Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Strong compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

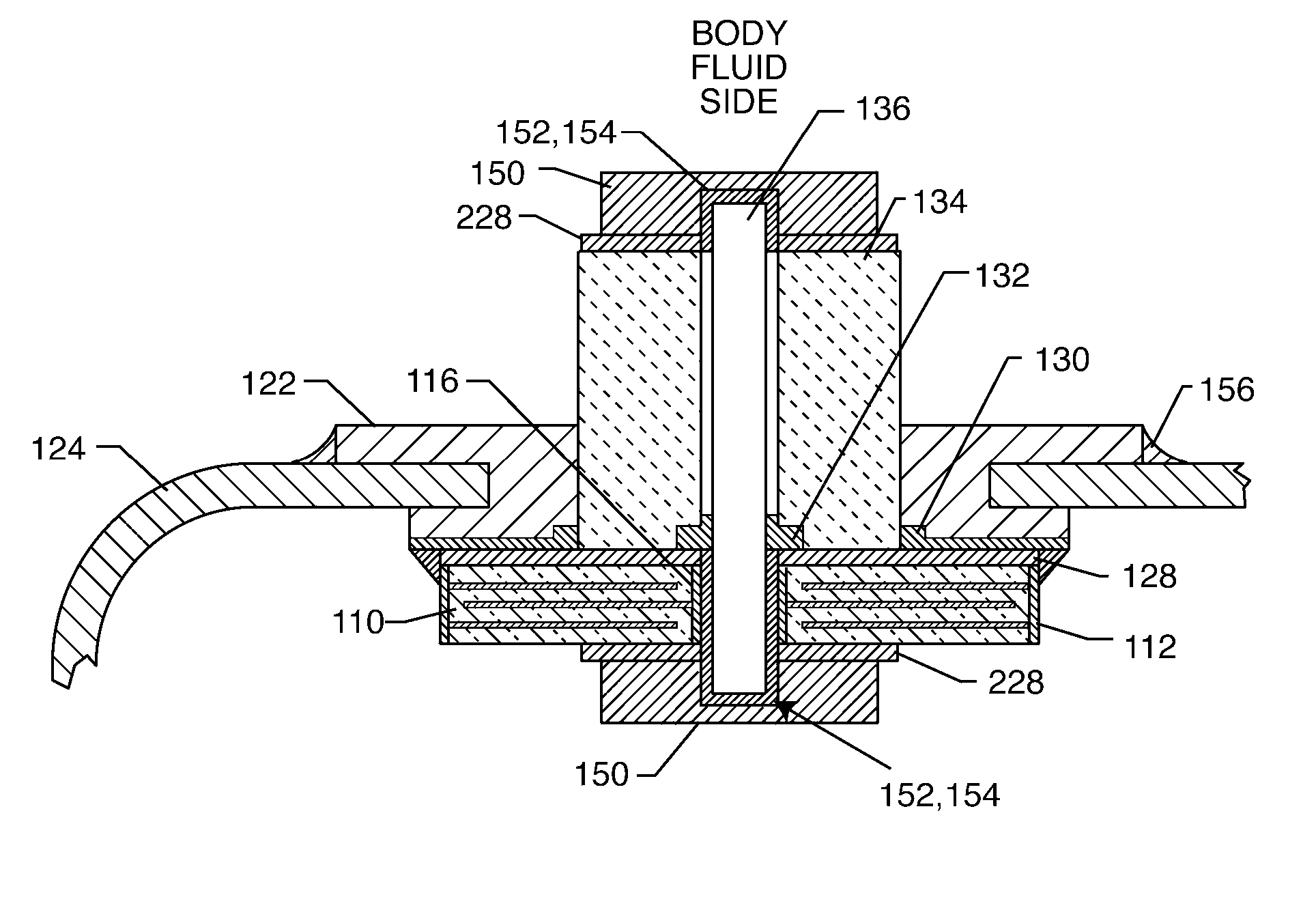

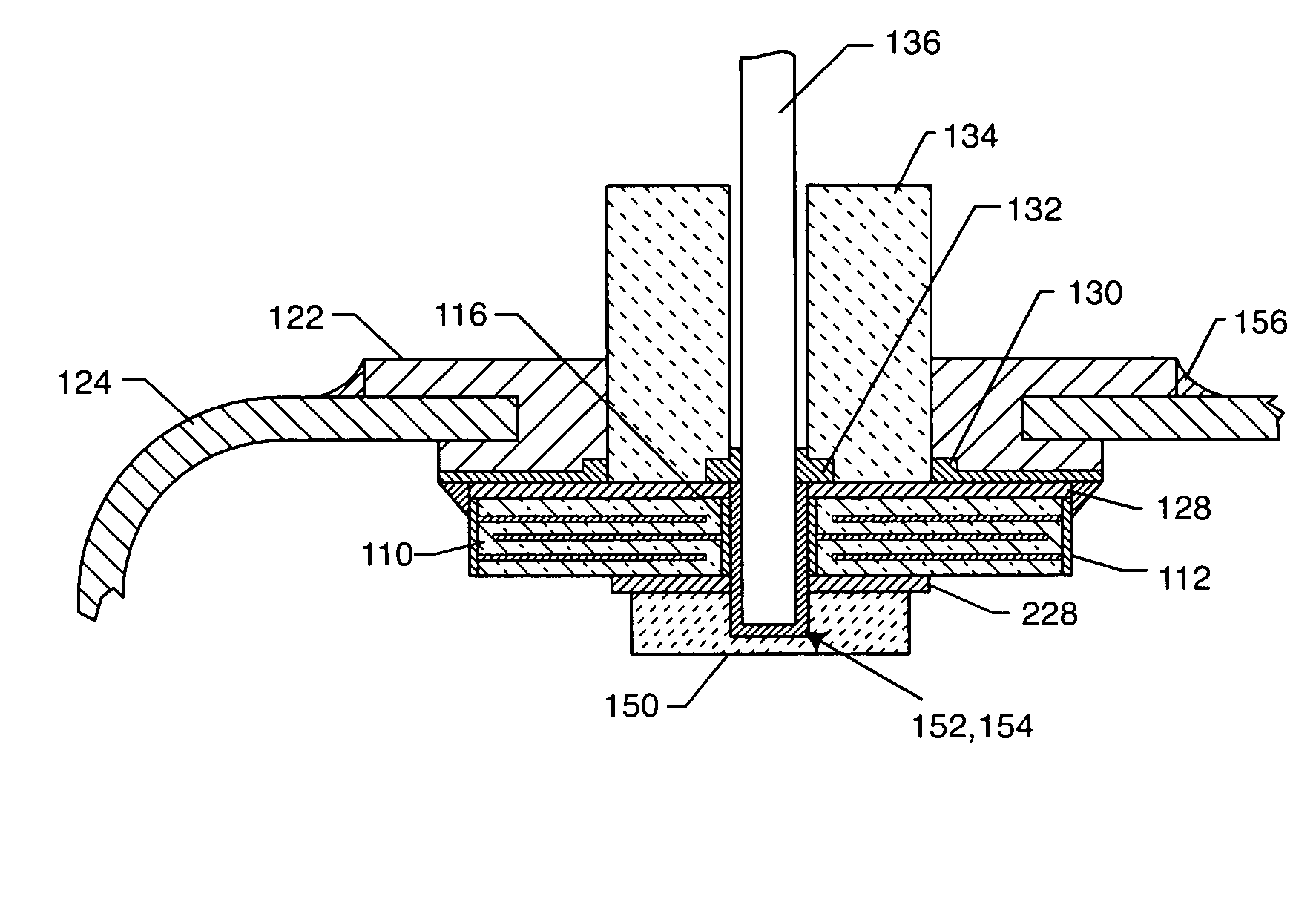

Hermetic feedthrough terminal assembly with wire bond pads for human implant applications

ActiveUS20060259093A1Consume energyReduce tensionMultiple-port networksAnti-noise capacitorsUltrasonic bondingMedical device

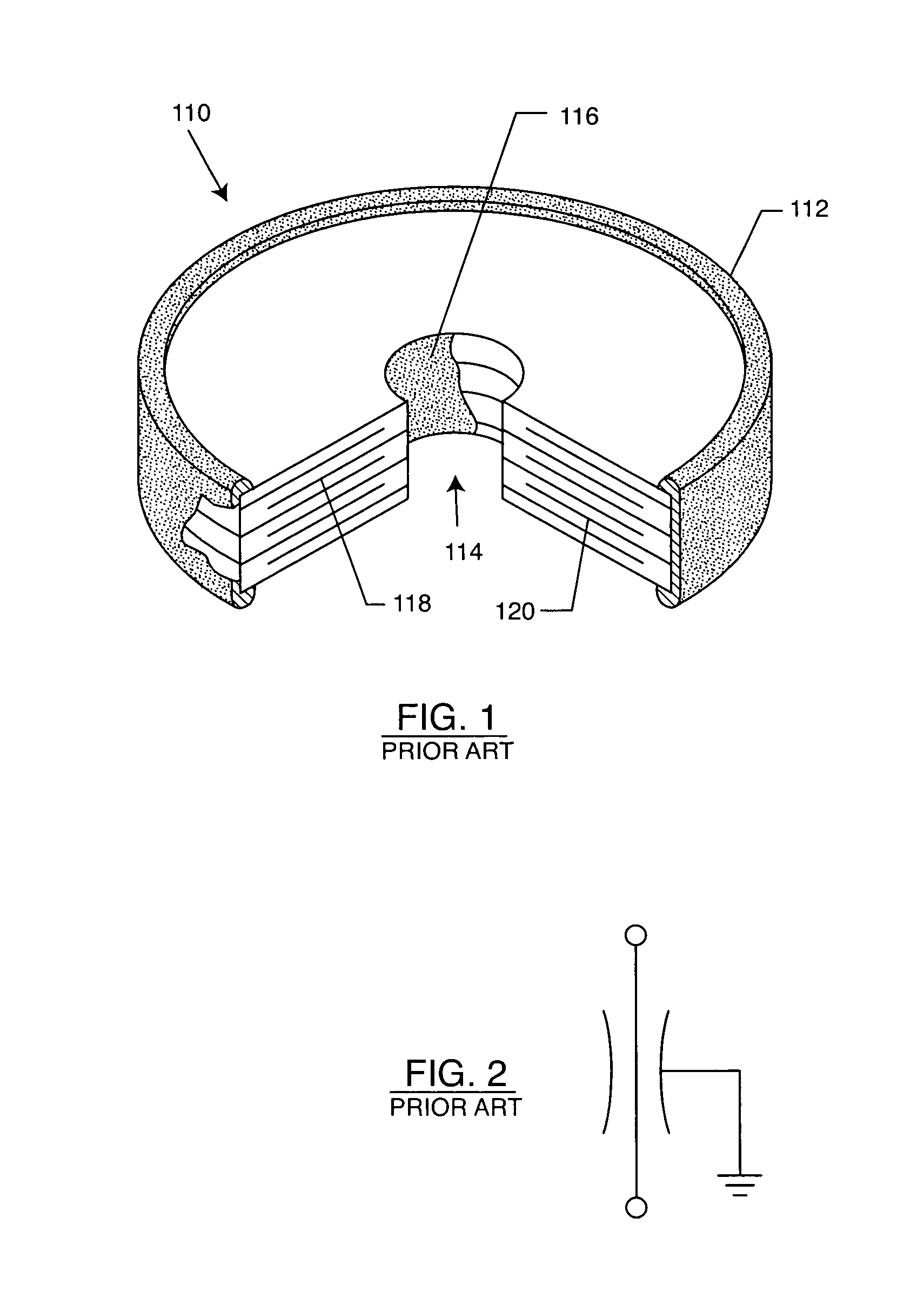

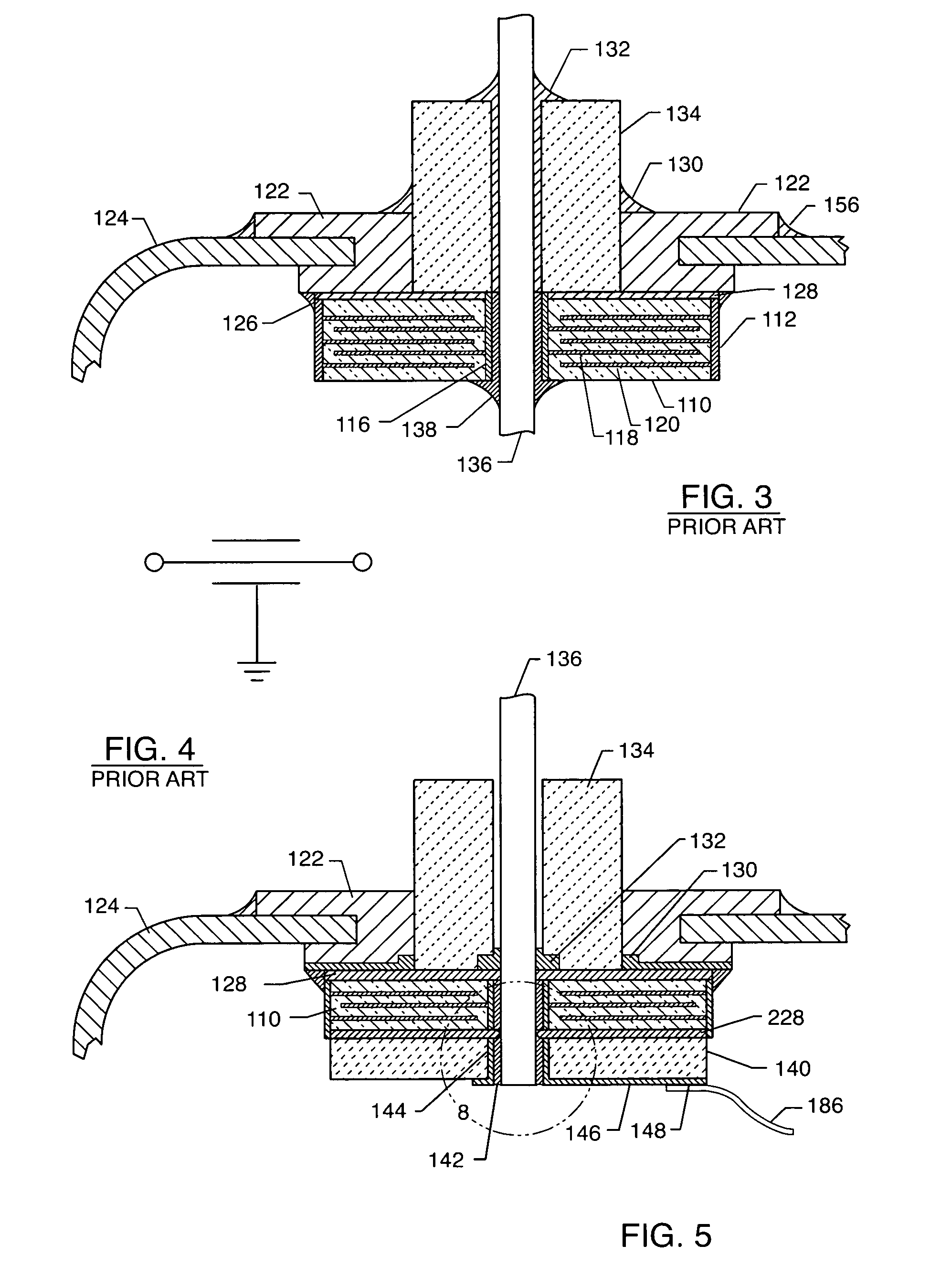

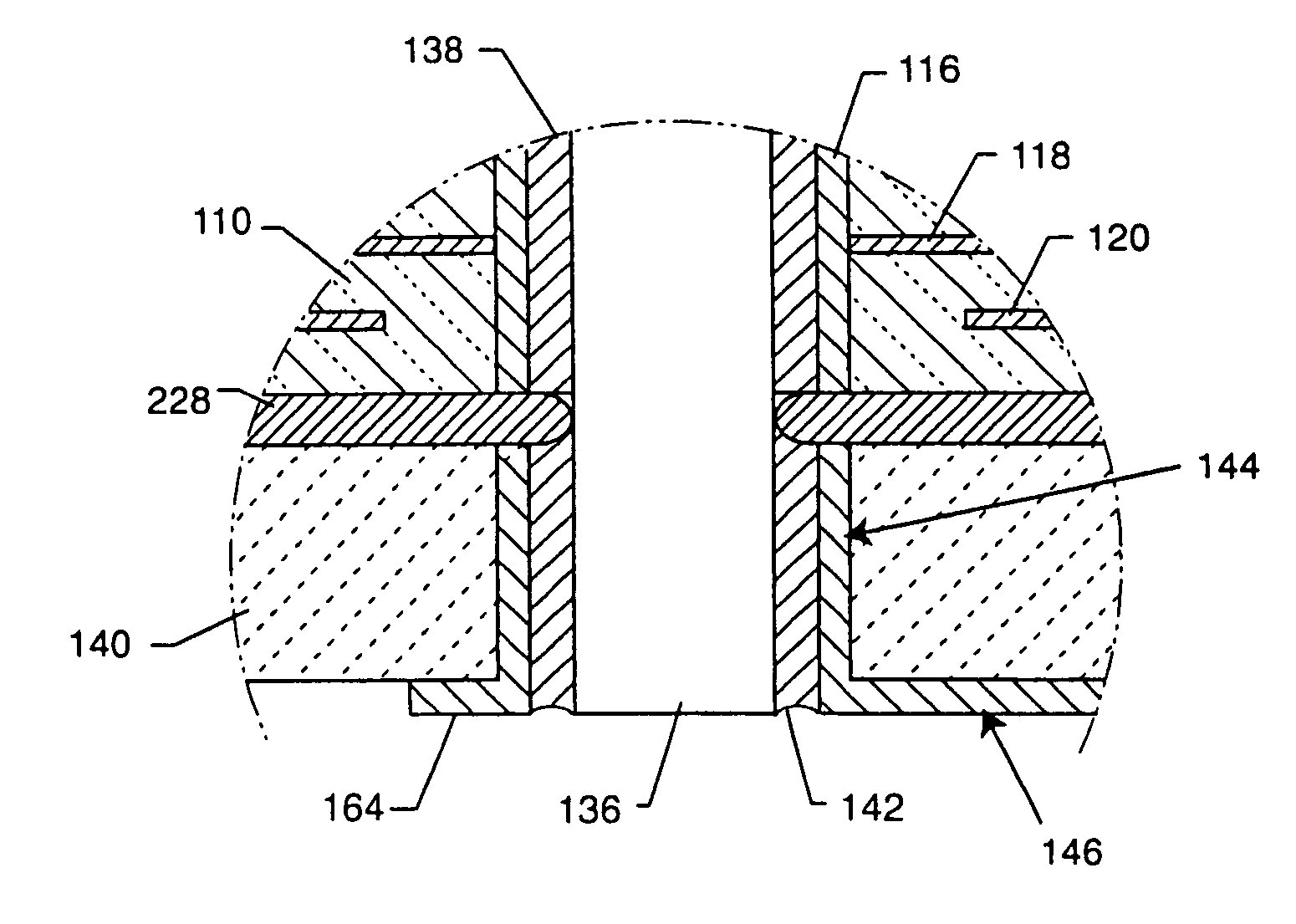

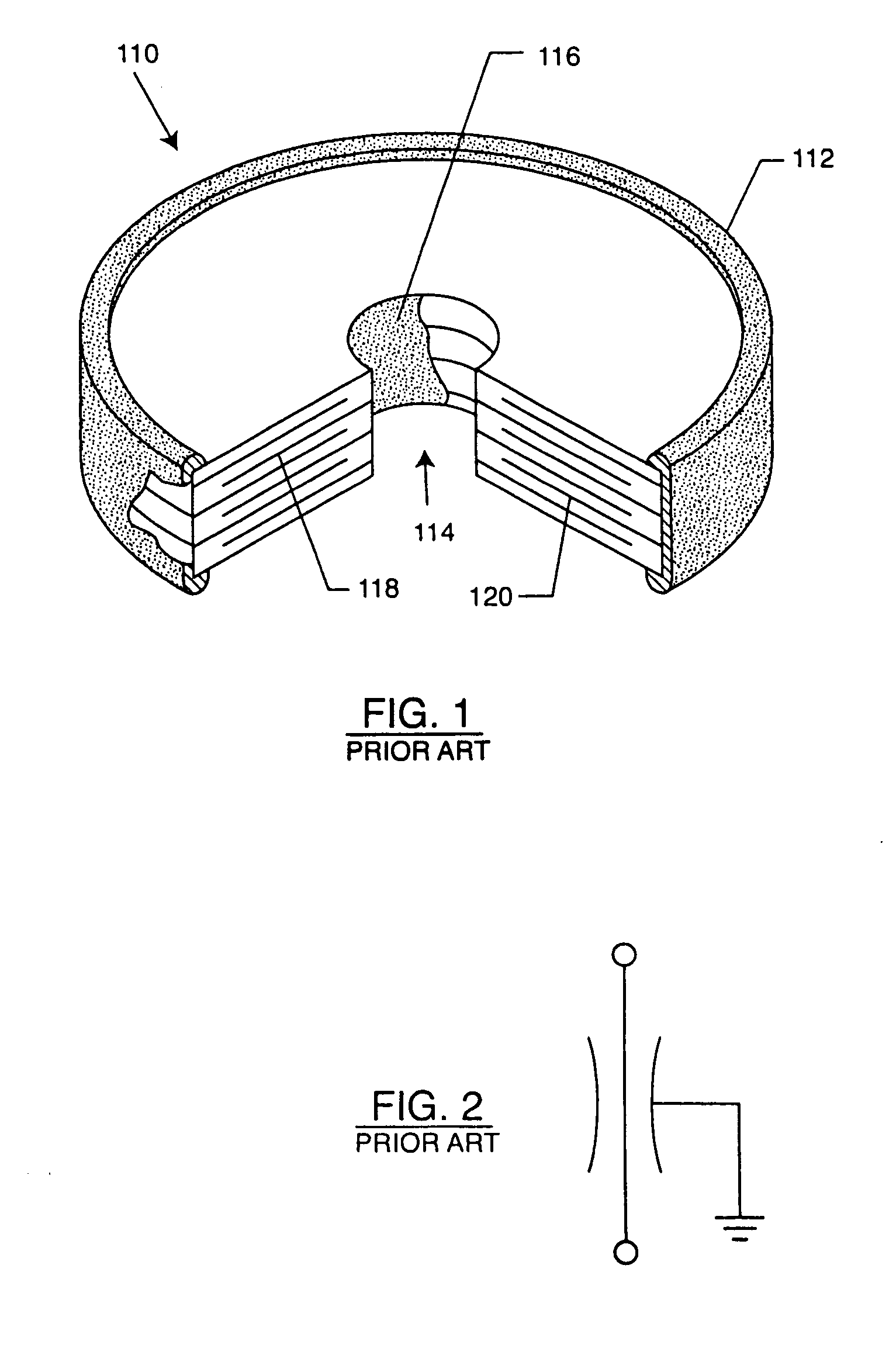

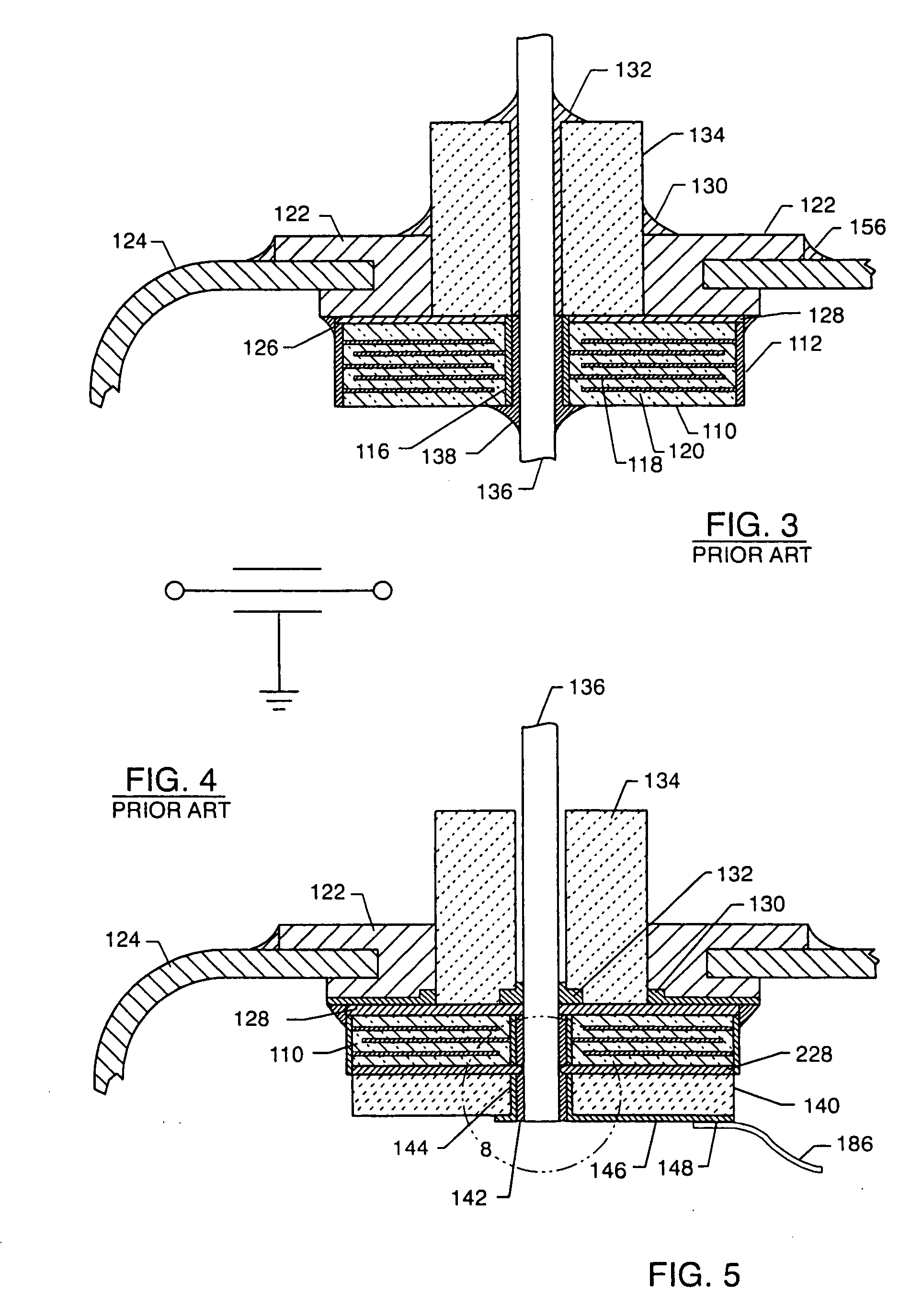

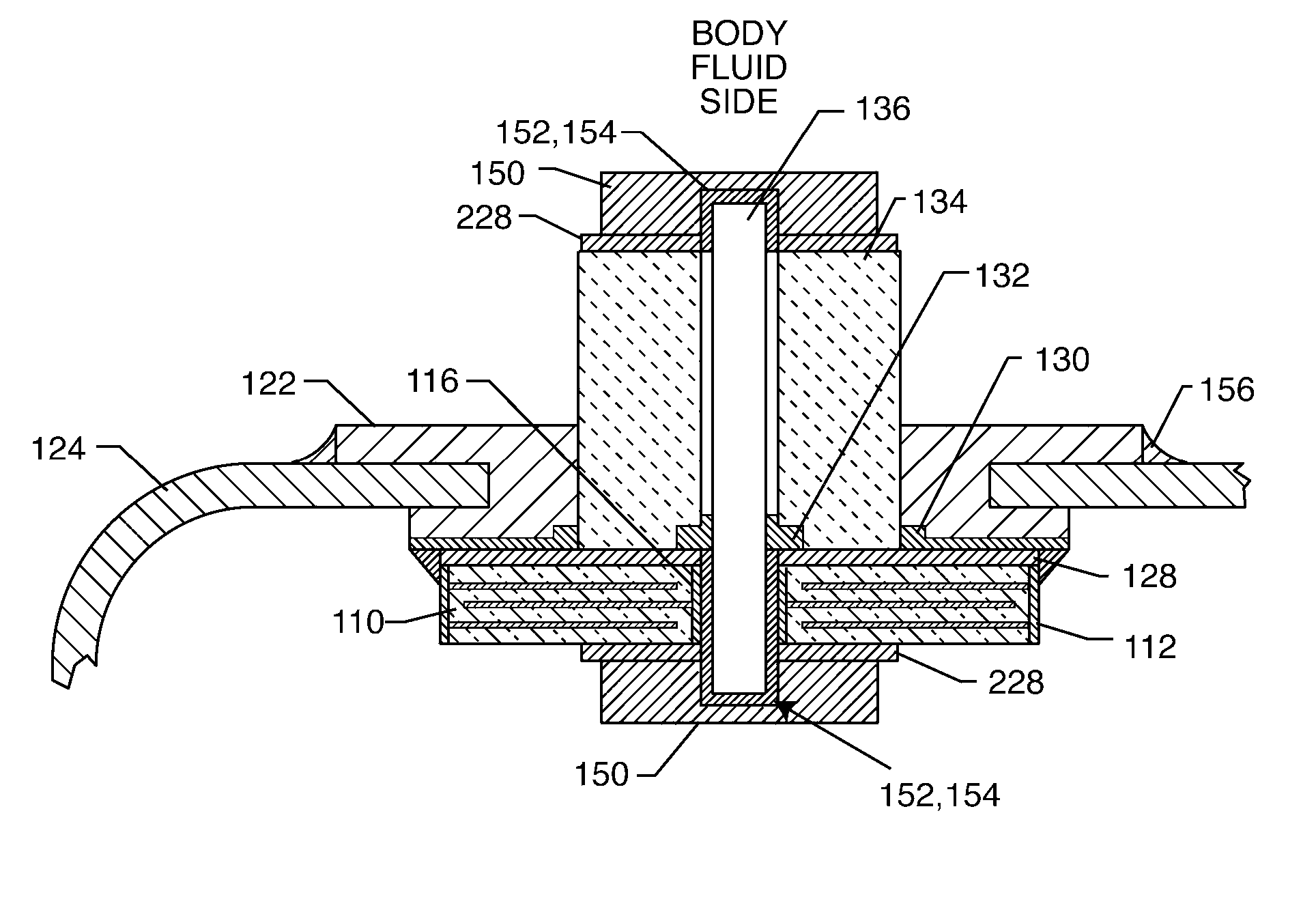

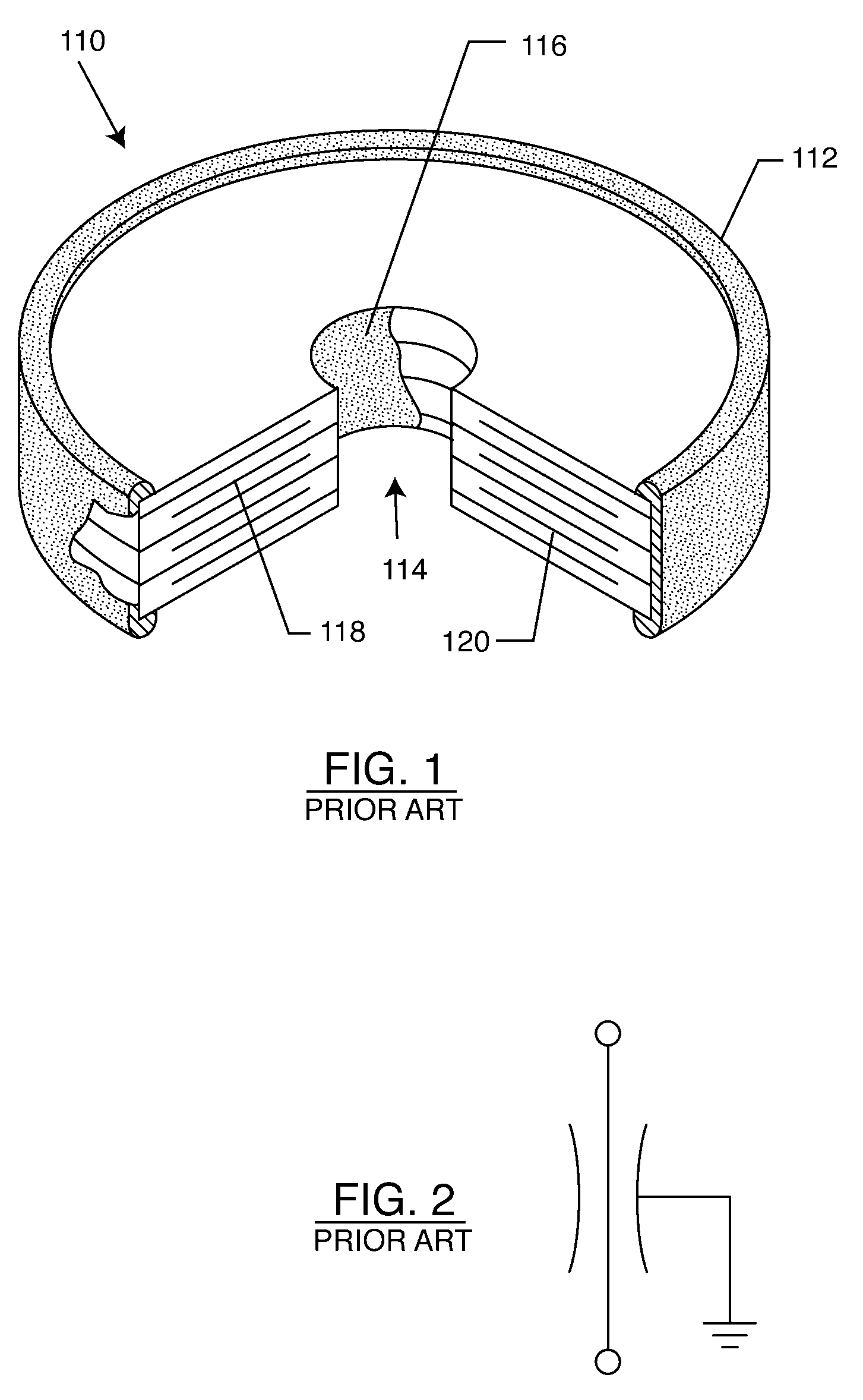

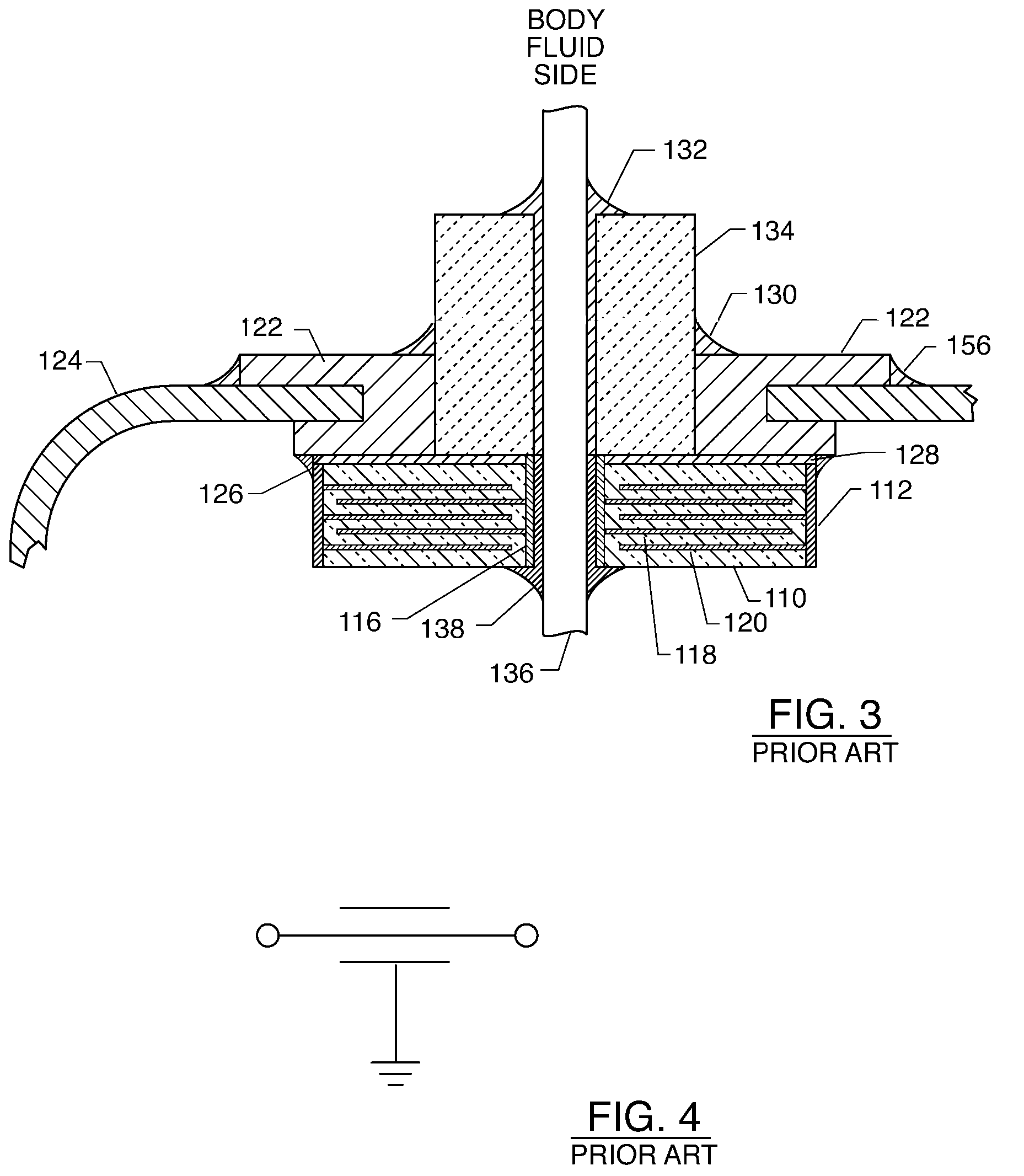

A feedthrough terminal assembly for active implantable medical devices includes a structural wire bond pad for a convenient attachment of wires from either the circuitry inside the implantable medical device or wires external to the device. Direct attachment of wire bond pads to terminal pins enables thermal or ultrasonic bonding of lead wires, while shielding the capacitor or other delicate components from the forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

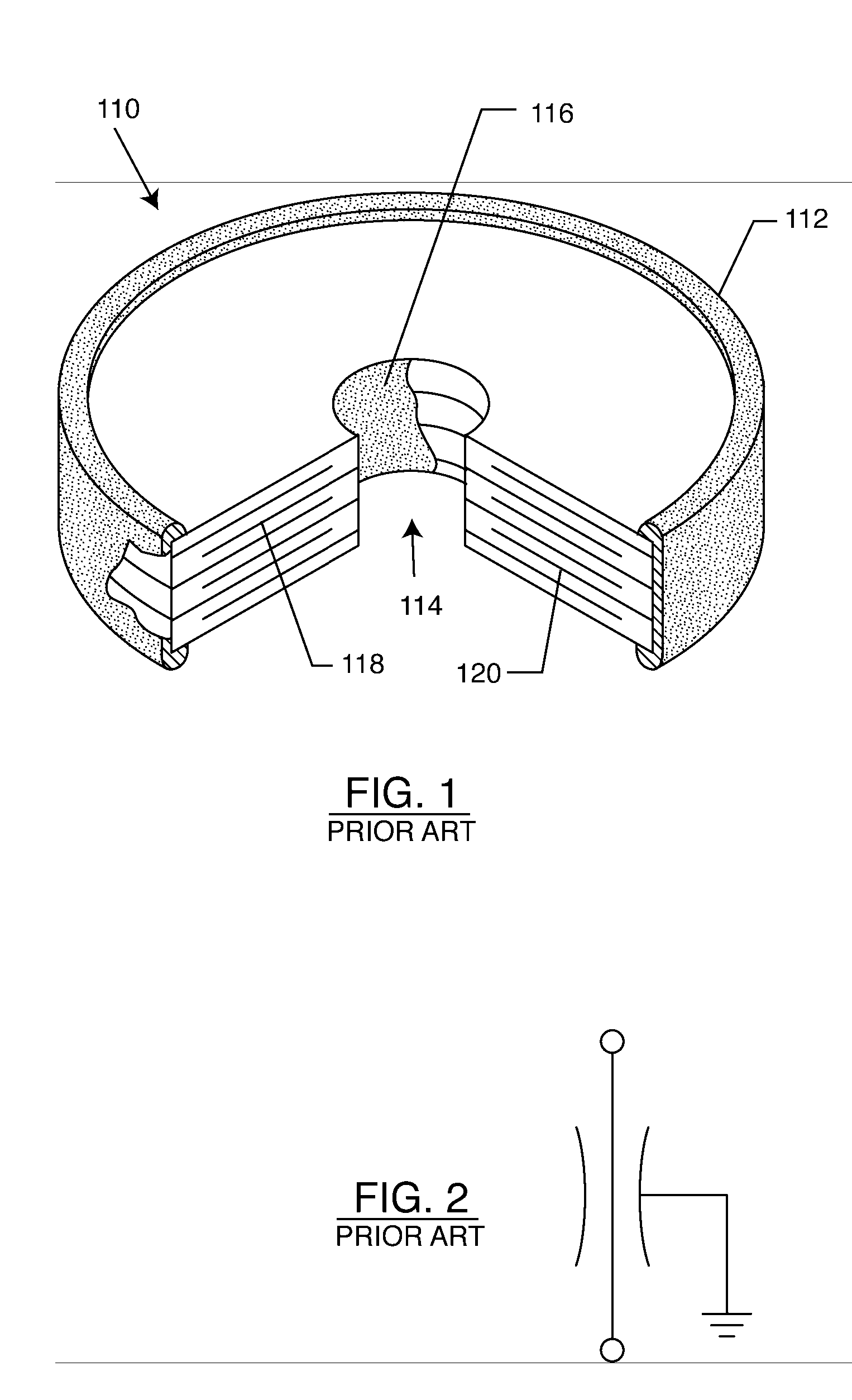

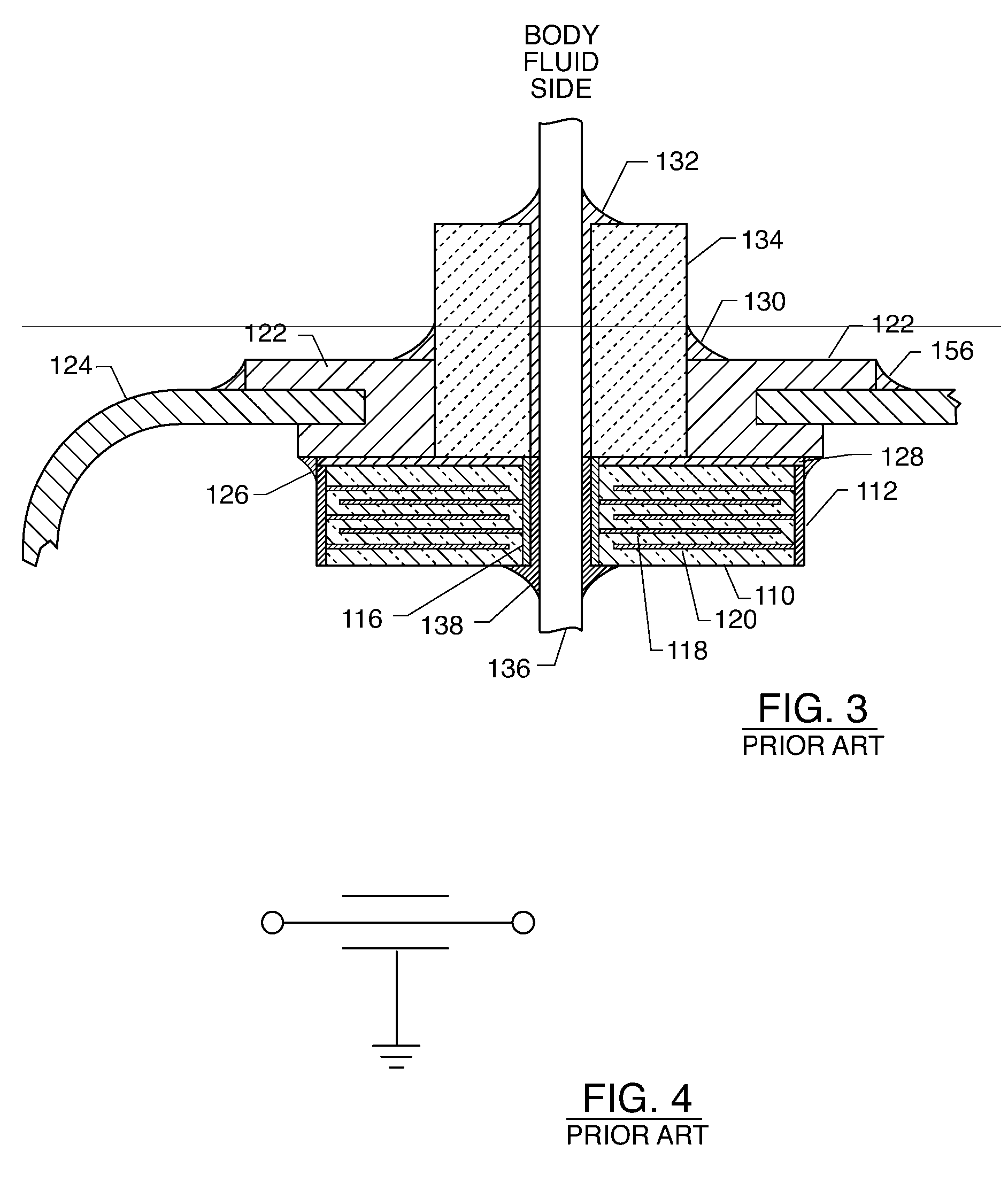

EMI filter terminal assembly with wire bond pads for human implant applications

ActiveUS20050007718A1Avoid crackingAbsorbs stressMultiple-port networksElectrotherapyElectromagnetic interferenceSoldering

An electromagnetic interference filter terminal assembly for active implantable medical devices includes a structural pad in the form of a substrate or attached wire bond pad, for convenient attachment of wires from the circuitry inside the implantable medical device to the capacitor structure via thermal or ultrasonic bonding, soldering or the like while shielding the capacitor from forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

EMI filter terminal assembly with wire bond pads for human implant applications

ActiveUS20050248907A1More stressImprove featuresAnti-noise capacitorsElectrotherapyElectromagnetic interferenceSoldering

An electromagnetic interference filter terminal assembly for active implantable medical devices includes a structural pad in the form of a substrate or attached wire bond pad, for convenient attachment of wires from the circuitry inside the implantable medical device to the capacitor structure via thermal or ultrasonic bonding, soldering or the like while shielding the capacitor from forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

Hermetic feedthrough terminal assembly with wire bond pads for human implant applications

ActiveUS7623335B2Increases moment of inertiaIncrease volumeMultiple-port networksAnti-noise capacitorsEngineeringUltrasonic bonding

A feedthrough terminal assembly for active implantable medical devices includes a structural wire bond pad for a convenient attachment of wires from either the circuitry inside the implantable medical device or wires external to the device. Direct attachment of wire bond pads to terminal pins enables thermal or ultrasonic bonding of lead wires, while shielding the capacitor or other delicate components from the forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

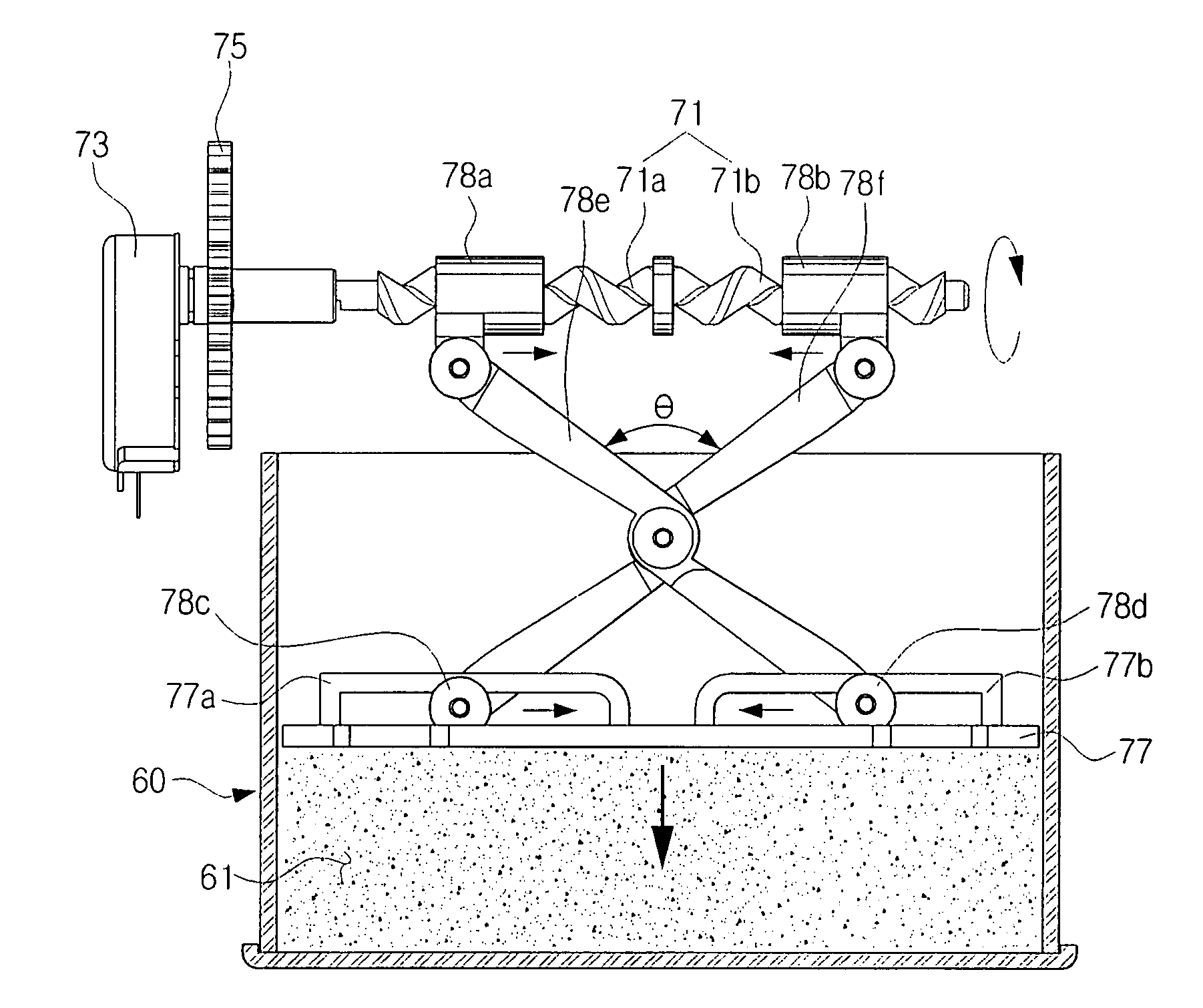

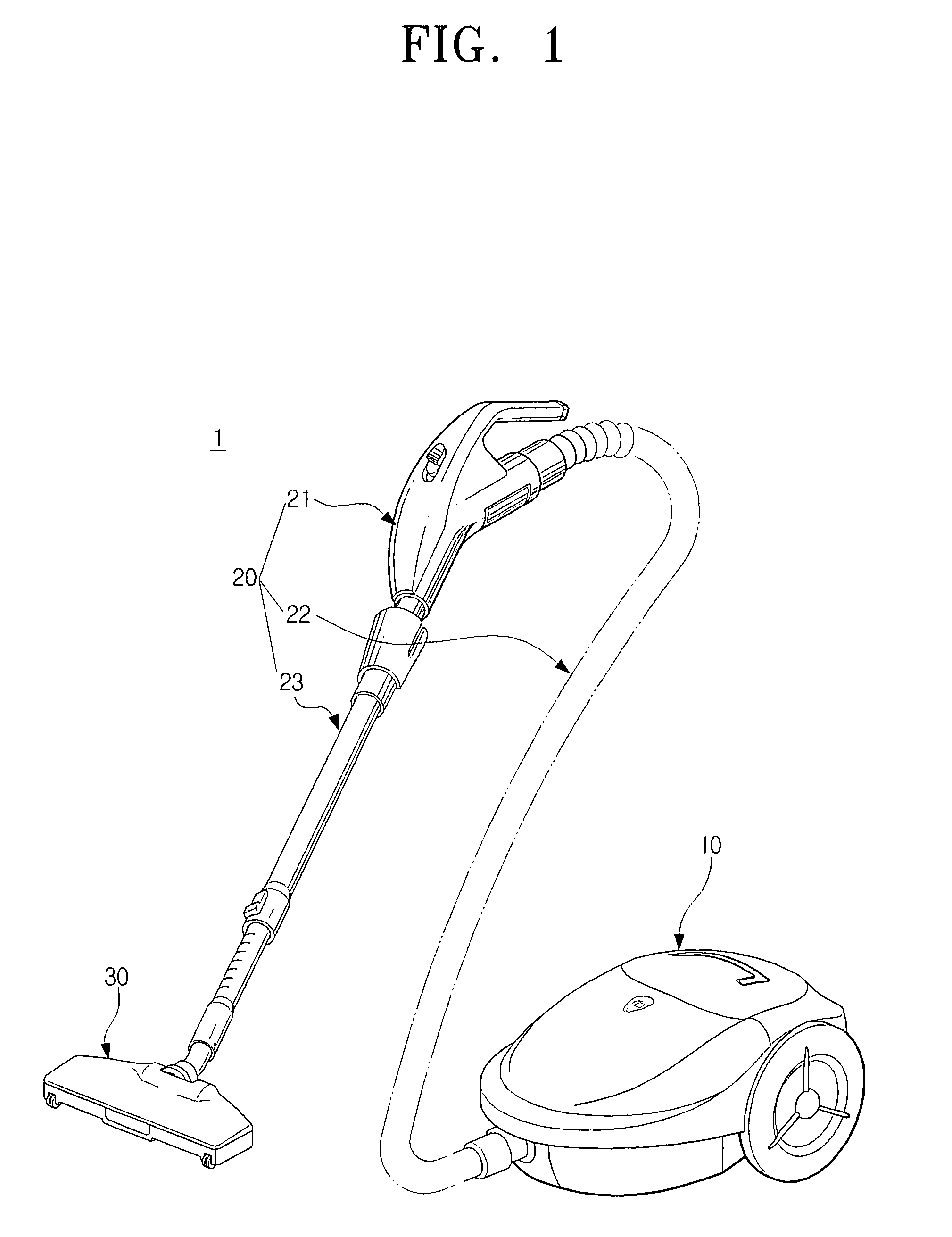

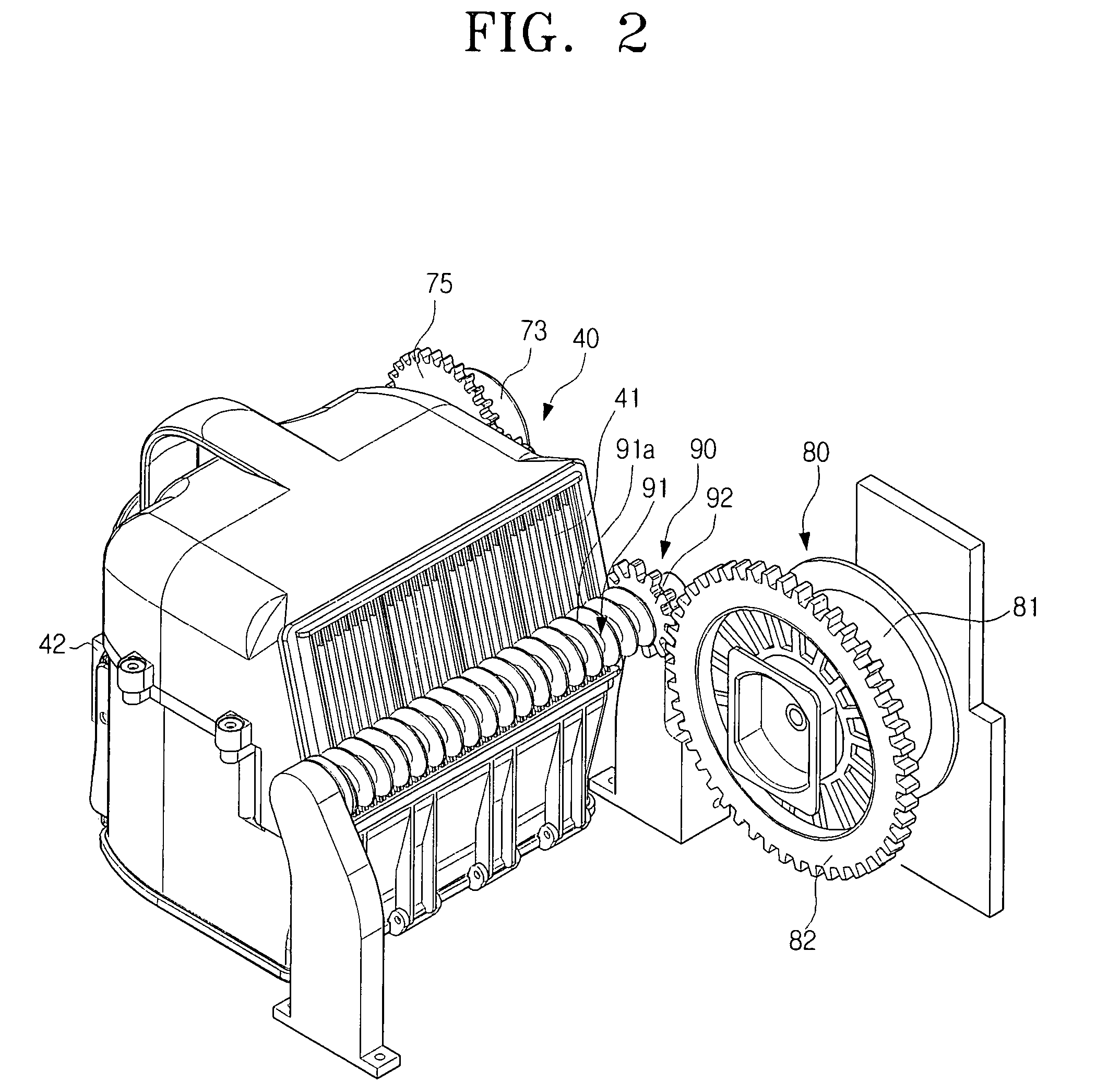

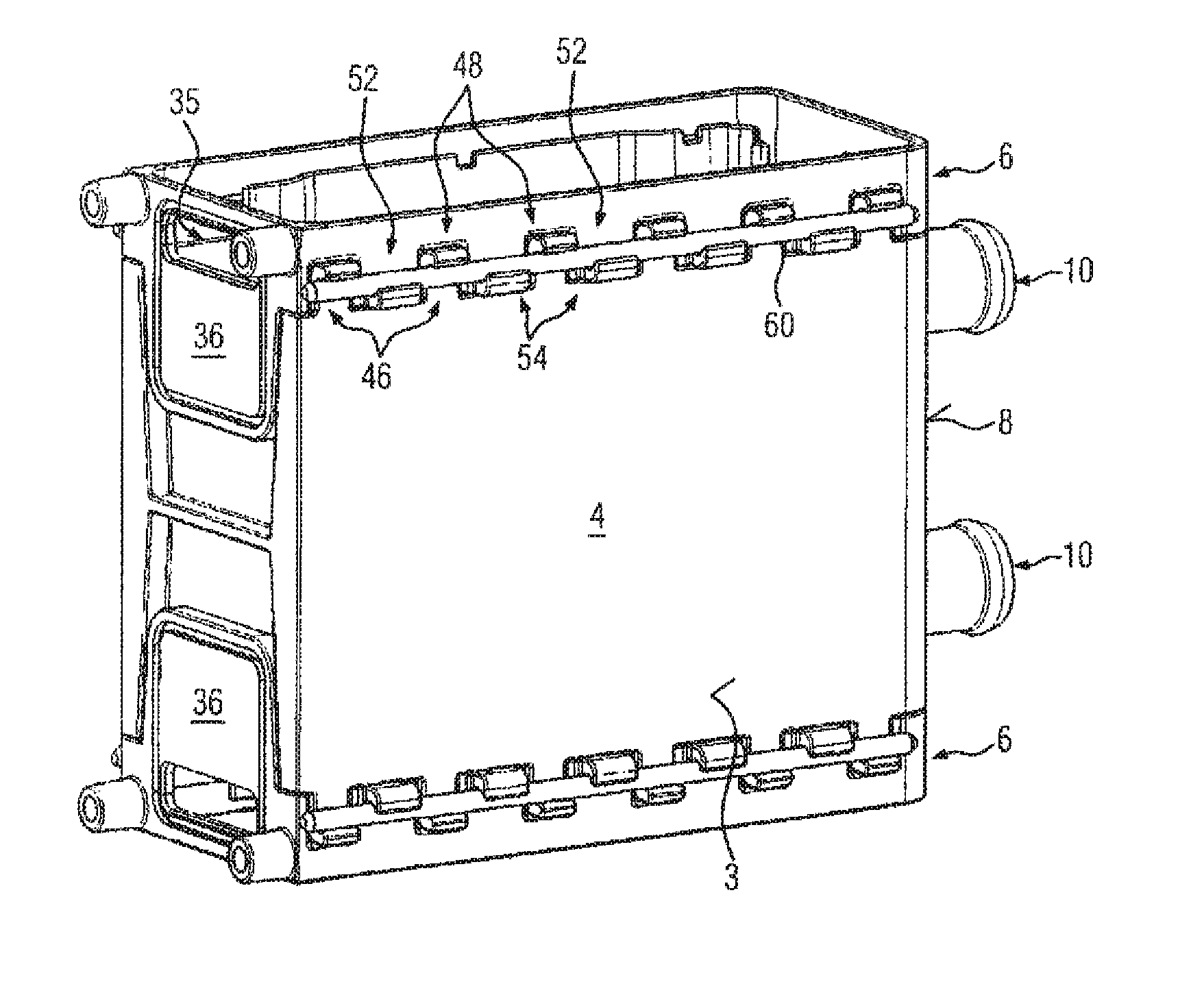

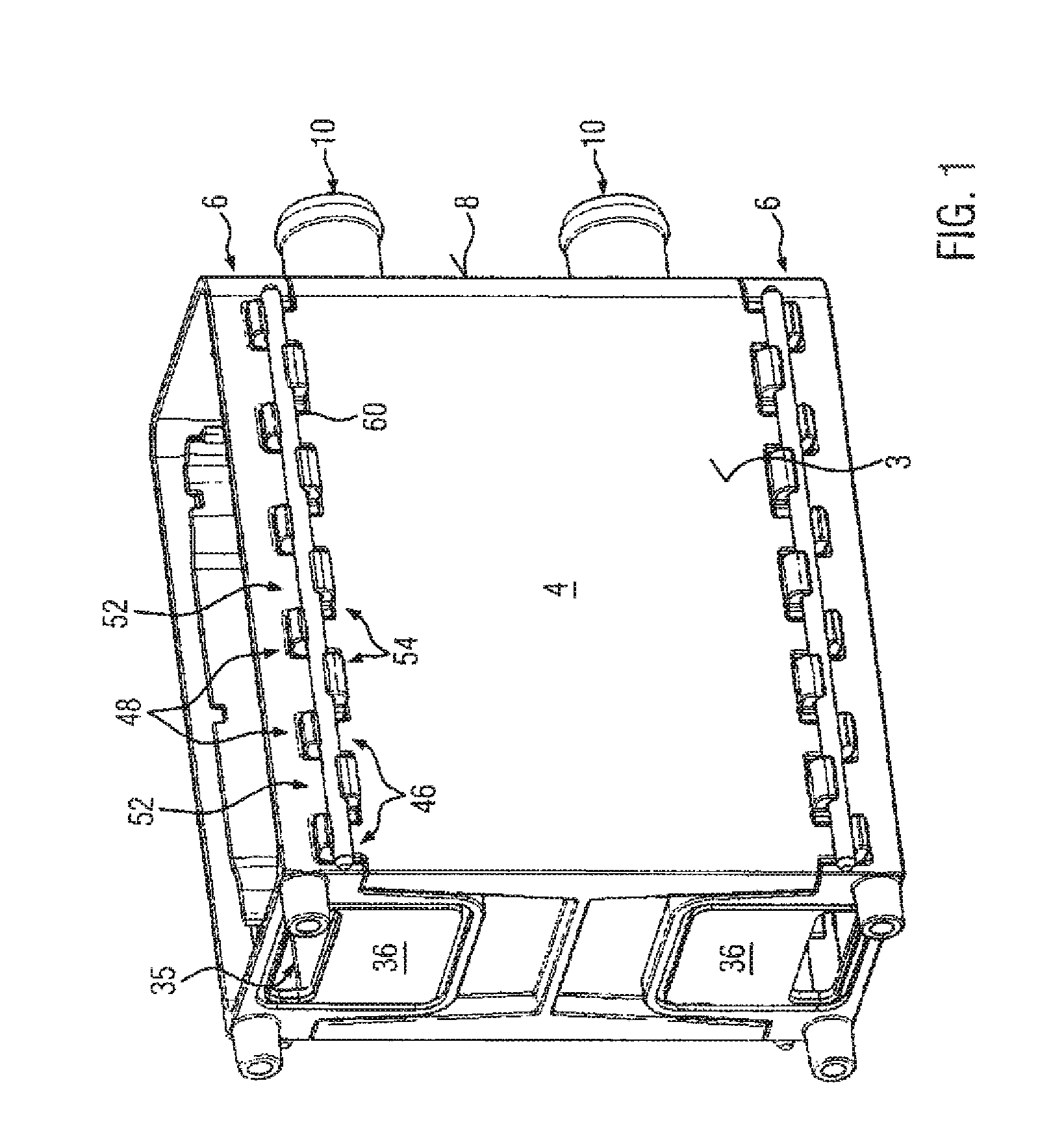

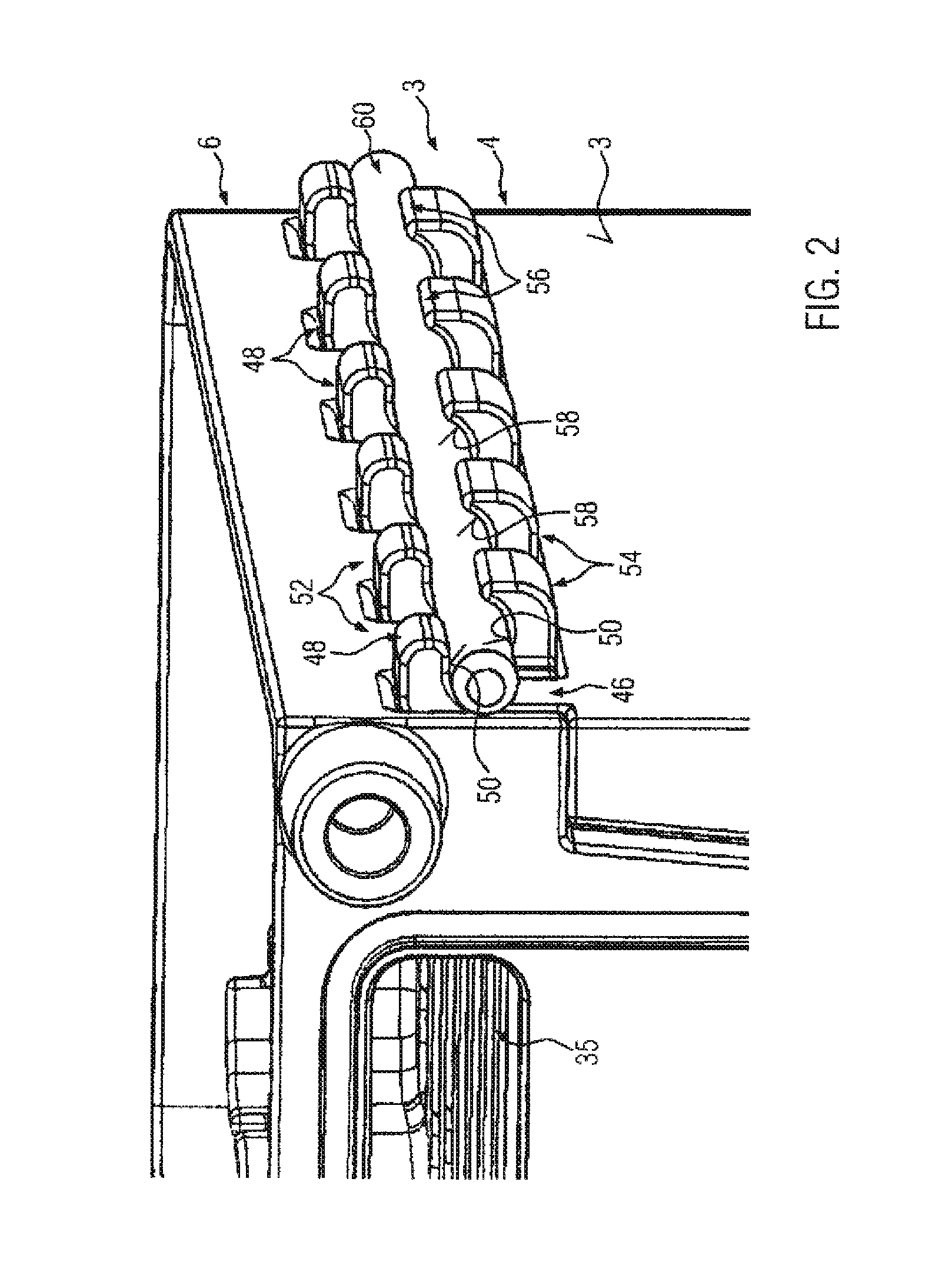

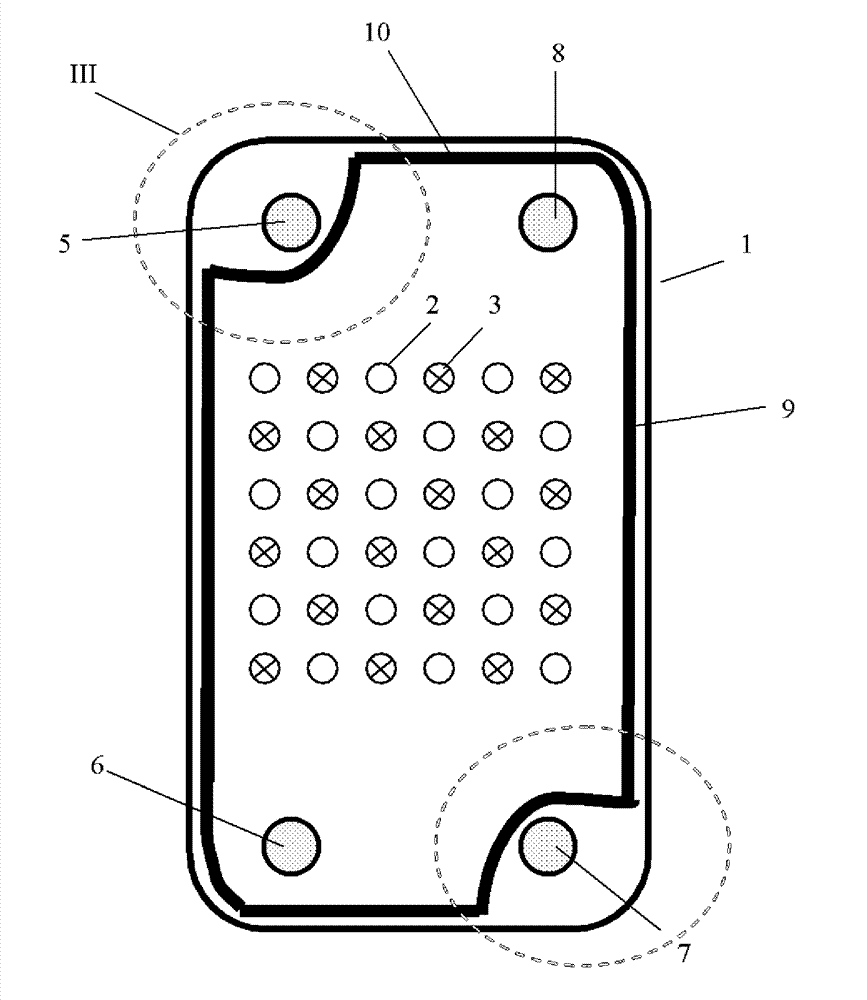

Vacuum cleaner

InactiveUS7640625B2Strong compressionSpace minimizationCleaning filter meansSuction filtersEngineeringCentrifugal force

A vacuum cleaner includes a cyclone dust separating unit which includes a cyclone part to separate dust from a dust-laden air drawn from a surface being cleaned using a centrifugal force, a dust collecting part comprising a dust chamber to accommodate the dust separated at the cyclone part, and a compressing part to compress the dust accommodated in the dust chamber. The compressing part includes a driving part to rotatably drive a driving axis, and a compressing plate driven in a substantially perpendicular direction with respect to the driving axis according to the rotation of the driving axis, and to compress the dust accommodated in the dust chamber. As a result, a vacuum cleaner is provided, which requires a minimum space for the installation of a compressing part to compress dust inside the dust collecting part, and provides maximum compressing force of the compressing part.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

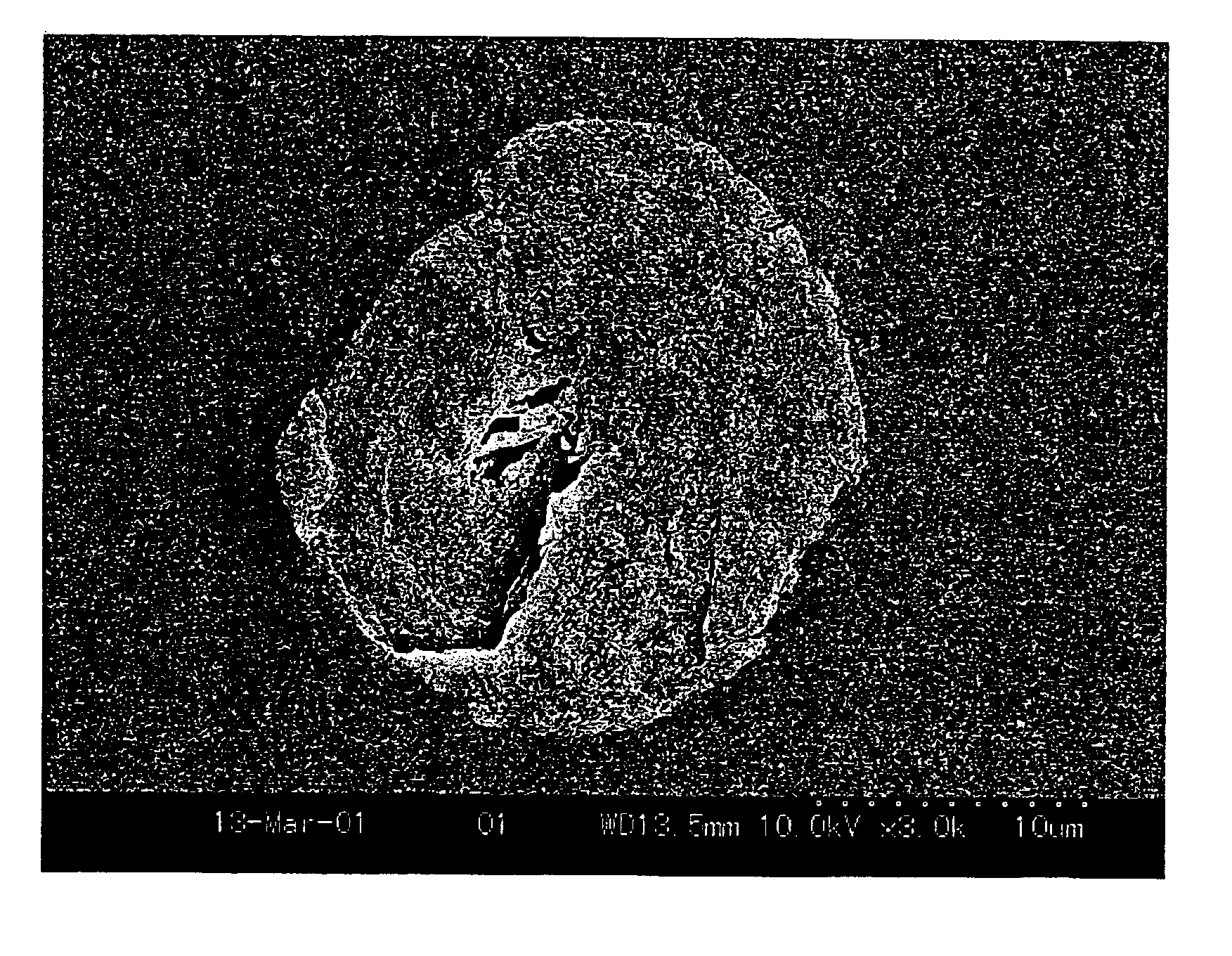

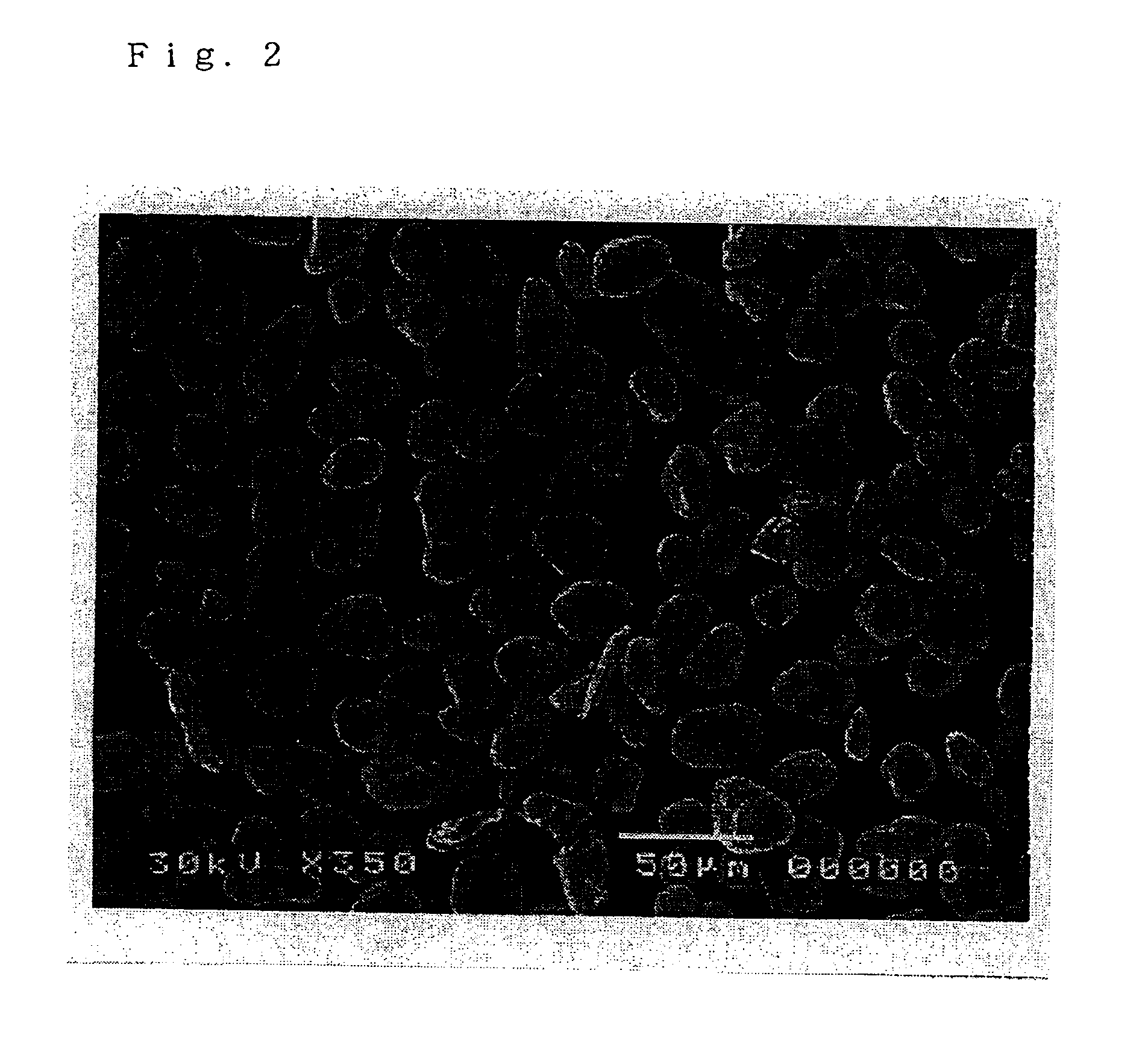

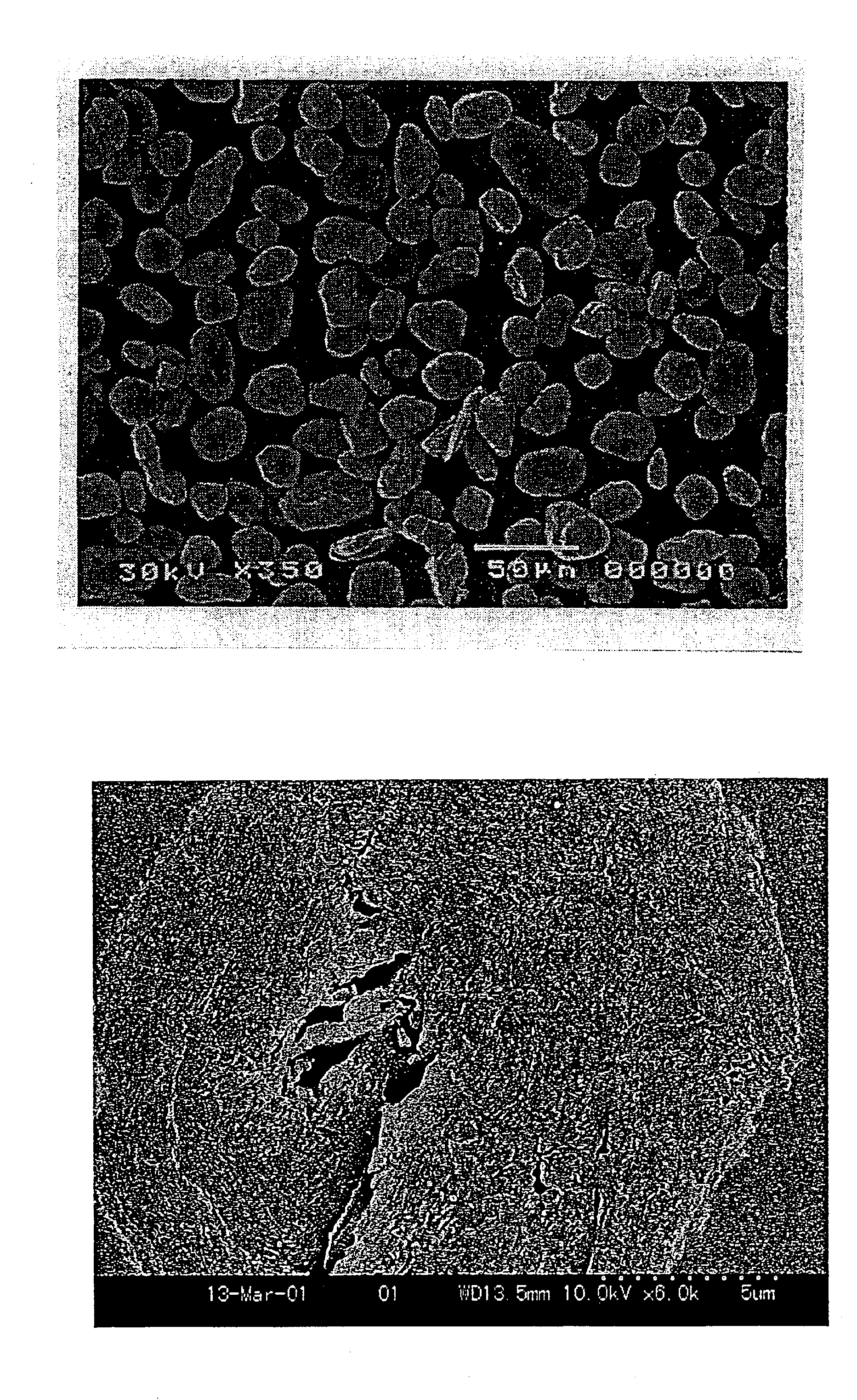

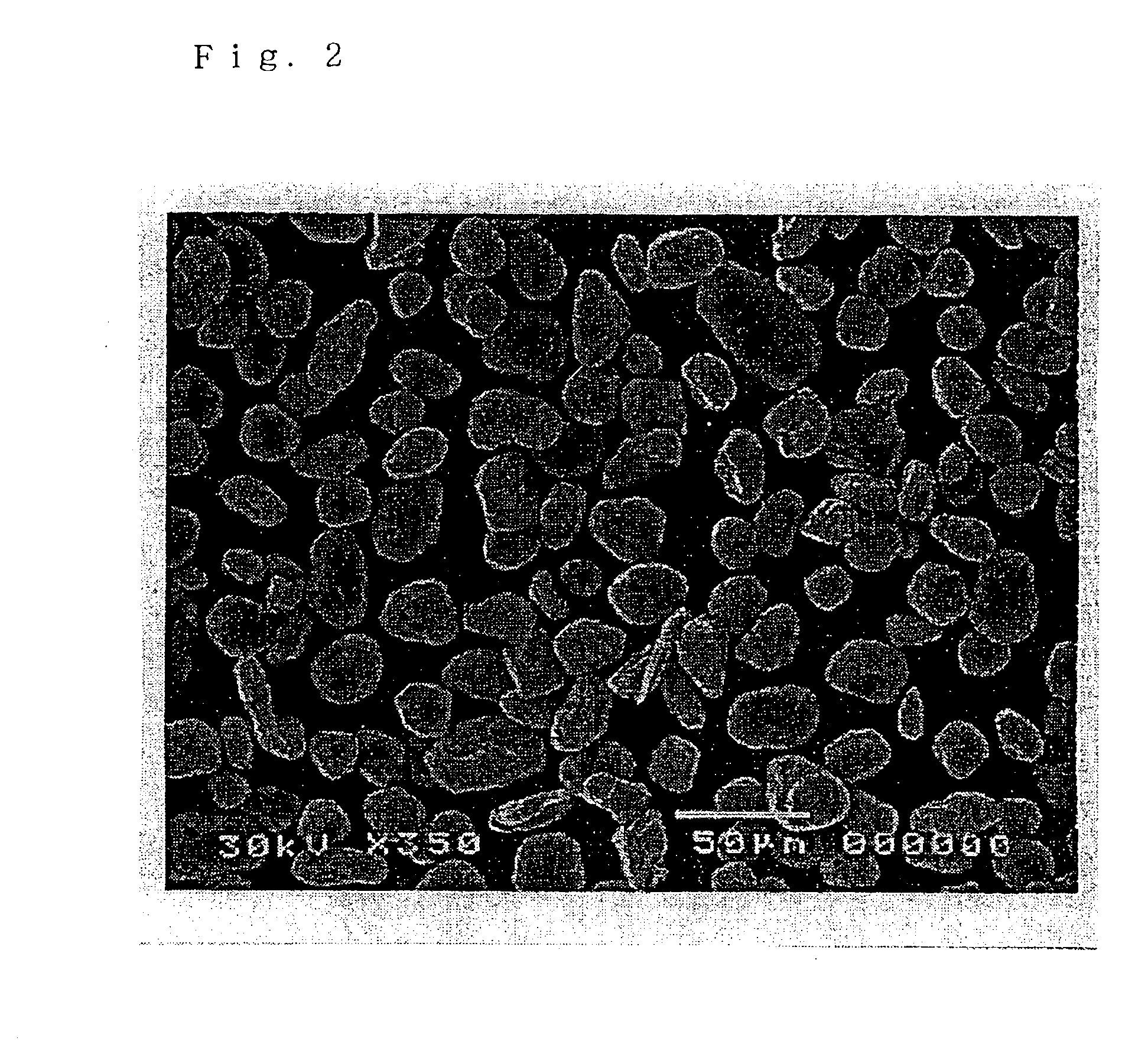

Graphite particles and process for production thereof

InactiveUS6939526B2Strong shear forceStrong compressionPigmenting treatmentNon-aqueous electrolyte accumulatorsSpherical shapedGraphite particle

Graphite particles having a bent laminate structure inside each particle are produced by feeding, into an impact grinder, graphite particles having an average particle diameter of 5 mm or less together with a gas current to apply an impact to the graphite particles to form, by a compression force, a bent laminate structure inside each graphite particle. The resulting graphite particles have an average particle diameter of 100 μm or less, are low in anisotropy, have a nearly spherical shape, and are highly crystalline.

Owner:NIPPON POWER GRAPHITE CO LTD

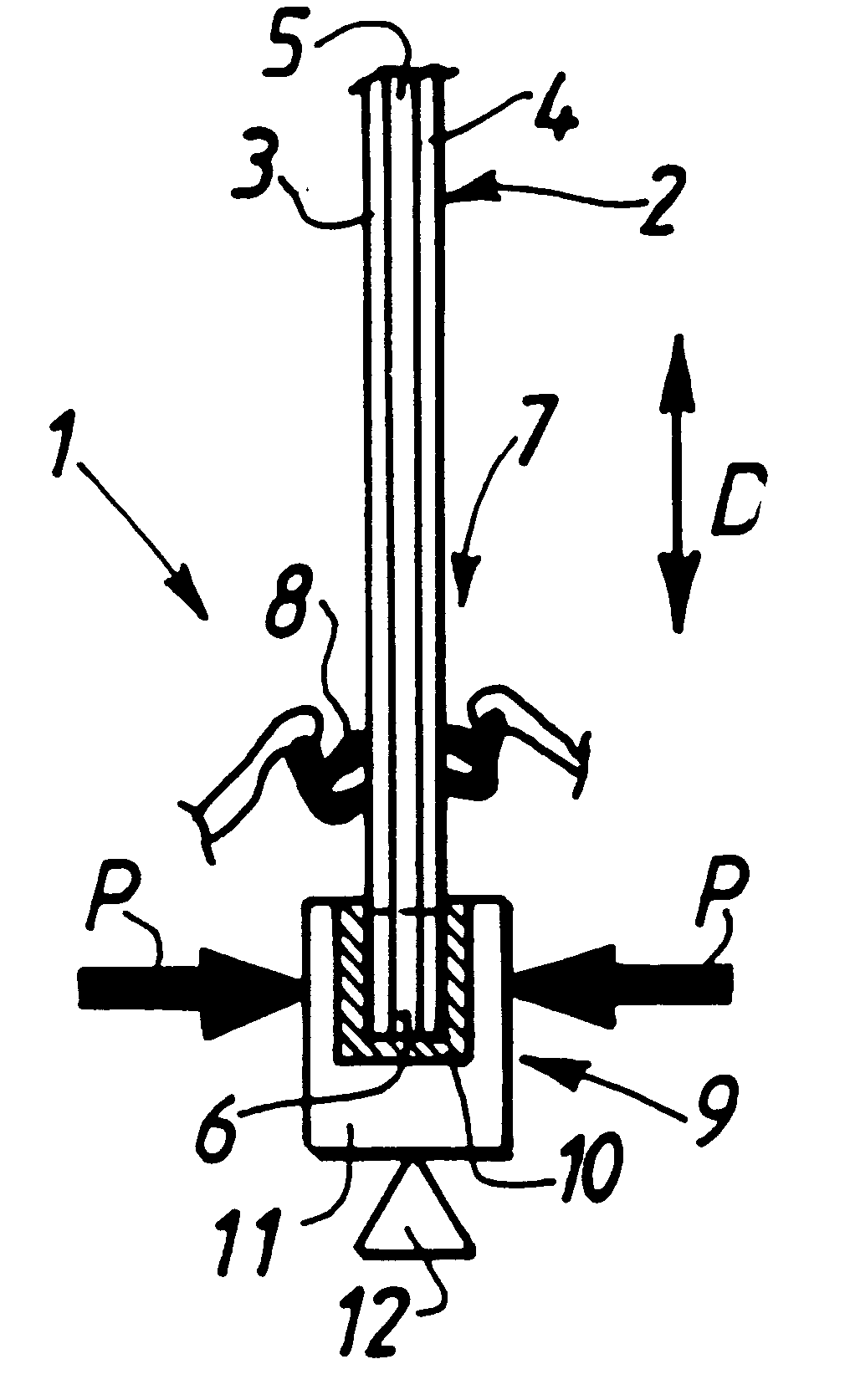

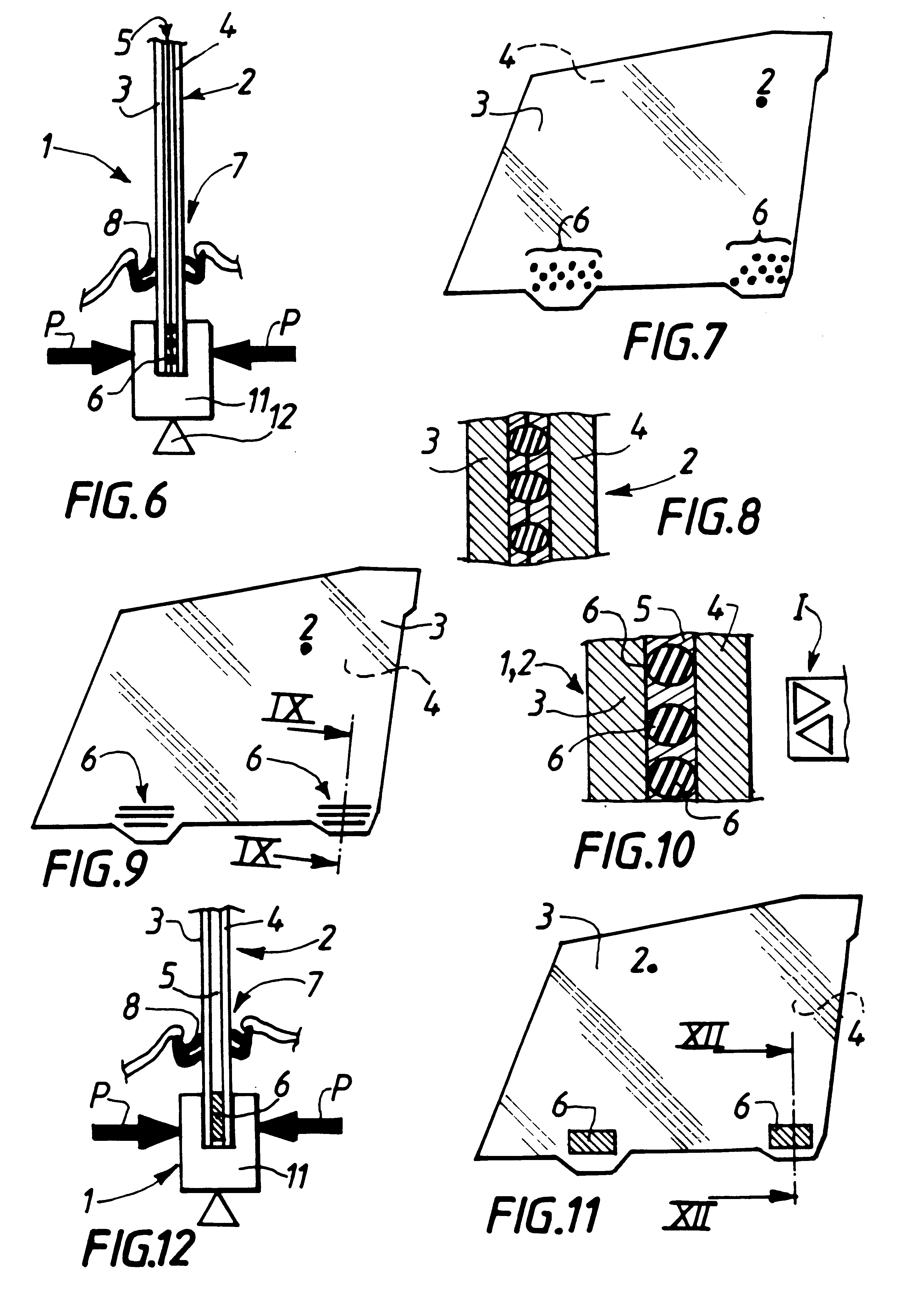

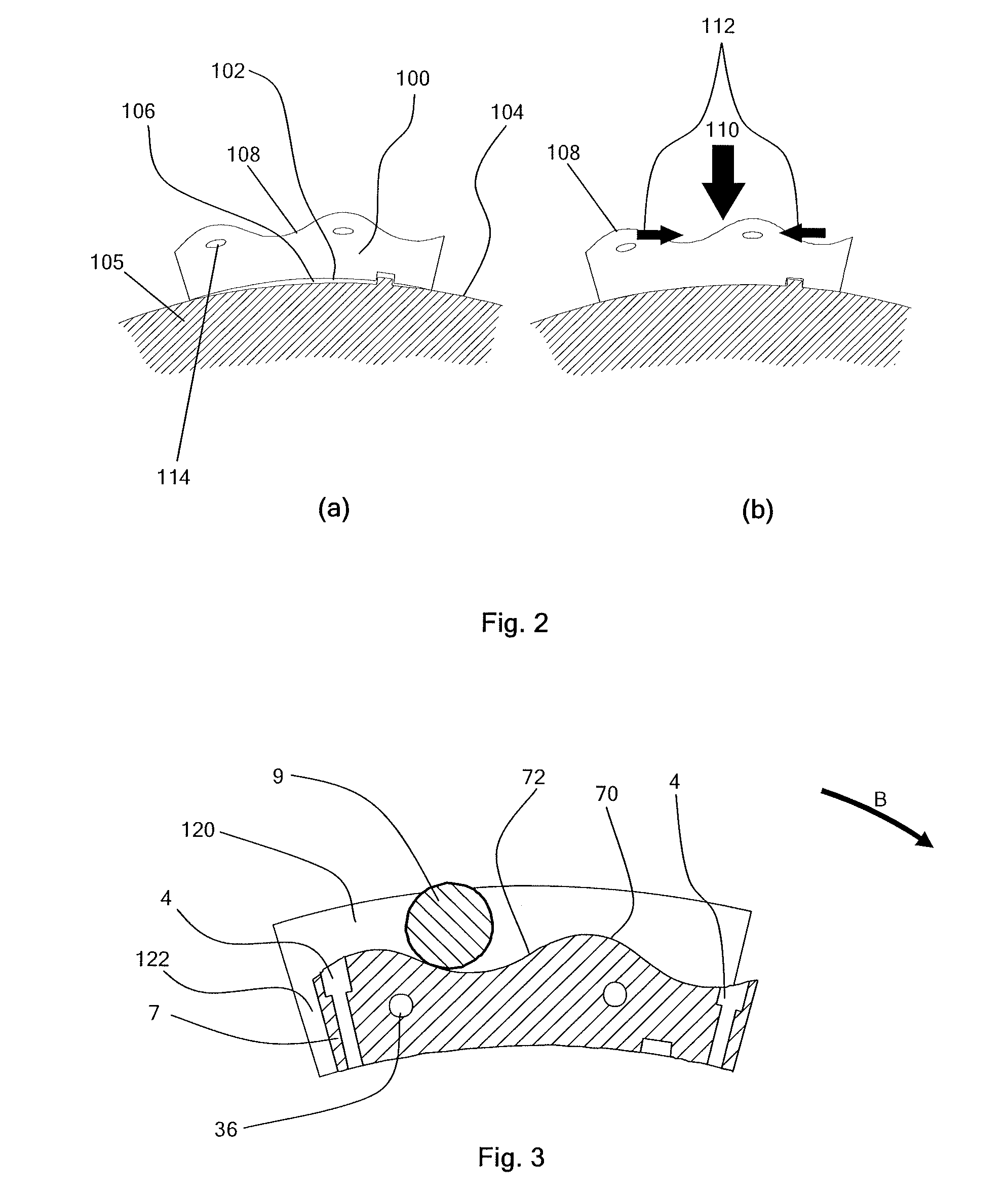

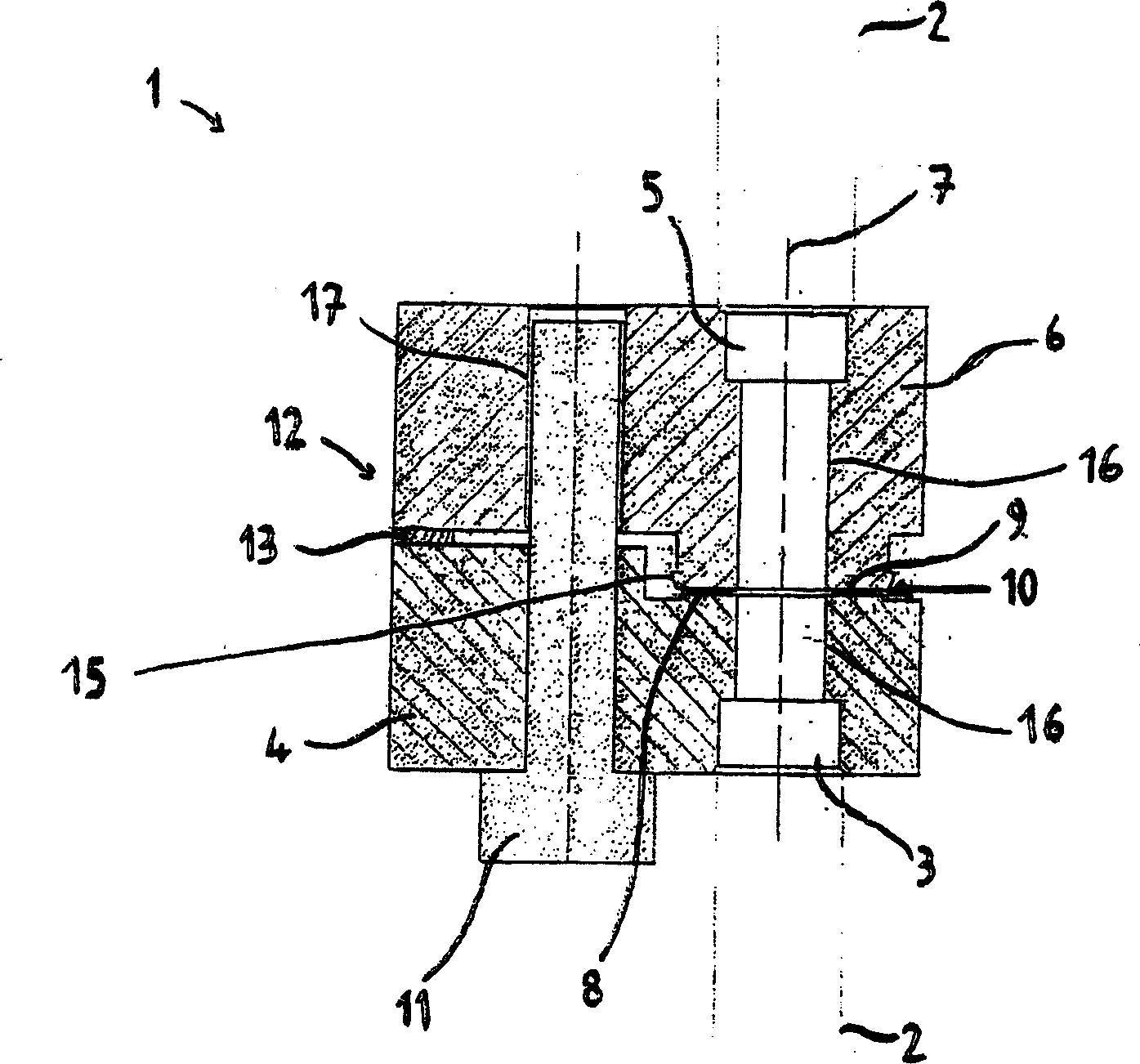

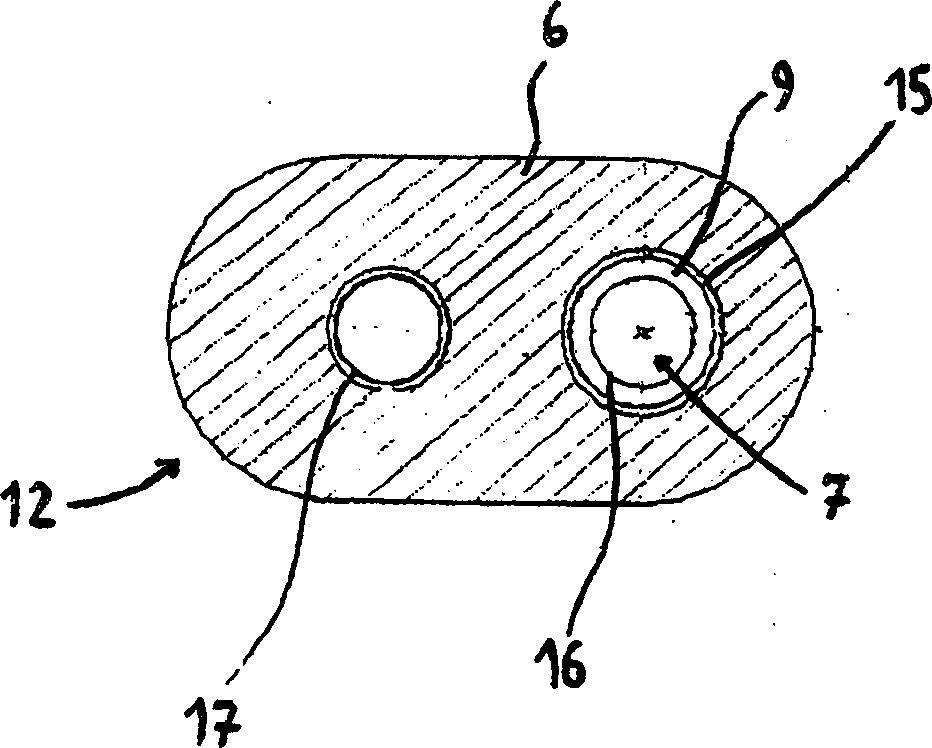

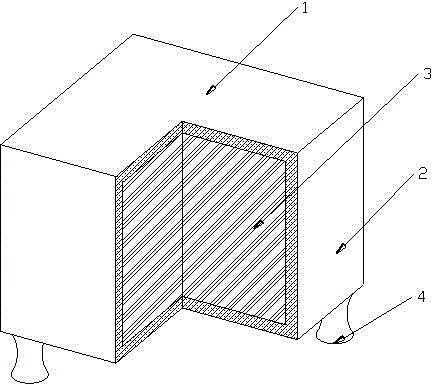

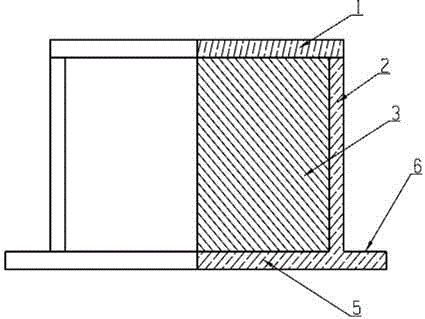

Assembly method and installation, a device assembled thereby, and a unit including the device

InactiveUS6502365B1Strong compressionAvoid injuryWindowsPicture framesEngineeringMechanical engineering

The invention relates to assembling together at least two envelope elements with at least one deformable element between the two envelope elements so that the elements are secured together rigidly in irreversible manner, the assembled-together elements being designed to be subjected to compression stresses in a direction that at least intersects an assembly surface; bonding treatment is provided so that at least one compression pad has its first assembly surface in contact with the assembly surface of the first envelope element and so that a second assembly surface of a pad is in contact with an assembly surface of the second envelope element.

Owner:PPG IND GLASS

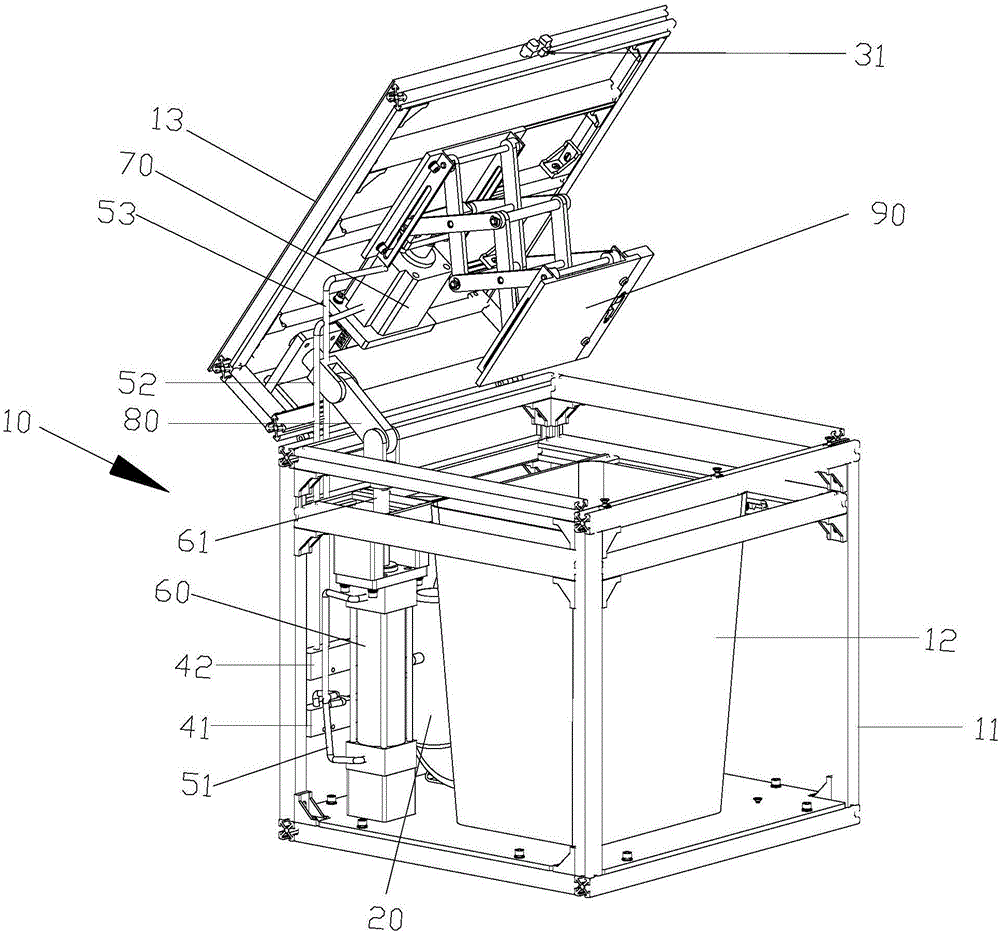

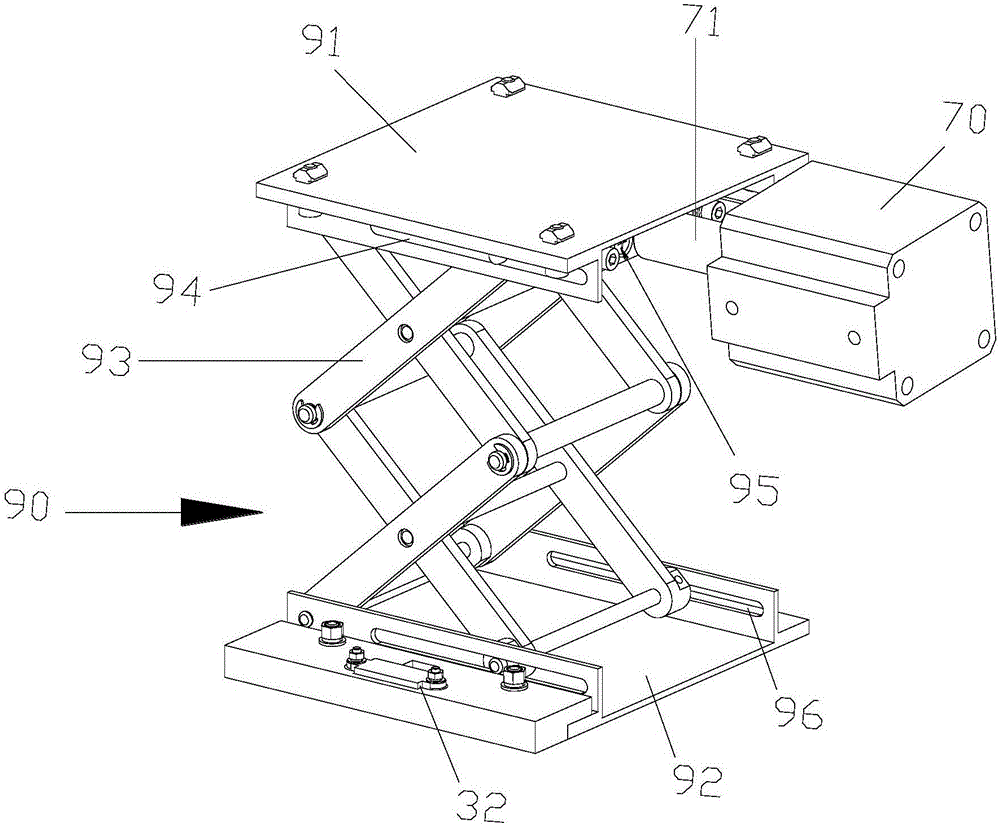

Intelligent trash can device and method for pneumatic uncovering and trash compression

PendingCN106628740AAchieve true compressionStrong compressionRefuse receptaclesGas cylinderEngineering

The invention relates to an intelligent trash can device and a method for pneumatic uncovering and trash compression. The intelligent trash can device comprises a trash can body. The trash can body comprises an outer can, an inner can and a can cover. An air pump, a first infrared sensor, a first five-way three-position electromagnetic valve, a first gas pipe, a first gas cylinder, a second infrared sensor, a second five-way three-position electromagnetic valve, a second gas pipe, a third gas pipe, a second gas cylinder, a linkage mechanism and a shear-fork type connection rod lifting table are installed. The intelligent trash can device which is adopted is simple in structure, pneumatic uncovering can be accurately and efficiency sensed in an infrared manner, trash can also be powerfully compressed, true compression of the trash is achieved, the human cost is saved, and sanitation and health are ensured.

Owner:GUANGZHOU UNIVERSITY

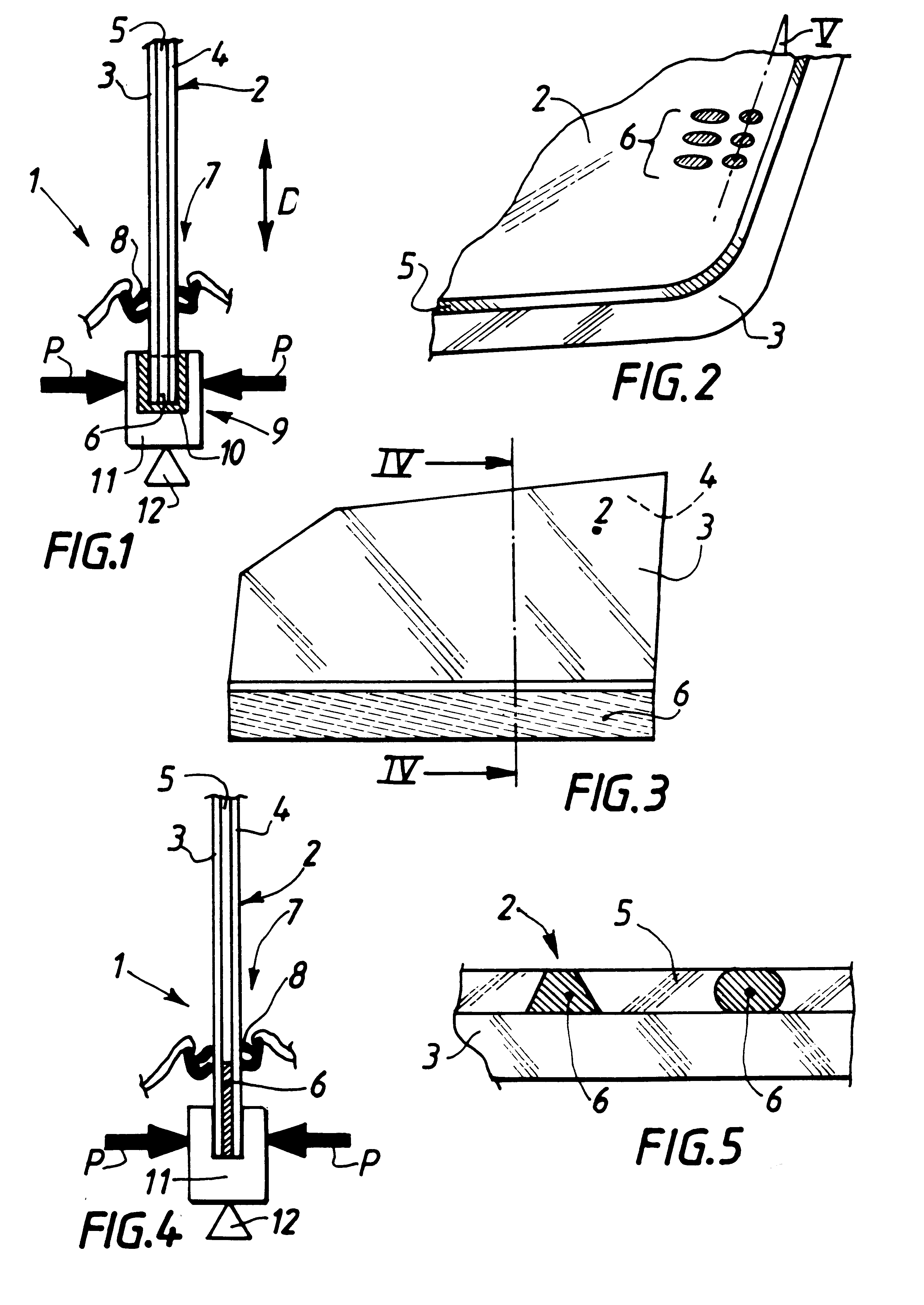

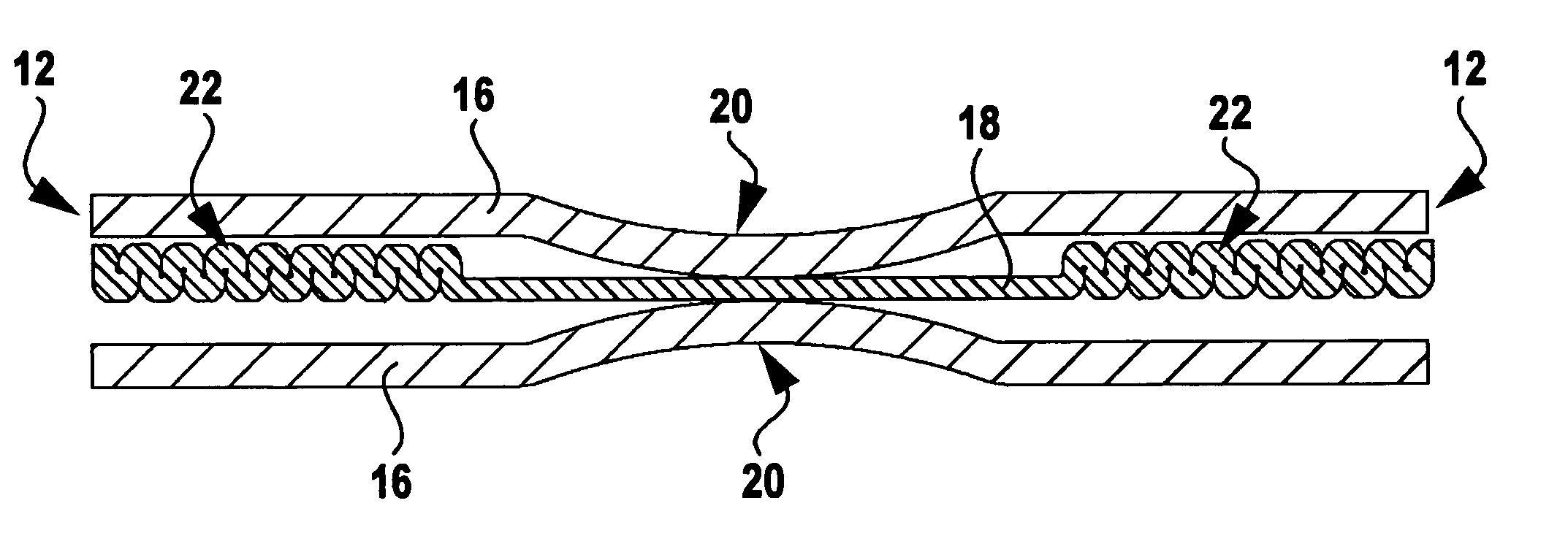

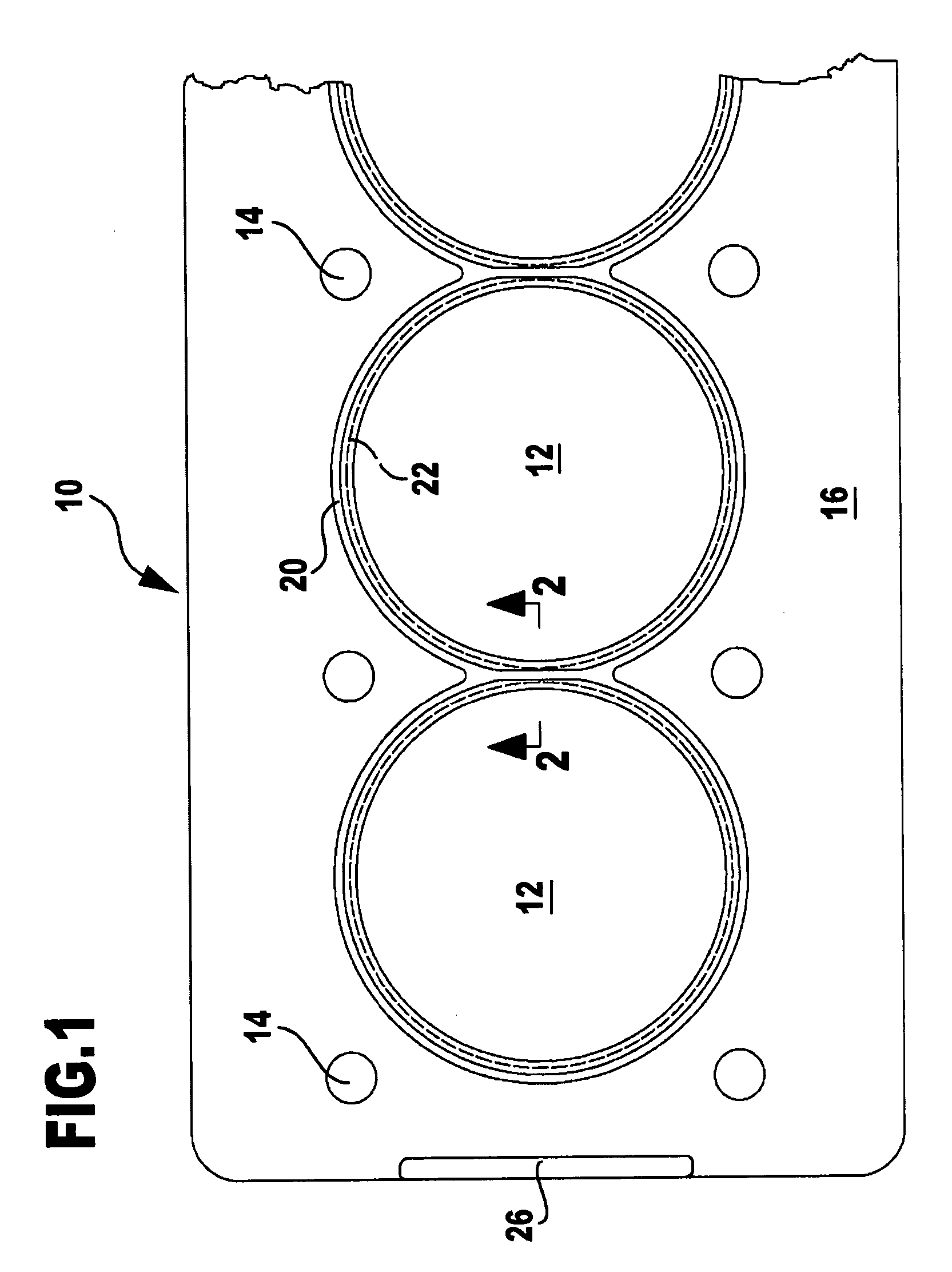

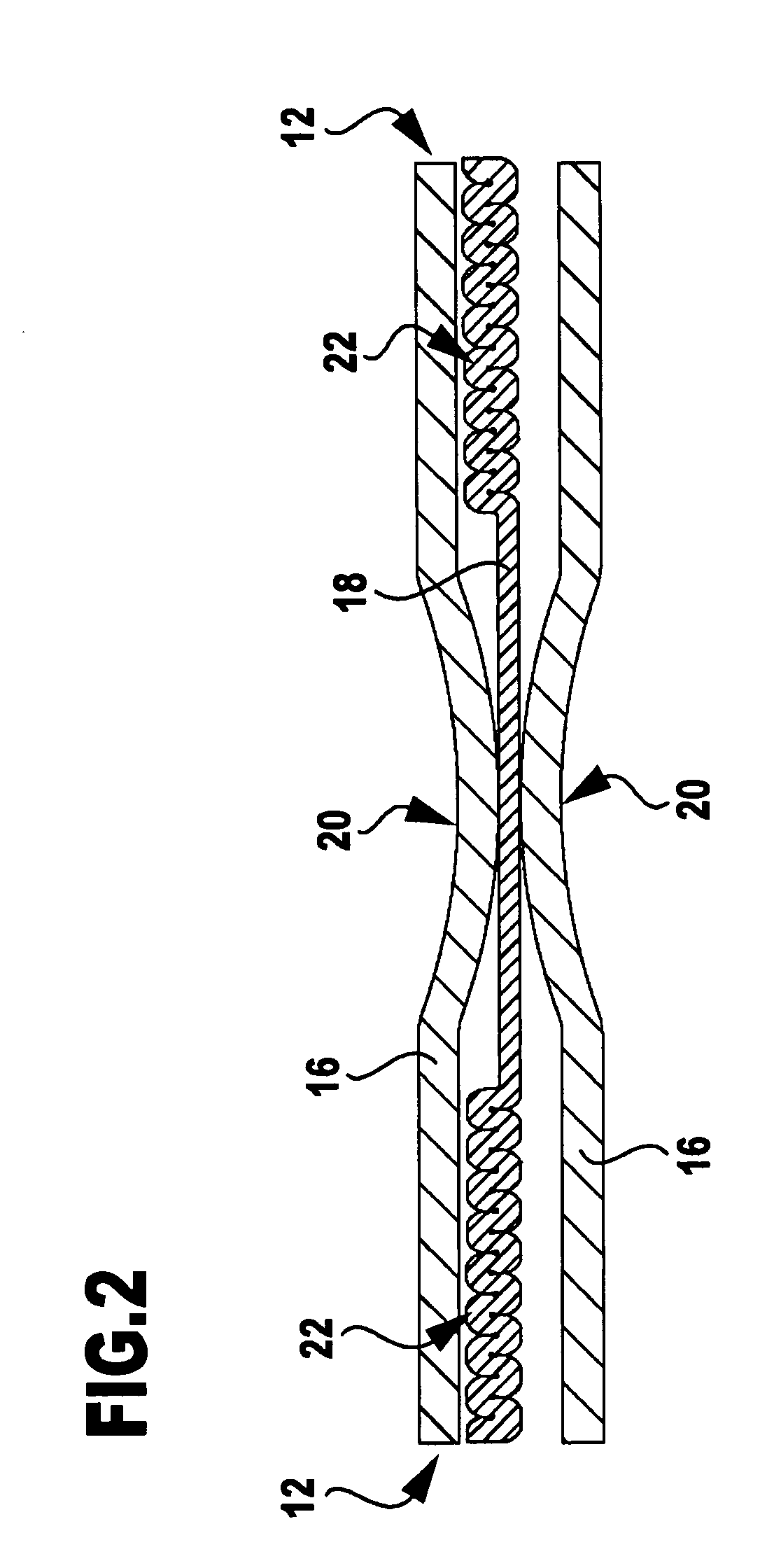

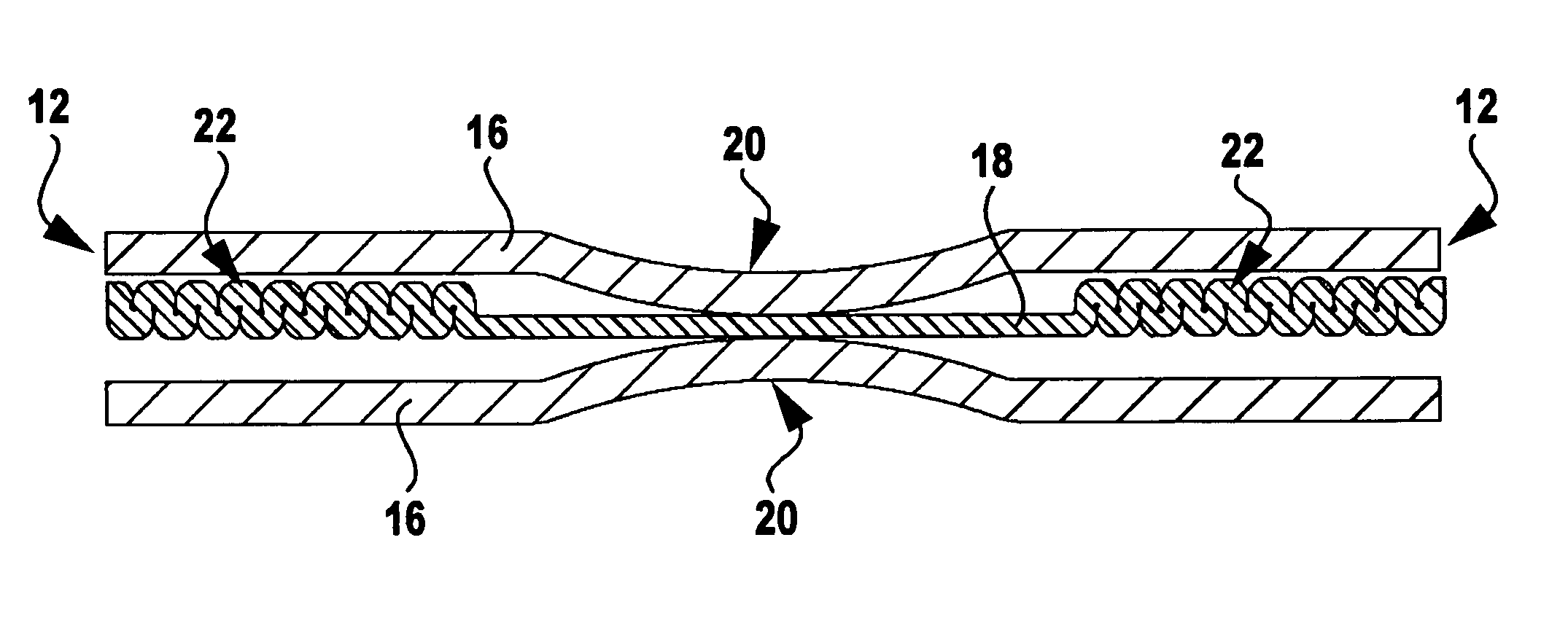

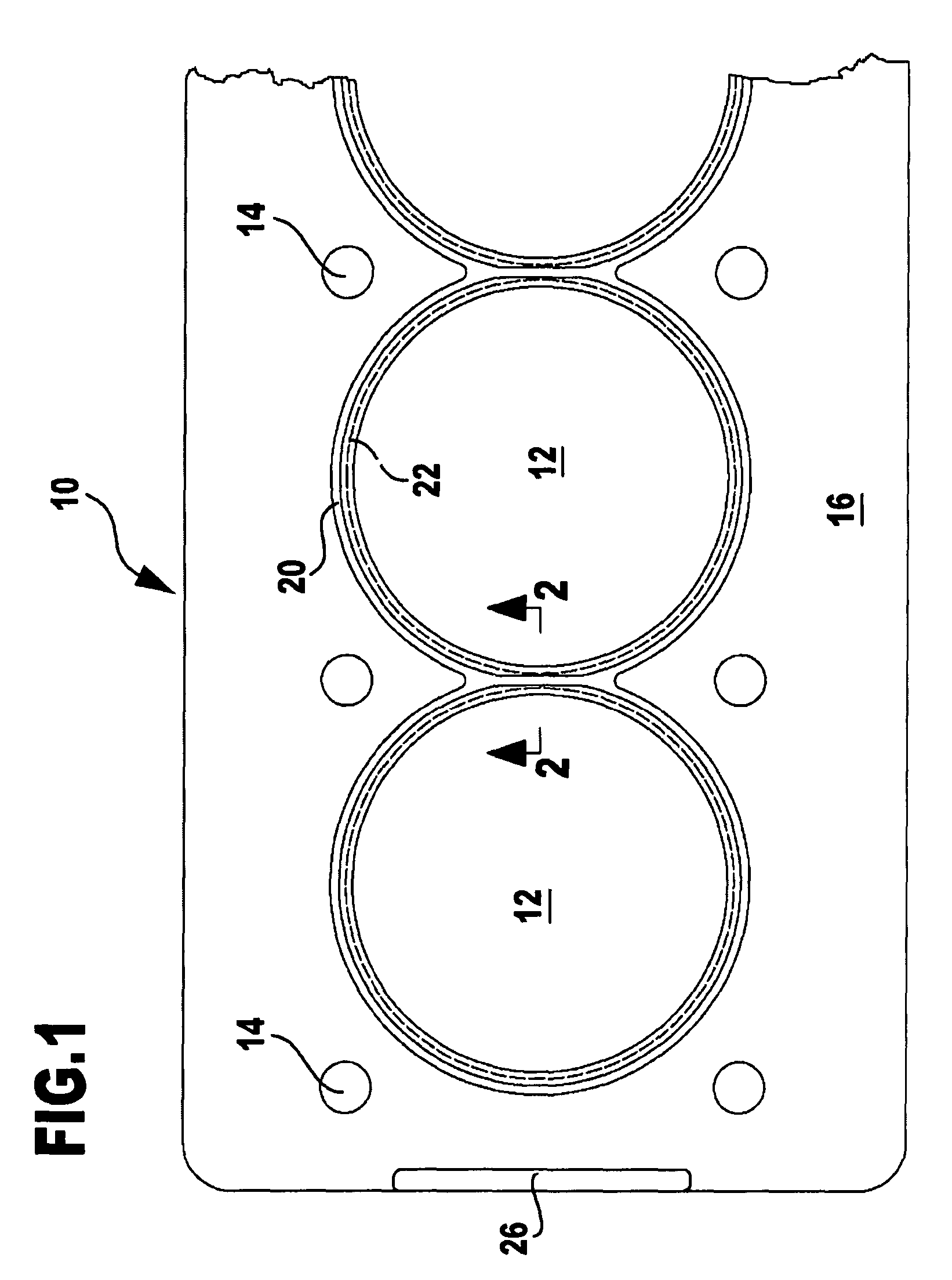

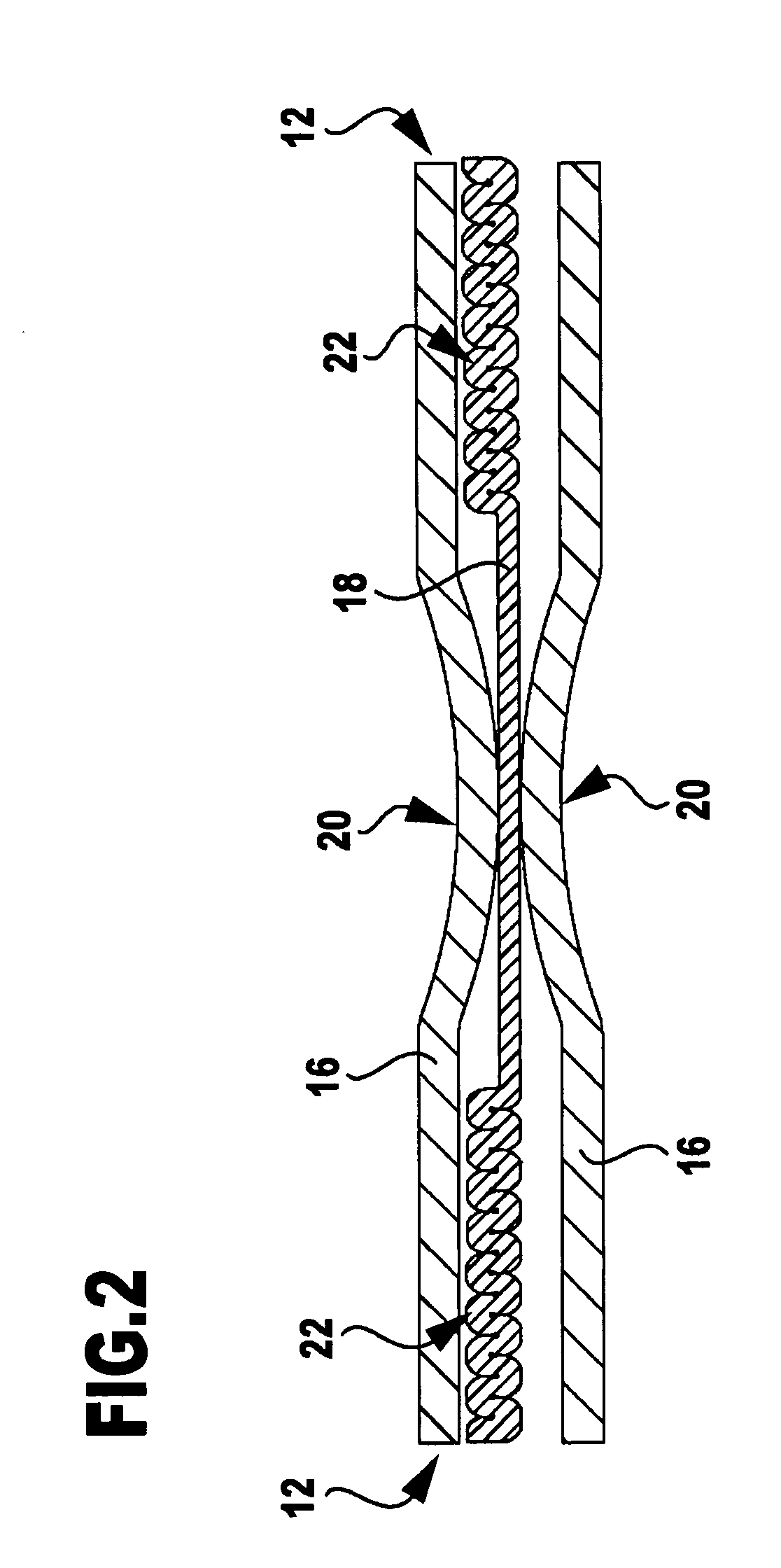

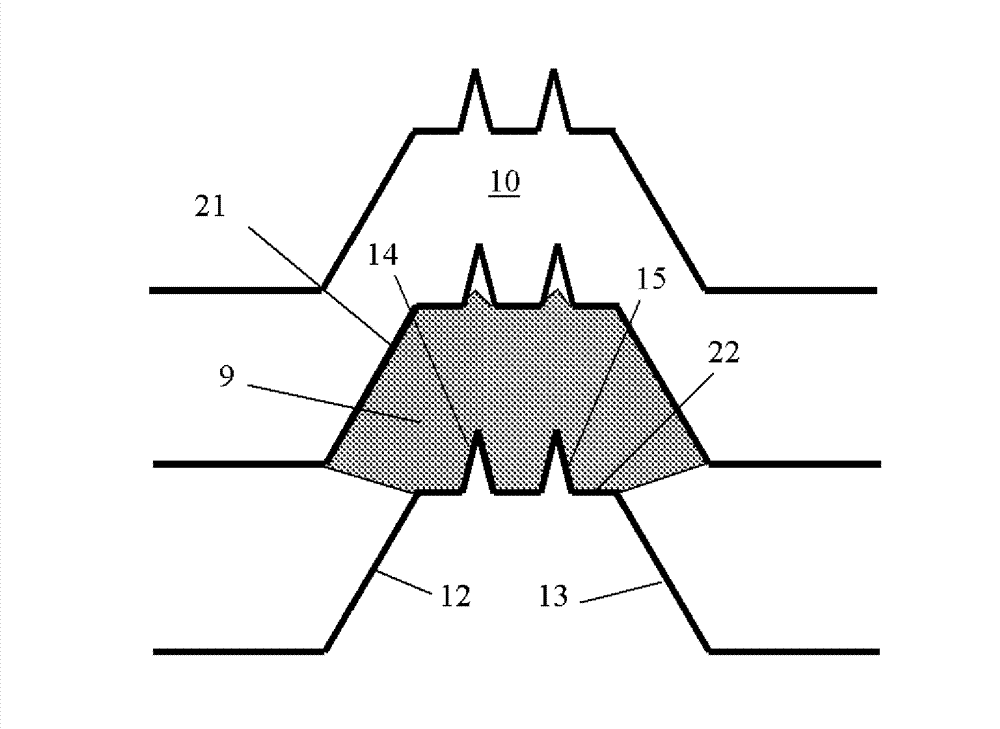

Flat gasket, in particular, cylinder head gasket

InactiveUS20070262536A1Reduce sheet thicknessEasy to produceEngine sealsMetal-working apparatusFree edgeEngineering

Flat gasket comprising a first sheet metal layer consisting of a spring steel and a second sheet metal layer consisting of a ductile steel, the first layer being provided with a sealing bead, and the second layer being provided in an edge area bordering on an edge of the layer with a thickened zone as supporting element for receiving pressing forces; to increase the design possibilities for such a supporting element, the latter is formed by at least one elongate arch of the second layer, which is stamped into the edge area of the second layer and extends approximately parallel to the free edge of the edge area, the arch being compressed in such a way that the metal volume of the supporting element is at least three times the total hollow space volume which the supporting element and two tangential planes abutting on the latter and extending parallel to the plane of the second layer include between them.

Owner:ELRINGKLINGER AG

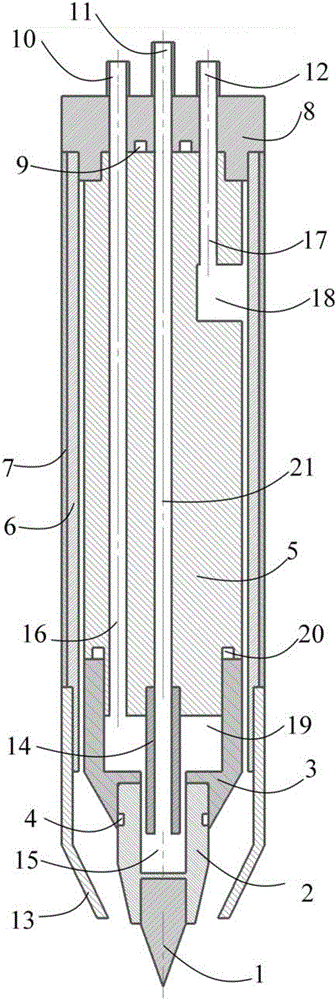

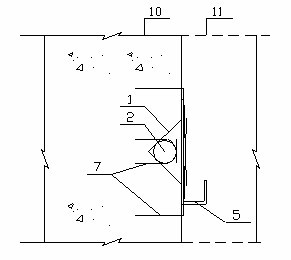

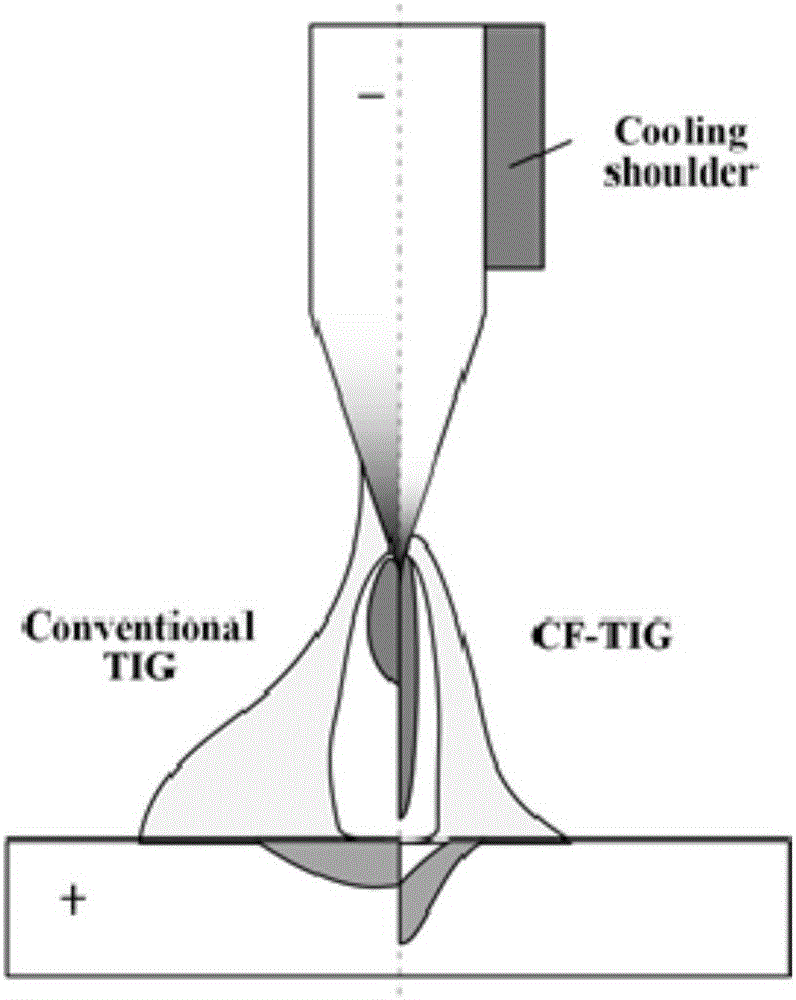

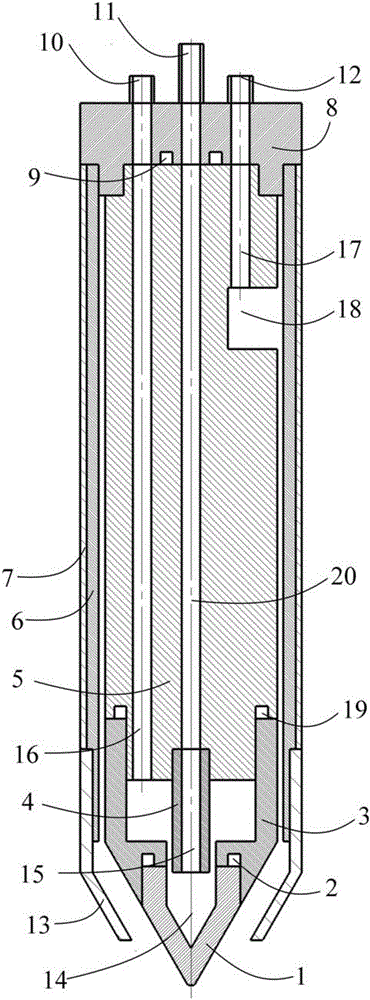

Water-cooling TIG welding gun with copper-coated tungsten electrode on basis of cathode compression effect

ActiveCN105983774AStrong compressionStrong penetrating powerCooled electrode holdersElectrode accessoriesShielding gasEngineering

The invention relates to an argon tungsten-arc welding gun and discloses a water-cooling TIG welding gun with a copper-coated tungsten electrode on the basis of cathode compression effect. The water-cooling TIG welding gun comprises a center column with the upper part connected to a tail cover and the lower part connected to an electrode base, the lower part of the electrode base is connected to a porous electrode sleeve provided with an electrode tip internal hole chamber, and a tungsten electrode tip is installed at the lower end of the porous electrode sleeve in an embedded mode; a sleeve is arranged outside the center column, and a gap air channel is formed between the sleeve and the center column; the lower part of the sleeve is connected to a shielding gas hood; the tail cover is provided with a water outlet pipe, a water inlet pipe and an air inlet pipe, and a water return hole, a water inlet hole, a ventilation hole and a gas stilling chamber communicating with the gap air channel are correspondingly formed inside the gun body; a water spray nozzle communicating with the water inlet hole is connected to the bottom of the center column; a cooling water channel and a shielding gas channel are separated by an upper sealing ring and a lower sealing ring. According to the water-cooling TIG welding gun, cooling liquid is directly guided into the tungsten electrode for strongly cooling the tungsten electrode, the area of a cathode zone can be compressed, arc columns can be compressed more strongly, the penetrating power of arcs can be improved, and the welding arcs can have better penetrability.

Owner:TIANJIN UNIV

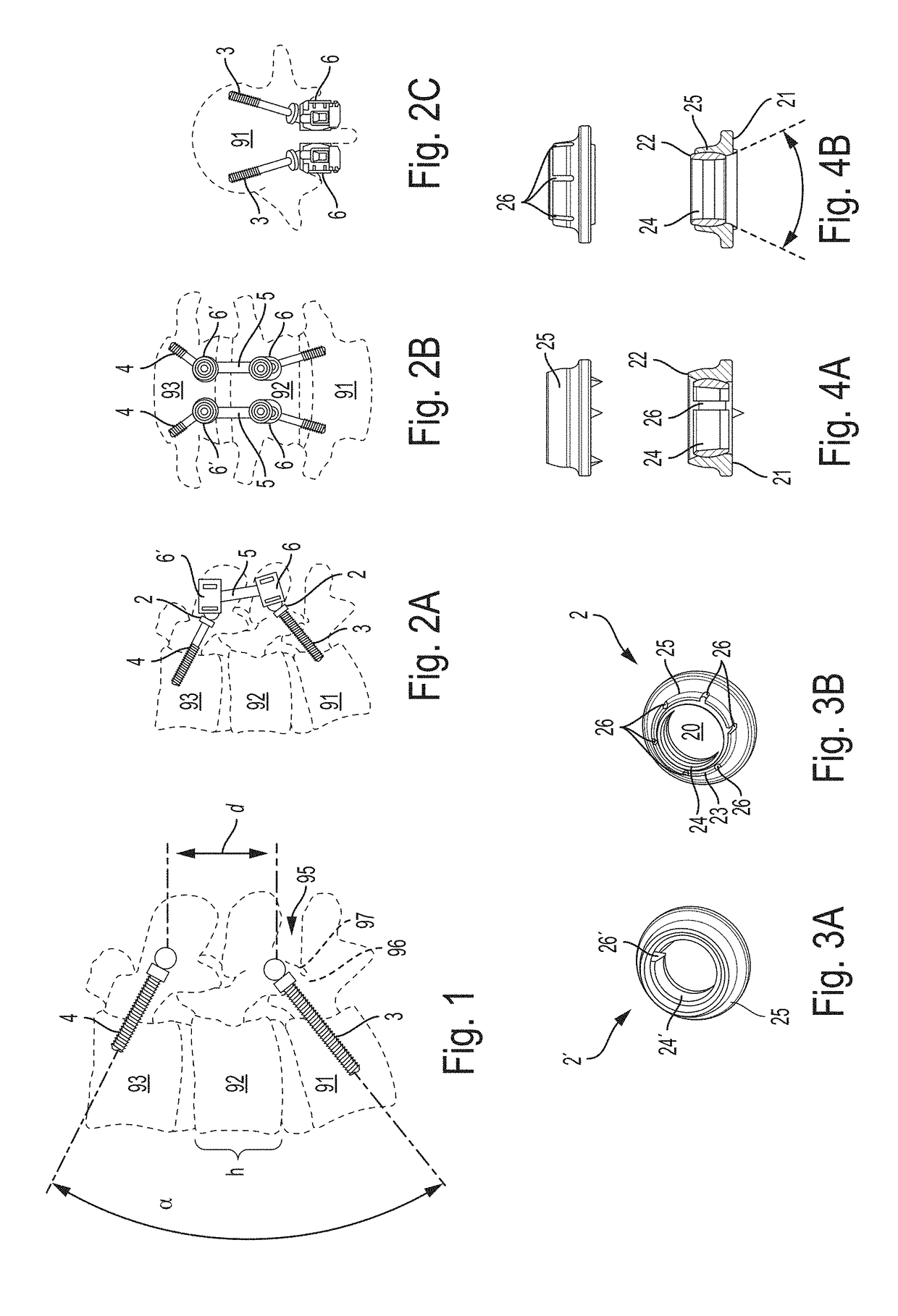

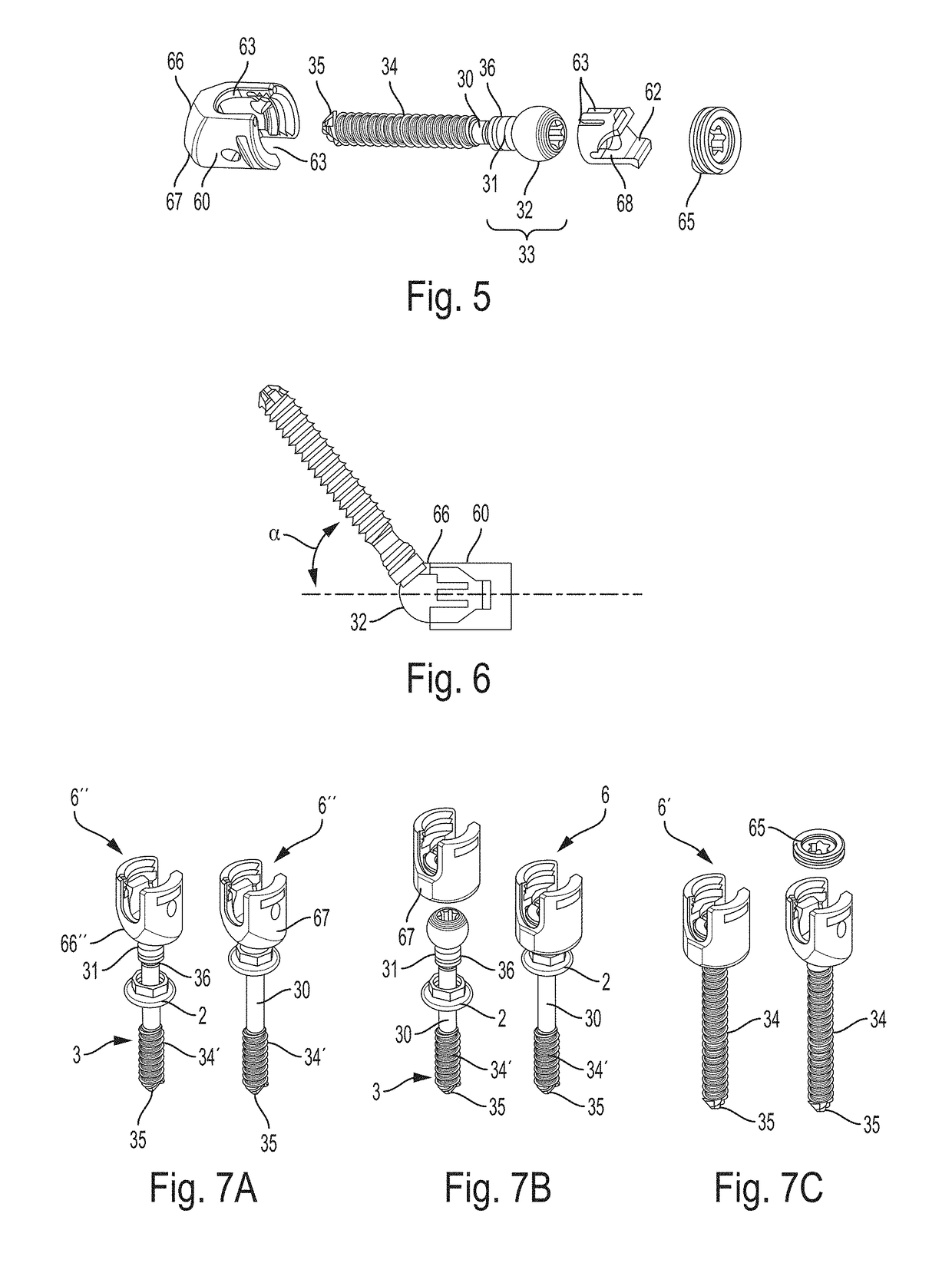

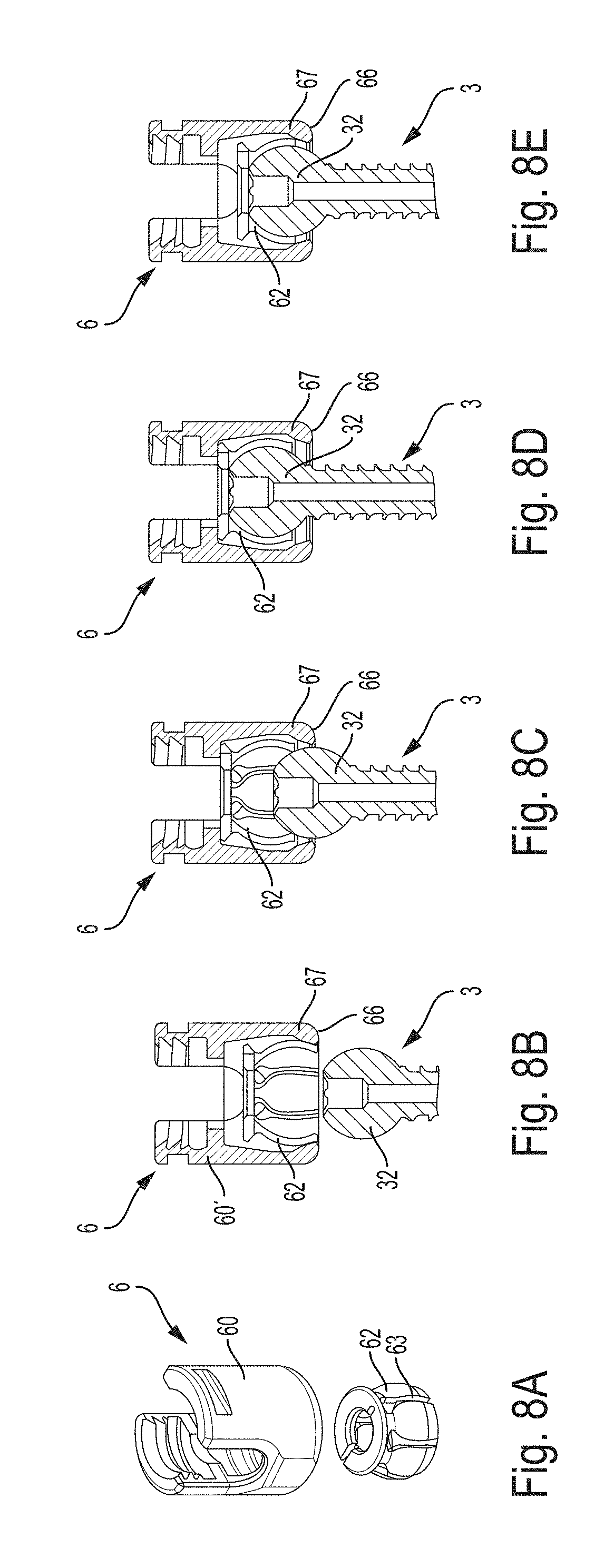

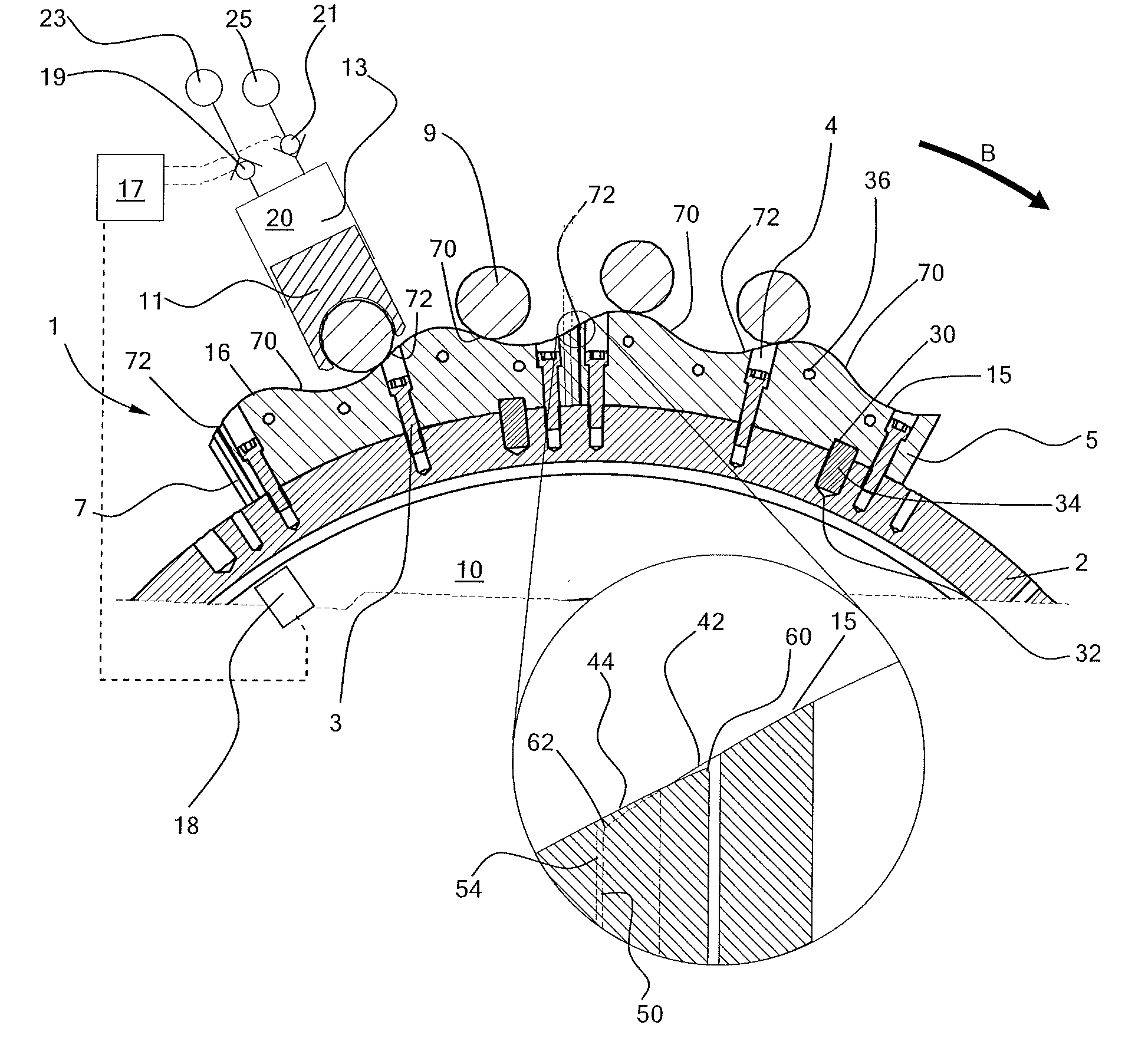

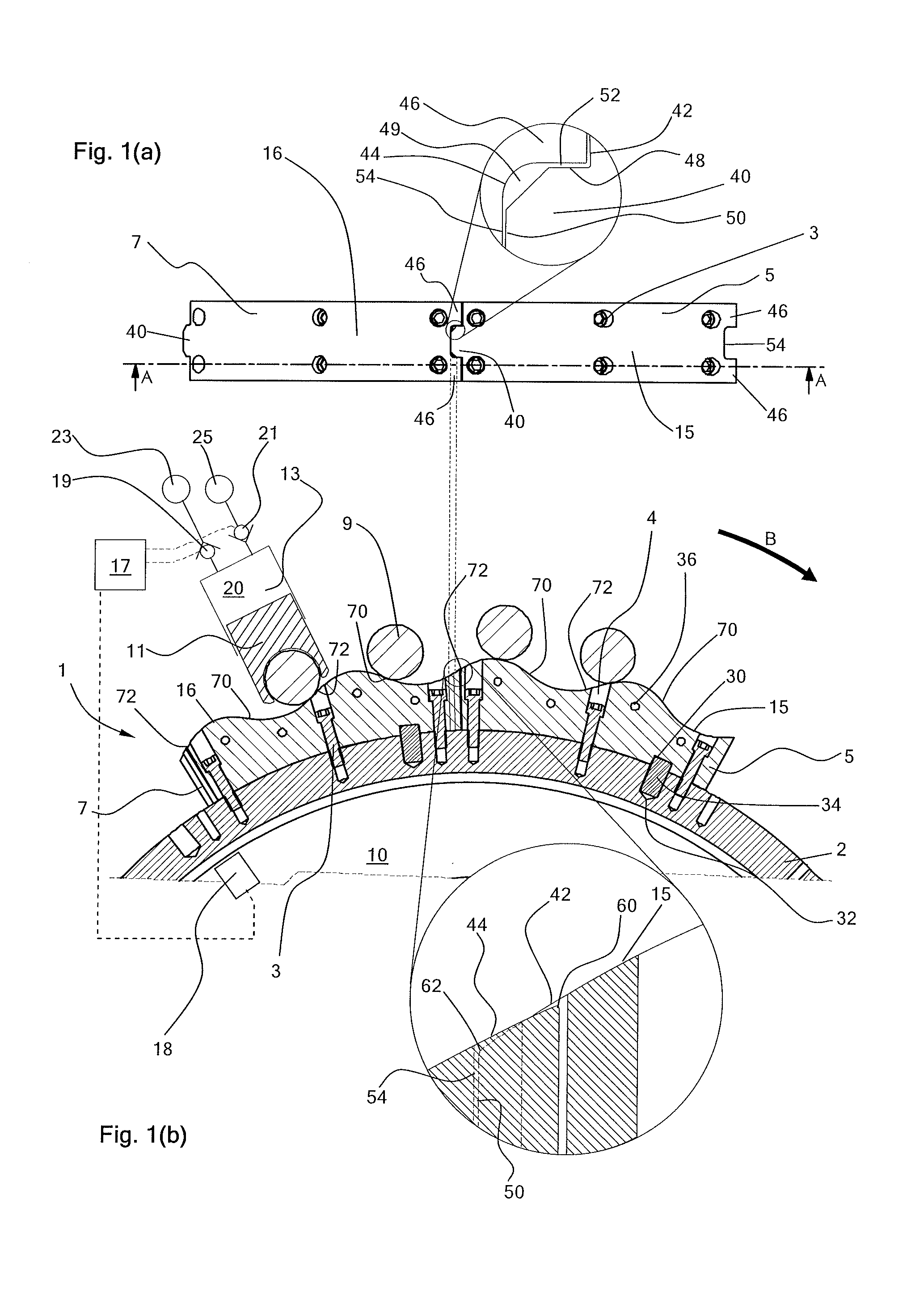

Spinal multi-level intersegmental stabilization system and method for implanting

InactiveUS20190069932A1Fast recoveryIncrease efficiencyInternal osteosythesisSpinal implantsVertebraFacet joint

A multi-level intersegmental stabilization implant for a facet joint of a first vertebra includes a lower retainer module having a transfacetal fastener and an upper retainer module having a second fastener configured for fastening through the pedicle of an upper vertebra. The lower and upper retainer modules are connected by an elongated carrier element dimensioned such as to span across at least two vertebrae. The transfacetal fastener is configured as a screw having a head and a shaft ending with a tip, the shaft being provided with a thread at least in a region near its tip such that it engages exclusively the lower section of the facet joint, wherein a washer is provided co-operatively connected with the transfacetal fastener, the washer being configured for bearing on an outer surface of the upper section of the facet joint.

Owner:LINKSPINE INC

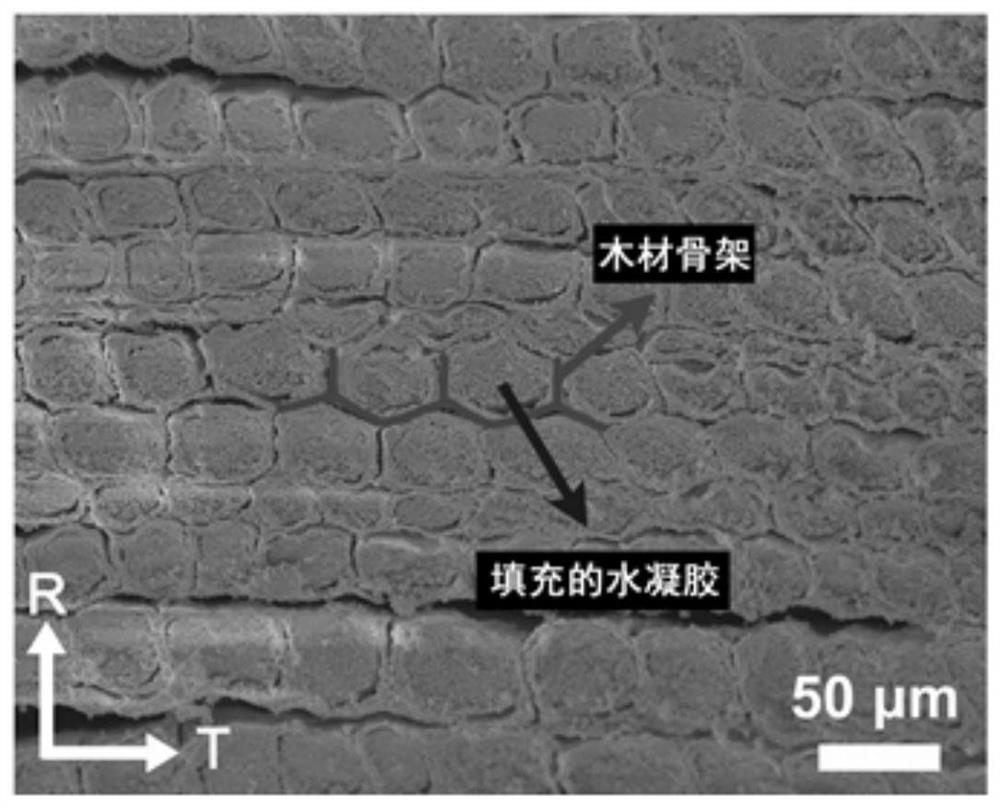

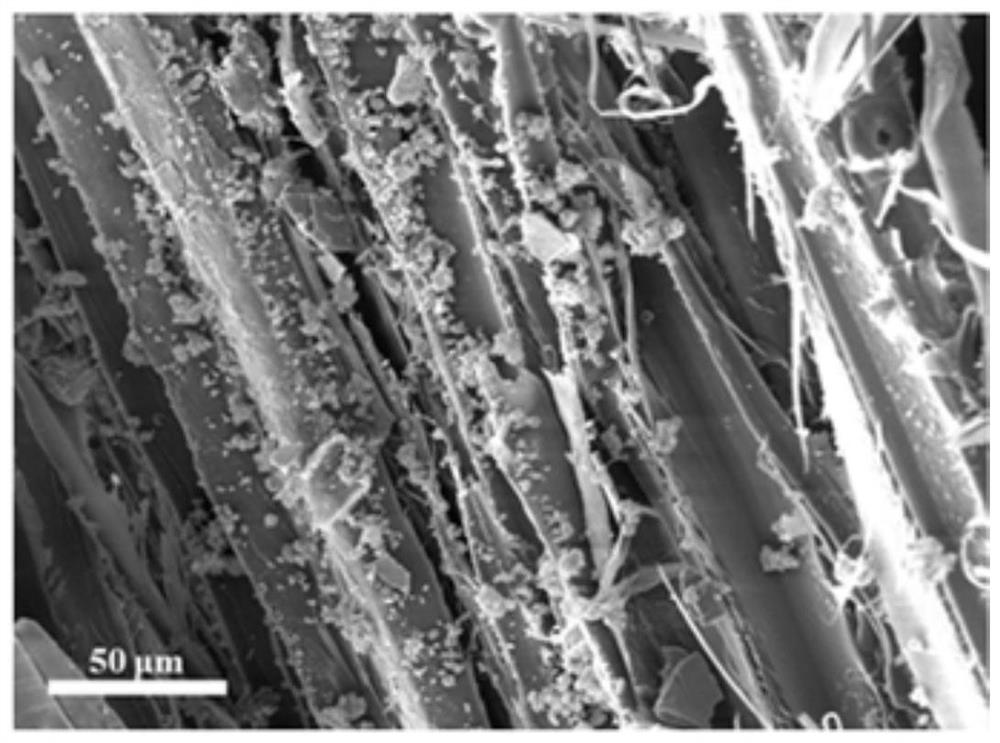

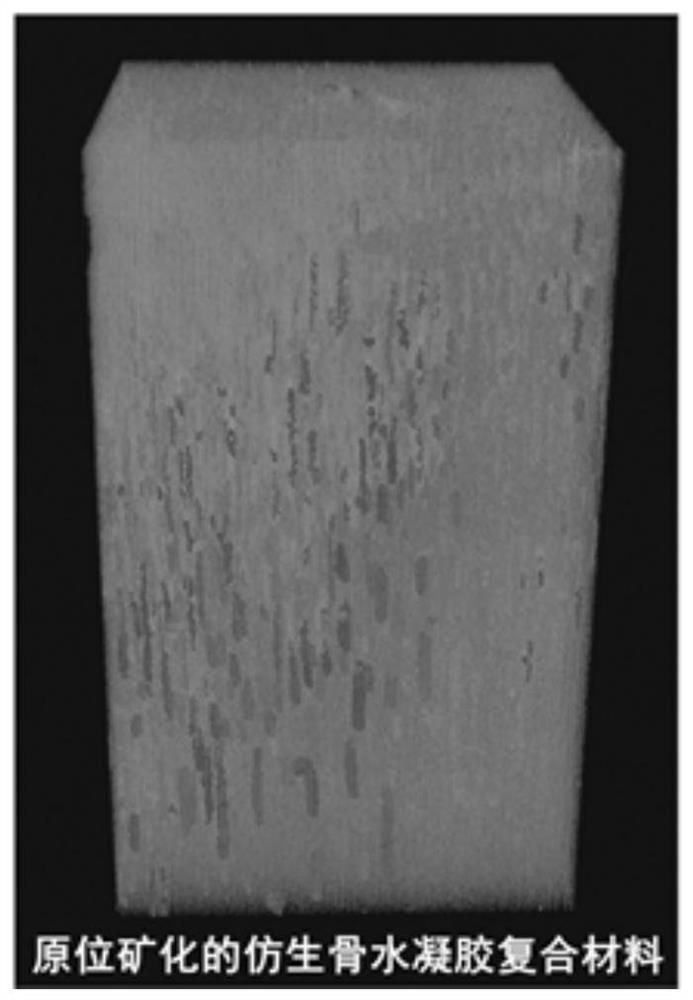

In-situ mineralized bionic bone hydrogel composite material with oriented structure as well as preparation method and application thereof

ActiveCN112402695APromote new bone growthGood osseointegration and mechanical stabilityTissue regenerationProsthesisOsteoblast adhesionMacromolecule

The invention relates to an in-situ mineralized bionic bone hydrogel composite material with an oriented structure as well as a preparation method and application thereof, which comprises a natural plant fiber template, natural polymer hydrogel directionally filled in the natural plant fiber template and hydroxyapatite directionally deposited in the natural plant fiber template. The hydrogel composite material has a three-dimensional porous structure and is anisotropic, which overcomes the problem of uneven distribution of hydroxyapatite particles in the hydrogel matrix; the material has super-strong tensile strength, compression strength, bending strength and toughness, and the mechanical properties are matched with those of hard bone tissues. The material is beneficial to induce pre-osteoblast adhesion and osteogenic differentiation, promote new bone growth, has good osseointegration and mechanical stability, and is suitable for large-area hard bone tissue repair; in addition, the material has adjustable surface activity, and fine adjustment and control of the structure and the surface can be achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

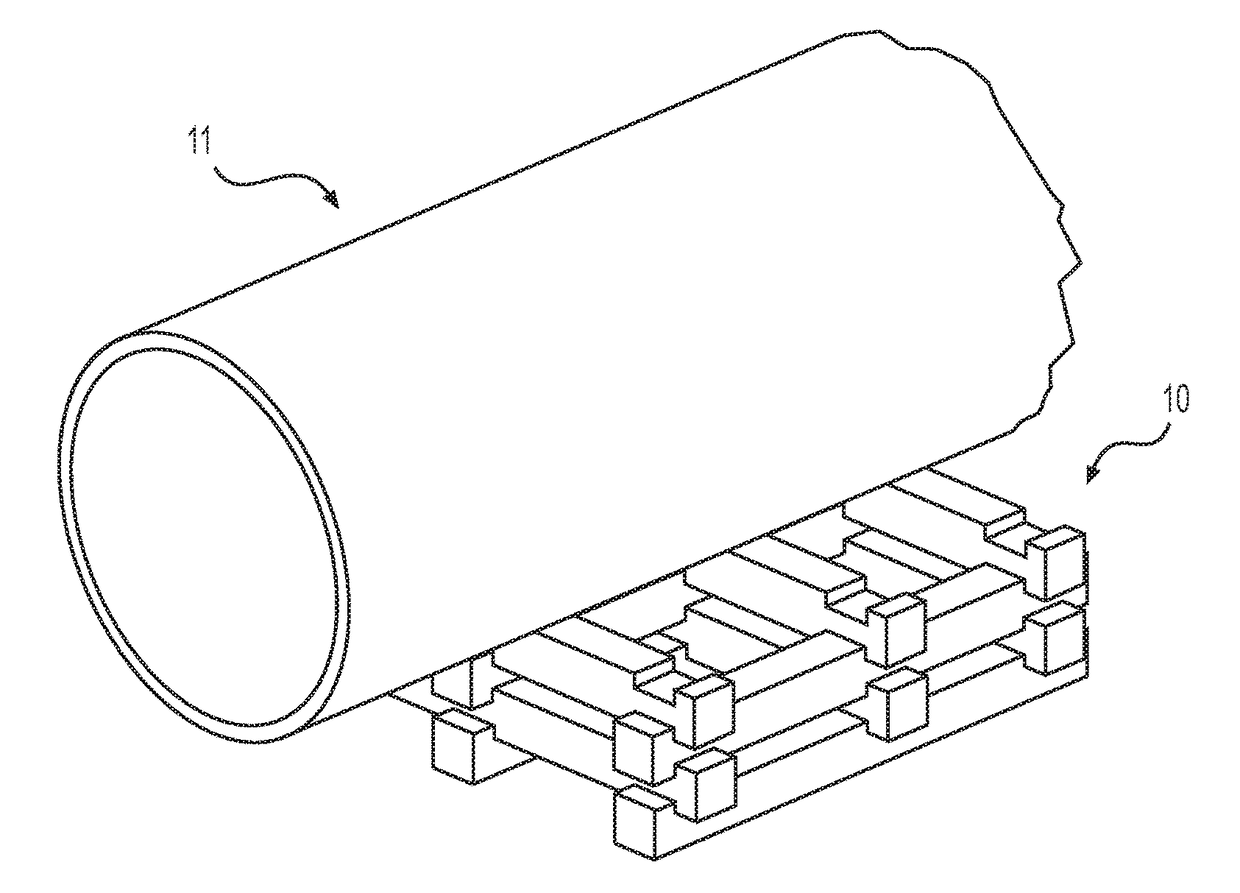

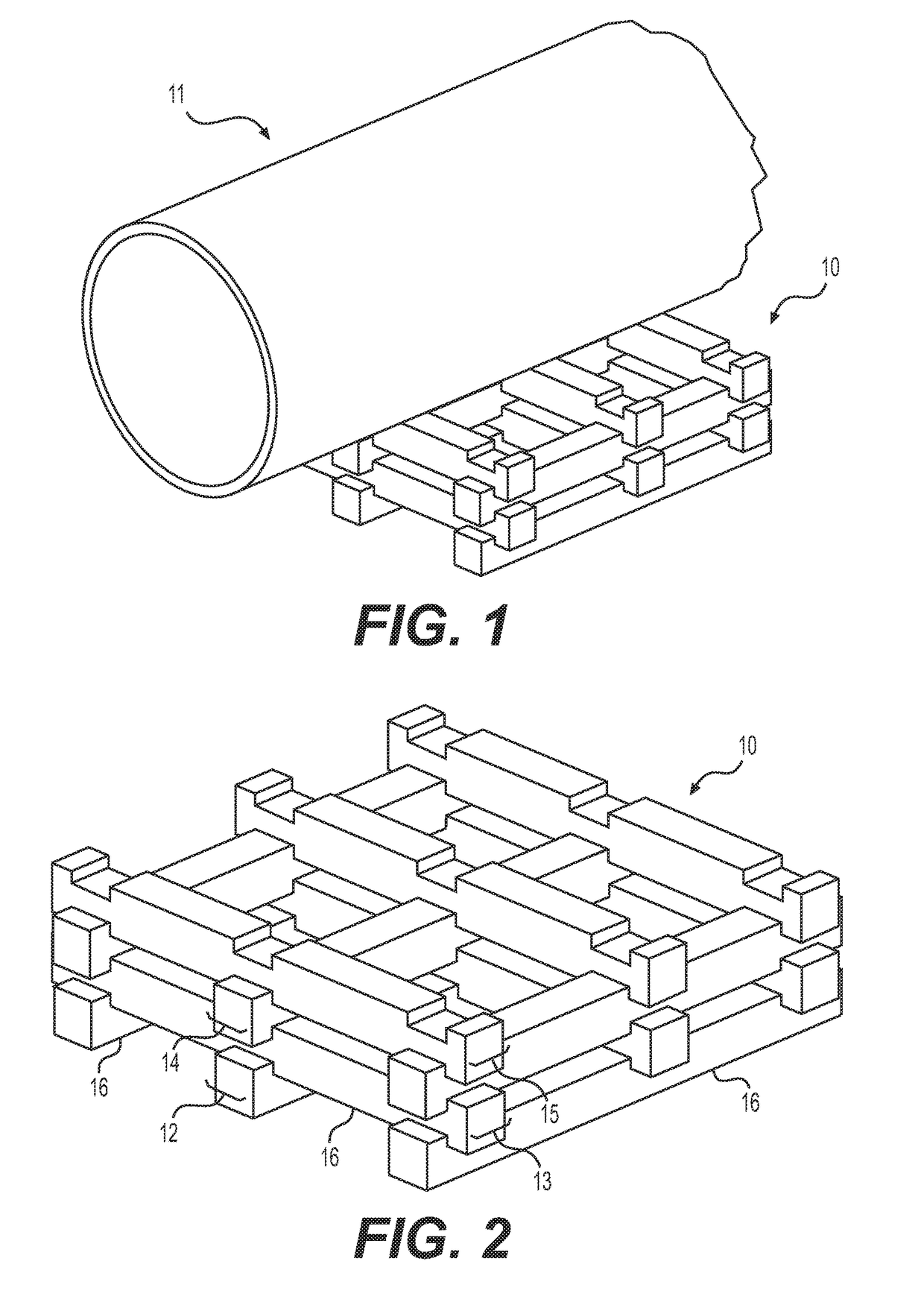

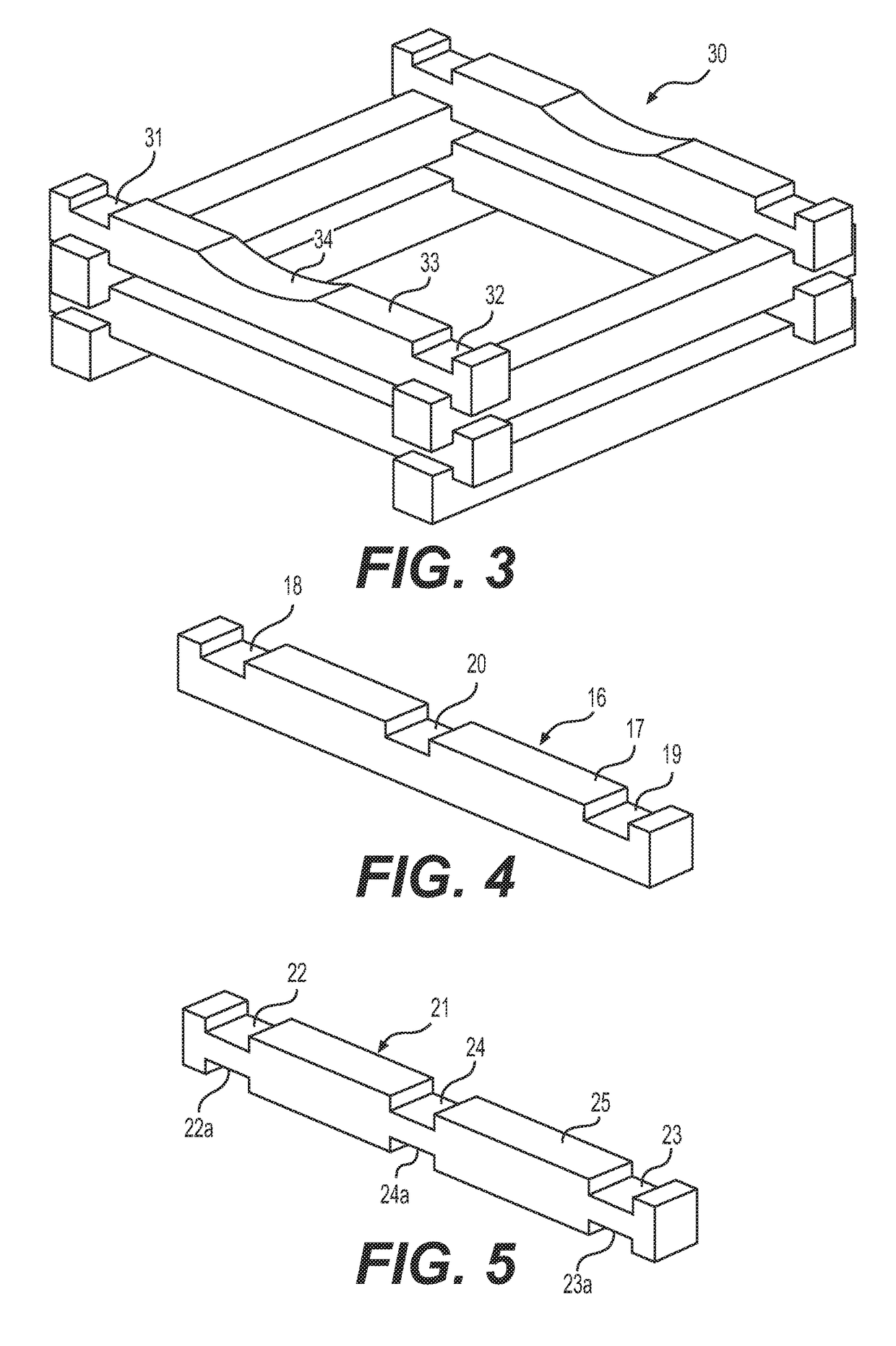

Support assembly and components

ActiveUS9739397B2Reduce manufacturing costEfficient capturePipe supportsPipe laying and repairBiomedical engineering

Owner:CO BLACK LLC

Anti-seismic foundation

InactiveCN101408029AReduce coefficient of frictionStrong compressionFoundation engineeringSteel barRetaining wall

The invention relates to the building technology field, in particular to an earthquake proof foundation which consists of a foundation main body, a concrete cover plate, a foundation soleplate, a downward oblique bar layer, an upward oblique bar layer, an upward longitudinal bar layer, an upward transverse bar layer, a foundation pit soleplate, a retaining wall, a quenched steel cover plate, a quenched steel support plate and a quenched steel clapboard. The foundation main body is positioned in the foundation pit, the foundation soleplate is a horizontal quenched steel plate, four bar layers forming an angle with one another are arranged between the foundation soleplate and the foundation pit soleplate, each bar layer consists of a row of cylindrical quenched steel bars which are horizontally arranged and have gaps with each other, and one horizontally positioned quenched steel clapboard is arranged between every two adjacent bar layers. The retaining wall is positioned at the peripheral walls of the foundation pit, and spaces are remained between the retaining wall and the foundation main body as well as the downward oblique bar layer, the upward oblique bar layer, the upward longitudinal bar layer, the upward transverse bar layer and the edges of the quenched steel clapboard.

Owner:梁伟

Method of manufacturing a flat gasket

InactiveUS7913386B2Easy to produceSimple technologyEngine sealsMetal-working apparatusFree edgeEngineering

Flat gasket comprising a first sheet metal layer consisting of a spring steel and a second sheet metal layer consisting of a ductile steel, the first layer being provided with a sealing bead, and the second layer being provided in an edge area bordering on an edge of the layer with a thickened zone as supporting element for receiving pressing forces; to increase the design possibilities for such a supporting element, the latter is formed by at least one elongate arch of the second layer, which is stamped into the edge area of the second layer and extends approximately parallel to the free edge of the edge area, the arch being compressed in such a way that the metal volume of the supporting element is at least three times the total hollow space volume which the supporting element and two tangential planes abutting on the latter and extending parallel to the plane of the second layer include between them.

Owner:ELRINGKLINGER AG

Anode material for lithium secondary battery, process for production thereof, and lithium secondary battery

InactiveUS6884545B2Avoid decompositionIncrease energy densityPigmenting treatmentElectrode manufacturing processesCarbon coatingFluidized bed

An anode material for lithium secondary battery, which comprises graphite particles and a crystalline carbon coating layer formed thereon, wherein each graphite particle has a bent laminate structure inside, is produced by grinding a graphite of 5 mm or less in average particle diameter using an impact grinder to produce graphite particles of 100 μm or less in average particle diameter having a bent laminate structure inside each particle and then subjecting the graphite particles to chemical vapor deposition in a fluidized bed type reaction furnace to form a crystalline carbon coating layer on the graphite particles.

Owner:NIPPON POWER GRAPHITE CO LTD

Ring cam and fluid-working machine including ring cam

InactiveUS20120260765A1Limit pressure of working fluidControl pressureRotary/oscillating piston combinations for elastic fluidsCamsCamMechanical engineering

A ring cam for a fluid-working machine is formed from a plurality of segments. The segments have piston facing surfaces together defining a working surface of the fluid-working machine. The segments comprise a leading cooperating formation which has a piston facing surface which forms part of the working surface, at a trailing end, and which is recessed from the working surface at a leading end, and a trailing cooperating formation which has a piston facing surface which forms part of the working surface at a leading end, and which is recessed from the working surface at a trailing end. The cooperating formations interlock and rollers are thereby handed over smoothly from one segment to the next irrespective of slight variations in alignment due to manufacturing tolerance or wear.

Owner:ARTEMIS INTELLIGENT POWER

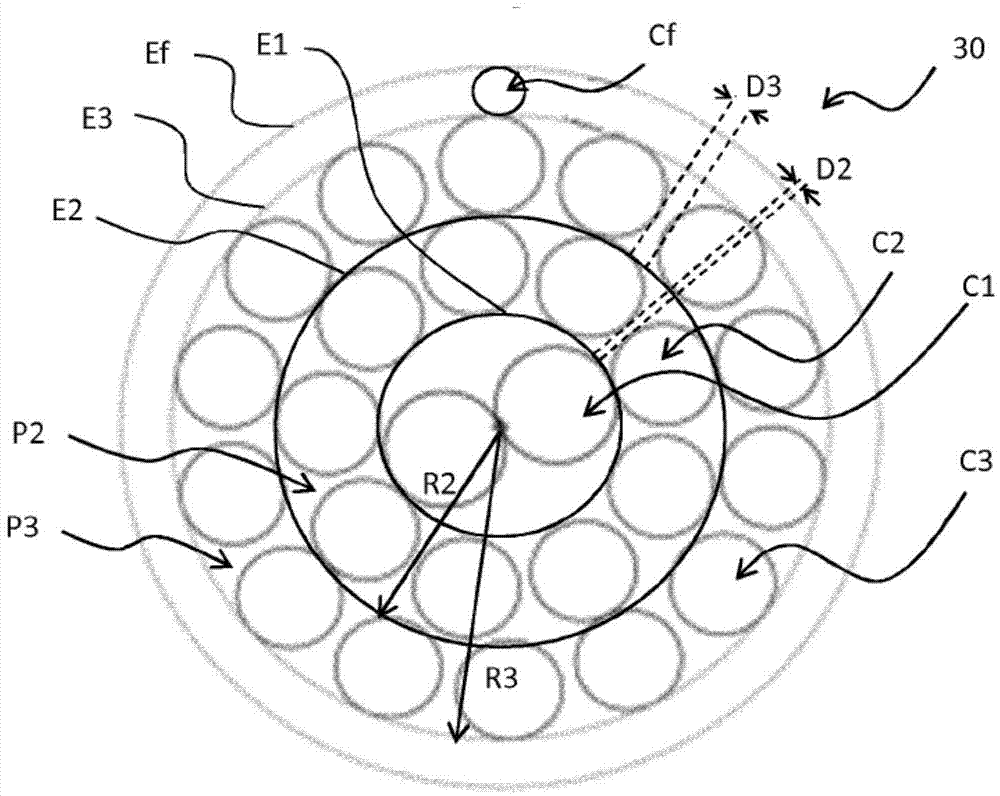

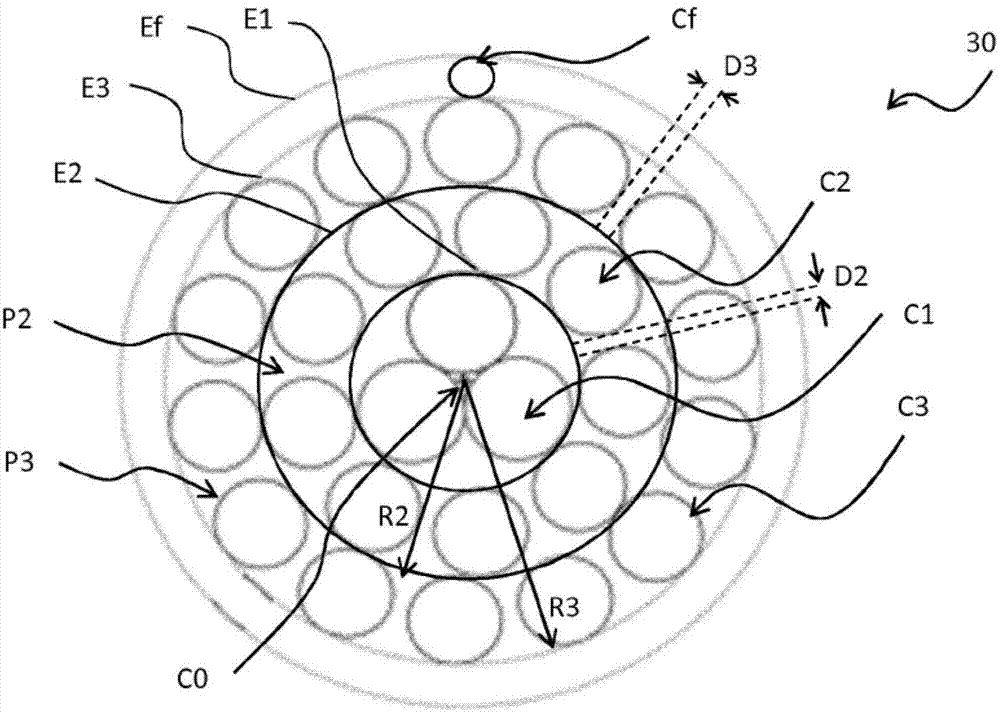

Steel cord comprising layers having high penetrability

ActiveCN104854274AHigh compressive strengthImprove corrosion resistancePneumatic tyre reinforcementsCoatingsEngineeringMechanical engineering

The invention relates to a steel cord (30) comprising cylindrical layers, said cord including: an inner layer (C1) formed by M wires, an intermediate layer (C2) formed by N wires helically wound around the inner layer (C1), and an outer layer (C3) formed by P wires helically wound around the intermediate layer (C2), in which the inter-wire distance D2 of the wires of the intermediate layer (C2) is greater than or equal to 25 µm and the inter-wire distance D3 of the wires of the outer layer (C3) is greater than or equal to 25 µm.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Groove-pipe combined exhaust technology for joint grouting for normal concrete arch dam

ActiveCN102677676AQuality assuranceAvoid cloggingFoundation engineeringMarine site engineeringArch damExhaust pipe

The invention discloses a groove-pipe combined exhaust technology for joint grouting for a normal concrete arch dam. An exhaust system adopted in the technology comprises a triangular exhaust groove, an exhaust main pipe, exhaust holes, hole sealing kraft paper, exhaust pipes and groove sealing galvanized sheet iron. The implementation process mainly comprises the steps as follows: forming the triangular exhaust groove on the side surface of a concrete pre-cast block; punching holes on the exhaust main pipe at equal intervals in a stagger manner; sealing the holes with the hole sealing kraft paper; mounting the exhaust main pipe before casting a post-cast block; connecting the exhaust main pipe with the exhaust pipes through elbows; and sealing the mouth of the exhaust groove with the galvanized sheet iron after the exhaust pipes are mounted, so as to form the pipe-groove combined exhaust system. The invention has the advantages as follows: the construction is simple, convenient and practicable and has higher reliability; and compared with other exhaust technologies, the groove-pipe combined exhaust technology can effectively prevent blockage of an exhaust pipeline system in the joint grouting arrangement of the arch dam in the concrete casting process.

Owner:POWERCHINA XIBEI ENG

TIG welding gun for water cooling of inner part of tungsten electrode based on negative electrode compression influence

InactiveCN106077920AStrong compressionStrong penetrating powerElectrode accessoriesWelding/cutting media/materialsWater channelAgricultural engineering

The invention relates to a tungsten electrode argon arc welding gun, and discloses a TIG welding gun for water cooling of the inner part of a tungsten electrode based on negative electrode compression influence. The TIG welding gun comprises a central column, wherein the upper part of the central column is connected with a tail cover and the lower part of the central column is connected with a base of the tungsten electrode; the lower part of the base of the tungsten electrode is connected with a tungsten electrode head with a hole, wherein the tungsten electrode head with the hole is provided with a tungsten electrode head inner hole chamber; a sleeve is arranged at the outer part of the central column; a gap gas channel is formed between the sleeve and the central column; a protective gas cover is connected to the lower part of the sleeve; a water outlet pipe, a water inlet pipe and a gas inlet pipe are assembled on the tail cover, a water returning hole corresponding to the water outlet pipe, a water inlet hole corresponding to the water inlet pipe, and a ventilation hole corresponding to the gas inlet pipe are formed in a gun body, and a gas stilling chamber which communicates with the gap gas channel is arranged in the gun body; a water guiding pipe is connected to the bottom of the central column; a water spray nozzle which communicates with the water inlet hole is arranged on the water guiding pipe; a cooling water channel and a protective gas channel are isolated through an upper sealing ring and a lower sealing ring. According to the TIG welding gun disclosed by the invention, cooling fluid is directly injected in the tungsten electrode, and the tungsten electrode is strongly cooled, so that the area of a negative electrode region can be compressed, strong compression of an arc column is realized, the penetrating capacity of an electric arc is improved, and a welding electric arc has a good penetrability.

Owner:TIANJIN UNIV

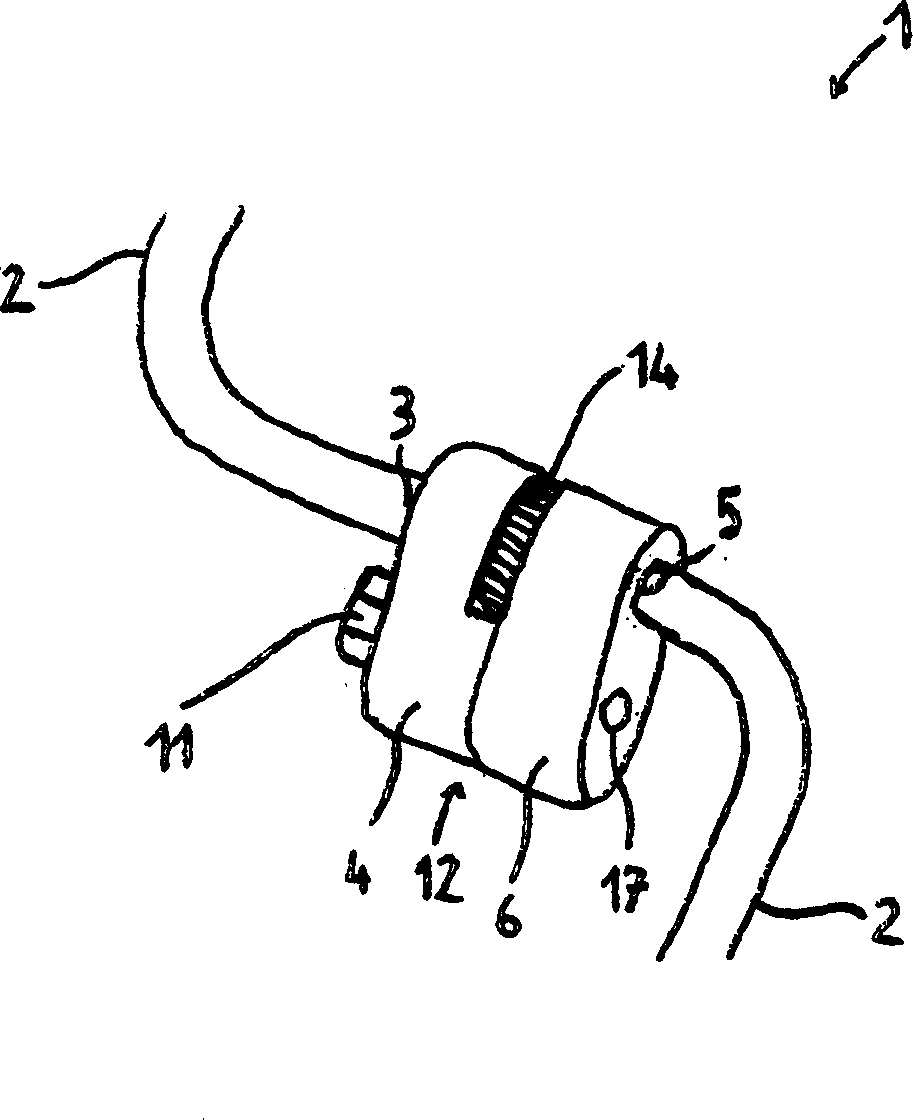

Connecter of refrigerant pipeline

ActiveCN1530584AUniform compressionEasy to assembleAir-treating devicesFlanged jointsEngineeringFastener

The connecting arrangement (1) for coolant pipes (2) has a first (4) and second (6) connecting piece joined together by a single screw (11) offset to the side of the sealing faces (8,9). Positioned away from the screw and on the side (12) furthest from the sealing faces is a non-compressible preformed component (13) acting as a spacer, and constructed in such a way that when the connecting pieces are screwed together a lever action ensues which results in a uniform compression of a sealing ring (10) between the sealing faces of the connecting pieces.

Owner:KANDITECKUNLE

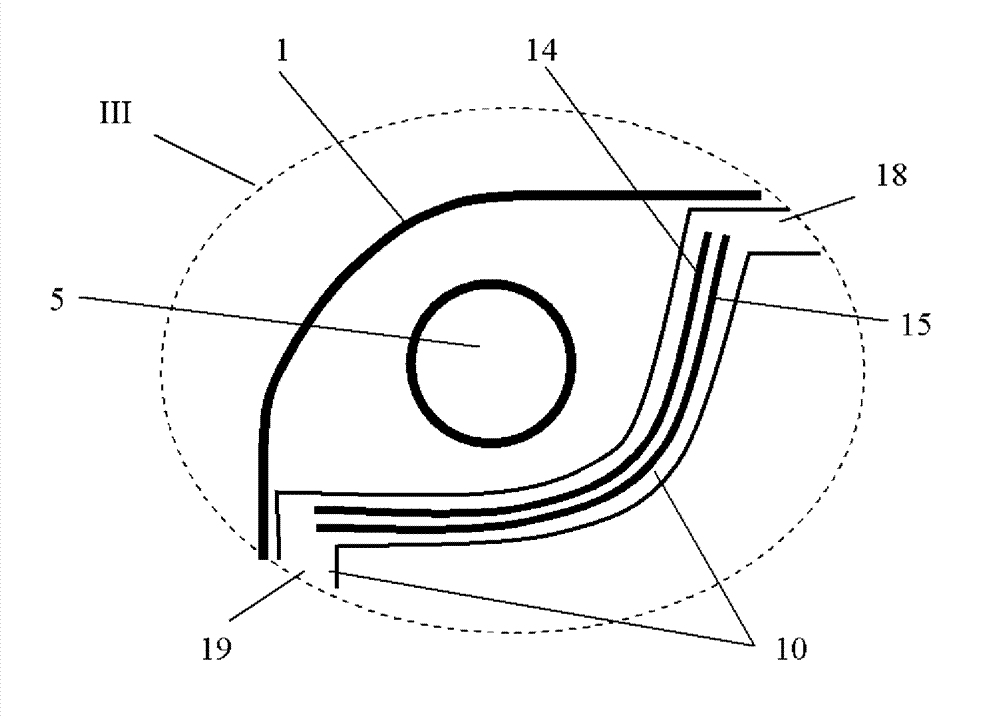

Volute type ecological wave dissipation structure

ActiveCN110004874AImprove wave efficiencyReduce consumptionBarrages/weirsBreakwatersMortise and tenonWeather resistance

The invention discloses a volute type ecological wave dissipation structure. The volute type ecological wave dissipation structure comprises a plurality of volute wave dissipation units, pre-stressedsteel bundles and pre-stressed anchorage devices. The multiple volute wave dissipation units are spliced in a staggered mode by adopting mortise and tenon, and all the volute wave dissipation units are connected with an embankment slope protection body through the pre-stressed steel bundles. The volute wave dissipation units are placed horizontally or vertically, and each include a spacer bar andtwo symmetrically arranged volute type wave dissipation flow passages. Each volute type wave dissipation flow passage is formed by enclosing a large arc surface and a small arc surface, and is provided with a circular wave inlet and outlet and a wave energy dissipation port. The wave inlets and outlets are located on the water-facing side, the vertical cross-sectional areas of the volute type wavedissipation flow passages are gradually reduced from the wave inlets and outlets to the wave energy dissipation ports, and the two wave energy dissipation ports in each volute wave dissipation unit coincide. The volute type ecological wave dissipation structure has high wave dissipation efficiency, low cost, high weather resistance, high erosion resistance, high scouring resistance, high compressive strength and shear strength, good overall stability, high uncoordinated deformation ability to adapt to a bank slope and good ecological protection and ecological landscape comprehensive benefits.

Owner:HOHAI UNIV

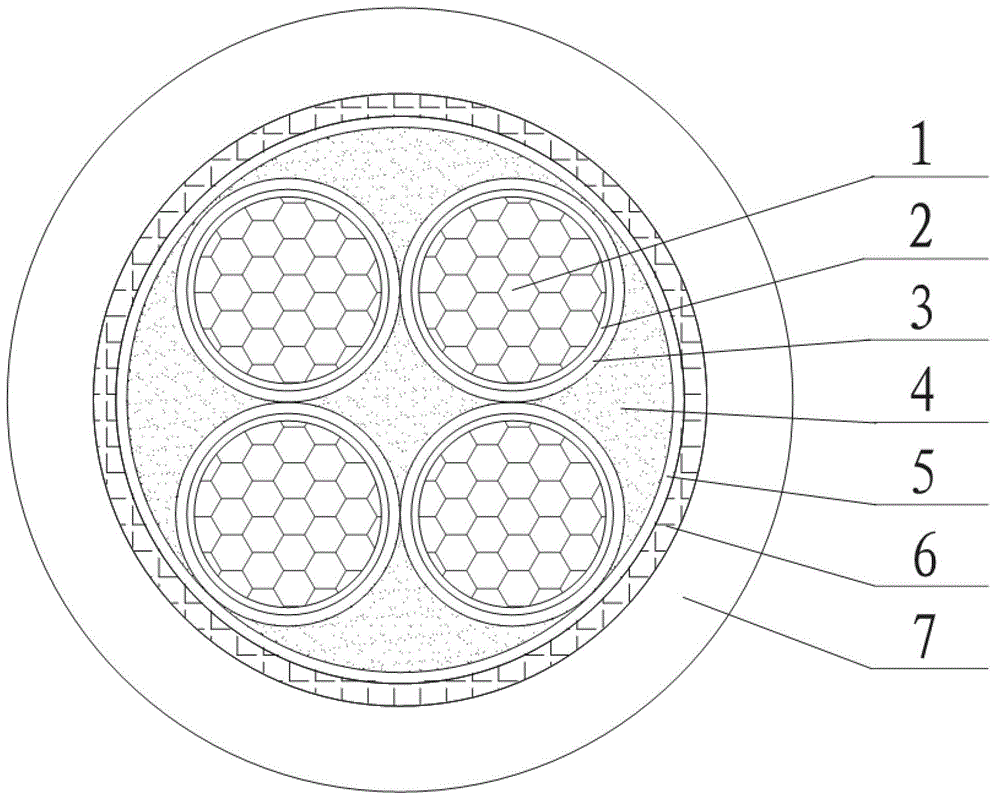

High-performance aluminium alloy cable for building

InactiveCN103337290AExtended durationHas flame retardant propertiesInsulated cablesPower cablesElectricityInsulation layer

The invention discloses a high-performance aluminium alloy cable for buildings, which solves the problems that the conventional power cables for buildings consume more copper resources, are worse in bending performance, and have short service life and the like, and has the advantages of light weight, the capability of corrosion-resistance and halogen-free flame retardant, small bending radius, excellent electrical property, long service life and the like. The high-performance aluminium alloy cable structurally comprises a cable core, wherein the cable core is formed by a plurality of wire core conductors arranged inside a filler and made of aluminium alloy; a conductor double-layer insulation layer is arranged on the outer wall of each wire core conductor; the plurality of wire core conductors are intertwisted in a symmetric arrangement manner; the outer wall of the filler is wrapped with a cable belting layer, a cable armored layer and a cable shield layer sequentially from the inside out.

Owner:SHANGDONG HUALING CABLE

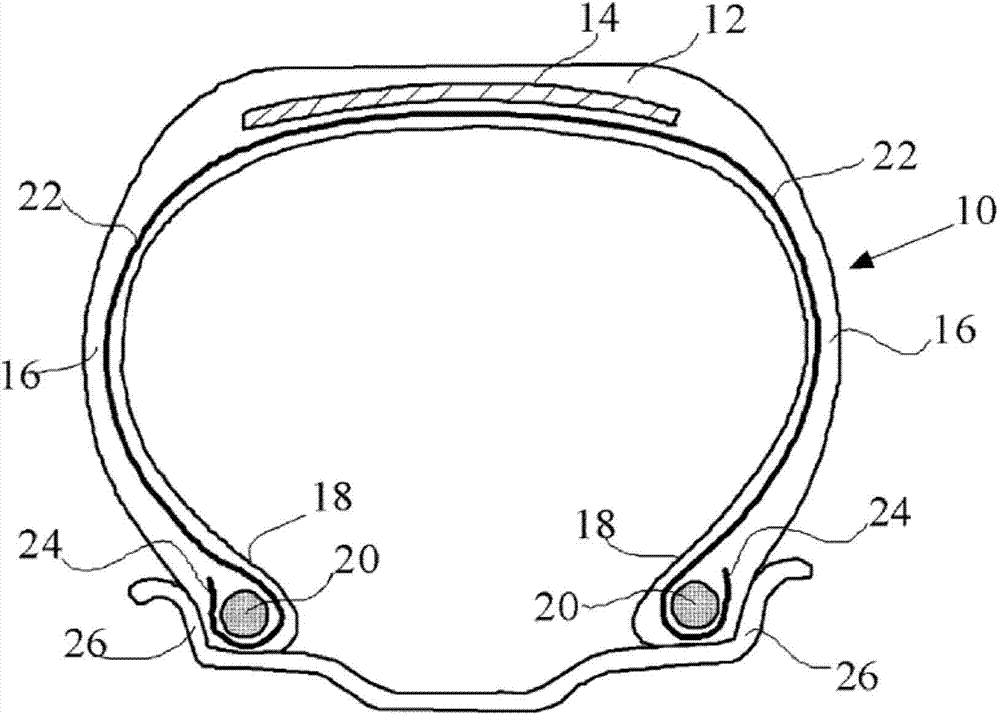

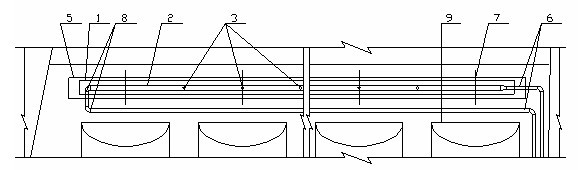

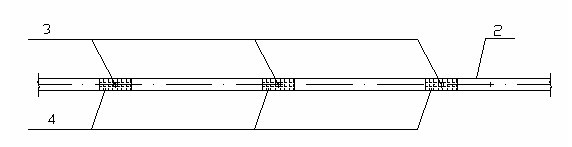

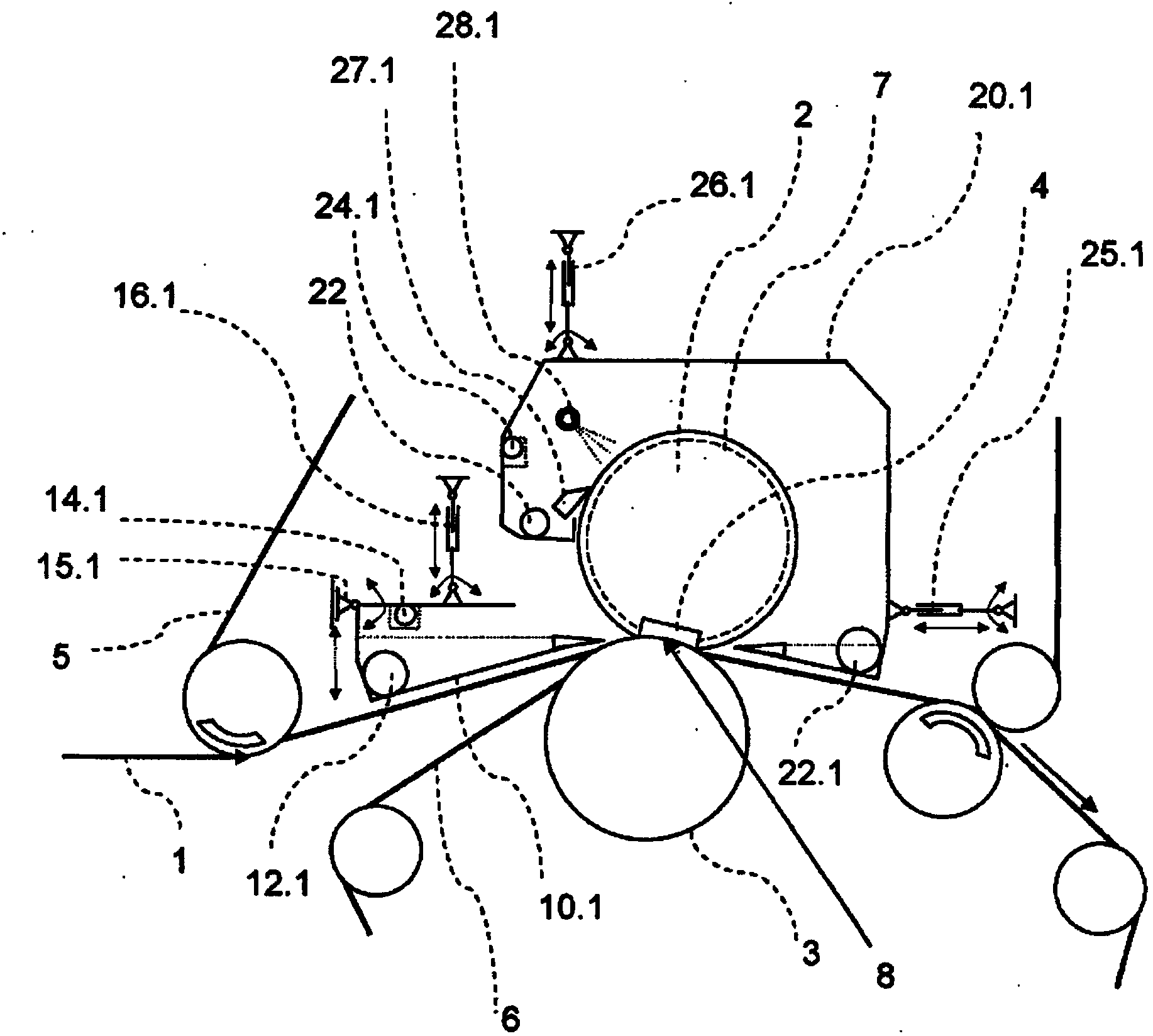

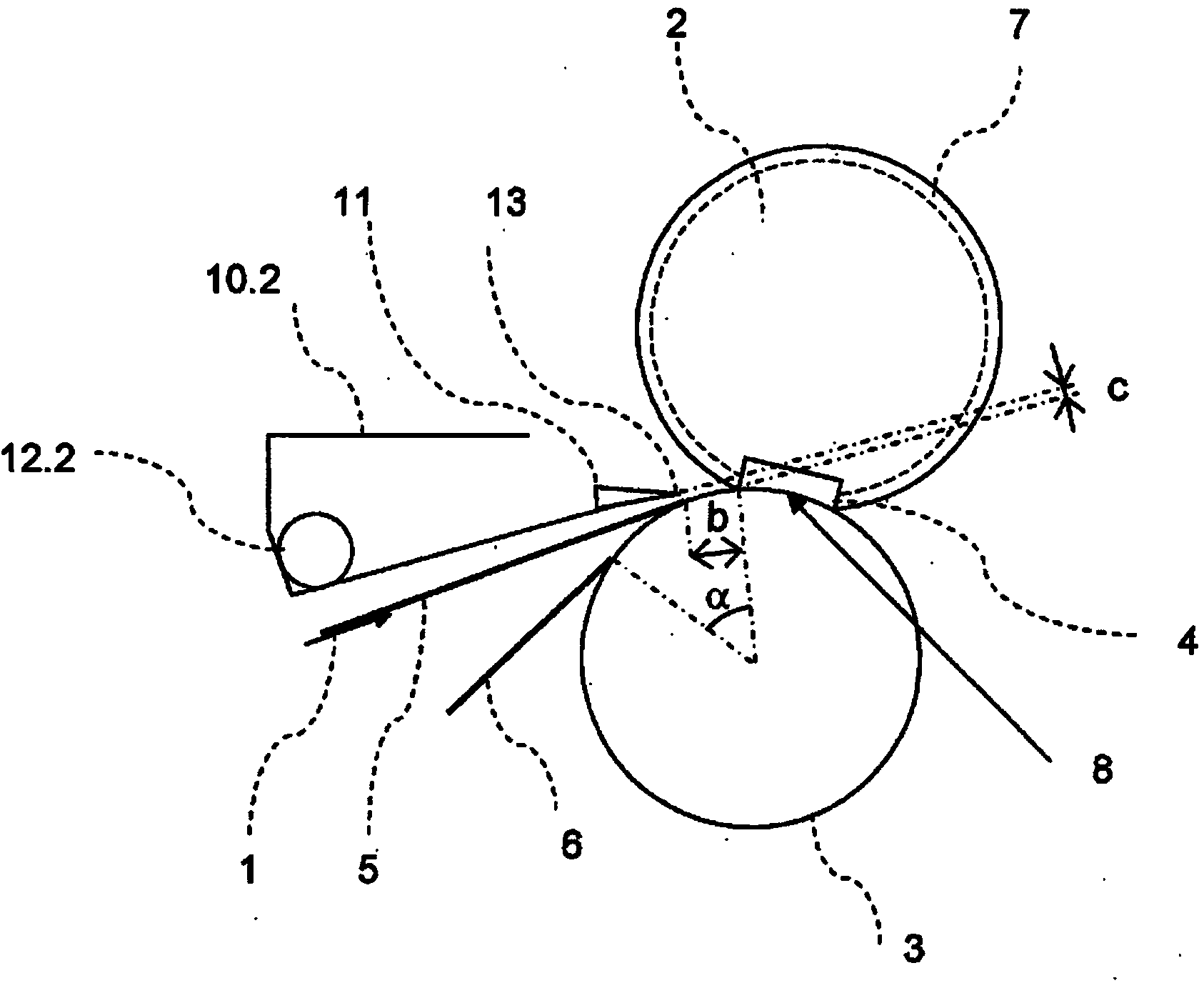

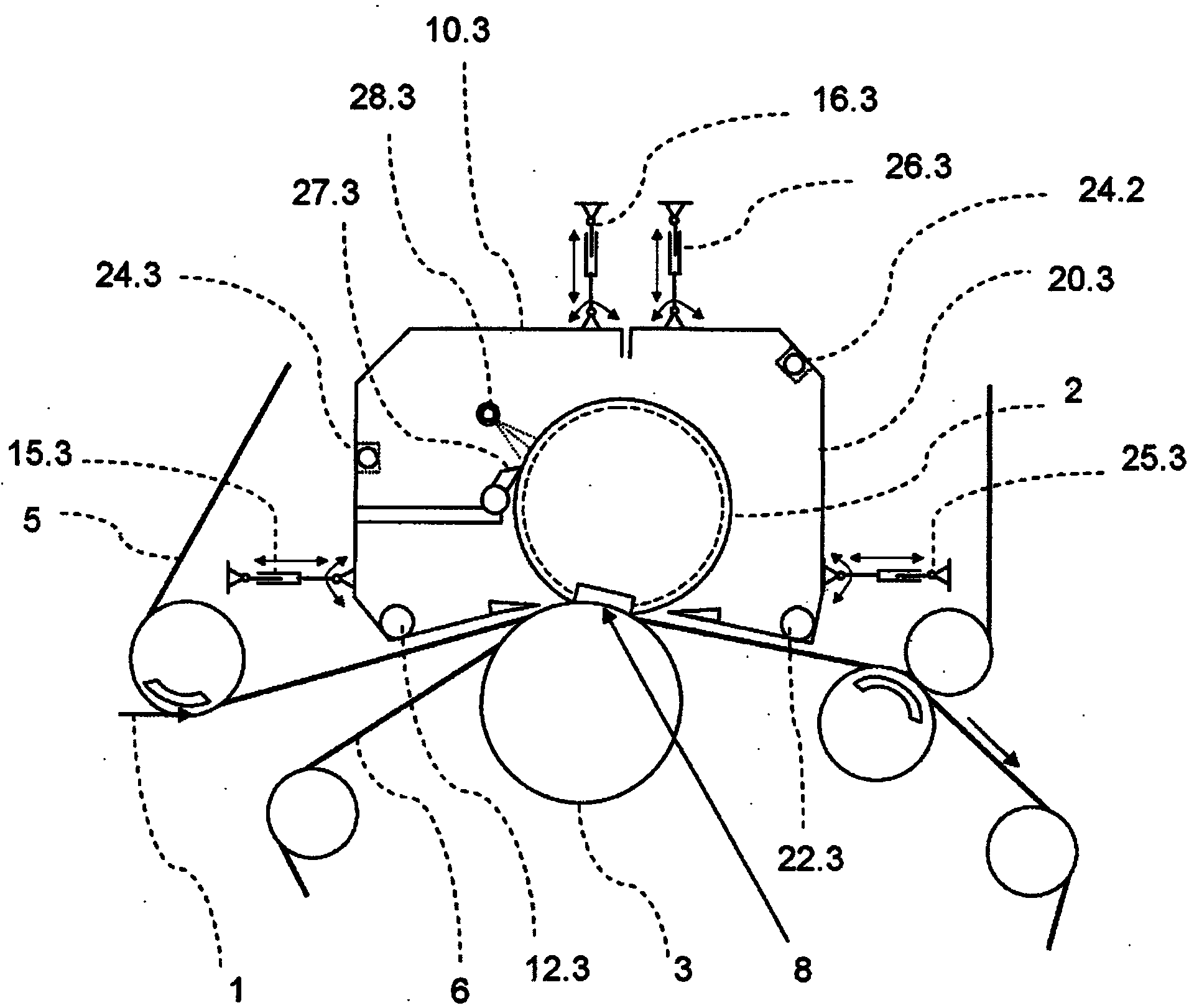

Press section of a machine for producing a fibrous web

The invention relates to a press section for dewatering in a machine for producing a fibrous web (1), in particular a paper, cardboard, or tissue web, comprising a shoe press nip (8) formed by a press roll (2) and a counter roll (3), wherein the press roll (2) has a circumferential flexible cylindrical surface, a supporting stationary yoke, a pressing element (4), and press-on devices, and wherein the press-on devices press the pressing element (4) against the cylindrical surface (7) and thus the cylindrical surface (7) against the counter roll (3), and wherein a collecting tray (20.1, 20.3, 20.4) is provided downstream of the shoe press nip (8) in the running direction of the web; the cylindrical surface (7) is grooved, wherein the length of the grooves in the circumferential direction is greater than the nip length (L), and a collecting tray (10.1, 10.2, 10.3, 10.4) is provided upstream of the shoe press nip (8) on the side of the press roll (2) so that a large amount of water sprays back from the shoe press nip in a direction opposite the running direction of the web and contributes to the improvement of the dewatering performance.

Owner:VOITH PATENT GMBH

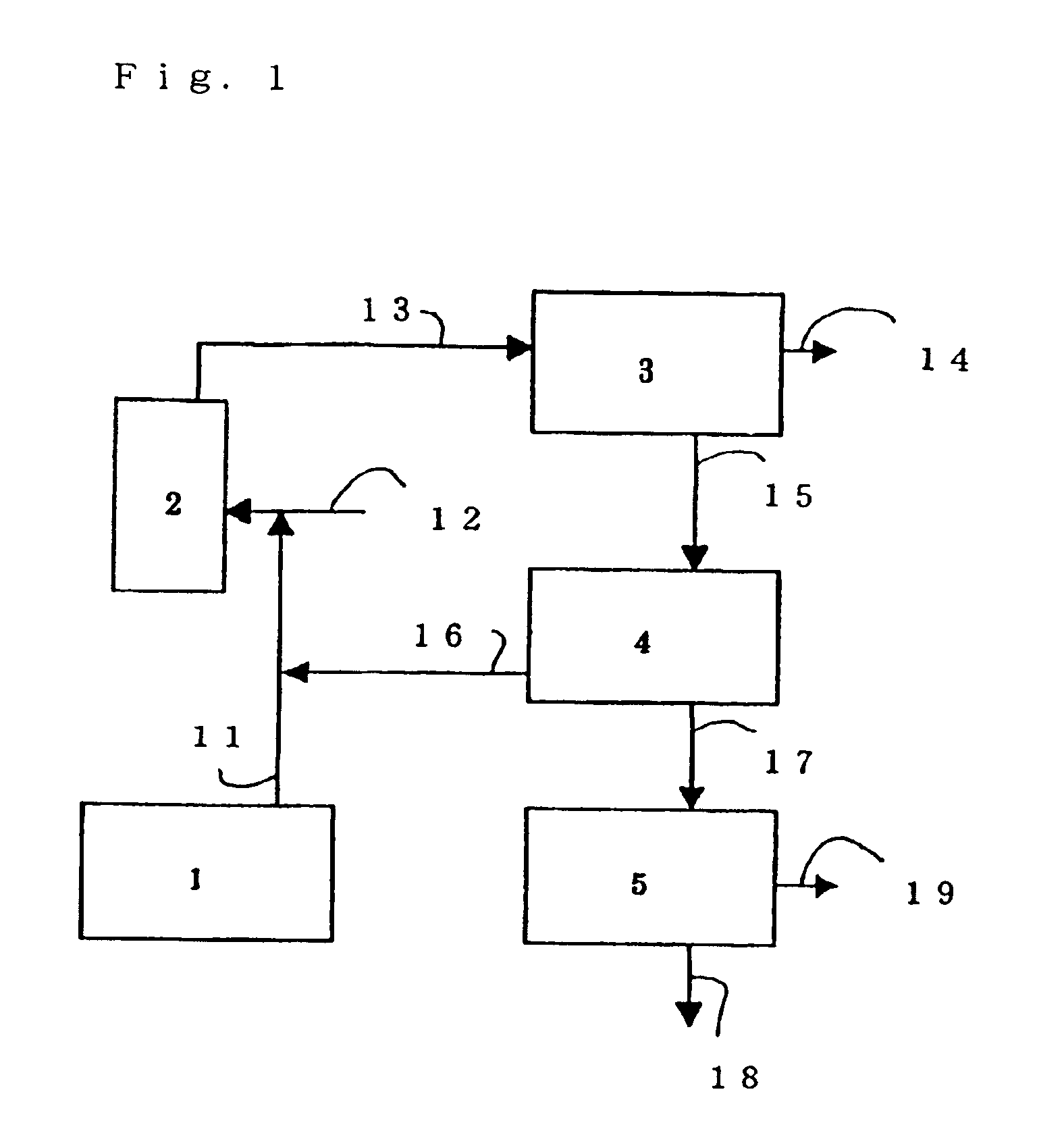

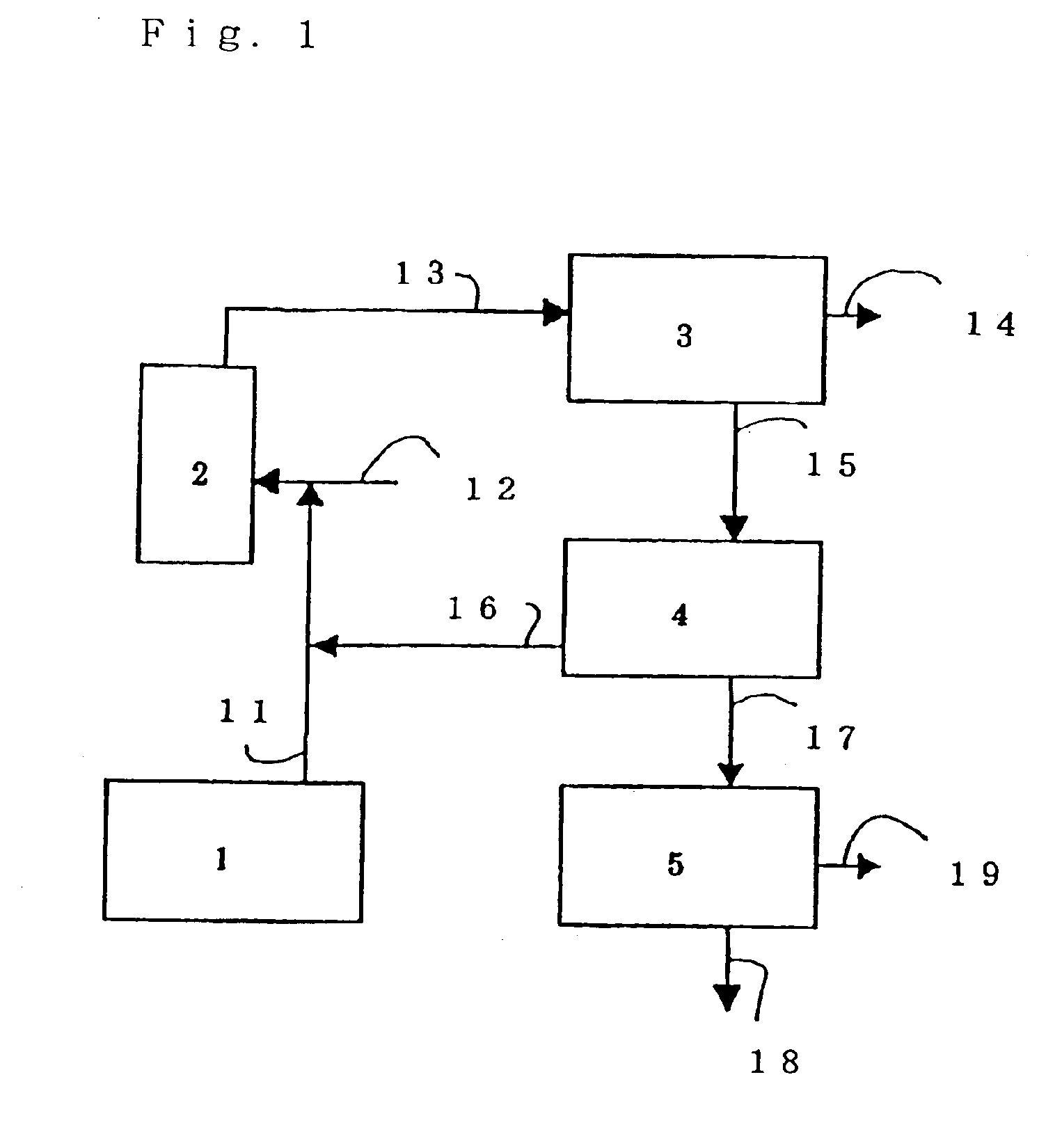

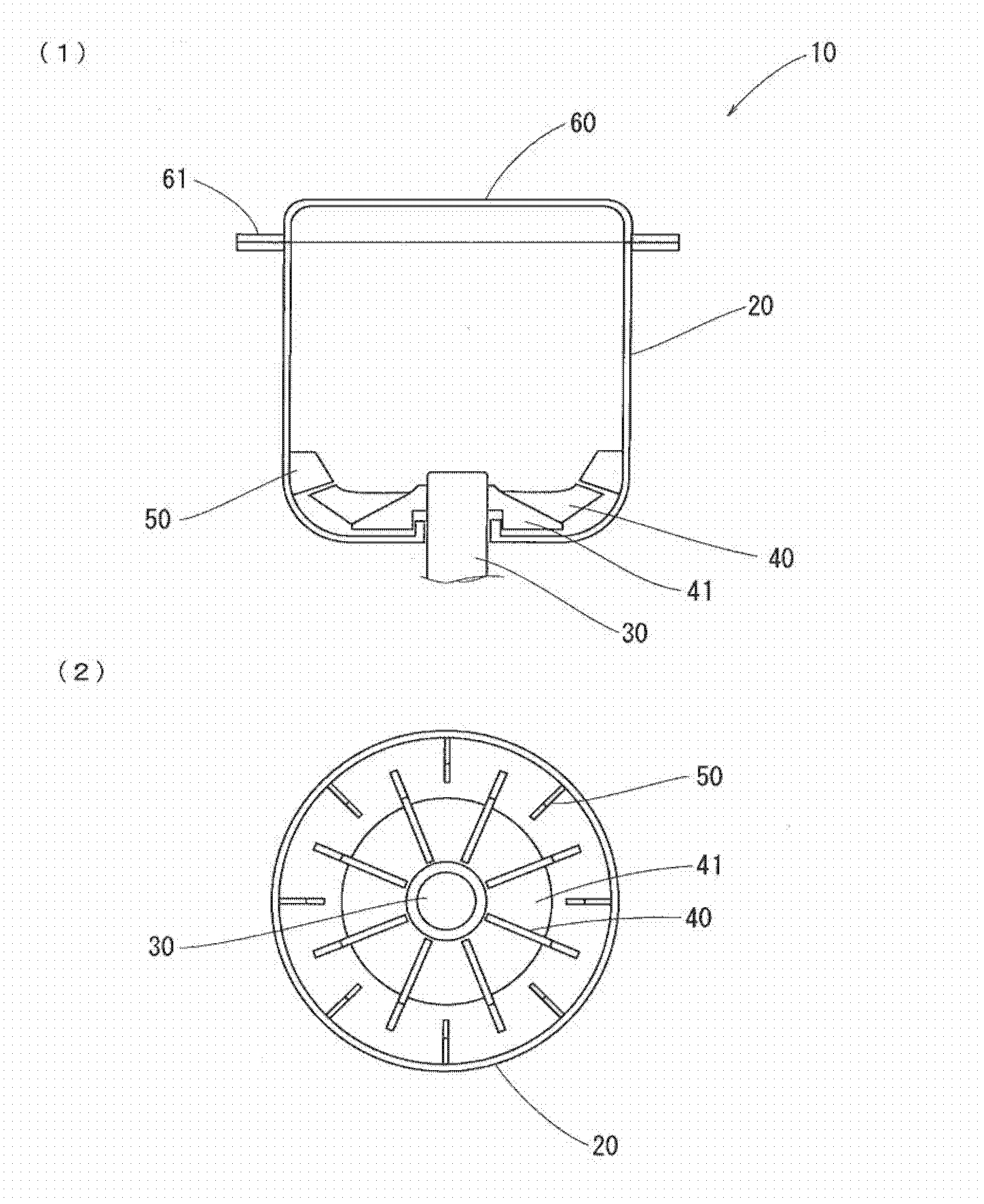

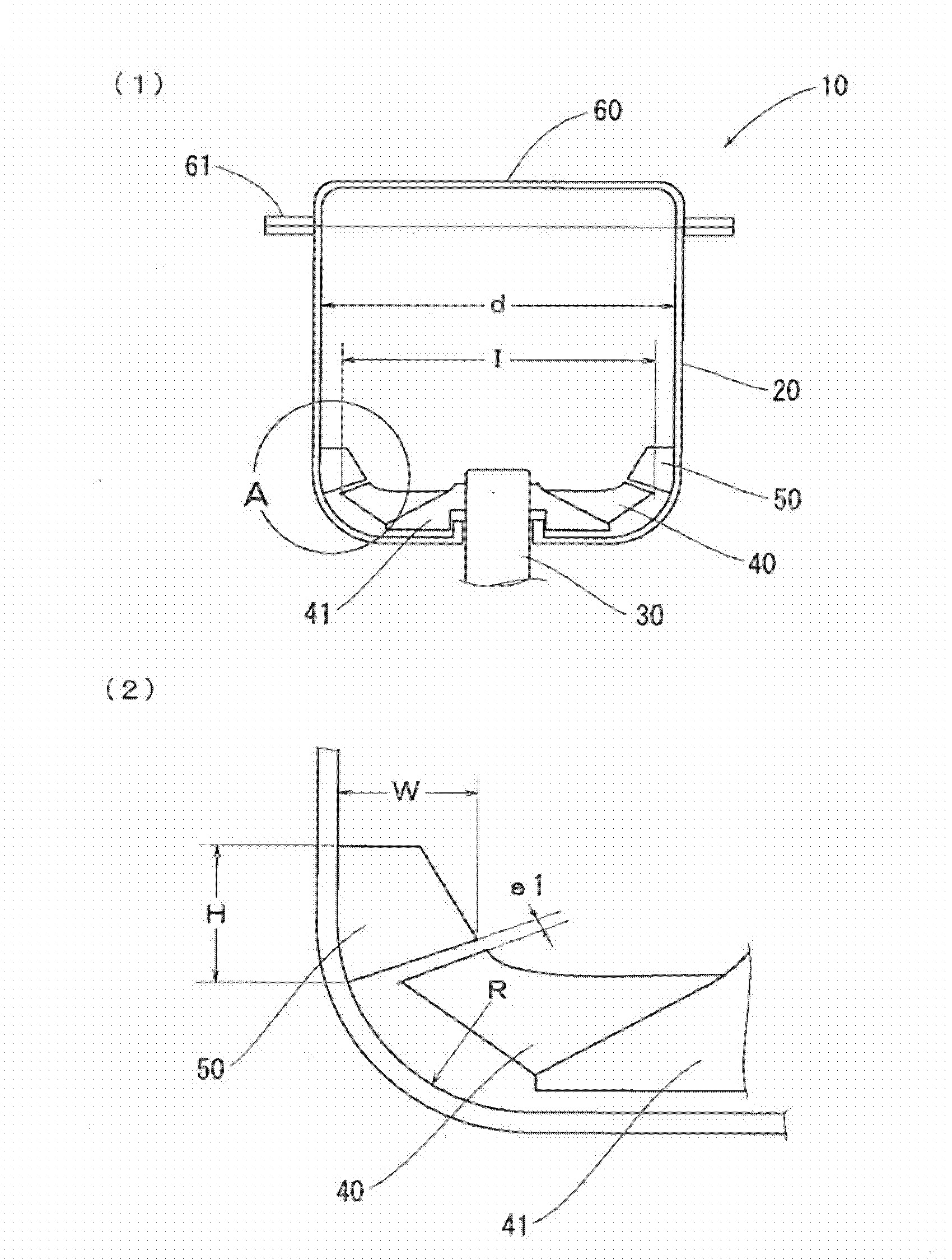

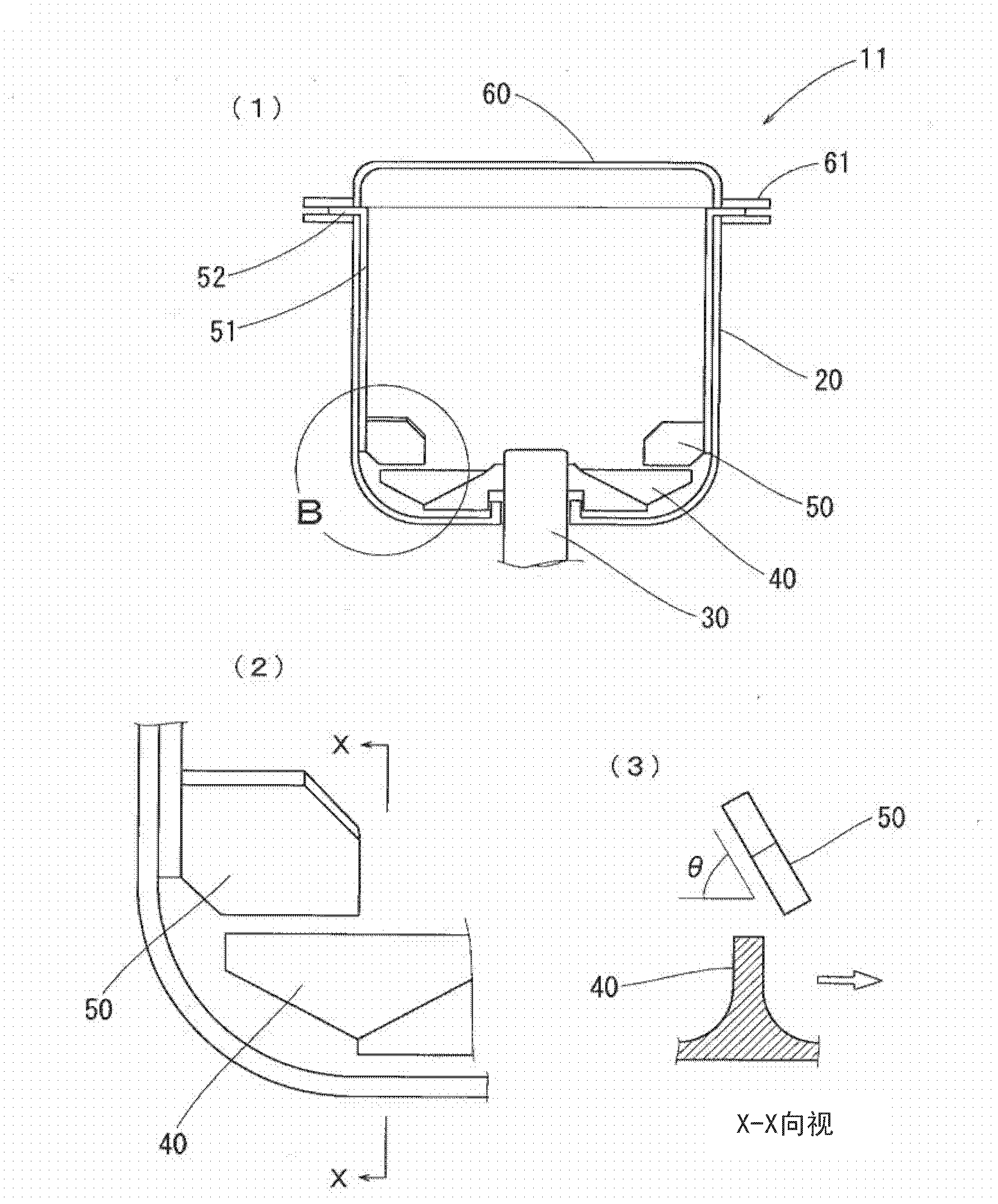

Processing device

ActiveCN102574084ASimple structureStrong compressionRotary stirring mixersTransportation and packagingVertical mixingEngineering

Disclosed is a processing device that performs processes such as compositing by applying strong pressure or shear force to granular materials. Said processing device, which has a simple structure and can easily find optimal processing conditions, is provided with: a vertical mixing vessel (20); a rotating shaft (30) inserted through the bottom of the mixing vessel (20); a plurality of stirring blades (40) provided on the rotating shaft (30); and a plurality of impact plates (50) affixed to the mixing vessel (20). Letting the diameter of the mixing vessel (20) be d, the minimum distance between the stirring blades (40) and the impact plates (50) is at most 0.1d.

Owner:NIPPON COKE & ENG

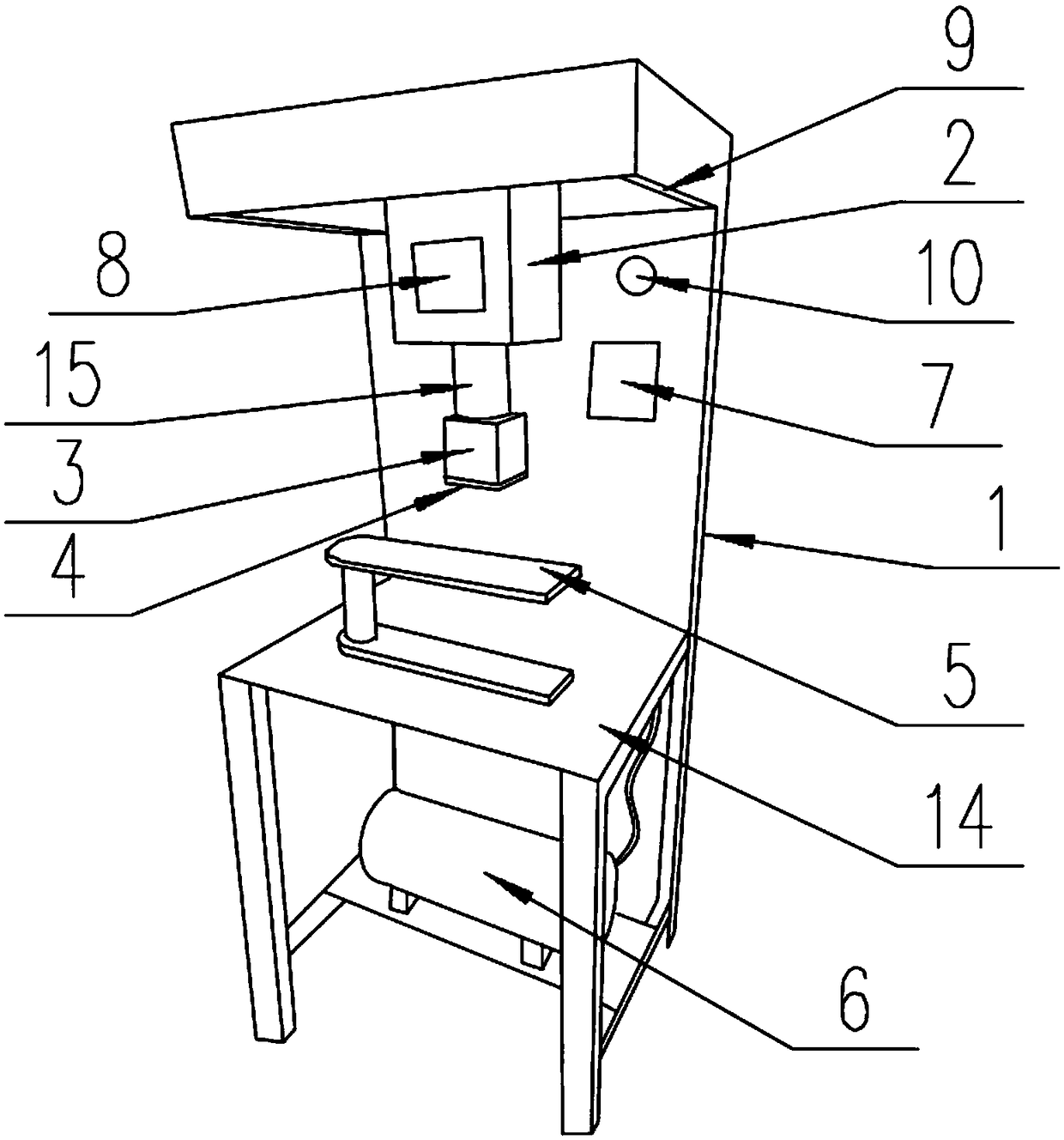

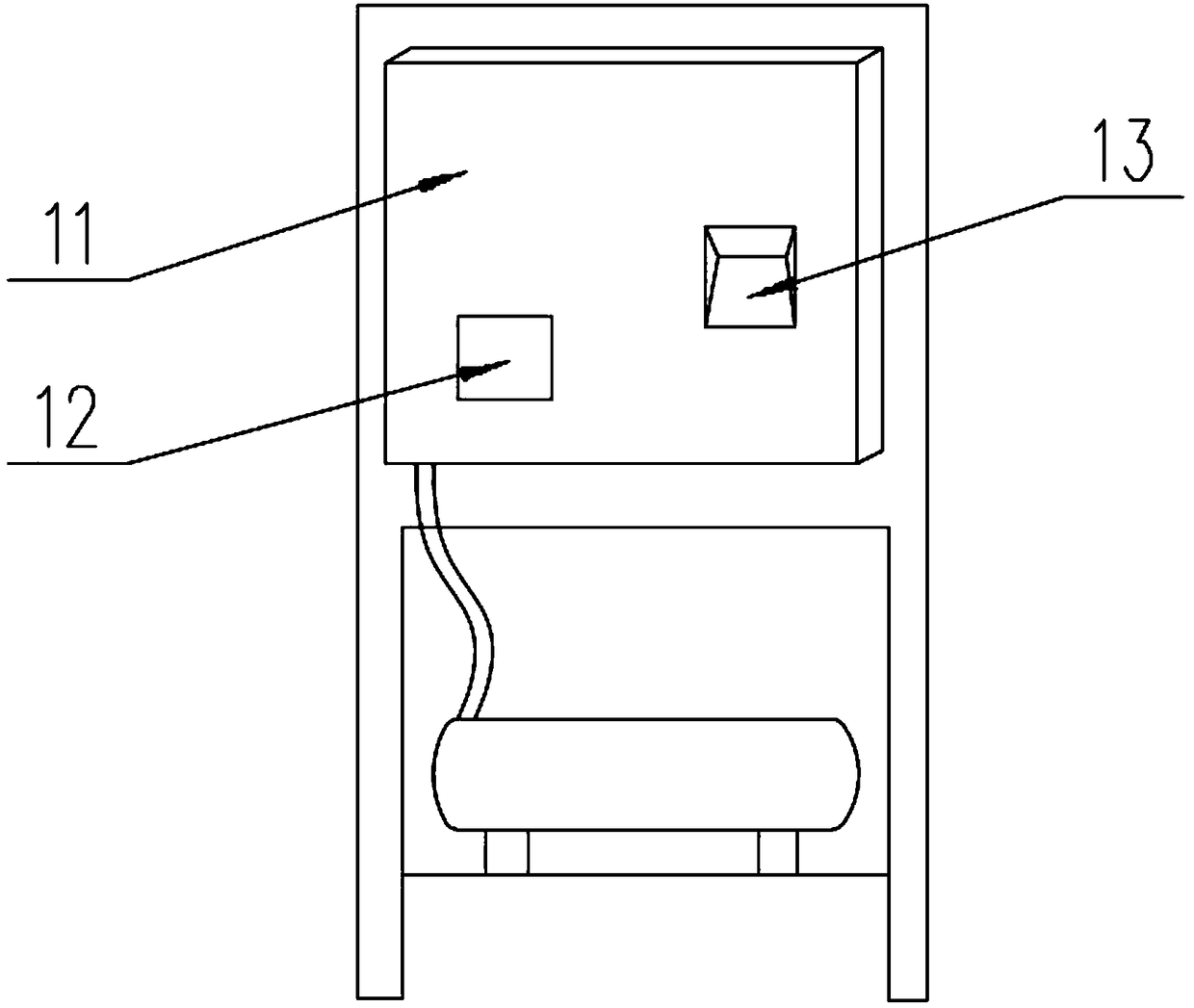

Leather repair machine and repair method thereof

PendingCN108588307AFast temperature transferEvenly heatedLeather surface finishingEngineeringRepair method

The invention discloses a leather repair machine and a repair method thereof and relates to the technical field of leather repair. The leather repair machine comprises a repair machine body, a temperature and pressure adjusting device, a I-shaped rack and a pneumatic device, wherein the temperature and pressure adjusting device is located at the upper end of the repair machine body and moves all around on the upper end surface of the repair machine body; a pressure head is arranged below the temperature and pressure adjusting device through a telescopic assembly; a heater is arranged below thepressure head; the I-shaped rack is placed on an operating table of the repair machine body; the pneumatic device is arranged below the repair machine body and is connected to the temperature and pressure adjusting device to provide kinetic energy for the temperature and pressure adjusting device; a circuit integrating box is arranged behind the repair machine body; and a power supply module is arranged on the circuit integrating box. The leather repair machine disclosed by the invention can solve the problem that the biofidelity of copied leather is low as the operating space of an existingrepair machine is narrow in space, and has the beneficial effects of being high in biofidelity and large in operating space.

Owner:江万伦

Sealed housing and method of producing the same

ActiveUS20140319125A1Easily produceReduce effectElectric heating systemHeater elementsElectric heatingMotorized vehicle

A sealed housing of an electric heating device to be installed in a motor vehicle includes a housing lower part and a housing cover abutting on the housing lower part via an intermediate sealing element. An elongate positive locking element, which interconnects the housing lower part and the housing cover in a form fit manner, is provided between opposed contact surfaces of the housing lower part and a housing cover. The positive locking element abuts on the contact surfaces under a pretensioning force caused by compression of the sealing element. A method of producing a sealed housing also is disclosed via which the contact surfaces move into contact with the elongate positive locking element under a pretensioning force of the sealing element.

Owner:WACKER NEUSON SE

Heat exchanger

A heat exchanger is provided comprising a stack of heat exchanger plates (1, 1a, 1b, 1 c) formed of sheet metal having a three-dimensional structured pattern (2, 3), each heat exchanger plate (1,1 a, 1b, 1 c) having a groove (10), a gasket (9) being arranged in said groove (10) and resting against an adjacent heat exchanger plate (1 a), said groove (10) having a bottom inner surface (11), said inner surface bottom (11) having at least a protrusion (14, 15) directed to said adjacent heat exchanger plate (1a). It is intended to minimize the risk of a leakage. To this end in the region of said protrusion (14, 15) said gasket (9) is compressed more than in a region out of said protrusion (14, 15).

Owner:DANFOSS AS

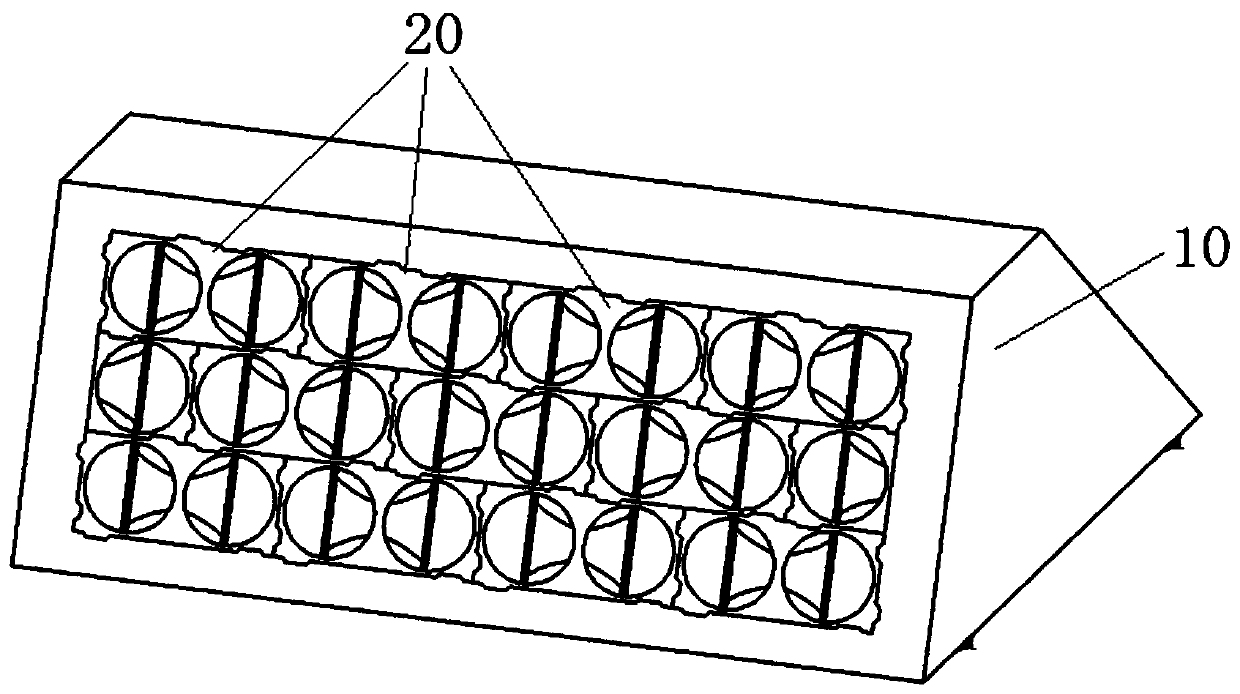

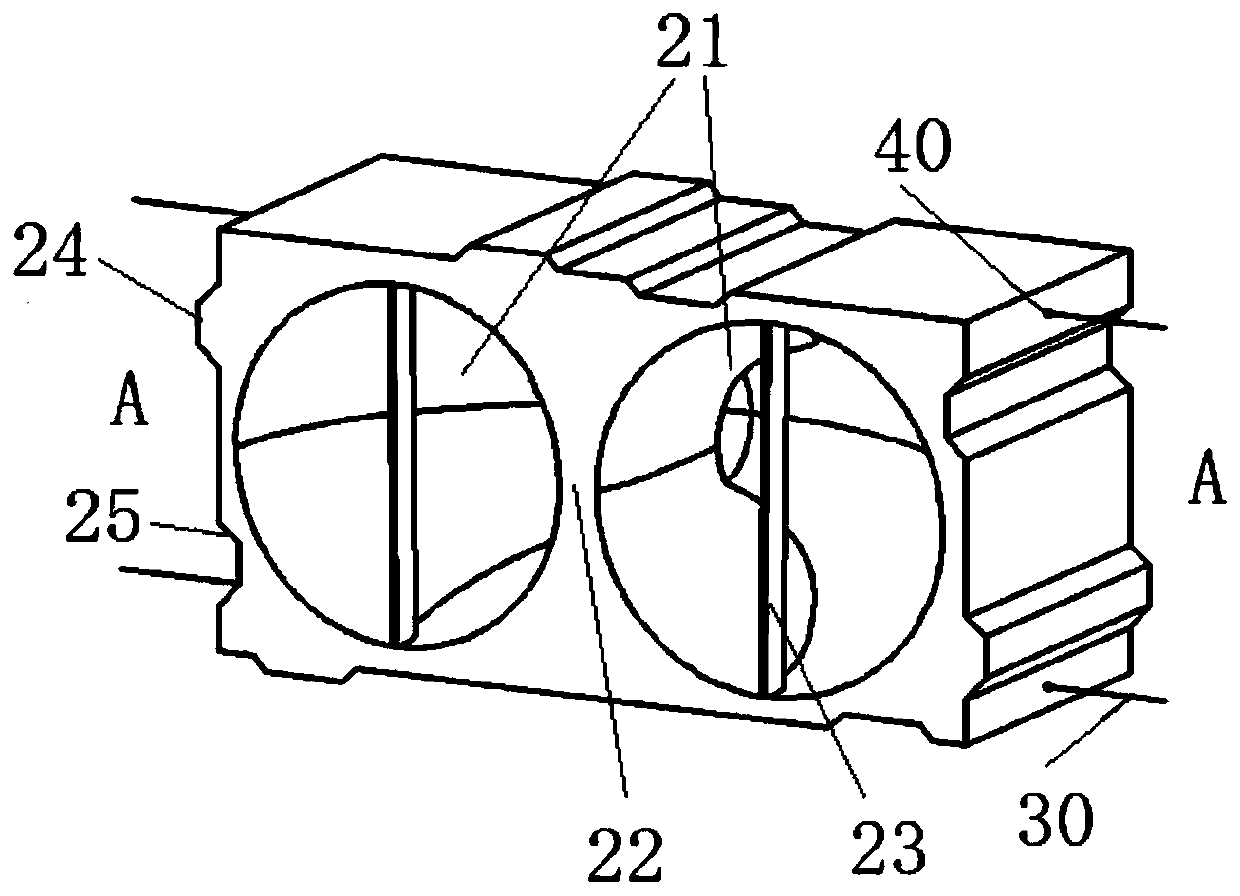

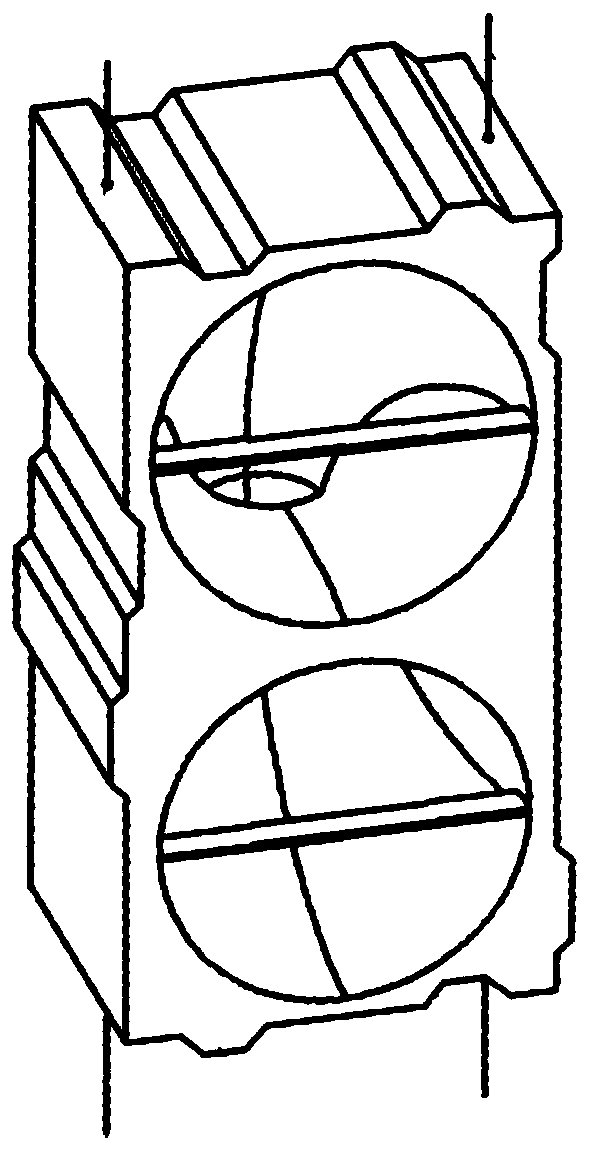

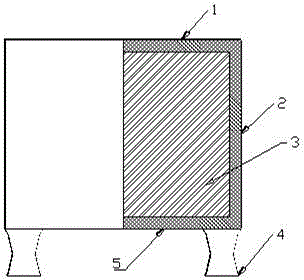

Cast-in-situ concrete filling component

A cast-in-situ concrete filling component comprises a sealing cover plate, a peripheral side face, a lower bottom plate and filling materials, and is characterized in that the filling materials are arranged in a cavity with an opening, the cavity is defined by the lower bottom plate and the peripheral side face, the opening of the cavity defined by the lower bottom plate and the peripheral side face is connected with the sealing cover plate, and the sealing cover plate, the peripheral side face, the lower bottom plate and the filling materials are sealed and overlapped to form a whole solid; a shell defined by the sealing cover plate, the peripheral side face and the lower bottom plate contains at least one of or more than one of or all of cement concrete, early strength agents, accelerating agents, sodium silicate, cellulose ether, polycarboxylate-type high-performance water reducing agents and polymer anti-crack mortar; the filling materials are formed by AB foam forming stearin and polyphenyl boards in a coextrusion mode. In addition, a protruding fixed component can be arranged on the face of the lower bottom plate according to the technological base or a formwork stretching outwards is arranged on the side face of the periphery of the lower bottom plate or chamfers are arranged along the periphery of the lower bottom plate and the periphery of the sealing cover plate. The cast-in-situ concrete filling component has the advantages of being easy and convenient to install, high in production efficiency, low in construction cost, high in seismic crack resistance and crush resistance, high in surface hardness and the like.

Owner:陈风平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com