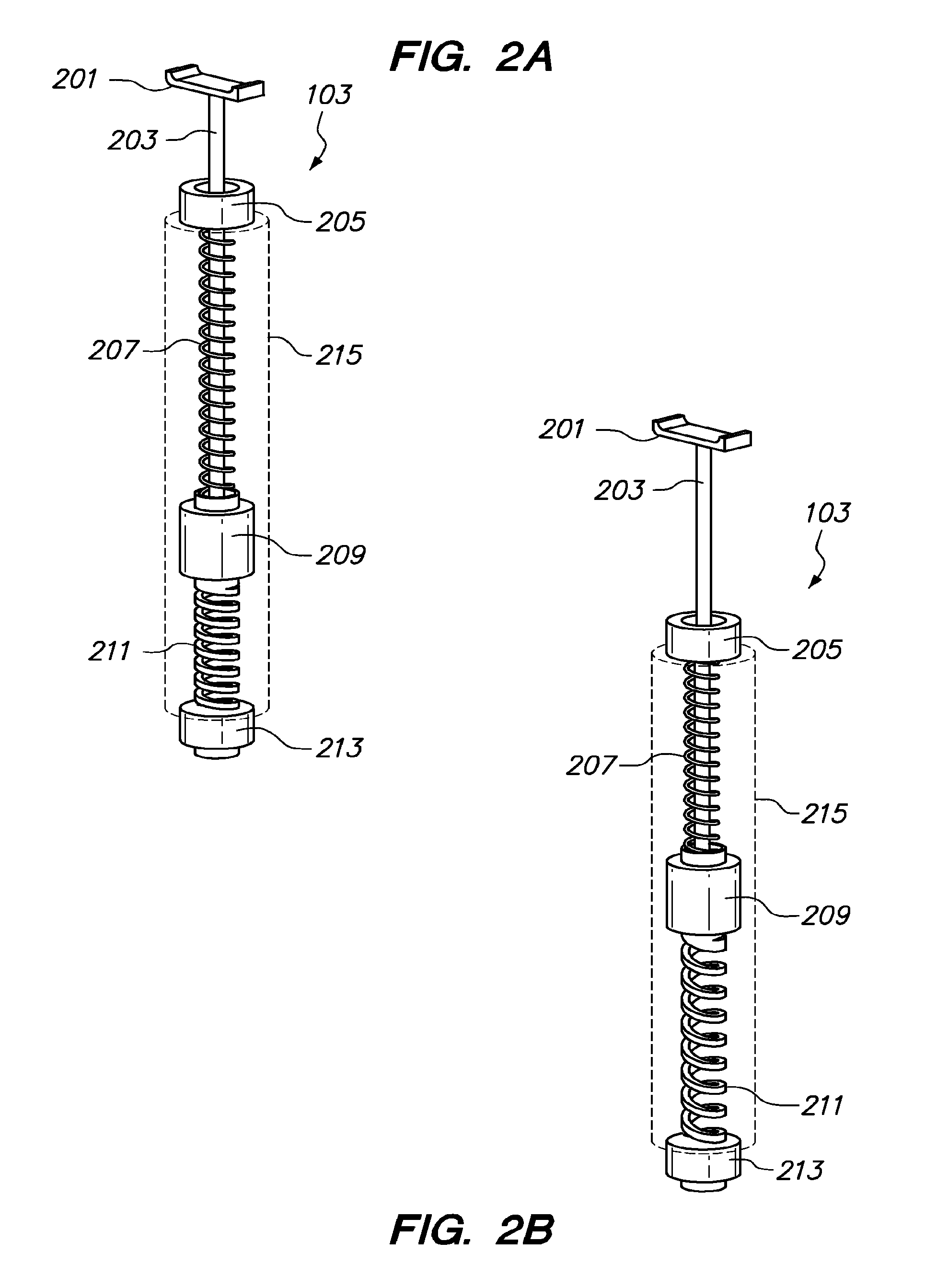

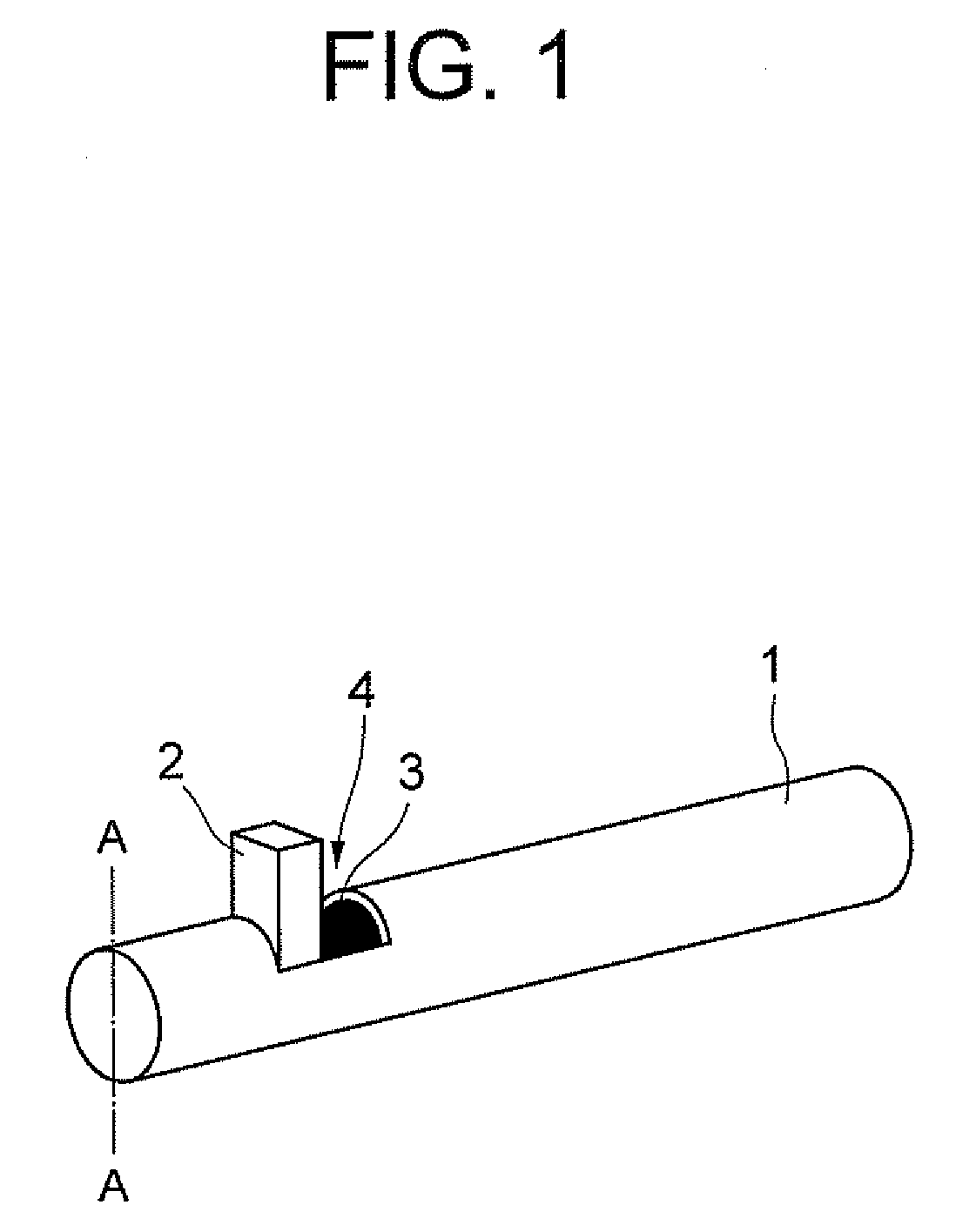

Miniature forward-looking ultrasound imaging mechanism enabled by local shape memory alloy actuator

ActiveUS20110263986A1Ultrasonic/sonic/infrasonic diagnosticsCatheterUltrasound deviceUltrasound imaging

The present invention relates to a new forward-looking ultrasound device including a local actuator embedded inside an elongate member such as a guide wire or catheter. The present invention includes an ultrasound transducer element configured to engage with the local actuator and rotate about an axis of rotation at least when the ultrasound transducer element and the local actuator are engaged. Also disclosed are methods of using the same.

Owner:VOLCANO CORP

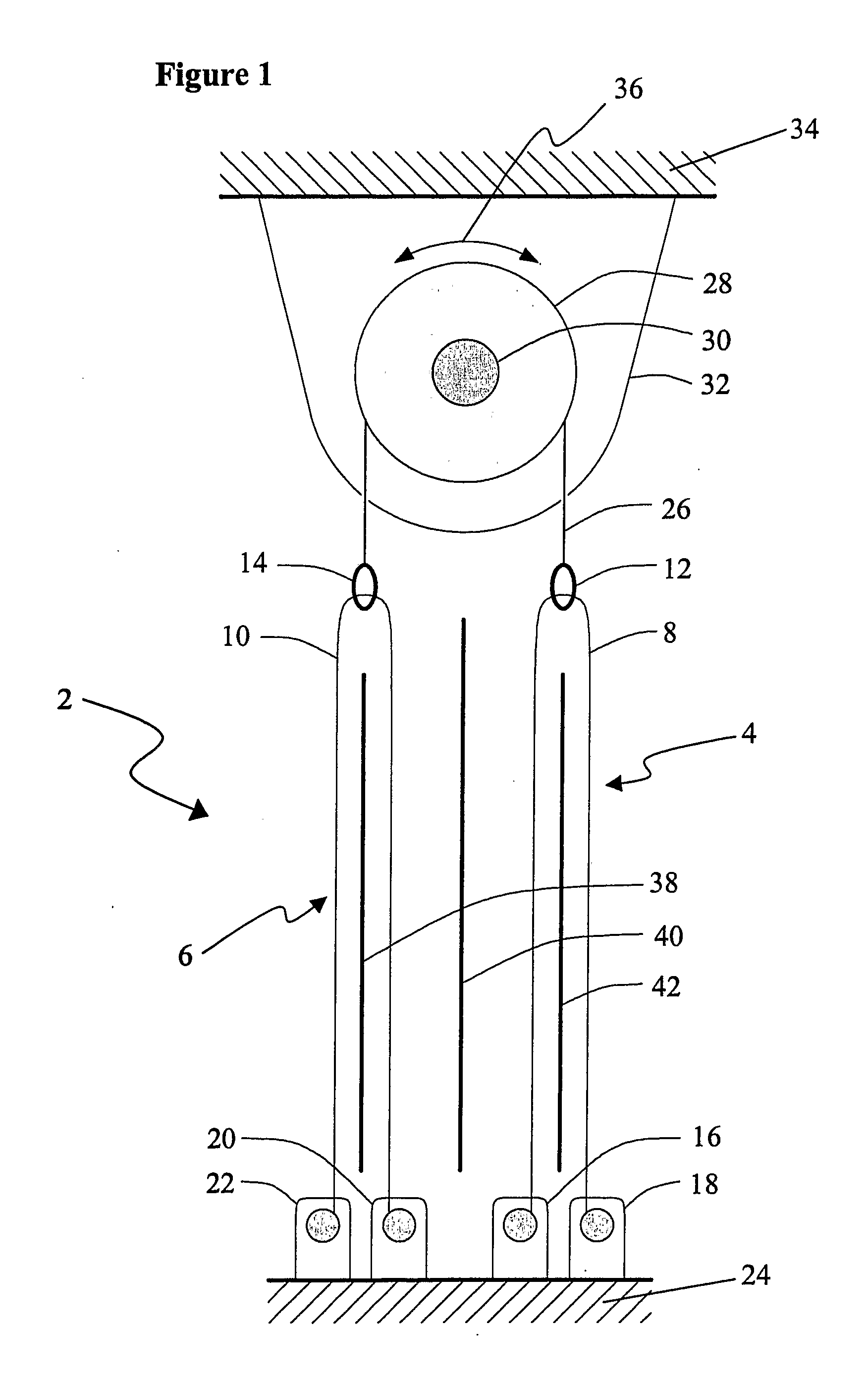

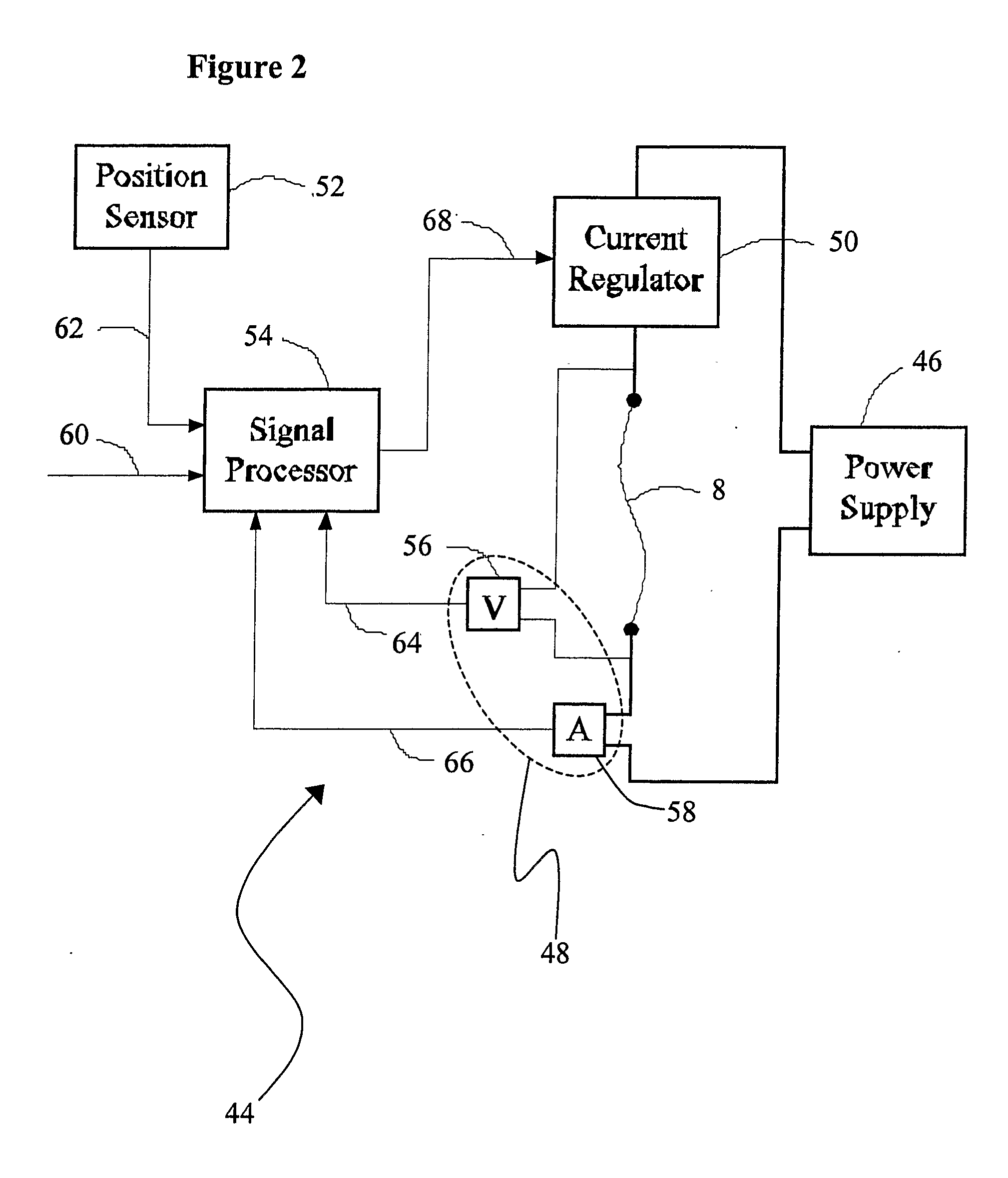

Shape memory alloy actuator

InactiveUS20070175213A1Increase movement speedIncrease ratingsMechanical power devicesClosed-cycle gas positive displacement engine plantElectrical resistance and conductanceControl theory

A controller (44) for a SMA actuator (2) includes an electgric power source (46) for applying an electric current through an SMA element (8), a sensor (48) to detect change in an electric resistance of the element (8); and a regulator (50) for controlling the magnitude of the applied electric current. The regulator (50) applies a first current above a safe limit current for the element (8) until a selected change in the electric resistance is detected and applies a second current less than the first current after the change is detected.

Owner:AUSTRALIEN NAT UNIV

Vehicle lock controlled by a shape memory alloy actuator

InactiveUS7364211B2Lower requirementLow costNon-mechanical controlsConstruction fastening devicesControl theorySma actuator

A contractible shape memory alloy (SMA) wire is used to throw a lever in a latch. The SMA actuator provides weight and space savings. In one embodiment, the SMA actuator is incorporated in the handle of the latch in order to provide a child lock or double lock function. The handle has a lever which includes a relatively short slot leg and a relatively long slot leg. A toggle sits in the slot. At least one SMA wire is connected to the toggle to move it between the relatively short slot leg, wherein the lever is prevented from pivoting, and the relatively long slot leg, where the lever is enabled to pivot. In another embodiment, the SMA actuator is embedded in the latch itself, and used to throw a lever that controls the child lock function.

Owner:INTIER AUTOMATIVE CLOSURES INC

Heat converter engine using a shape memory alloy actuator

InactiveUS6226992B1Mechanical power devicesClosed-cycle gas positive displacement engine plantEngineeringCrankshaft

A heat converter engine comprising a crank shaft, an actuator assembly coupled to the crank shaft, and a heating means. The actuator assembly includes a plurality of shape memory elements that are malleable when below a critical temperature and return to their original shape when above the critical temperature. The heating means raises the temperature of a first portion of the shape memory elements above the critical temperature and a cooling means lowers the temperature of a second portion of the shape memory elements below the critical temperature. This action of heating and cooling the shape memory elements causes rotation of the crank shaft.

Owner:EMERGENCY WARNING SYST

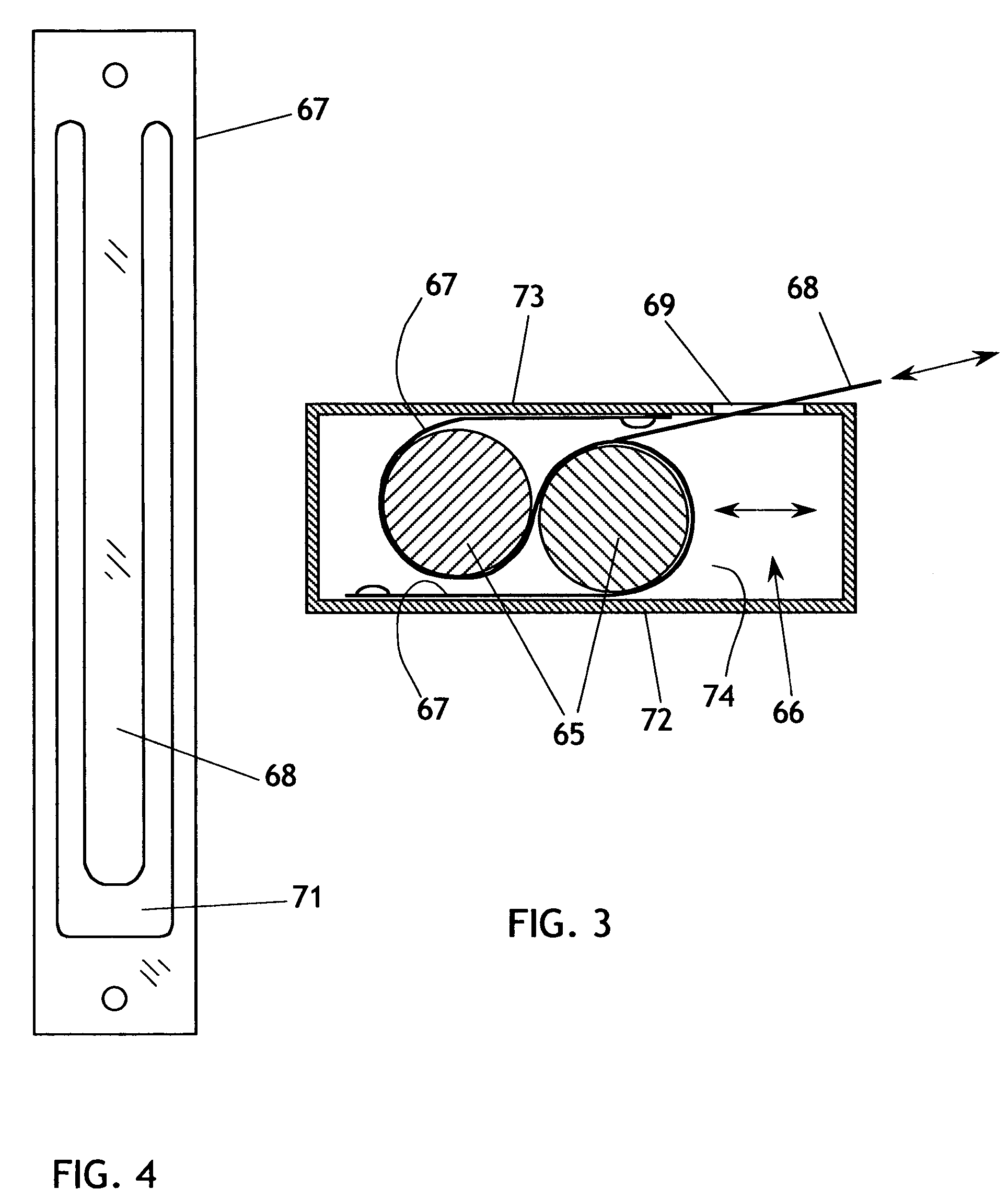

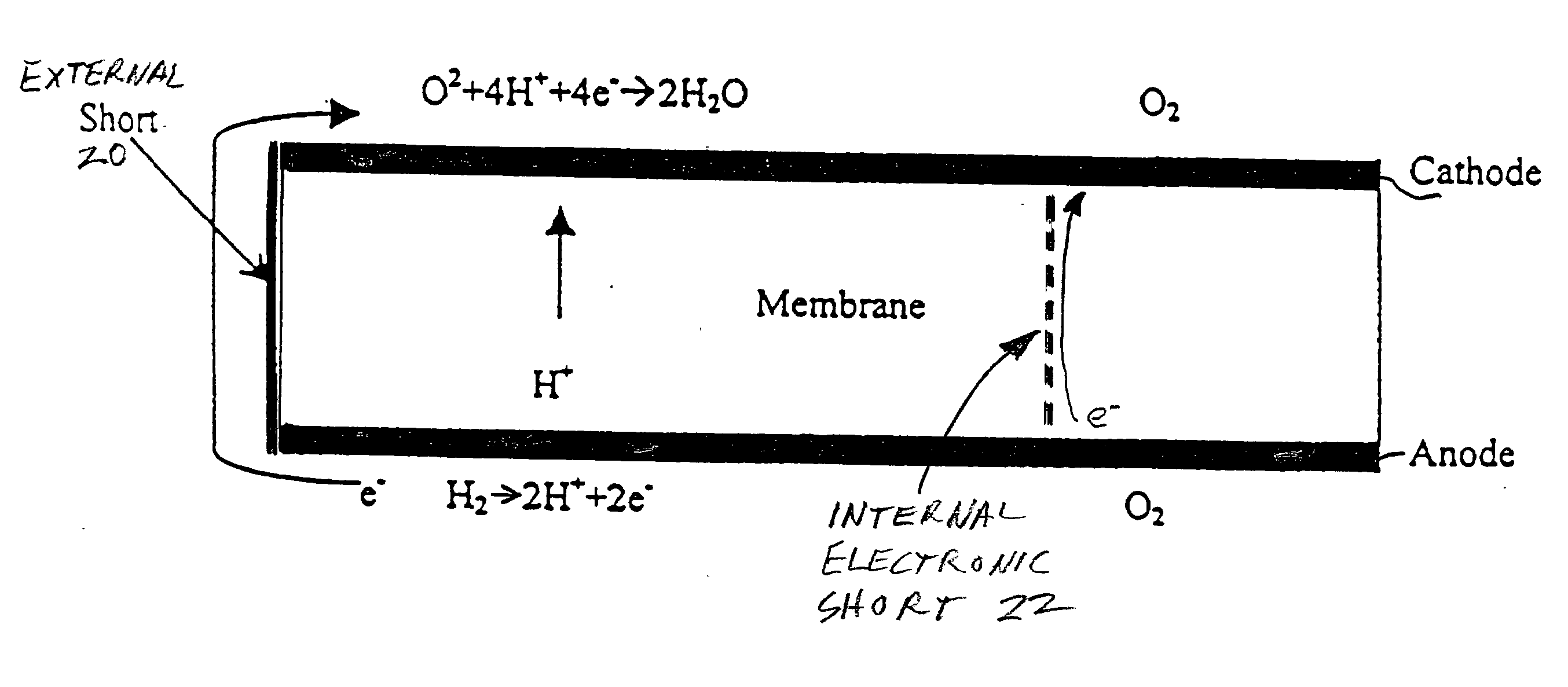

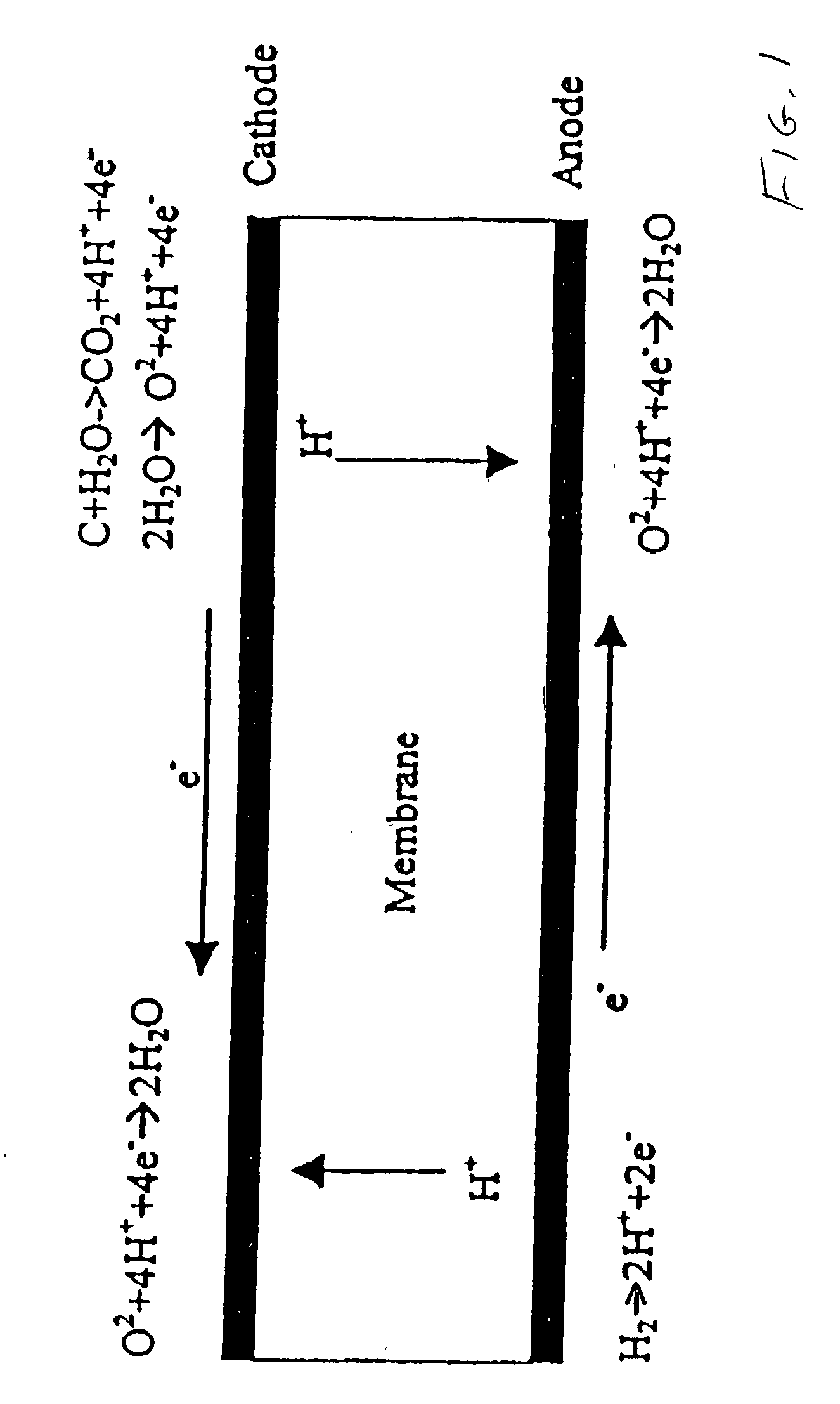

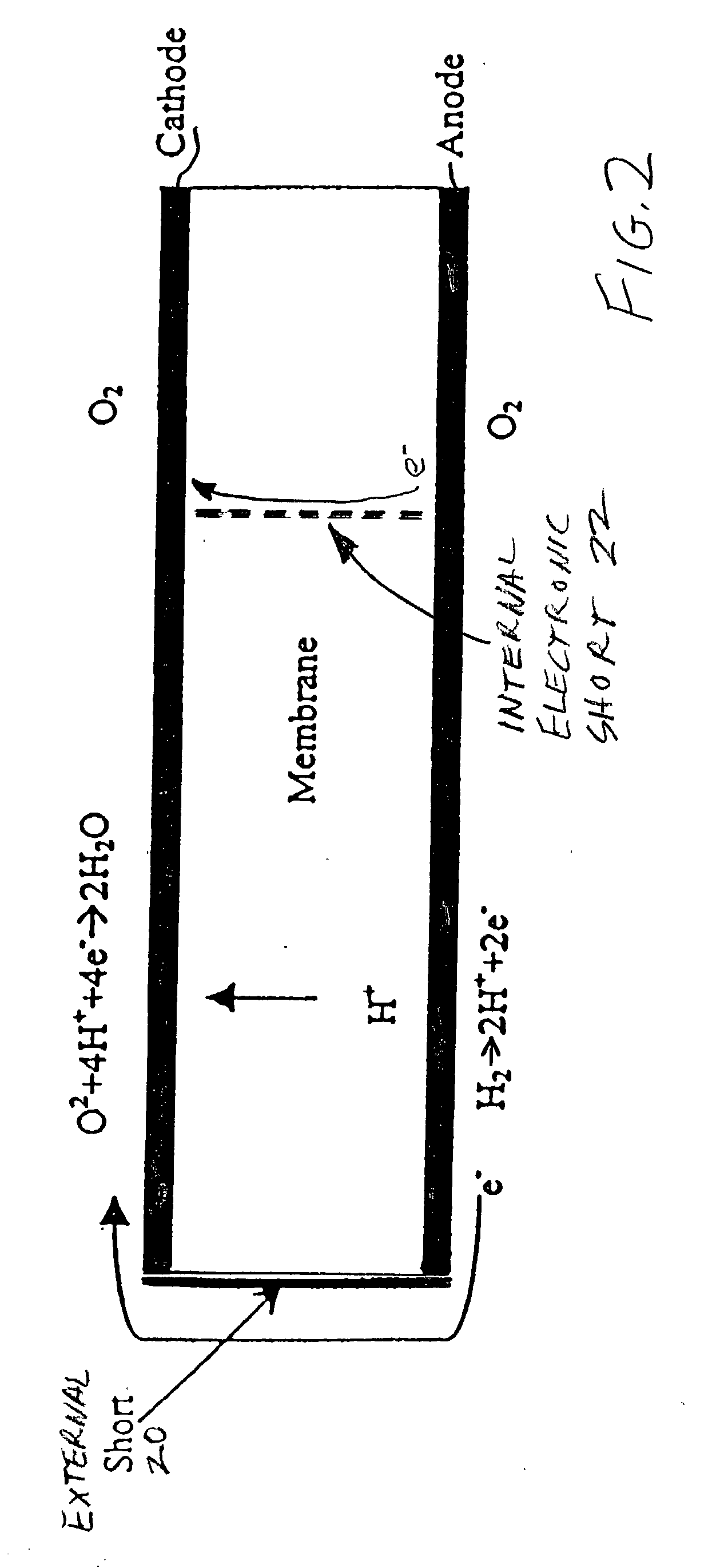

Reducing fuel cell cathode potential during startup and shutdown

InactiveUS6913845B2Reduce catalysisLower performance requirementsFuel cells groupingCell electrodesIonomerElectrical conductor

Owner:AUDI AG

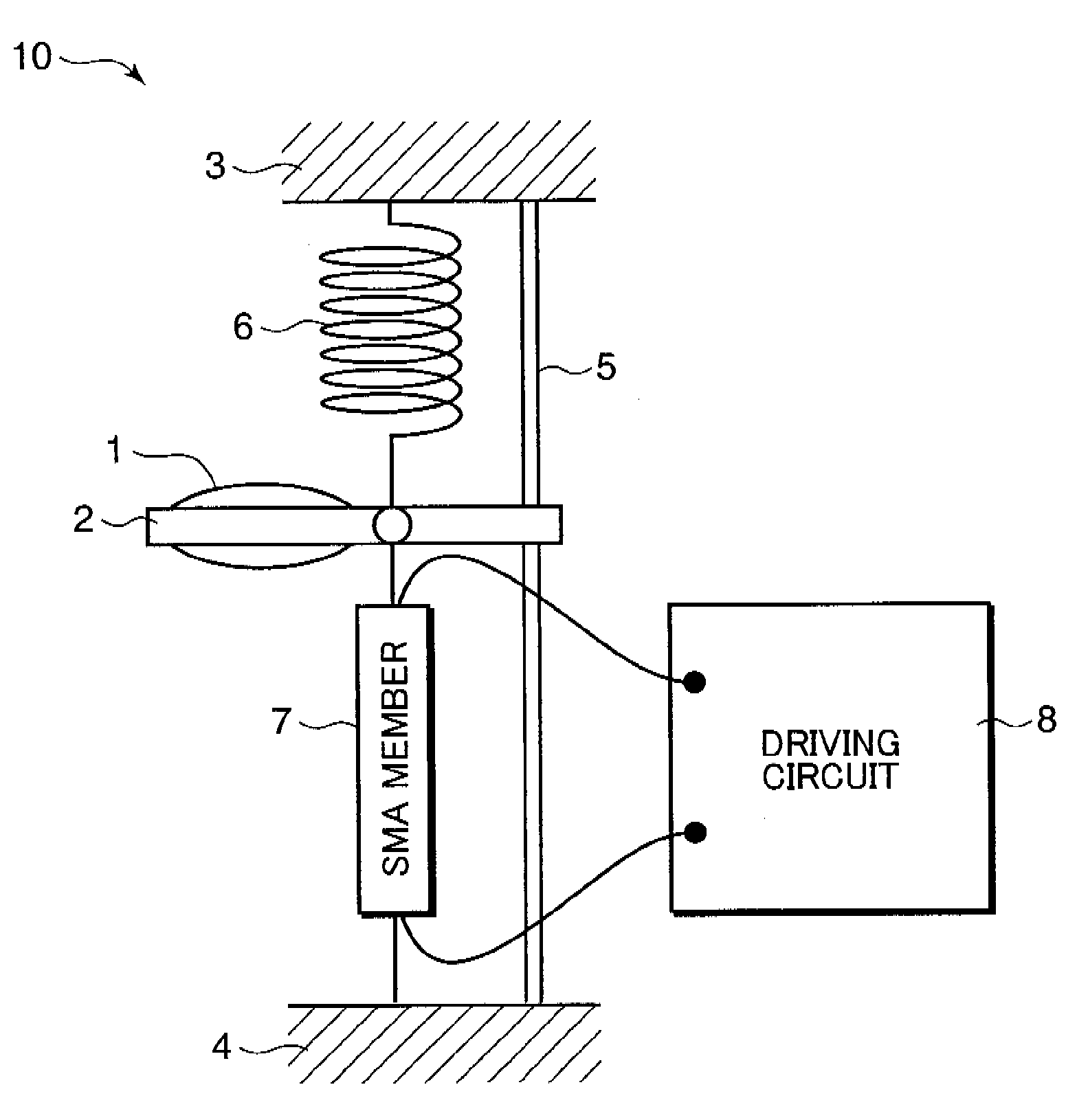

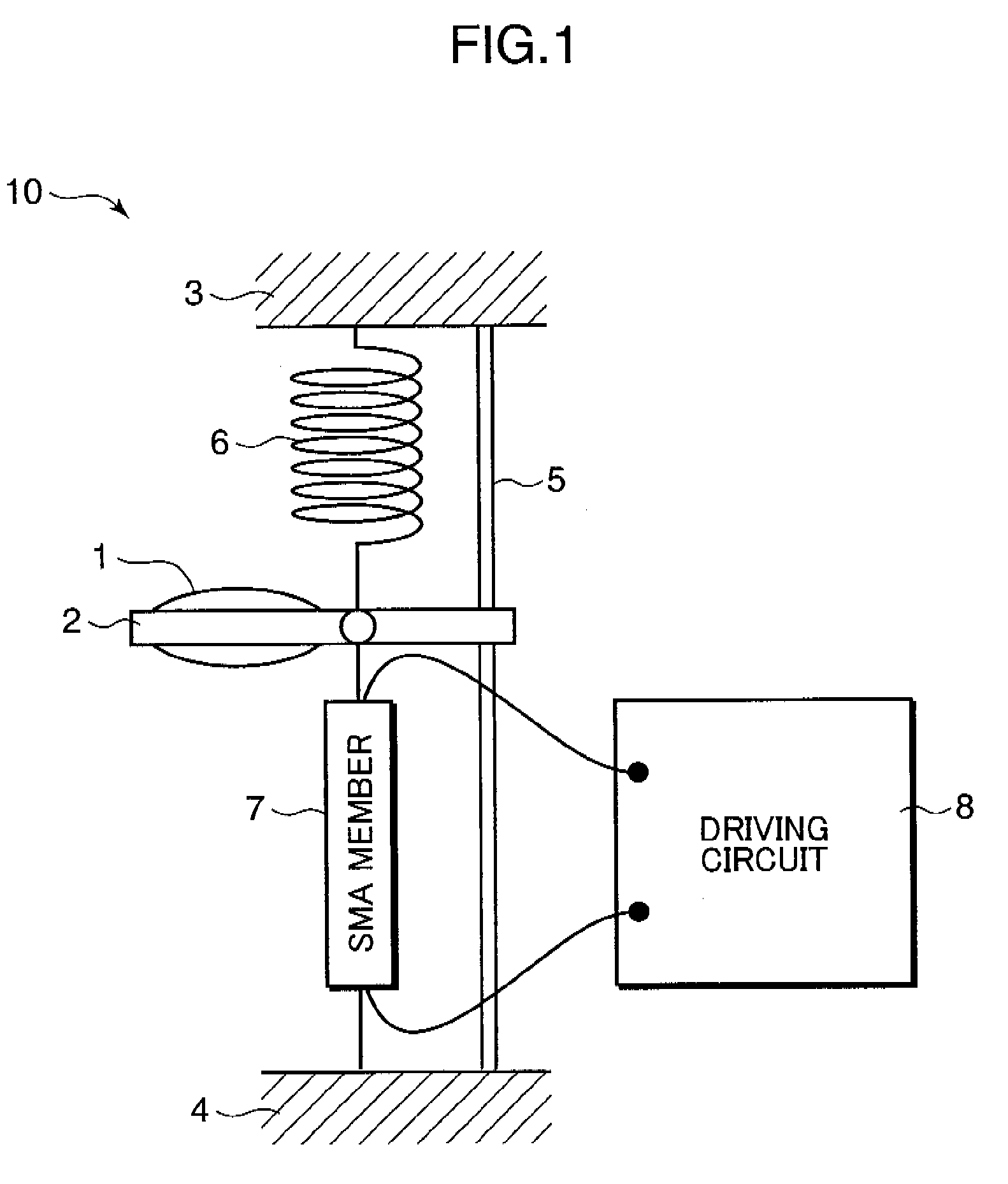

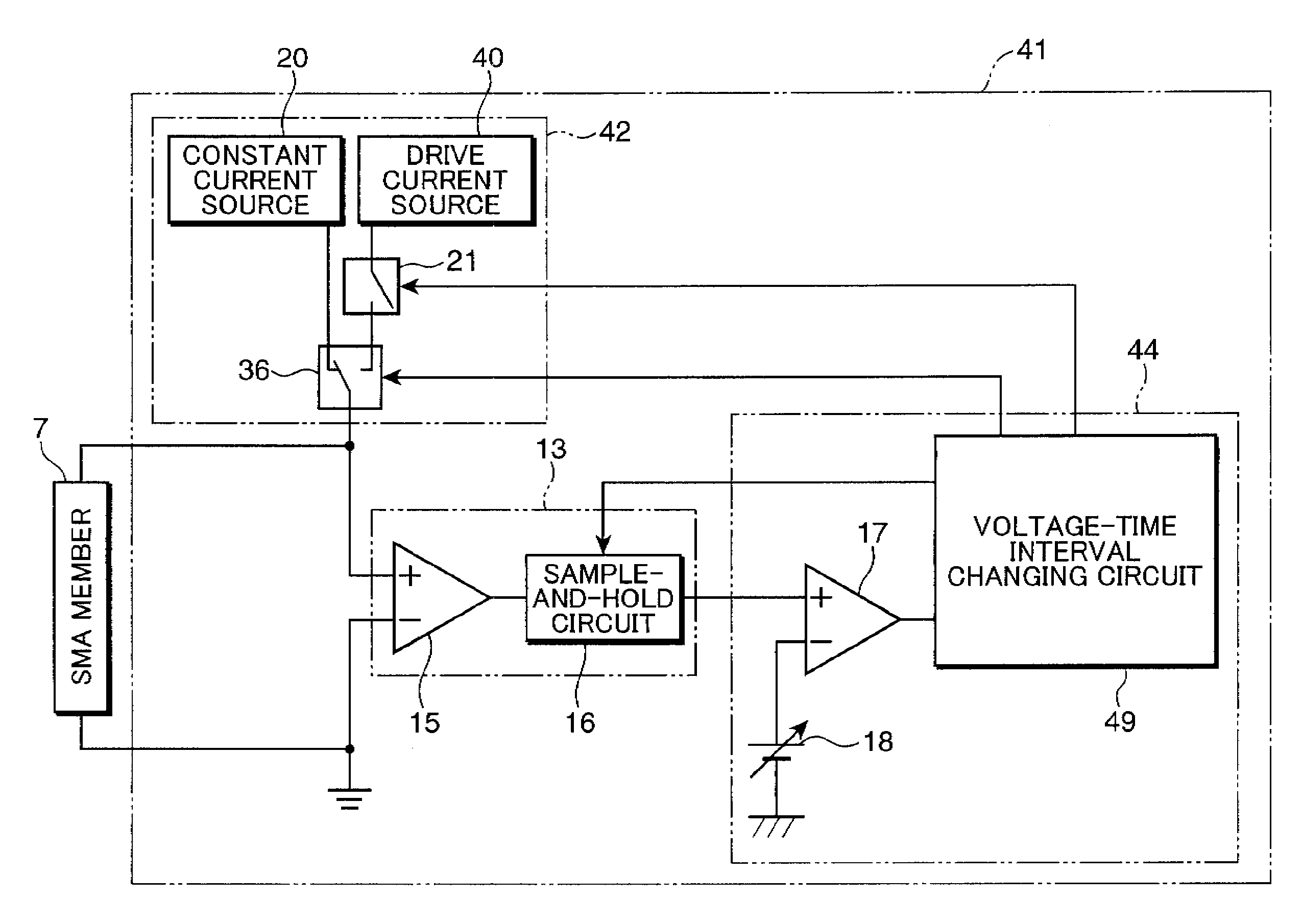

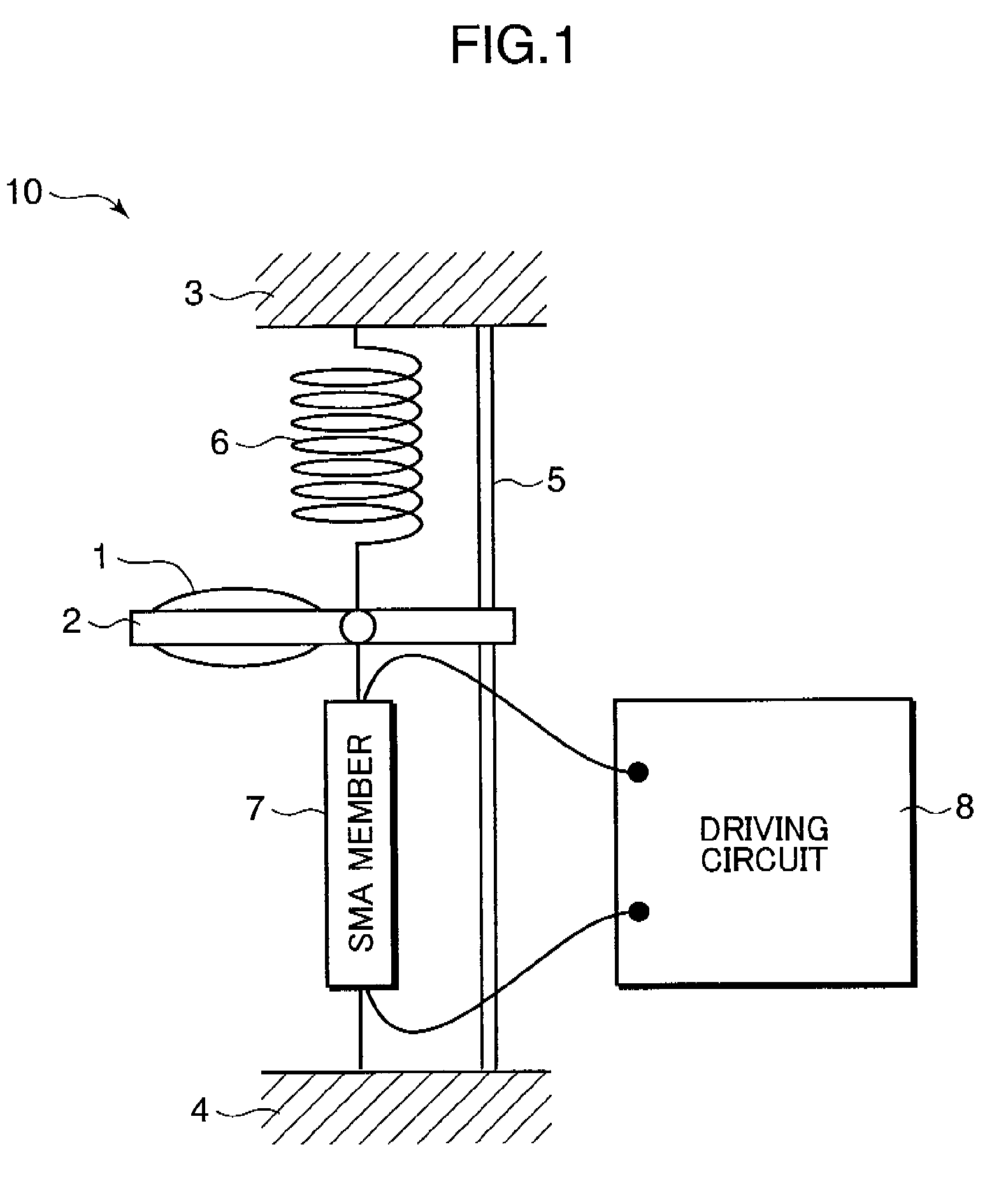

Sma actuator driving device, and image pickup device incorporated with the same

InactiveUS20090009656A1Suppress power lossGreat fabricationTelevision system detailsProjector focusing arrangementDriving currentElectrical resistance and conductance

In a shape memory alloy actuator driving device, a predetermined constant current is applied to a shape memory alloy member as a retrieval signal to detect a terminal voltage of the shape memory alloy member, and a detection result of the terminal voltage is compared with a target voltage value to be calculated based on a target resistance value of the shape memory alloy member and a value of the constant current to cause a driving circuit to output, to the shape memory alloy member, a drive current that makes the detection result substantially equal to the target voltage value.

Owner:KONICA MINOLTA OPTO

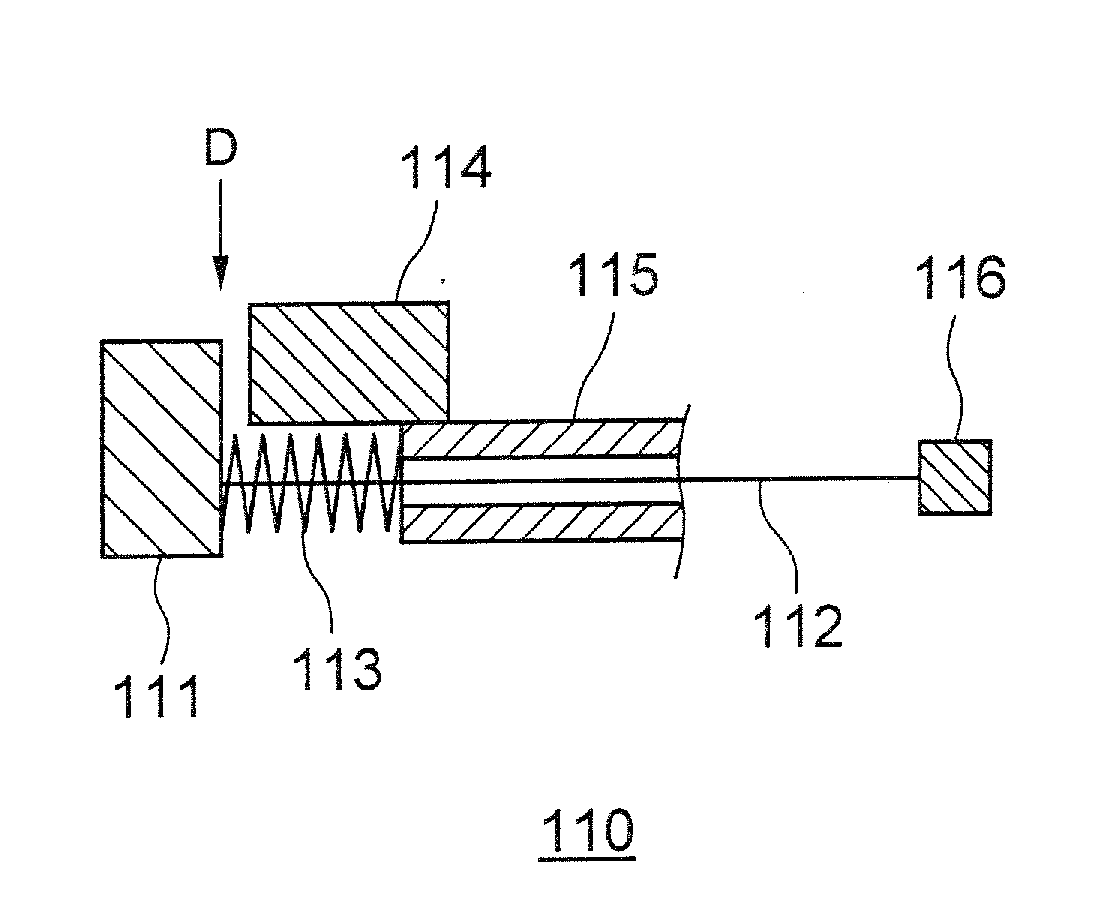

Shape memory alloy actuator

ActiveUS20090013684A1Avoid oscillationMotor/generator/converter stoppersDC motor speed/torque controlEngineeringAlloy

To provide a shape memory alloy actuator using a shape memory alloy that mechanically restrains a moving body in position to prevent oscillation, the actuator has a moving body pushing member adapted to be capable of abutting to the moving body, a bias spring for the moving body pushing member that exerts an external force on the moving body pushing member in the direction opposite to the direction of change in the shape of a shape memory wire caused by heating, a bias spring for the moving body that exerts an external force on the moving body in the direction same as the direction of change, a first stopper that restricts the movement of the moving body to a predetermined position upon cooling. One end of the shape memory wire is fixed, the other end is mechanically linked with the moving body pushing member. The moving body pushing member and the moving body are moved by deformation caused by heating, and the moving body and the moving body pushing member are separated, when the moving body is stopped at the position of the first stopper.

Owner:OLYMPUS CORP

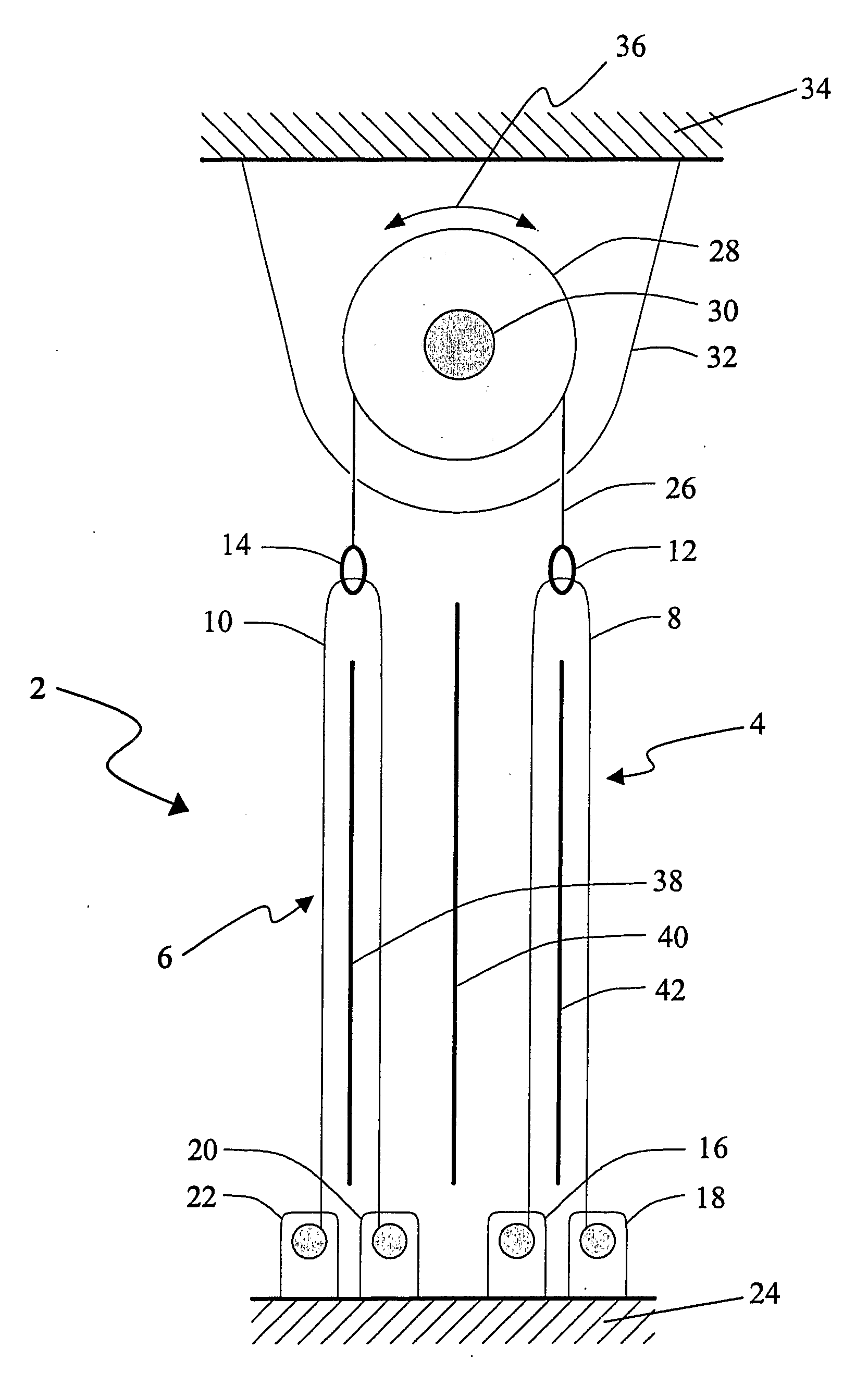

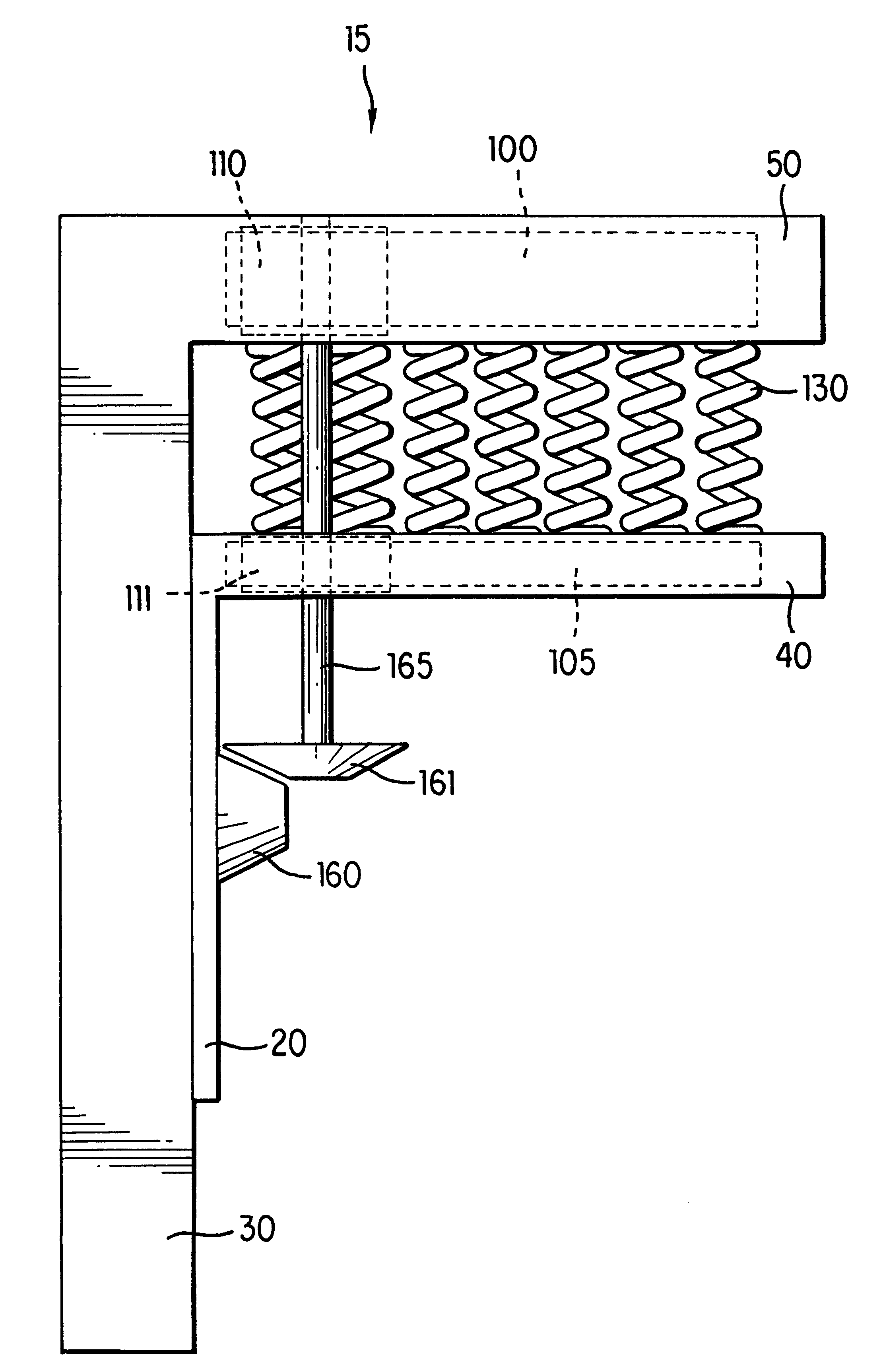

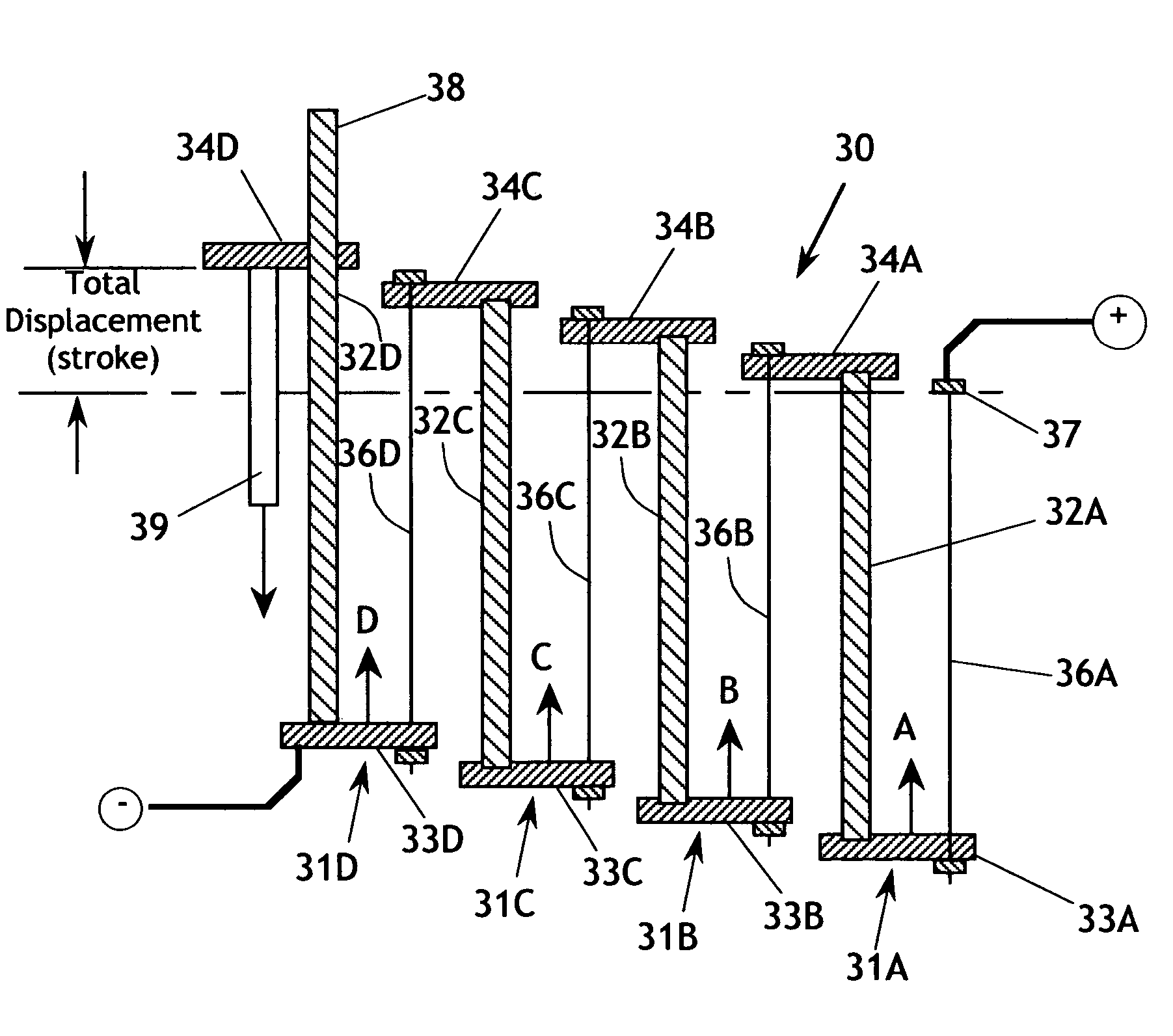

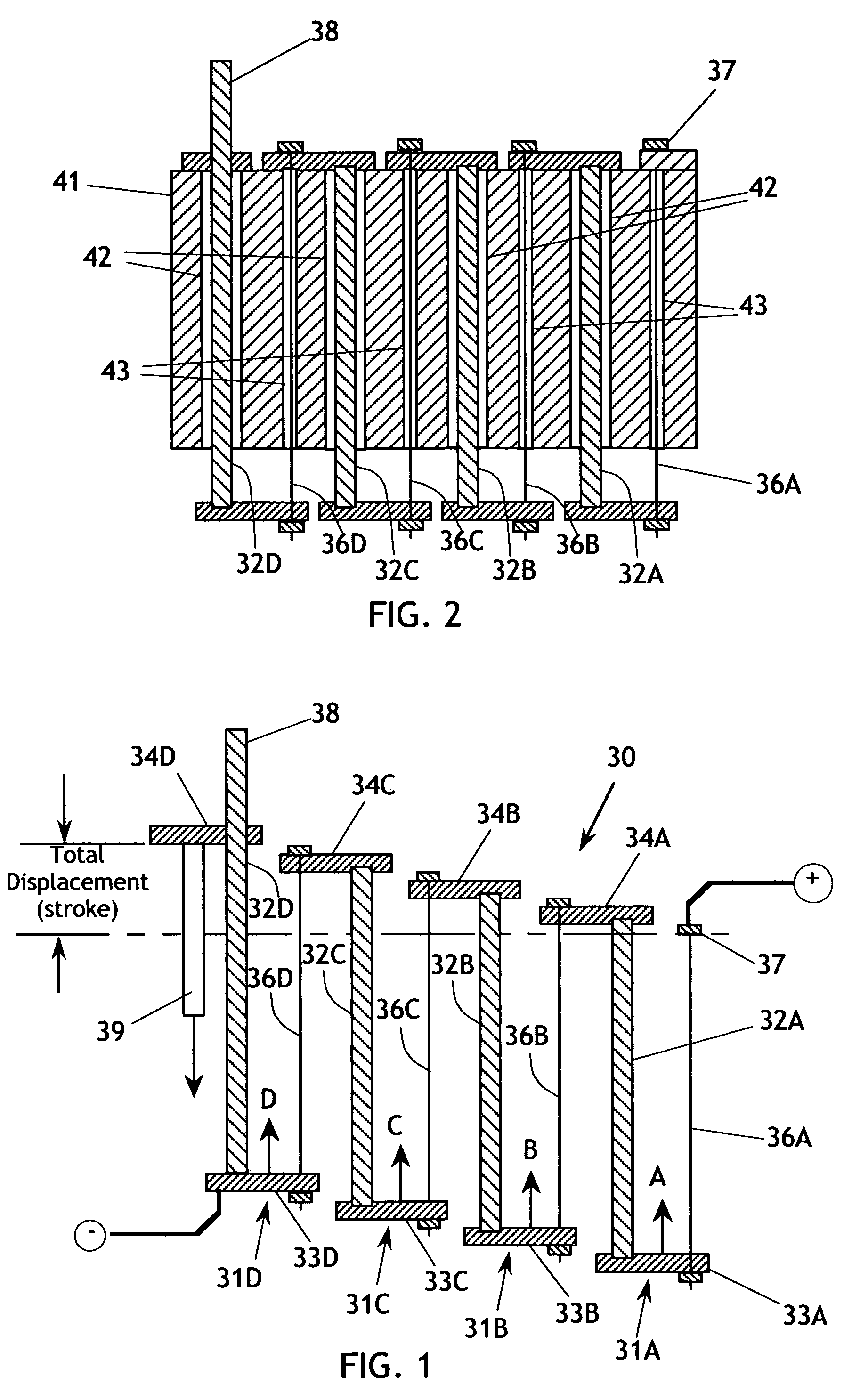

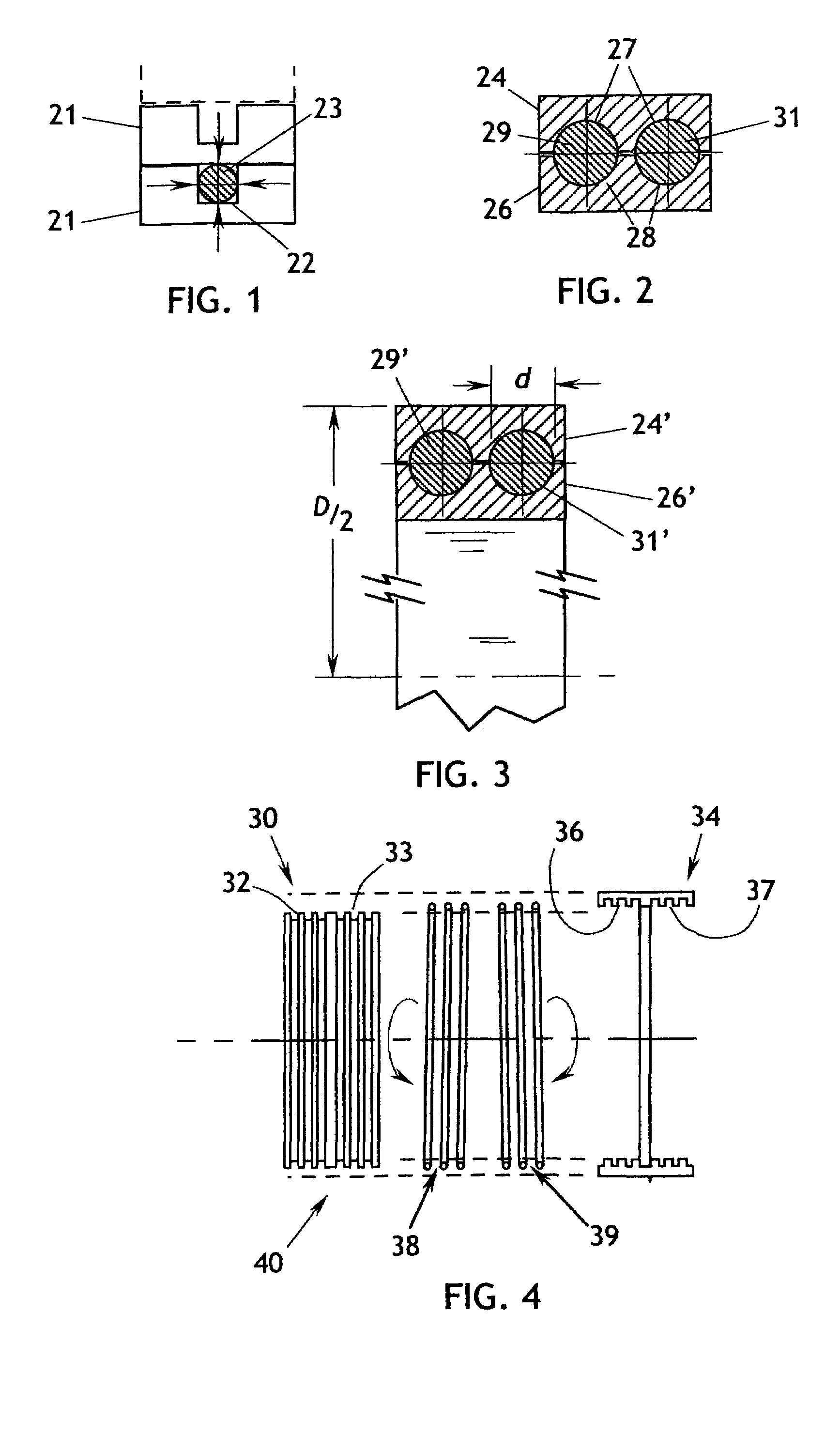

Shape memory alloy actuators

InactiveUS7256518B2Expand the scope ofShorter and powerful strokeMechanical power devicesPropulsion systemsEngineeringLinear actuator

Owner:PERIHELIAN

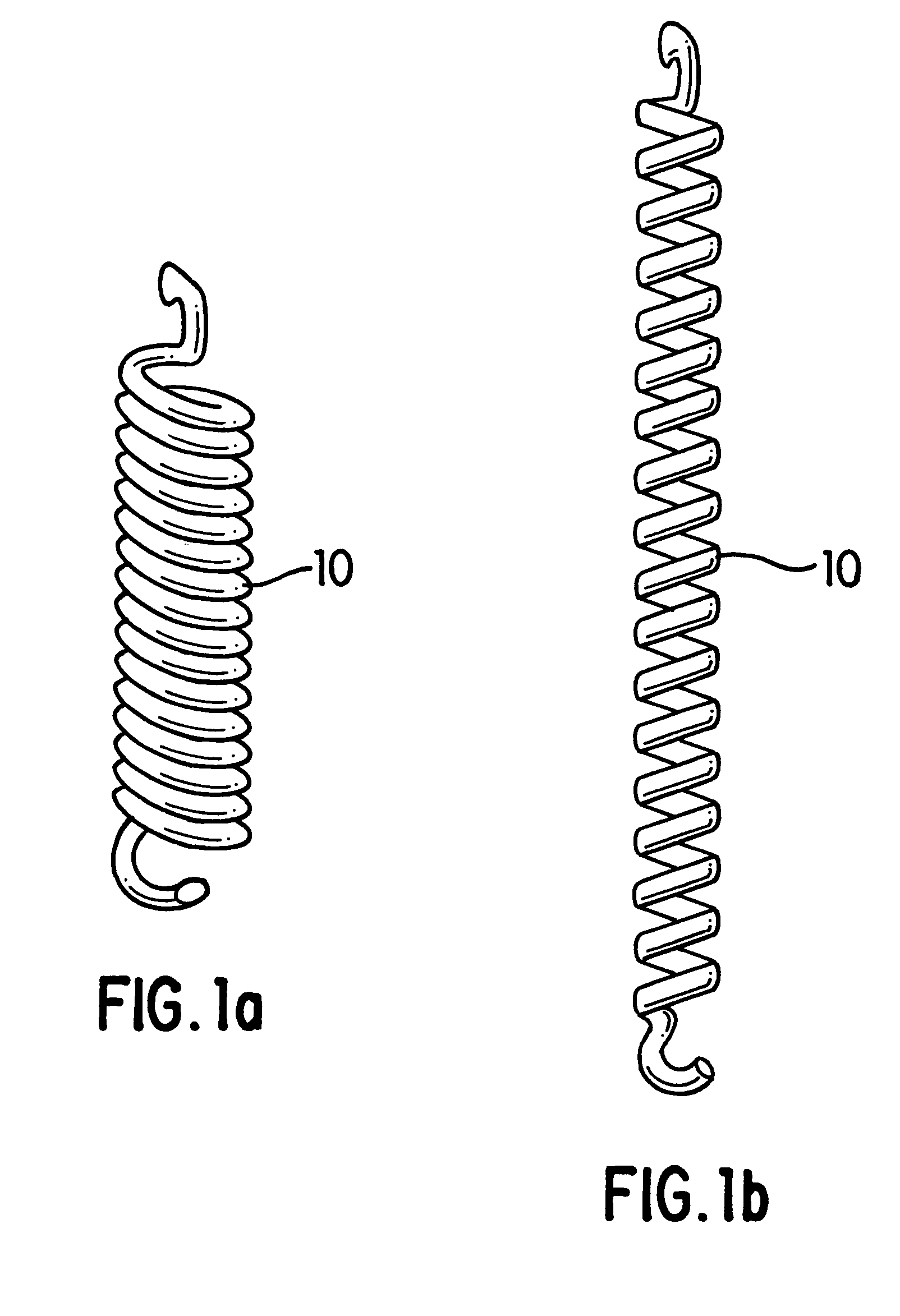

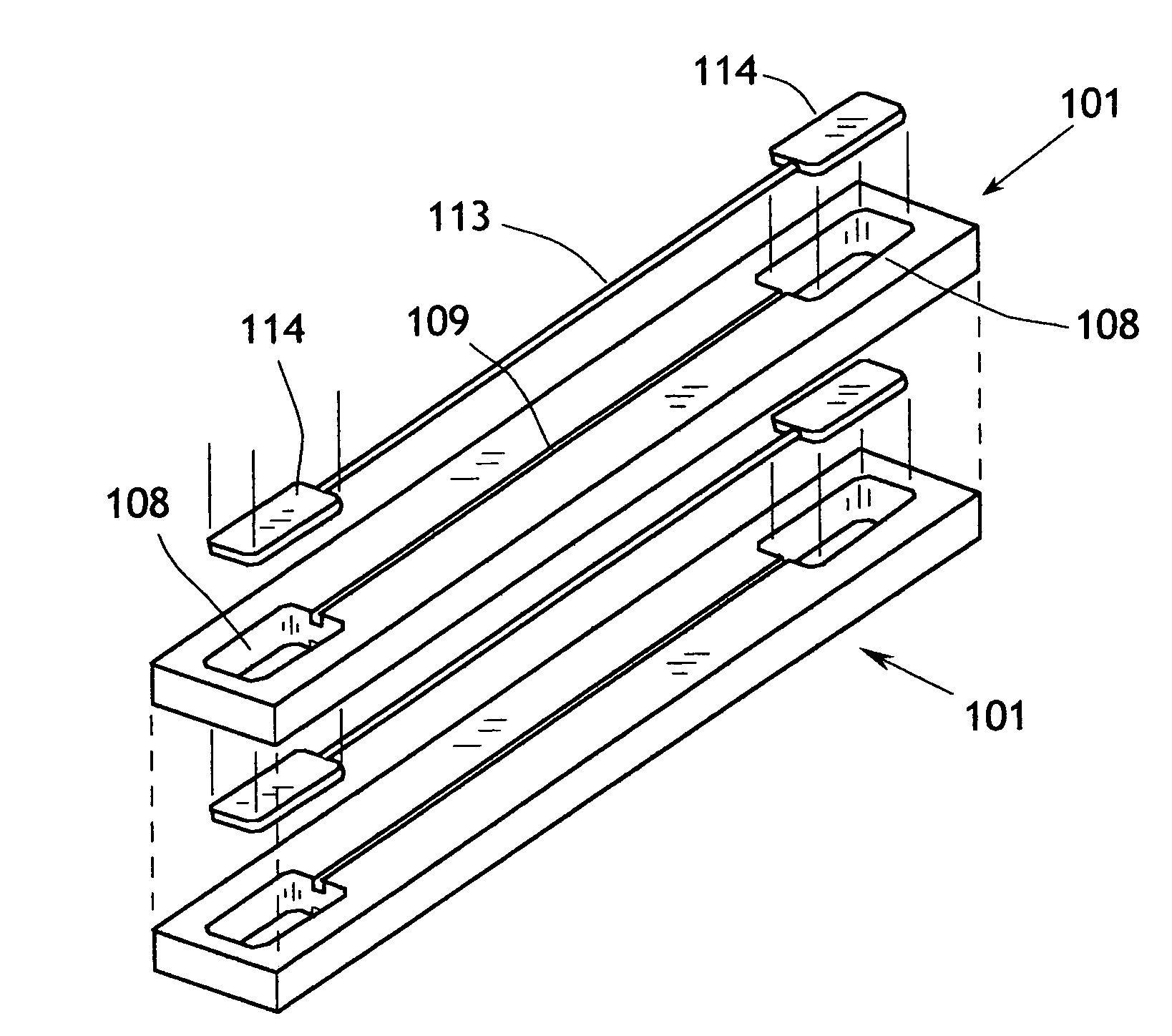

Flexible actuator based on shape memory alloy sheet

InactiveUS20110173970A1Raise the ratioReduce the cross-sectional areaMechanical power devicesClosed-cycle gas positive displacement engine plantElectrical resistance and conductanceElectricity

A flexible unit-cell actuator includes a shape memory alloy sheet having a fold between adjacent legs in one state and a heat source that upon activation concentrates heating of the shape memory alloy sheet at the fold relative to the legs to change the fold between one state and another state. The heat source may include resistive heating due to an electric current passing through the shape memory alloy sheet. The fold typically includes a reduced cross-sectional area and may include slits to increase electrical resistance at the fold relative to the adjacent legs. An actuator array includes a plurality of flexible unit-cell actuators formed in a sheet, each unit-cell actuator mechanically coupled to at least one other unit-cell actuator at a coupling region. Plural unit-cell actuators may be mechanically coupled in series, in parallel, or both, may be electrically connected in series, and may move along a defined curve or surface. A linear or curvilinear actuator includes a guide, a plurality of bearings or support elements slidable along the guide, and an array of actuators coupled between adjacent bearings and circumferentially about the bearings. An actuator includes a plurality of segments fanning from a hinge and shape memory alloy actuators coupled between adjacent segments to cause the segments to fan in an out about the hinge.

Owner:MASSACHUSETTS INST OF TECH

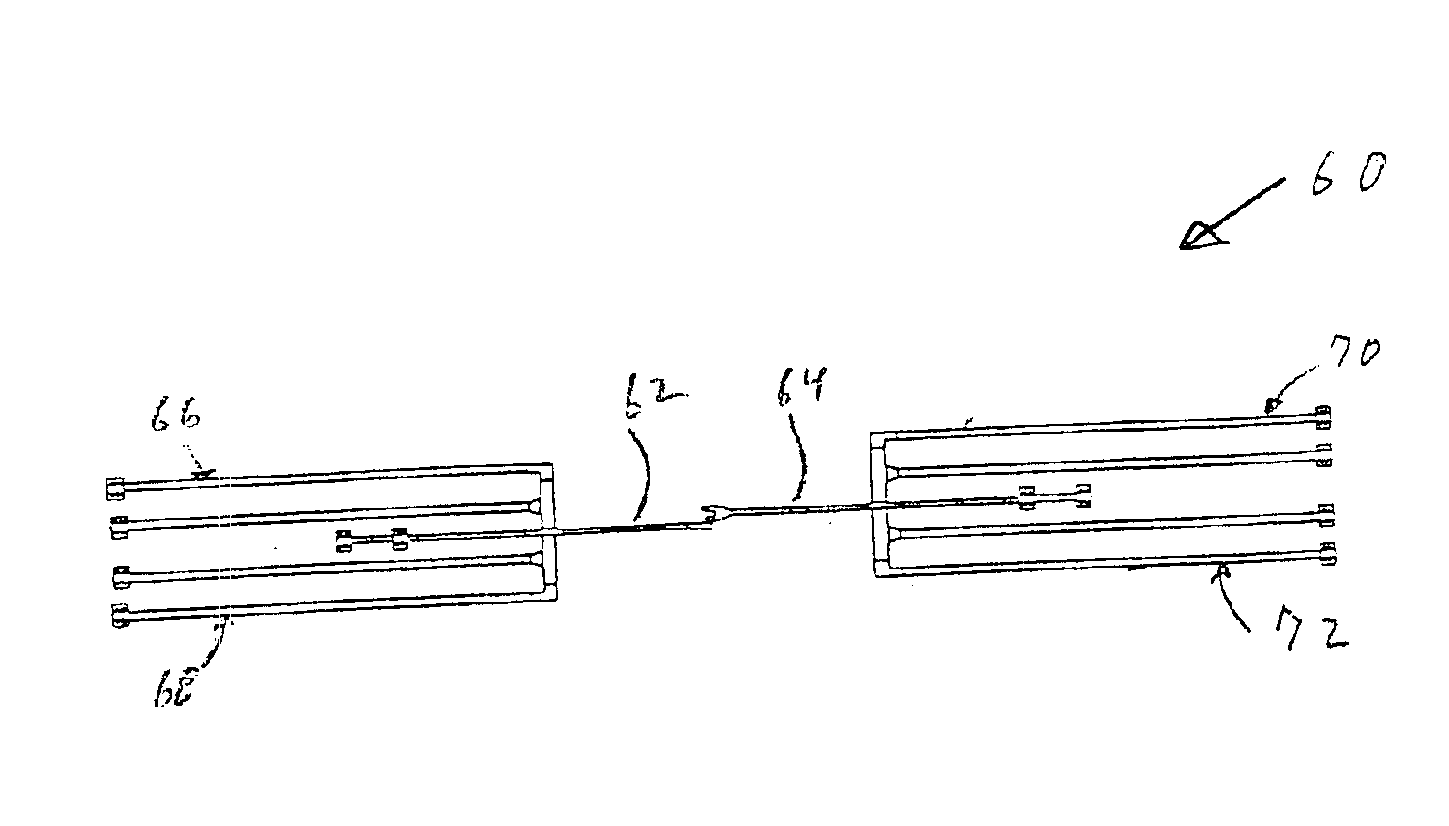

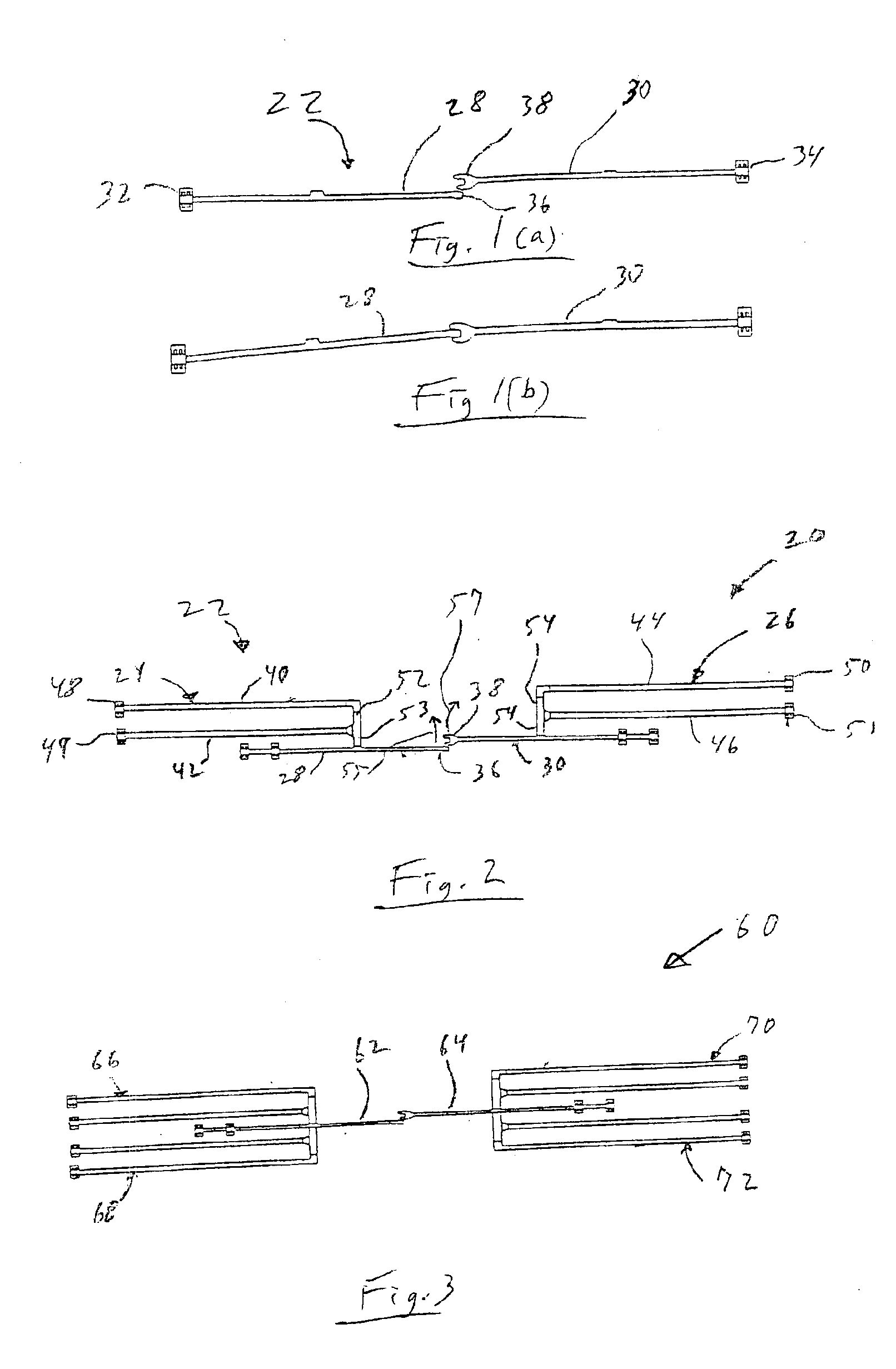

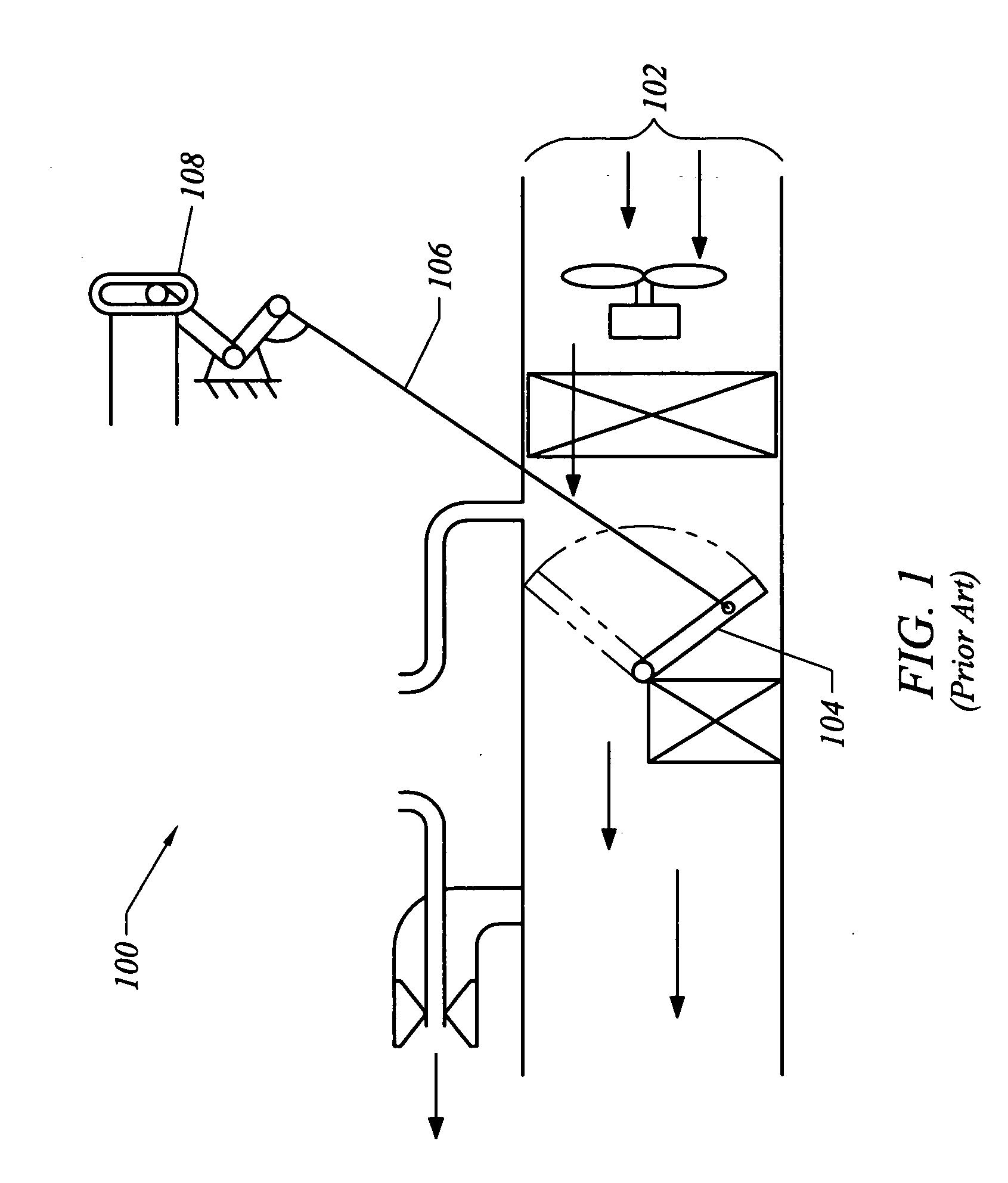

Reducing fuel cell cathode potential during startup and shutdown

InactiveUS20040081866A1Reduce supportImproved fuel cell stackFuel cells groupingCell electrodesShunt DeviceElectrical conductor

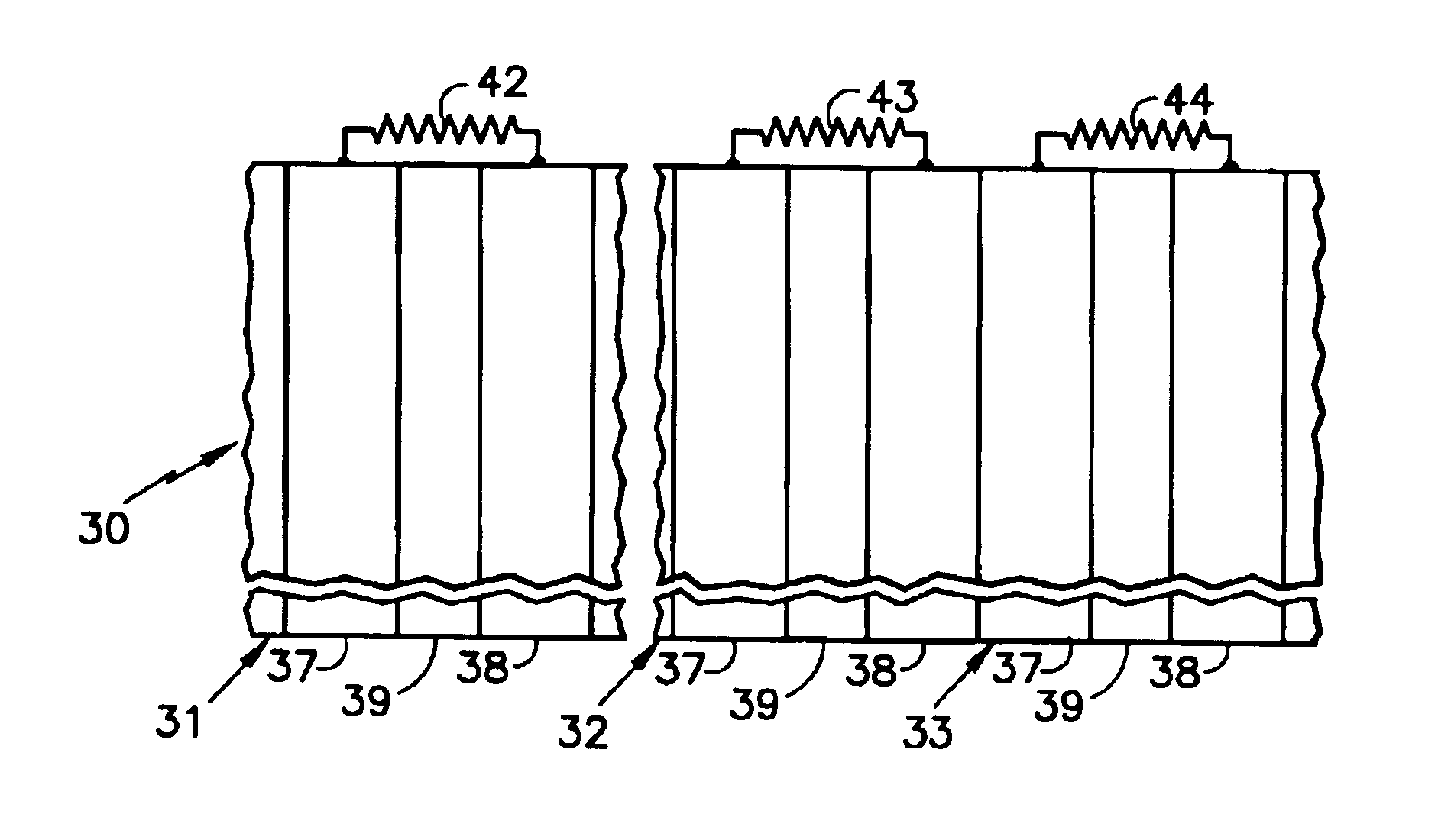

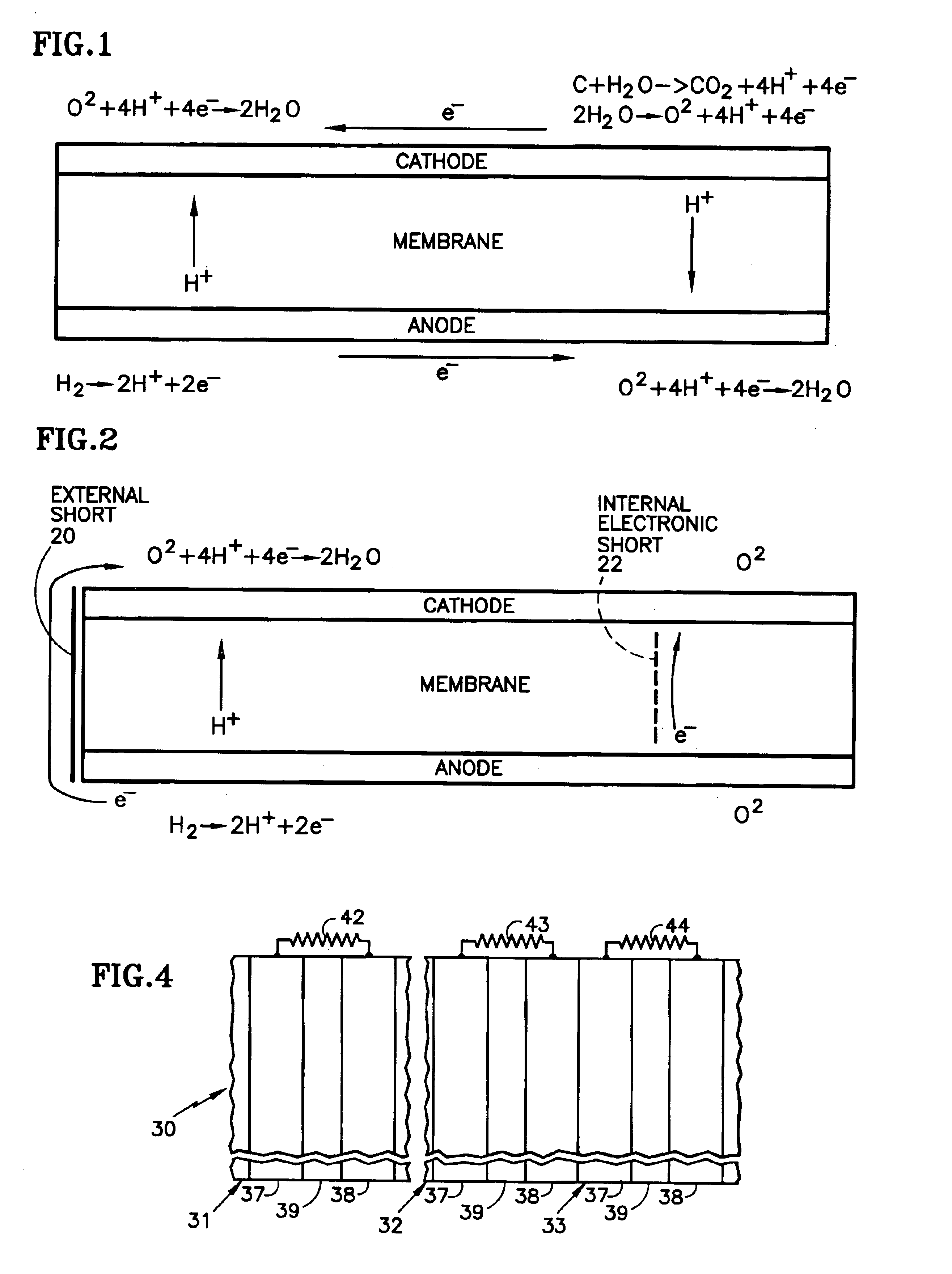

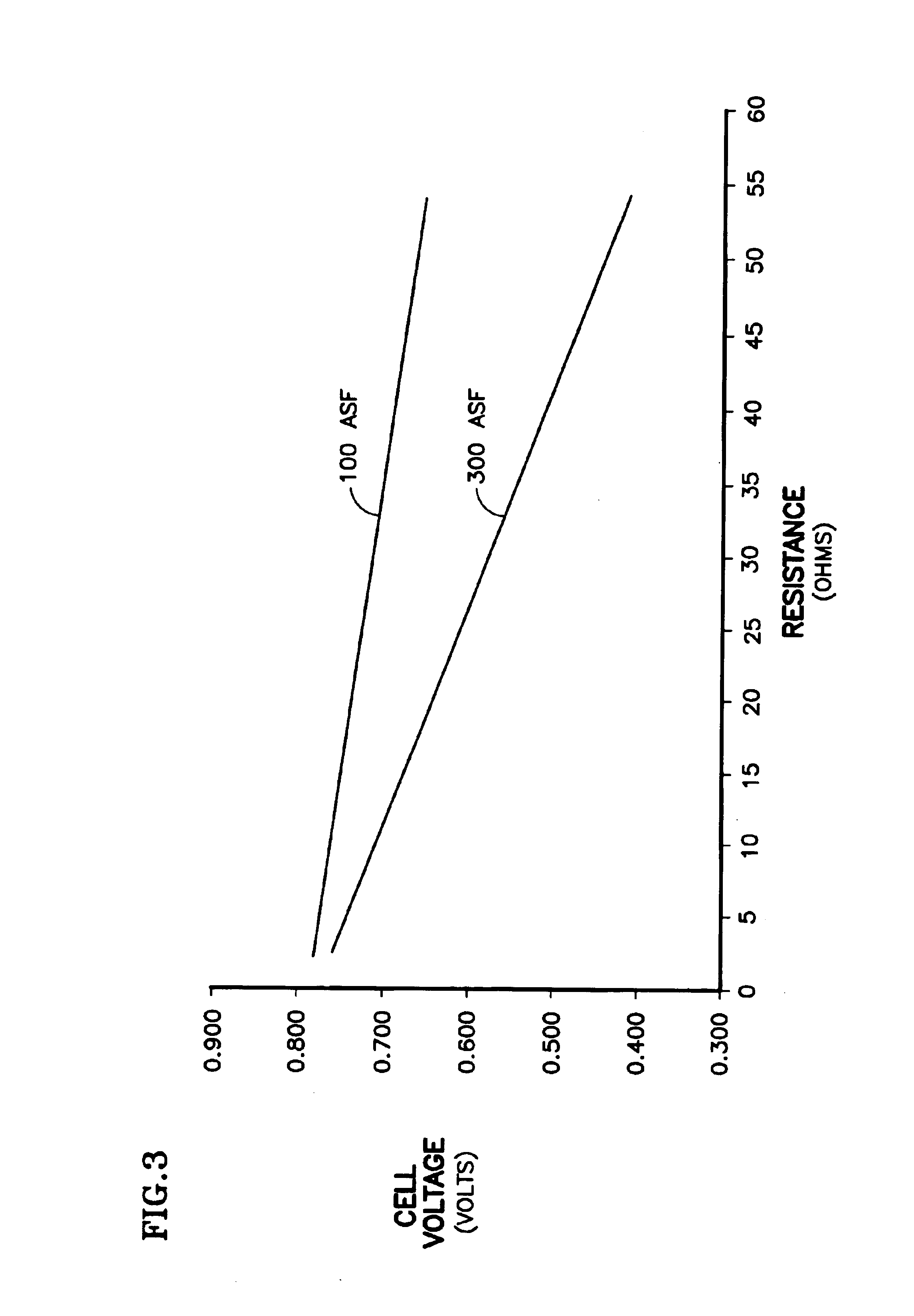

Each cell of a fuel cell stack is provided, between the anode 37 and cathodes 38, with either (a) a permanent shunt (20) which may be a discrete resistor (42-44), a diode (95), a strip of compliant carbon cloth (65), or a small amount of conductive carbon black (22) in the ionomer polymer mixture of which the proton exchange membrane (39) is formed, or (b) a removeable shunt such as a conductor (69) which may be rotated into and out of contact with the fuel cell anodes and cathodes, or a conductor (85) which may be urged into contact by means of a shape memory alloy actuator spring (90, 91), which may be heated.

Owner:AUDI AG

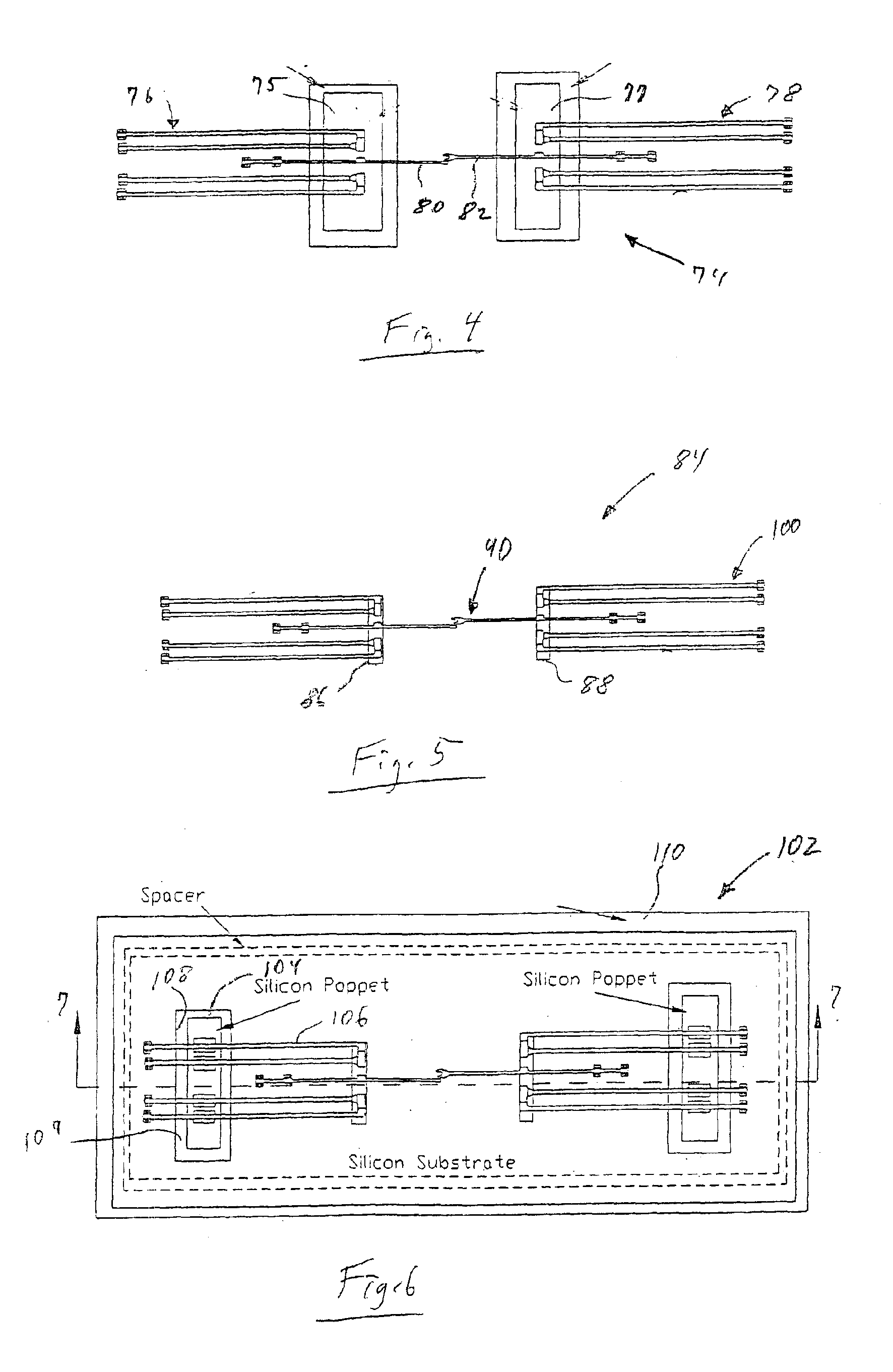

Thin film shape memory alloy actuated microrelay

InactiveUS7084726B2Average power consumptionHigh currentContact mechanismsElectrothermal relaysDevice formAlloy

A microrelay device formed on a silicon substrate wafer for use in opening and closing a current path in a circuit. A pair of electrically conducting latching beams are attached at their proximal ends to terminals on the substrate. Proximal ends of the beams have complementary shapes which releasably fit together to latch the beams and close the circuit. A pair of shape memory alloy actuators are selectively operated to change shapes which bend one of the beams in a direction which latches the distal ends, or bend the other beam to release the distal ends and open the circuit. The microrelay is bistable in its two positions, and power to the actuators is applied only for switching it open or closed.

Owner:TINI ALLOY

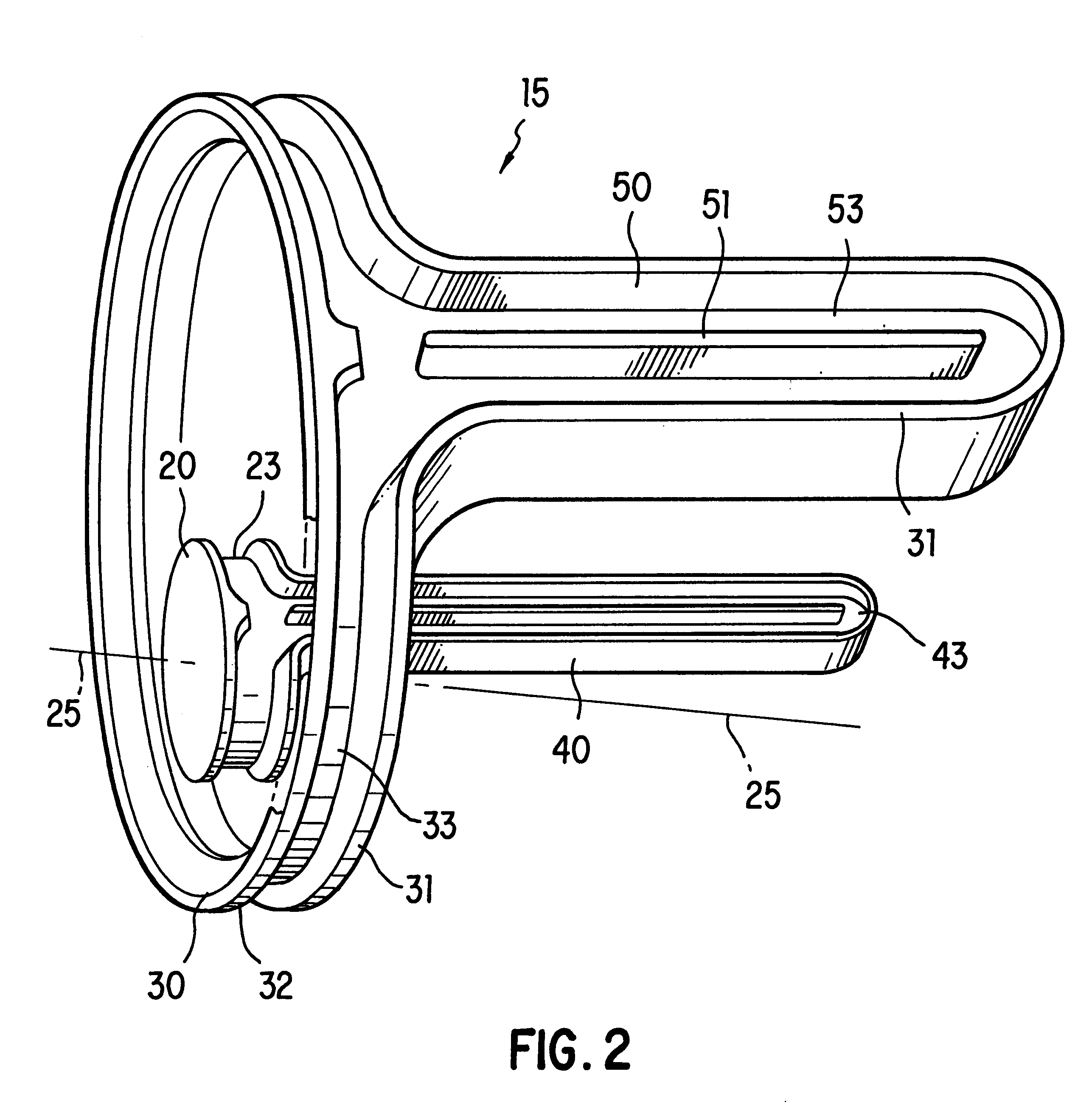

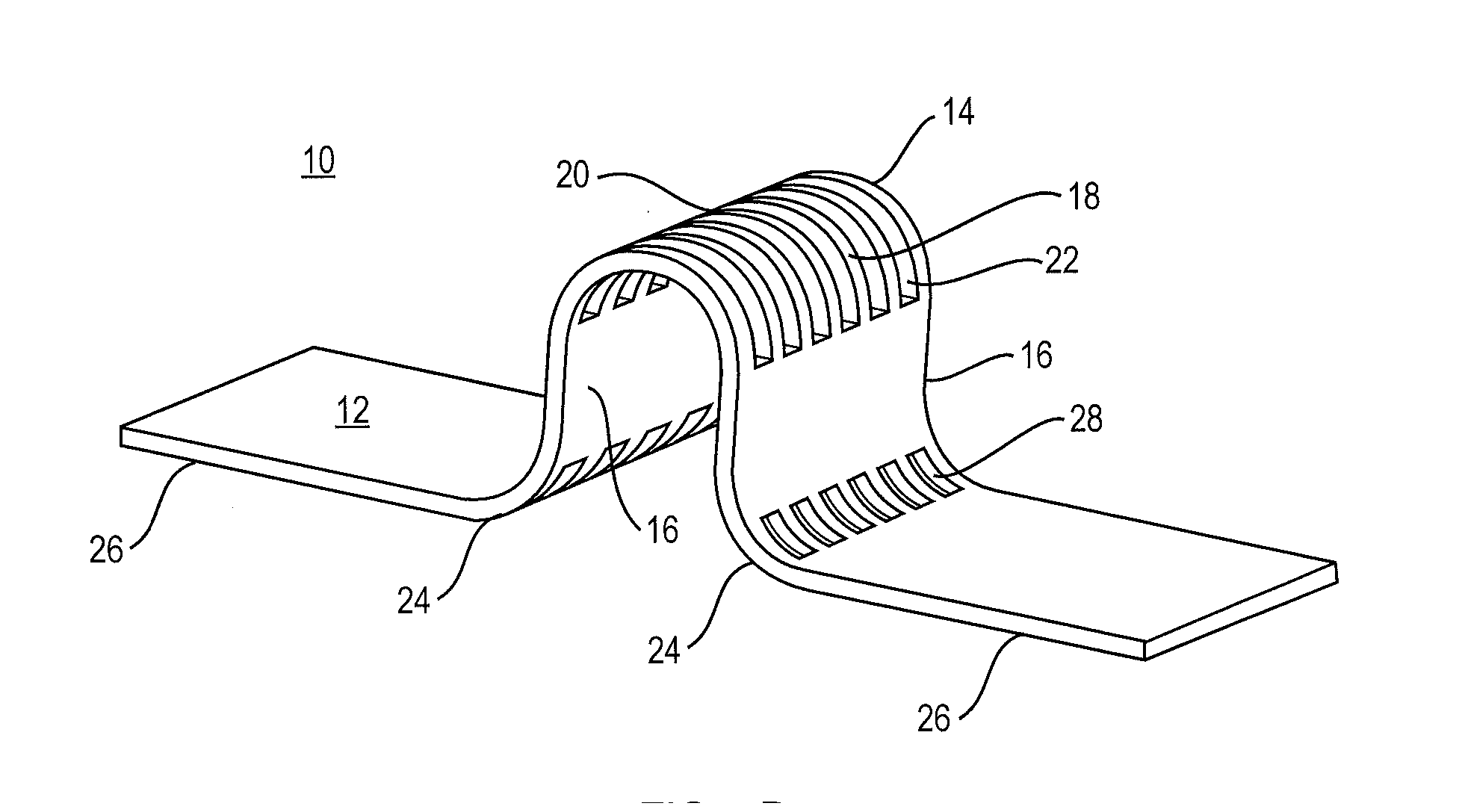

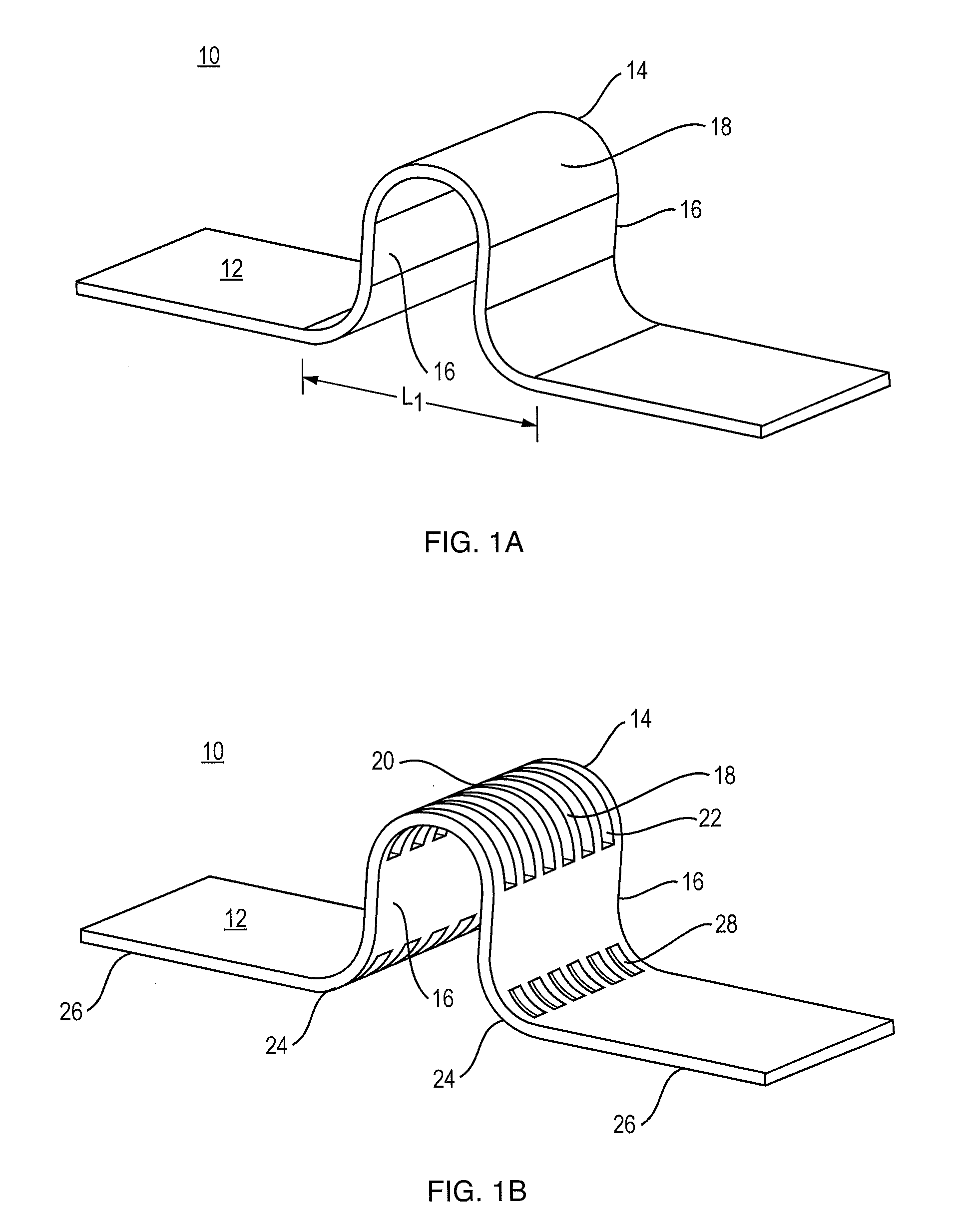

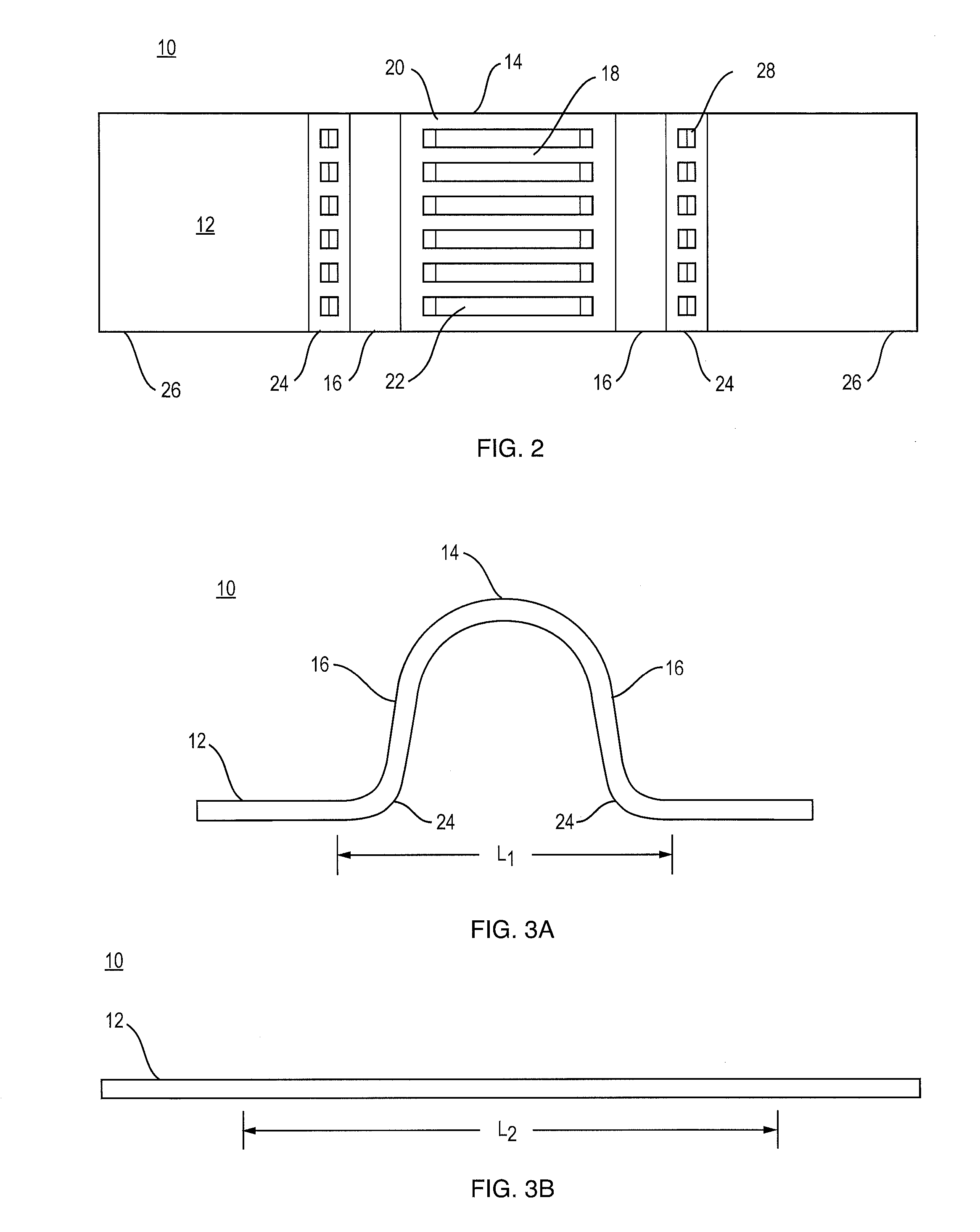

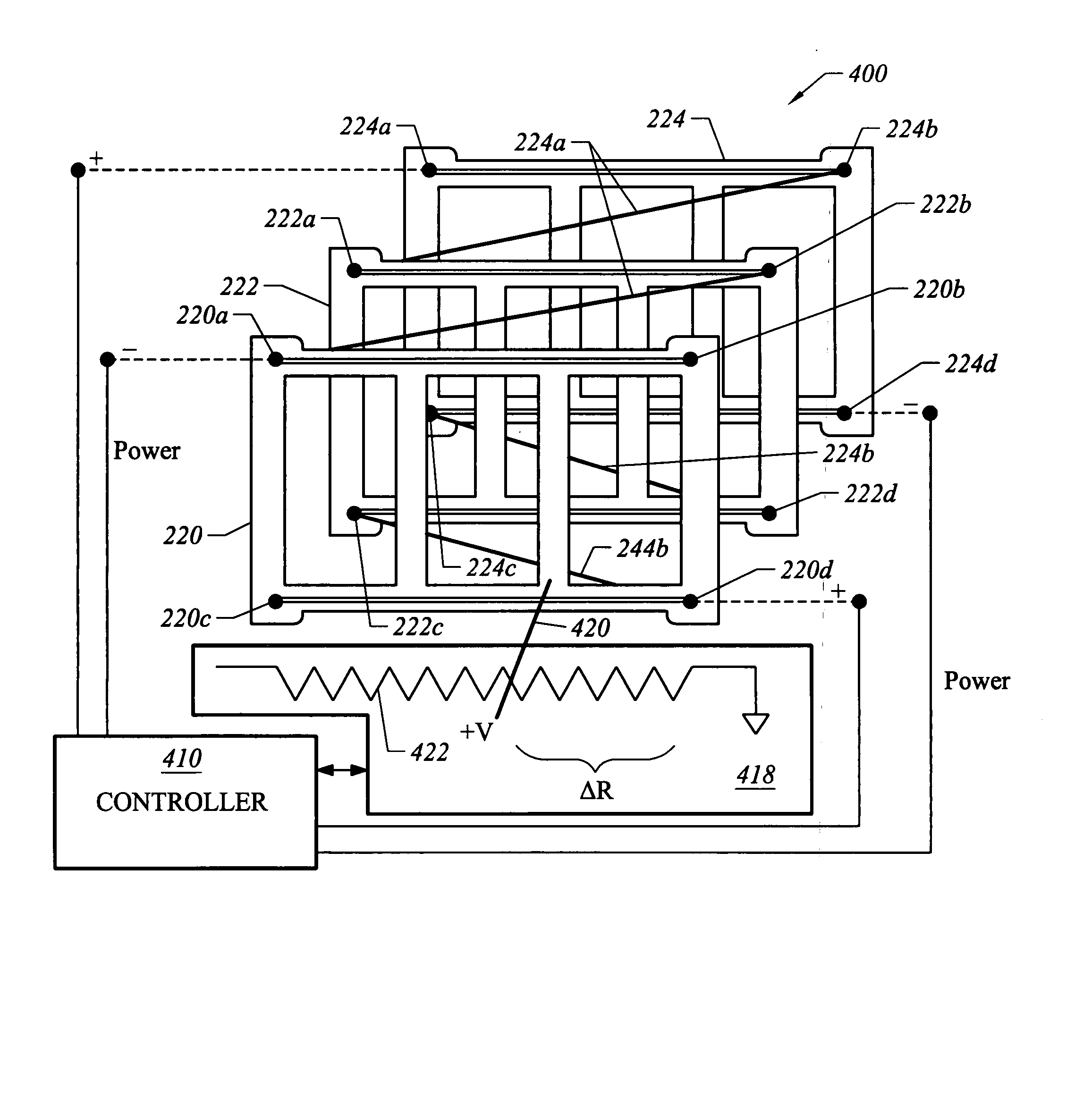

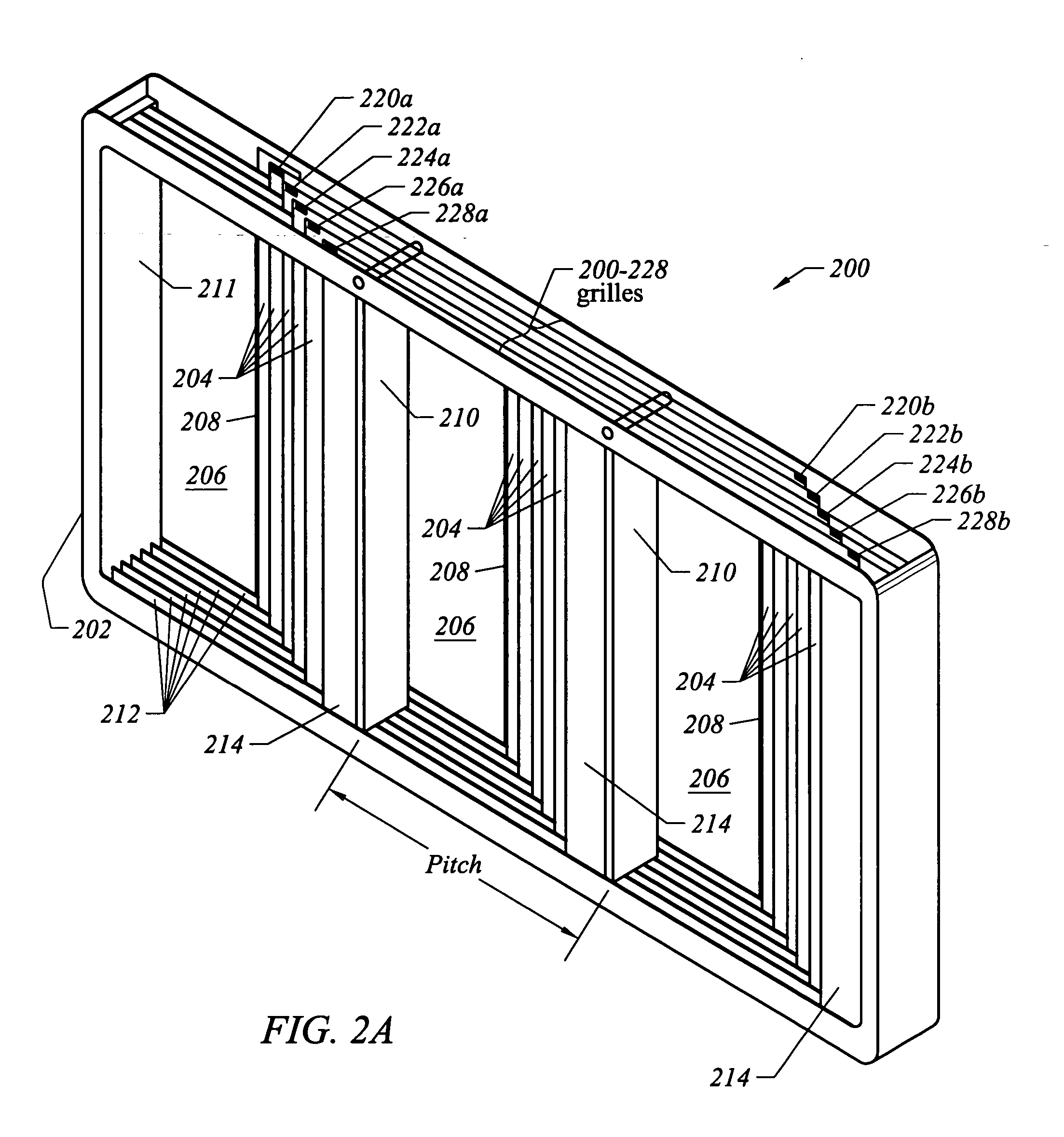

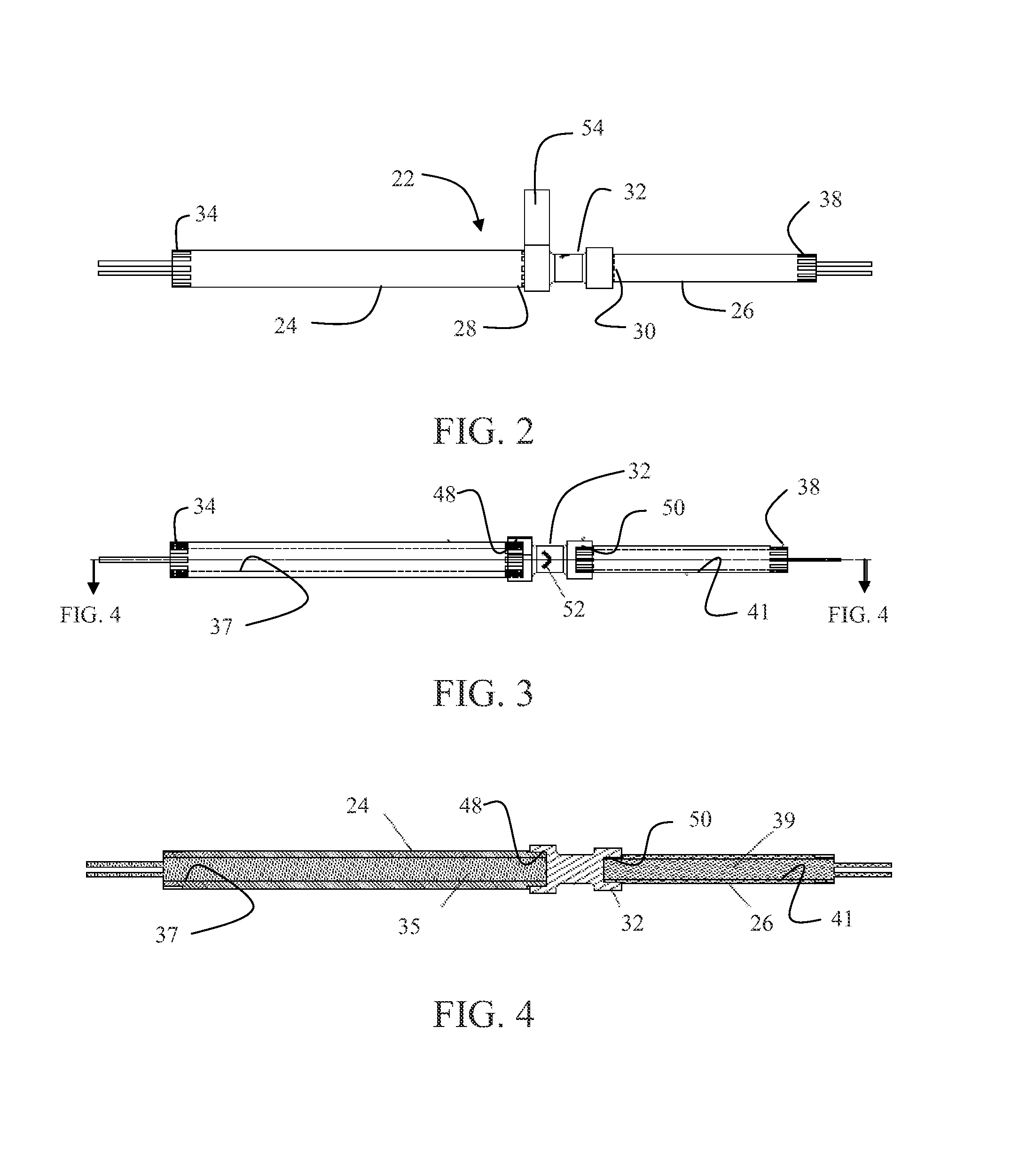

Flow control assemblies having integrally formed shape memory alloy actuators

ActiveUS20050000574A1Easy to integrateSimple and inexpensivePlug valvesAir-treating devicesLong axisEngineering

In one embodiment of the present invention, a shape memory alloy (“SMA”)-actuated flow controller comprises a number of grille members, each having a long axis and being slideable relative to one another parallel to that long axis. The SMA-actuated flow controller also includes a frame configured to guide the number of grille members, and an actuator disposed within the frame to move at least one of the number of grille members for varying a size of an aperture. Further, the actuator includes an SMA actuator that includes a number of SMA elements each connecting one grille number to another.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

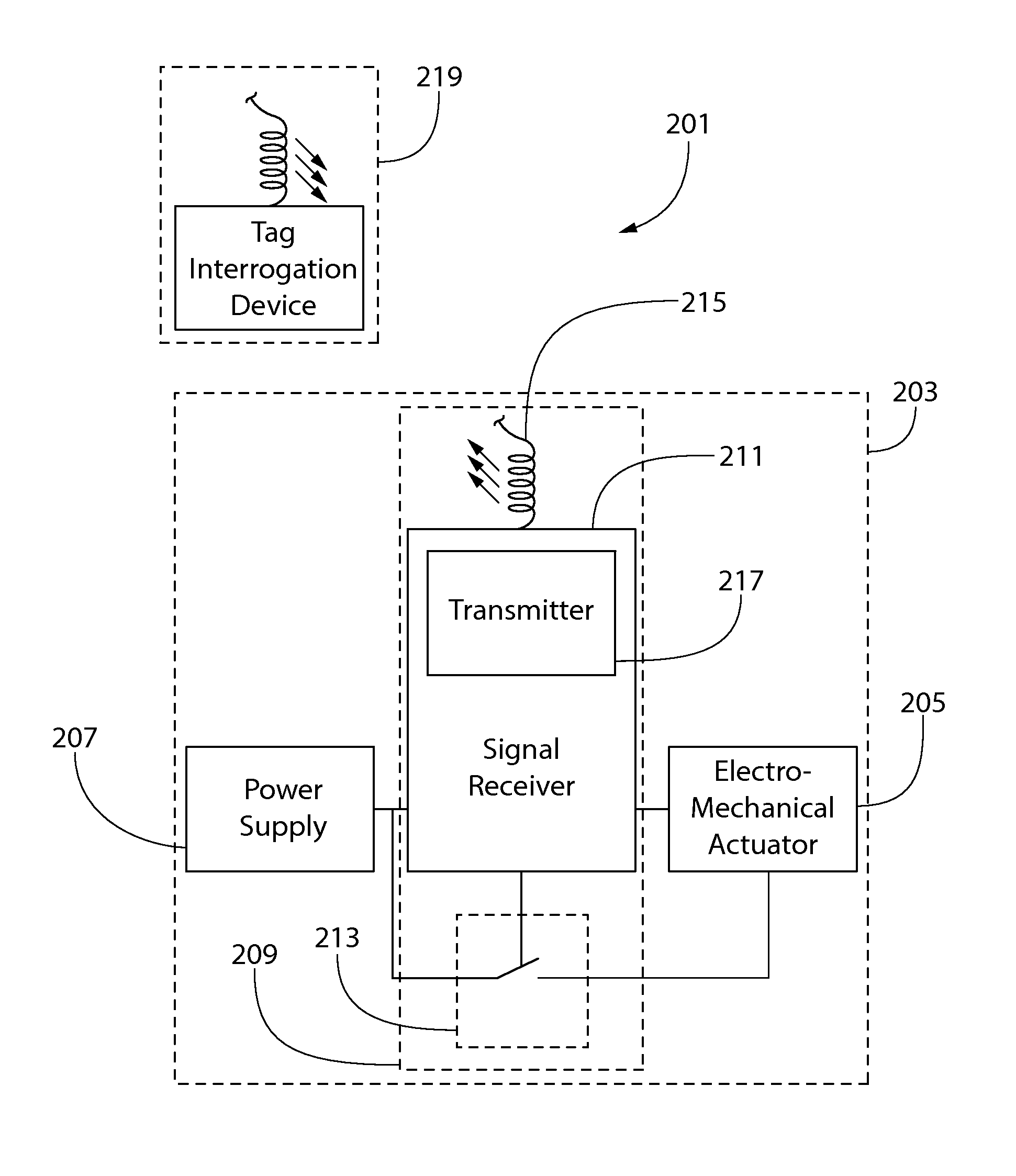

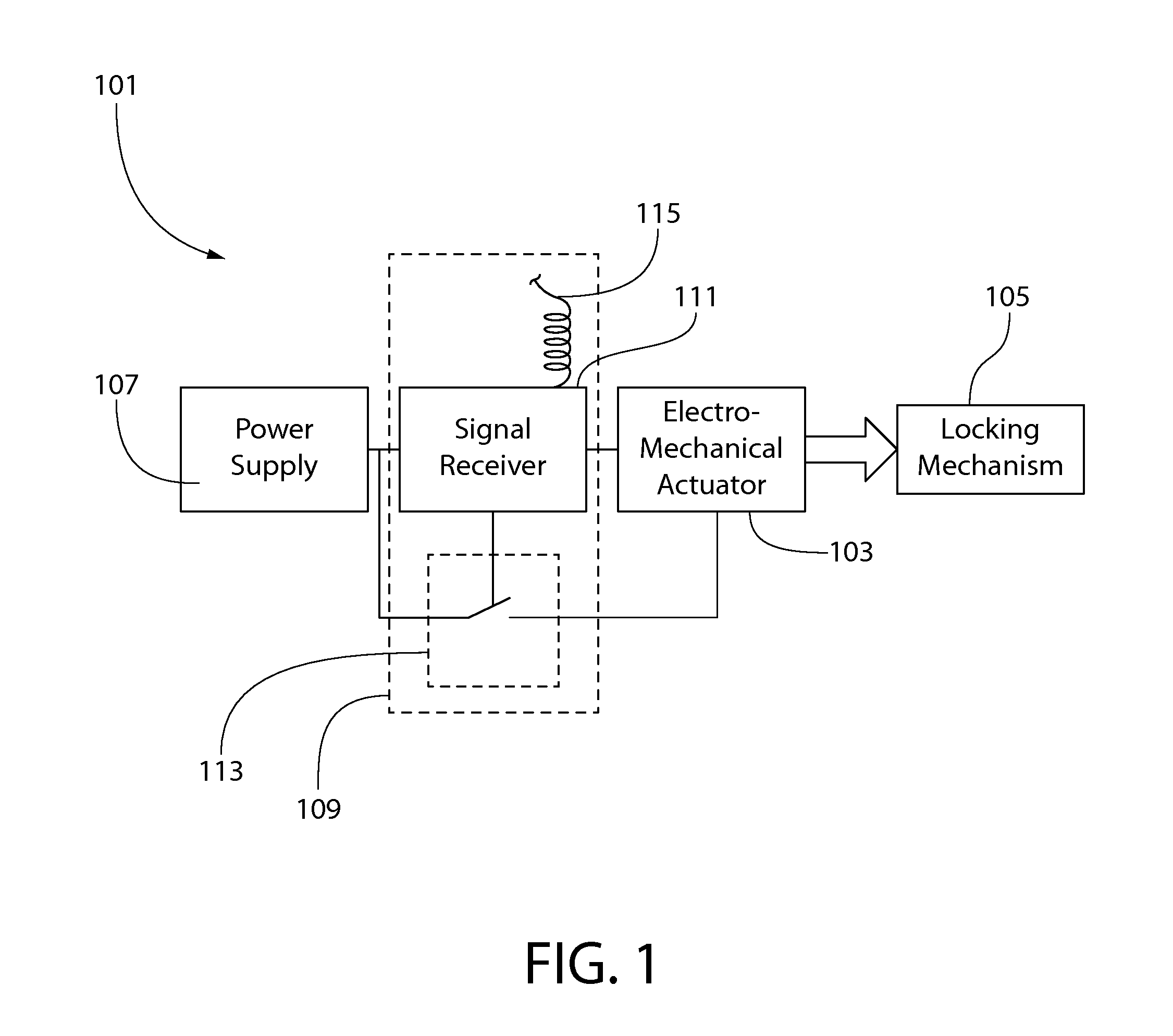

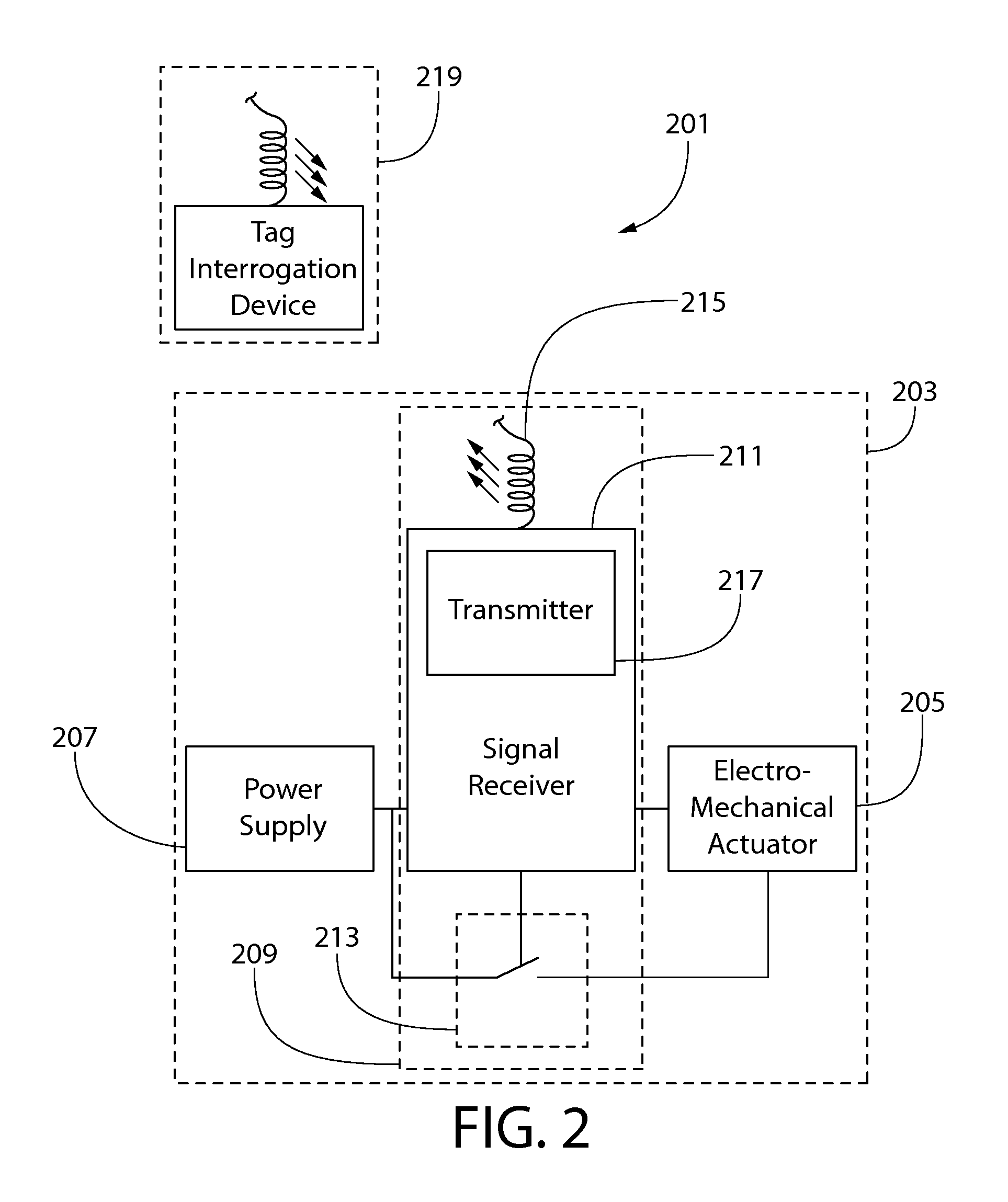

Merchandise security device having shape memory alloy actuator and method of use

InactiveUS20160321894A1Locks for portable objectsNon-mechanical controlsLocking mechanismEngineering

In one aspect of the present disclosure, a security device includes a body housing configured to receive a coupler to affix the body housing to an article of merchandise; a locking mechanism configured to maintain the coupler in a fixed position with respect to the body housing and in retaining engagement with the article of merchandise; and a shape memory alloy (SMA) spring configured to alter from a first state to a second state in response to receipt of a wireless signal; wherein the alteration of the SMA spring from the first state to the second state enables the coupler to move with respect to the body housing.

Owner:CHECKPOINT SYST INC

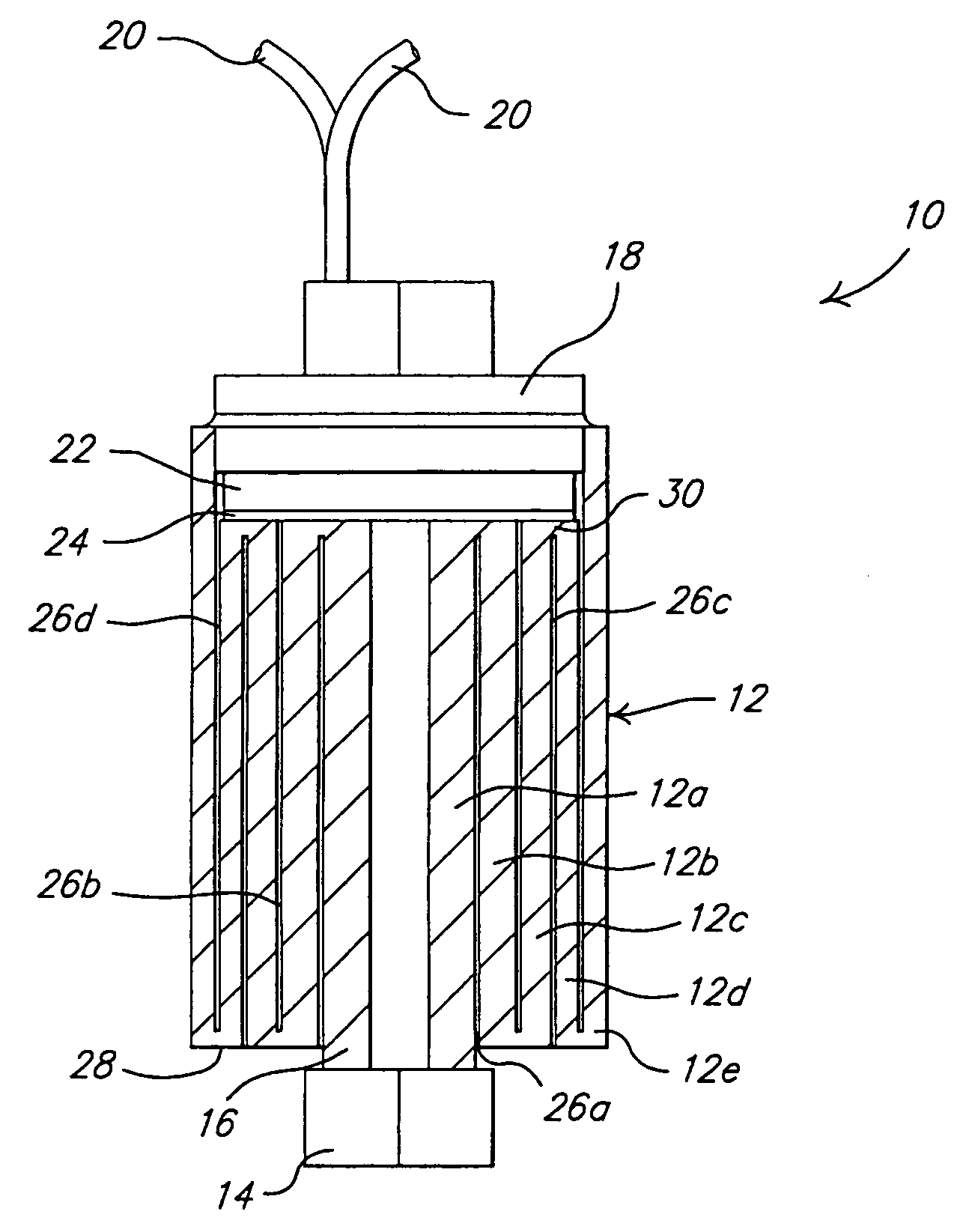

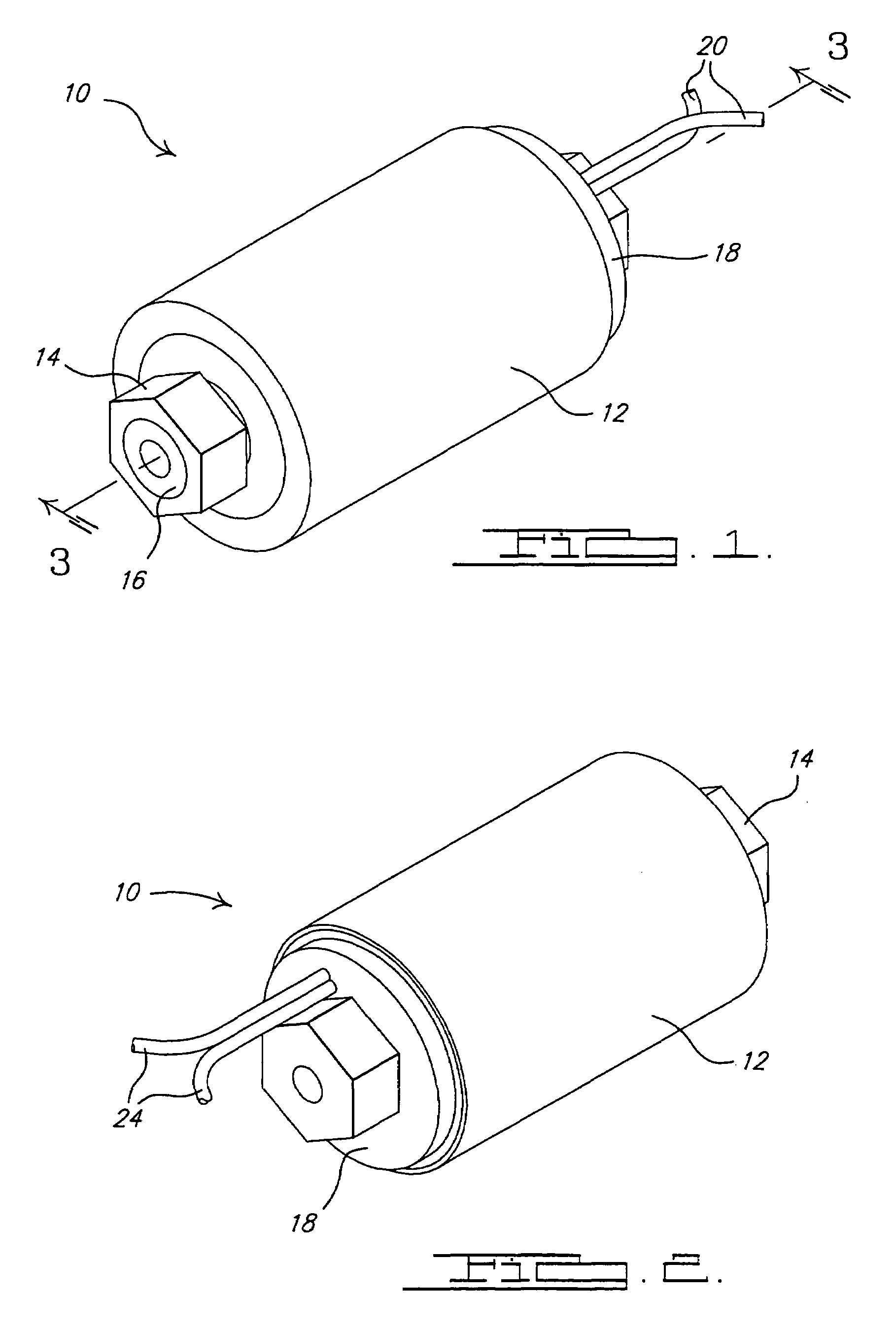

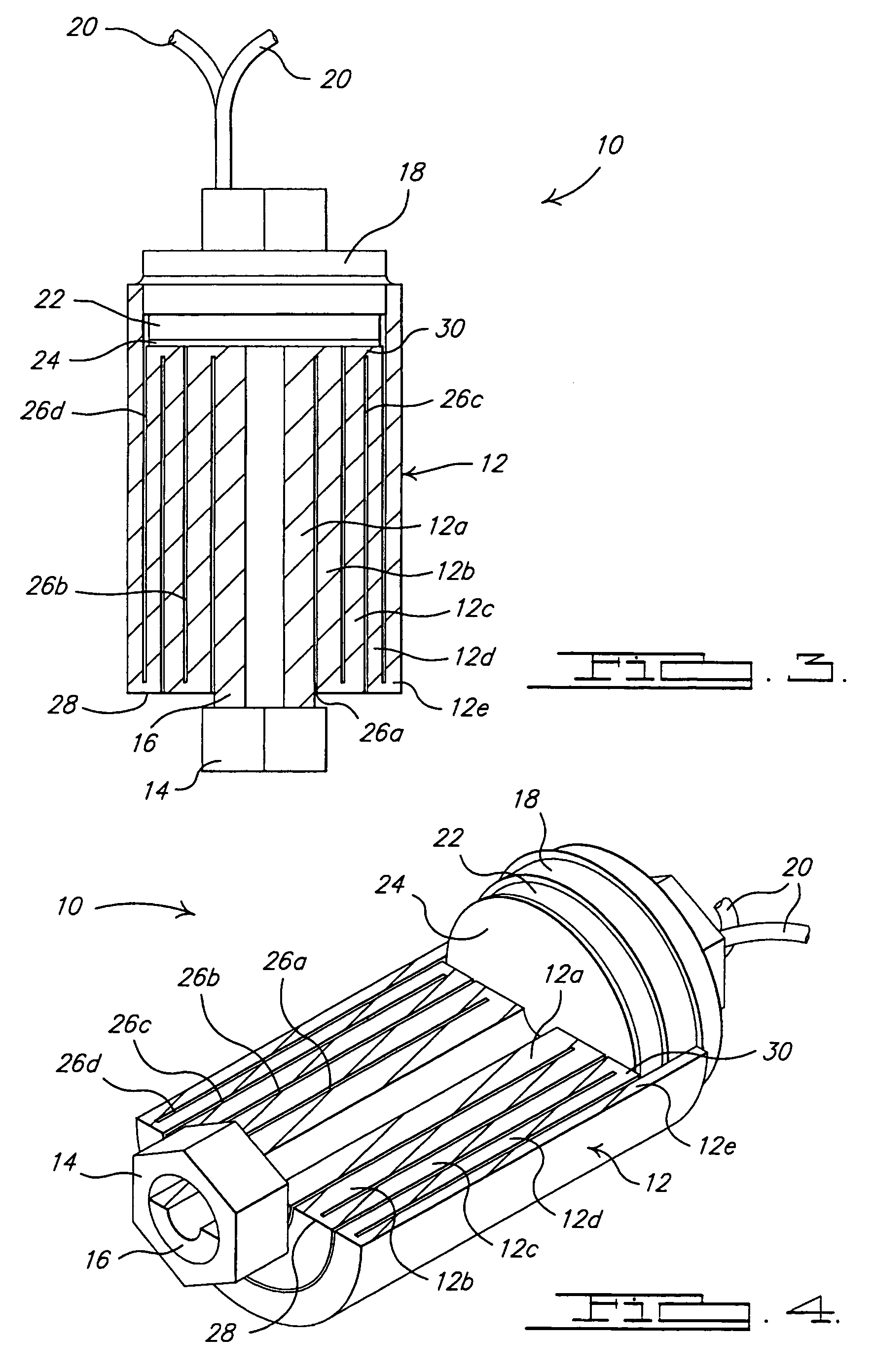

Shape memory alloy actuator

InactiveUS7021055B2Excursion can be increasedEasy to controlMechanical power devicesClosed-cycle gas positive displacement engine plantBobbinEngineering

Actuators that employs a shape memory alloy component as the driving element include linear and rotational devices. An Intrinsic Return Means (IRM) may be imparted to the SMA actuator, thereby reducing the use of a spring return mechanism. The rotational actuator may include a cylindrical bobbin with a helical groove to receive an SMA wire. A number of turns may be placed in a small length of bobbin to amplify the rotational excursion. In another rotational actuator, a plurality of narrow, coaxial rings are provided, the rings being nested in close concentric fit or stacked in side-by-side fashion. Each ring is provided with a groove extending thereabout to receive an SMA wire and contraction of the wire causes each ring to rotate with respect to the adjacent ring. In an embodiment for linear actuation, the invention provides a bar-like component having SMA wires joined between bars. The invention includes a lost motion coupling to join two counter-acting SMA stroke amplification devices, whether linear or rotational.

Owner:PERIHELIAN

Torque controlled antagonistic shape memory alloy actuator

A rotational actuator assembly employs a drive torque actuator having a shape memory alloy (SMA) tube with a first trained twist direction and a return actuator having a SMA tube with an opposite trained twist direction collinear with the drive torque actuator with abutting proximal ends. A central fitting joins the proximal ends. A control system employs a position sensor for the drive torque actuator and the torque sensor for the return actuator for combined antagonistic rotation of the central fitting.

Owner:THE BOEING CO

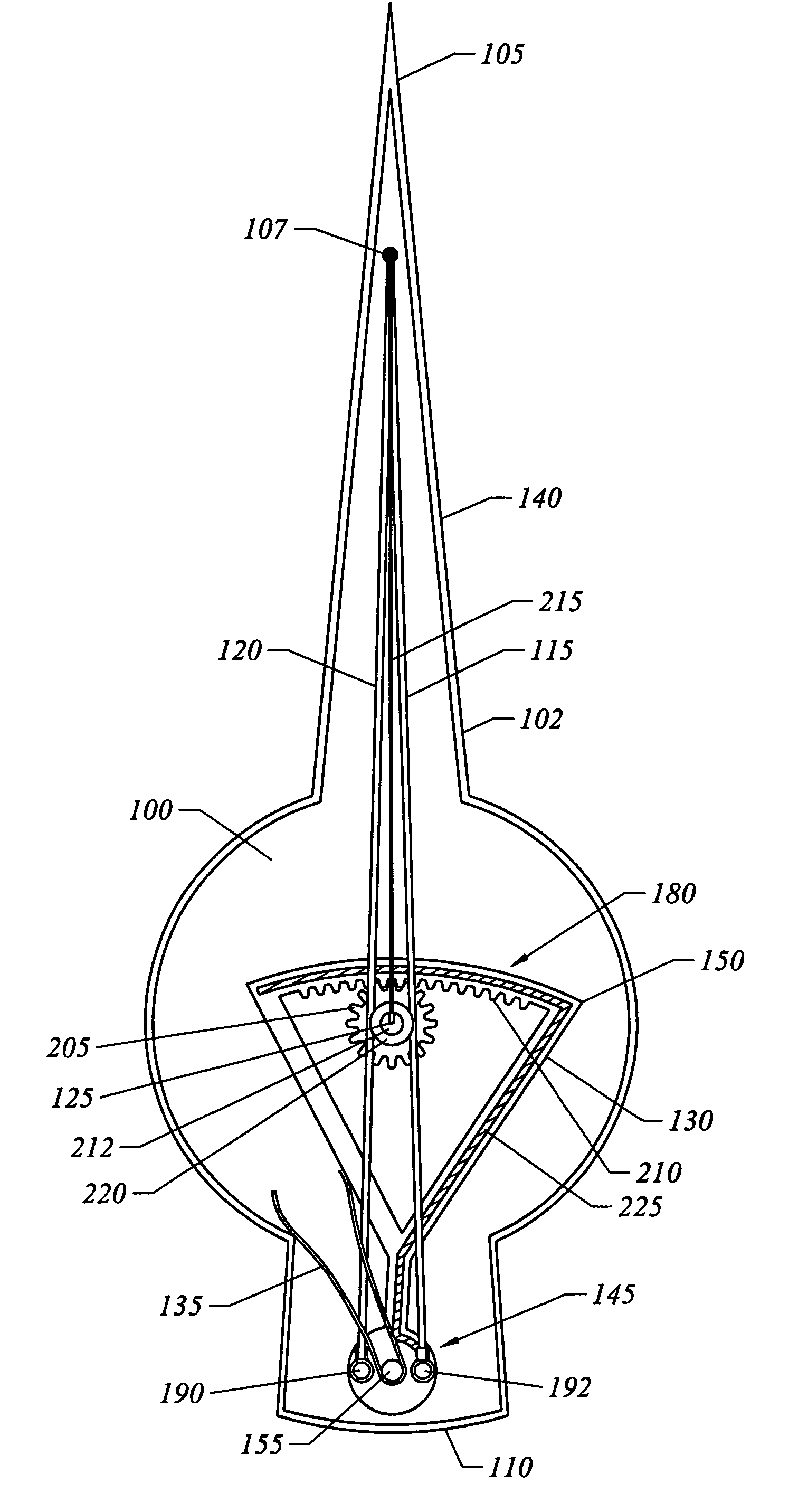

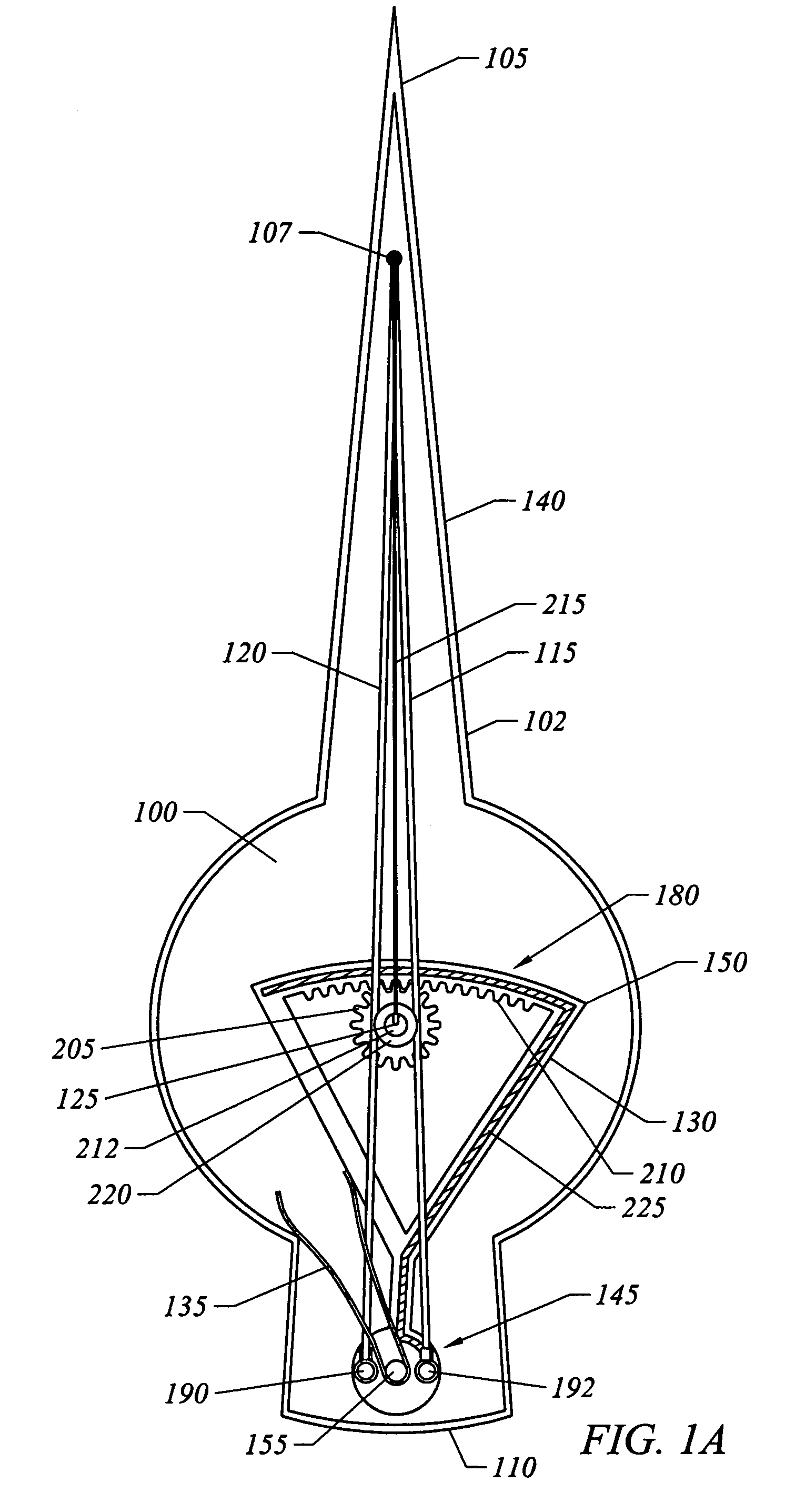

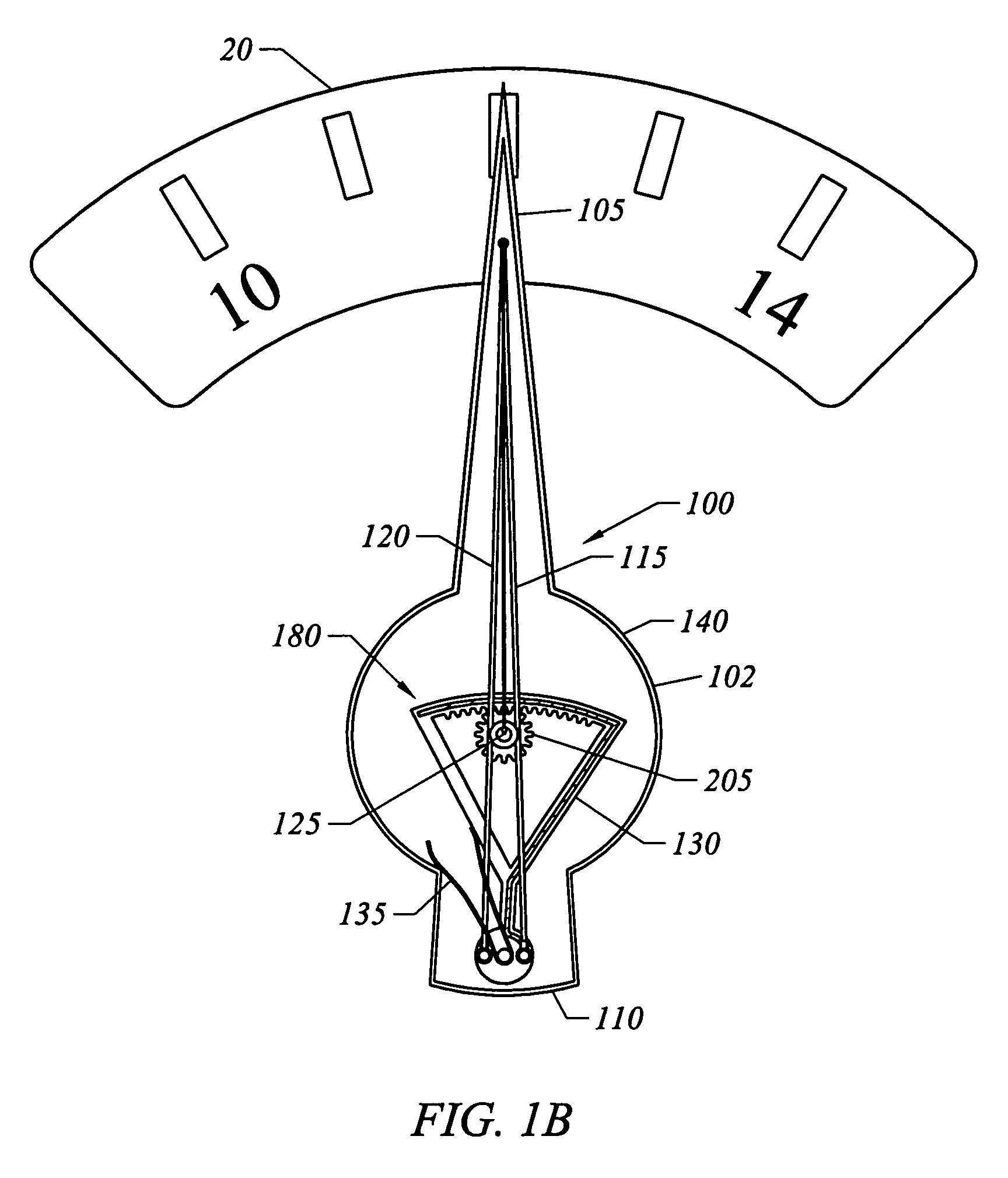

Gauge pointer with integrated shape memory alloy actuator

InactiveUS7082890B2Indicator componentsThermometers using material expansion/contactionAlloyMaterials science

An actuated gauge pointer that includes a shape memory alloy element configured to move the gauge pointer when activated is provided. The actuated gauge pointer includes a first shape memory alloy element disposed within the perimeter of the gauge pointer housing. Additionally, the actuated gauge pointer may include a second shape memory alloy element to provide temperature compensation, and a bias member to return the gauge pointer to an initial condition.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

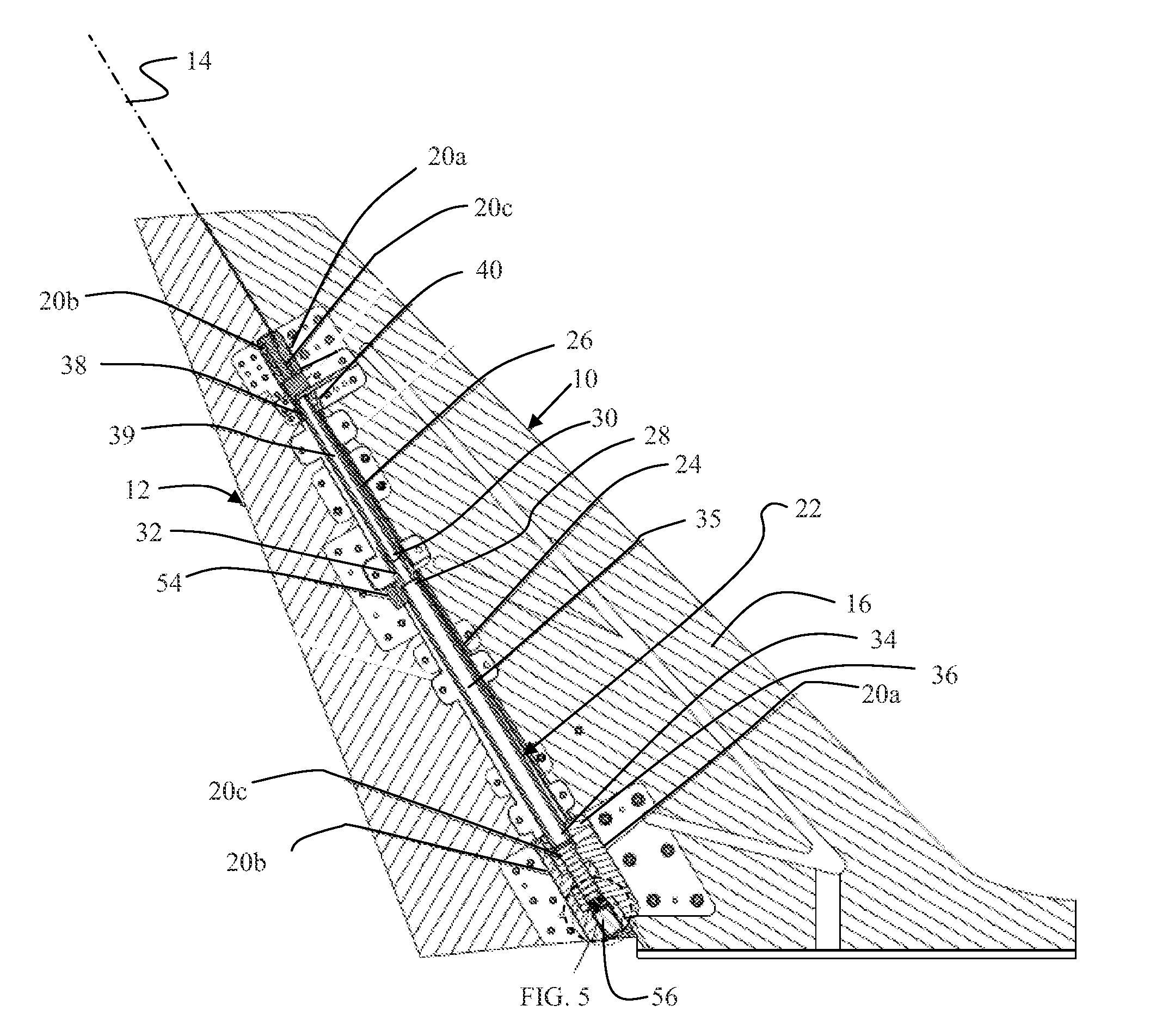

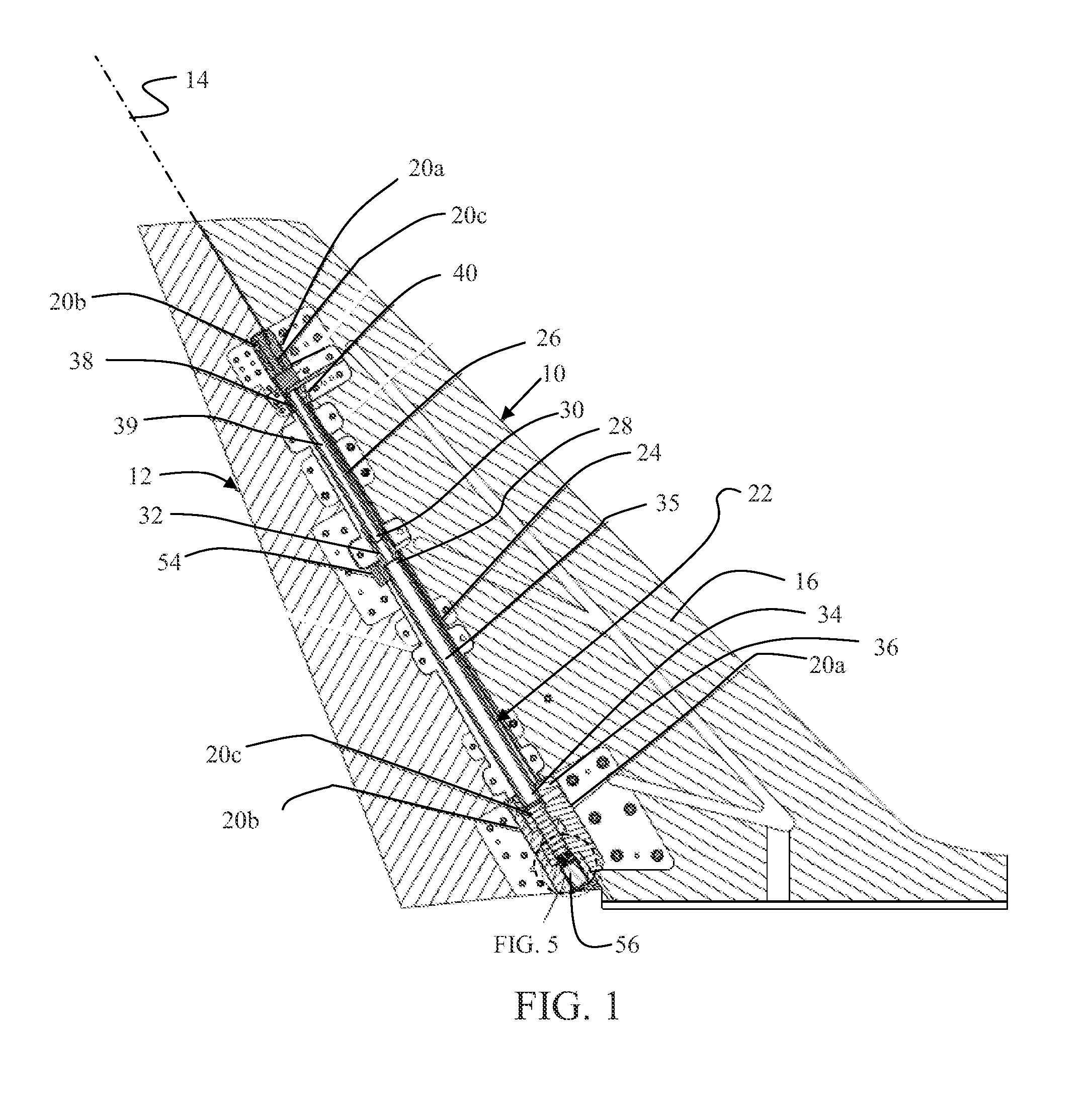

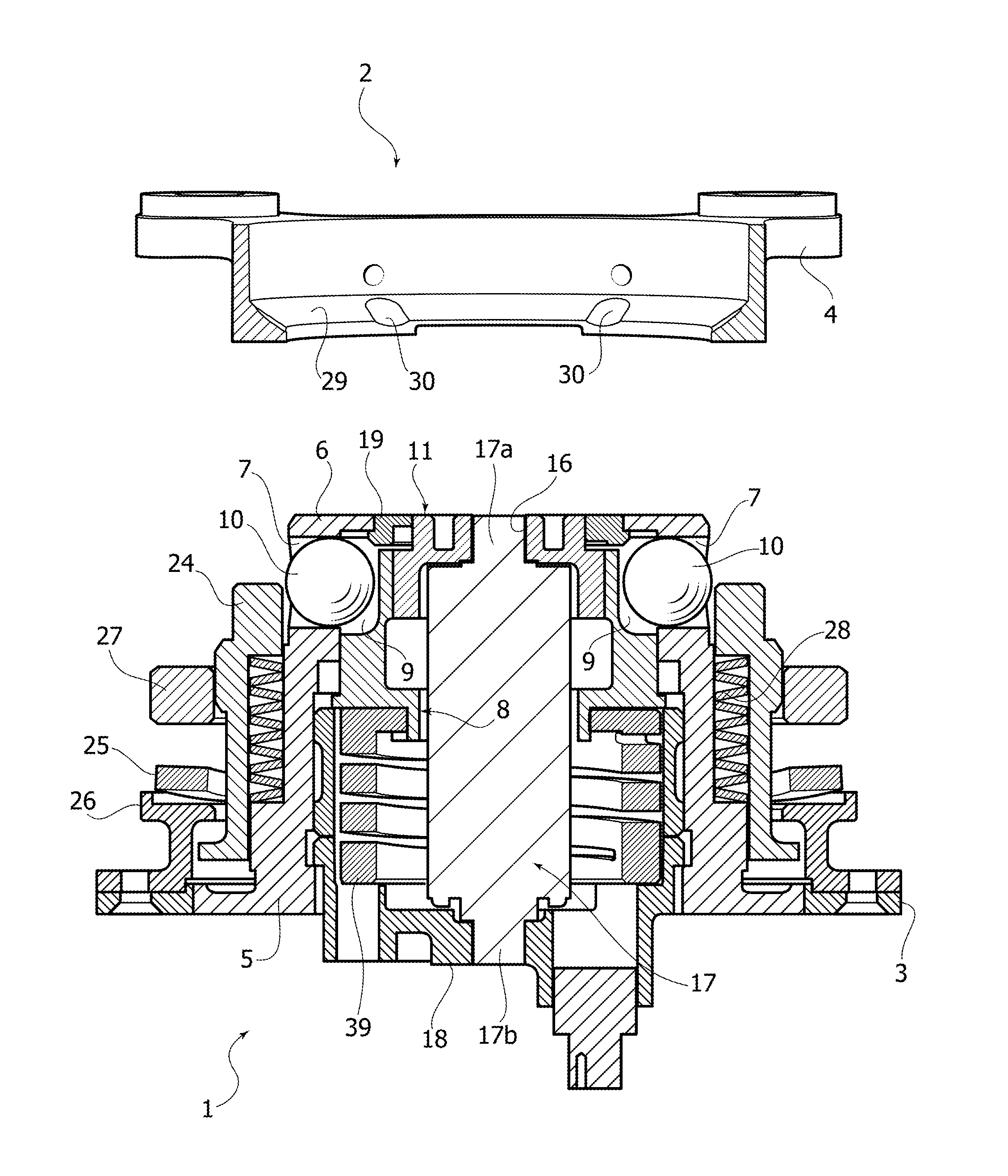

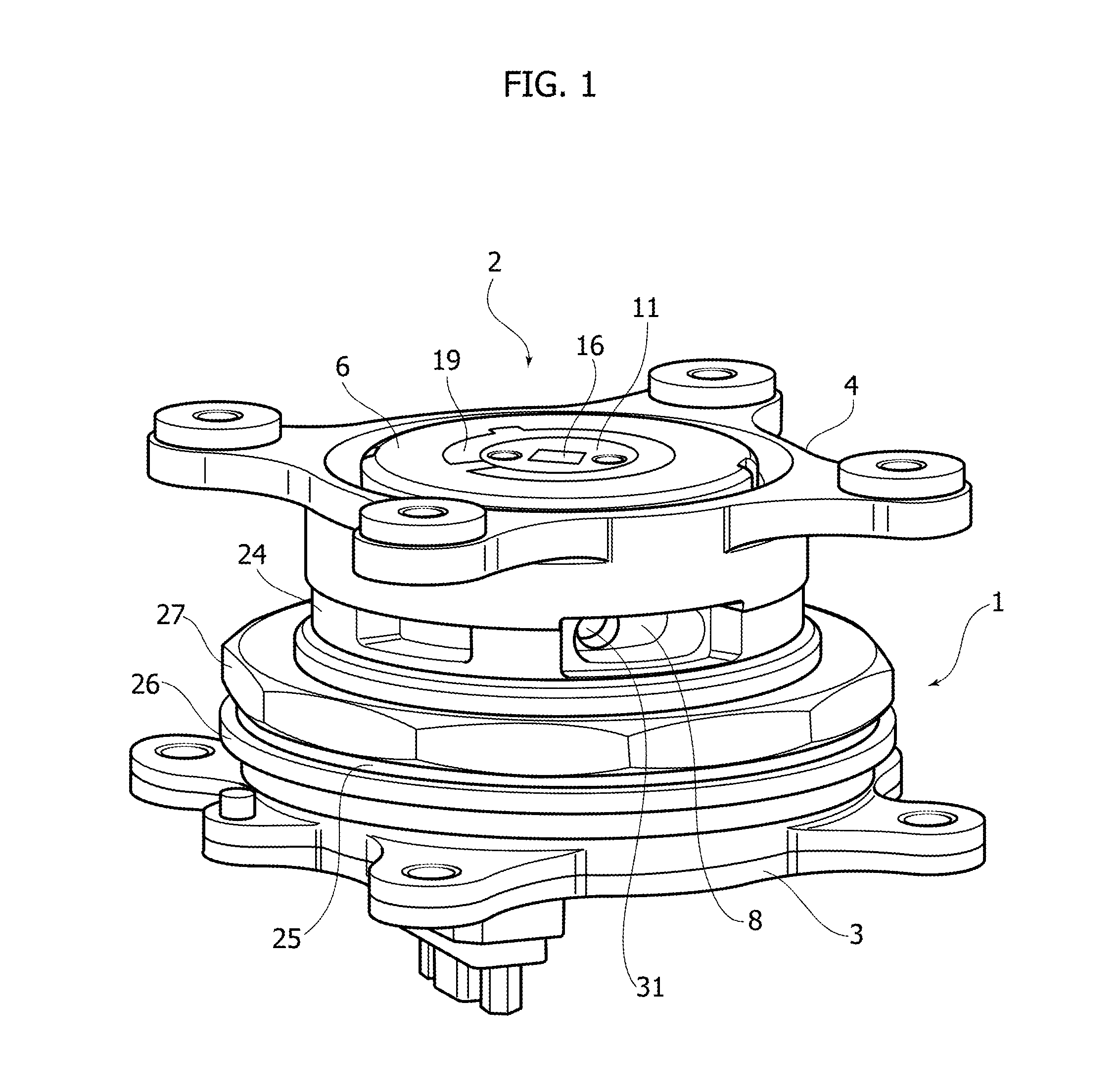

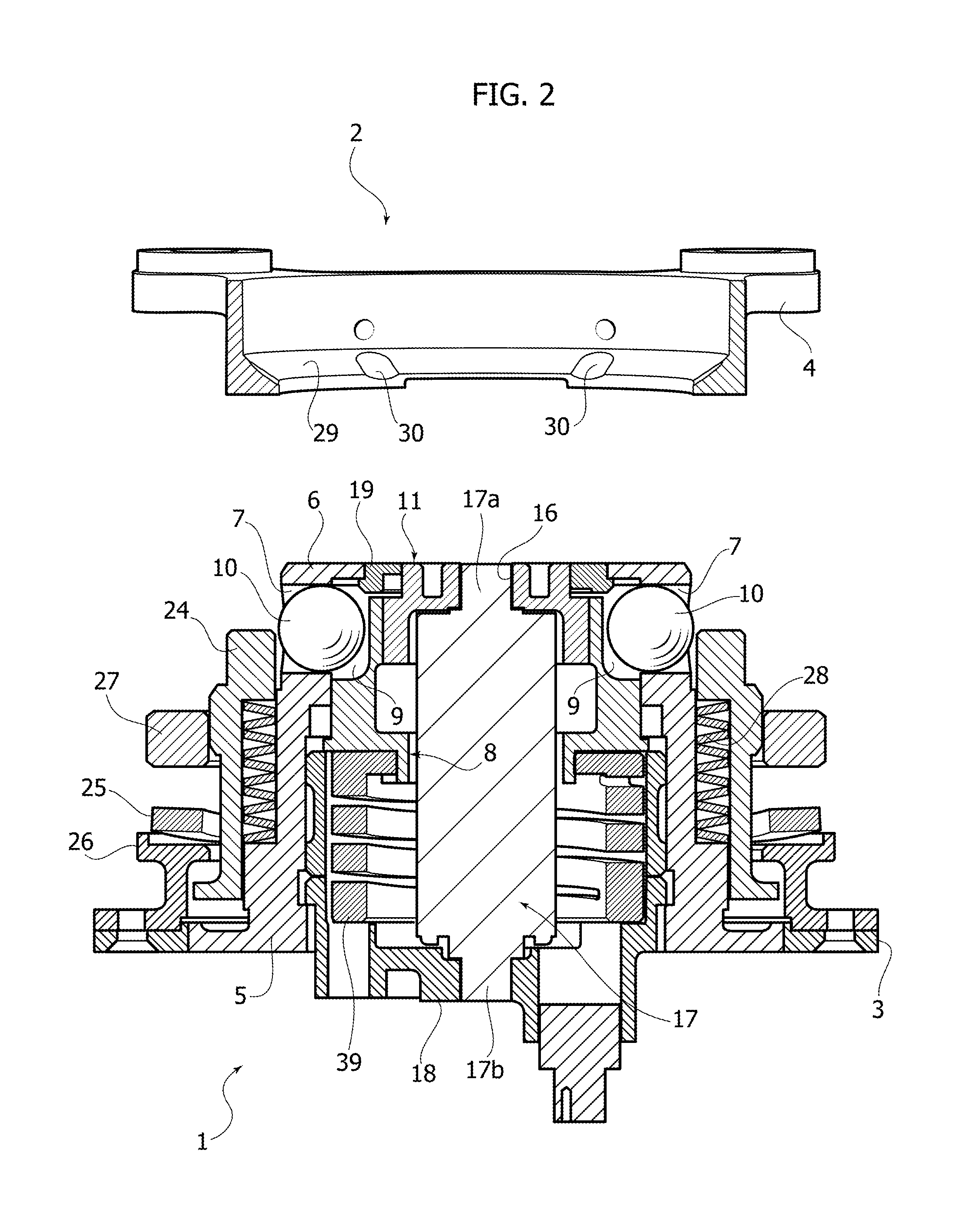

Device for holding and deploying apparatus for use in space

ActiveUS20160290323A1Small dimensionGood exploitationCosmonautic vehiclesCosmonautic power supply systemsAxial thrustEngineering

A device for holding and deploying apparatus for use in space includes a fixed body and a movable body coaxially connected to each other through balls displaceable from a retention position to a release position, and a shape memory alloy actuator remote-controllable to displace the balls from the retention position to the release position and the ensuing separation of the moveable body from the fixed body under the action of axial thrust elastic means. The shape memory alloy actuator consists of a torsionally-deformable bar.

Owner:AEREA

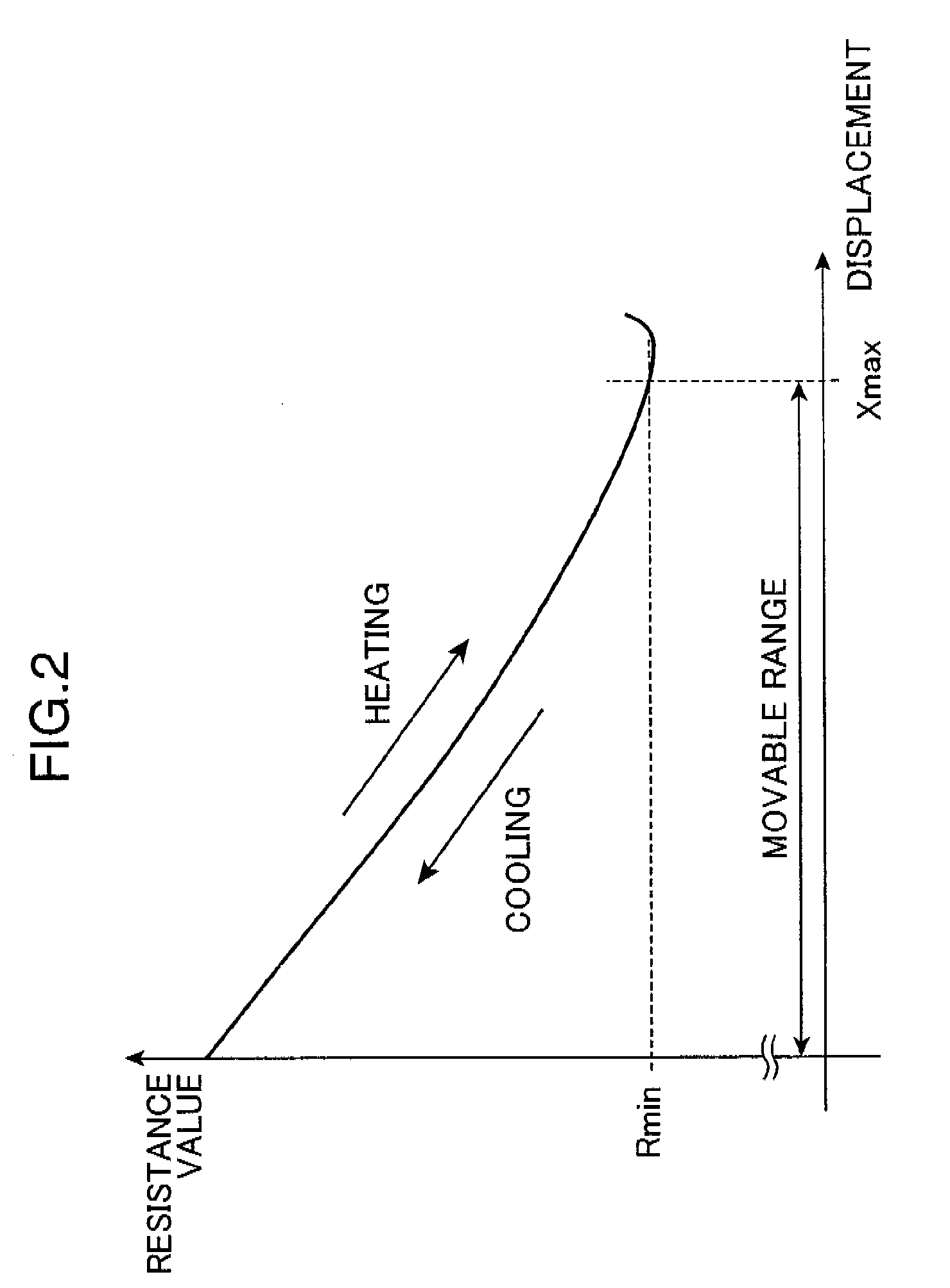

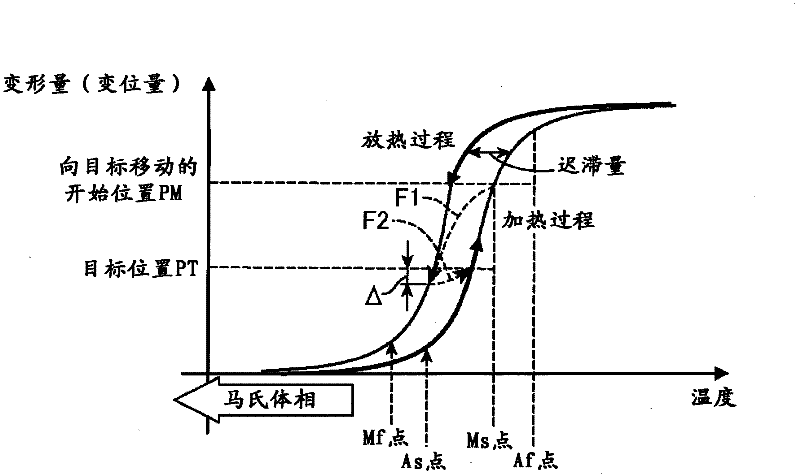

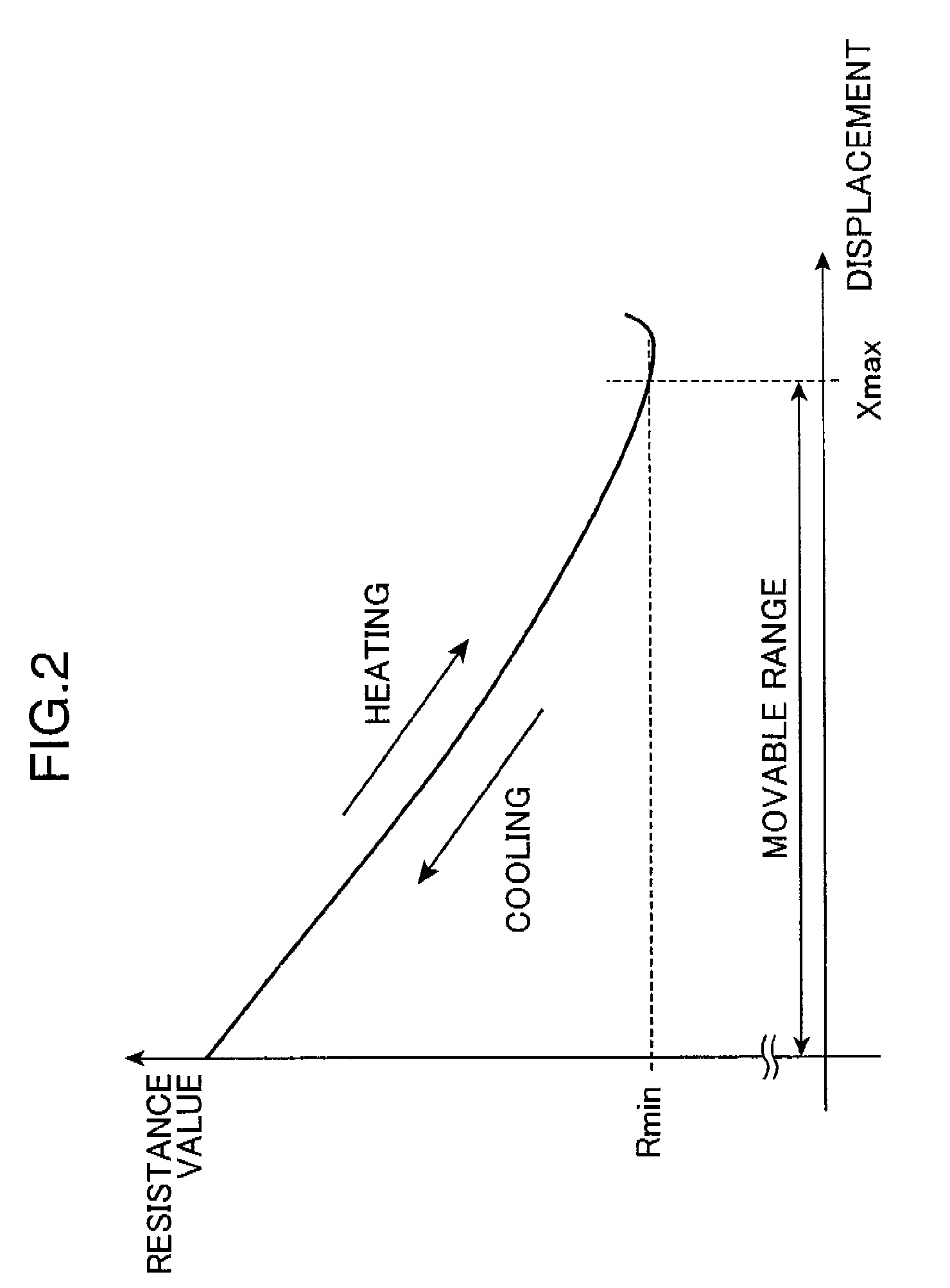

Driving device of shape memory alloy actuator, driving method thereof, and imaging device using same

InactiveCN102265032AIncrease temperatureIncrease or decrease in temperatureMachines/enginesMountingsHysteresisEngineering

The shape memory alloy actuator drive device (21) is configured such that a shape memory alloy (SMA 15) expands and contracts with temperature changes and has hysteresis for distortion characteristics of parameters regarding that expansion and contraction, wherein the parameter values corresponding to the target positions of a moving part, which is displaced and driven by the expansion and contraction of the SMA (15) as the temperature of the SMA (15) rises and falls, are measured by a measurement part and set as target parameters, the crystal phase of the SMA (15) is pre-martensitic, and the temperature of the SMA (15) is caused to rise or fall so that the parameter value measured by the measurement part passes the target parameter, after which, the temperature of the SMA (15) is again caused to rise or fall so that the parameter measured by the measurement part reaches the target parameter.

Owner:KONICA MINOLTA OPTO

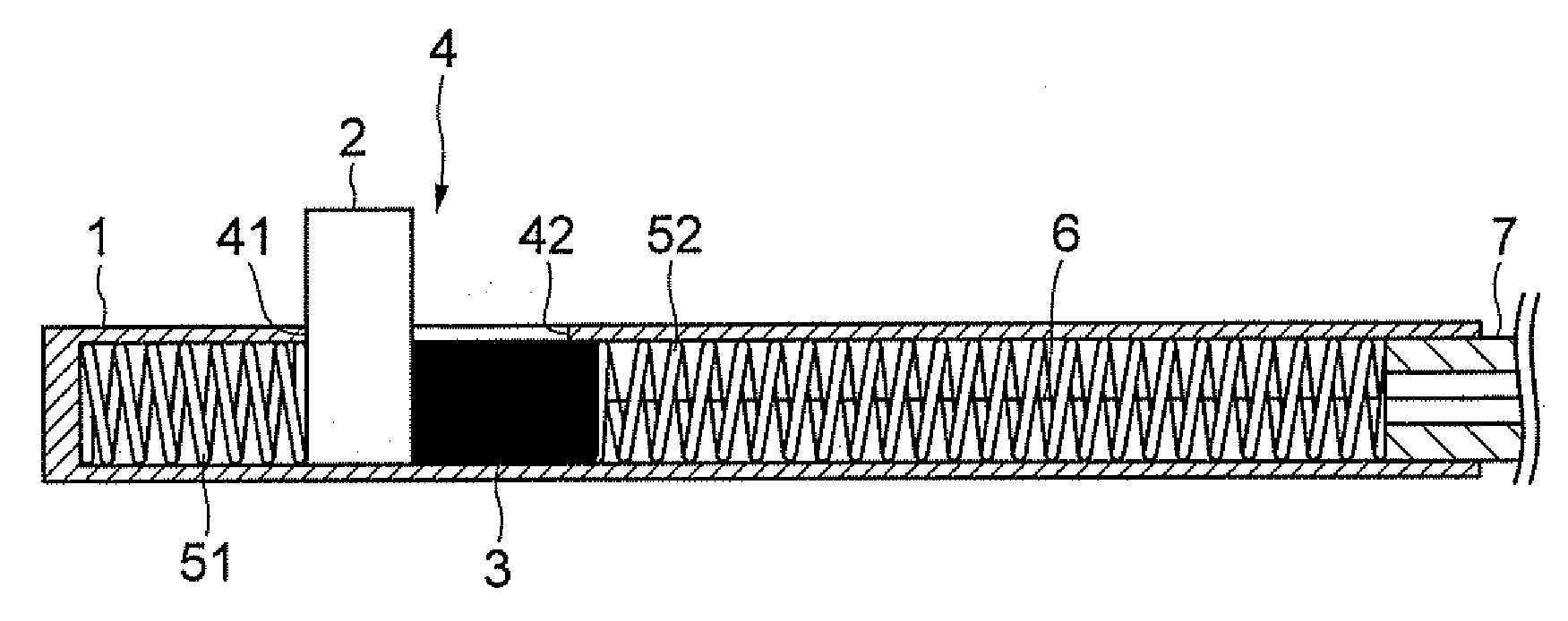

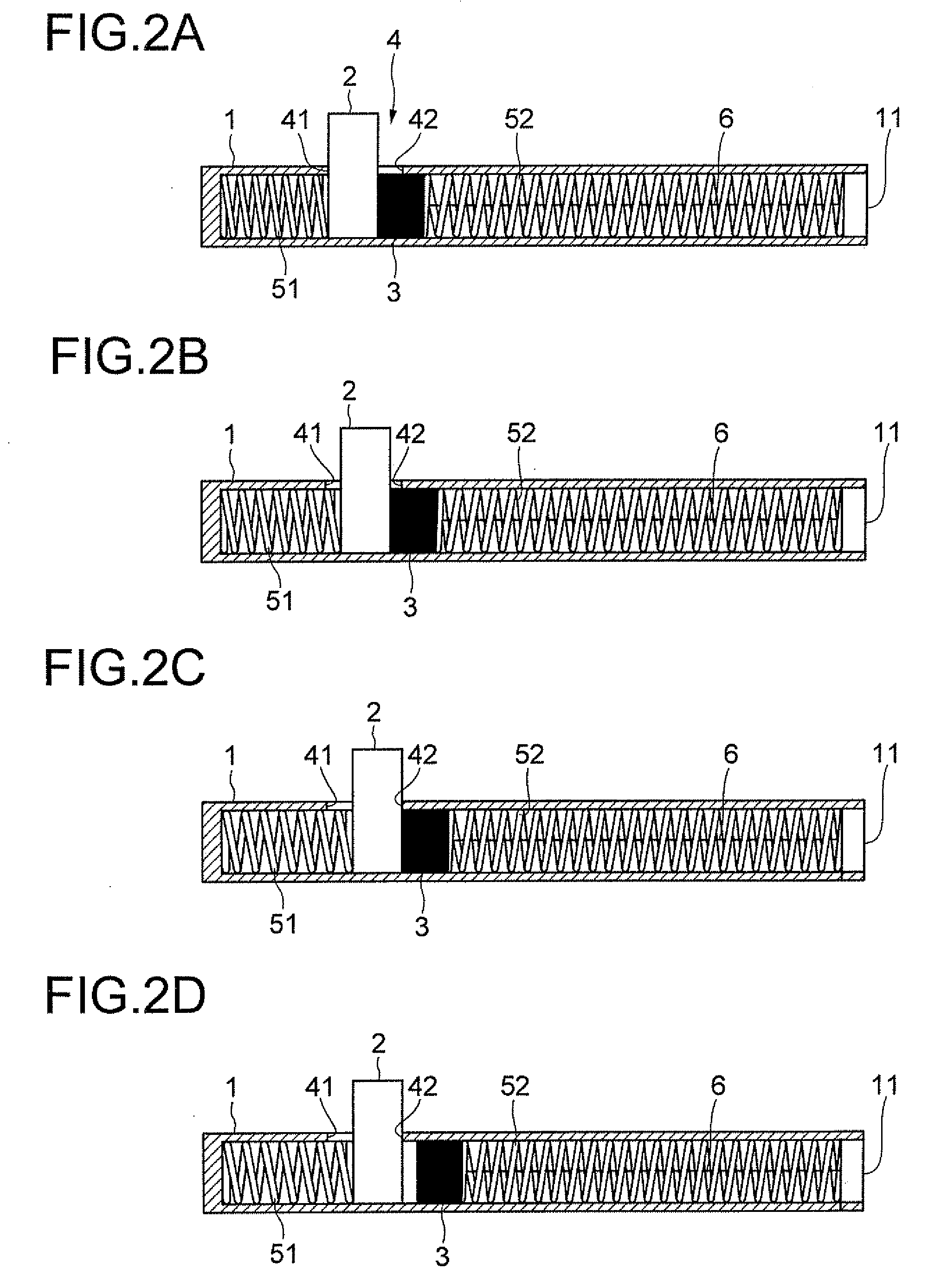

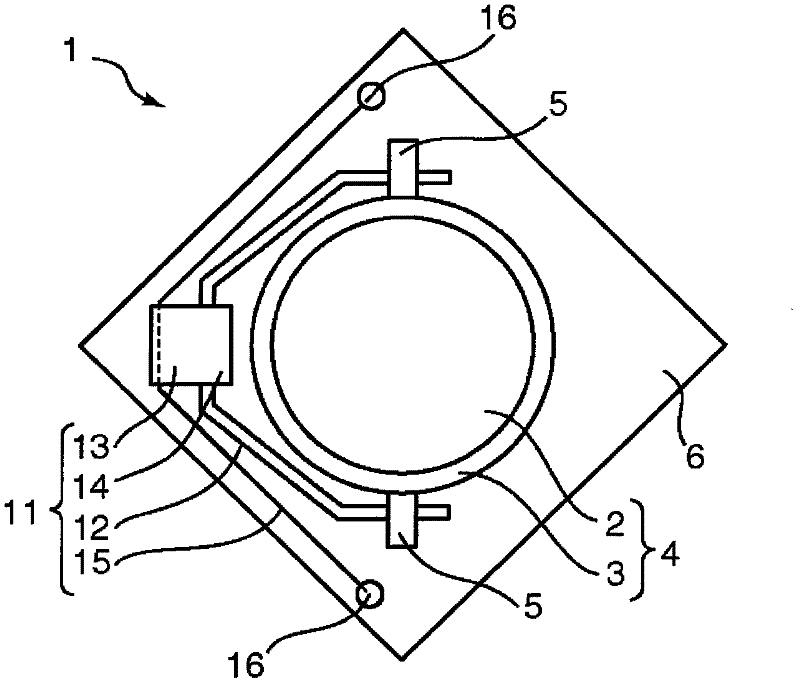

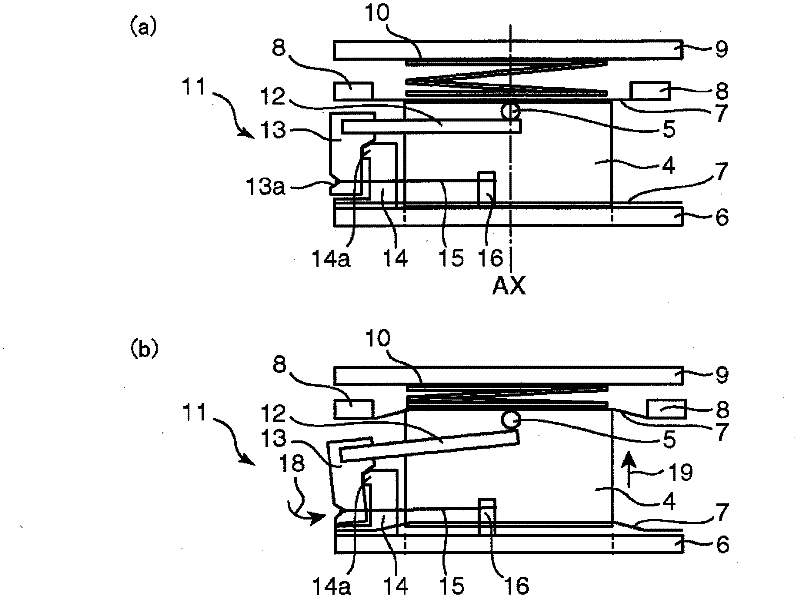

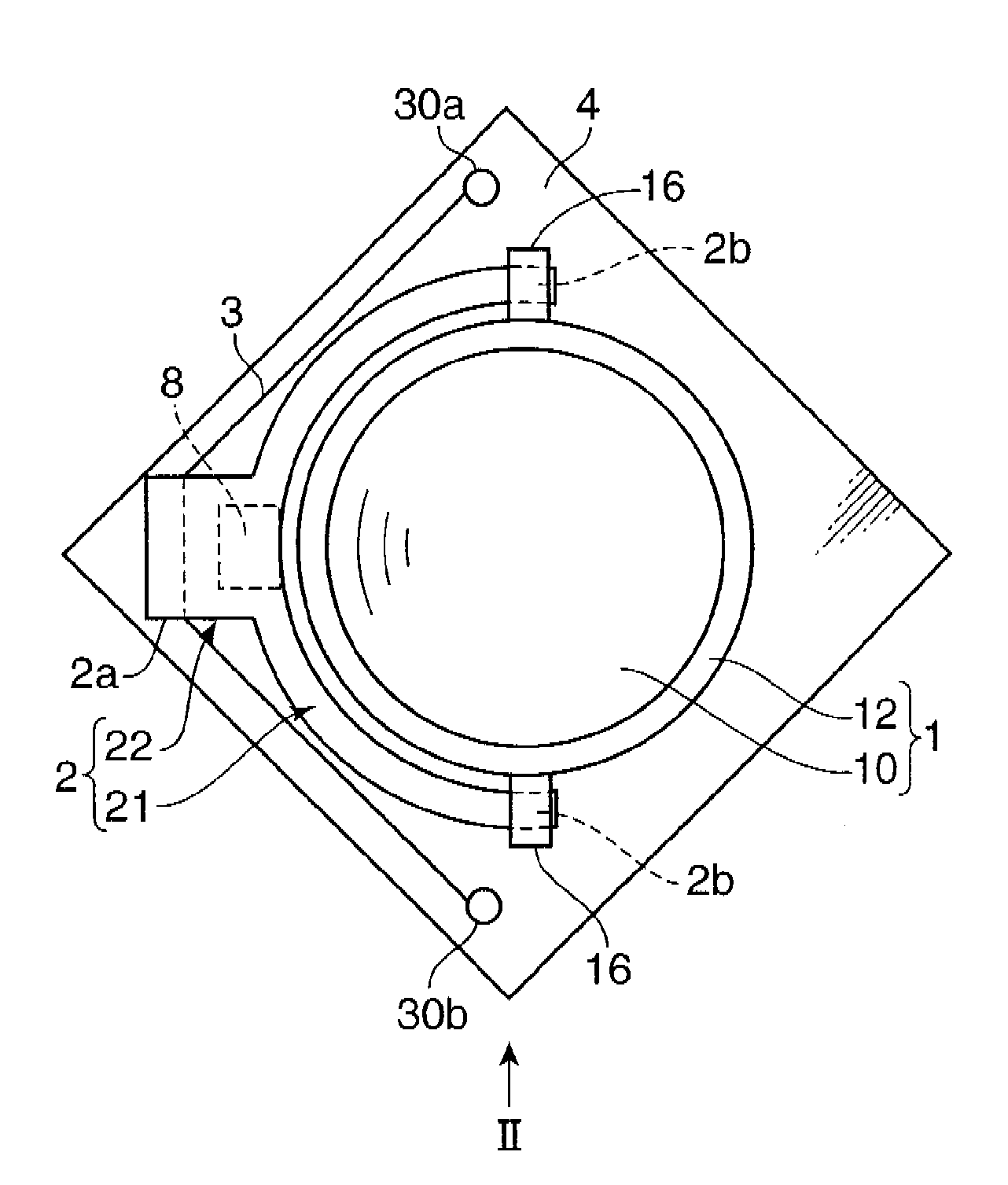

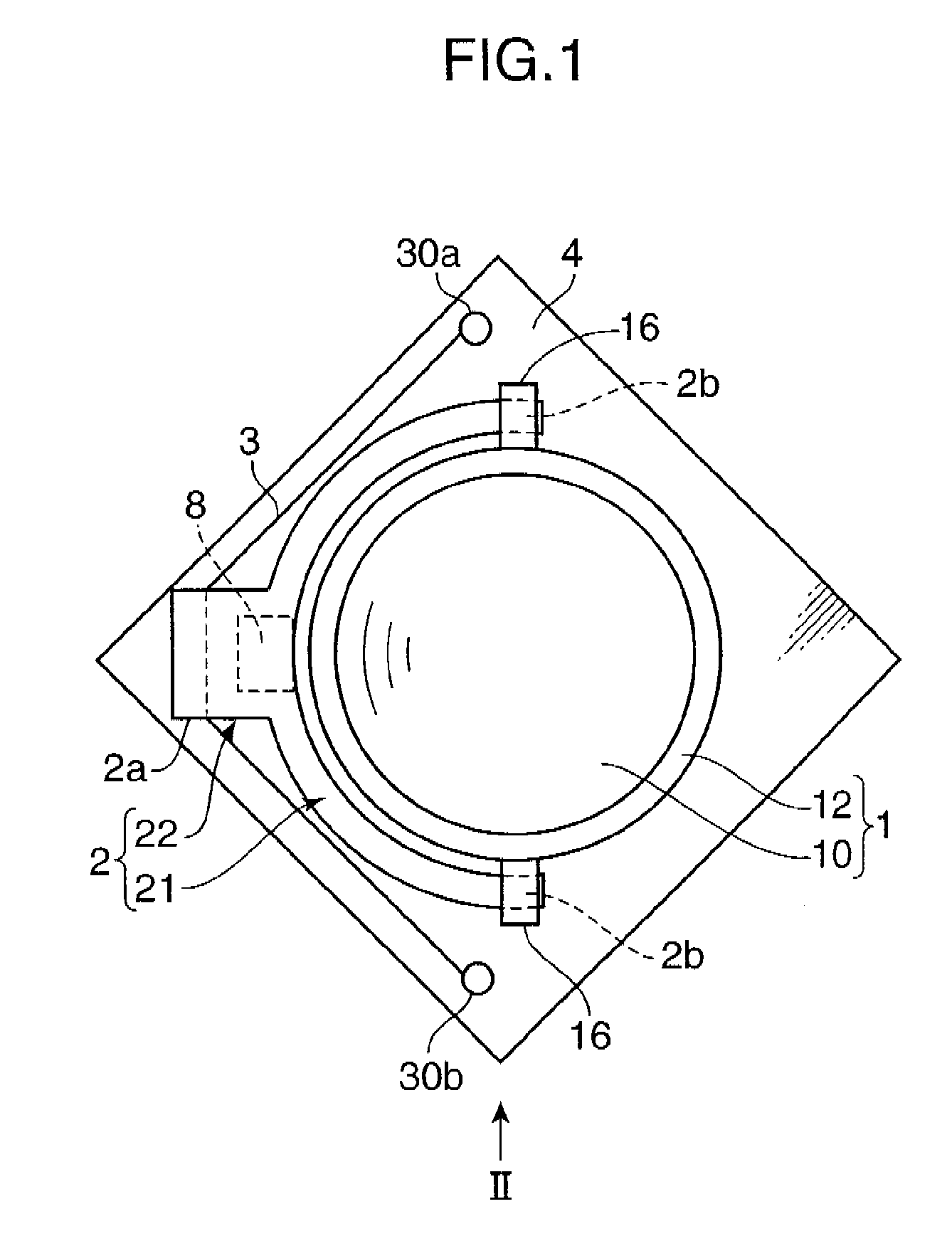

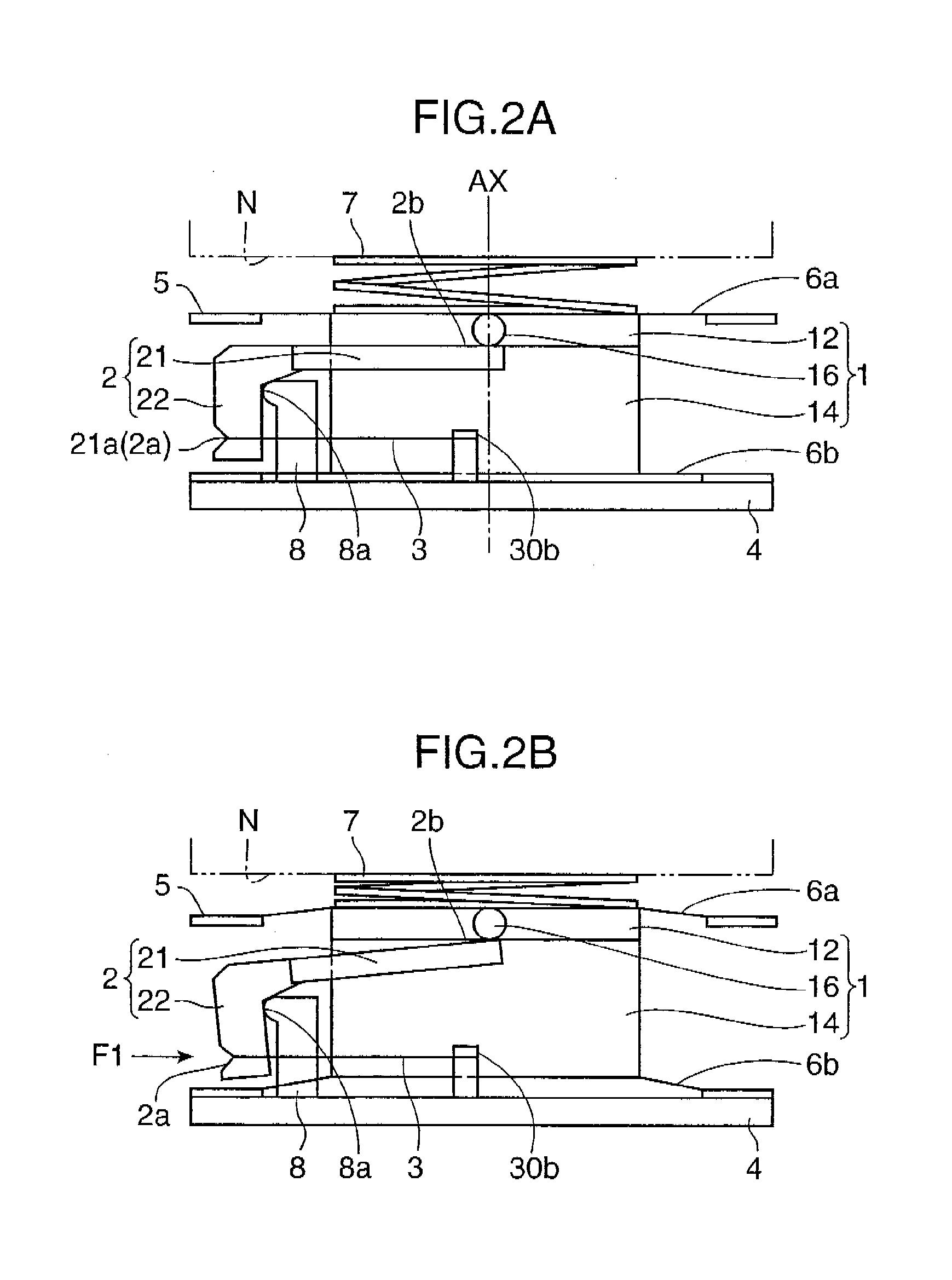

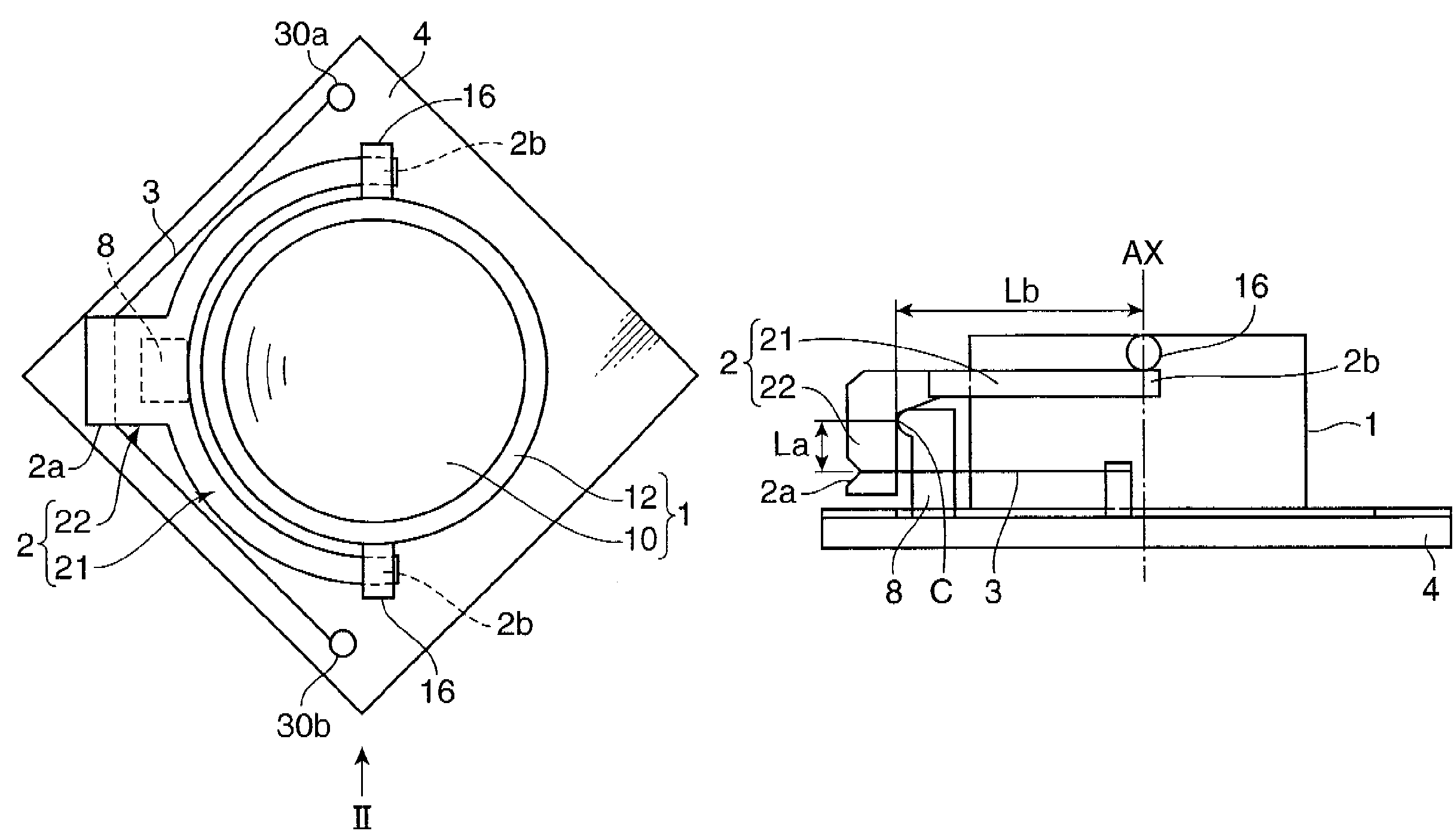

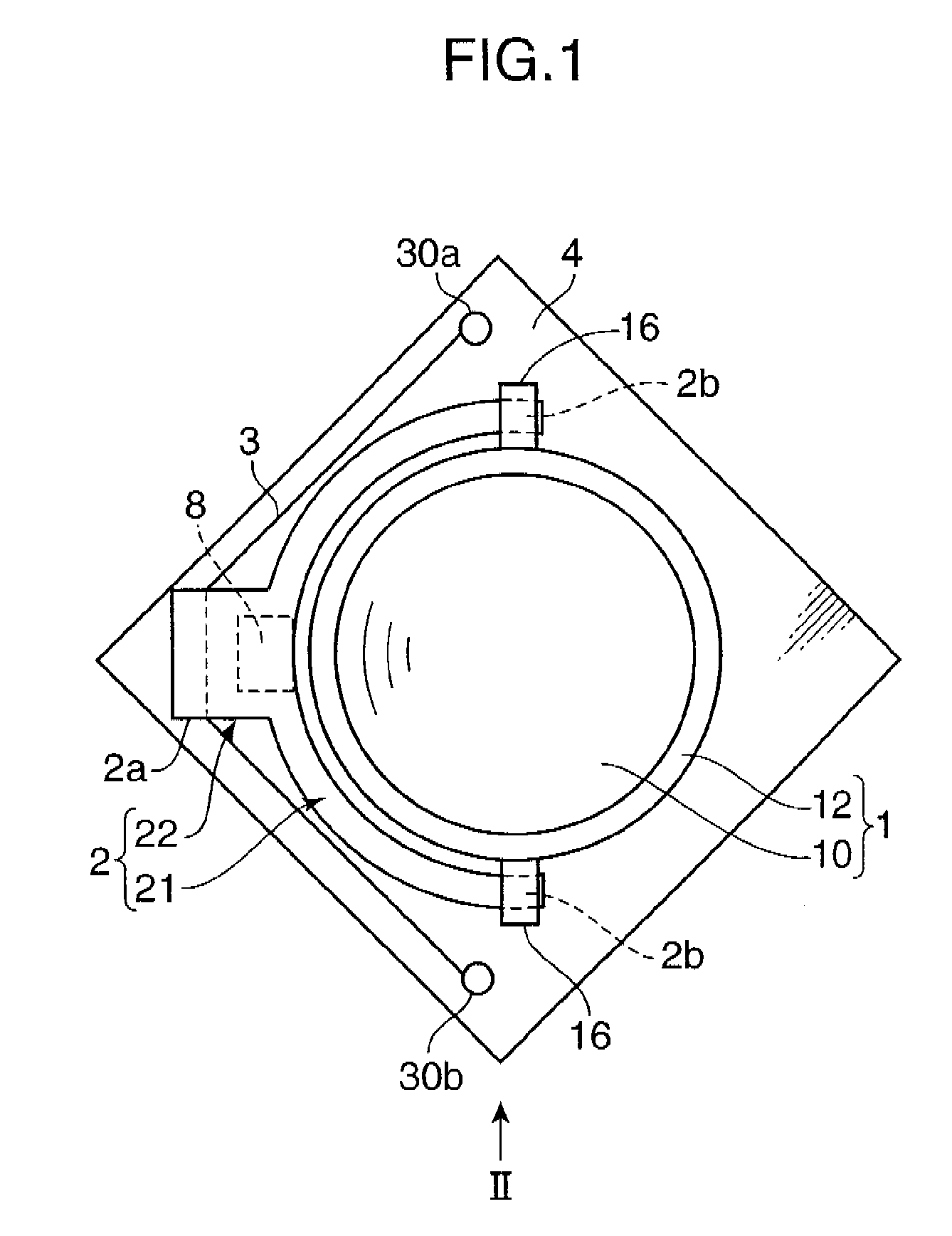

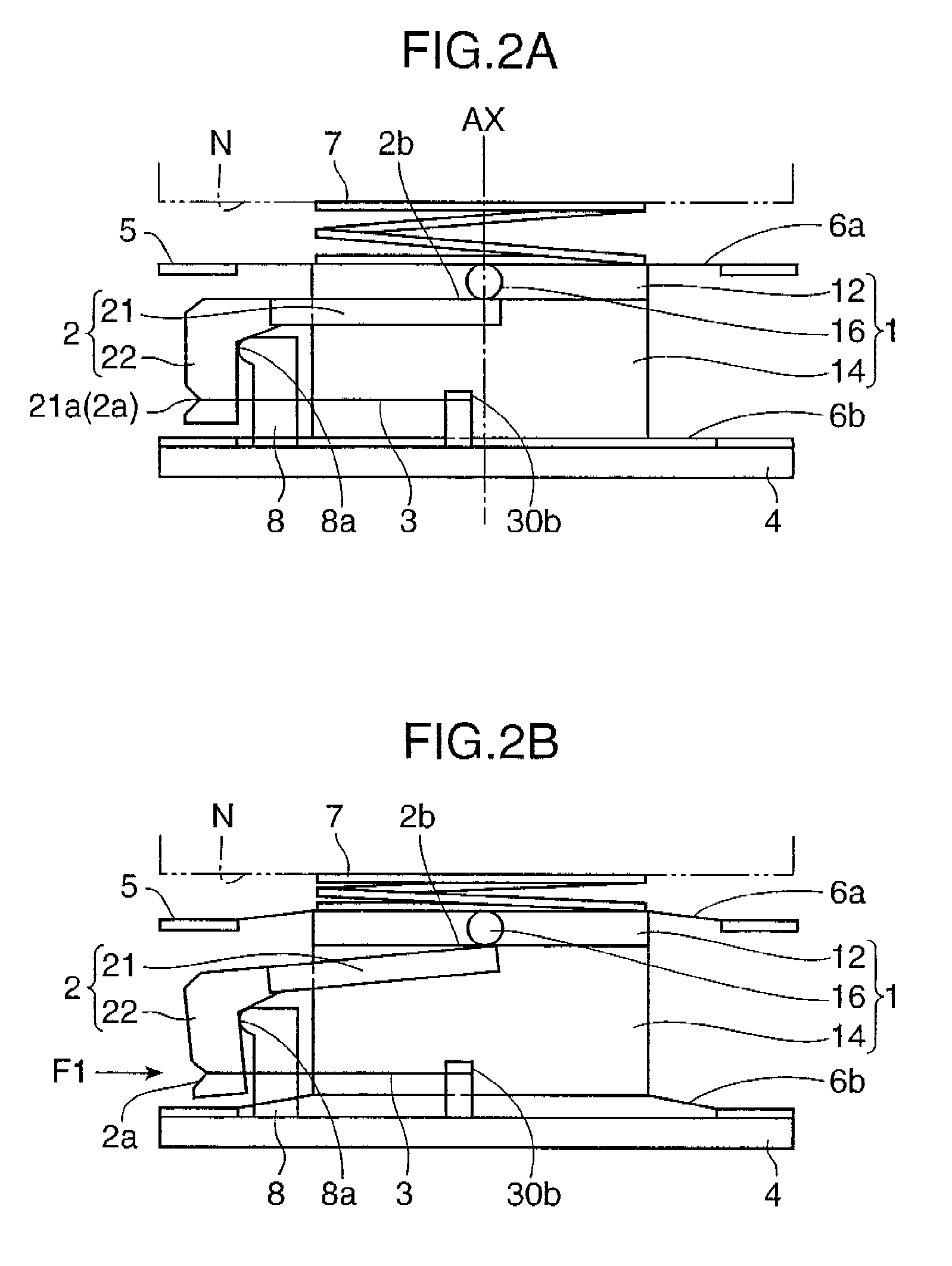

Driving mechanism, driving device, and lens driving device

InactiveUS20090034094A1Stably movingSmall sizeProjector focusing arrangementCamera focusing arrangementCamera lensReduced size

A driving mechanism, a driving device, and a lens driving device includes a lever member. The lever member includes an arm portion for surrounding a part of a driven member in a side direction. The arm portion has a plurality of displacement output portions to be engaged with the driven member. The lever member is constructed in such a manner that a displacement amount of the displacement output portions in a predetermined first axis direction is set larger than a displacement amount of a displacement input portion to be generated by input of a moving force to be applied by a shape memory alloy actuator. The driving mechanism, the driving device, and the lens driving device enable to obtain a large displacement amount with a reduced size and a reduced weight, and stably move the driven member.

Owner:KONICA MINOLTA OPTO

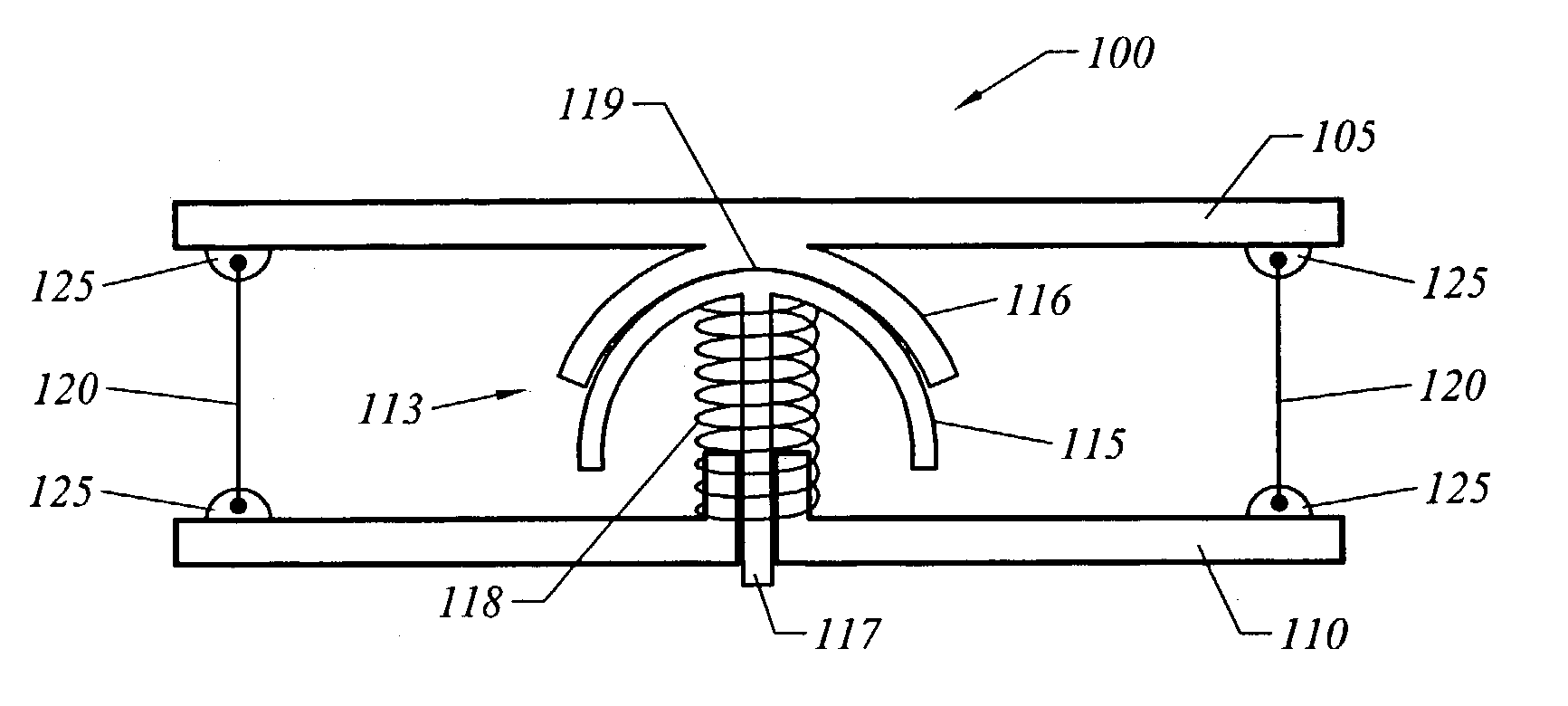

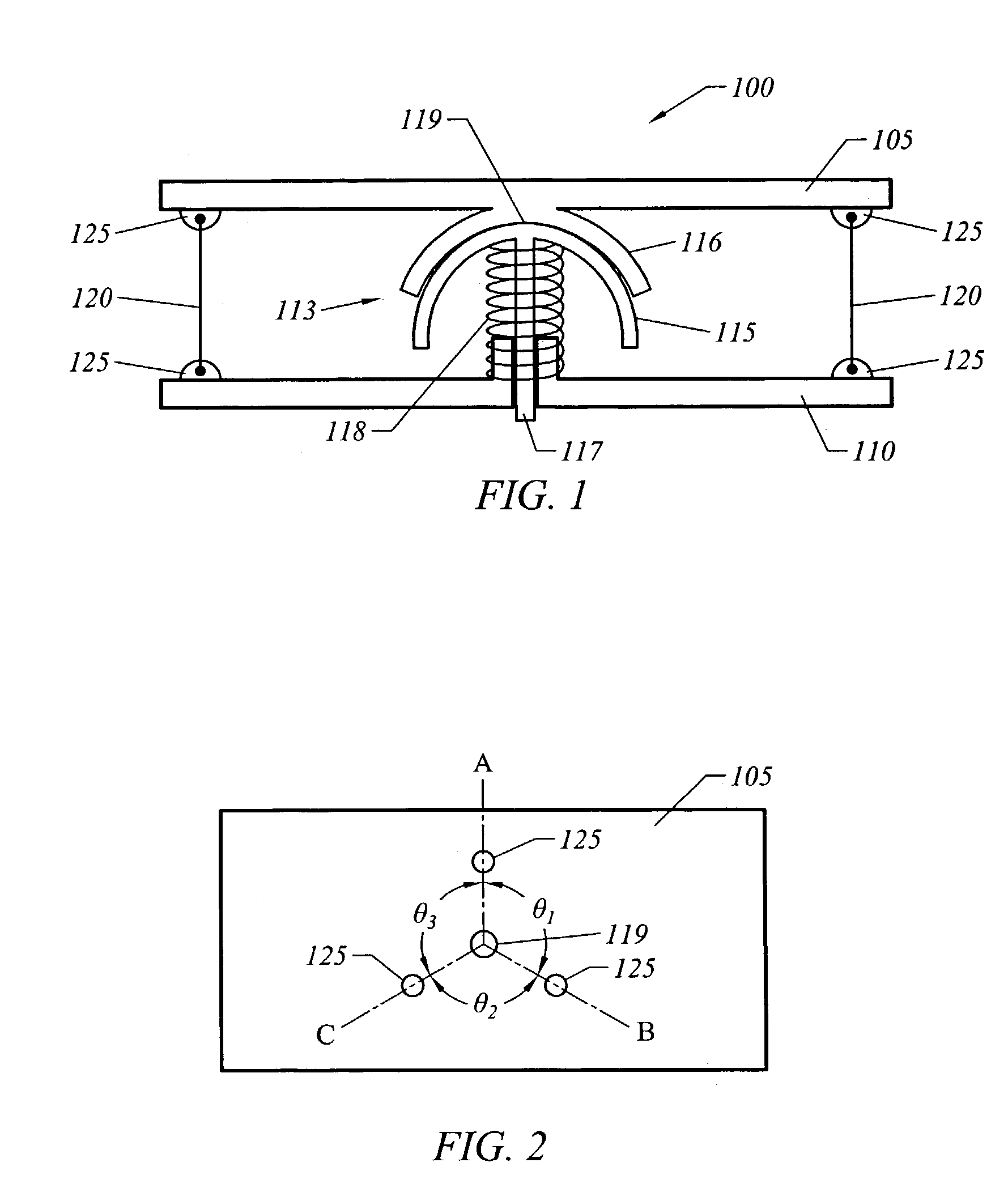

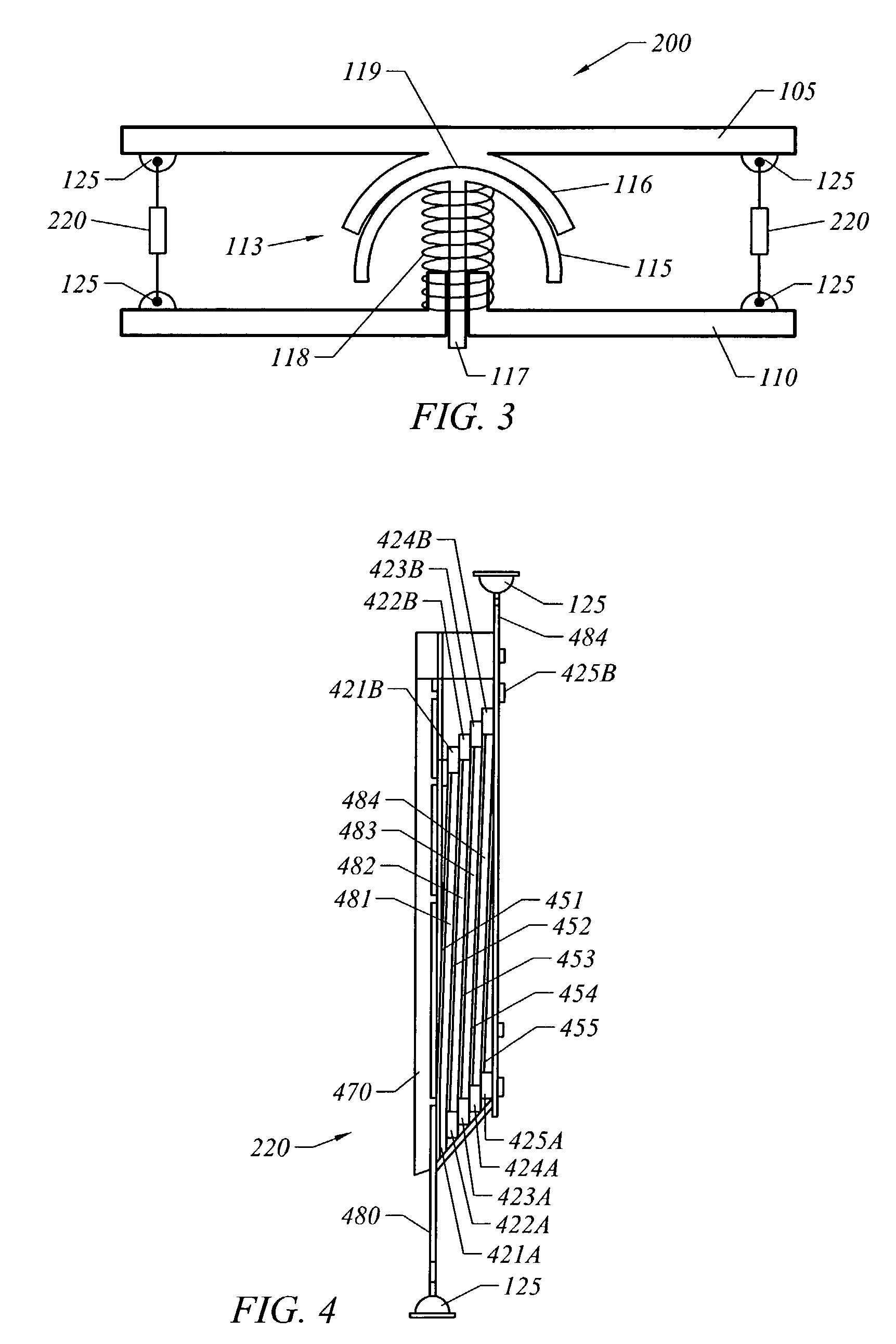

Actuator for two angular degrees of freedom

An apparatus for two degree of freedom positioning a moveable structure relative to a support structure is provided. The apparatus includes a moveable structure, a support structure, a compliant support disposed between the moveable structure and the support structure. The compliant support biases the moveable structure away from the support structure. In addition, three shape memory alloy actuators are provided between the structures and symmetrically arranged about the compliant support. The shape memory alloy actuators are selectively activated to provide two degrees of freedom of movement for the moveable structure relative to the support structure.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

Driving mechanism, driving device, and lens driving device

InactiveUS7663811B2Stably movingSmall sizeProjector focusing arrangementMechanical recordingCamera lensReduced size

Owner:KONICA MINOLTA OPTO

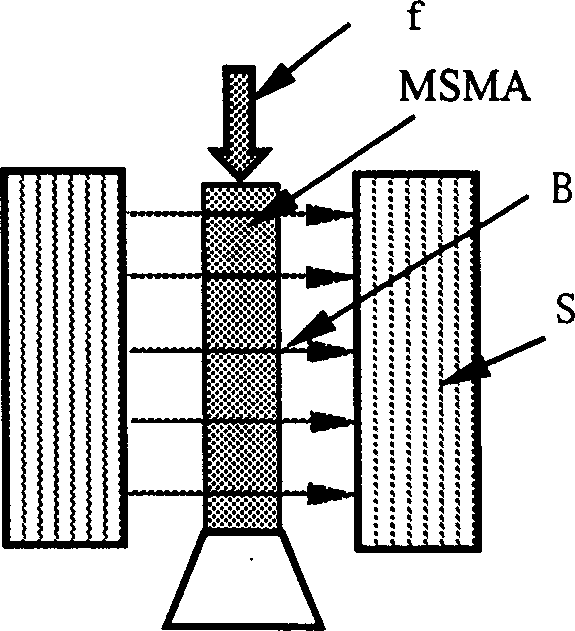

Differential-mode magnetic control shape memory alloy actuator

InactiveCN1633021ALarge deformationReduce volumePiezoelectric/electrostriction/magnetostriction machinesExcitation currentEngineering

A differential magnet-control shape-memory alloy performer includes MSMA elements, a magnet, an excitation coil, iron-core, two pairs of magnet baffle plates, a connecter and an excitation circuit controller. Excitation coil is winded on the iron-core laminated by dynamic steel, the connector is at center of the gap preserved between two cores, the MSMA elements magnet baffle plates and the magnet are set symmetrically along the gap from the connector to both sides, the two cores are connected by a press board and screws, finally, the excitation coil is connected to the current controller. The magnet generates bias magnetic fields with equal diameter and same direction in two MSMA elements and the excitation coil current generates a control magnetic field in equal diameter and counter direction, one field is increased, the other is reduced by laminating the two fields. The connector moves since the deformation volumes of the two MSMA elements are different to control the shift of the performer.

Owner:SHENYANG POLYTECHNIC UNIV

SMA actuator driving device, and image pickup device incorporated with the same

InactiveUS8068167B2Suppress power lossGreat fabricationTelevision system detailsProjector focusing arrangementDriving currentTerminal voltage

In a shape memory alloy actuator driving device, a predetermined constant current is applied to a shape memory alloy member as a retrieval signal to detect a terminal voltage of the shape memory alloy member, and a detection result of the terminal voltage is compared with a target voltage value to be calculated based on a target resistance value of the shape memory alloy member and a value of the constant current to cause a driving circuit to output, to the shape memory alloy member, a drive current that makes the detection result substantially equal to the target voltage value.

Owner:KONICA MINOLTA OPTO

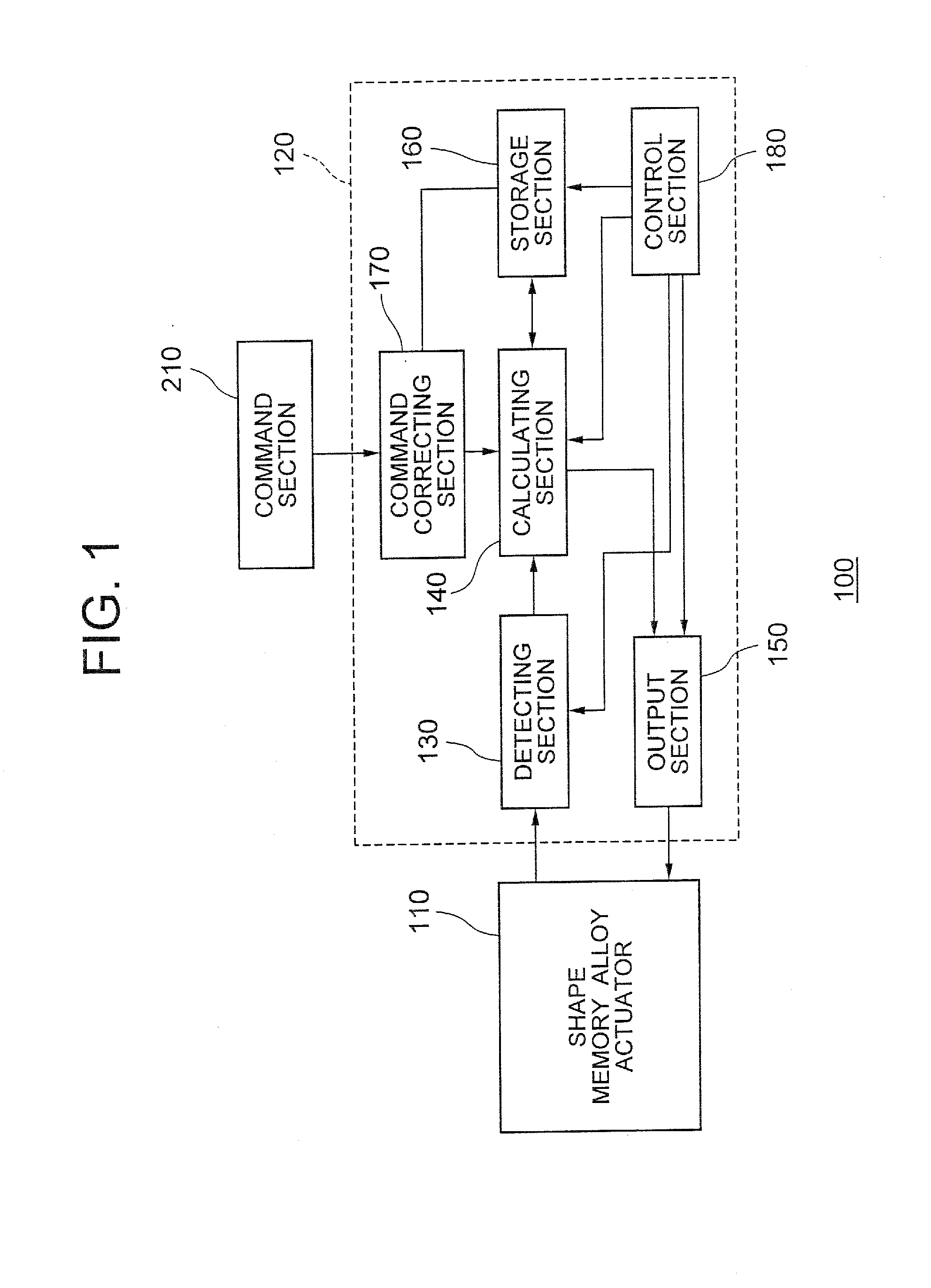

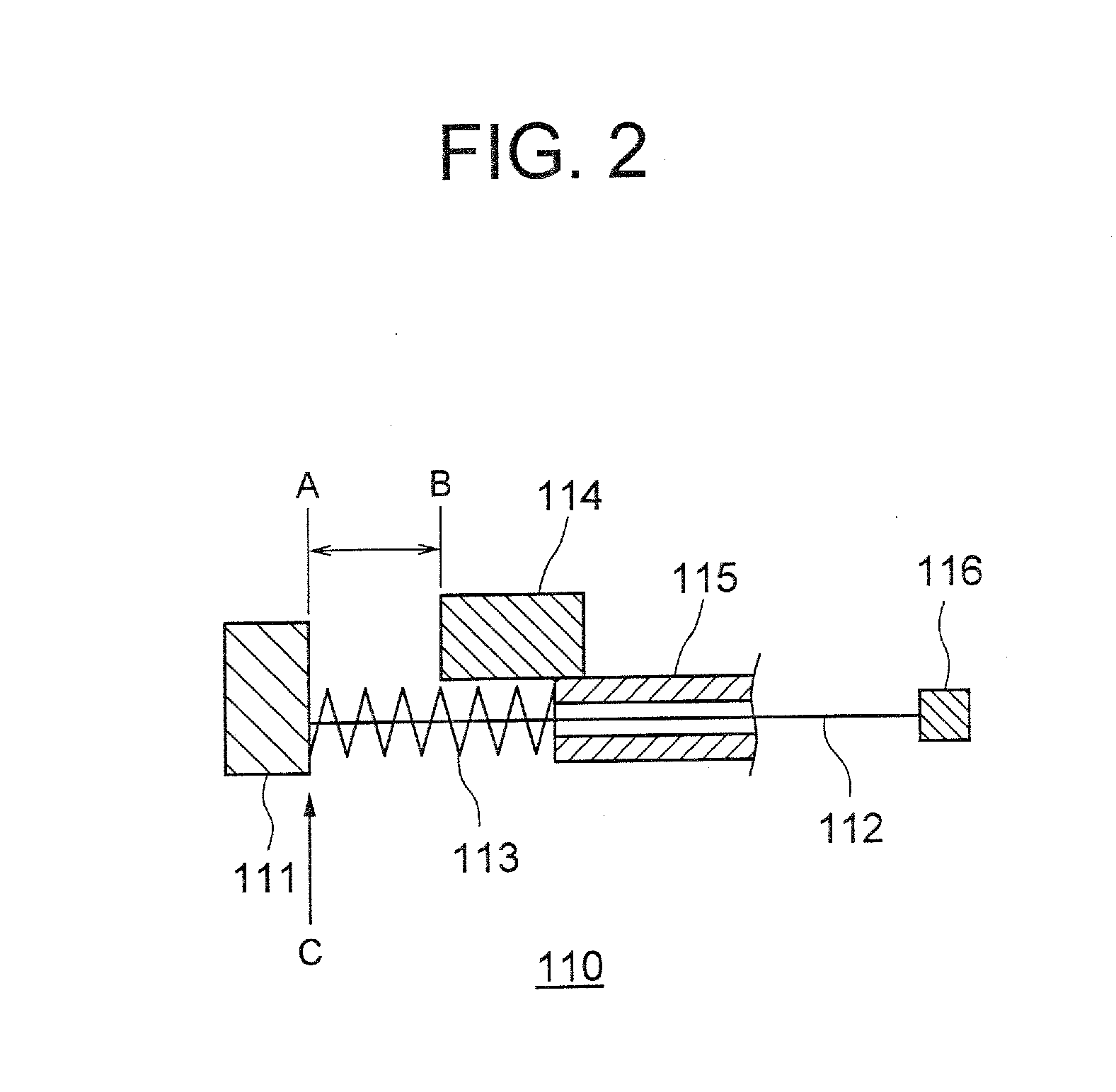

Shape memory alloy actuator system

InactiveUS20100045214A1Avoid excessive heatAvoid overall overheatingMachines/enginesMechanical power devicesElectrical resistance and conductanceFeedback circuits

A resistance feedback circuit has a detecting section which detects a resistance of a shape memory alloy wire at the time of contraction and elongation, a calculating section which compares an output signal acquired from the detecting section and a signal input by a command section, and calculates an applied electric current corresponding to the resistance value detected, an output section which outputs the applied electric current which is output from the calculating section, to the shape memory alloy actuator, a control section which controls the detecting section, the calculating section and the output section, a storage section which stores a maximum value and a minimum value of the resistance which is measured in advance, and a command correcting section which corrects a signal output from the command section, based on the resistance value stored in the storage section, and a command signal which is output from the command correcting section is set to a resistance value which is higher than the minimum resistance value by a correction value.

Owner:OLYMPUS CORP

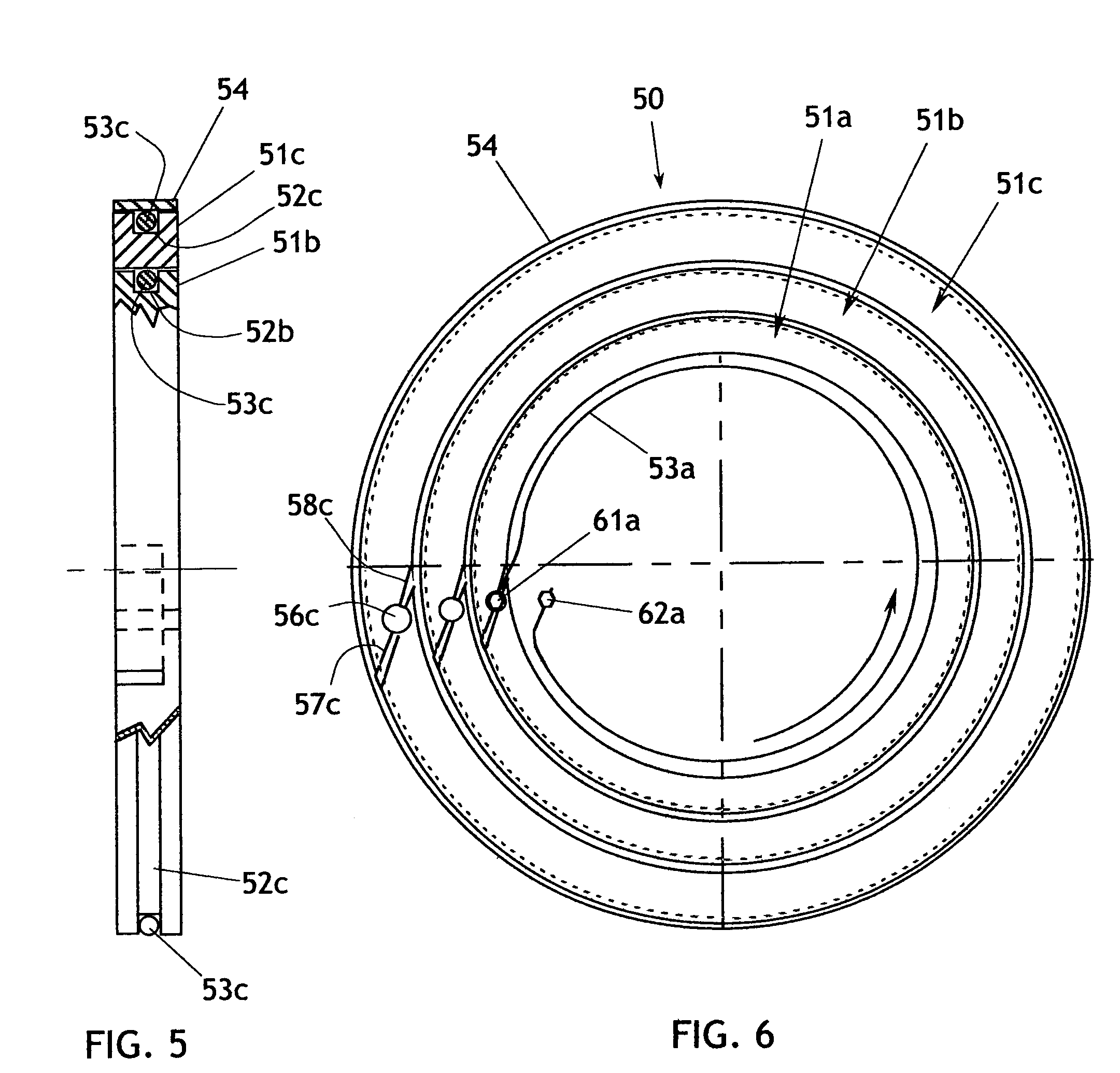

Concentric tube shape memory alloy actuator apparatus and method

ActiveUS7159398B1High torque outputIncreasing angular deflectionWing lift eficiencyMechanical power devicesPower flowAlloy

A rotary SMA actuator includes an SMA assembly having a plurality of grooves formed therein to form a plurality of concentrically arranged SMA tubes. A heater element is disposed against an input end of the SMA tubes and generates heat when electrical current is applied thereto. The heat is used to heat the SMA tubes, which causes an angular deflection of each of the tubes at an output end thereof. An innermost one of the SMA tubes is used as an output member and its angular deflection is the sum of the angular deflections of all of the SMA tubes. The actuator is of a smaller size and lighter weight than electrical, mechanical, hydraulic or pneumatic actuators of comparable torque output. The actuator also provides greater deflection capability than similarly sized SMA type actuators that do not employ concentric tubes.

Owner:THE BOEING CO

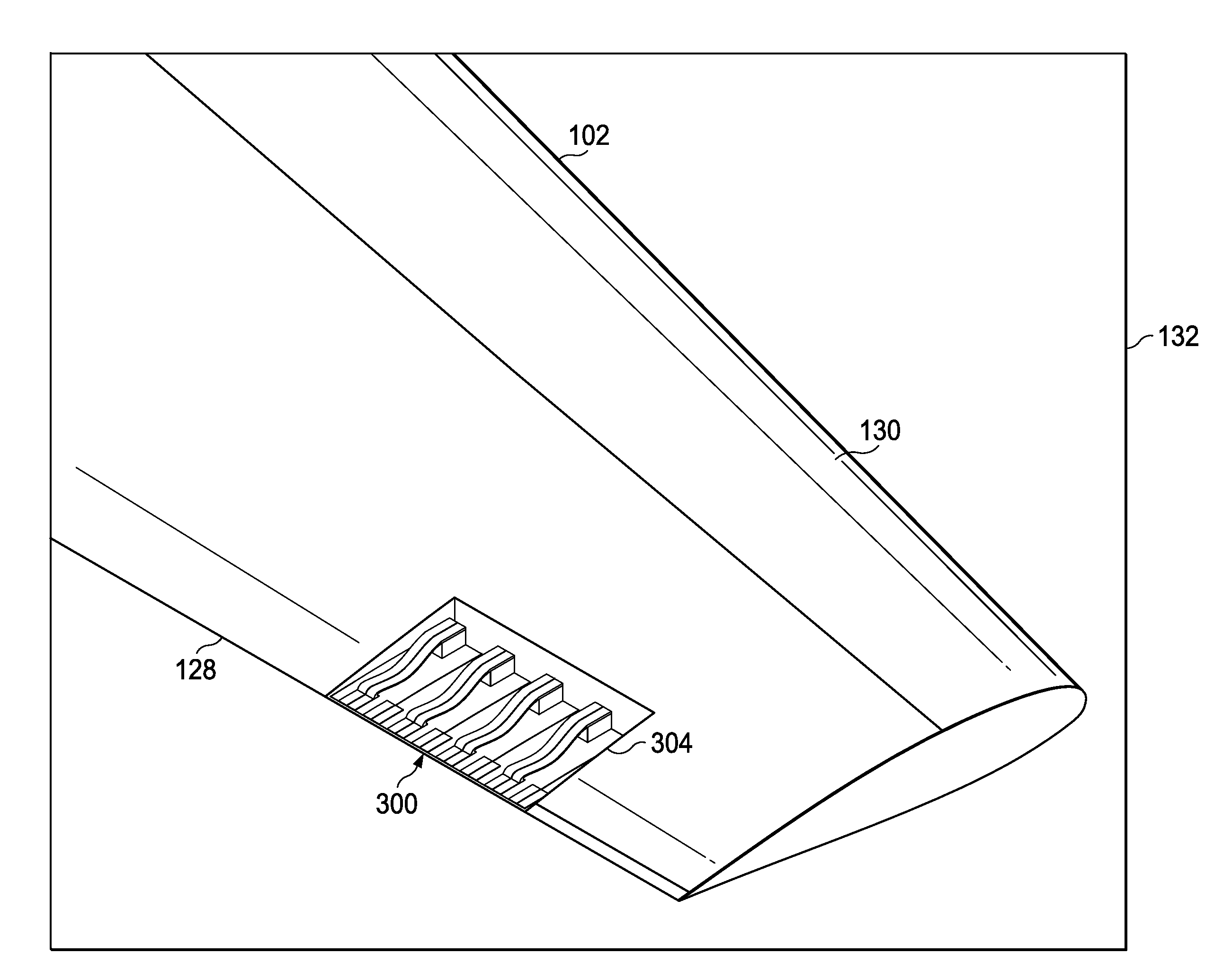

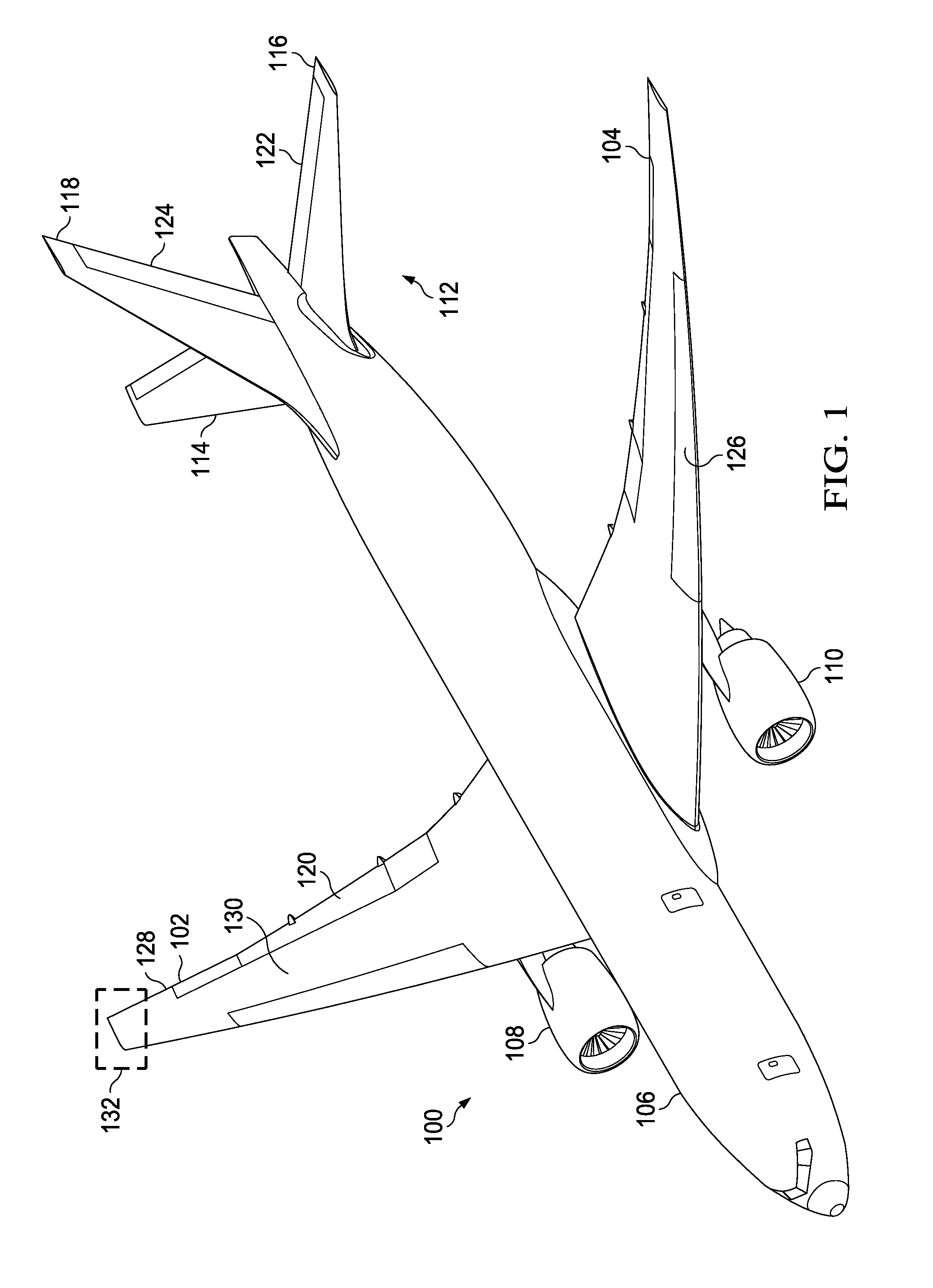

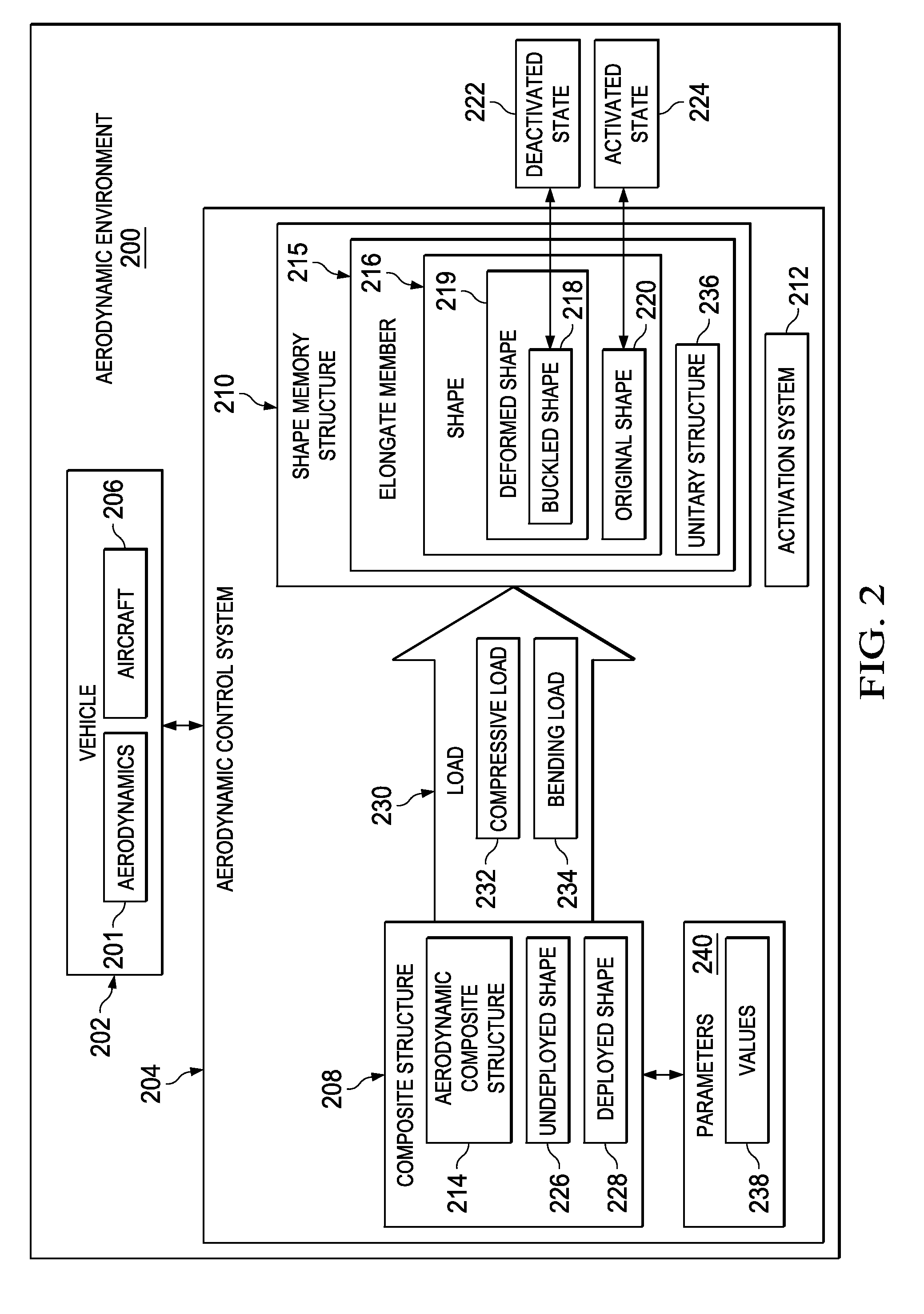

Shape Memory Alloy Actuator System for Composite Aircraft Structures

Method and apparatus for controlling a shape of a composite structure. A shape memory structure associated with the composite structure is activated. The shape memory structure changes from a buckled shape to an original shape and causes the composite structure to change from an undeployed shape to a deployed shape. The shape memory structure is deactivated. The shape memory structure changes from the original shape to the buckled shape in response to a load from the composite structure and causes the composite structure to change from the deployed shape to the undeployed shape.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com