Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Gas–liquid contactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas–liquid contactor is a particular chemical equipment used to realize the mass and heat transfer between a gas phase and a liquid phase. Gas–liquid contactors can be used in separation processes (e.g. distillation, absorption) or as gas–liquid reactors or to achieve both purposes within the same device (e.g. reactive distillation).

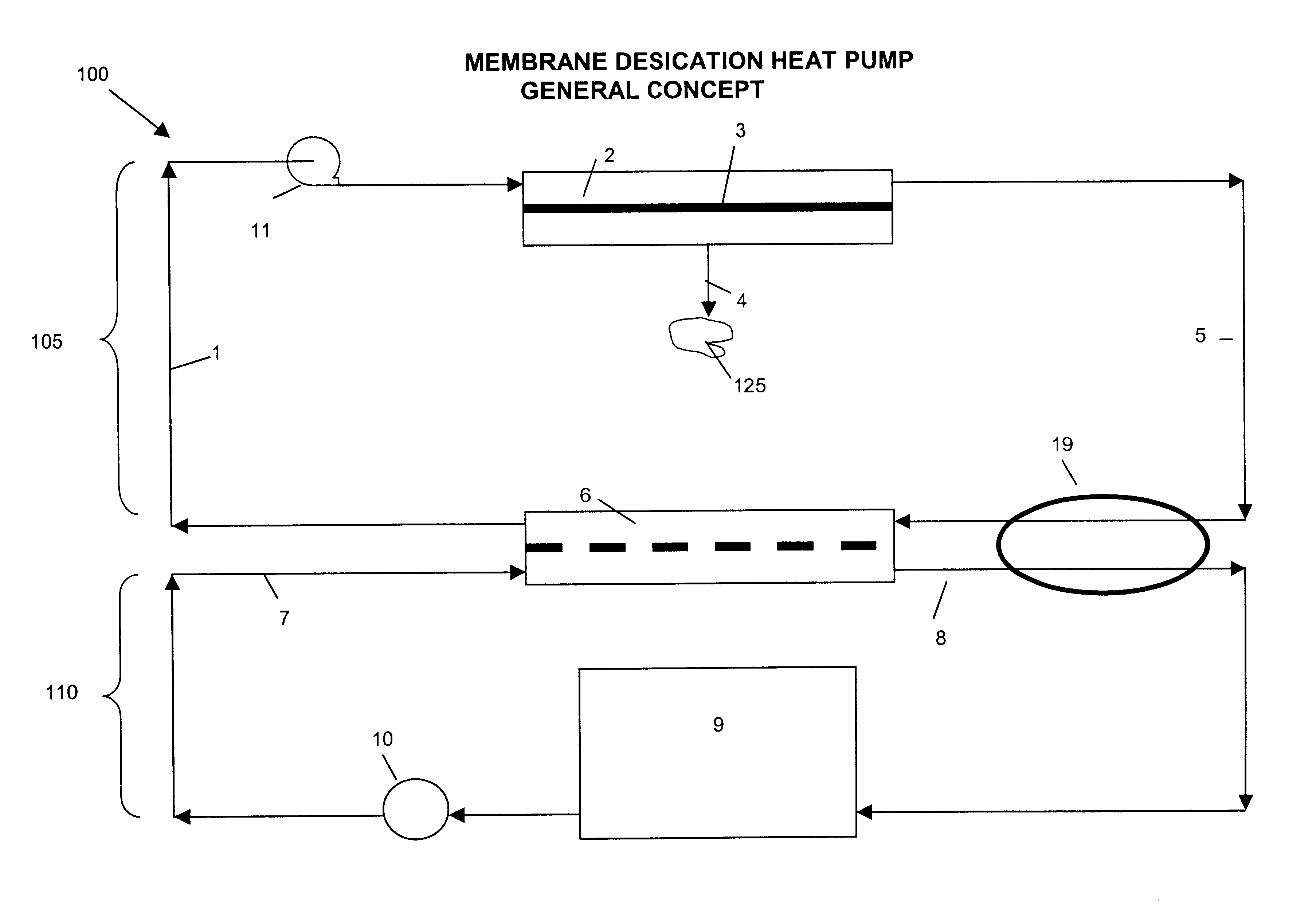

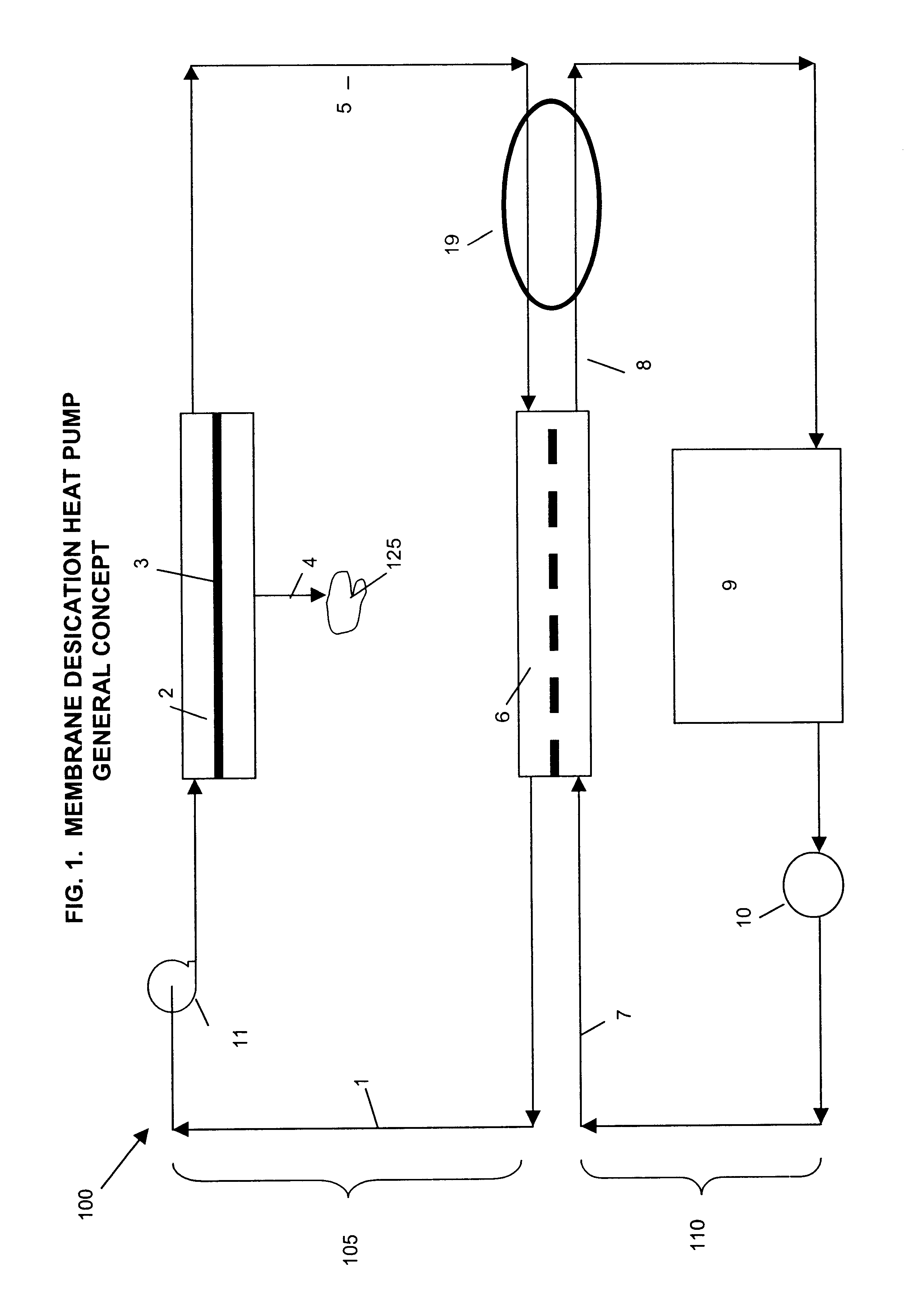

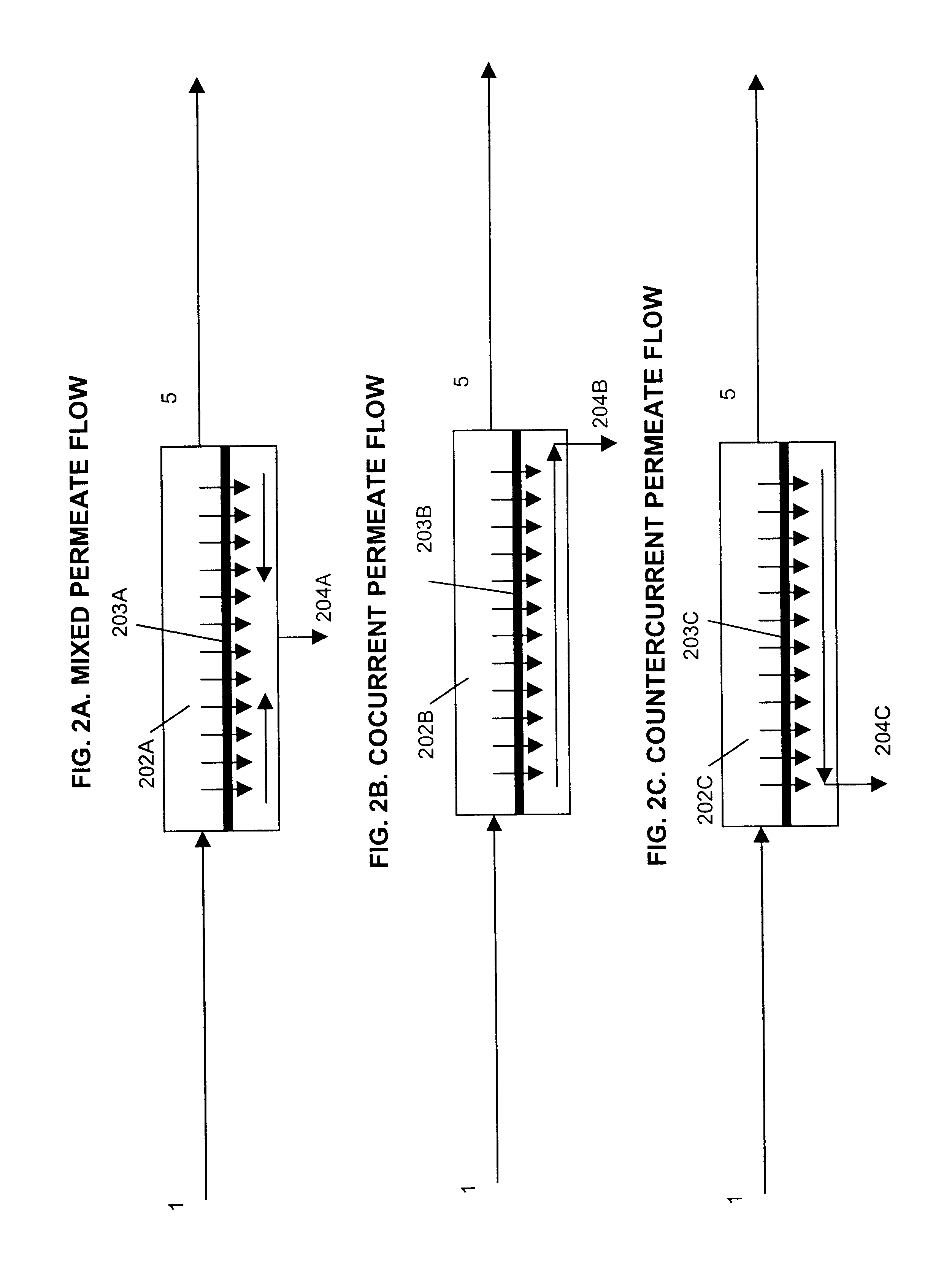

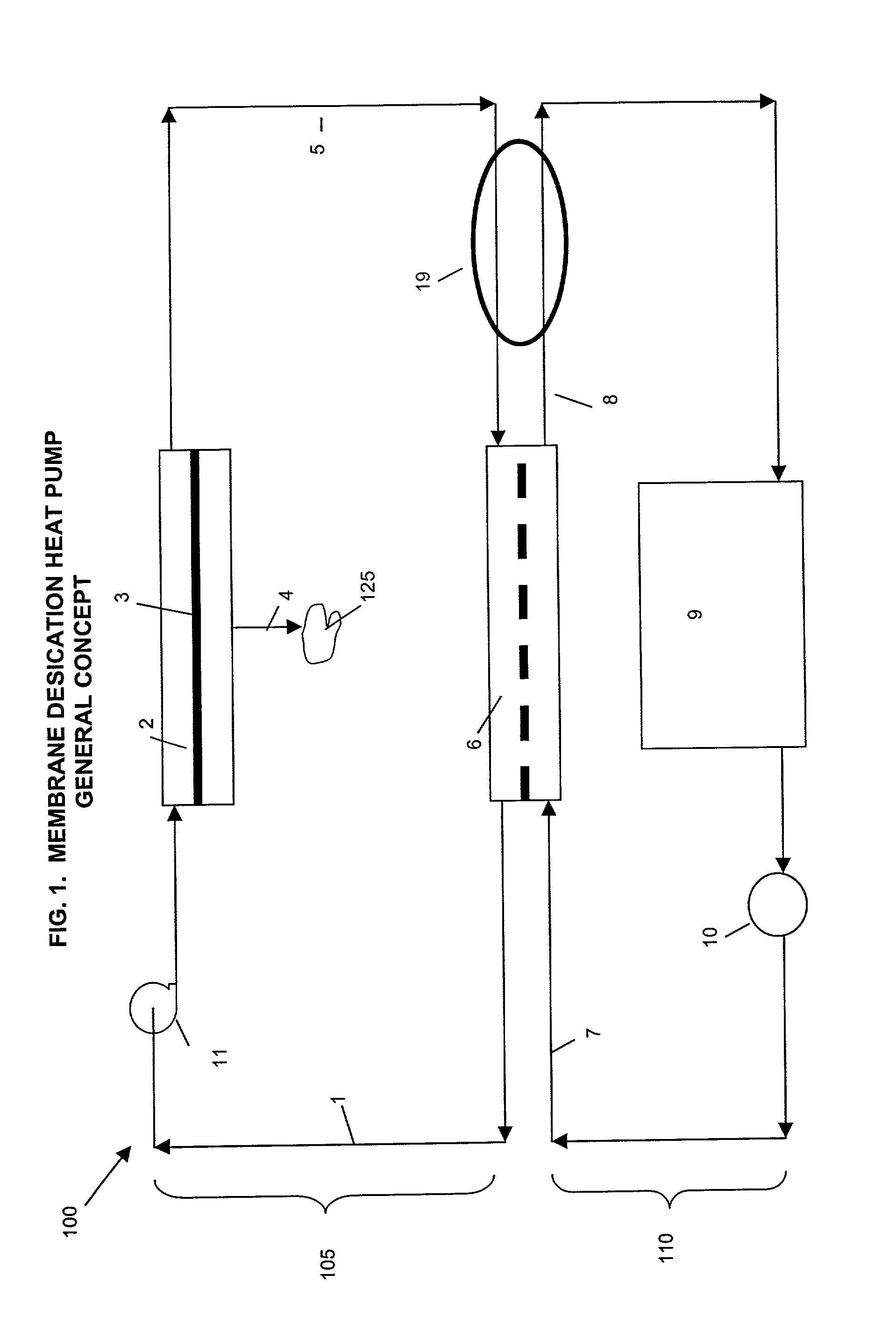

Membrane desiccation heat pump

InactiveUS6739142B2Great flexibility and controlReduce in quantityAir-treating devicesHeat pumpsThermal energyProcess engineering

Owner:KORIN AMOS

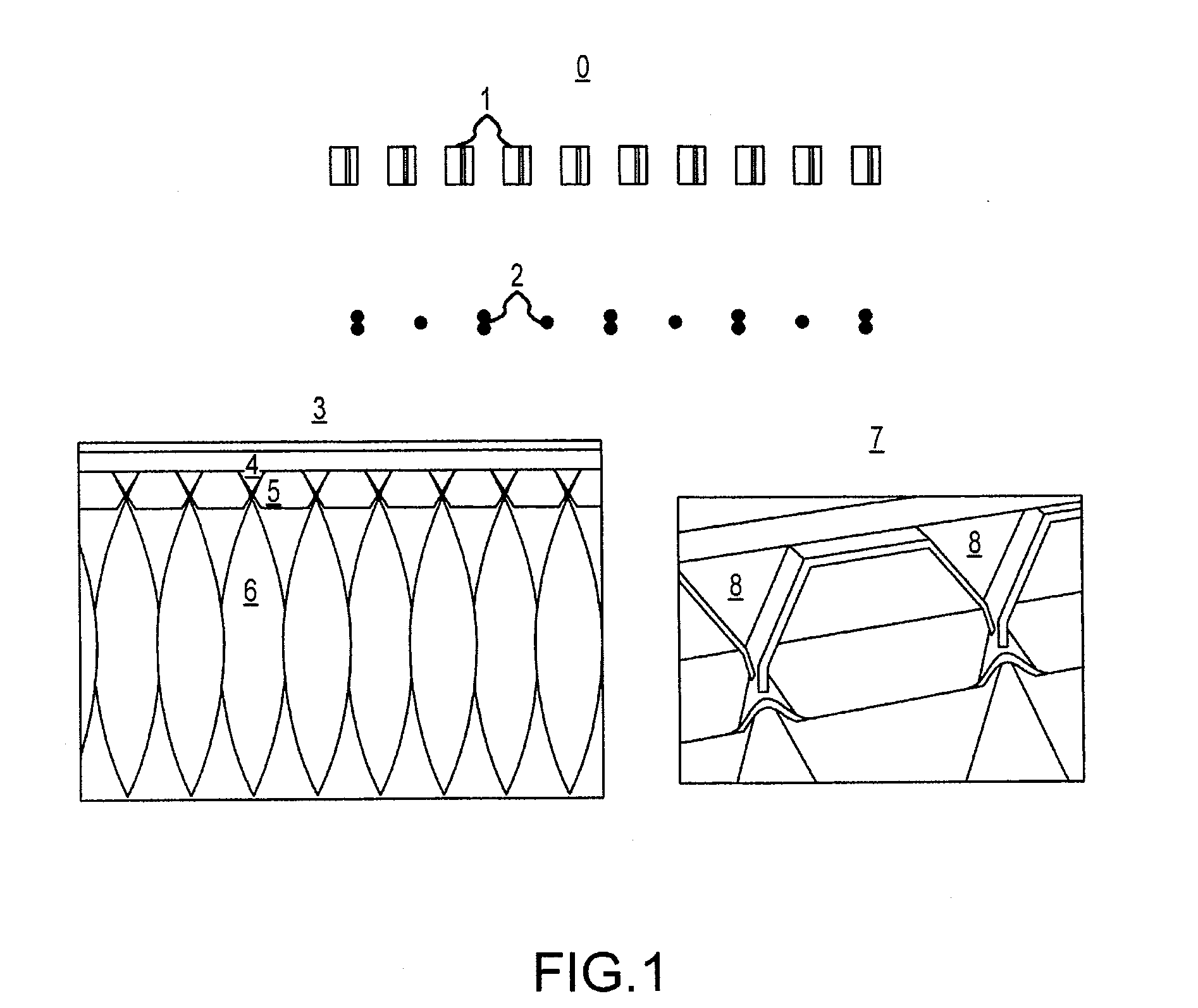

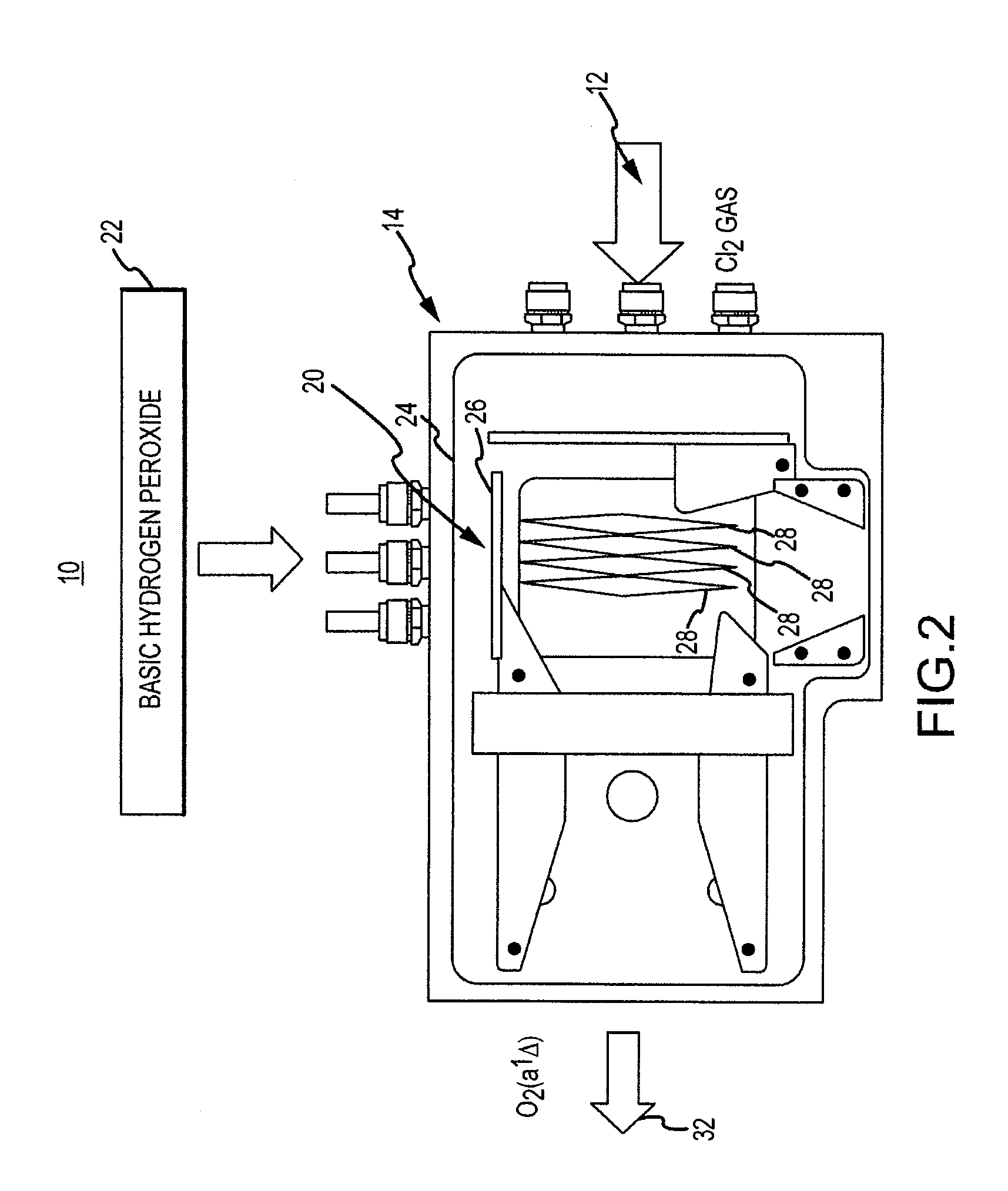

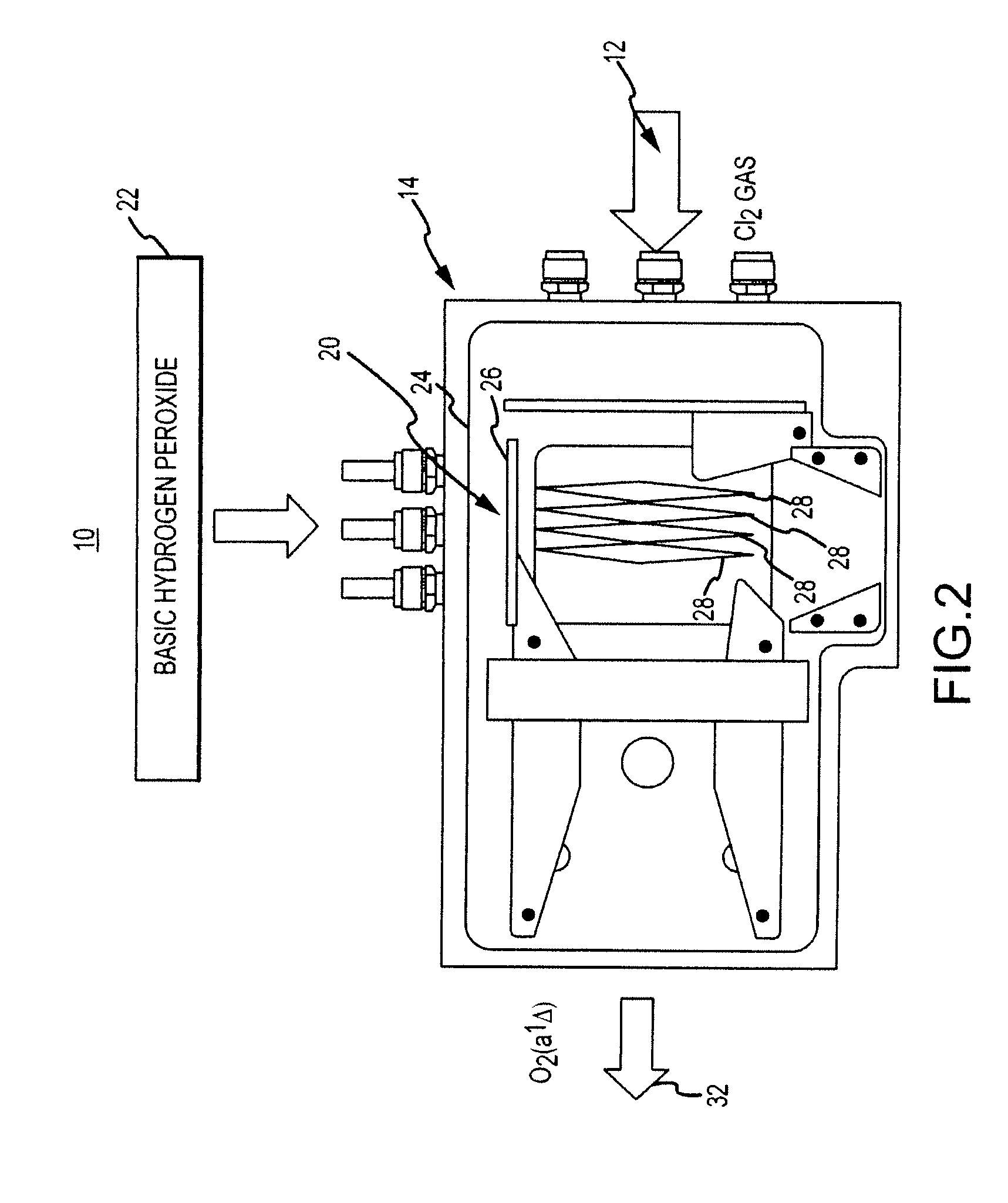

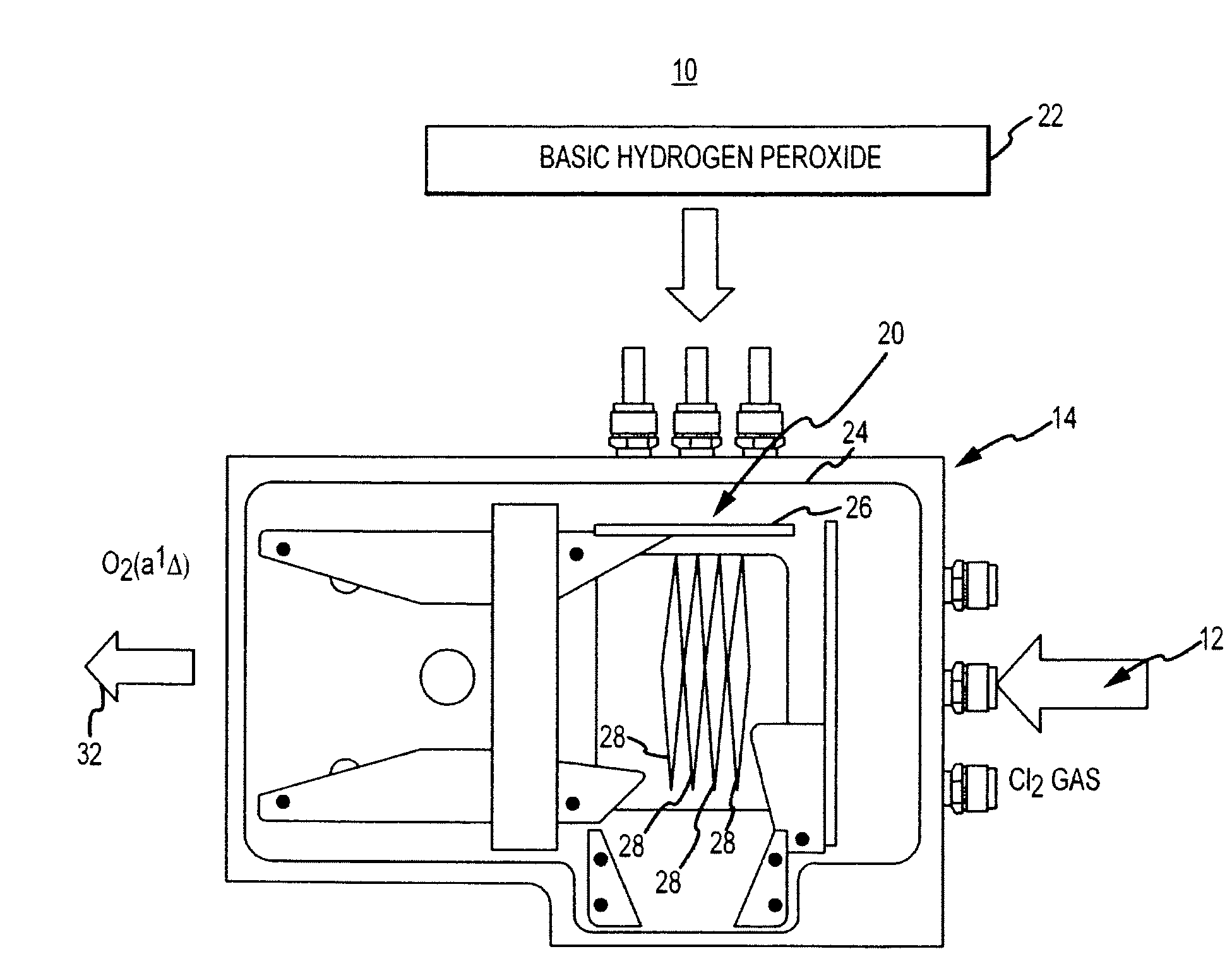

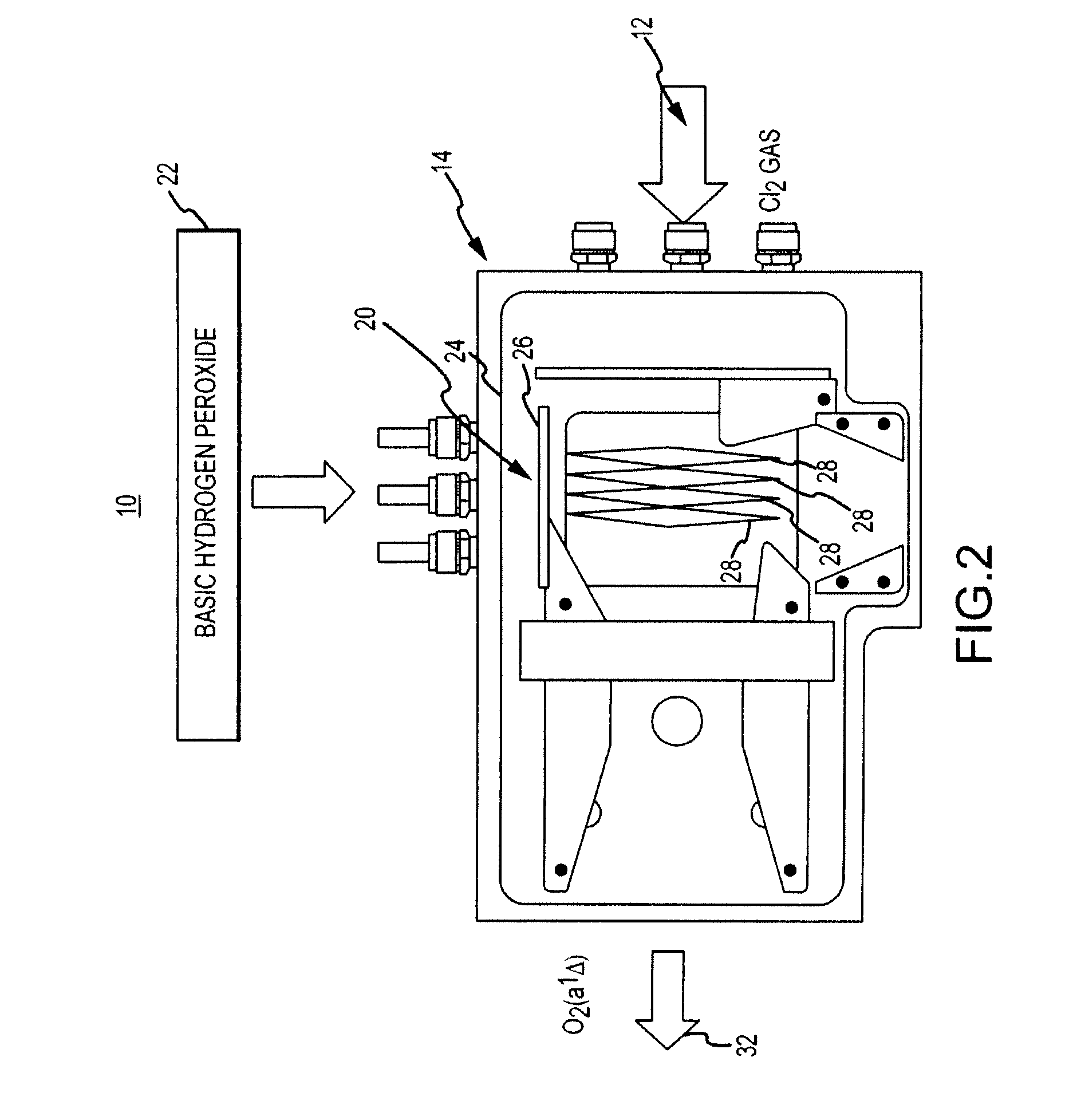

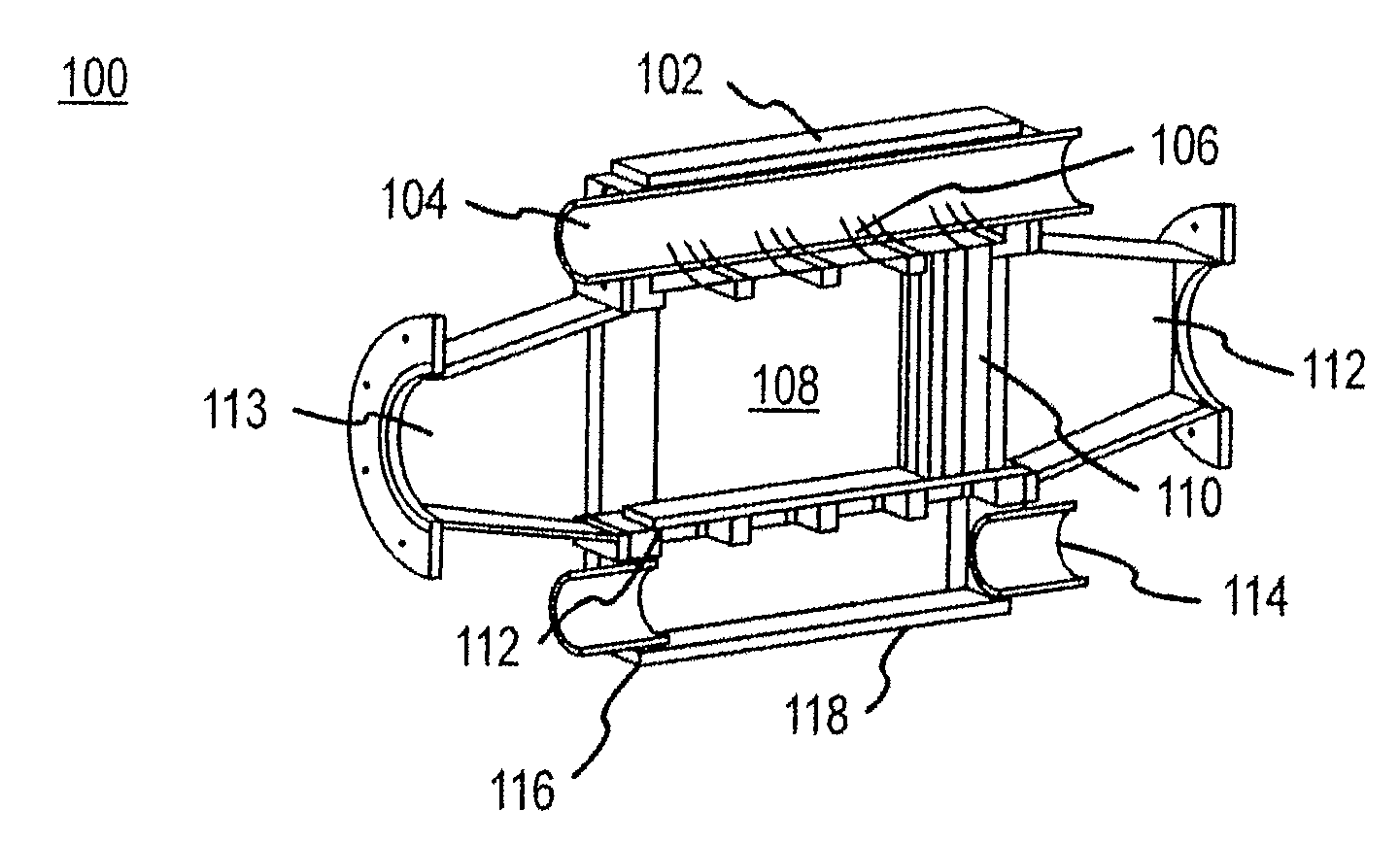

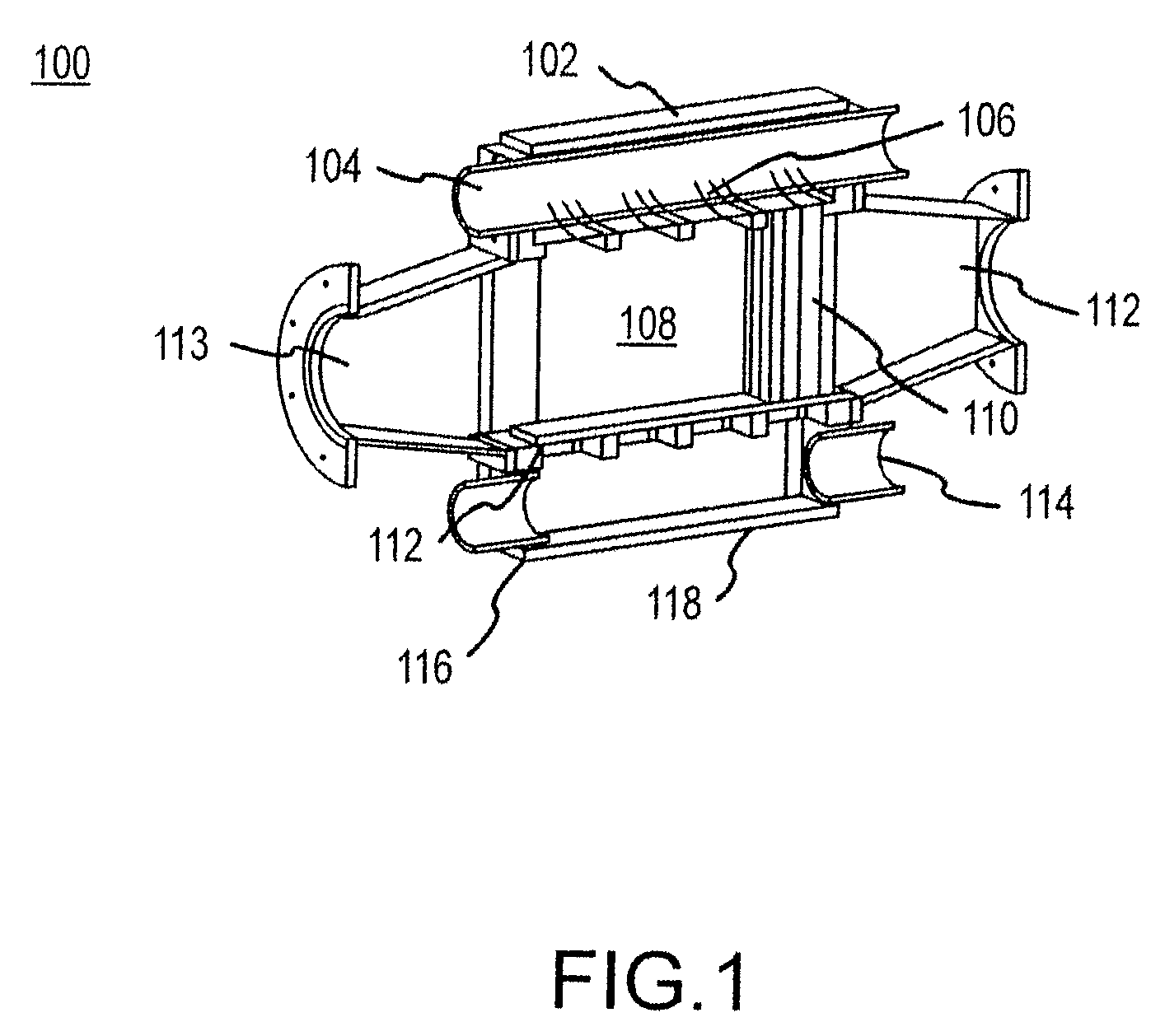

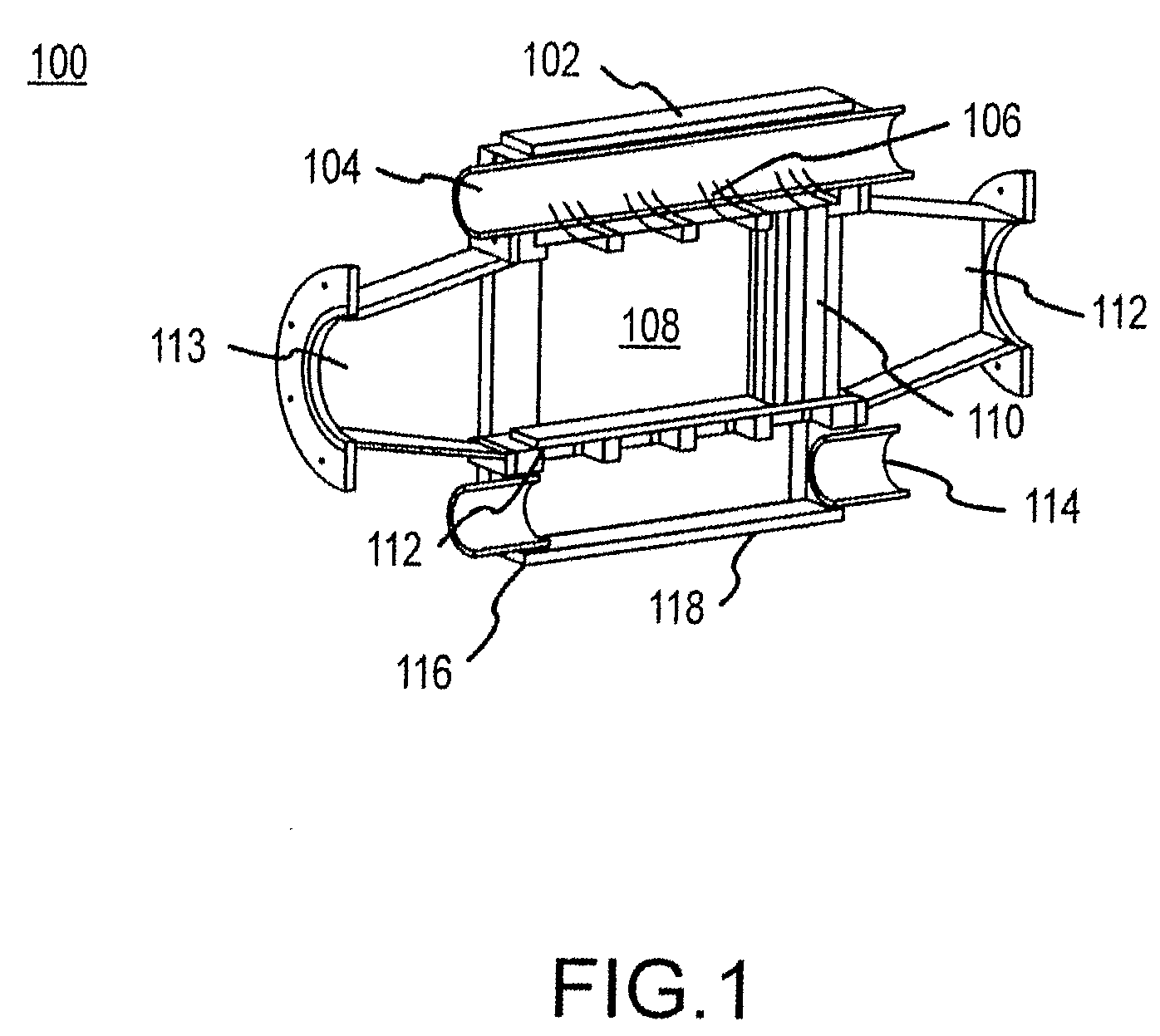

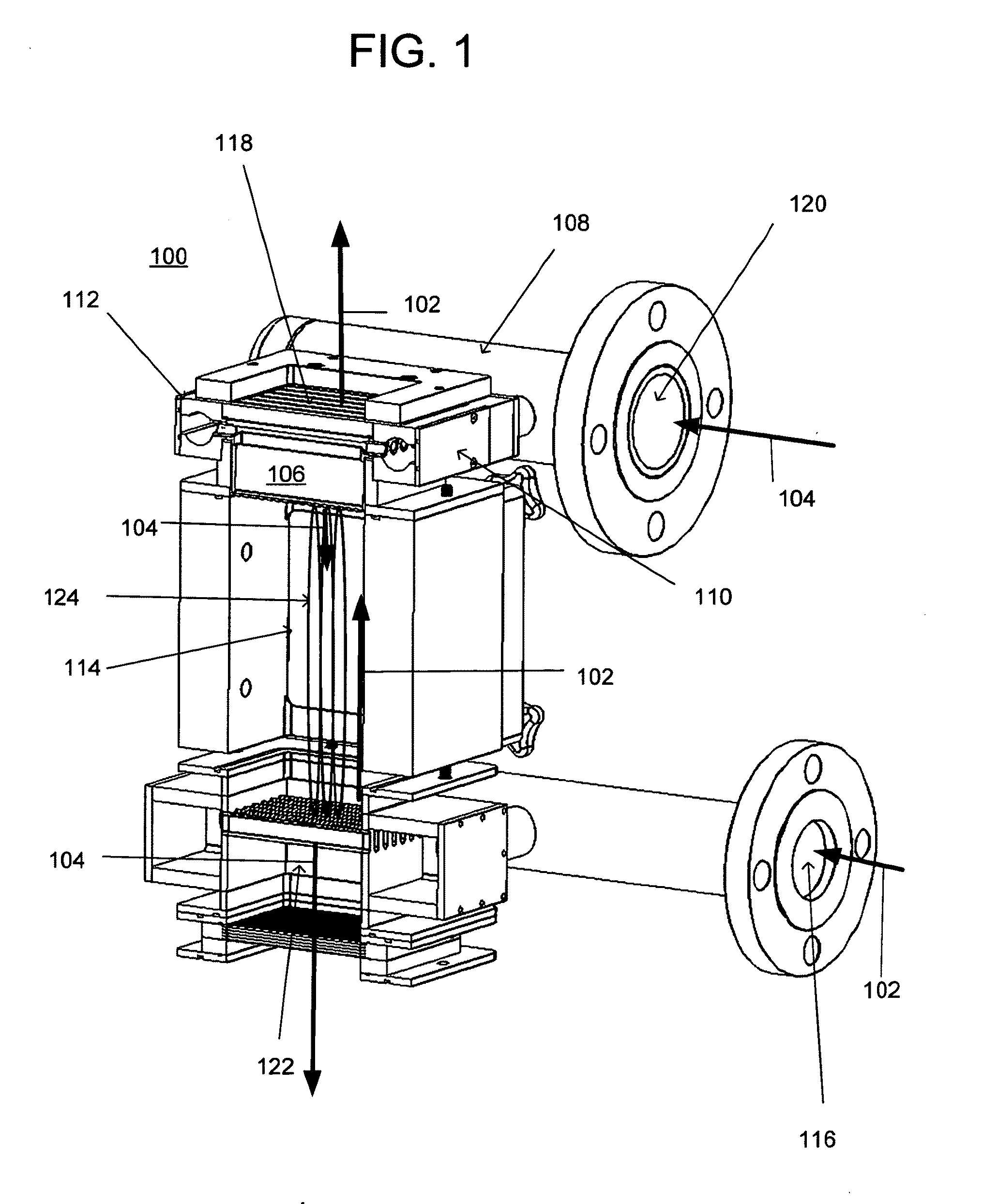

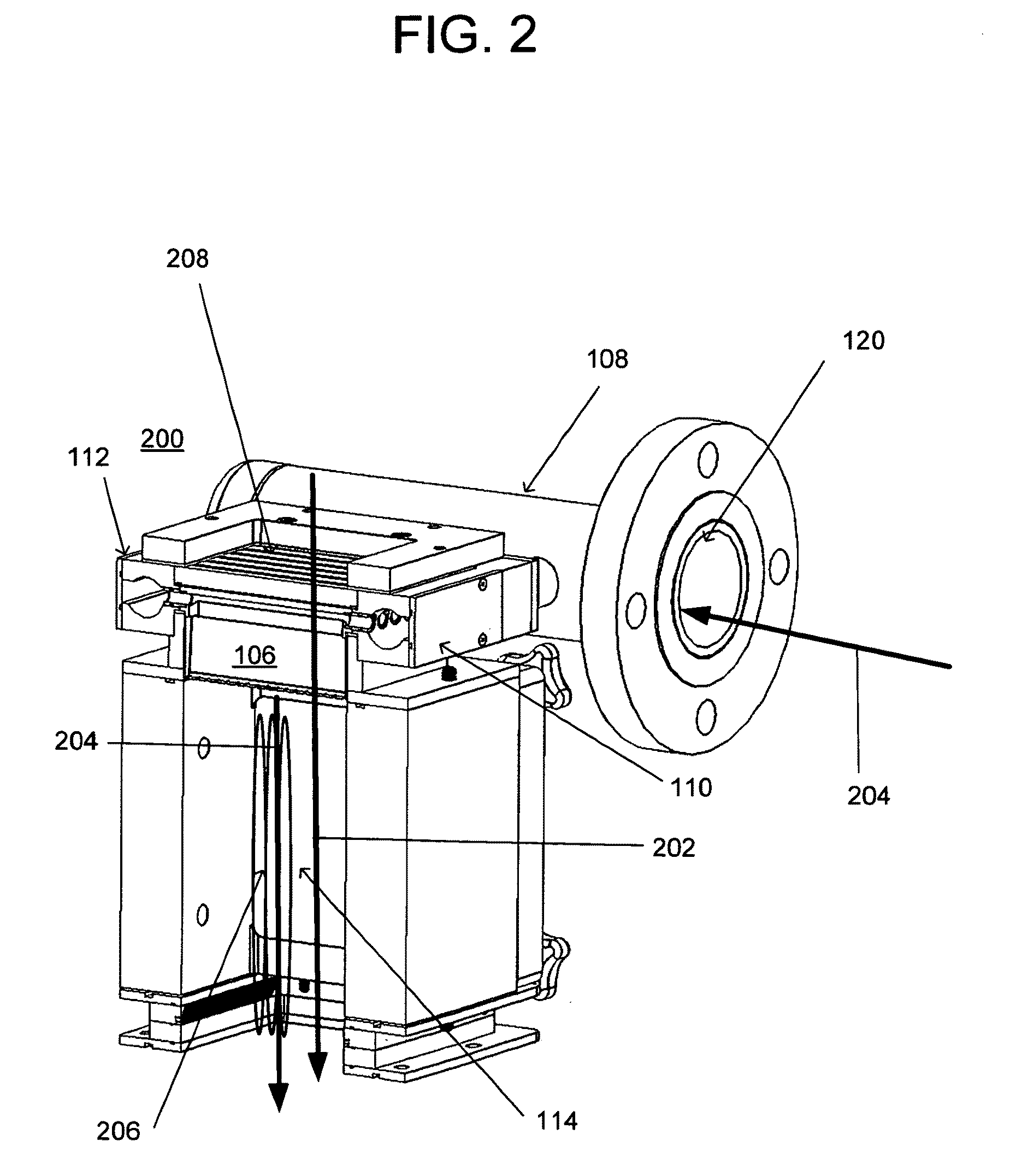

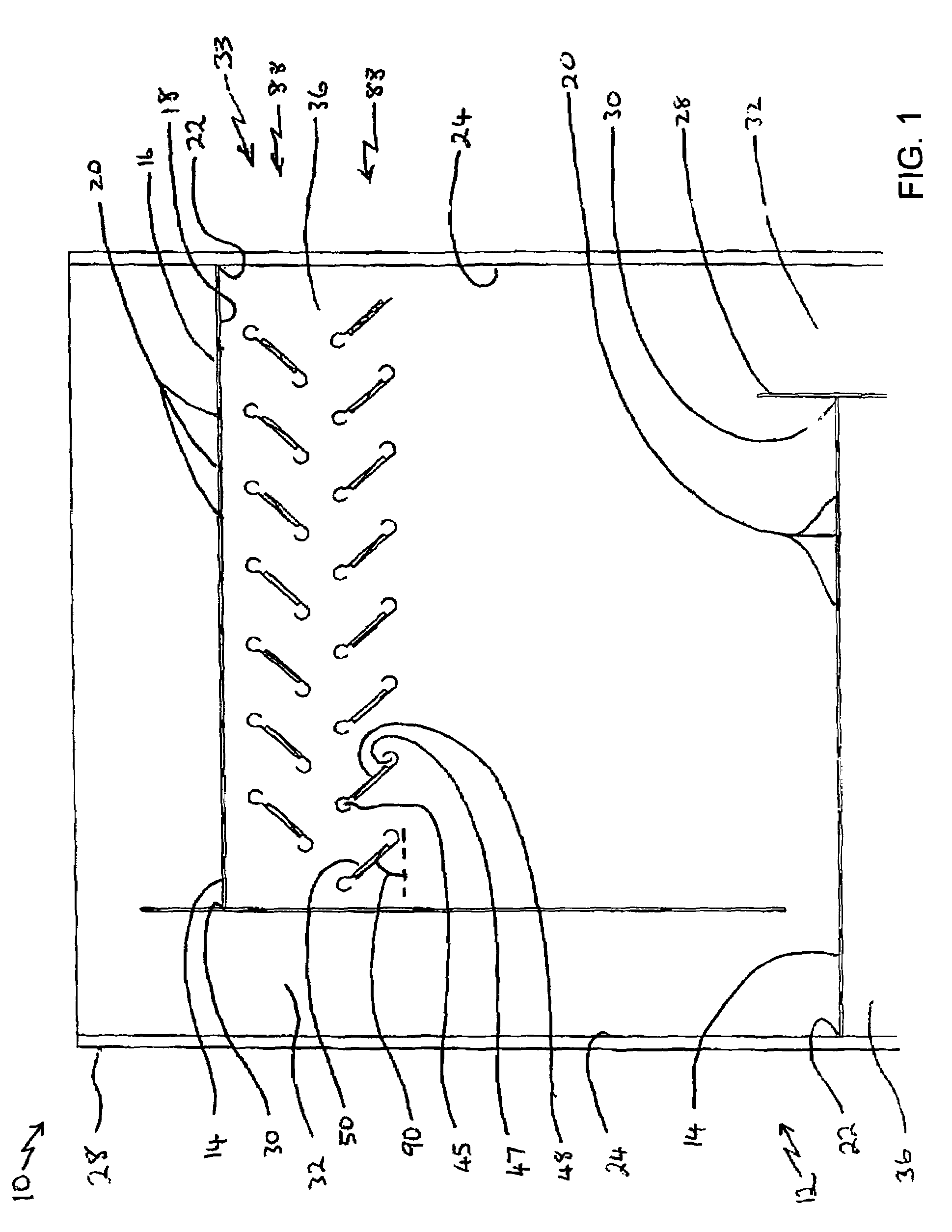

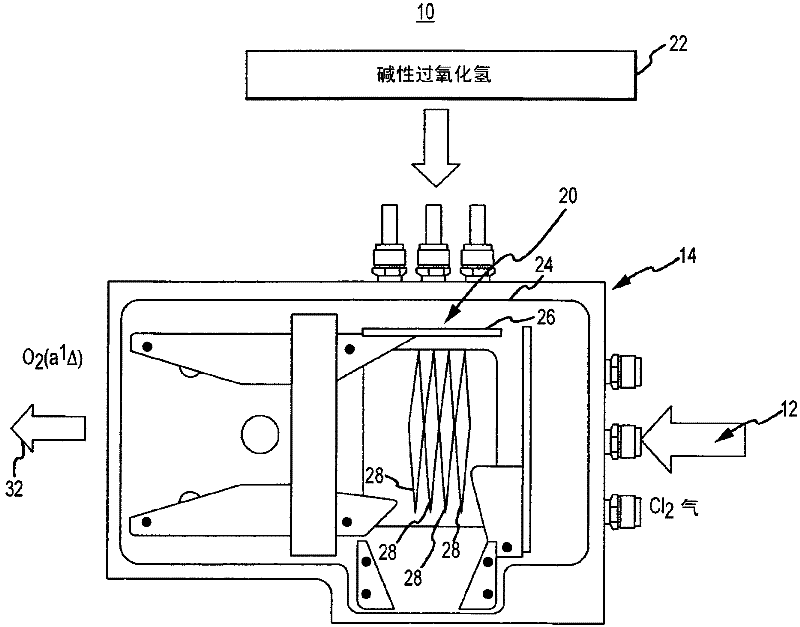

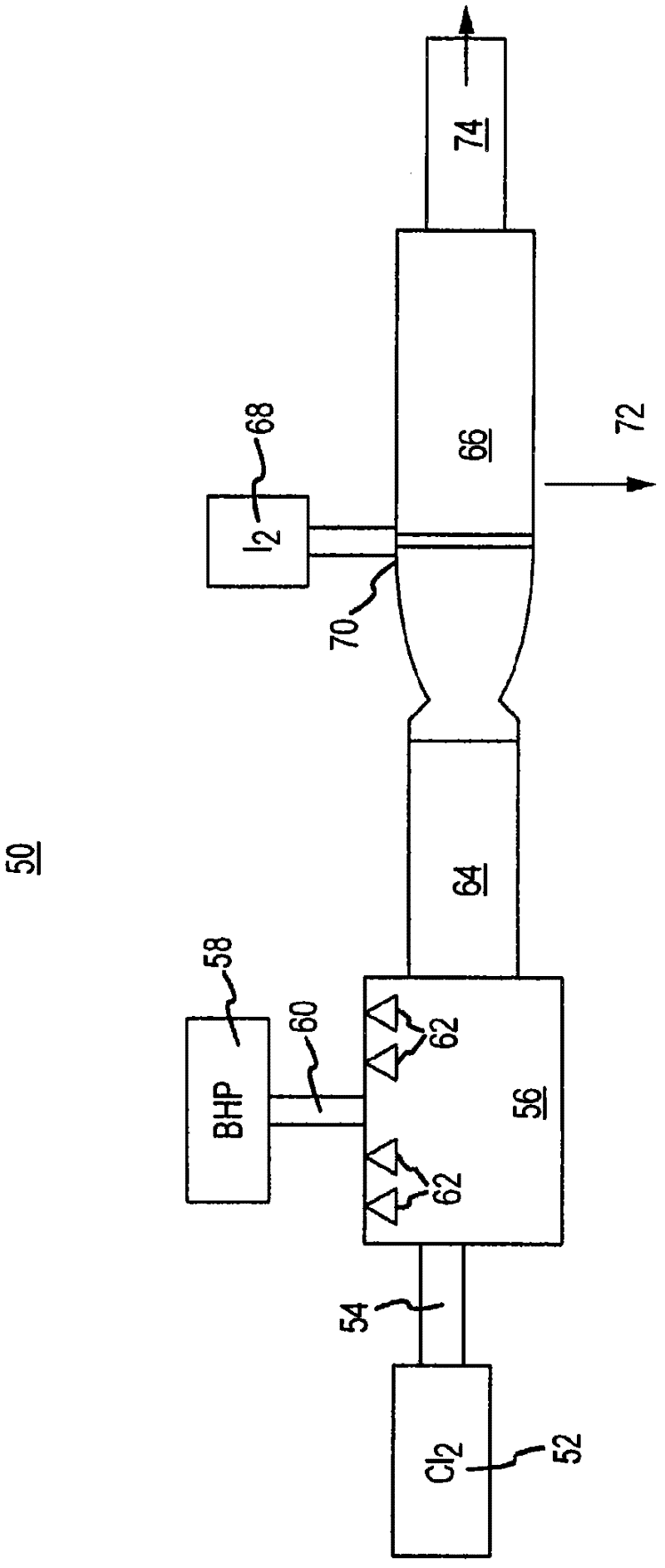

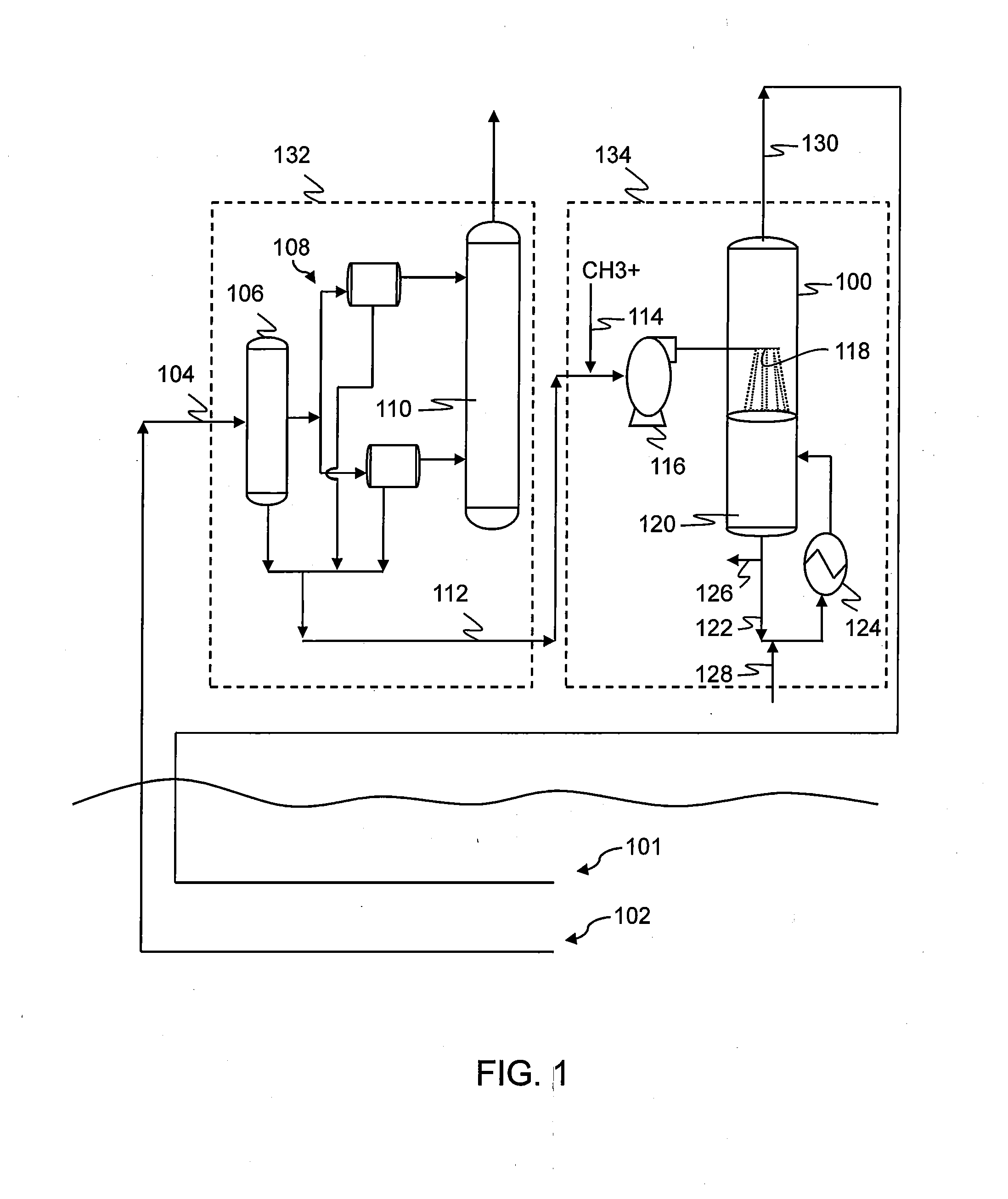

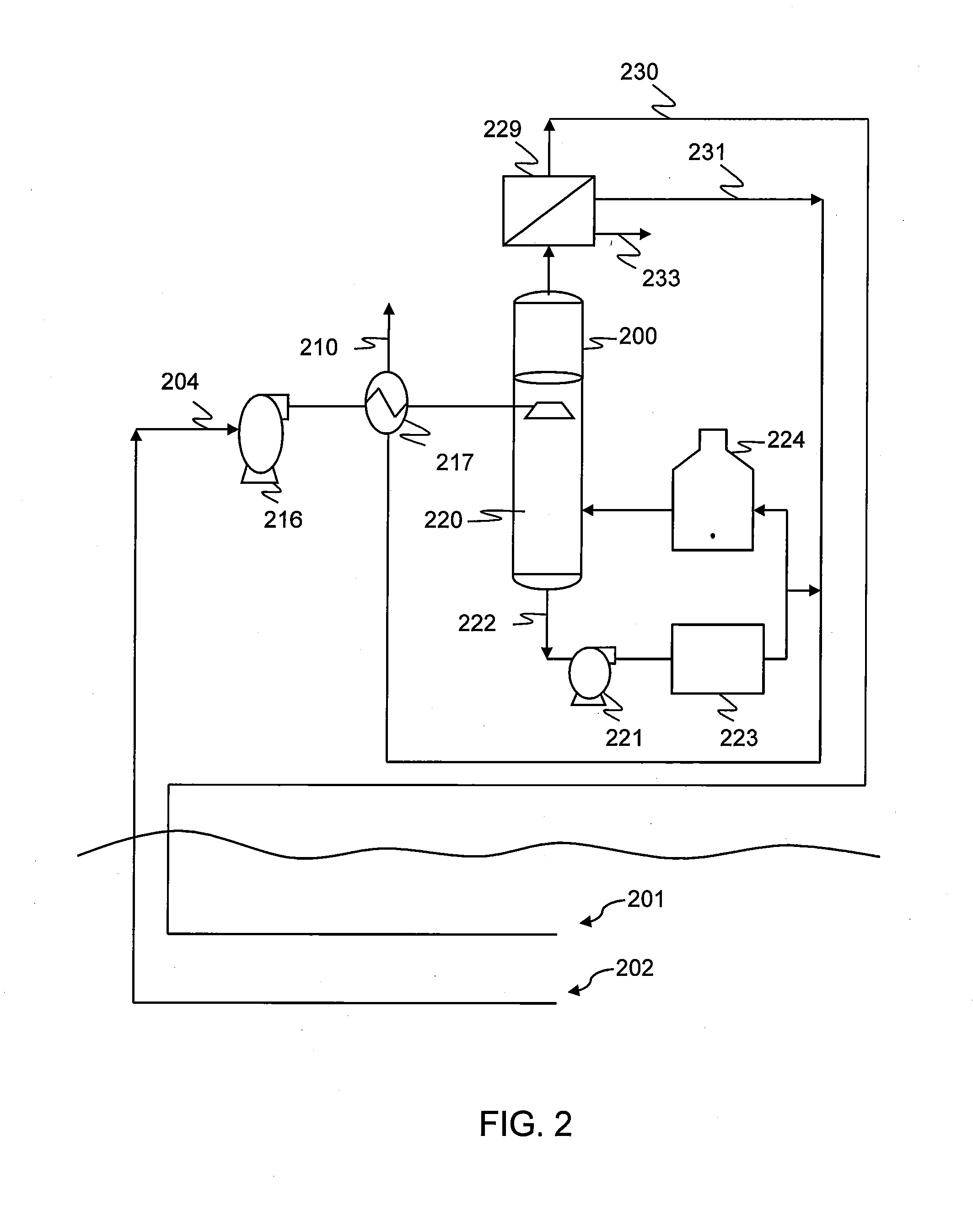

Gas liquid contactor and effluent cleaning system and method

InactiveUS20100011956A1Large volumetric mass transport coefficientSmall sizeLaser detailsFlow mixersLiquid jetEngineering

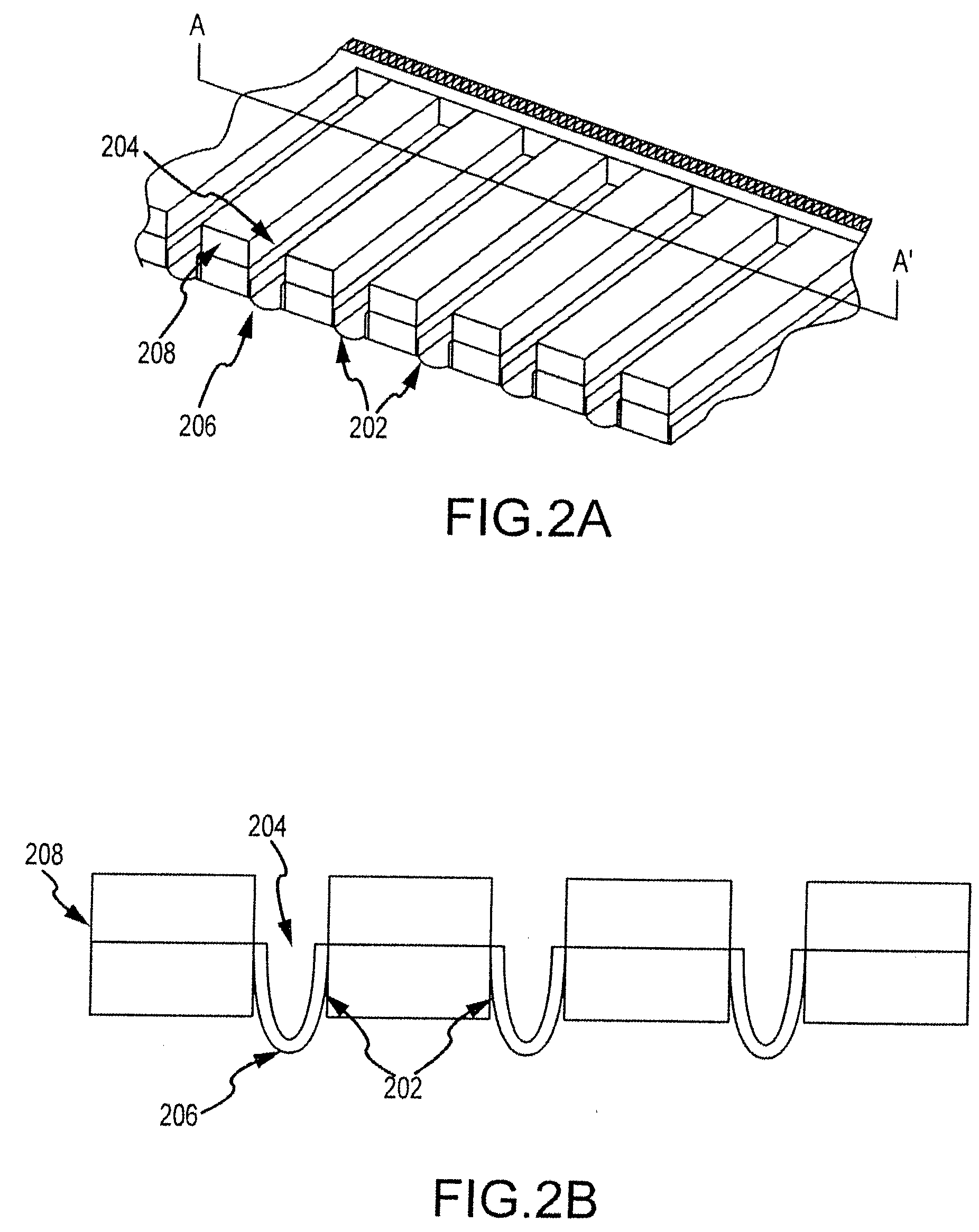

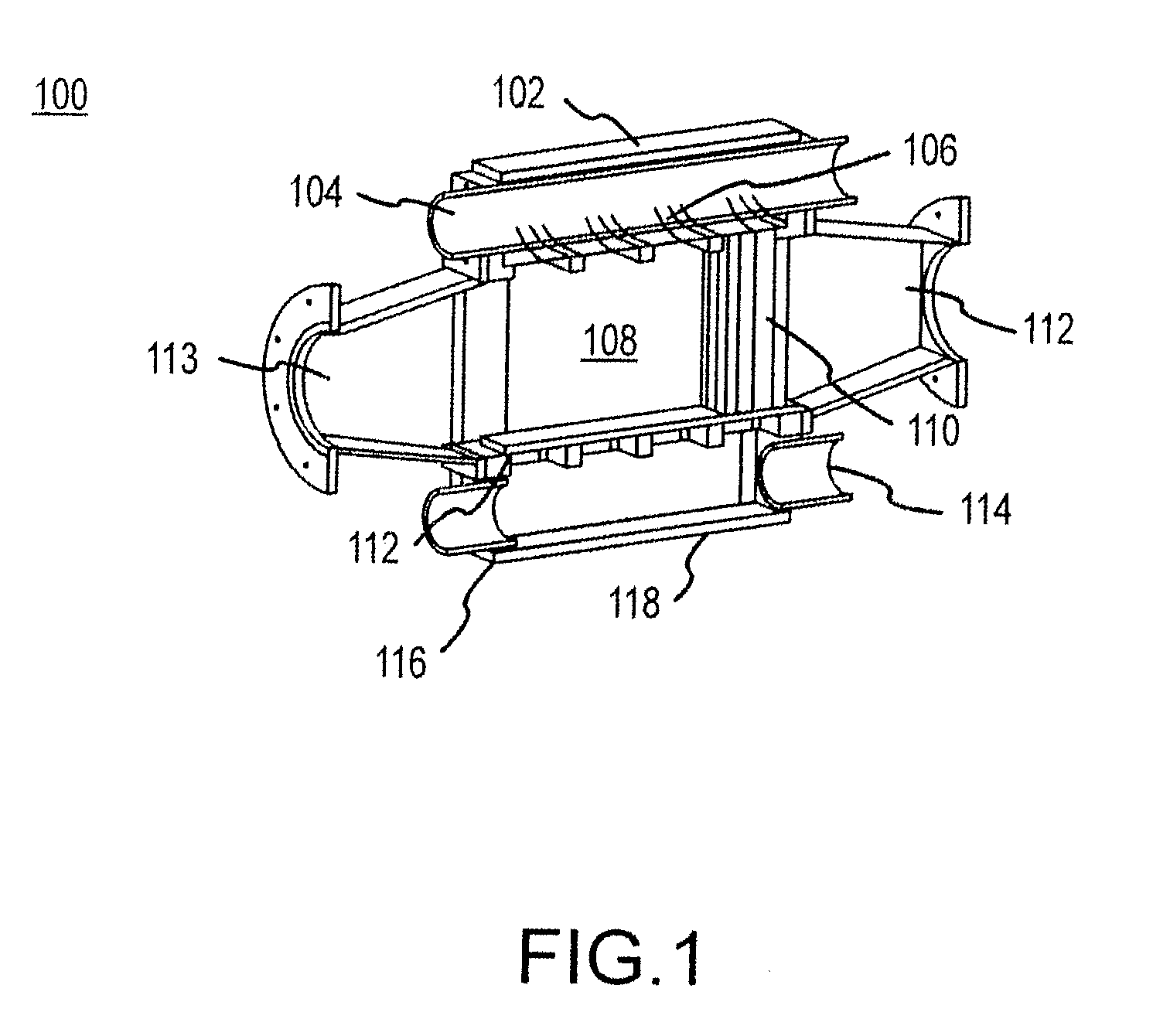

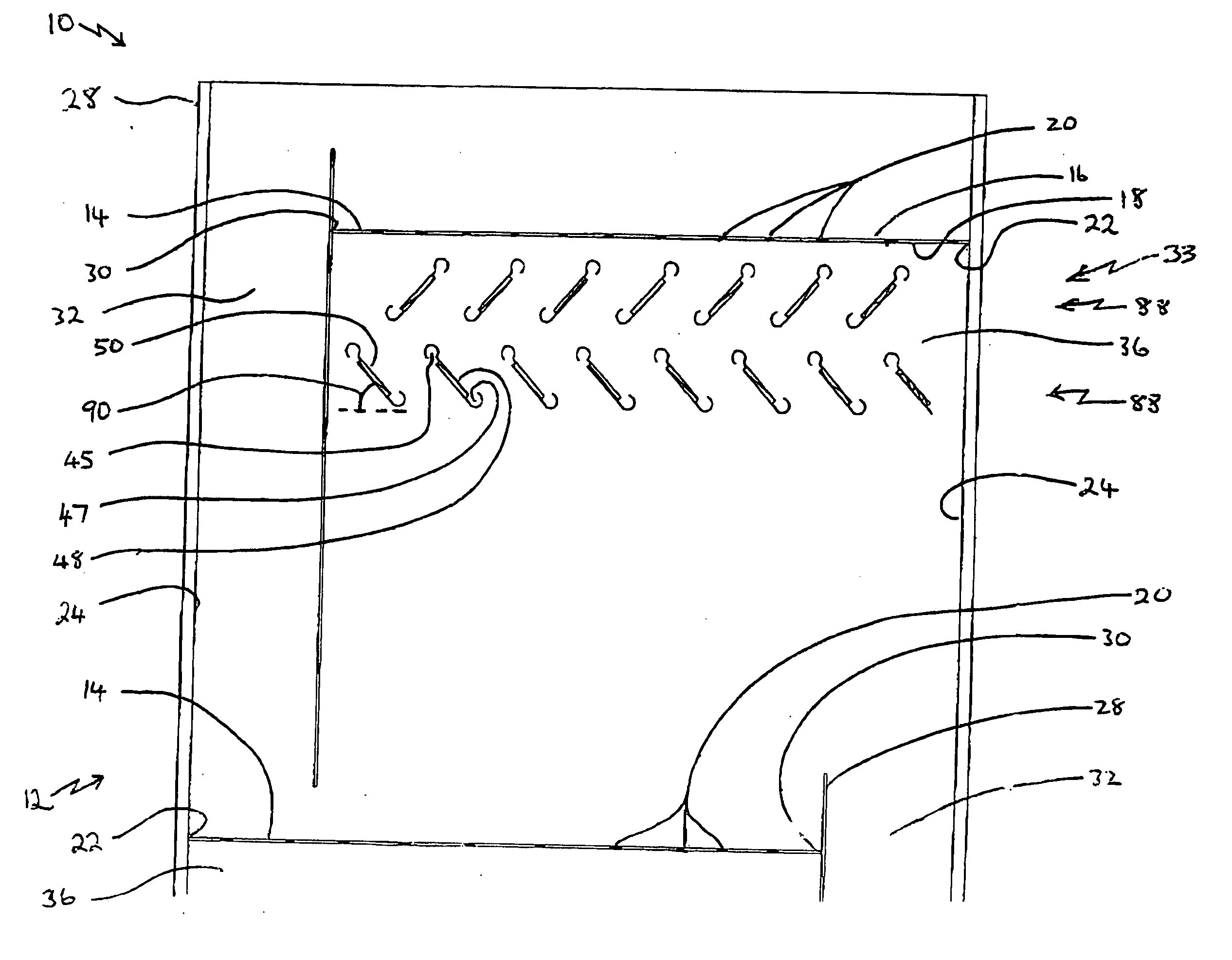

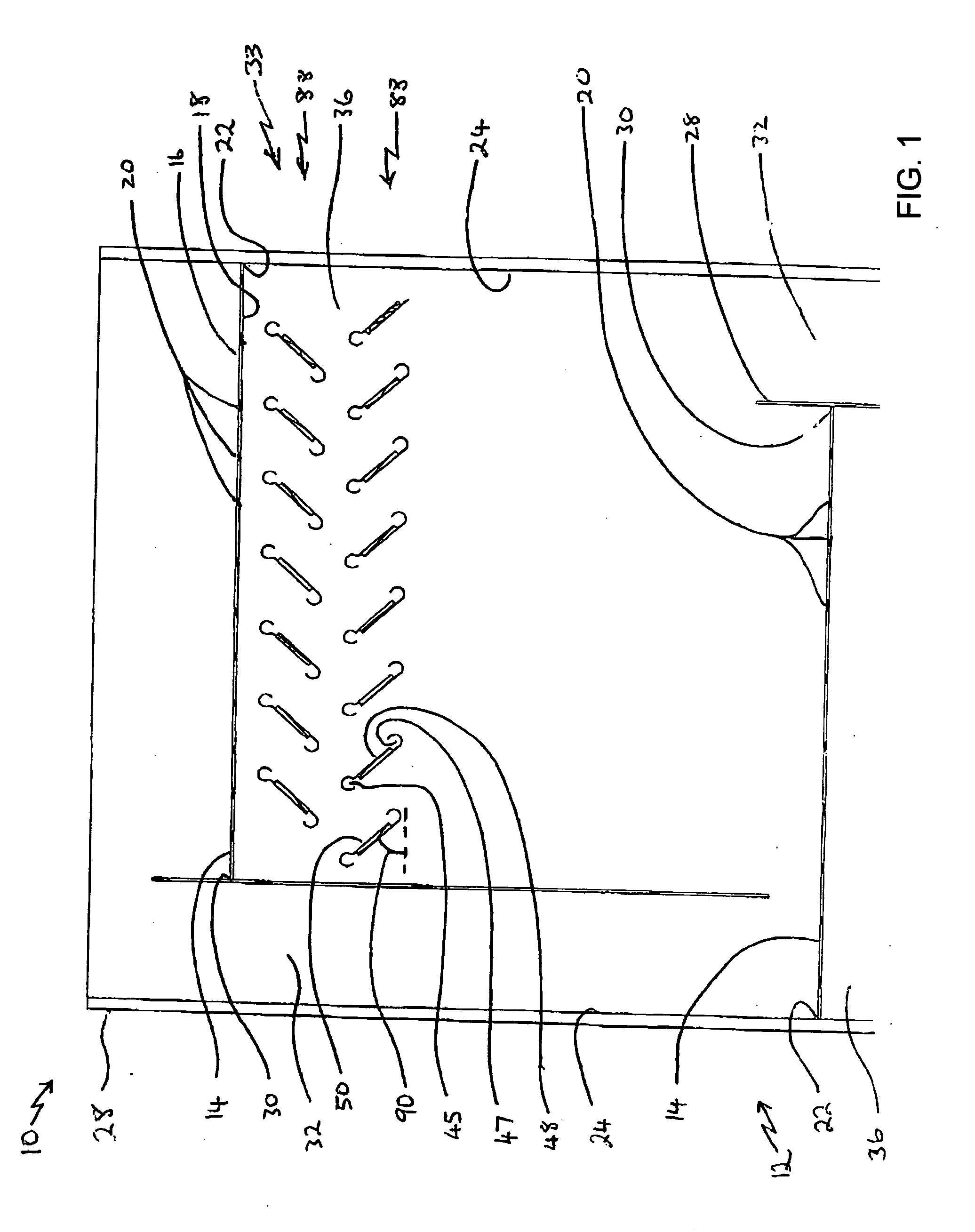

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas. An embodiment of the invention is directed towards a gas liquid contactor module including a liquid inlet and outlet and a gas inlet and outlet. An array of nozzles is in communication with the liquid inlet and the gas inlet. The array of nozzles is configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas flow and maximize gas flow and liquid flow interactions while rapidly replenishing the liquid.

Owner:NEUMANN SYST GROUP

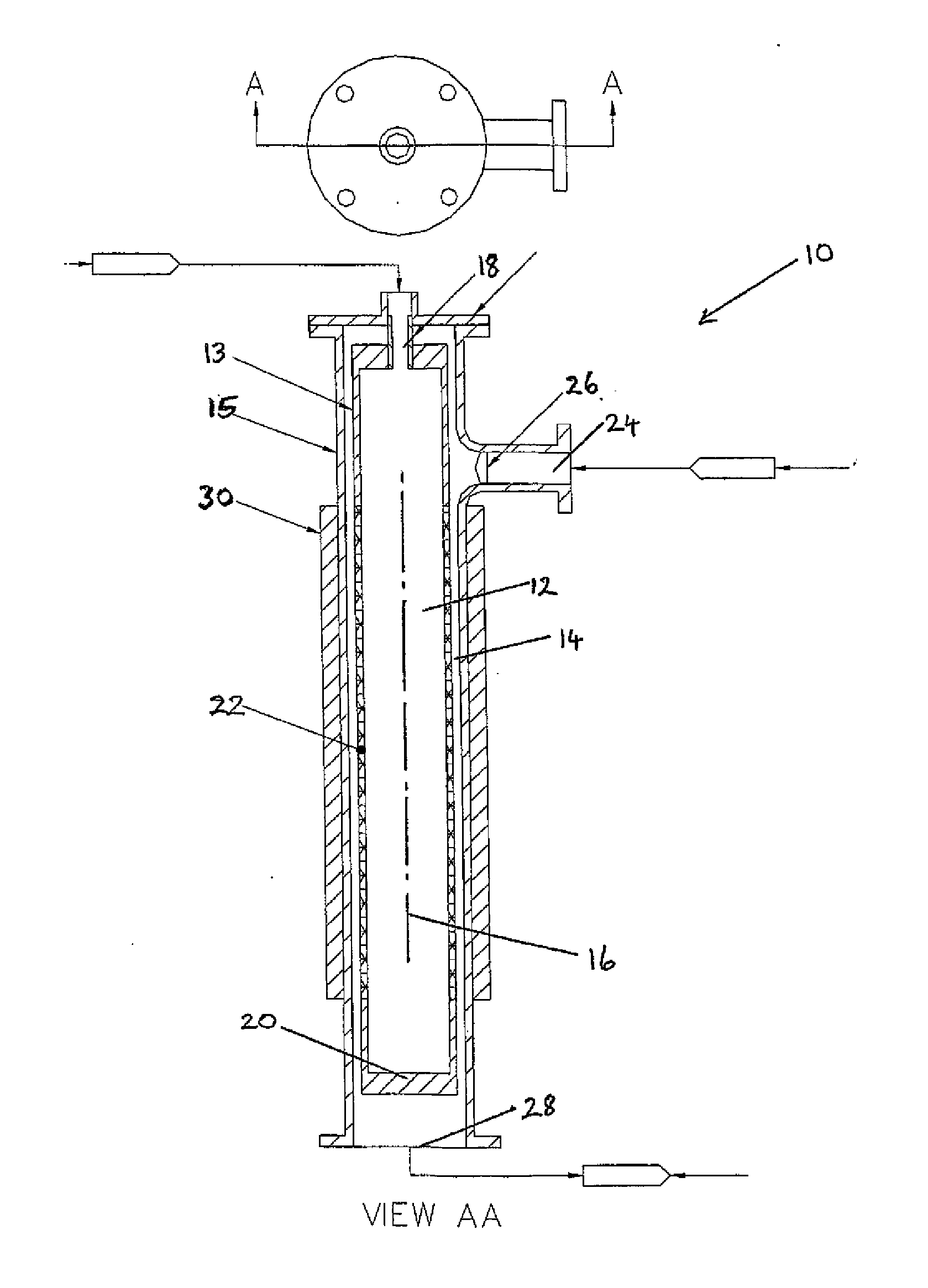

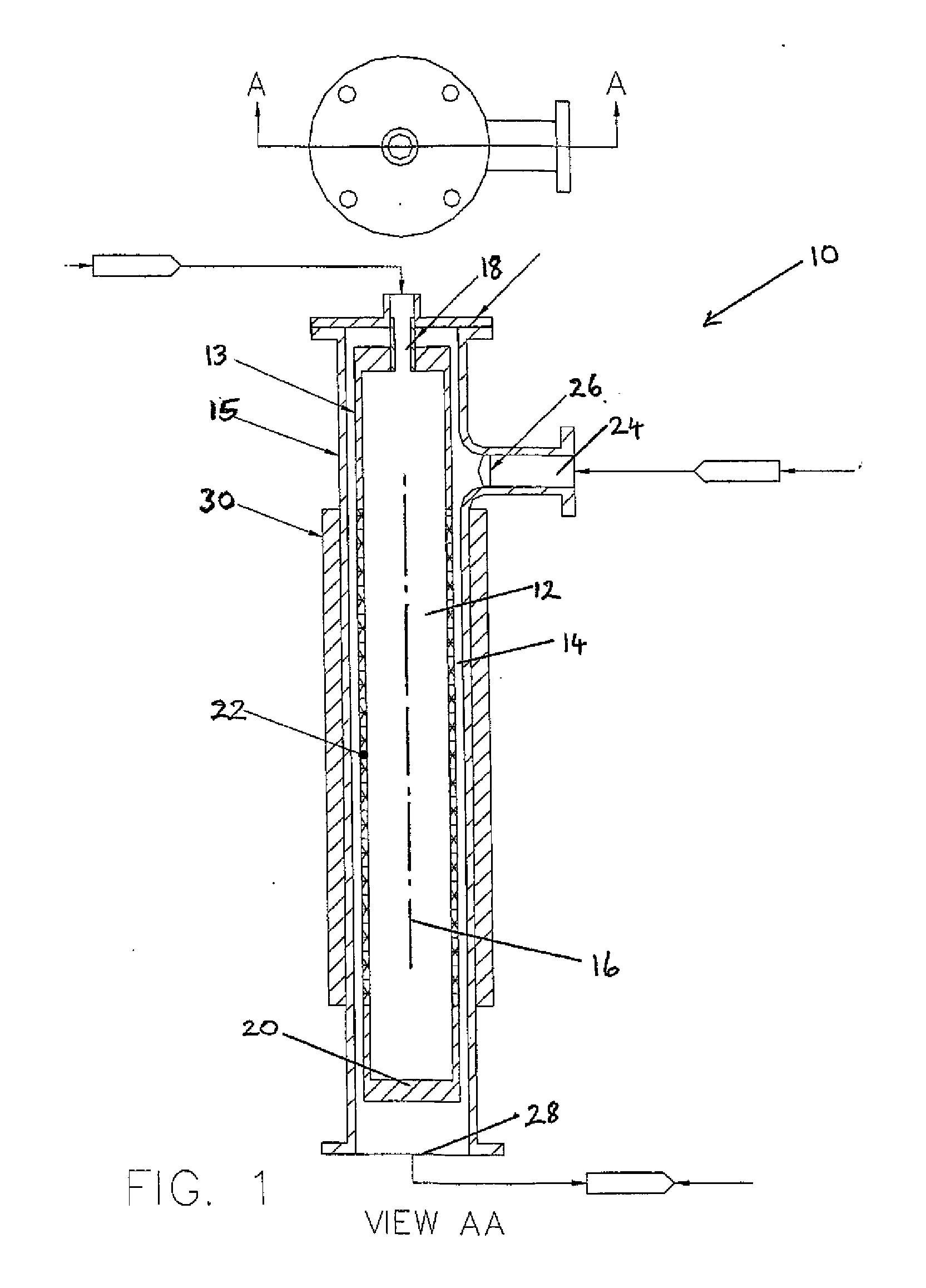

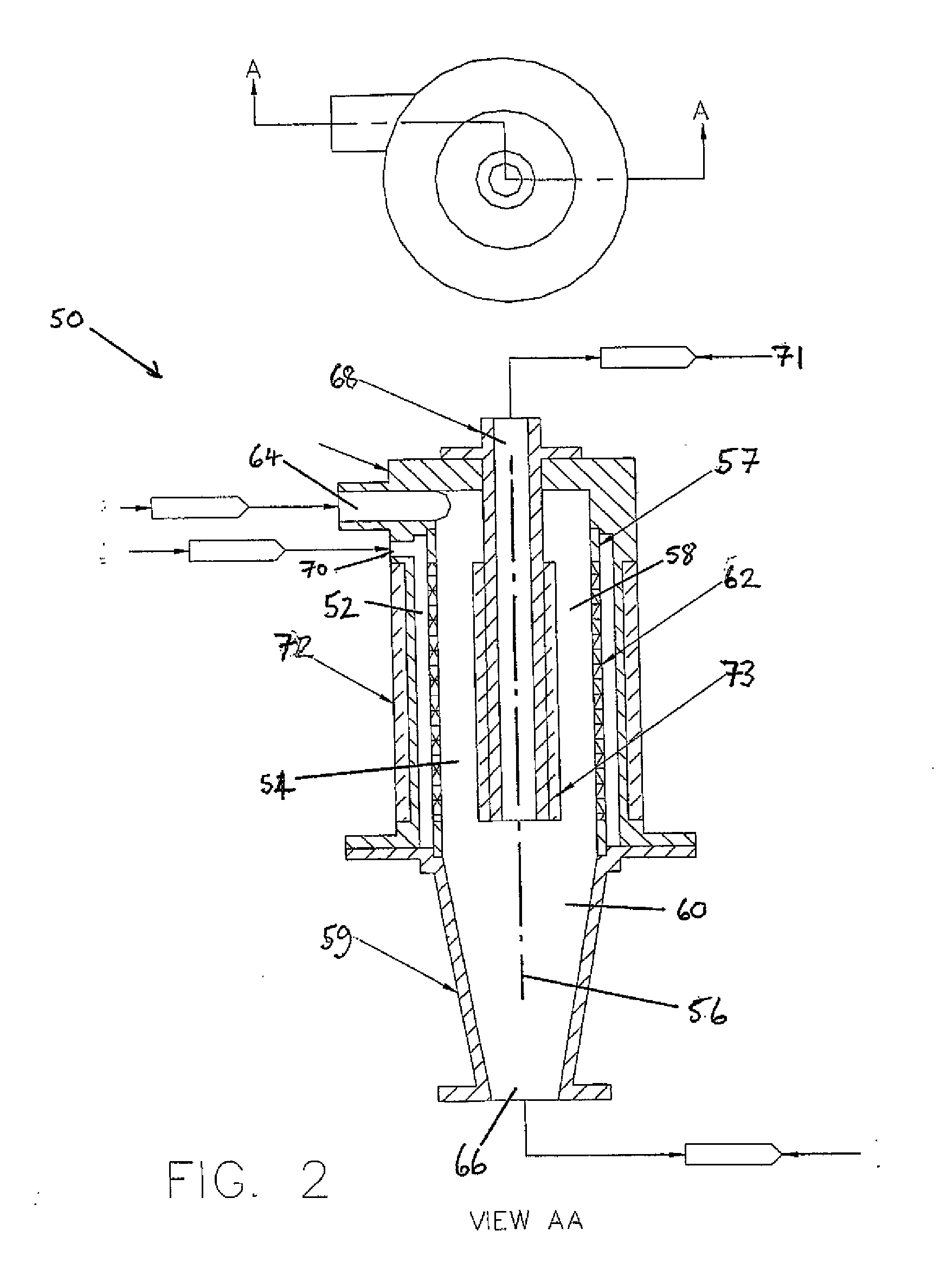

Membrane desiccation heat pump

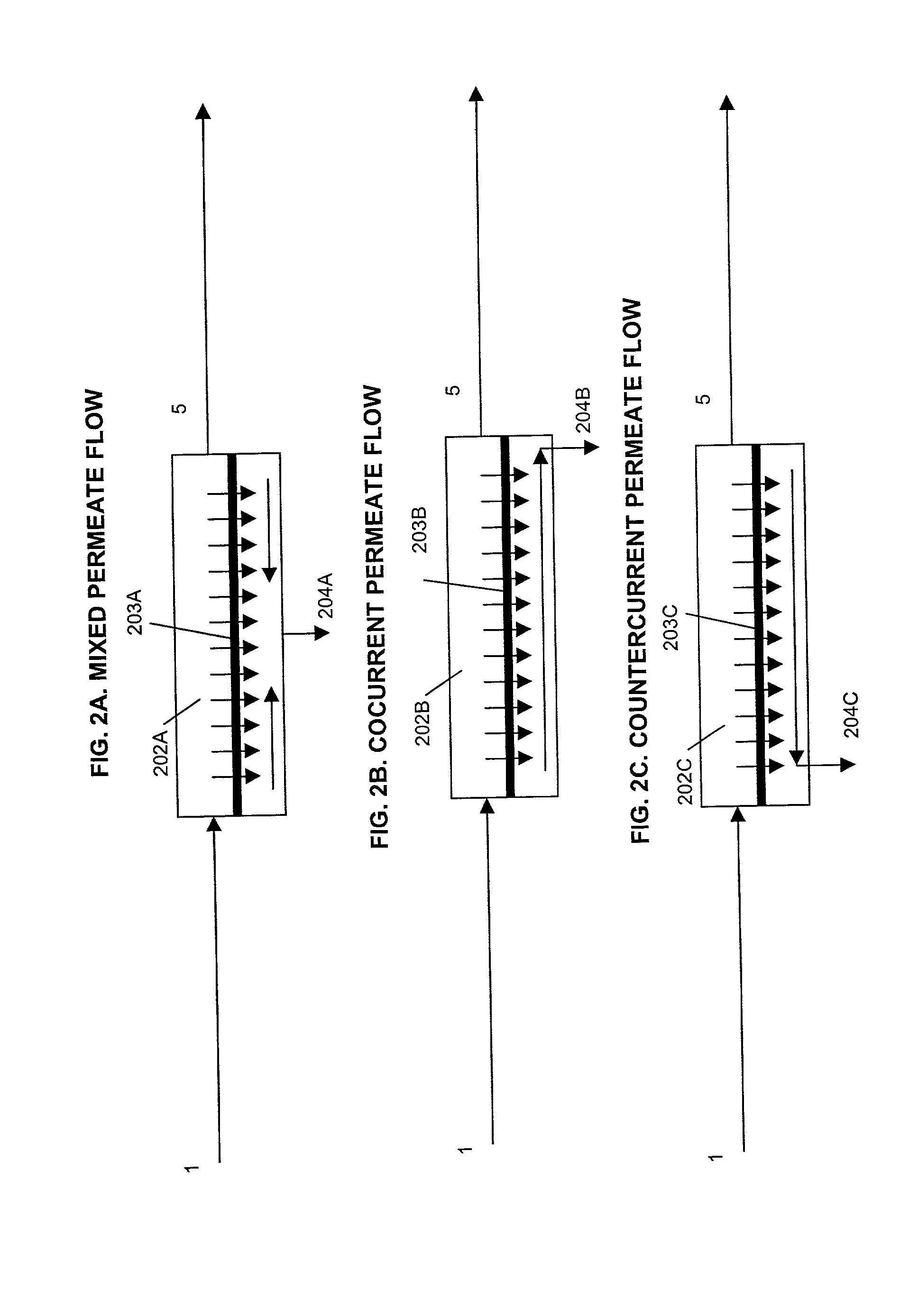

InactiveUS20020096312A1Great flexibility and controlReduce in quantityAir-treating devicesHeat pumpsThermal energyProduct gas

There is provided a system for pumping thermal energy. The system includes (a) a membrane permeator for removing vapor from a process gas and for providing a vapor-depleted process gas, and (b) a gas-liquid contactor for adding vapor from a liquid to a vapor-depleted gas to produce a vapor-added process gas. The system transfers a quantity of thermal energy from the liquid to the vapor-added process gas, and is also capable of upgrading the thermal energy to a higher temperature. The system may be used for various heat pump applications including chilling and waste heat or low level heat recovery.

Owner:KORIN AMOS

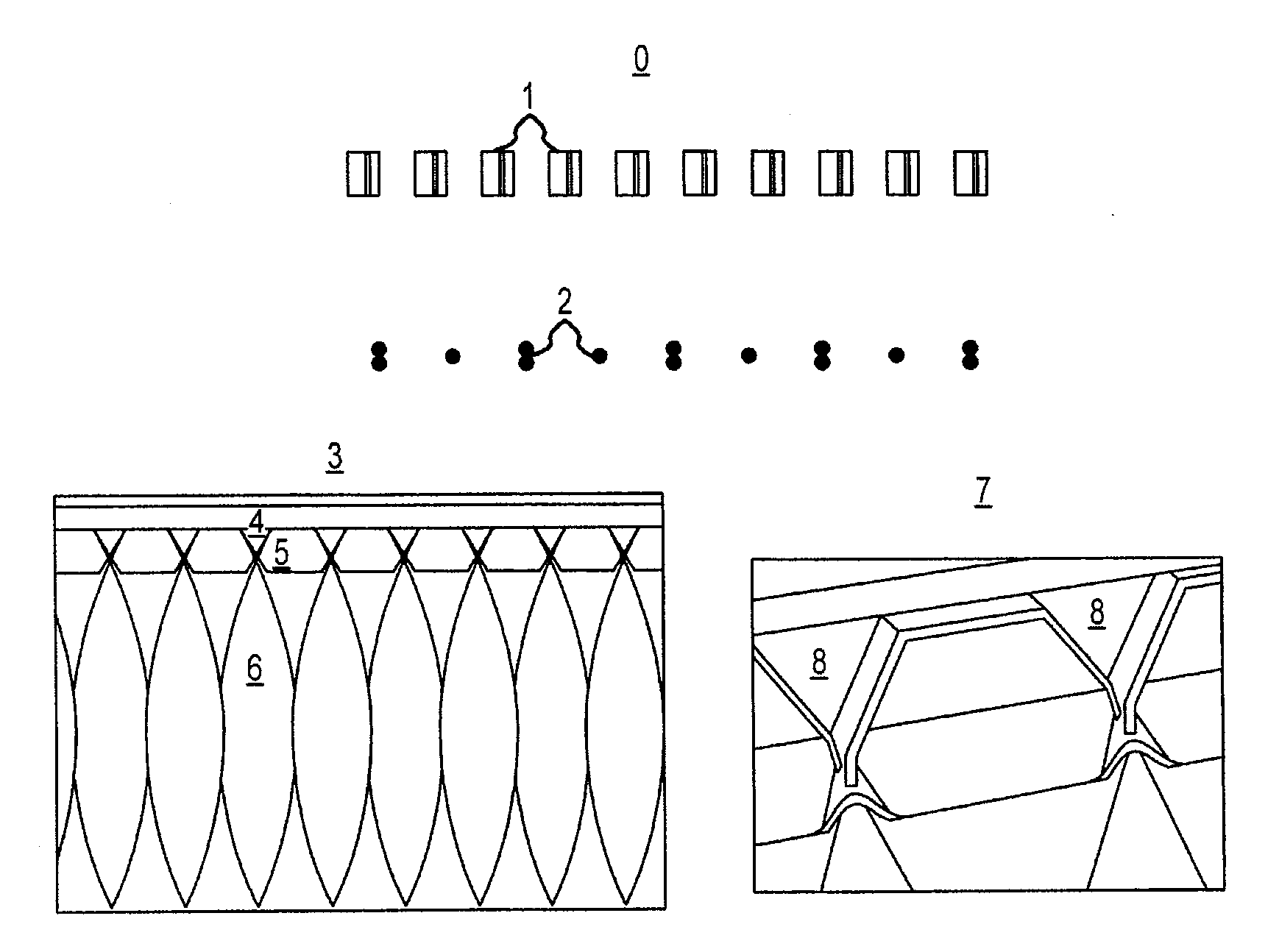

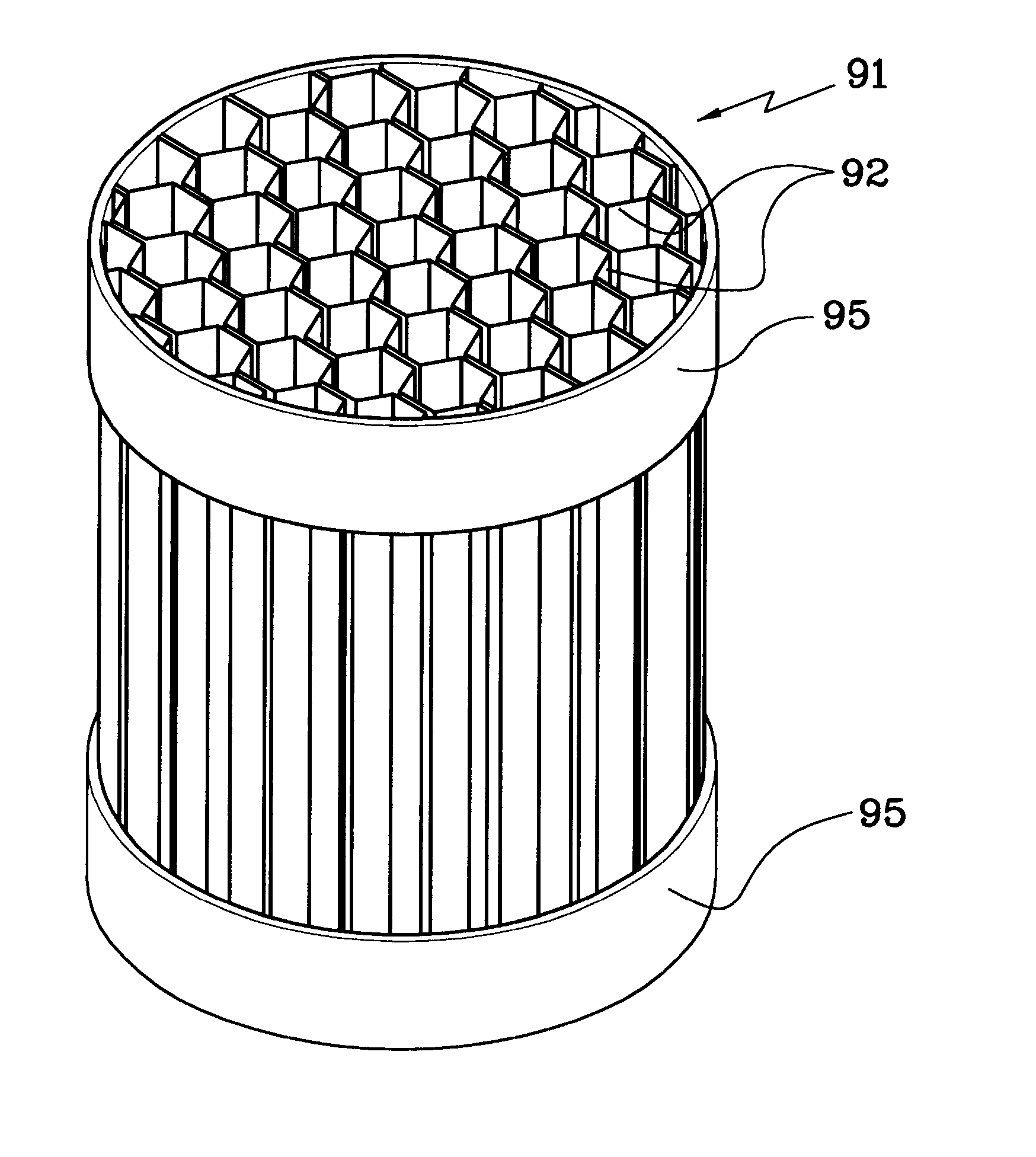

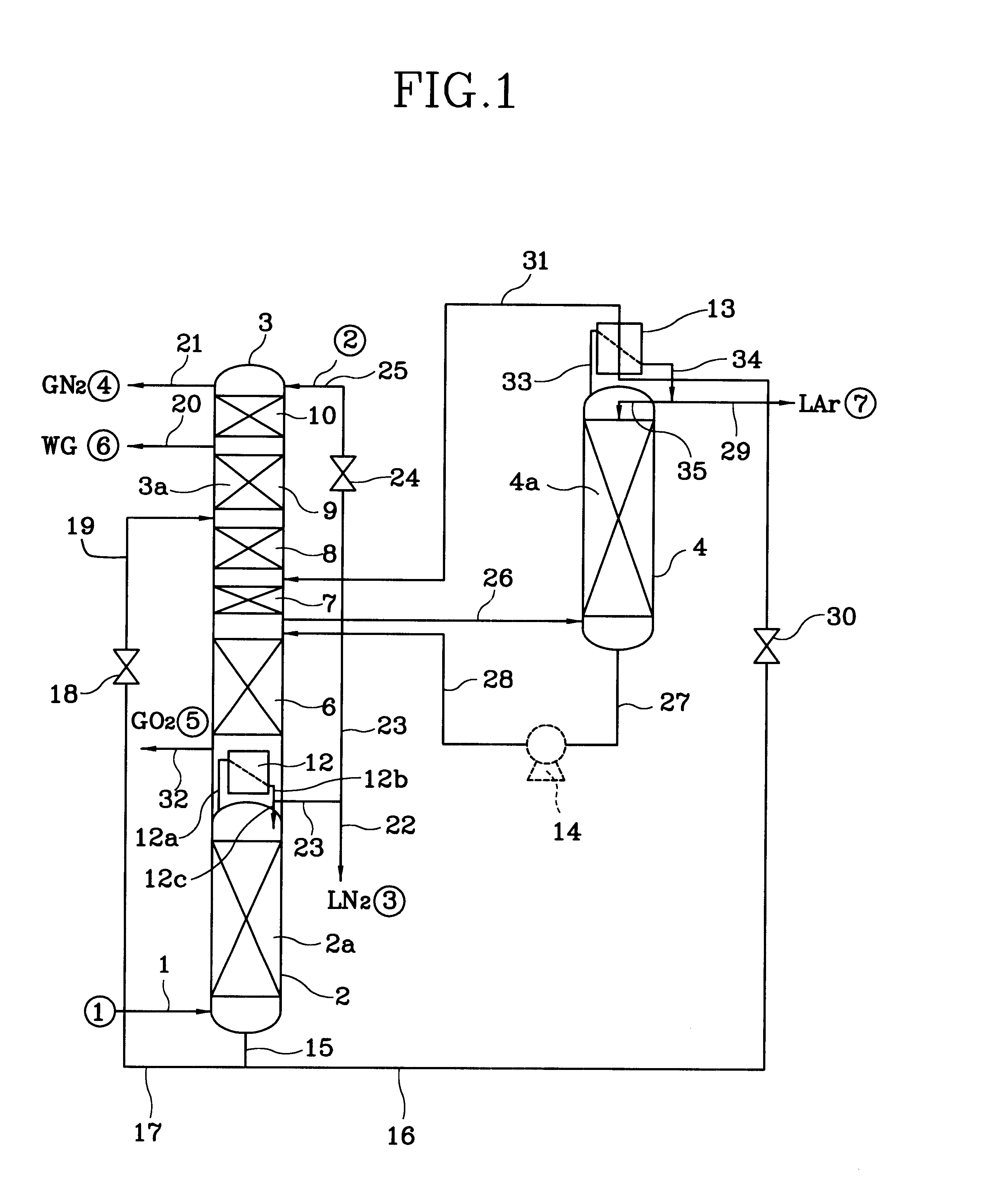

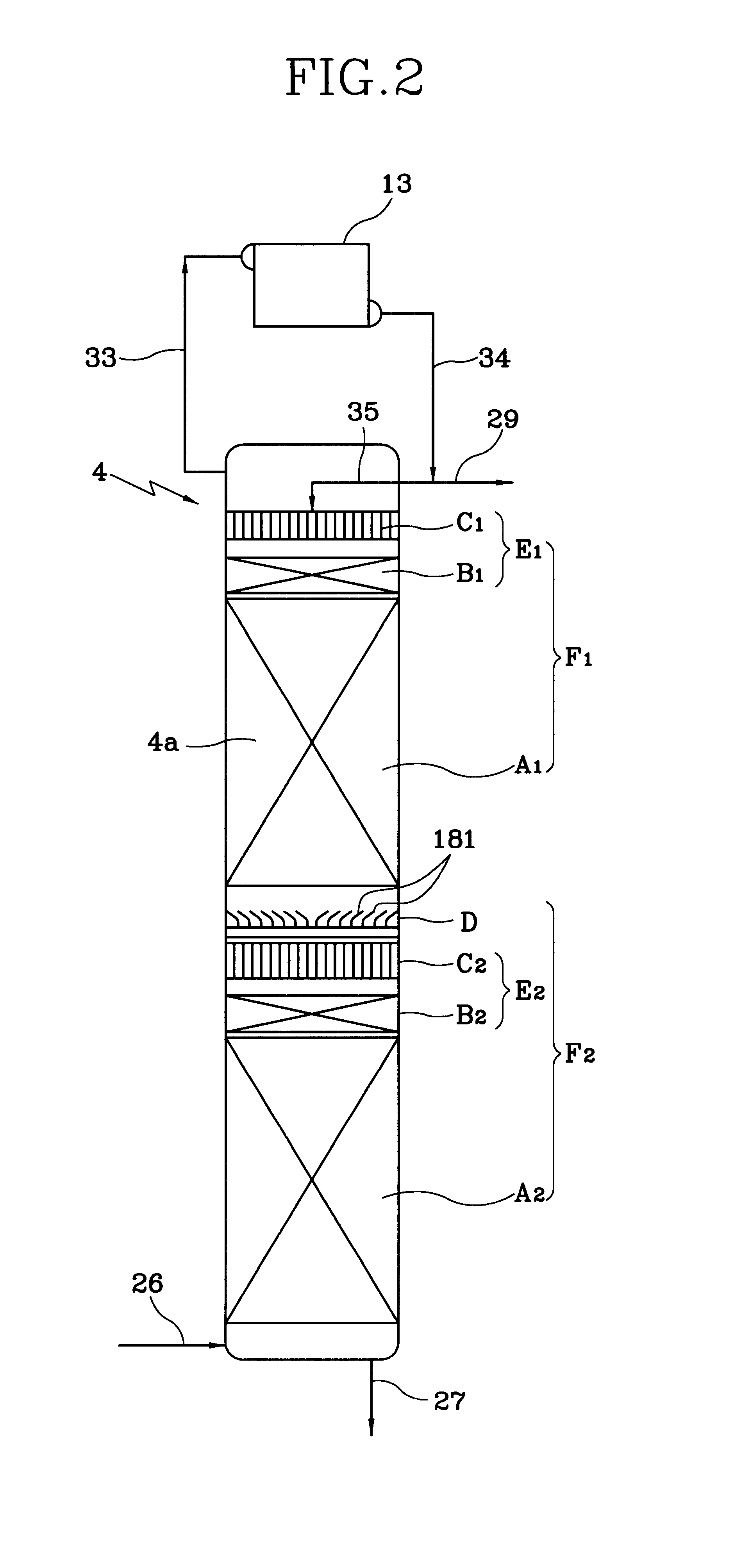

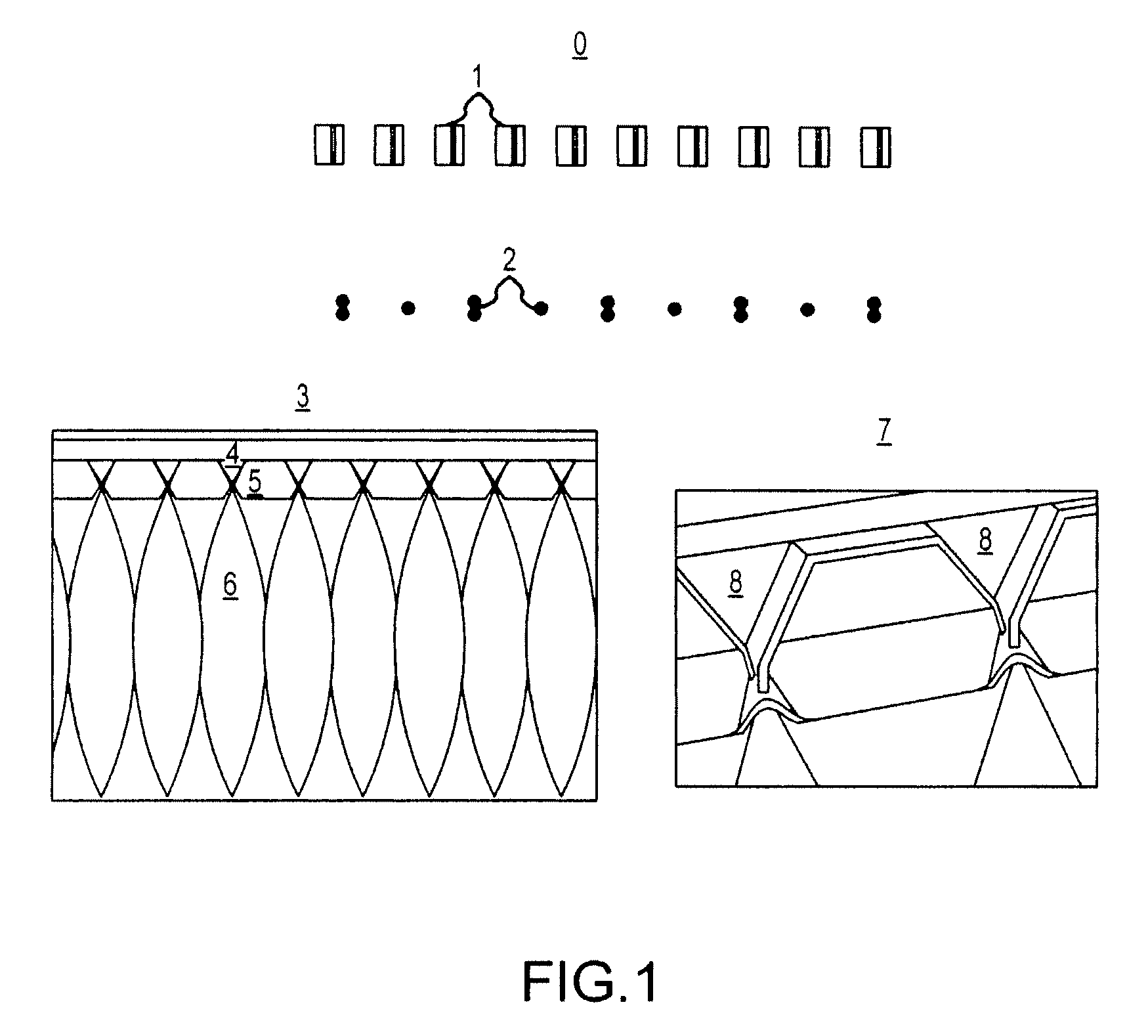

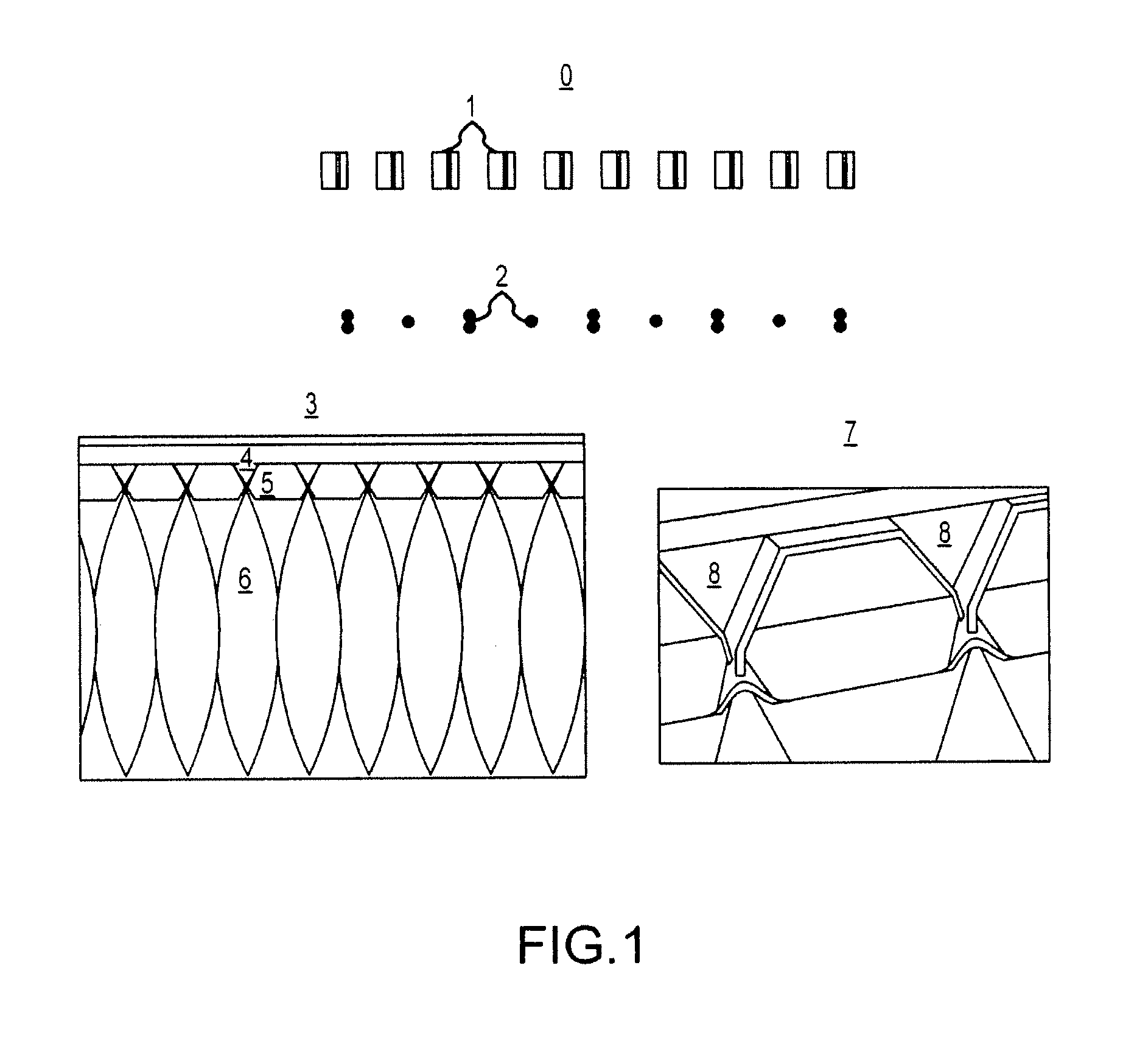

Vapor-liquid contactor, cryogenic air separation unit and method of gas separation

InactiveUS6565629B1Increased pressure lossIncrease flow resistanceCarburetting airSolidificationAir separationMechanical engineering

In an vapor-liquid contactor 4a for flowing down a liquid along the surface of a packing and contacting said liquid with the vapor while ascending the vapor, the improvement being characterized in that said packing is a non-promoting-fluid-dispersion type structured packing A1, A2 in which various types of thin sheets or tubes for determining the flow direction of the above liquid or vapor is laminated and arranged in the perpendicular direction, and said contactor includes at least one fluid distribution unit E1, E2 formed of a rough distribution part C1, C2 to distribute the liquid roughly and a minute distribution part B1, B2 to distribute the liquid minutely and equally.

Owner:NIPPON SANSO CORP

Gas liquid contactor and effluent cleaning system and method

Owner:NEUMANN SYST GROUP

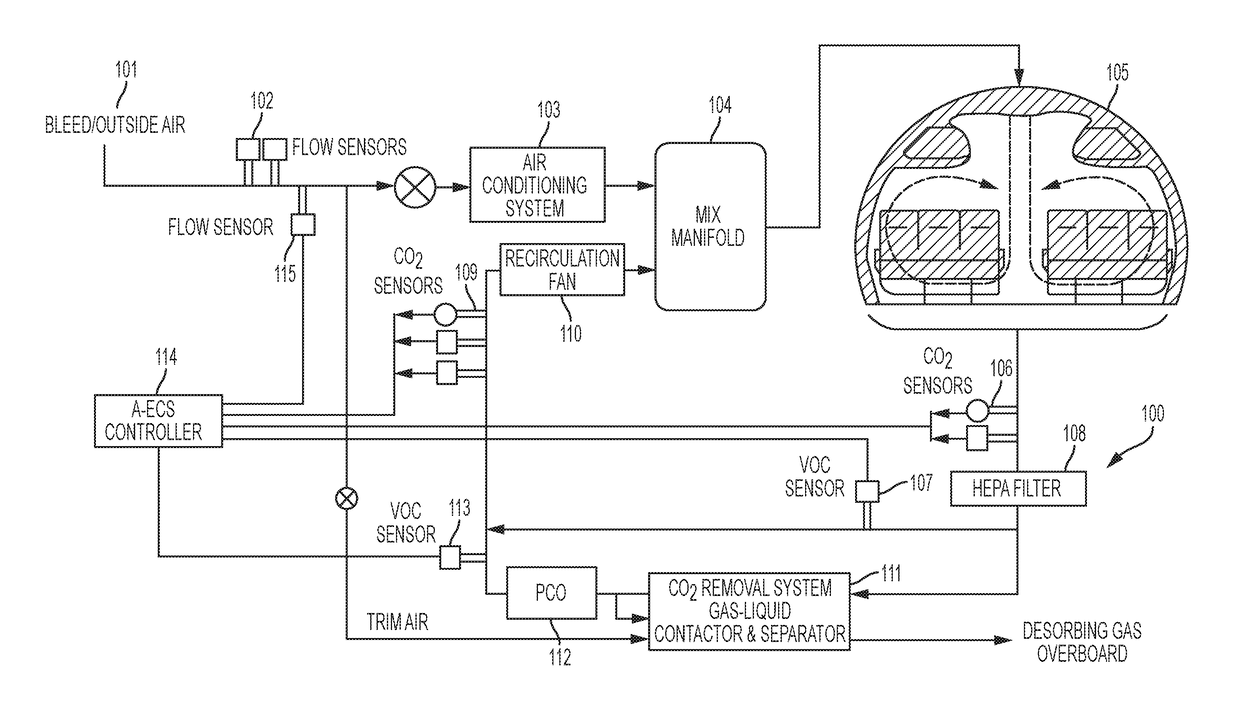

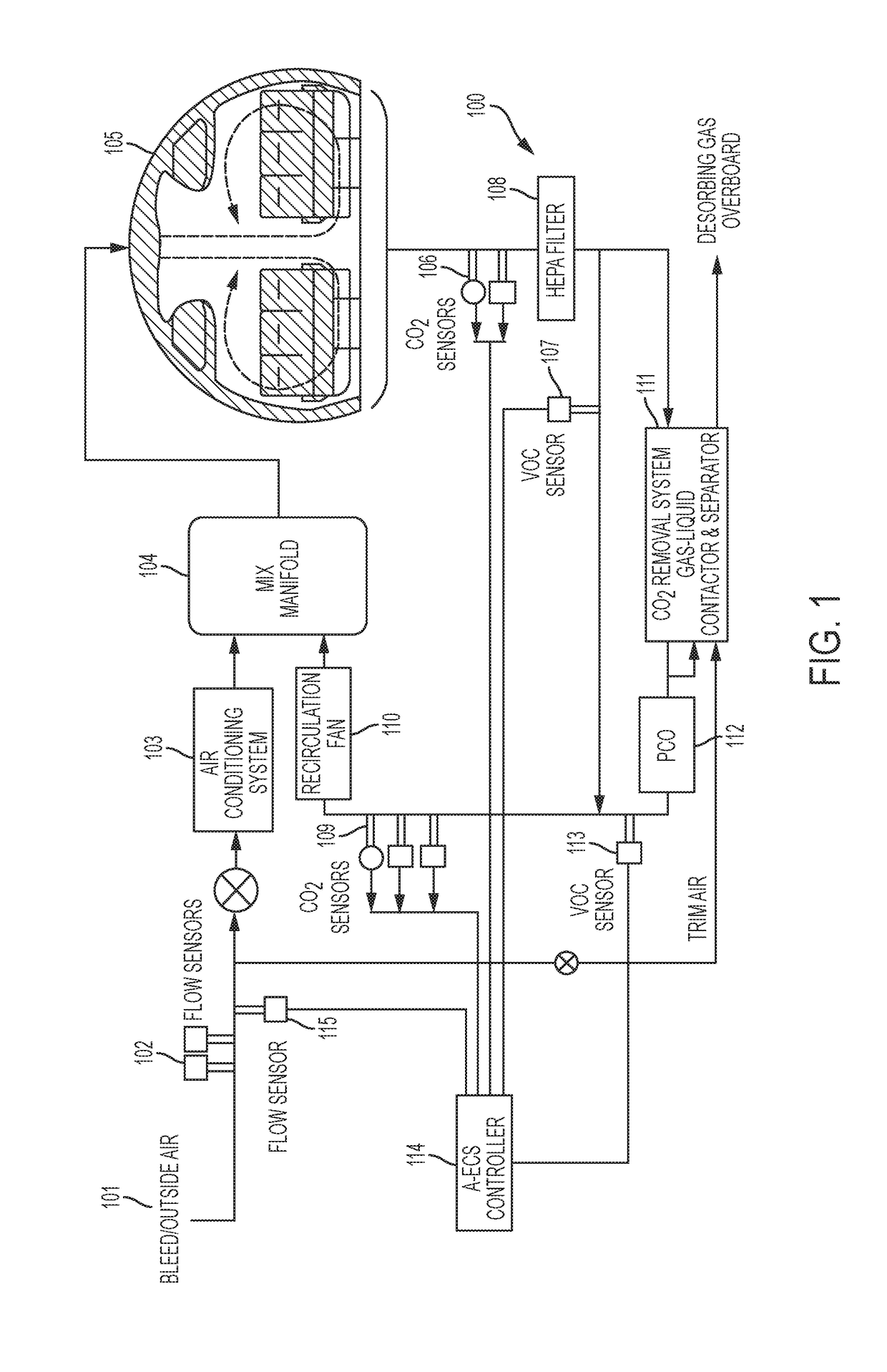

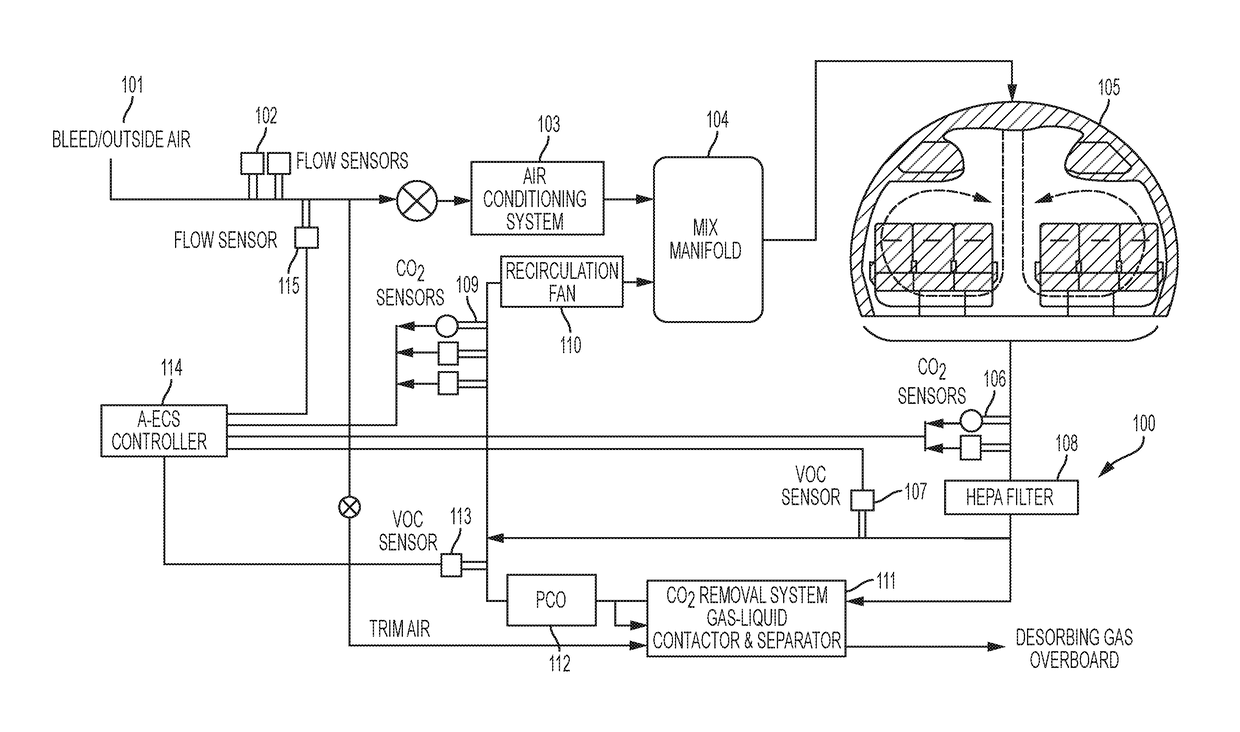

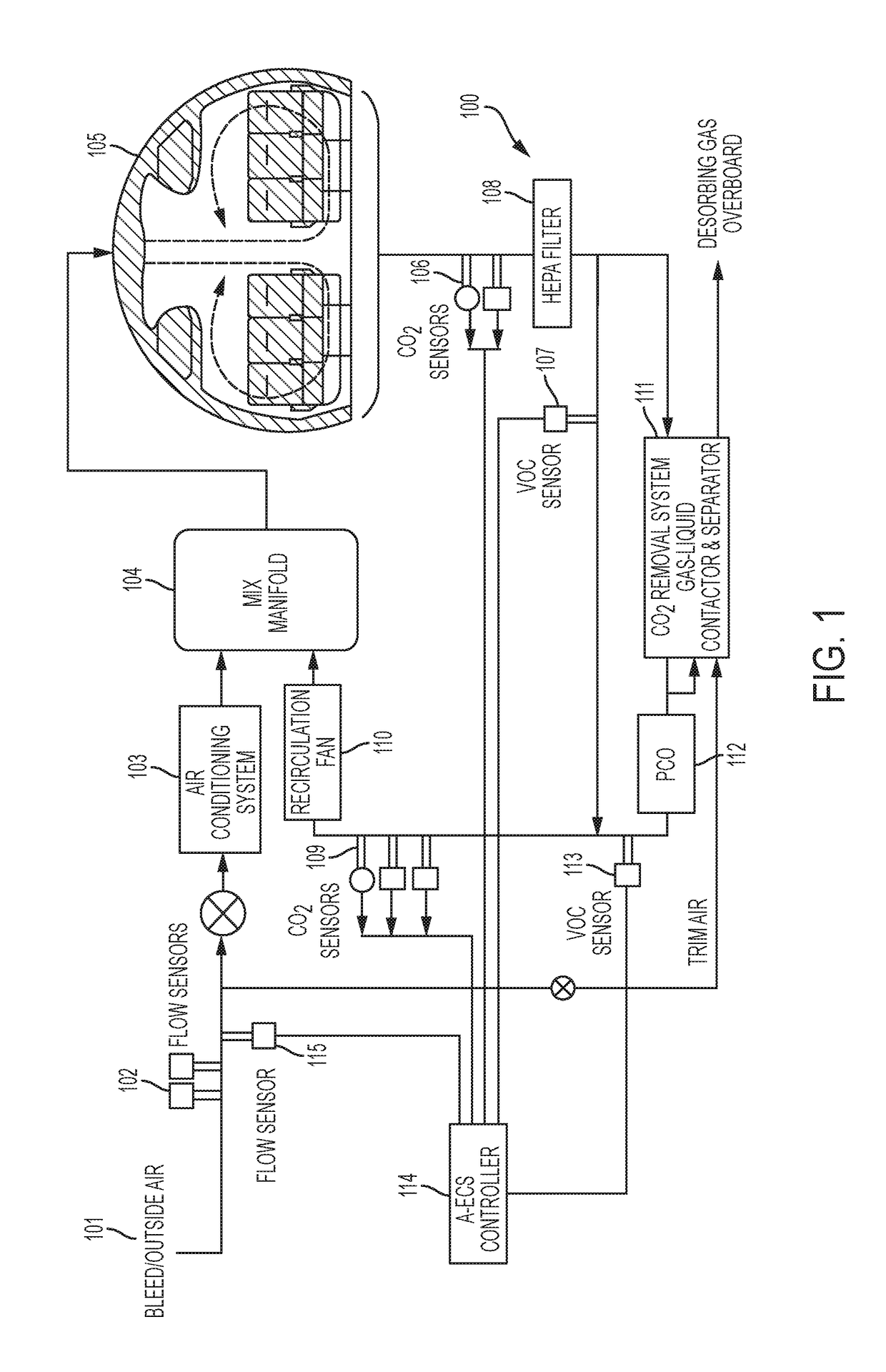

Apparatus and methods for enhancing gas-liquid contact/separation

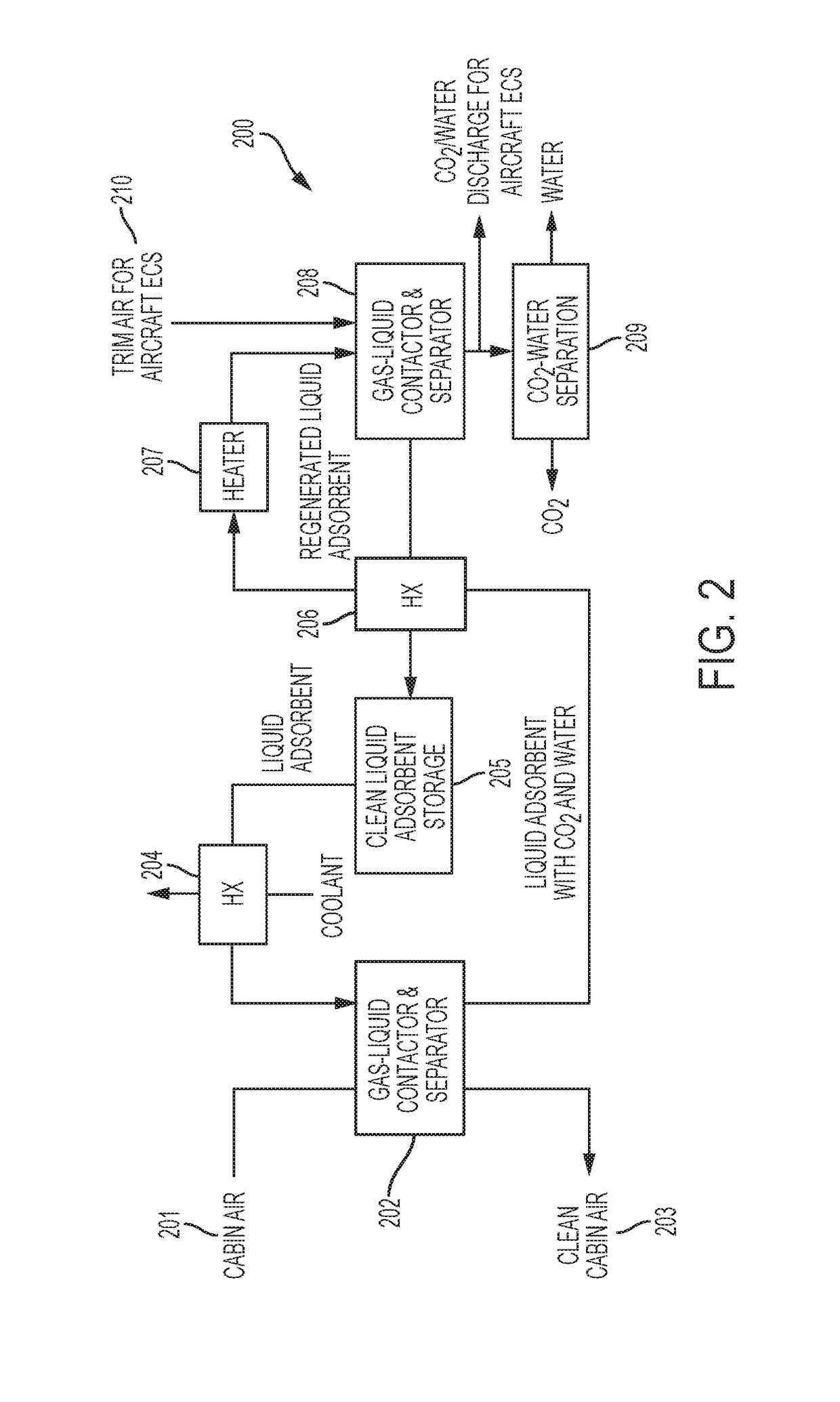

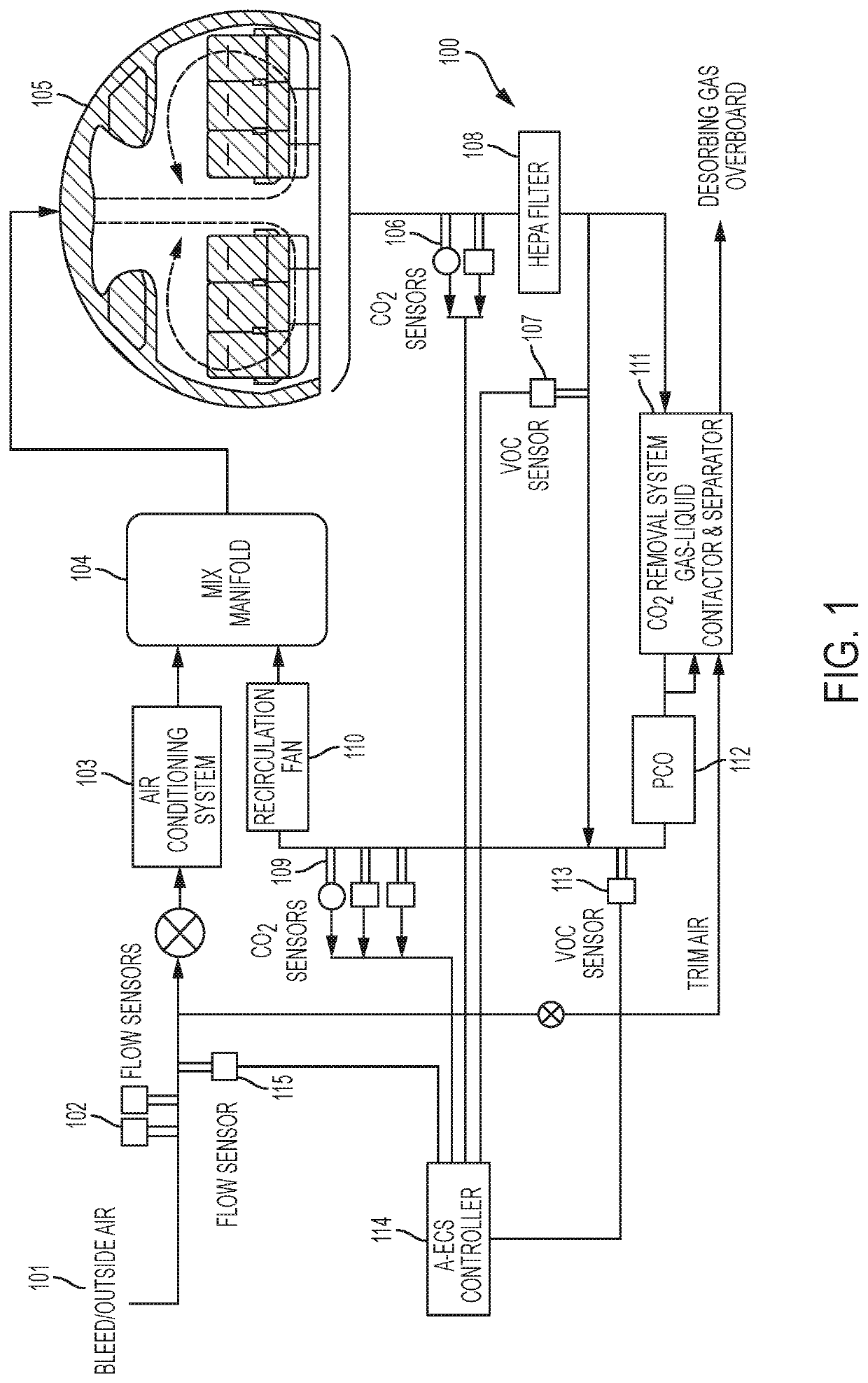

ActiveUS20180056234A1Smooth connectionCosmonautic environmental control arrangementGas treatmentControl systemEnvironmental control system

An environmental control system includes an air conditioning subsystem; a mix manifold downstream of the air conditioning subsystem and upstream of an environment to be conditioned; and a contaminant removal subsystem downstream of the environment to be conditioned. The contaminant removal subsystem includes a first gas-liquid contactor-separator. The first gas-liquid contactor-separator includes a first rotating porous bed that provides a heat / mass transfer surface for contact between a contaminated air from the environment and a liquid absorbent.

Owner:HONEYWELL INT INC

Gas liquid contactor and effluent cleaning system and method

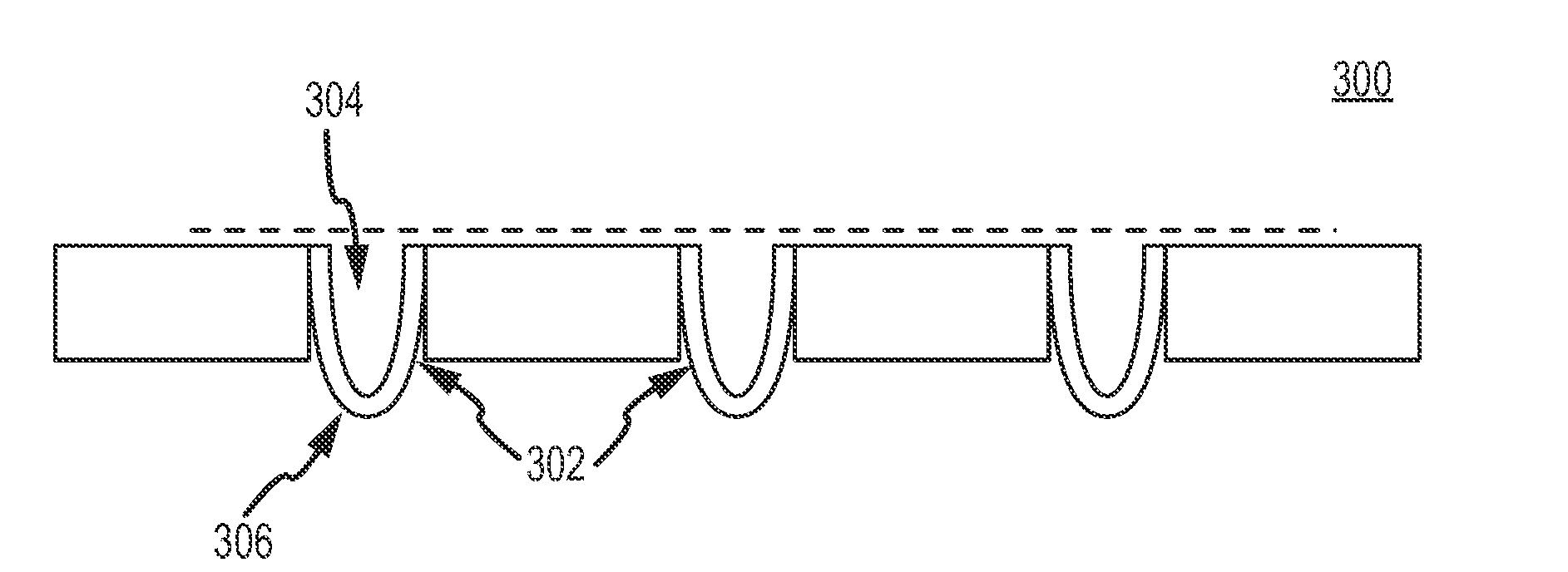

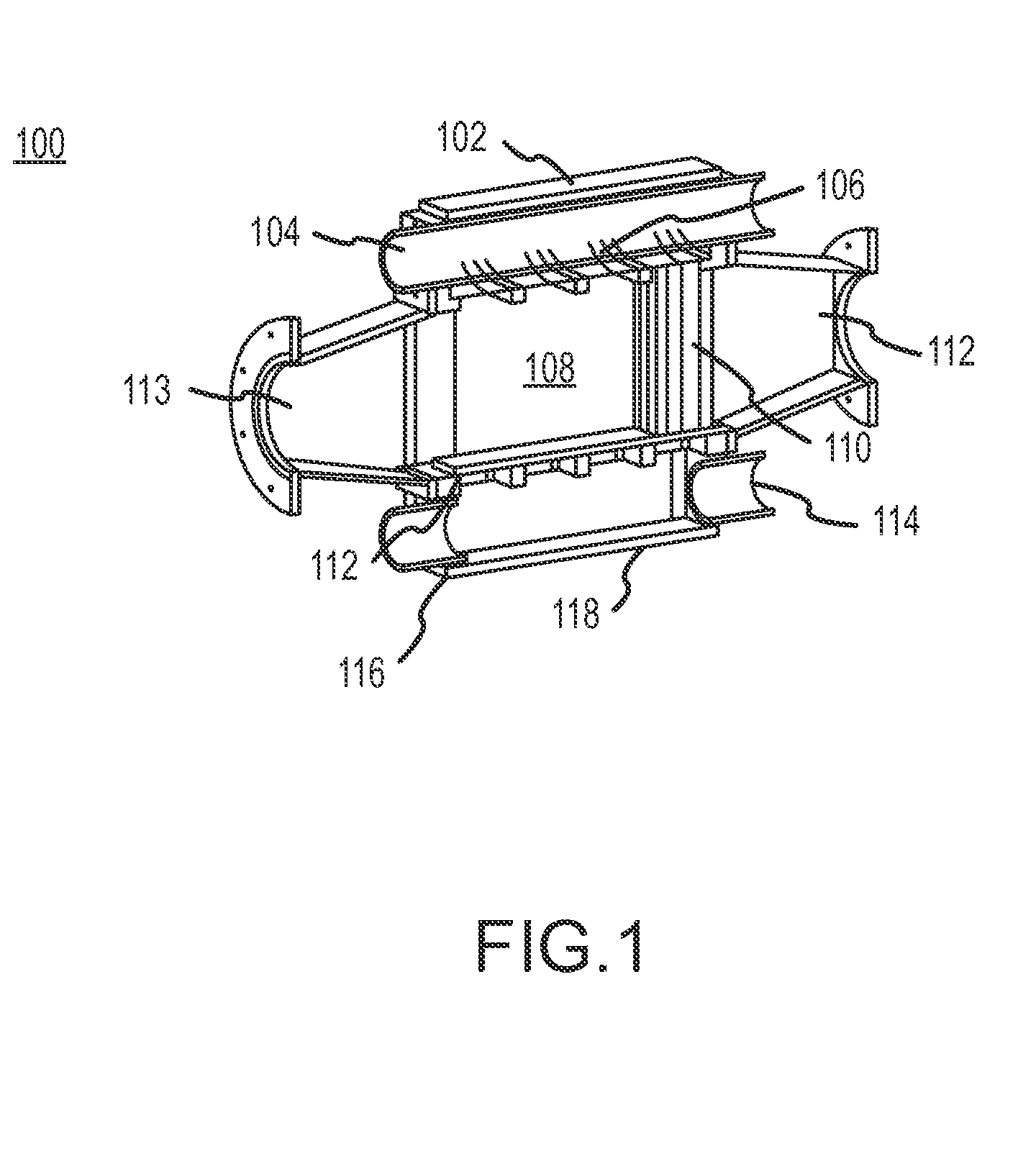

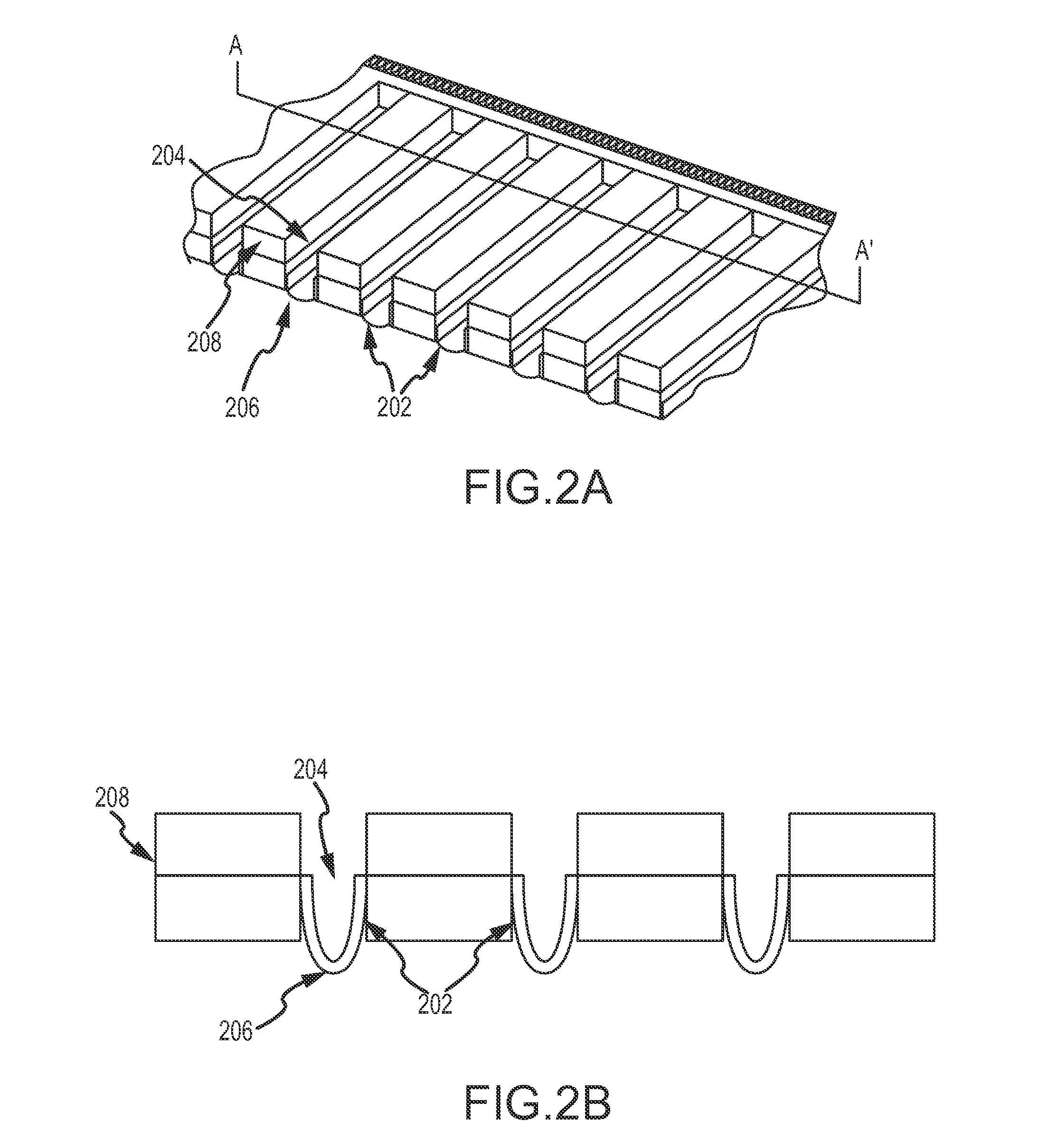

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas. An embodiment of the invention is directed towards a gas liquid contactor module including a liquid inlet and outlet and a gas inlet and outlet. An array of nozzles is in communication with the liquid inlet and the gas inlet. The array of nozzles is configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas flow and maximize gas flow and liquid flow interactions while rapidly replenishing the liquid.

Owner:NEUMANN SYST GROUP

Apparatus and method thereof

InactiveUS20110061530A1Improve jetting stabilityArea maximizationGas treatmentLaser detailsLiquid jetSpray nozzle

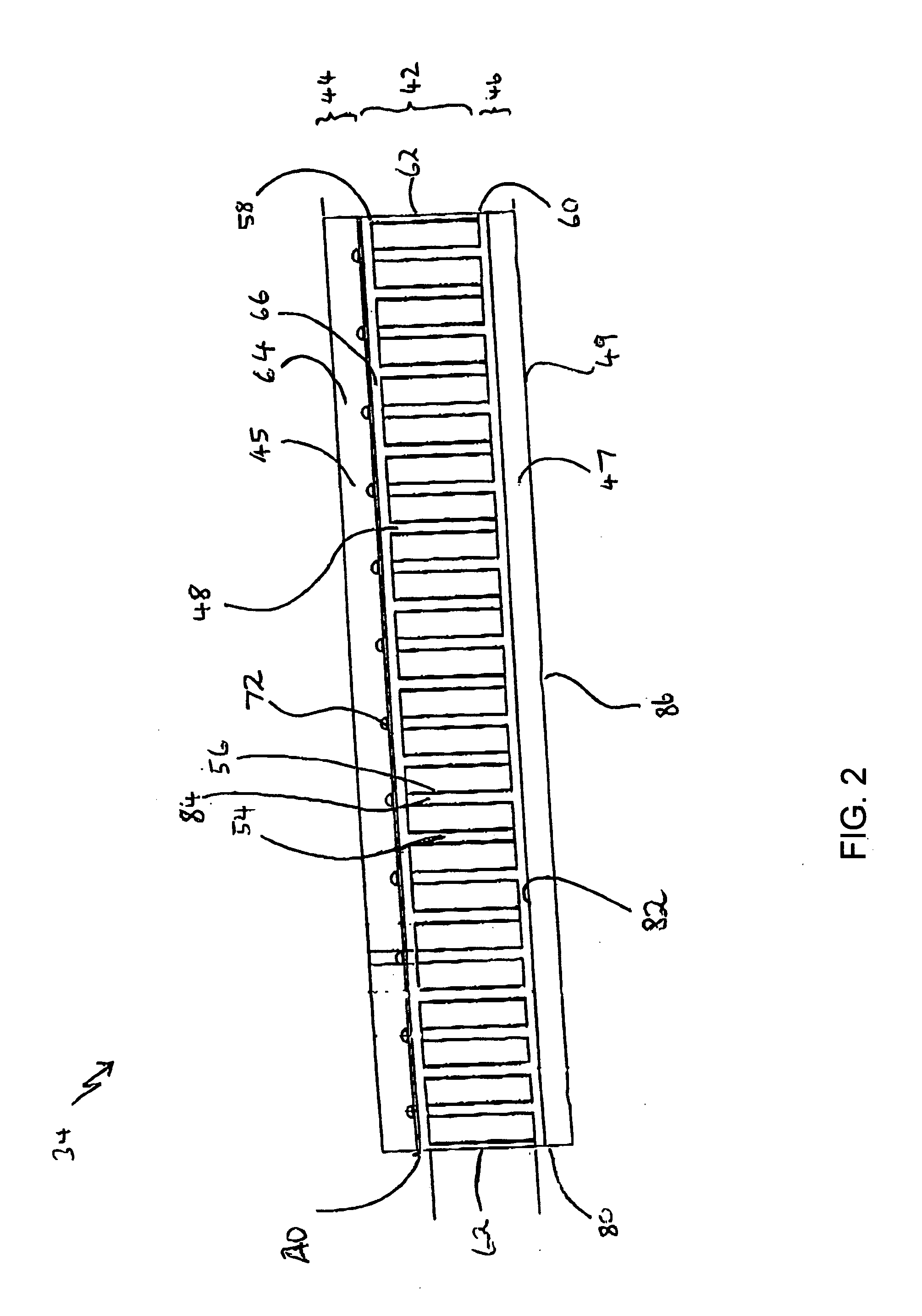

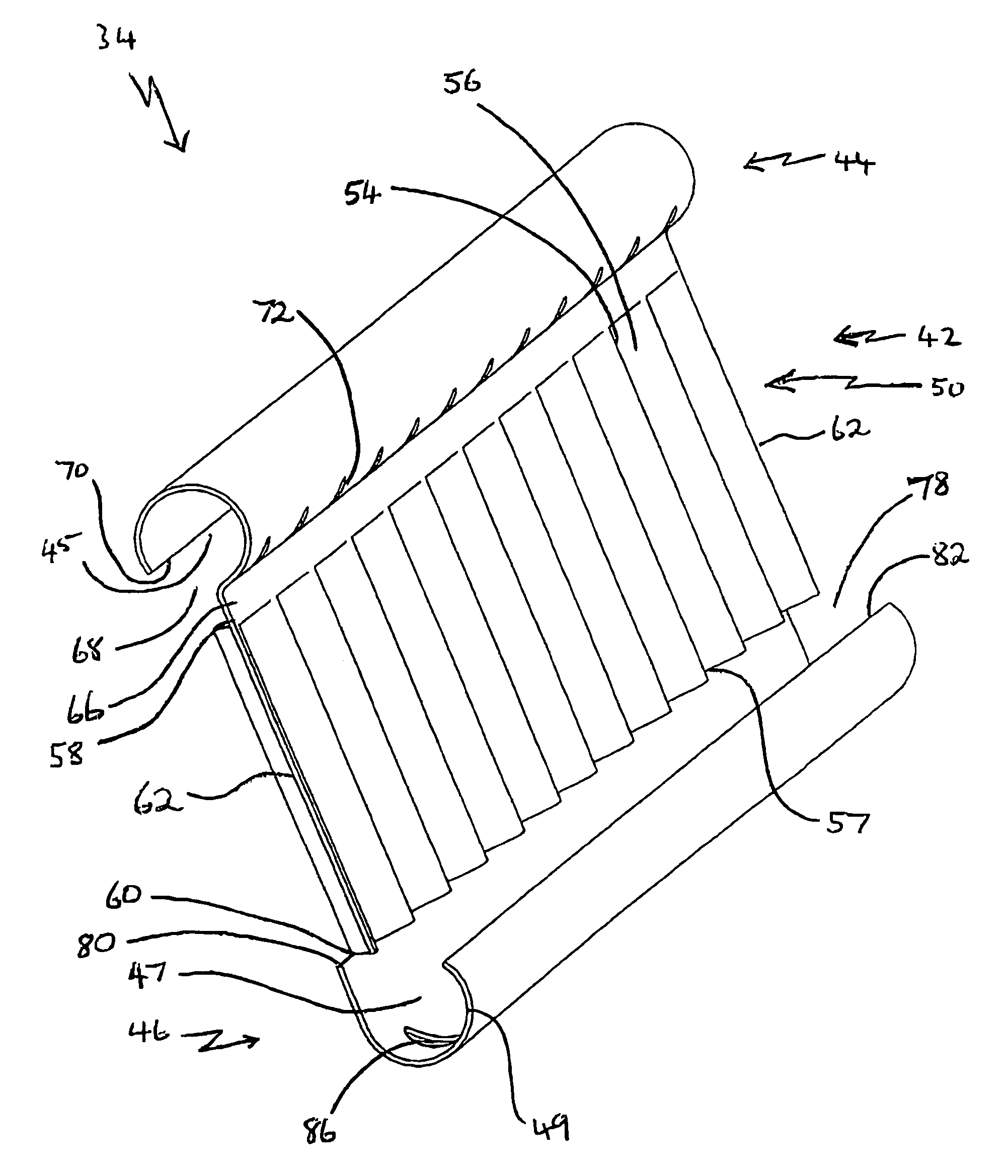

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

Apparatus and method thereof

InactiveUS20110061531A1Improve jetting stabilityArea maximizationLaser detailsGas treatmentLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

Apparatus and method thereof

InactiveUS20110072968A1Improve jetting stabilityArea maximizationLaser detailsLiquid degasificationLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

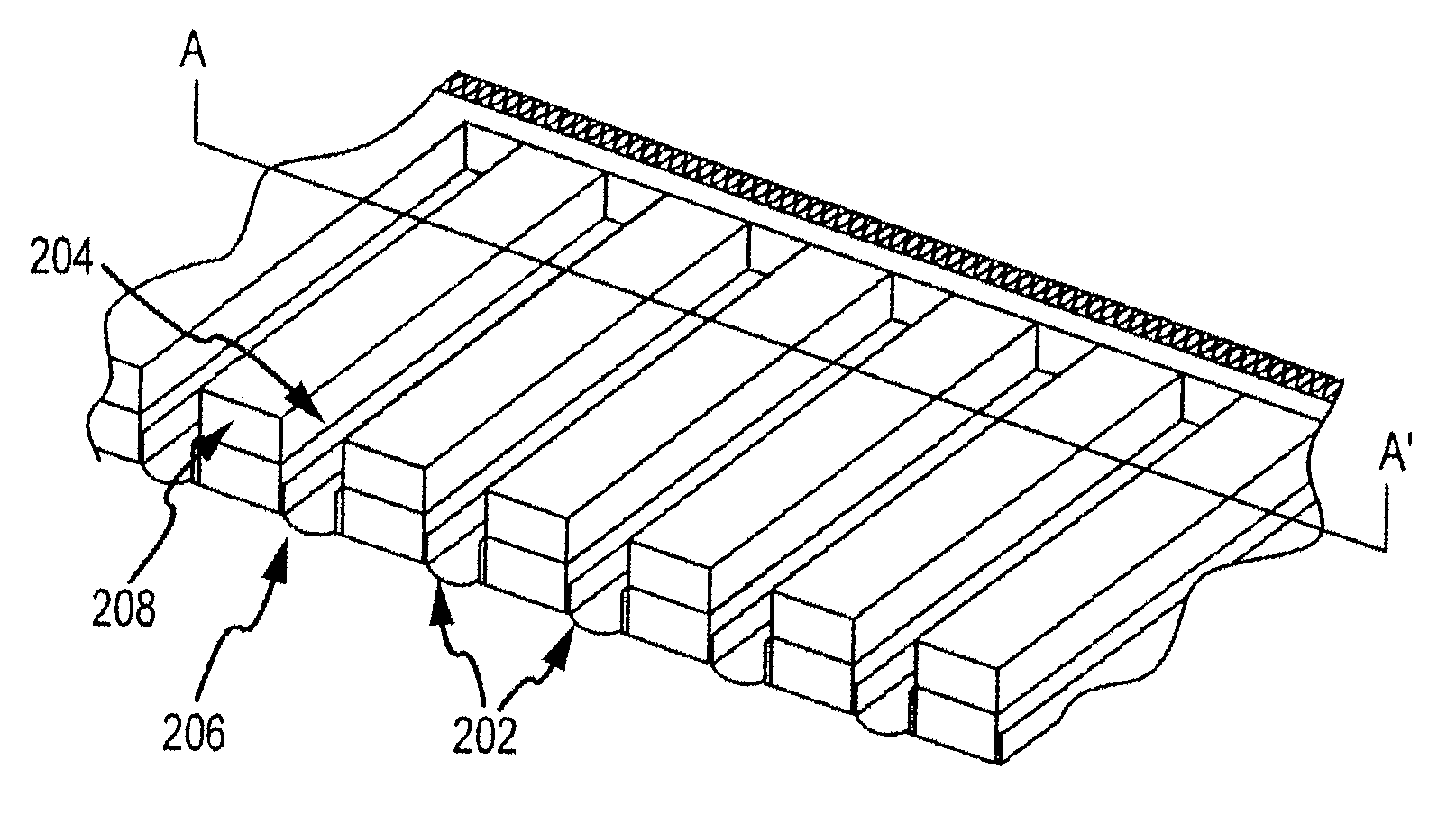

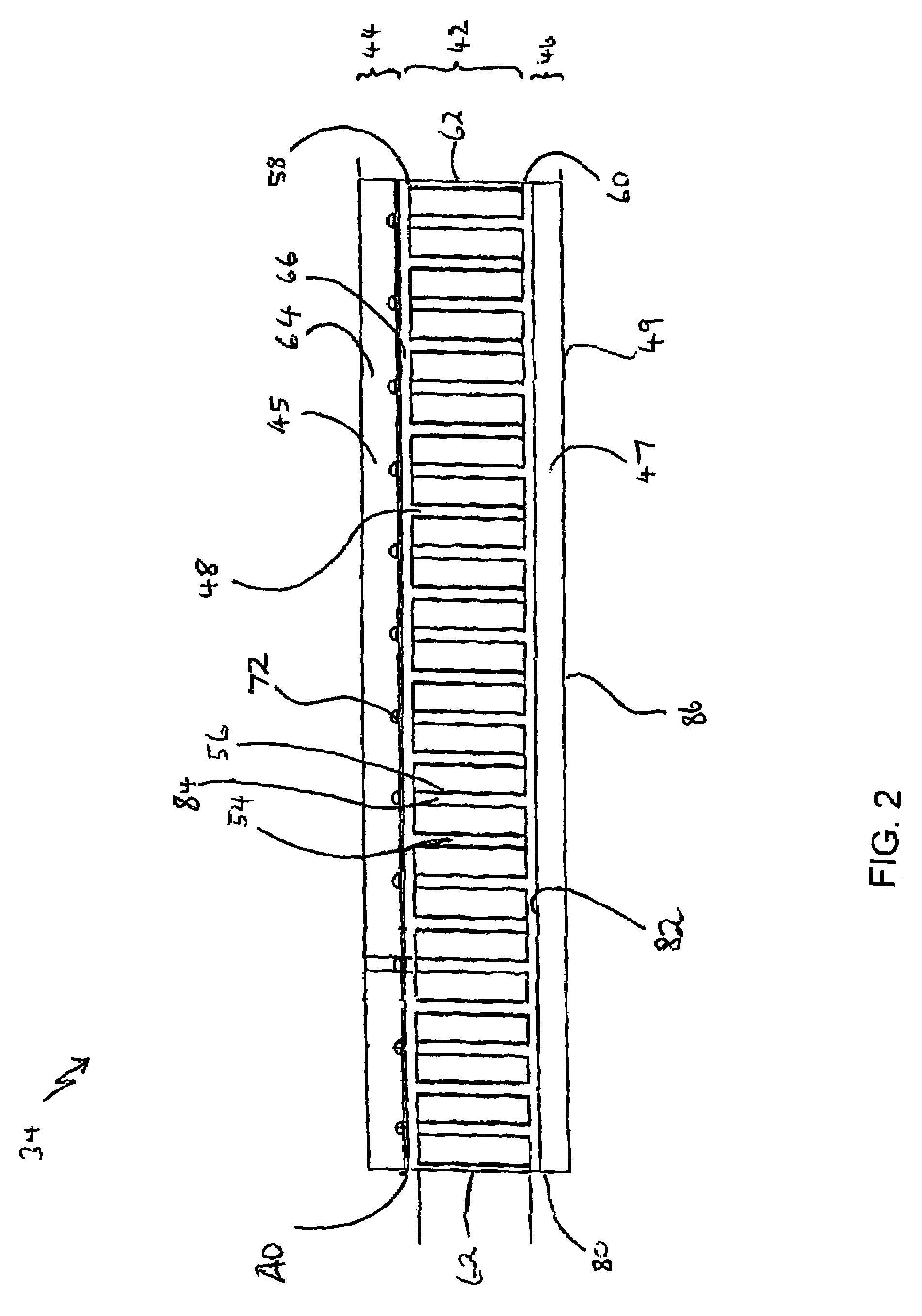

Liquid contactor and method thereof

InactiveUS20100089232A1Large volumetric mass transport coefficientSmall sizeLaser detailsGas treatmentLiquid jetEngineering

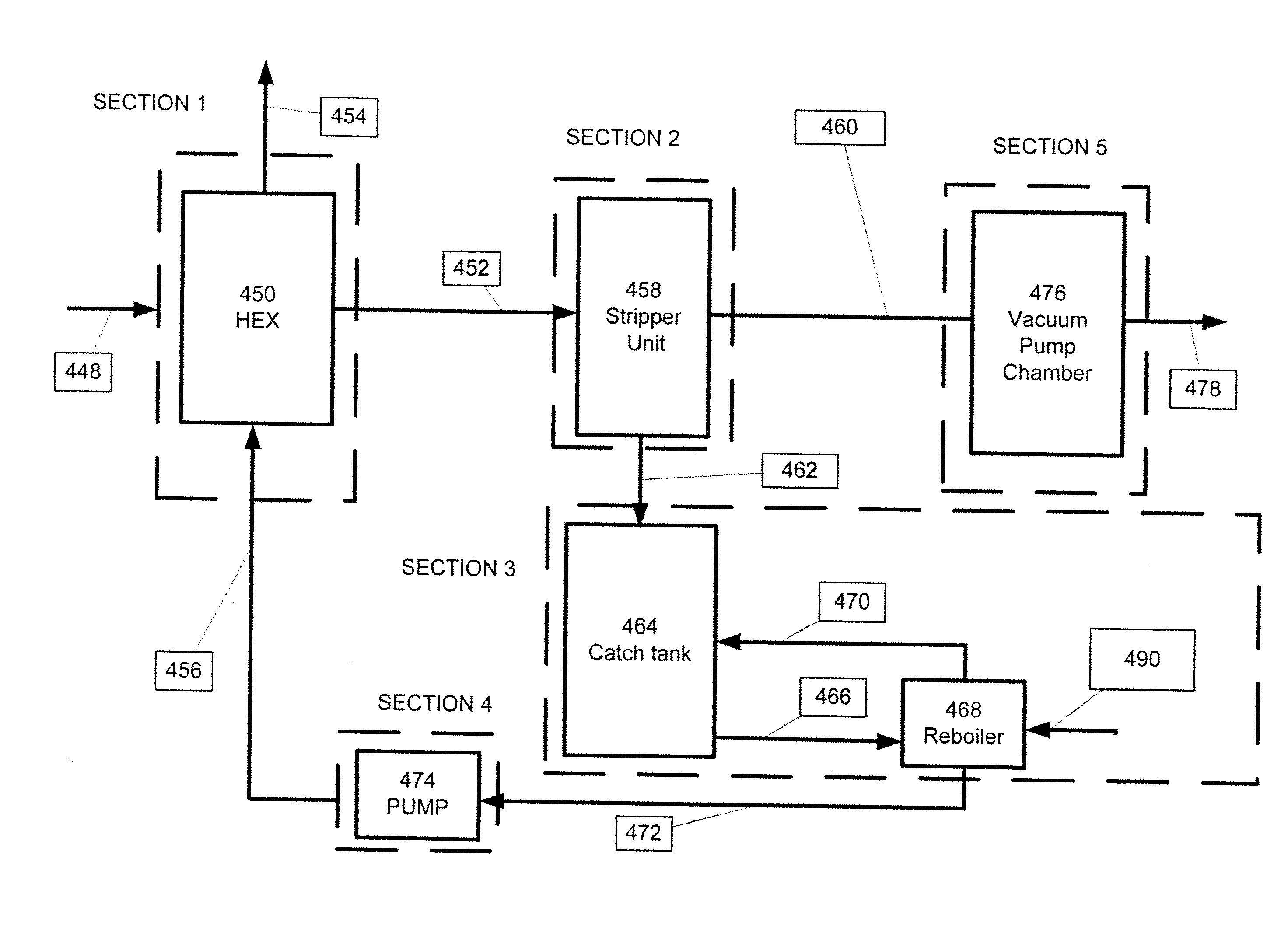

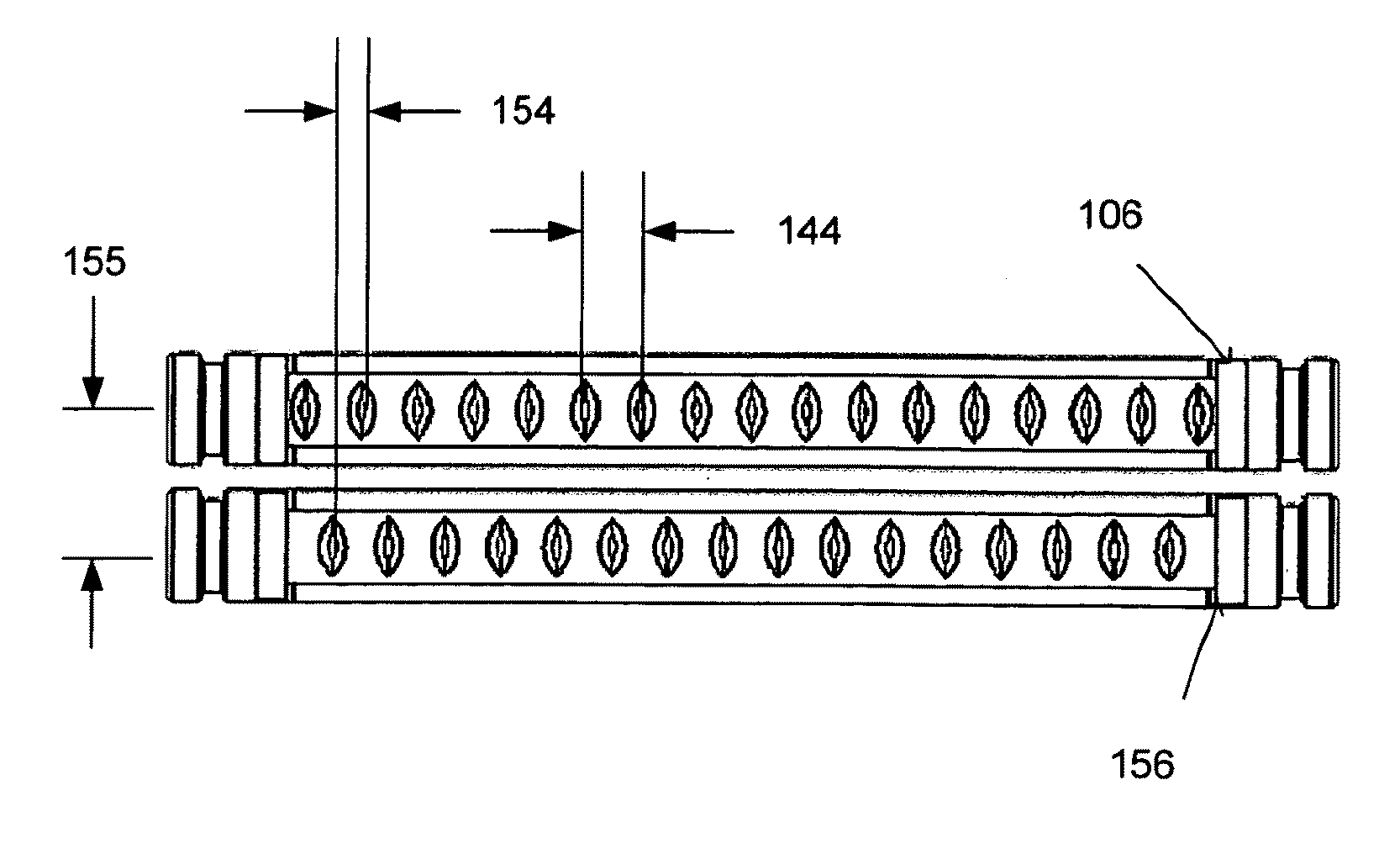

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to individually fed nozzle banks including an array of nozzles configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas. An embodiment of the invention is directed towards a gas liquid contactor having a plurality of modules including a liquid inlet and outlet and a gas inlet and outlet. An array of nozzles is in communication with the liquid inlet and the gas inlet. The array of nozzles is configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas flow and maximize gas flow and liquid flow interactions while rapidly replenishing the liquid.

Owner:NEUMANN SYST GROUP

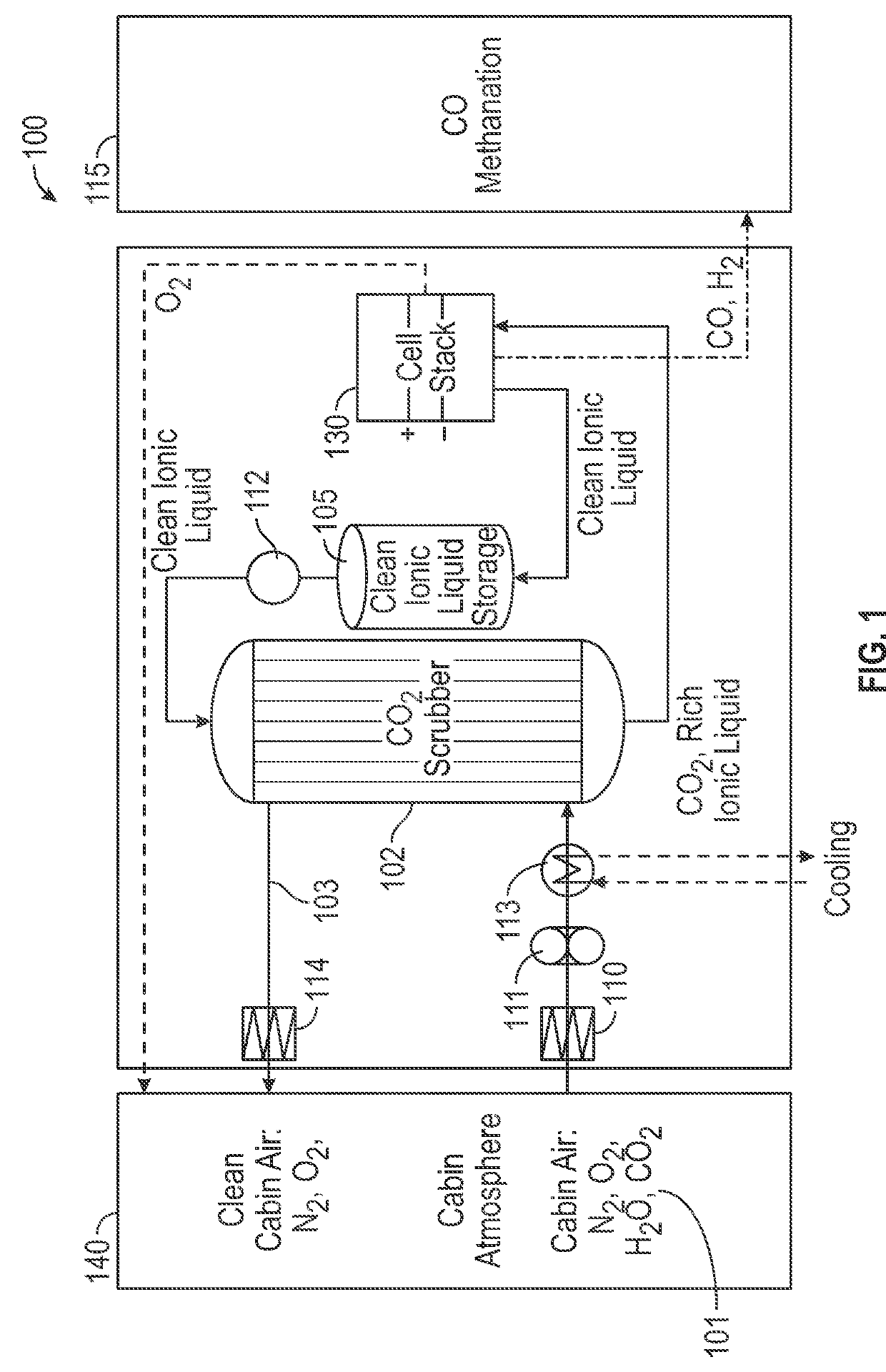

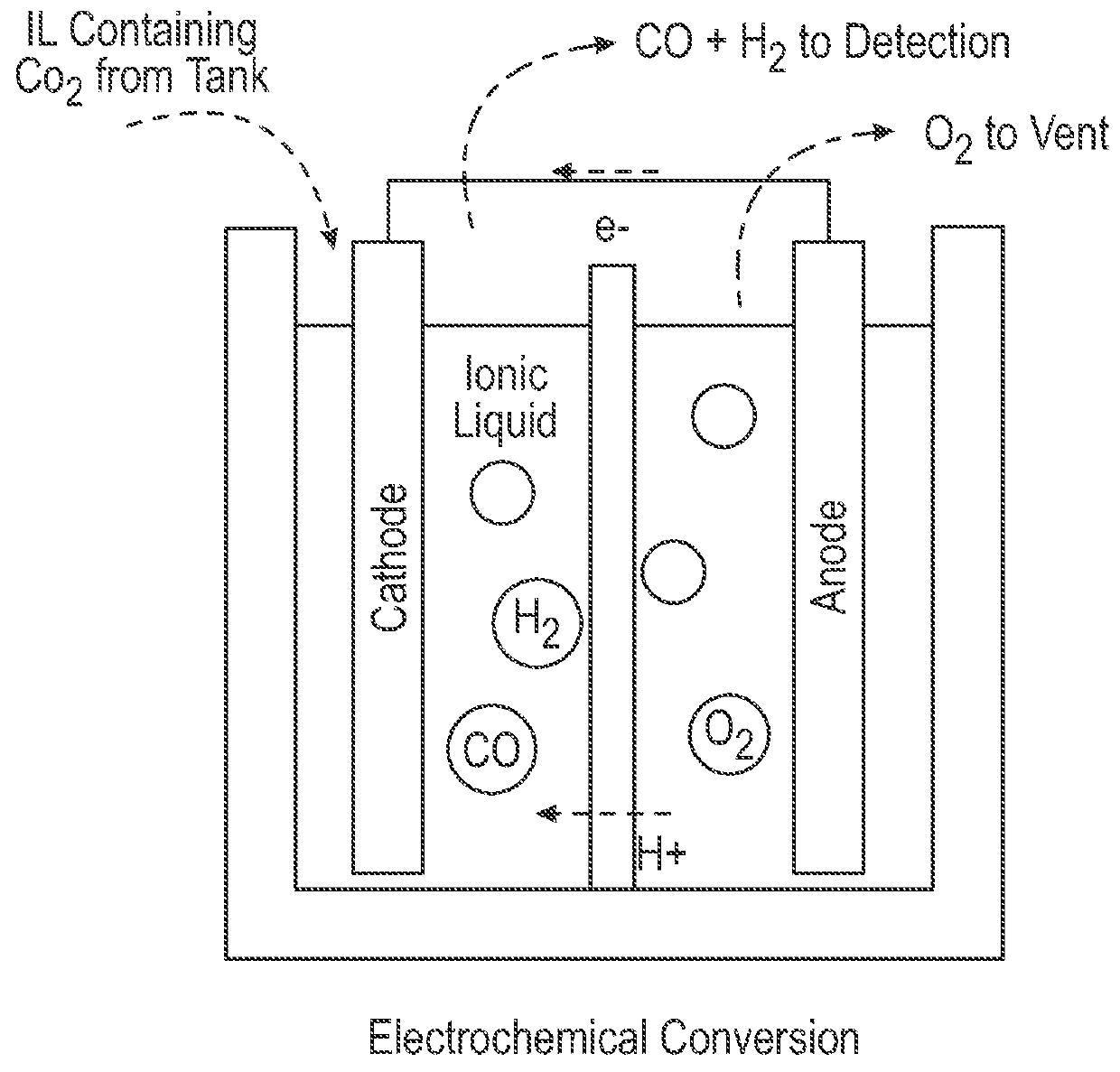

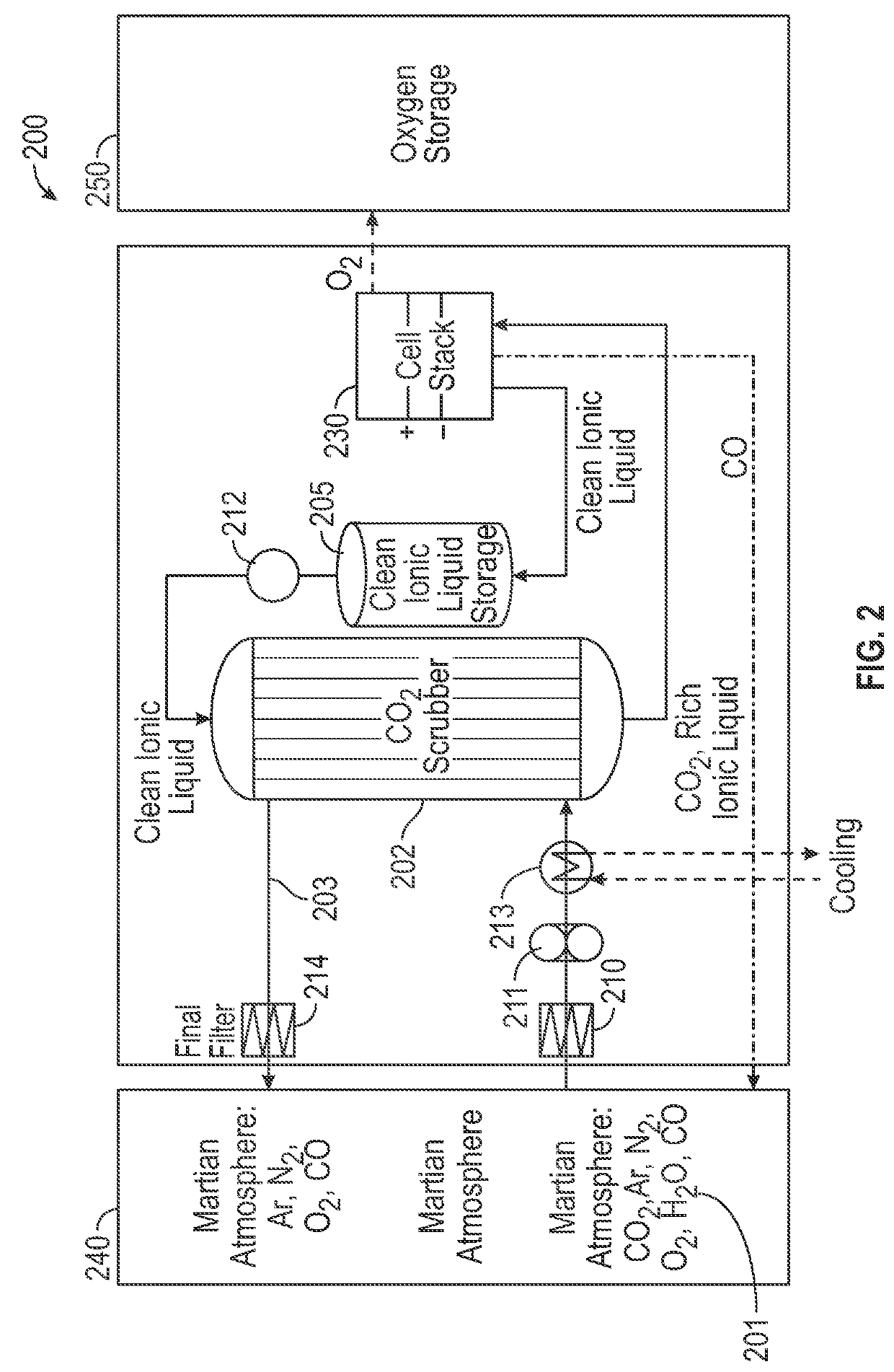

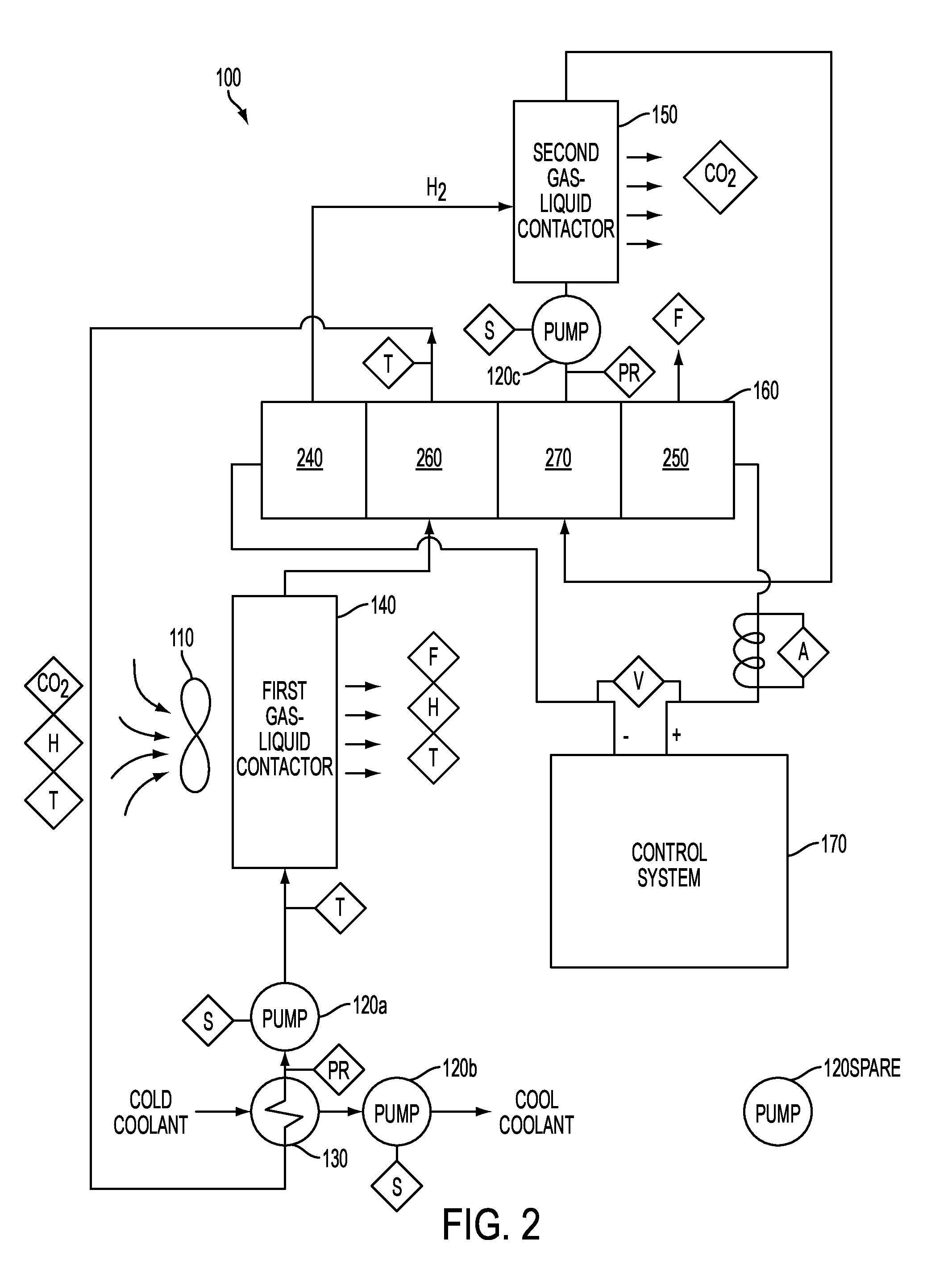

Electrochemical carbon dioxide converter and liquid regenerator

A carbon dioxide conversion system for an environment includes a first gas-liquid contactor-separator downstream of the environment; an electrochemical conversion cell downstream of the first gas-liquid contactor-separator; and a cleaned ionic liquid storage intermediate the first gas-liquid contactor-separator and the electrochemical conversion cell.

Owner:HONEYWELL INT INC

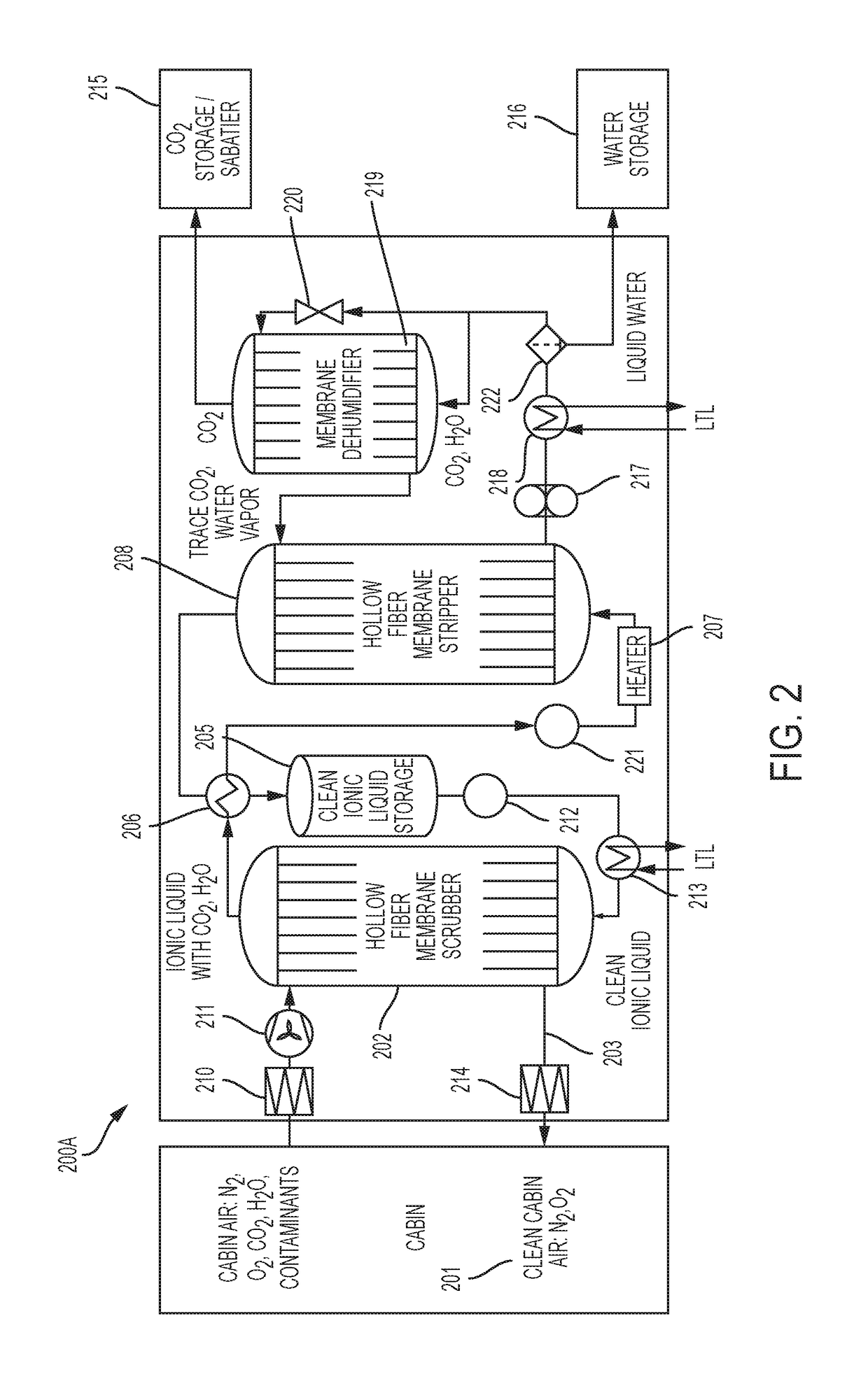

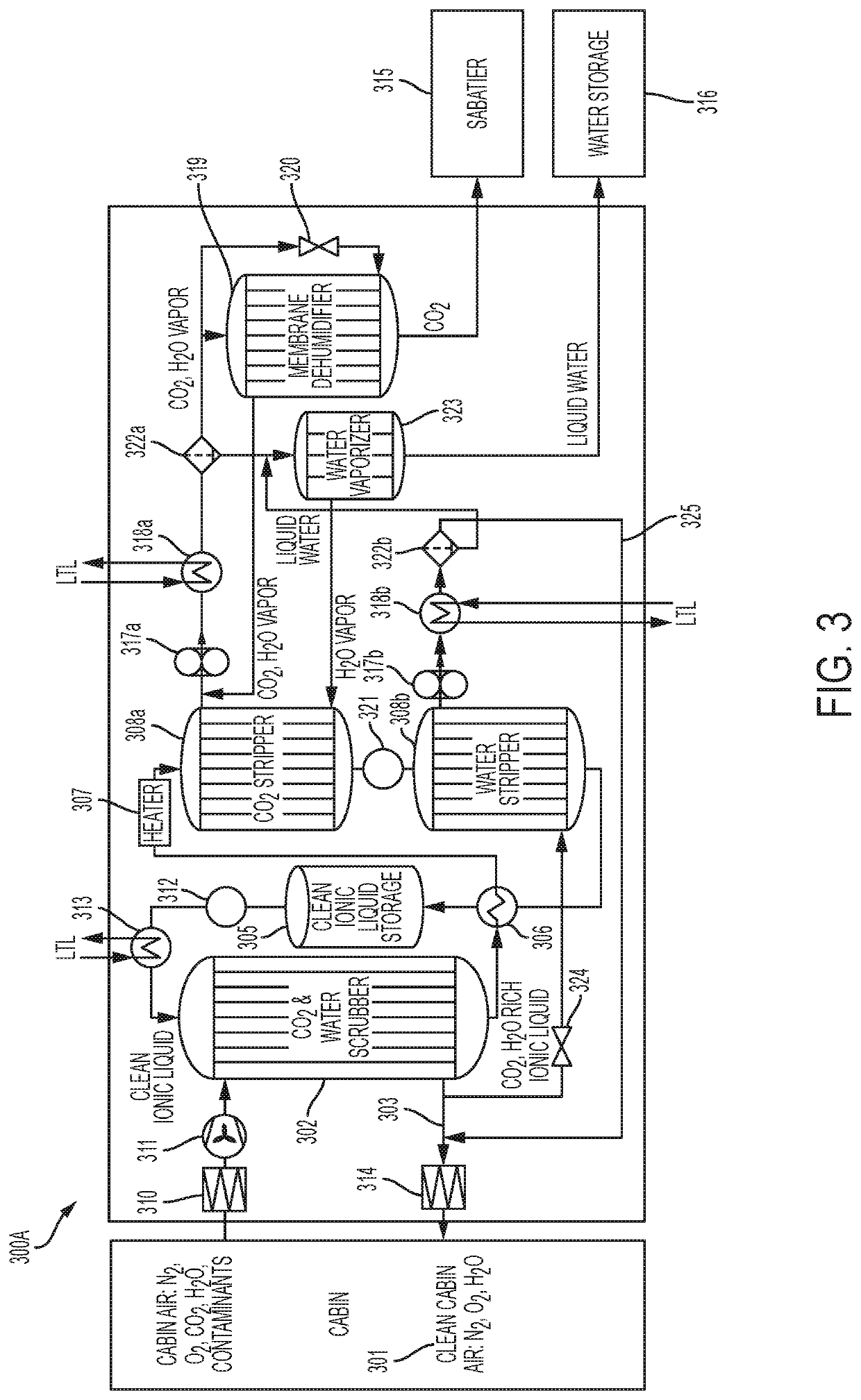

Hollow fiber membrane contactor scrubber/stripper for cabin carbon dioxide and humidity control

ActiveUS20180243682A1Cosmonautic environmental control arrangementSemi-permeable membranesControl systemEnvironmental control system

An environmental control system includes an air conditioning subsystem and a contaminant removal subsystem downstream of the environment to be conditioned. The contaminant removal subsystem includes: a first gas-liquid contactor-separator; a second gas-liquid contactor-separator; and a dehumidifier disposed either upstream of the first gas-liquid contactor-separator or downstream of the second gas-liquid contactor-separator.

Owner:HONEYWELL INT INC

Apparatus and method thereof

InactiveUS20100089231A1Improve jetting stabilityMaximize specific areaGas treatmentLaser detailsLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

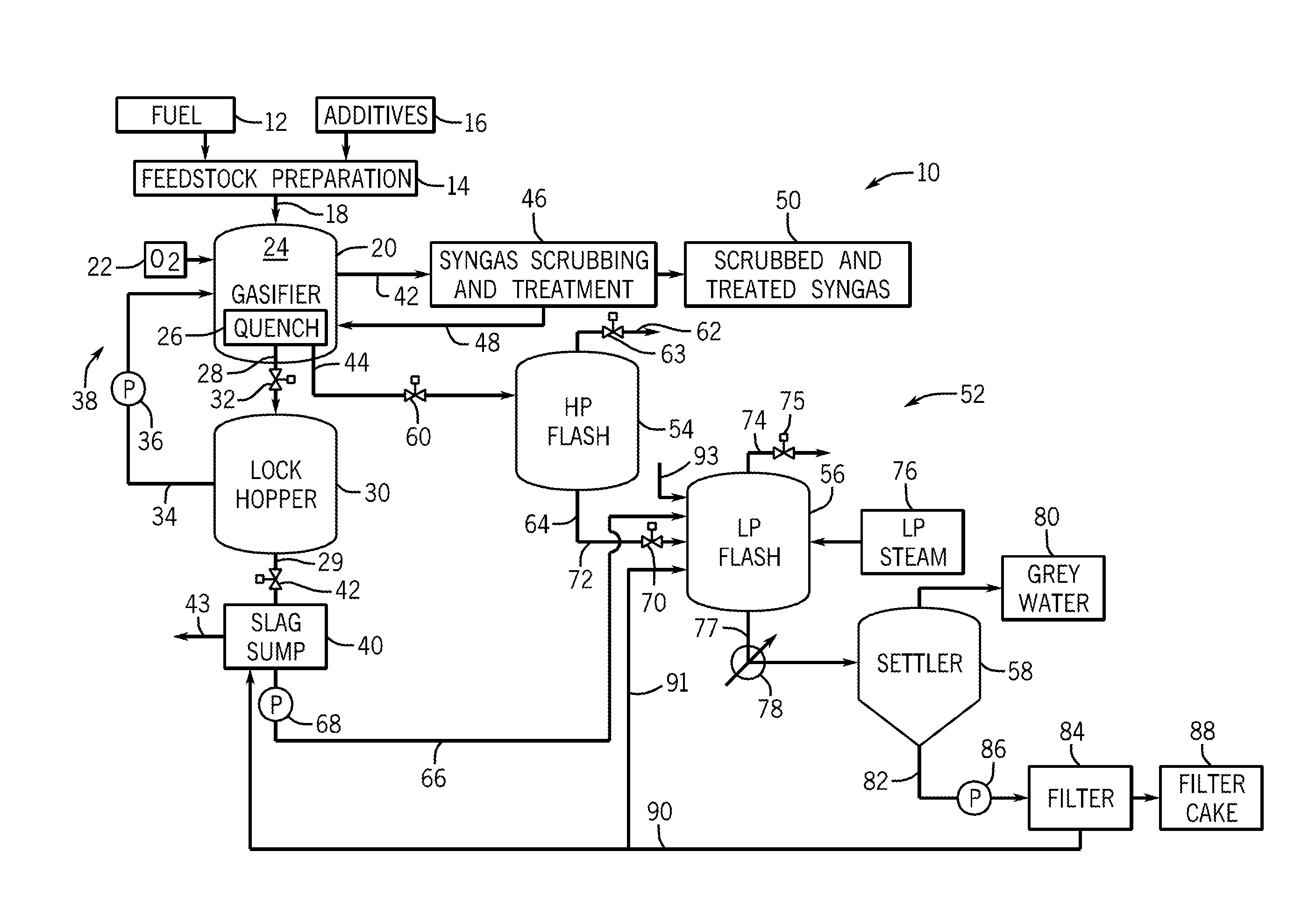

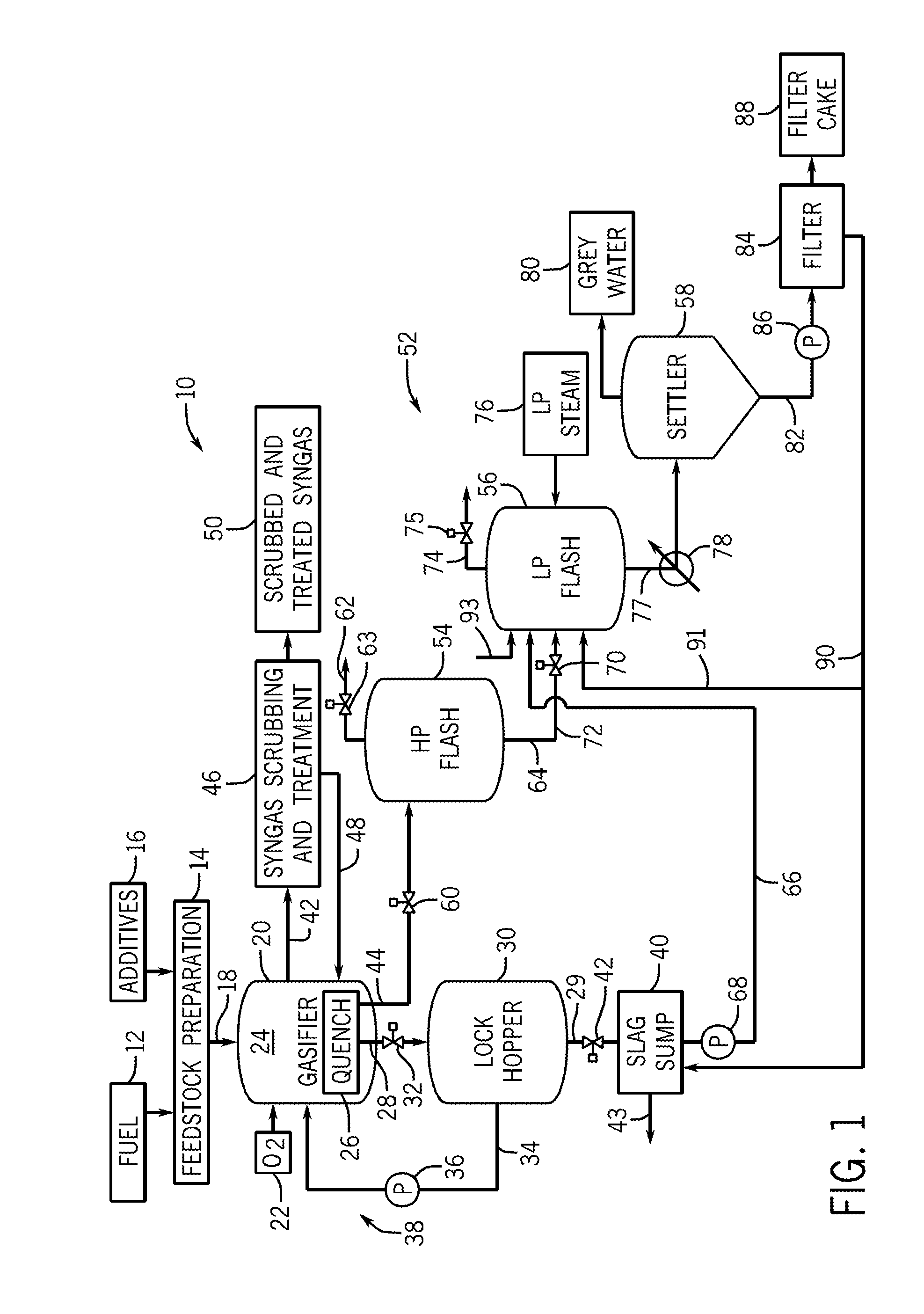

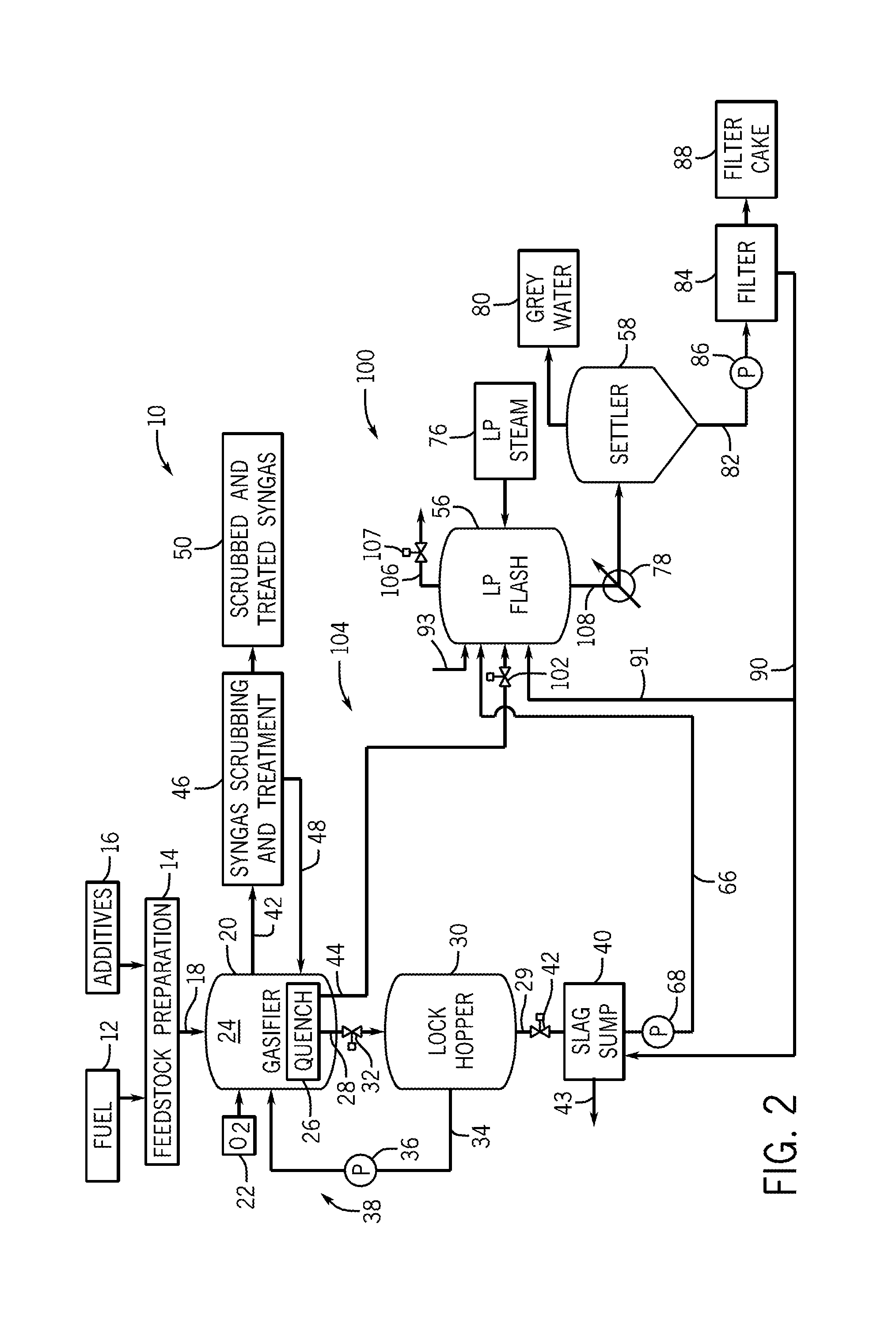

System for deaeration in a flash vessel

ActiveUS20130183204A1Gasification processes detailsWaste water treatment from gaseous effluentsSlagWater flow

The disclosed embodiments relate to systems for deaerating a stream of slag sump water produced by a gasifier. For example, in one embodiment, a system includes a flash vessel having a first inlet configured to introduce a first fluid into the flash vessel, wherein the flash vessel is configured to flash the first fluid to produce a first flash gas, a second inlet configured to introduce a stream from slag sump into the flash vessel, wherein the stream from slag sump comprises a mixture of a gasification fine slag, dissolved oxygen (O2), and water. A gas-liquid contactor in the flash vessel is configured to contact the stream from slag sump with the first flash gas to enable the first flash gas to deaerate the stream from slag sump. A first outlet of the vessel is configured to output an overhead discharge comprising the first flash gas and oxygen from the stream from slag sump.

Owner:AIR PROD & CHEM INC

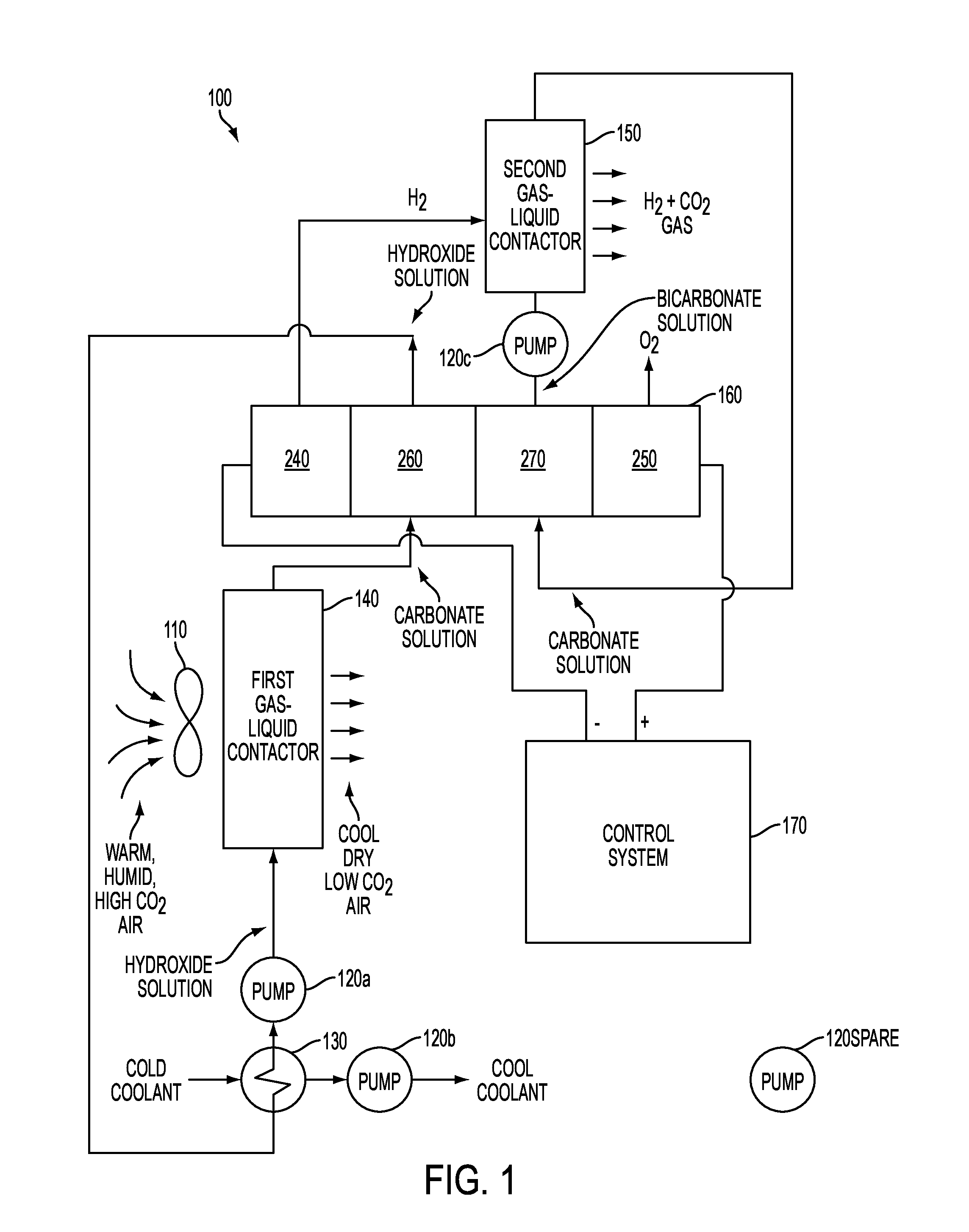

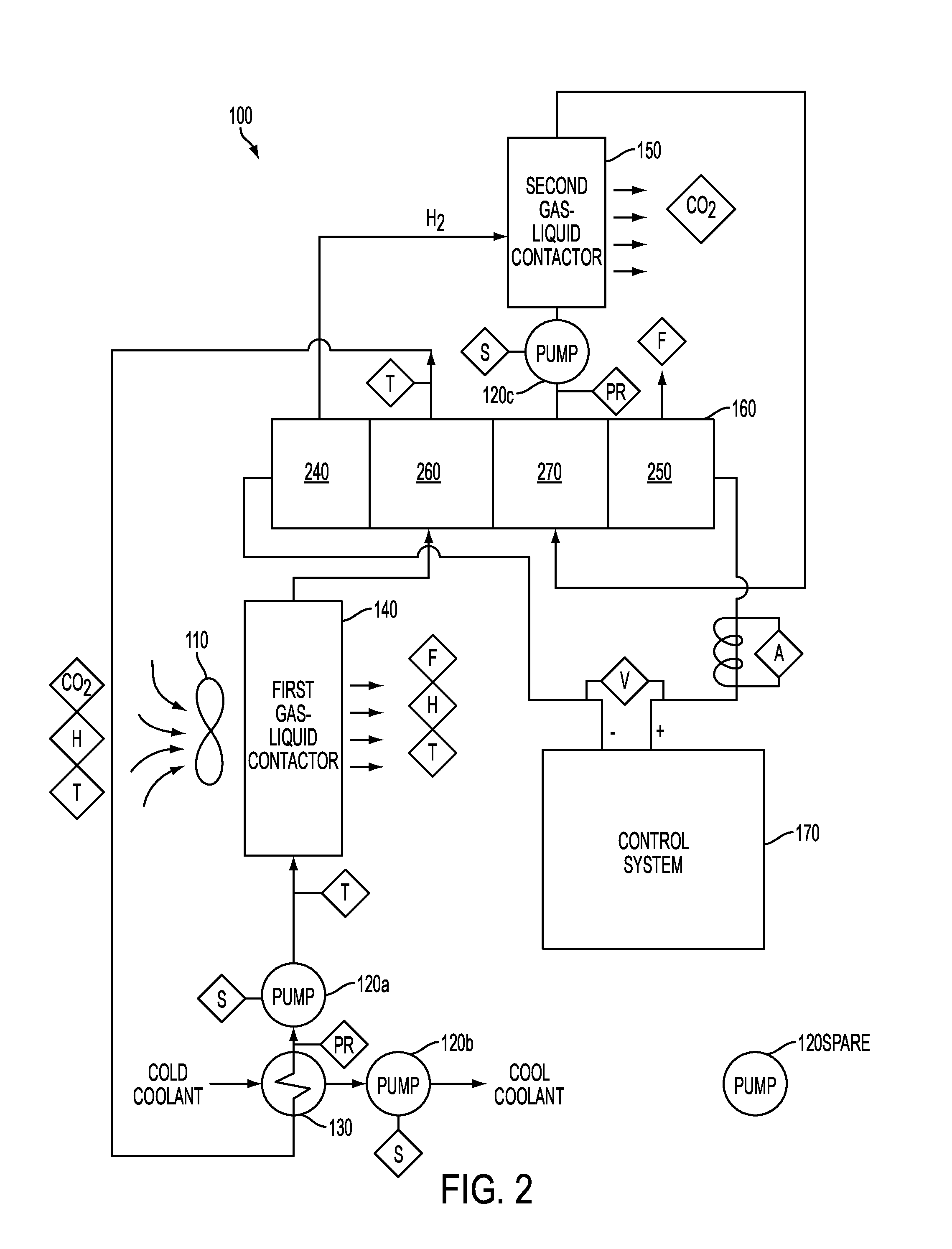

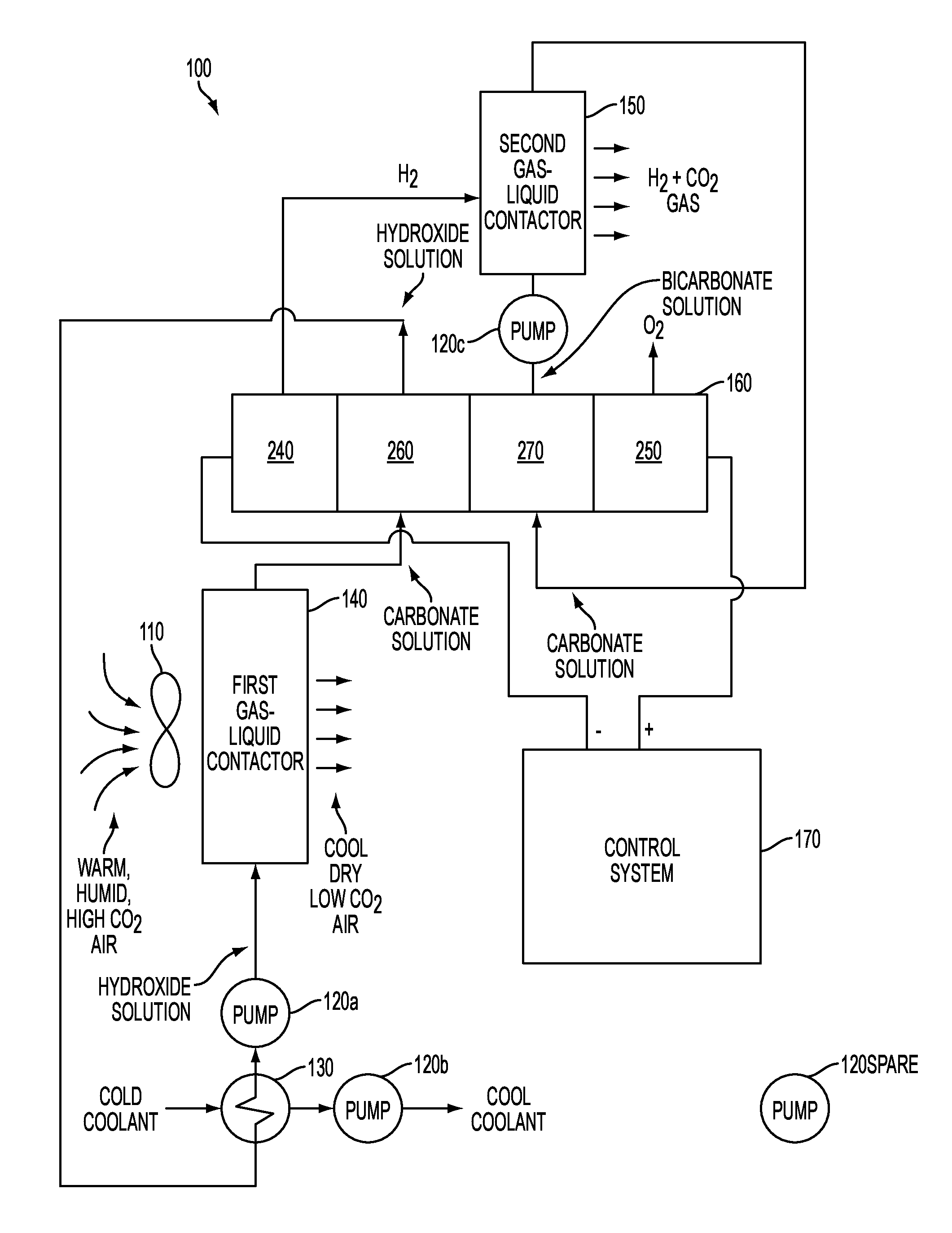

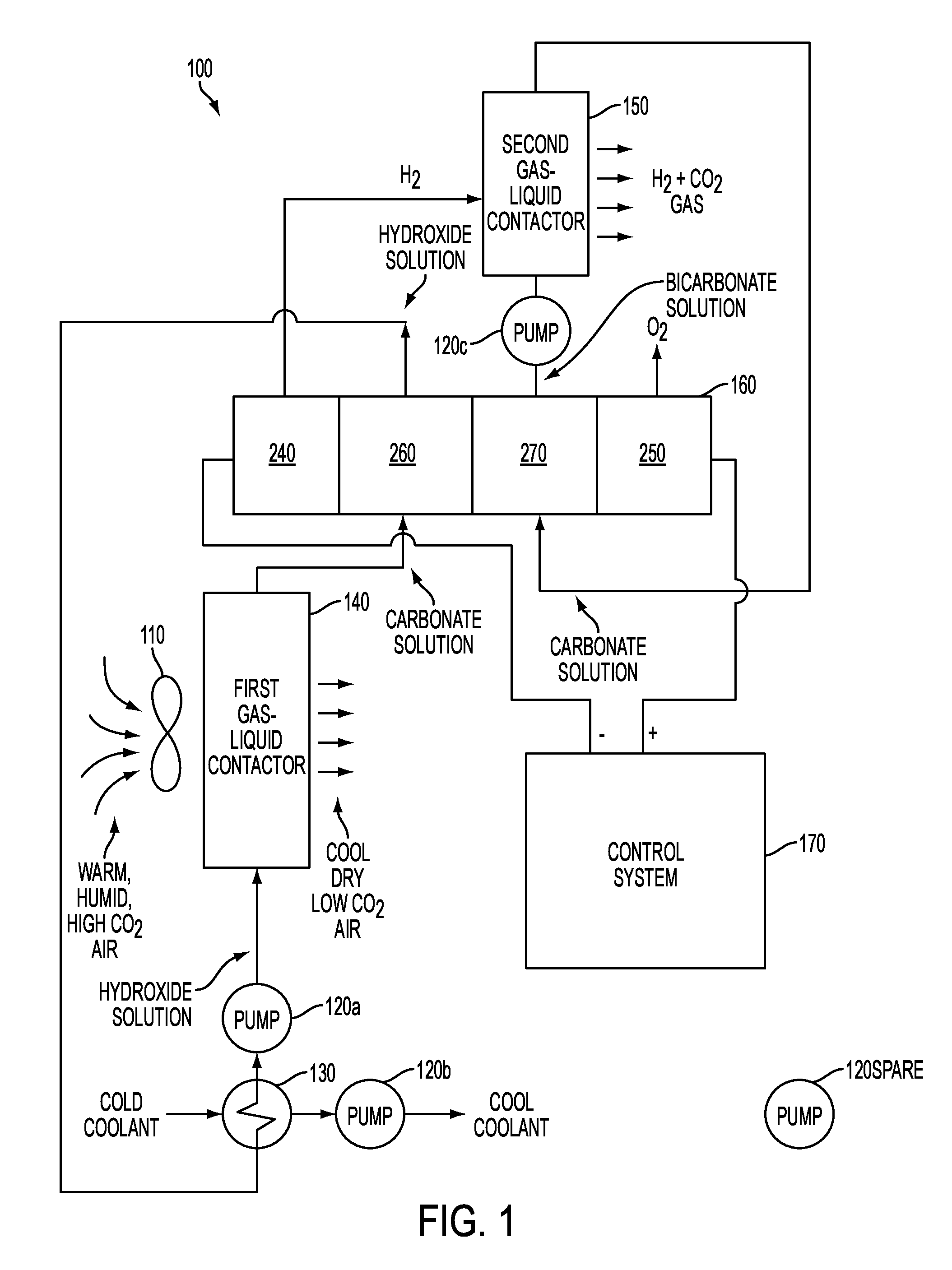

Membrane-enabled reverse lung

An air revitalization apparatus and method simultaneously removes carbon dioxide, water vapor, and heat from air and produces oxygen gas, hydrogen gas, and concentrated carbon dioxide gas, does not require an explosion proof enclosure, and includes a fan configured to blow air into a first gas-liquid contactor, an electrochemical cell including first through fourth passages configured to emit hydrogen gas, permit a flow of a carbonate-hydroxide solution, permit a flow of carbonate-bicarbonate solution, and emit oxygen gas, respectively, the first and fourth passages separated by at least three gas-impermeable membranes, and a second gas-liquid contactor, where the first gas-liquid contactor, second passage, and a first pump are configured to circulate the carbonate-hydroxide solution therethrough, where the second gas-liquid contactor, third passage, and a second pump are configured to circulate the carbonate-bicarbonate solution therethrough, and where the output of the first passage is operationally coupled to the second gas-liquid contactor.

Owner:OCEANEERING INTERNATIONAL

Gas-liquid contactor baffle

InactiveUS20070145611A1Improve efficiencyEnhanced mass transferCarburetting airCombination devicesBiomedical engineeringRidge

A gas-liquid contactor baffle includes a body having a first portion, a second portion and a middle portion, the middle portion being positioned between the first portion and the second portion. The middle portion is a corrugated sheet having a first face and a second face. The corrugated sheet has alternating ridges and open ended channels extending across each of the first face and the second face between the first portion and the second portion. The first portion has a first collection channel adapted to collect liquids from the open ended channels of the middle portion when flow is along the first face in a first direction. The second portion having a second collection channel adapted to collect liquids from the open ended channels of the middle portion when flow is along second face in a second direction.

Owner:AMT INT INC

Gas-liquid contactor baffle

InactiveUS7445200B2Improve efficiencyImprove capacity and efficiencyCarburetting airCombination devicesBiomedical engineeringRidge

Owner:AMT INT INC

Gas liquid contactor and effluent cleaning system and method

InactiveCN102217152ABulk mass transfer coefficientSmall sizeLaser detailsGas treatmentLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas. An embodiment of the invention is directed towards a gas liquid contactor module including a liquid inlet and outlet and a gas inlet and outlet. An array of nozzles is in communication with the liquid inlet and the gas inlet. The array of nozzles is configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas flow and maximize gasflow and liquid flow interactions while rapidly replenishing the liquid.

Owner:NEUMANN SYST GROUP

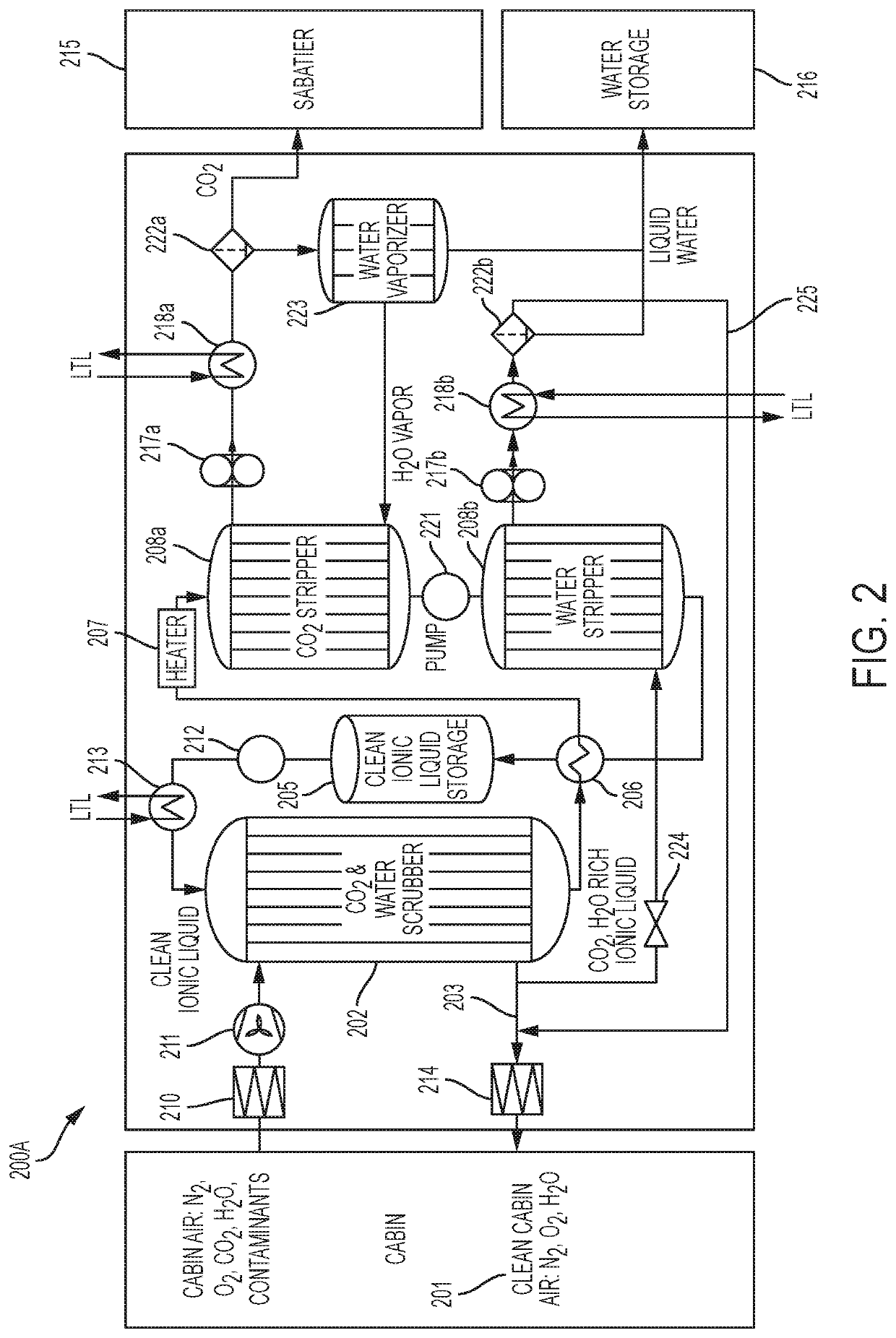

Dual stripper with water sweep gas

ActiveUS10688435B2Cosmonautic environmental control arrangementGas treatmentControl systemEnvironmental engineering

An environmental control system includes an air conditioning subsystem and a contaminant removal subsystem downstream of the environment to be conditioned. The contaminant removal subsystem includes a first gas-liquid contactor-separator, a second gas-liquid contactor-separator, and a third gas-liquid contactor-separator. One of the first, the second, and the third gas-liquid contactor-separators is configured to receive used absorbent liquid having at least a first contaminant and discharge at least a first contaminant for recovery and reuse. Another of the first, the second and the third gas-liquid contactor-separators is configured to receive used absorbent liquid having at least a second contaminant and discharge at least the second contaminant for recovery and reuse.

Owner:HONEYWELL INT INC

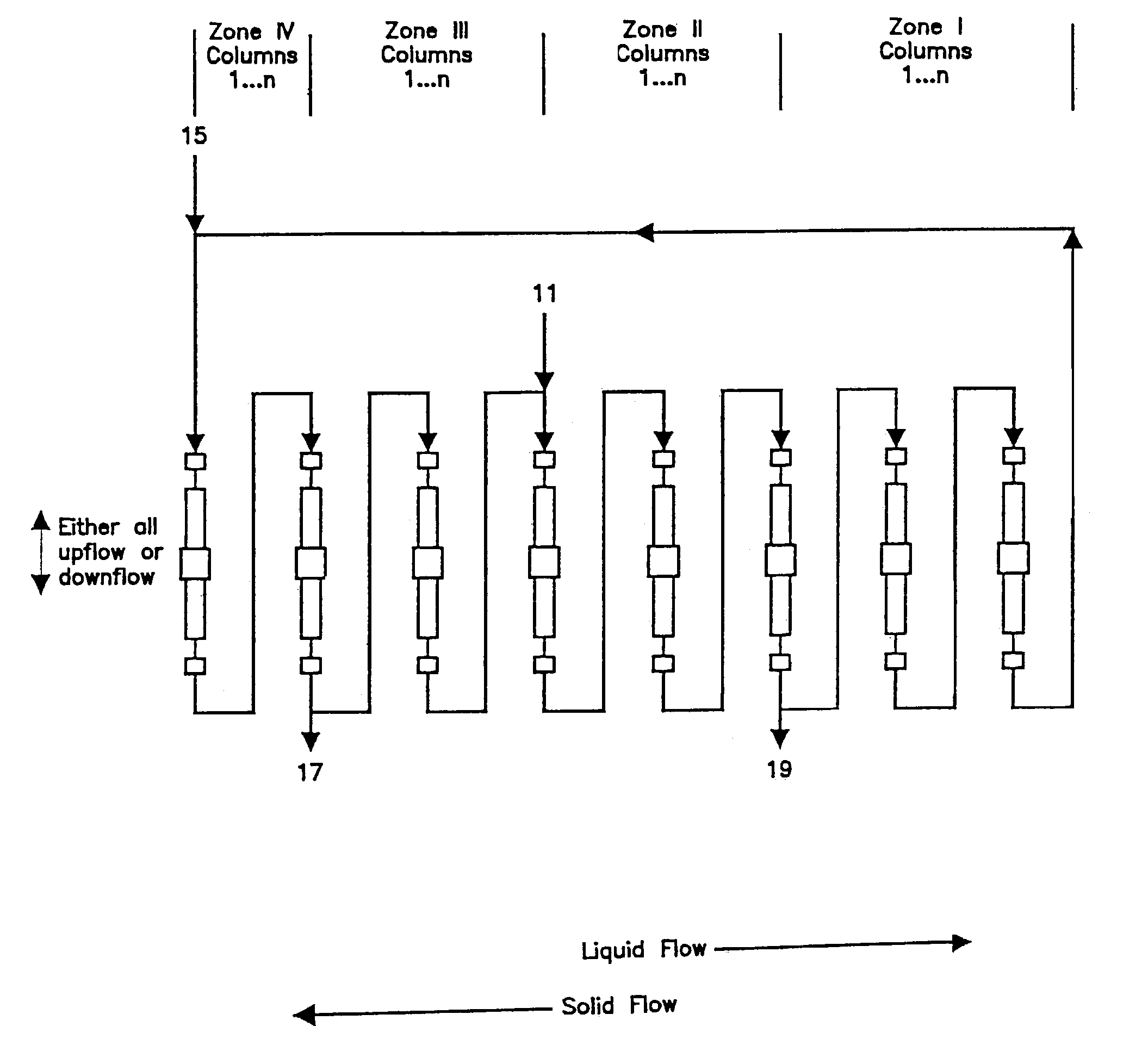

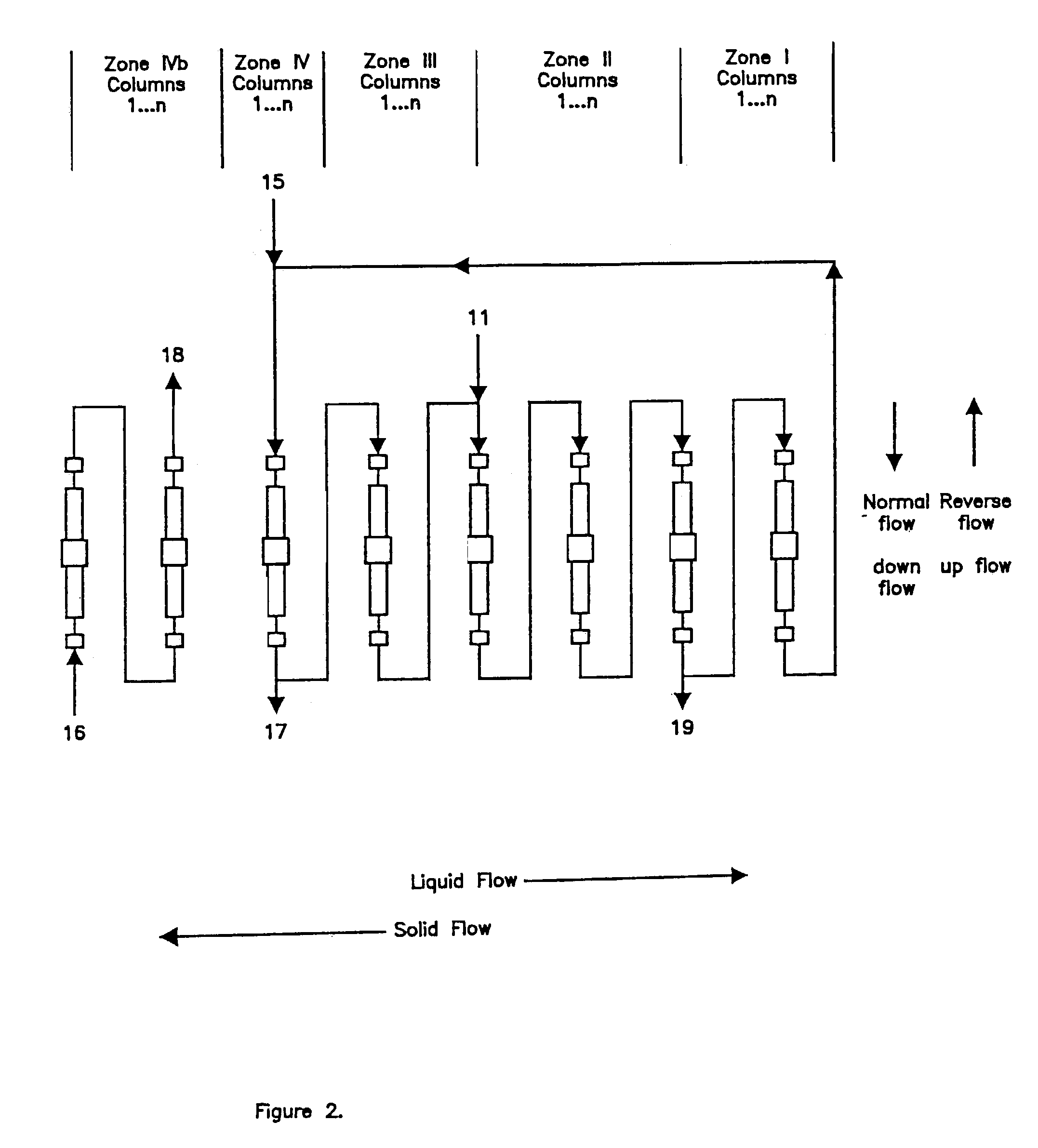

High performance continuous reaction/separation process using a continuous liquid-solid contactor

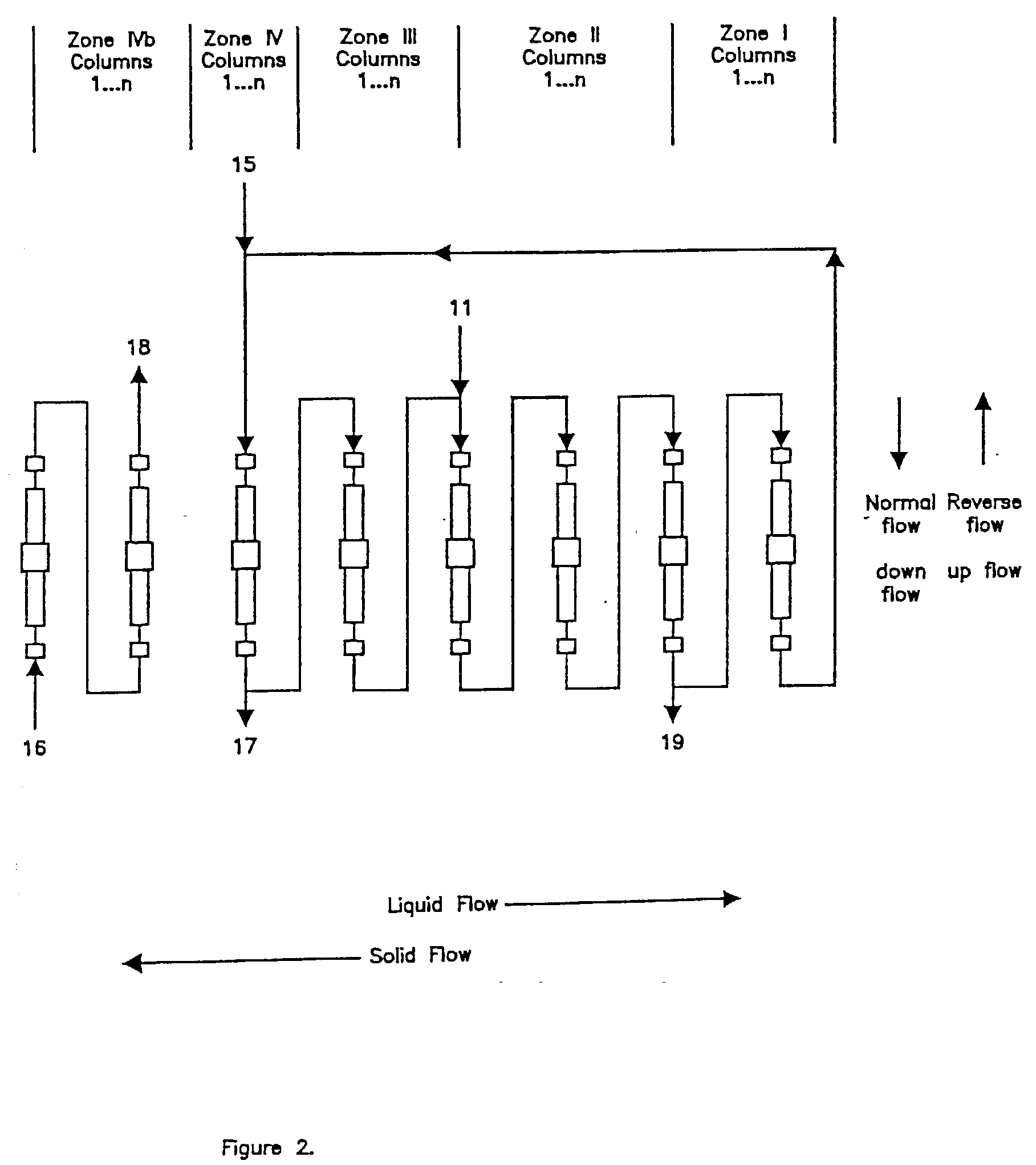

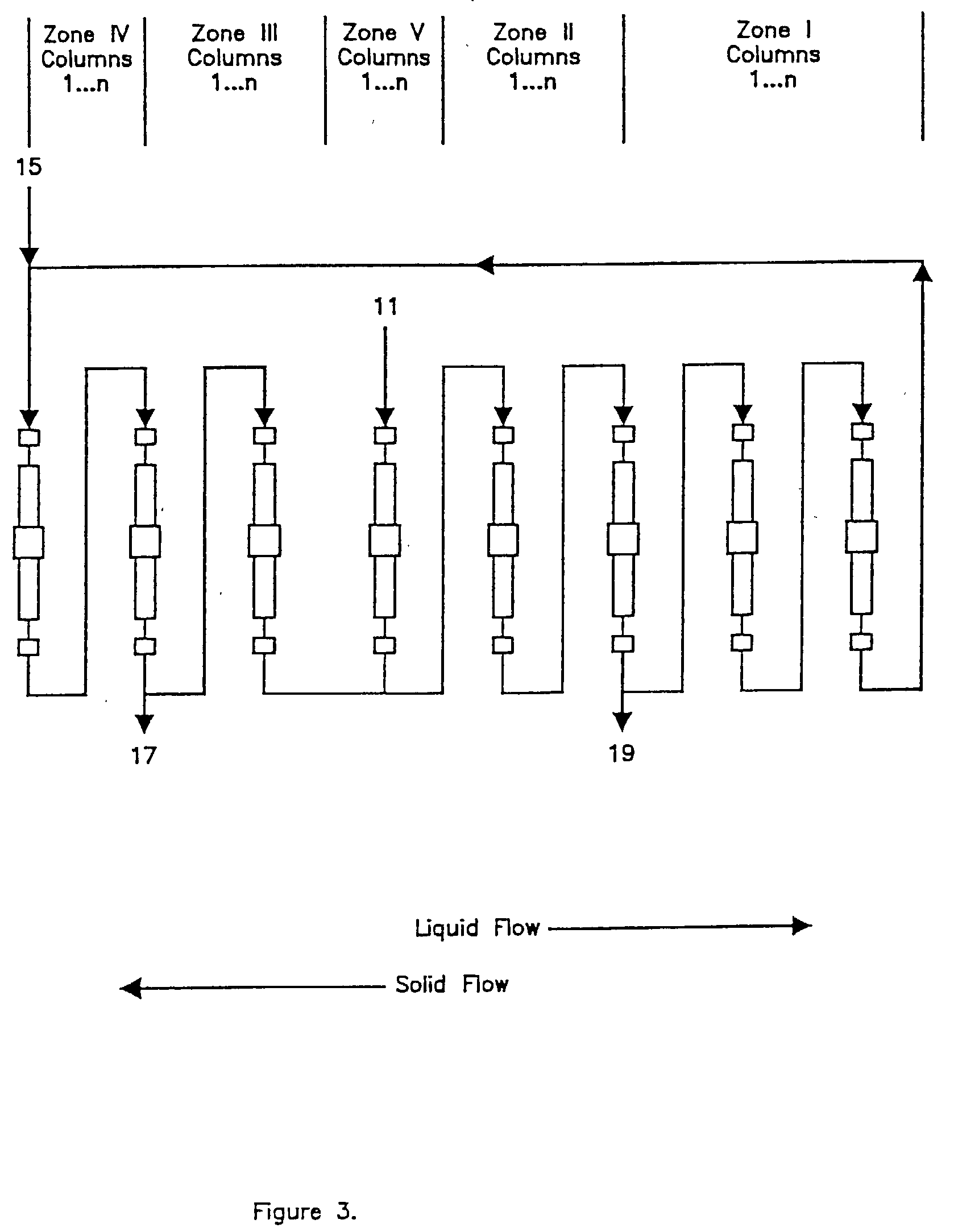

InactiveUS7108789B2Removal of highly adsorbed species easier and more economicalReduce consumptionOrganic chemistryComponent separationContinuous reactionLiquid solid

A process for reaction and separation which comprises inputting a process material into at least one column of a plurality of columns wherein each column has at least one inlet for accepting flow from another column or group of columns, an external feed stream, an external eluent stream or a combination thereof, and each column has at least one outlet for connecting to another column, a group of columns, an external product stream or a combination thereof. Each column is independently operable in an up-flow or down-flow mode and connected independently to one of the group comprising another column, an external feed stream, an external eluent stream, an external product stream and combinations thereof.

Owner:CALGON CARBON

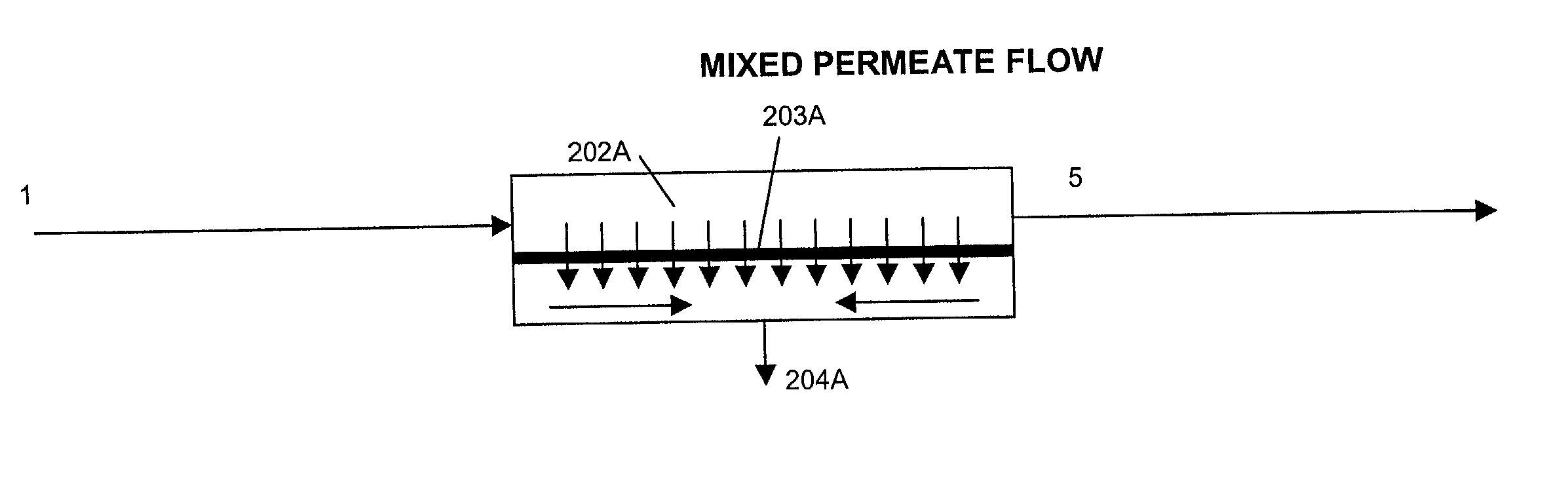

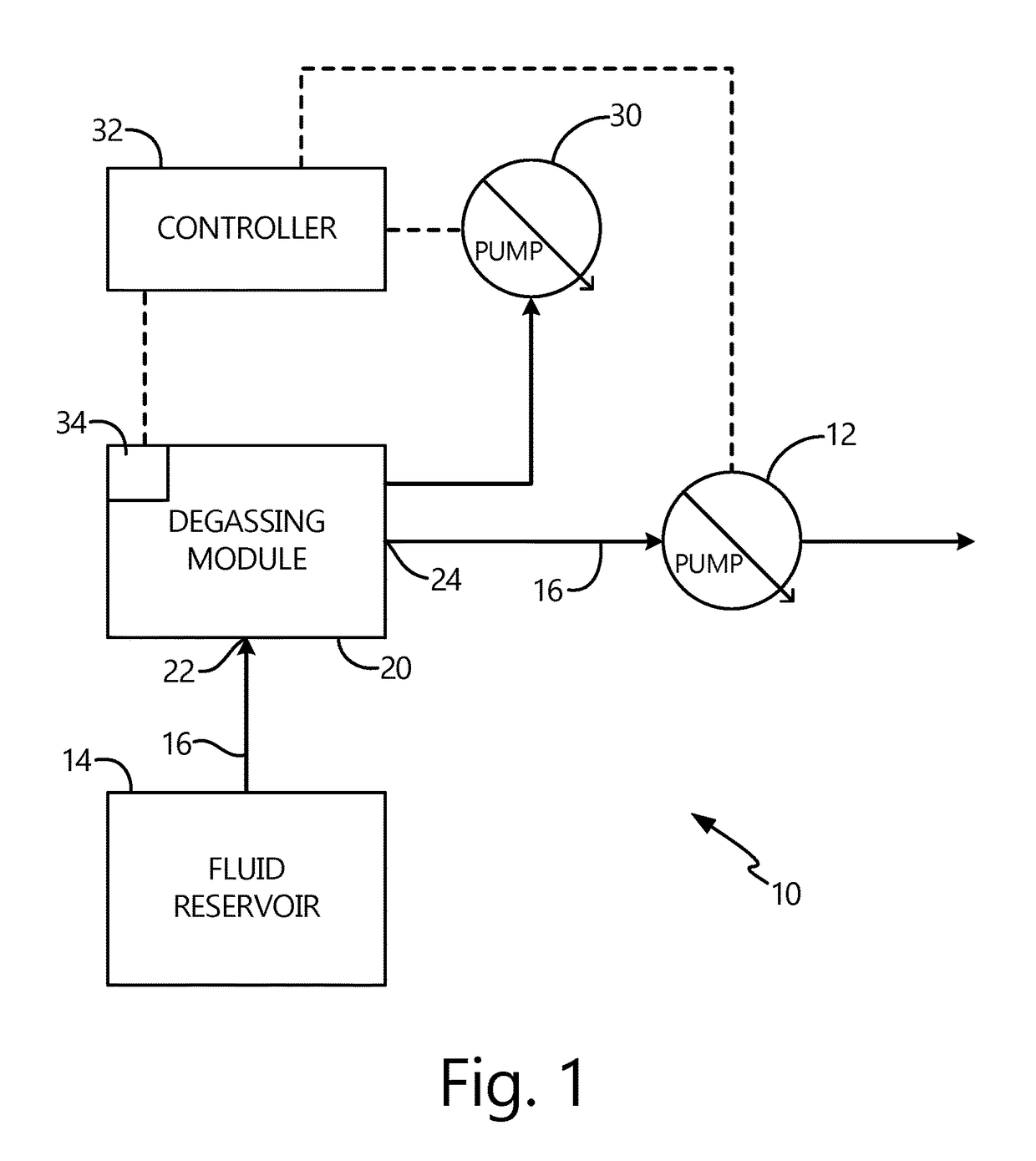

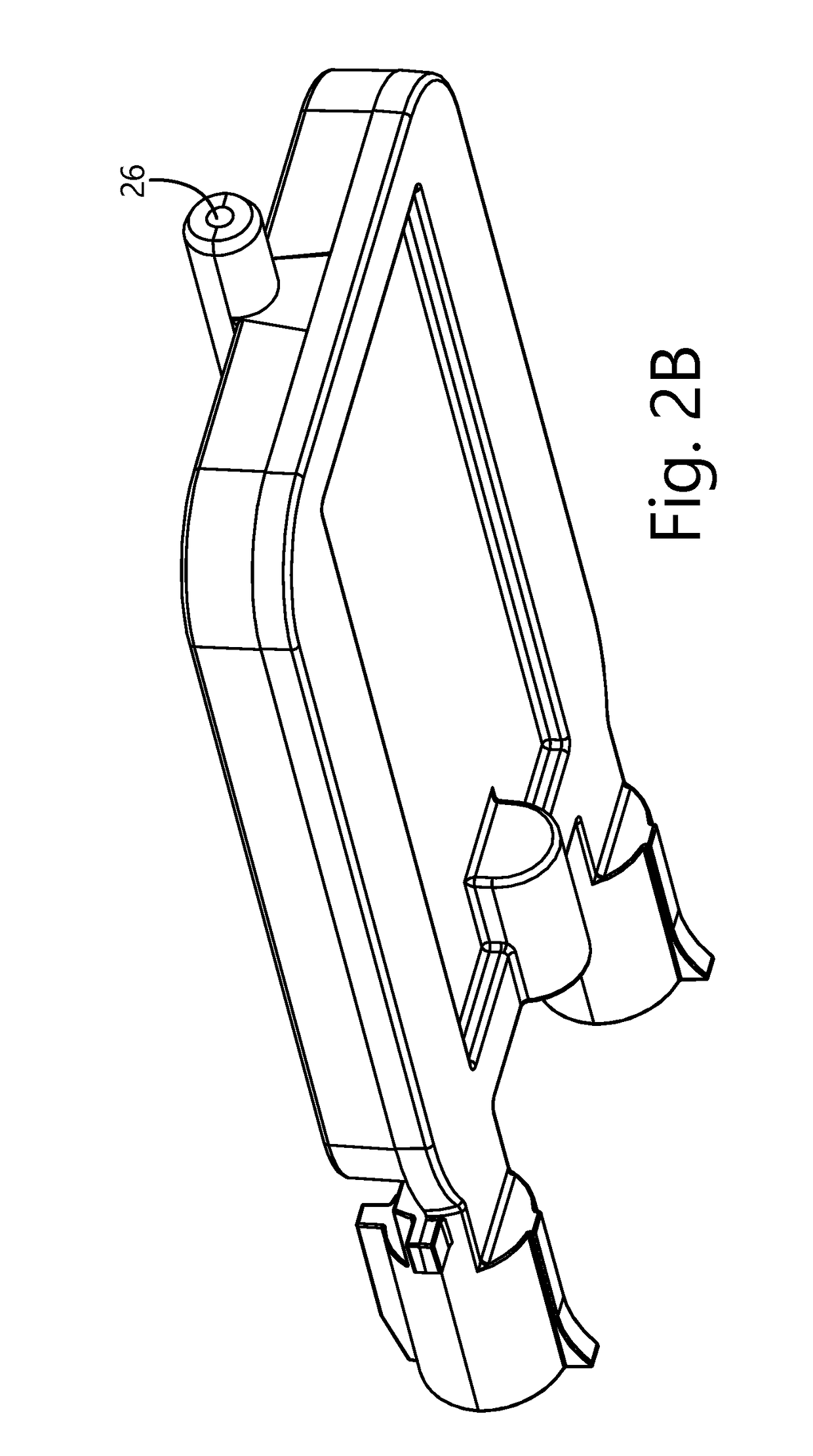

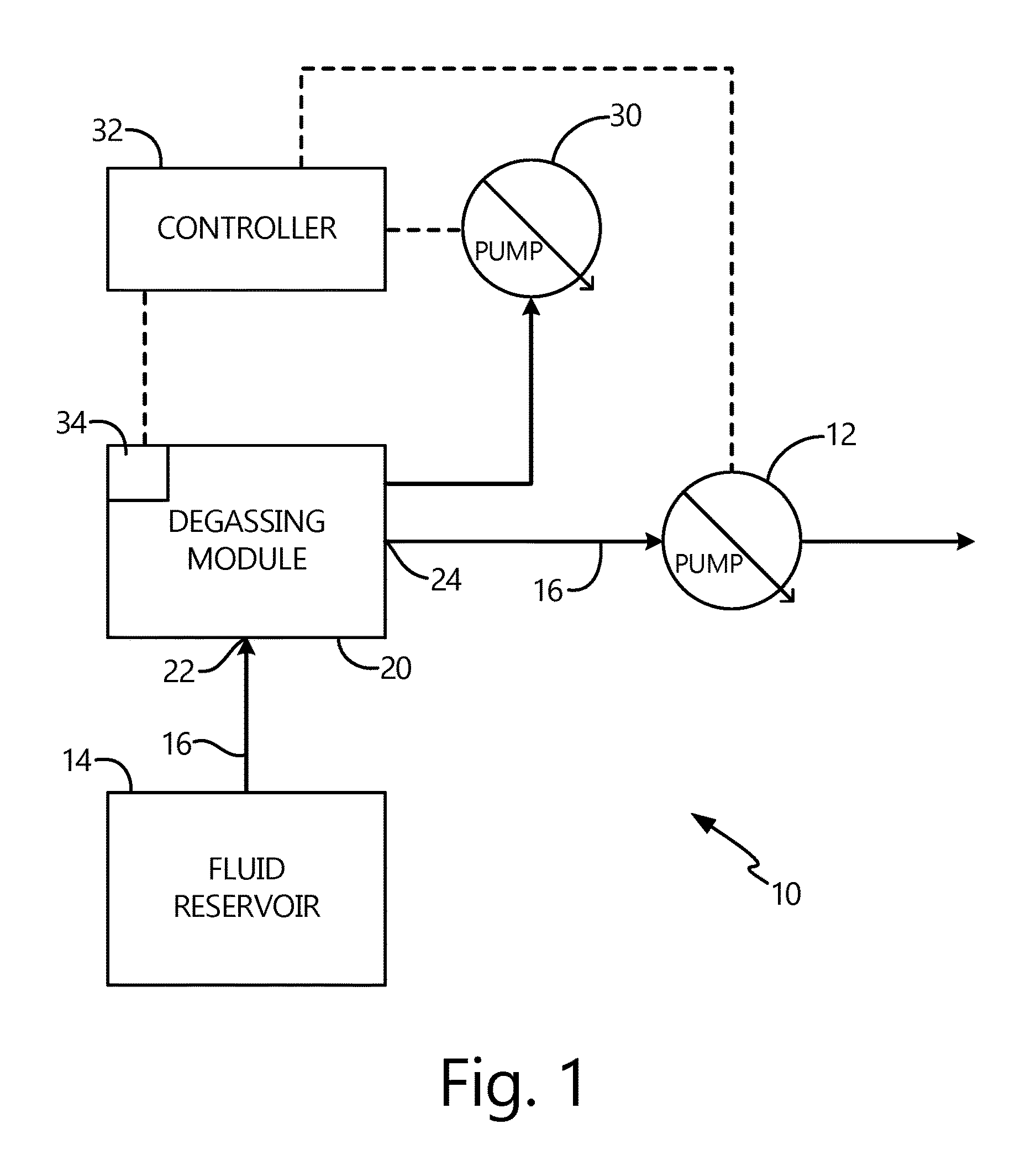

Membrane gas/liquid contactor

ActiveUS10143942B2Reduce gas concentrationSemi-permeable membranesSolid sorbent liquid separationBiomedical engineeringMembrane configuration

A membrane gas-liquid contactor is arranged to define a fluid flow path for contact with a membrane in a manner to improve degassing efficiency. A degassing module housing the membrane is arranged with flow fields for distributing the fluid flow throughout the membrane contact area. The distributed fluid flow may have a uniform membrane contact opportunity.

Owner:IDEX HEALTH & SCI

Membrane Gas/Liquid Contactor

ActiveUS20170056788A1Reduce gas concentrationSemi-permeable membranesSolid sorbent liquid separationBiomedical engineeringMembrane configuration

A membrane gas-liquid contactor is arranged to define a fluid flow path for contact with a membrane in a manner to improve degassing efficiency. A degassing module housing the membrane is arranged with flow fields for distributing the fluid flow throughout the membrane contact area. The distributed fluid flow may have a uniform membrane contact opportunity.

Owner:IDEX HEALTH & SCI

Gas-Liquid Contactor

InactiveUS20130089480A1Minimum retentionMinimum timeGas treatmentTransportation and packagingEngineeringAirflow

Owner:SPECIALIST PROCESS TECH

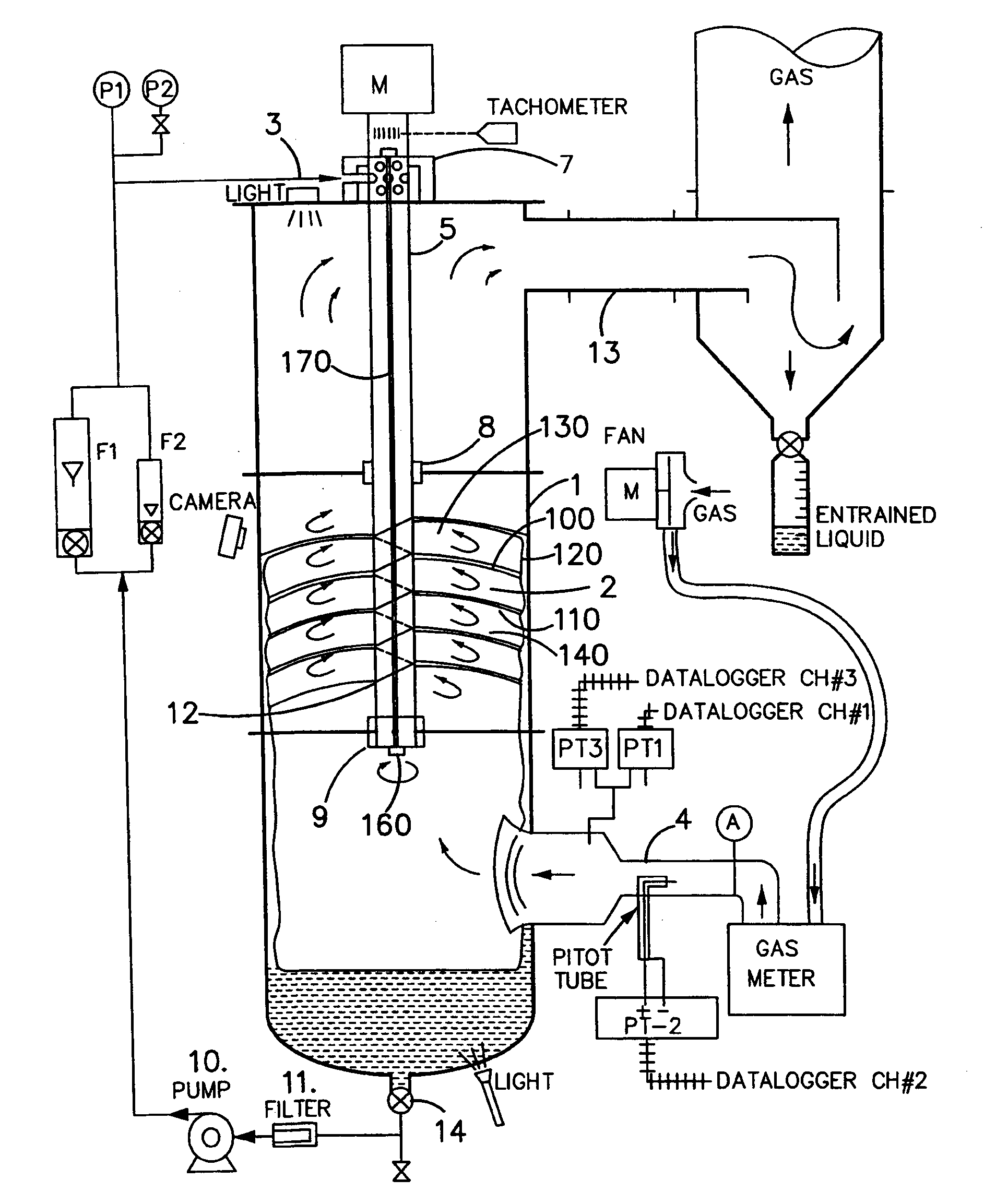

Gas liquid contactor

ActiveUS20130305923A1Performance maximizationSimple designRespiratorsRotating receptacle mixersProduct gasEngineering

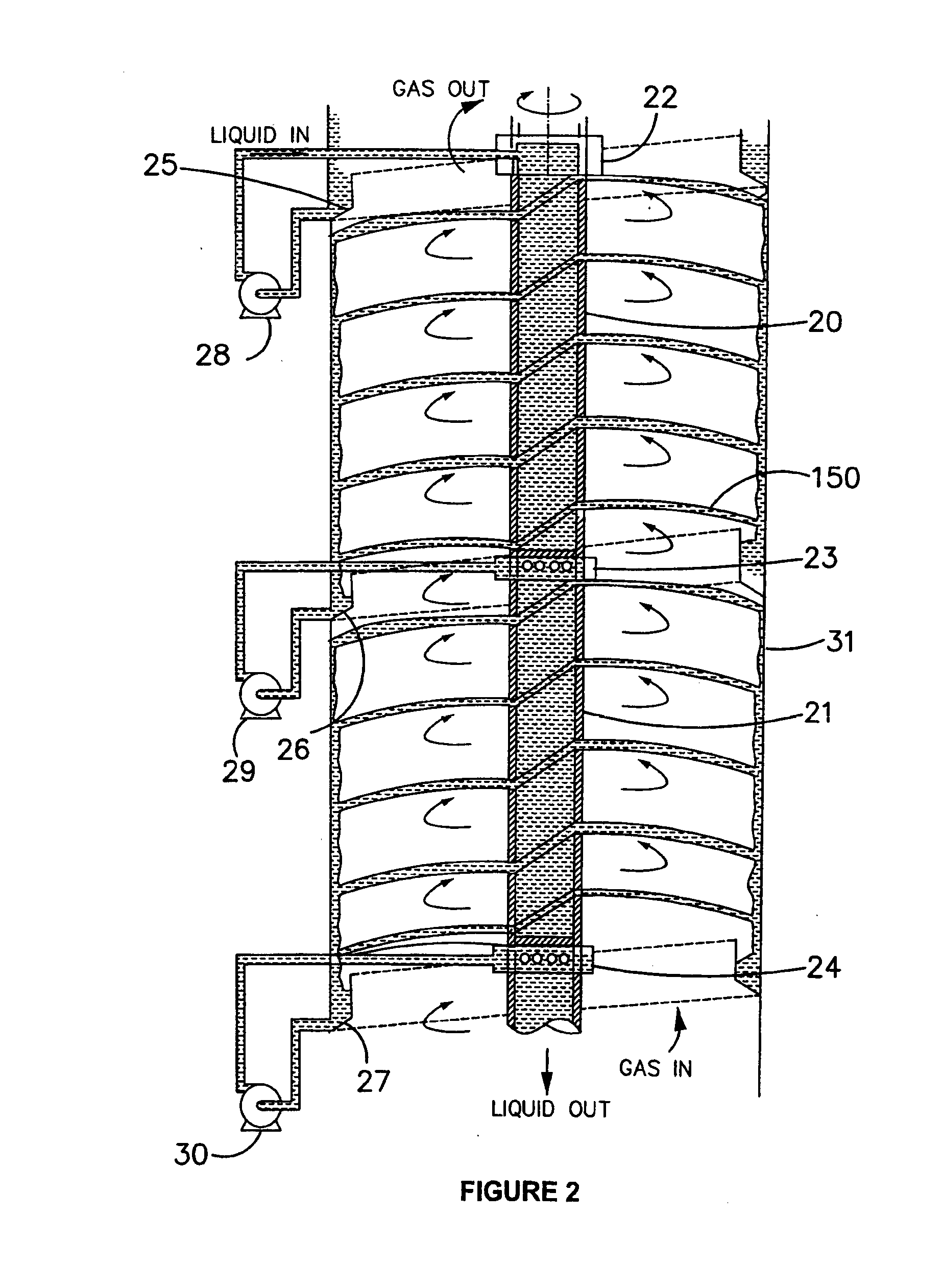

A gas and liquid contacting vessel comprises a distributor apparatus. The distributor apparatus comprising at least one housing rotatable about an axis of the housing for receiving liquid. Each rotatable housing having a distributor region comprising at least one liquid outlet or arrangement of liquid outlets formed in the housing from which liquid is projected from the housing as at least one liquid sheet onto an inner wall of the vessel. A pressurised source of liquid such as via a pump for providing liquid through the liquid outlets in the distributor apparatus to project liquid from the housing at least initially, in a stream of liquid extending continuously along the length of the liquid outlet corresponding to the inner wall of the vessel, and a gas inlet communicating with the gas liquid contacting space, the gas inlet directing gas into contact with the liquid sheets projected from the outlets in the housing.

Owner:COMMONWEALTH SCI & IND RES ORG

Oxygen-Containing Reducing Aqueous Beverages and Method of Producing Same

InactiveUS20090068313A1Low oxidation-reduction potentialHydrogen concentrationMilk preservationFood mechanical treatmentHydrogen contentOxygen content

To produce oxygen-containing reducing aqueous beverages with substantial hydrogen content and very low oxidation-reduction potential in spite of their substantial oxygen content, such as water, mineral water, tea, coffee and juice beverages, the oxygen is dissolved under pressure of 1-1000 atmospheres using a gas-liquid contactor, and then the hydrogen therein is dissolved under pressure of 1-1000 atmospheres. These oxygen-containing reducing aqueous beverages can be consumed as reducing aqueous beverages for daily use, without giving rise to any health problems.

Owner:MUROTA WATARU

High performance continuous reaction/separation process using a continuous liquid-solid contactor

InactiveUS20040099605A1Improve productivityLow costIon-exchange process apparatusOrganic chemistryContinuous reactionLiquid solid

A process for reaction and separation which comprises inputting a process material into at least one column of a plurality of columns wherein each column has at least one inlet for accepting flow from another column or group of columns, an external feed stream, an external eluent stream or a combination thereof, and each column has at least one outlet for connecting to another column, a group of columns, an external product stream or a combination thereof. Each column is independently operable in an up-flow or down-flow mode and connected independently to one of the group comprising another column, an external feed stream, an external eluent stream, an external product stream and combinations thereof.

Owner:CALGON CARBON

Brine based indirect steam boiler

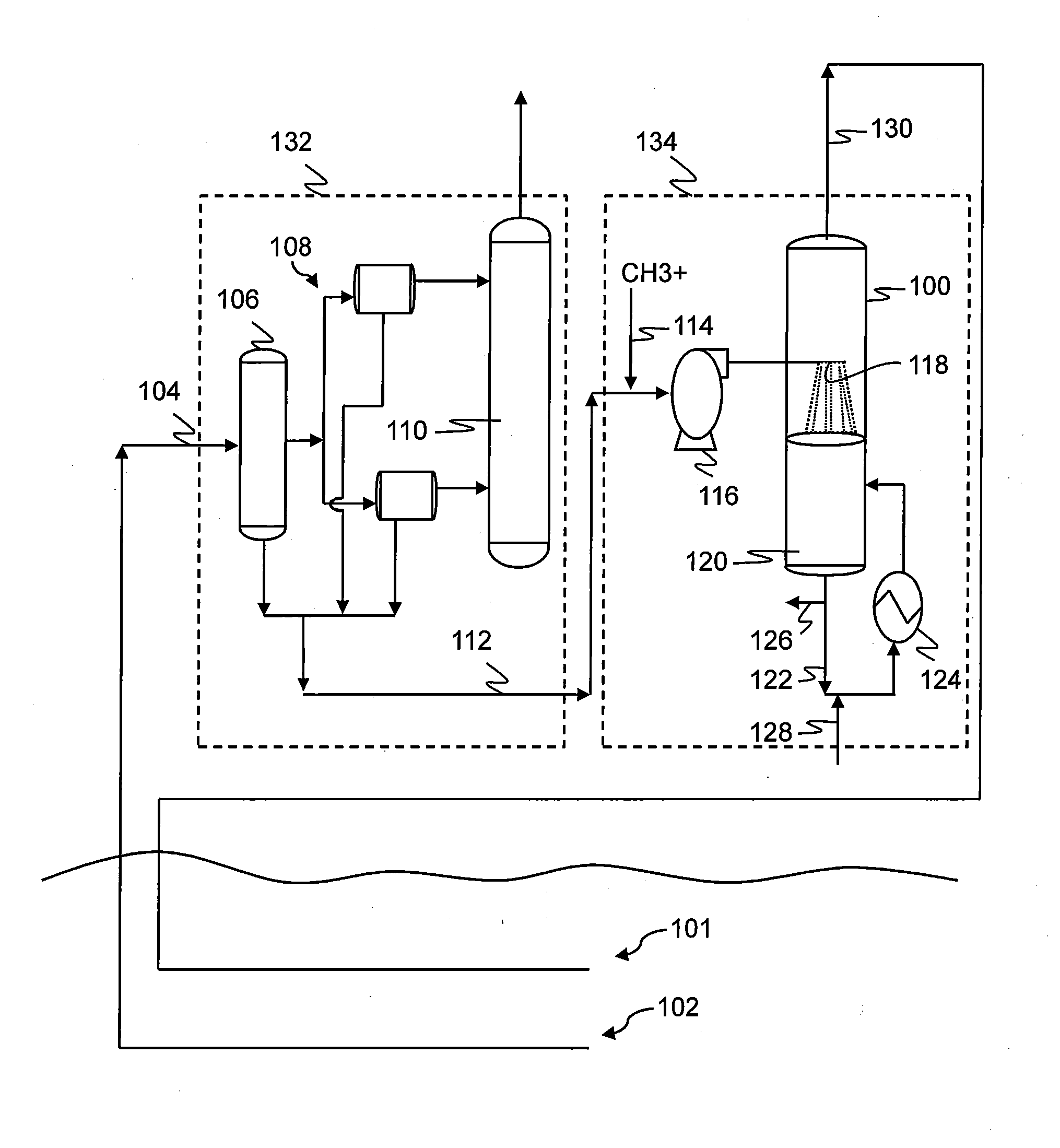

InactiveUS20140166263A1Facilitate additional hydrocarbon recoveryUsing liquid separation agentInsulationSaline waterEmulsion

Systems and methods generate steam in hydrocarbon recovery operations and may further enable emulsion separation and product upgrading. The methods rely on indirect boiling of water by contact with a thermal transfer liquid heated to a temperature sufficient to vaporize the water. Examples of the liquid include oils, recovered hydrocarbons, liquid metals and brine. Heating of the liquid may utilize circulation of the liquid across or through a furnace, heat exchangers, or a gas-liquid contactor supplied with hot gas. Further, a solvent for bitumen introduced into the water may also vaporize upon contact with the thermal transfer liquid.

Owner:CONOCOPHILLIPS CO

Membrane-enabled reverse lung

An air revitalization apparatus and method simultaneously removes carbon dioxide, water vapor, and heat from air and produces oxygen gas, hydrogen gas, and concentrated carbon dioxide gas, does not require an explosion proof enclosure, and includes a fan configured to blow air into a first gas-liquid contactor, an electrochemical cell including first through fourth passages configured to emit hydrogen gas, permit a flow of a carbonate-hydroxide solution, permit a flow of carbonate-bicarbonate solution, and emit oxygen gas, respectively, the first and fourth passages separated by at least three gas-impermeable membranes, and a second gas-liquid contactor, where the first gas-liquid contactor, second passage, and a first pump are configured to circulate the carbonate-hydroxide solution therethrough, where the second gas-liquid contactor, third passage, and a second pump are configured to circulate the carbonate-bicarbonate solution therethrough, and where the output of the first passage is operationally coupled to the second gas-liquid contactor.

Owner:OCEANEERING INTERNATIONAL

Oxygen-containing reductive aqueous beverage and process for production of the same

InactiveCN101146459ALower redox potentialFood mechanical treatmentGaseous food ingredientsOxygenOxidation reduction

An oxygen-containing reductive aqueous beverage produced by dissolving oxygen in an aqueous beverage (for example, water, mineral water, tea, coffee, juice, etc.) under a pressure of 1 to 1000 atm and then dissolving hydrogen therein under a pressure of 1 to 1000 atm using a well-known gas-liquid contactor. The beverage is rich in both oxygen and hydrogen and has an extremely low oxidation-reduction potential. The beverage can be used on a day-to-day basis as a reductive aqueous beverage without causing any health problems.

Owner:室田涉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com