TIG welding gun

A welding gun and mandrel technology, which is applied in the characteristics of electrodes, welding equipment, arc welding equipment, etc., to achieve the effect of high speed, large welding penetration and high welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

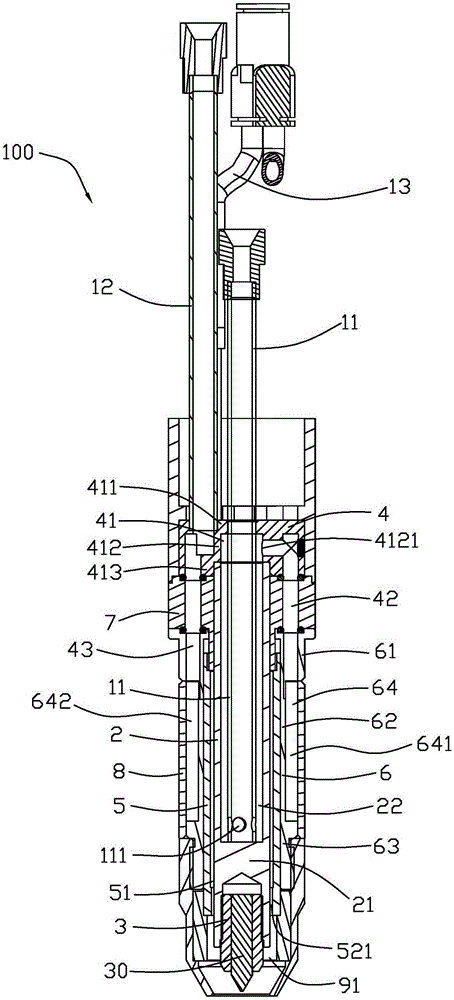

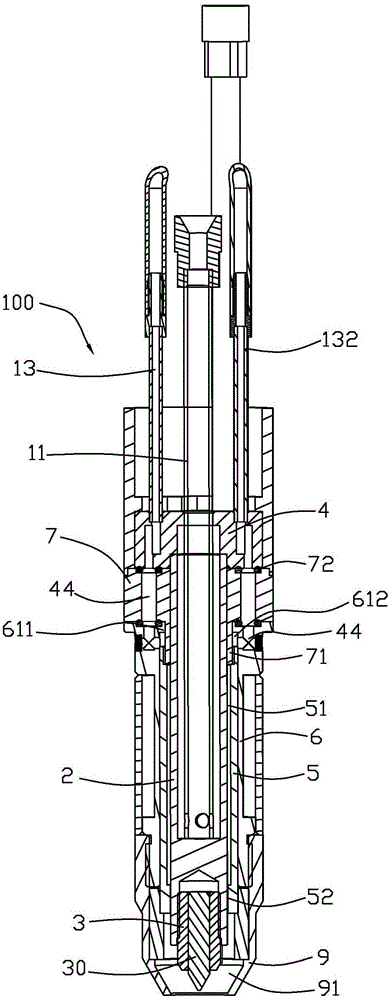

[0021] Please refer to Figure 1 to Figure 4 Shown is a first preferred embodiment of a TIG welding torch 100 of the present invention. The TIG welding torch 100 of the present invention includes a hydroelectric tube 11 located at the axial center, a core rod 2 arranged on the periphery of the hydroelectric tube 11, a tungsten pole clip 3 fixed on one end of the core rod 2, and a tungsten electrode 30 fixed on the tungsten pole clip 3 , the other end of the core rod 2 is fixedly connected to the conductive connection seat 4 of the water pipe 11, the inner insulating sleeve 5 set on the outer periphery of the core r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com