Heat exchanger

A technology of heat exchangers and grooves, which is applied to heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., and can solve problems such as leakage and openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

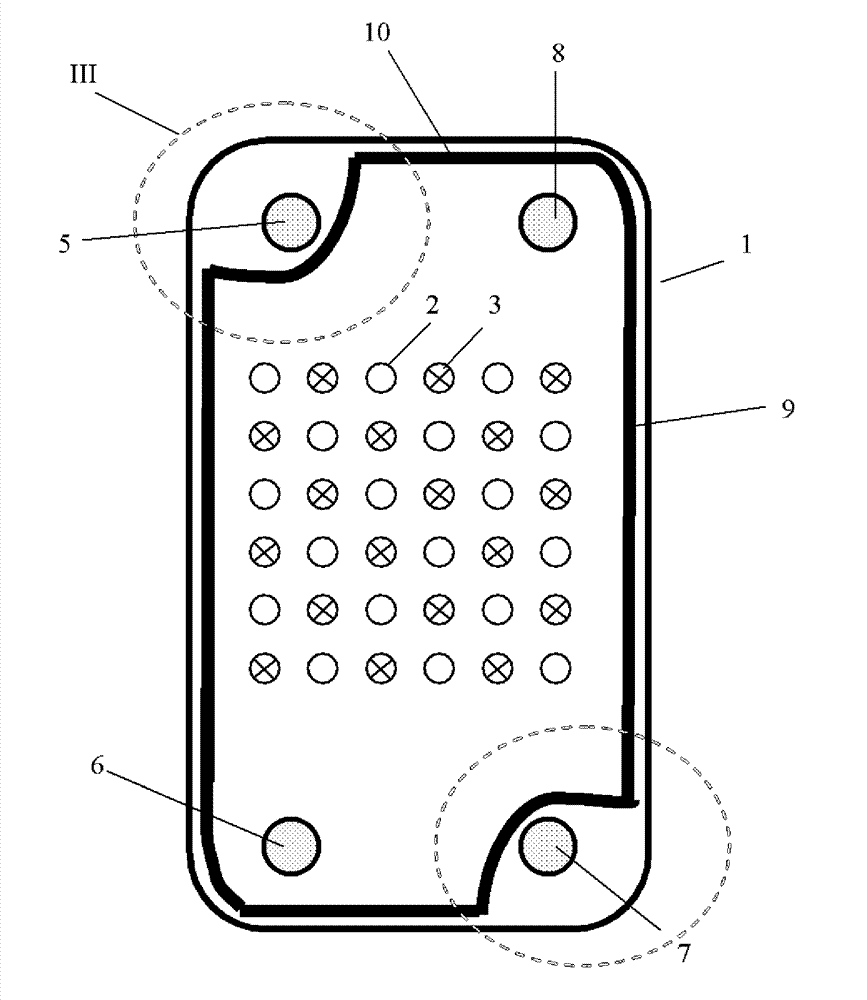

[0027] figure 1 A heat exchanger plate 1 is shown. The heat exchanger plate 1 comprises a raised portion 2 which rises a given height above the plane of the heat exchanger plate 1 . Furthermore, the heat exchanger plate 1 includes a hollow portion 3 sunk to a given depth in this heat exchanger plate 1 . Protrusions 2 are marked with open circles, while hollows 3 are marked with crossed circles.

[0028] As is known in the art, two such heat exchanger plates 1 when stacked on top of each other form a pair of plates. Two such adjacent plates will usually be shaped slightly differently so that when they are stacked, the raised portion 2 of one plate fits into the hollow portion 3 of the adjacent plate, and so on.

[0029] Flow paths are formed in these pairs in this way. Usually the flow paths formed on one side of the heat exchanger plate 1 will belong to the first flow path and the flow paths formed on the opposite side will belong to the second flow path which is sealed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com