Driving device of shape memory alloy actuator, driving method thereof, and imaging device using same

A memory alloy, driving device technology, applied in the direction of the mechanism, instrument, installation, etc. that generate mechanical power, can solve the problems of long heat release time and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

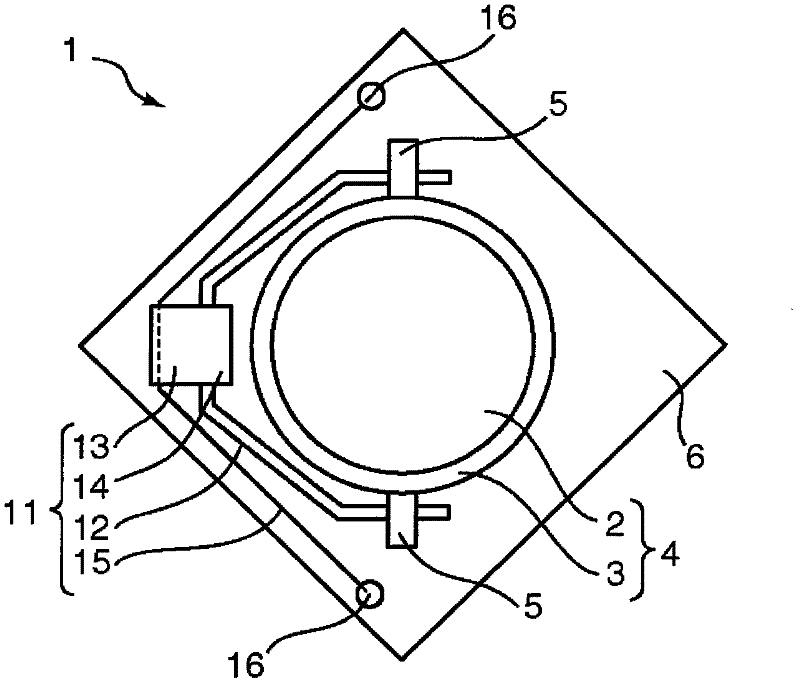

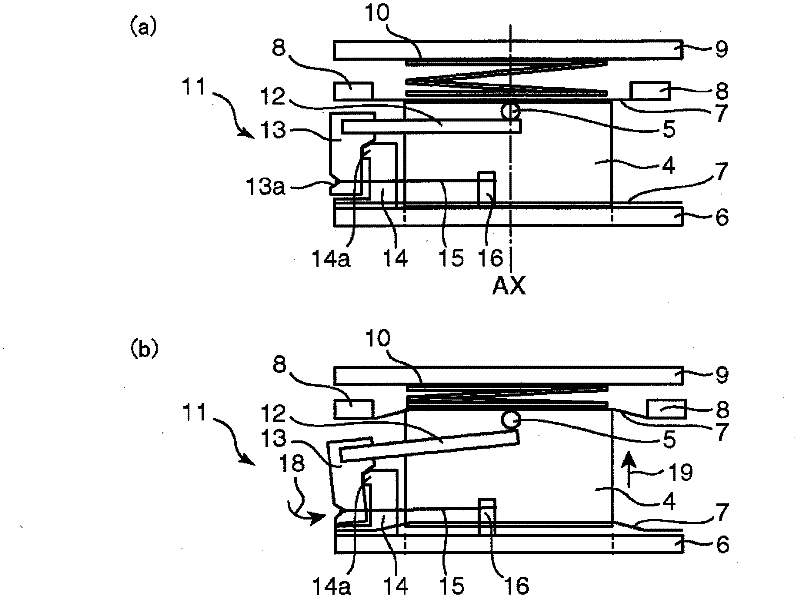

[0025] figure 1 It is a front view (viewed from the lens opening surface) of the autofocus lens drive mechanism 1 of the imaging device in one embodiment of the present invention, figure 2 is a side view for explaining its operation. figure 2 (a) shows that the SMA15 is stretched by the elastic force of the bias spring 10, figure 2 (b) shows the case where the SMA 15 contracts against the elastic force of the bias spring 10 . The drive mechanism 1 performs focusing by displacing the lens 2 in the axis AX (front-rear) direction. The lens barrel 4 includes a lens 2 and a lens driving frame 3 , and the lens 2 is mounted on the lens driving frame 3 . On the outer peripheral surface of the lens barrel 4, a pair of protrusions 5 are formed at the front end (the front end in the above-mentioned front-rear direction), and the protrusions 5 are mounted on the arm portion 12 of the shape memory alloy actuator 11 so that the lens barrel 4 Movement is performed in the direction of...

Embodiment approach 2

[0047] Figure 9 It is a block diagram showing an electrical configuration of a control circuit 31 which is a second driving device for driving the above-mentioned SMA actuator 11 . The control circuit 31 includes a resistance value detection unit 32 , a comparison unit 33 , a microcomputer 34 , an image sensor 25 , a drive control calculation unit 26 , and a drive element 27 , and the drive element 27 controls the drive current flowing into the SMA 15 . This control circuit 31 is similar to the above-mentioned control circuit 21, and the corresponding parts are denoted by the same reference numerals, and description thereof will be omitted. However, in the second embodiment, in the control circuit 31 , the resistance value of the SMA 15 is used as a parameter for detecting the parameter related to the expansion and contraction of the SMA 15 , that is, the position of the lens barrel 4 . Therefore, the resistance value between the electrodes 16 of the SMA15 is detected by the...

Embodiment approach 1

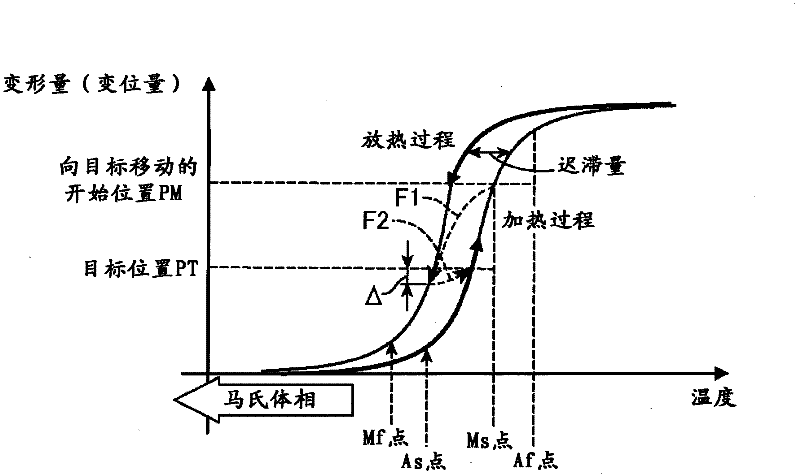

[0056] The driving device of the shape memory alloy actuator in the first embodiment is a driving device of the shape memory alloy actuator that drives the shape memory alloy actuator. It expands and contracts due to heat generation, and the parameter-deformation characteristic related to the expansion and contraction has hysteresis; the movable part is driven by displacement through the above-mentioned expansion and contraction, and the driving device of the above-mentioned shape memory alloy actuator is equipped with: a drive circuit, which controls the above-mentioned shape The memory alloy conducts the above-mentioned energization; the measurement part measures the above-mentioned parameters related to the expansion and contraction of the above-mentioned shape memory alloy; the target displacement position detection part detects the target displacement position of the above-mentioned movable part; and the control part responds from the above-mentioned The output of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com