Leather repair machine and repair method thereof

A repair method and repair machine technology, applied in the field of leather repair, can solve problems such as narrow operating space and low dermatoglyphic simulation, and achieve the effects of increasing operating space, fast temperature transfer, and accurate and rapid repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

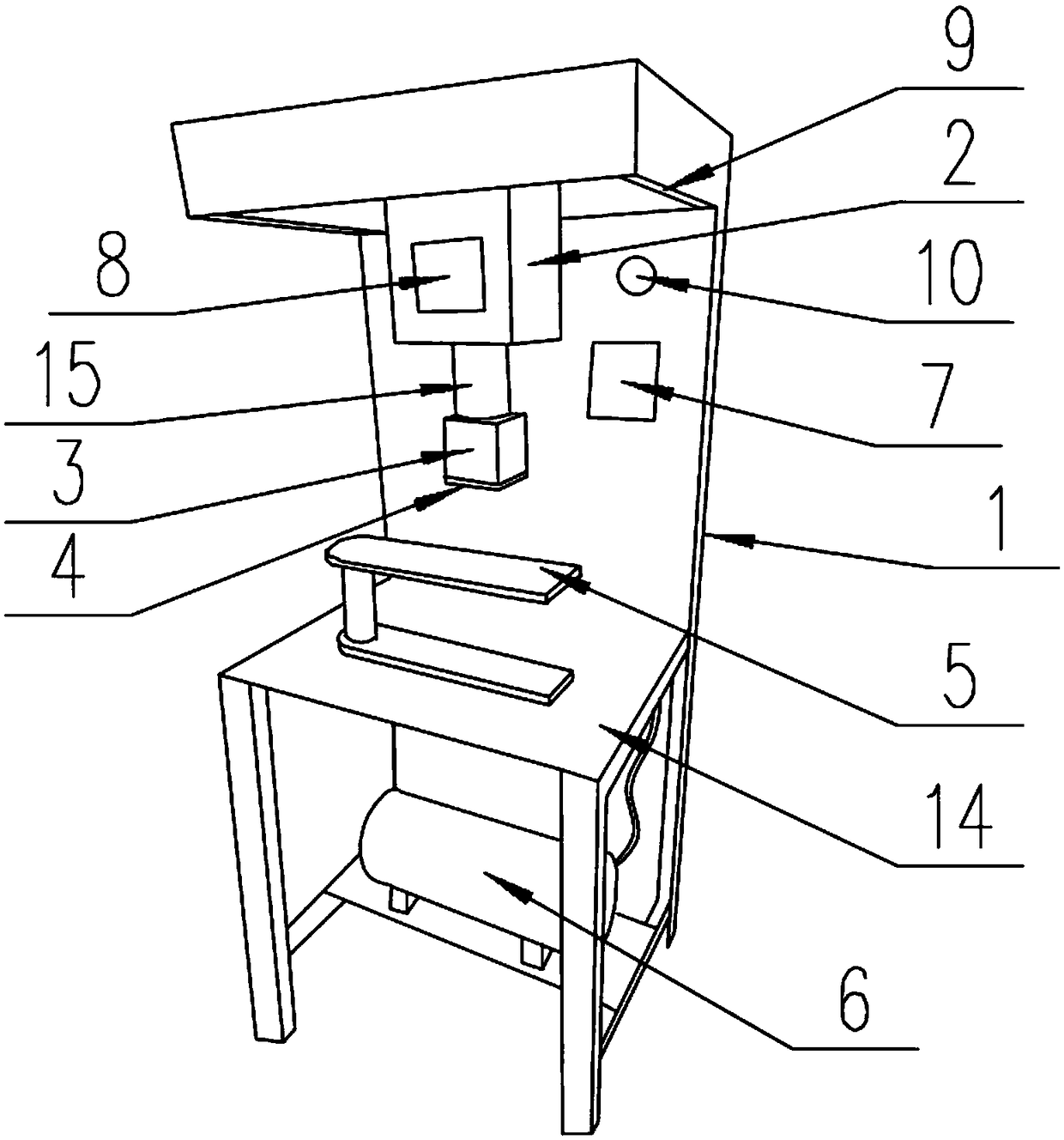

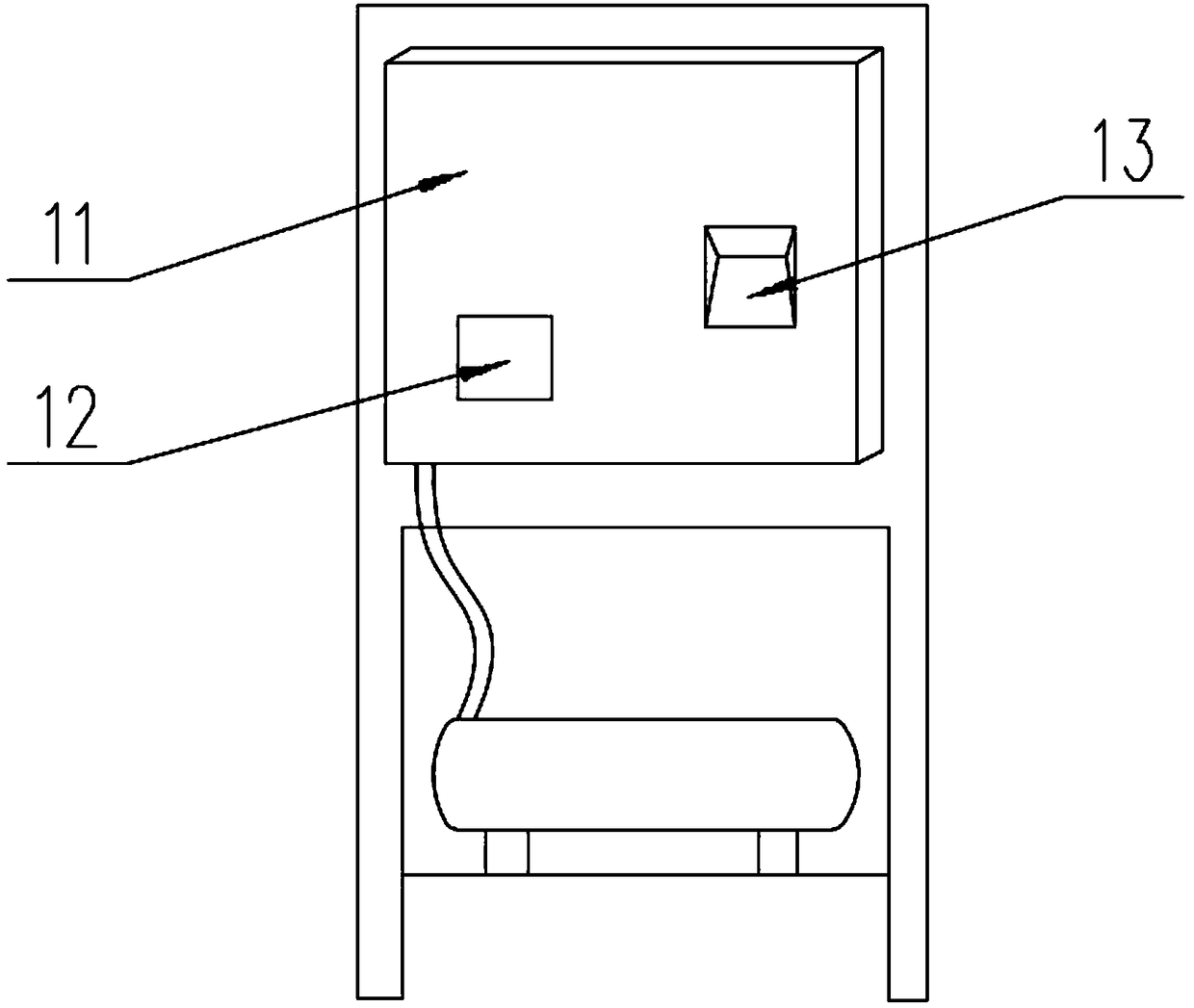

[0026] refer to figure 1 , the present embodiment provides a leather repairing machine, comprising: a repairing machine body 1, a temperature and pressure regulating device 2, an I-shaped frame 5 and a pneumatic device 6, and the temperature and pressure regulating device 2 is located at the upper end of the repairing machine body 1 and on the repairing machine body The upper end surface of 1 moves in all directions, the pressure head 3 is set under the temperature and pressure adjustment device 2 through the telescopic assembly 15, the heater 4 is set under the pressure head 3, and the I-shaped frame 5 is placed on the operation table 14 of the repair machine body 1 Above, the pneumatic device 6 is arranged under the main body 1 of the repairing machine, and the pneumatic device 6 provides kinetic energy for the temperature and pressure regulating device 2 .

[0027] Further, the repair machine body 1 is provided with a thermostat 7 and a main power switch 10, the thermostat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com