Efficient ingot casting semi-melting technology capable of achieving low dislocation density

A low dislocation and density technology, applied in single crystal growth, polycrystalline material growth, crystal growth, etc., can solve the problems of inconsistent crystal orientation, uneven growth crystal interface, and low photoelectric conversion efficiency of large grains, and achieve stable lifting , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ingot semi-melting process is carried out according to the following steps:

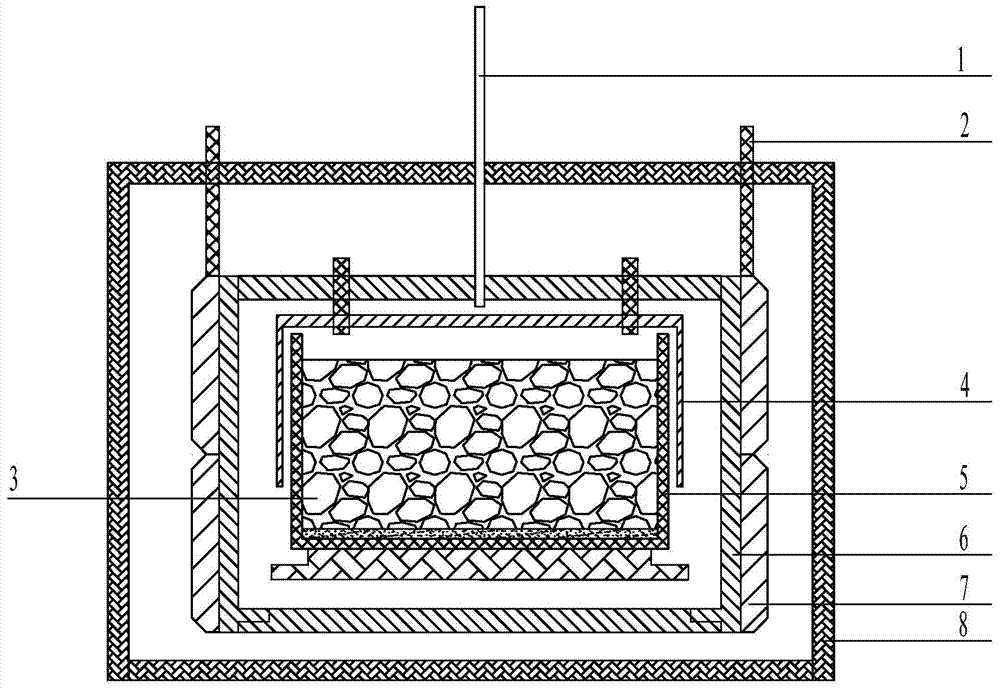

[0020] 1. Vacuumize the material and start heating: add the crushed single crystal with a particle size of 2mm to the bottom of the quartz crucible 5, the thickness of the pavement is 3cm, and then continue to add 450Kg of silicon material 3 into the quartz crucible 5, and control the furnace body 8 Evacuate to 0.5 Pa; control the heating of the heater 4 to evaporate the moisture of the graphite carbon felt 6 and the silicon material 3, etc., and raise the temperature to 1100 ° C within 2 hours, and pass the argon gas through the vent pipe 1 as a protective gas. Keep the pressure in the furnace body 8 at 40KPa, and make the temperature in the quartz crucible 5 reach 1545°C within 3 hours. During this process, the heat insulation cage 7 is always at 0 position (that is, closed state).

[0021] 2. Melting stage: Keep the pressure inside the furnace body 8 at 50KPa, keep the temperature of th...

Embodiment 2

[0026] The ingot semi-melting process is carried out according to the following steps:

[0027] 1. Vacuumize the material and start heating: add the crushed polycrystal with a particle size of 10mm to the bottom of the quartz crucible 5, the thickness of the pavement is 4cm, and then continue to add 500Kg of silicon material 3 into the quartz crucible 5, and control the furnace body 8 Vacuumize to 0.5 Pa; control the heating of the heater 4 to evaporate the moisture of the graphite carbon felt 6 and the silicon material 3, etc., and raise the temperature to 1200°C within 3 hours, and pass argon gas through the vent pipe 1 as a protective gas. Keep the pressure inside the furnace body 8 at 60KPa, and make the temperature inside the quartz crucible 5 reach 1560°C within 5 hours. During this process, the heat insulation cage 7 is always at 0 position (that is, closed state).

[0028] 2. Melting stage: Keep the pressure in the furnace body 8 at 50KPa, keep the temperature of the s...

Embodiment 3

[0033] The ingot semi-melting process is carried out according to the following steps:

[0034] 1. Vacuumize the material and start heating: add the crushed single crystal with a particle size of 15mm to the bottom of the quartz crucible 5, the thickness of the pavement is 4cm, and then continue to add 450Kg of silicon material 3 into the quartz crucible 5, and control the furnace body 8 Evacuate to 0.5Pa; control the heating of the heater 4 to evaporate the moisture of the graphite carbon felt 6 and the silicon material 3, etc., and raise the temperature to 1150°C within 2.5h, and pass argon gas through the vent pipe 1 as a protective gas , keep the pressure inside the furnace body 8 at 40KPa, make the temperature inside the quartz crucible 5 reach 1550°C within 4 hours, and during this process, the heat insulation cage 7 is always at 0 position (that is, closed state).

[0035] 2. Melting stage: Keep the pressure in the furnace body 8 at 50KPa, keep the temperature of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com