Gas liquid contactor and effluent cleaning system and method

A technology of gas-liquid contact and gas-liquid separator, which is applied in the field of nozzle arrays, can solve the problems of short residence time of bubbles, small interface surface area of bubbles, etc., and achieve low impact on cost and site selection, good consistency, and high potential quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

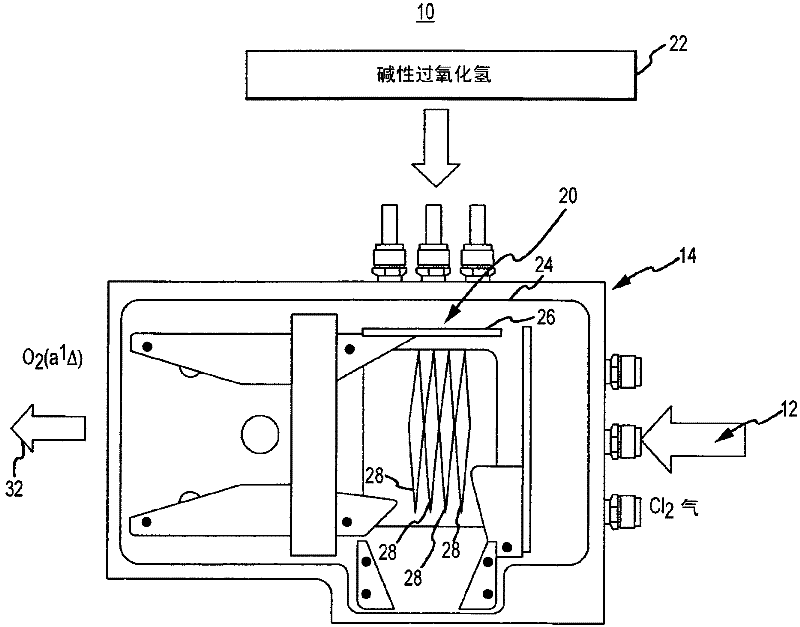

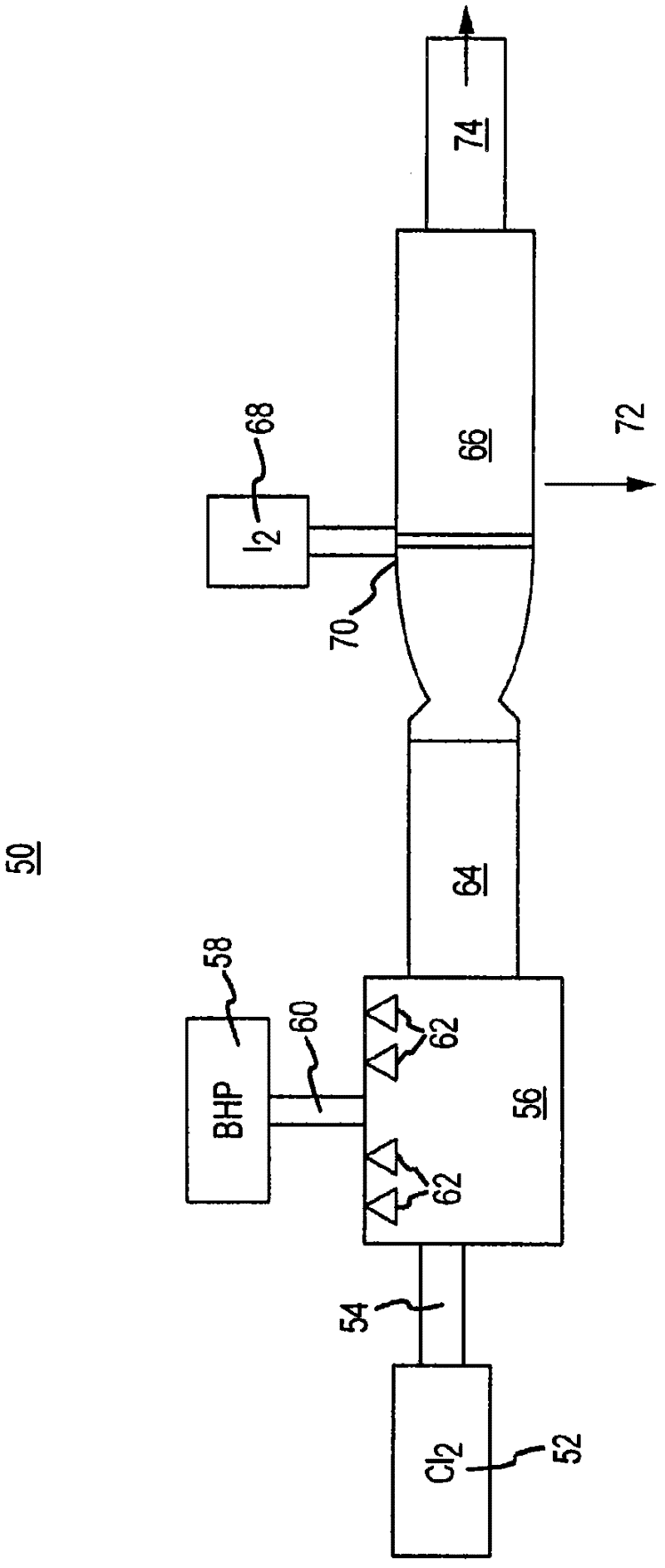

[0108] The present invention relates to gas liquid contactor and effluent cleaning systems and methods, and more particularly to an array of nozzles configured to produce uniformly spaced horizontal liquid jets shaped to minimize disturbance from gas flow. Furthermore, the various embodiments directly provide multiple small single unit methods that can be combined into modules, by which the disadvantages of conventional designs can be overcome. The modularity of the single-unit approach enables the size of the small system adaptation approach to be scaled up by simply multiplying the modules by a convenient integer.

[0109] Furthermore, a single gas-liquid contactor capable of generating thin horizontal liquid jets can be easily multiplied and combined into one or more modules that can perform over a range of gas flow rates in a very compact design that is significantly smaller than equivalent reaction yields. rate of conventional countercurrent reactors. Combination into on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com