Vacuum cooling-heating stage for grazing incidence X-ray small-angle scattering experiment

A technology of small angle scattering and cold and hot stage, which is applied in the direction of material analysis, measuring devices, instruments, etc. using wave/particle radiation, and can solve the problem that grazing incident X-ray small angle scattering experiments cannot be applied, physical requirements cannot be met, and there is no experimental device yet. To achieve the effect of ensuring the vacuum atmosphere environment, improving reliability and ensuring uniform temperature change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

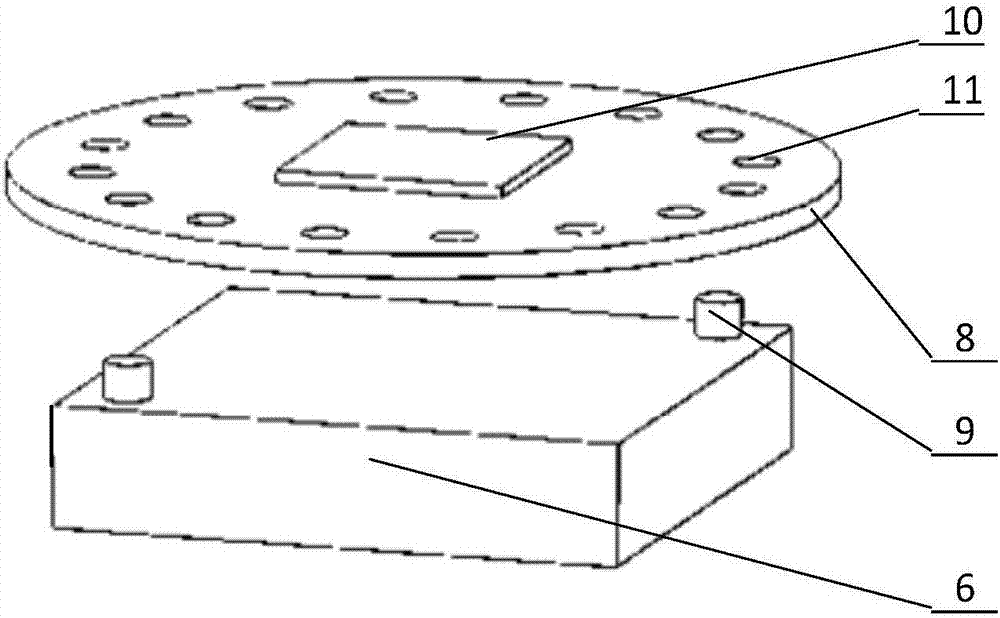

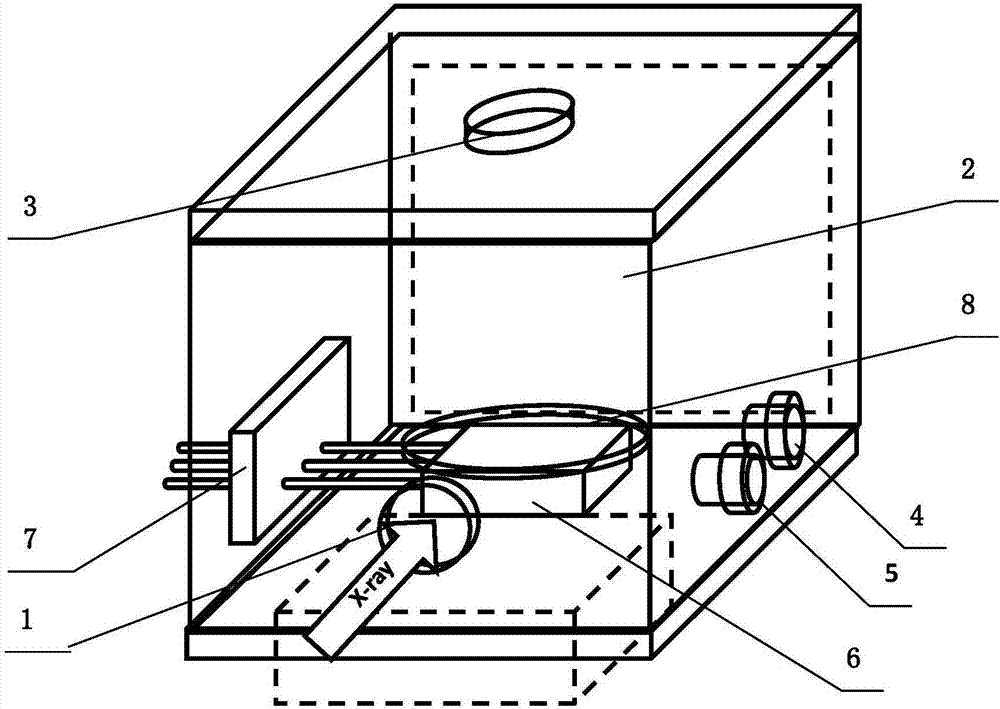

[0020] figure 1 is a perspective view of a vacuum cooling and heating table for grazing incidence X-ray small-angle scattering experiments according to a preferred embodiment of the present invention, wherein the vacuum cooling and heating table is shown as having a cuboid cavity in this embodiment, and the cuboid includes Front side, back side, left side, right side, top and bottom. The vacuum cooling and heating table includes an incident sealing window 1 , an exit sealing window 2 , a sampling sealing window 3 , vacuum joints 4 and 5 , a temperature variable block 6 , a fixed temperature variable block sealing window 7 and a sample tray 8 . Wherein, the incident sealing window 1 is shown as a circular window, which is fixed to the front side of the cuboid cavity through bolt connection. The exit sealing window 2 is shown as a square window fixed to the rear side of the cuboid cavity by bolting. The sampling sealing window 3 is shown as a circular sight glass piece fixed t...

Embodiment 2

[0030] The structure of this embodiment is the same as that of Embodiment 1. The difference is that two KF16 vacuum joints are fixed by bolts on the left side of the cuboid cavity, one joint 4 is connected to the gas outlet of the external protective gas cylinder, and the other joint 5 is connected to the pipe of the external exhaust gas treatment system. This embodiment provides an atmosphere environment for grazing incidence experimental samples, thereby improving the reliability of the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com