Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Save filling material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

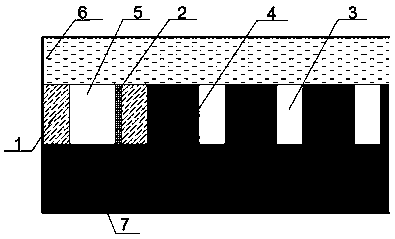

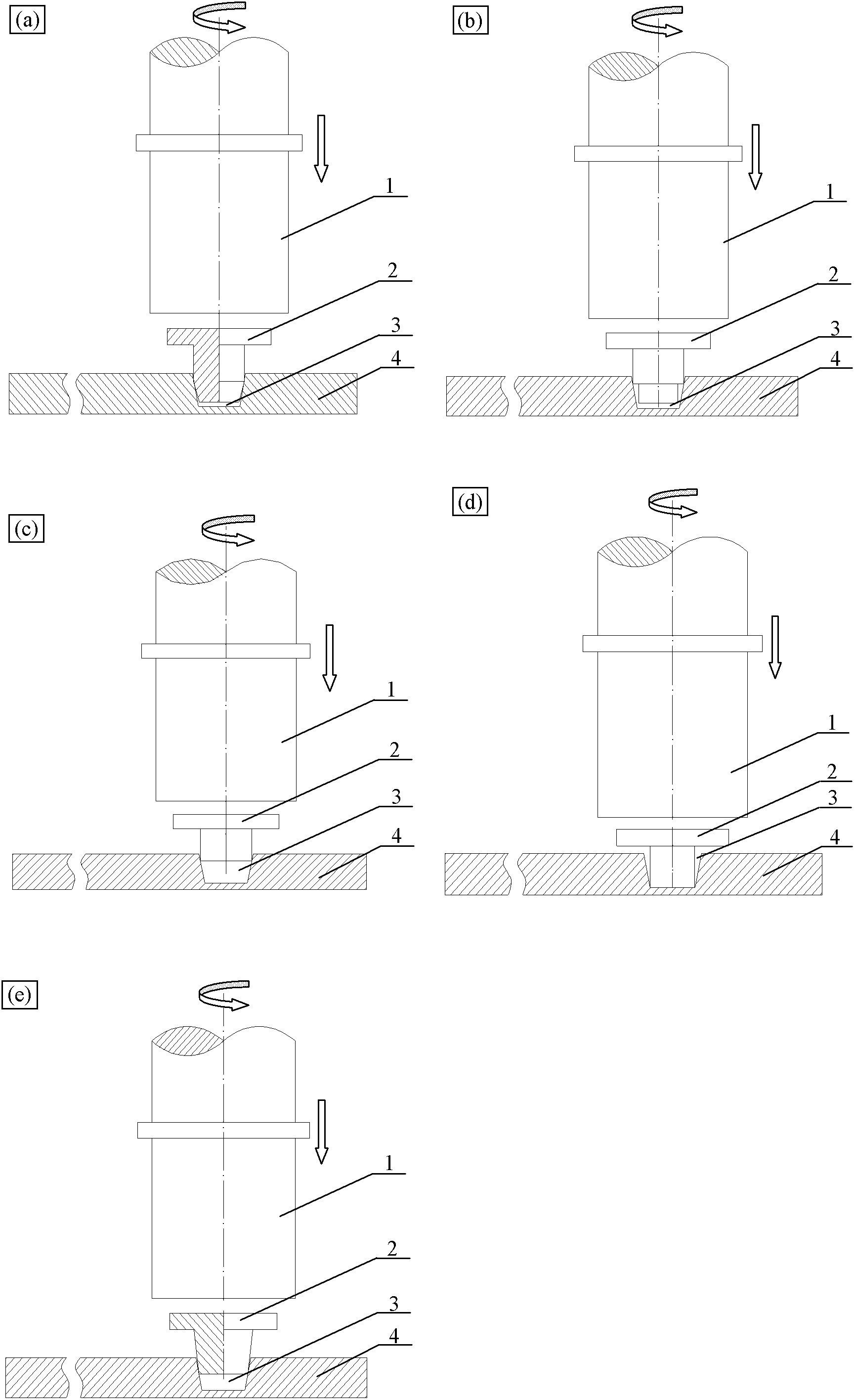

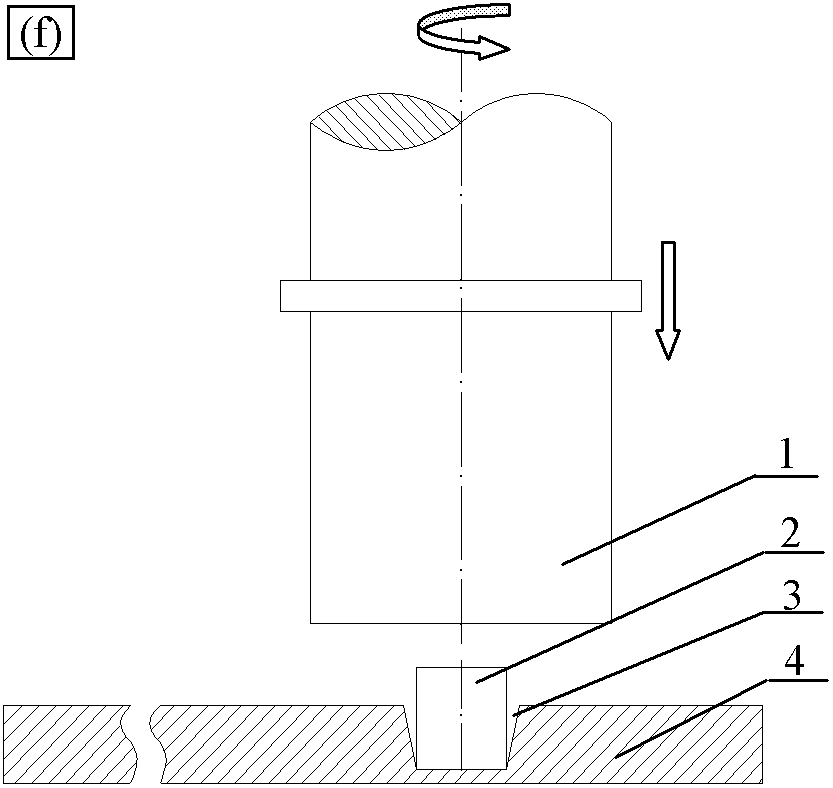

Method for filling friction stir welding keyhole by using T-shaped filling block and bitless stirring head

InactiveCN102500915ASimple designPreset operation is convenientWelding/cutting media/materialsSoldering mediaFilling materialsEngineering

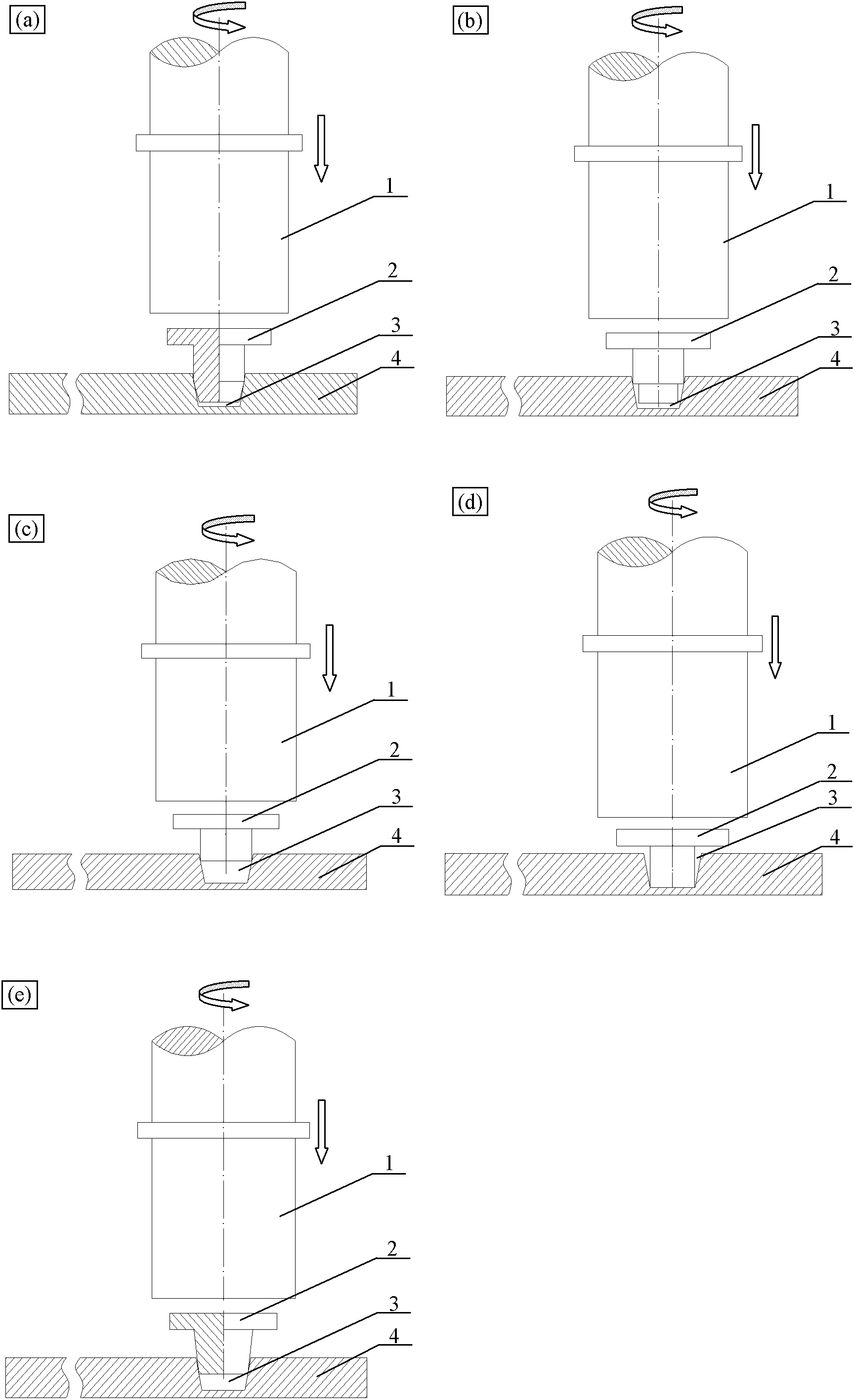

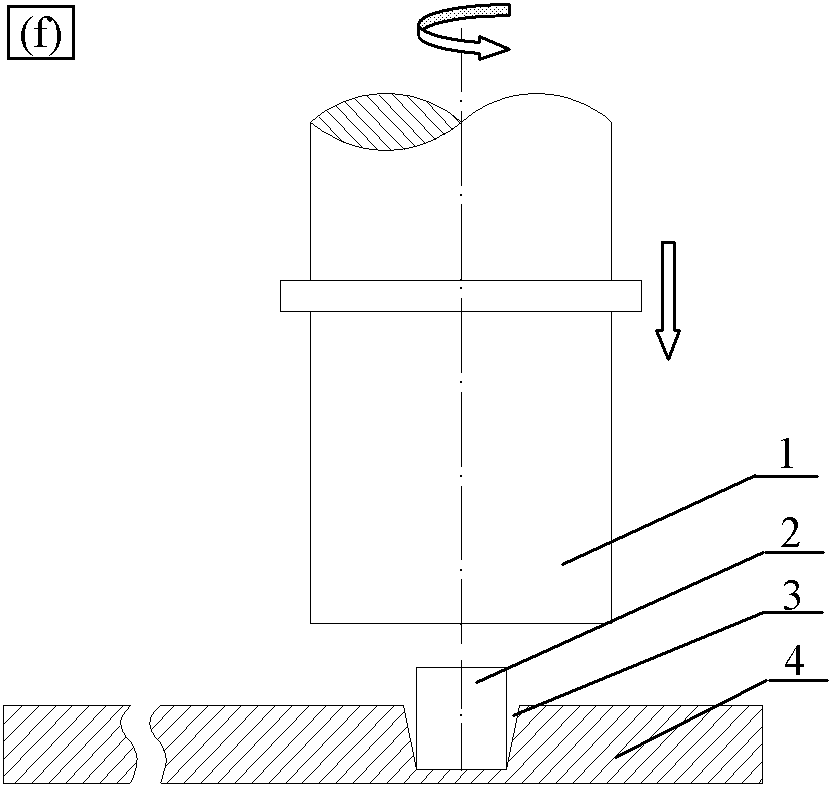

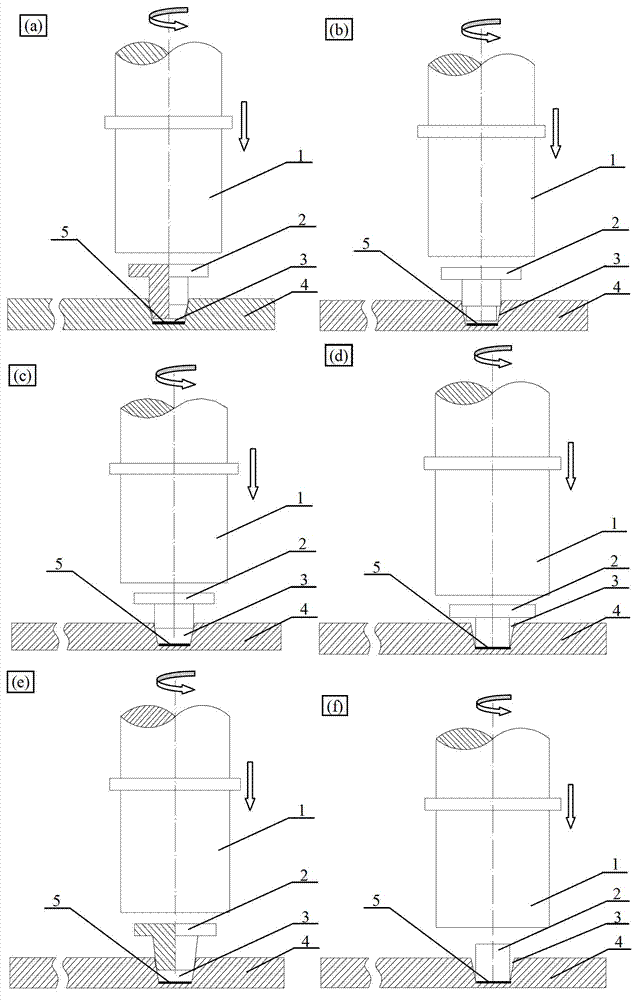

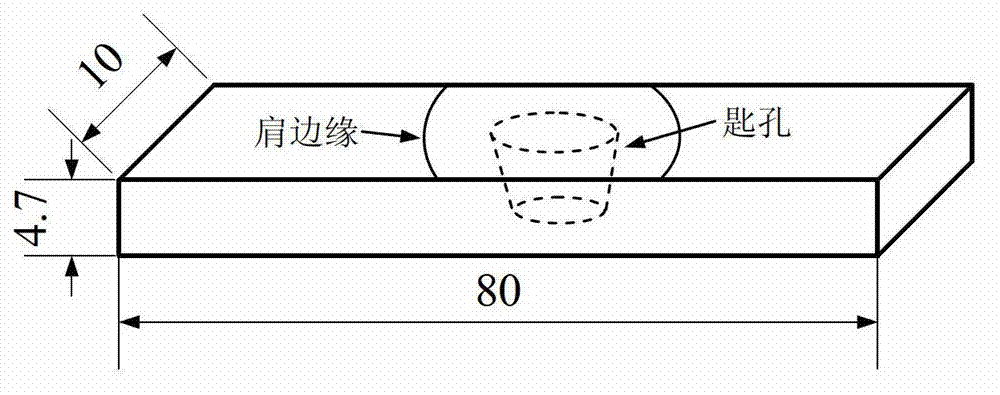

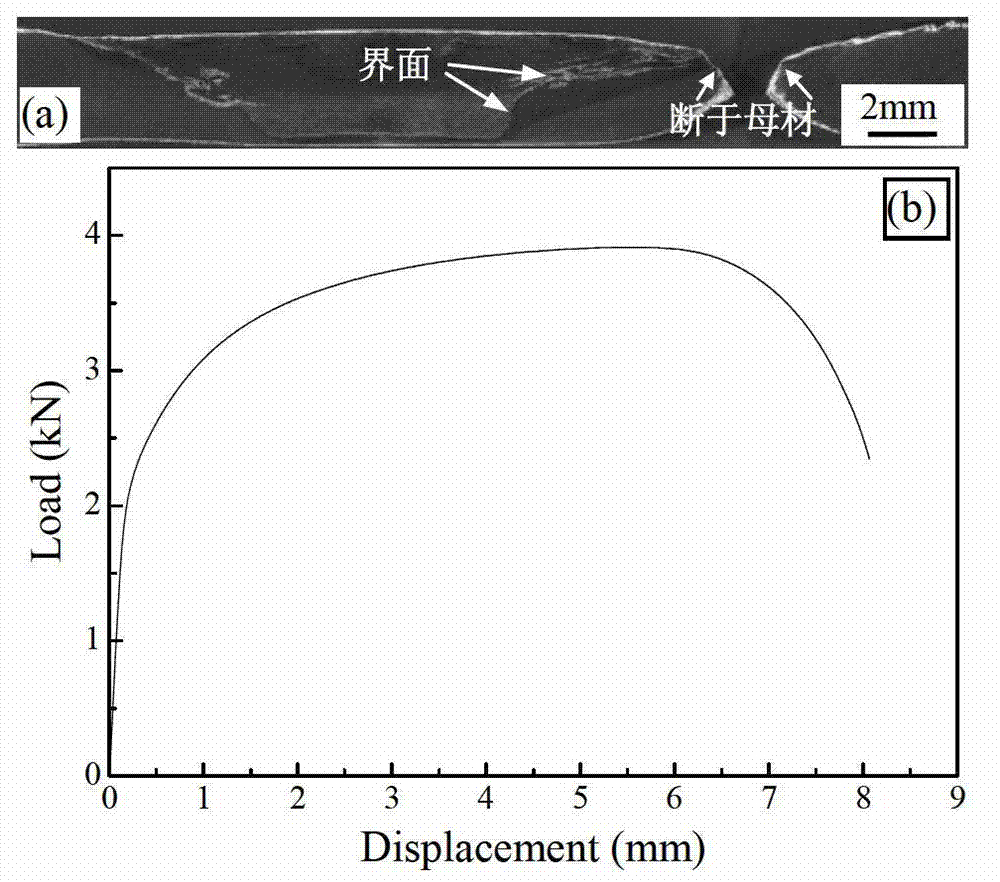

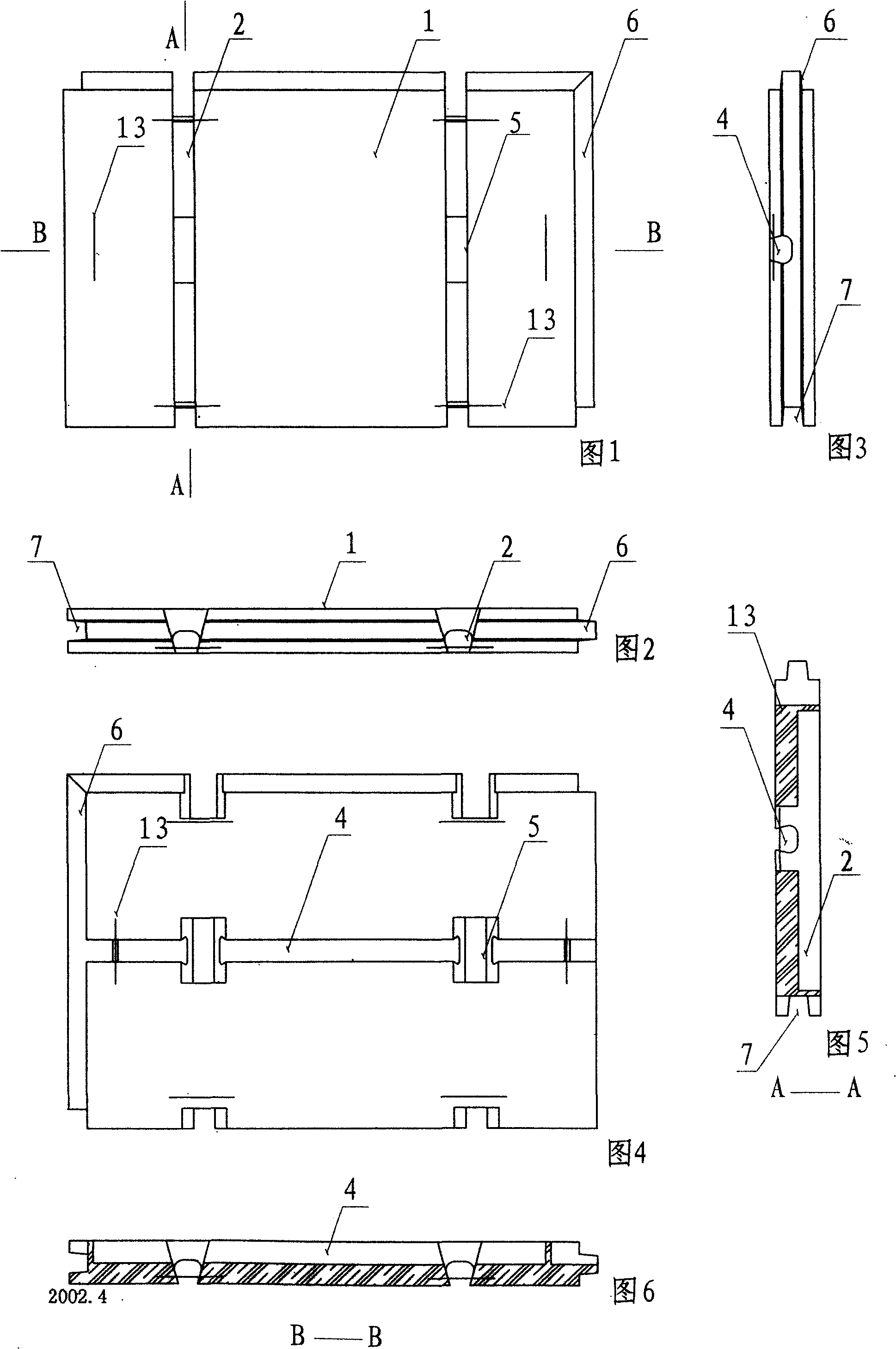

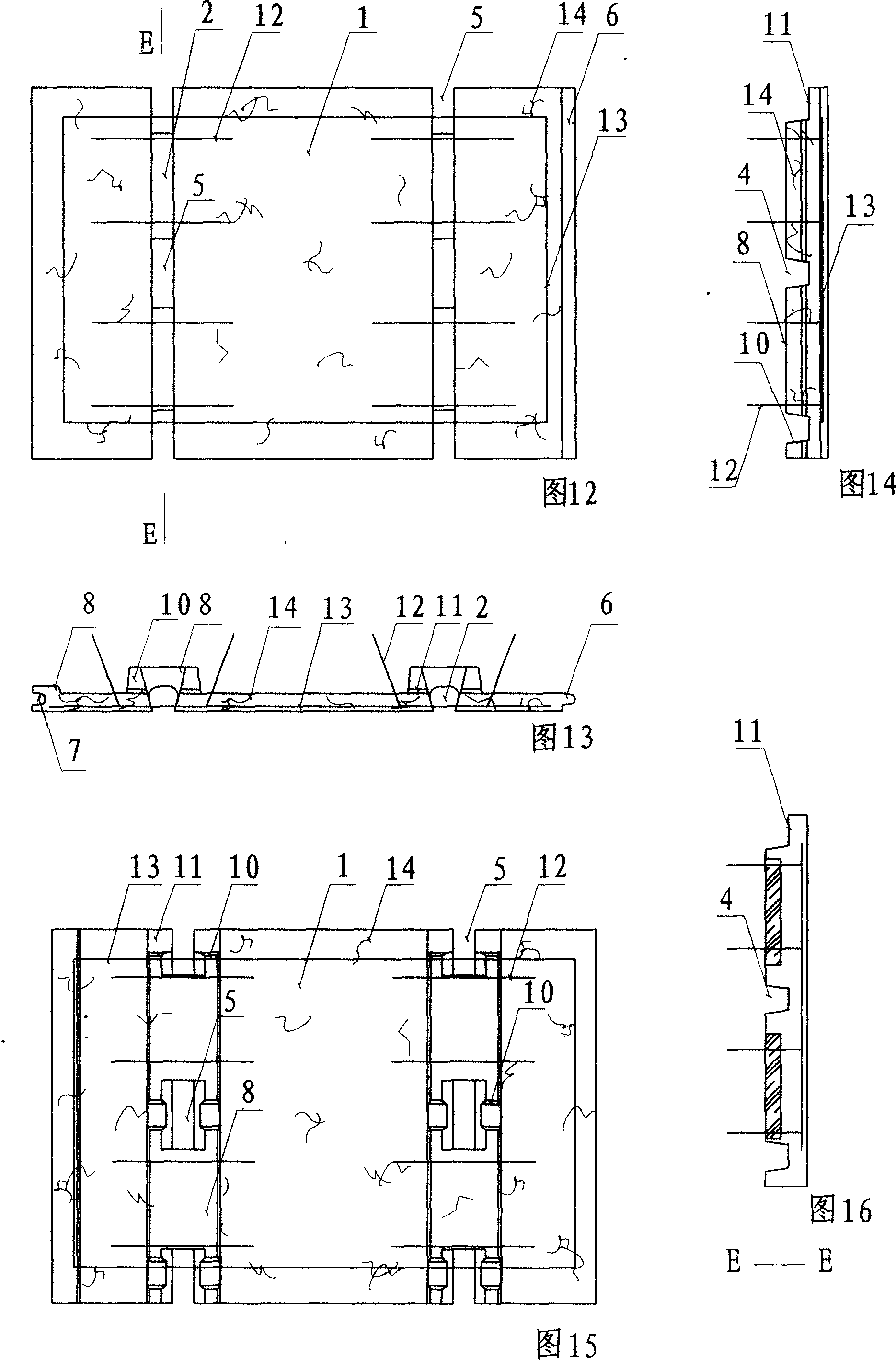

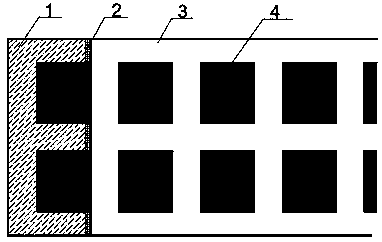

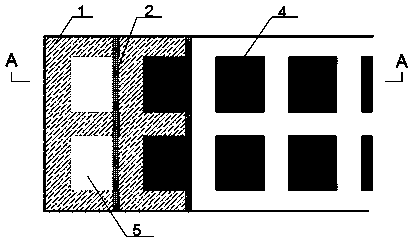

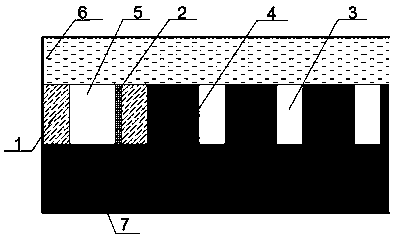

The invention discloses a method for filling a friction stir welding keyhole by using a T-shaped filling block and a bitless stirring head. The method comprises the following steps of: (1) performing chambering on the upper part of the friction stir welding keyhole, machining to form a table conical shape of which the upper side is wide and the lower side is narrow, and precleaning the inner wall of the friction stir welding keyhole; (2) preparing the T-shaped filling block; (3) prearranging the T-shaped filling block in a table conical hole, so that a T-shaped endshield is exposed with a certain height; (4) starting the bitless stirring head to rotate and press, so that the T-shaped filling block is subjected to rotary extrusion towards the keyhole; (5) when the stirring head is pressed to be flush with upper surfaces of workpieces to be subjected to repair welding basically, performing in-situ friction for a certain time; and (6) removing trimmings, so that the filling surface is smooth and beautiful. The method has the advantages that: tools (bitless tools) are easy to design and manufacture, the tools are not needed to be replaced when the keyholes are repaired in batch, the filling material is saved, the keyhole is not thinned or is thinned slightly after being welded, and membranes of the side wall and the bottom are well removed, so that the side wall and the bottom can be combined compactly. The method also can be used for repairing defects of casting surfaces and weld joints.

Owner:XI AN JIAOTONG UNIV

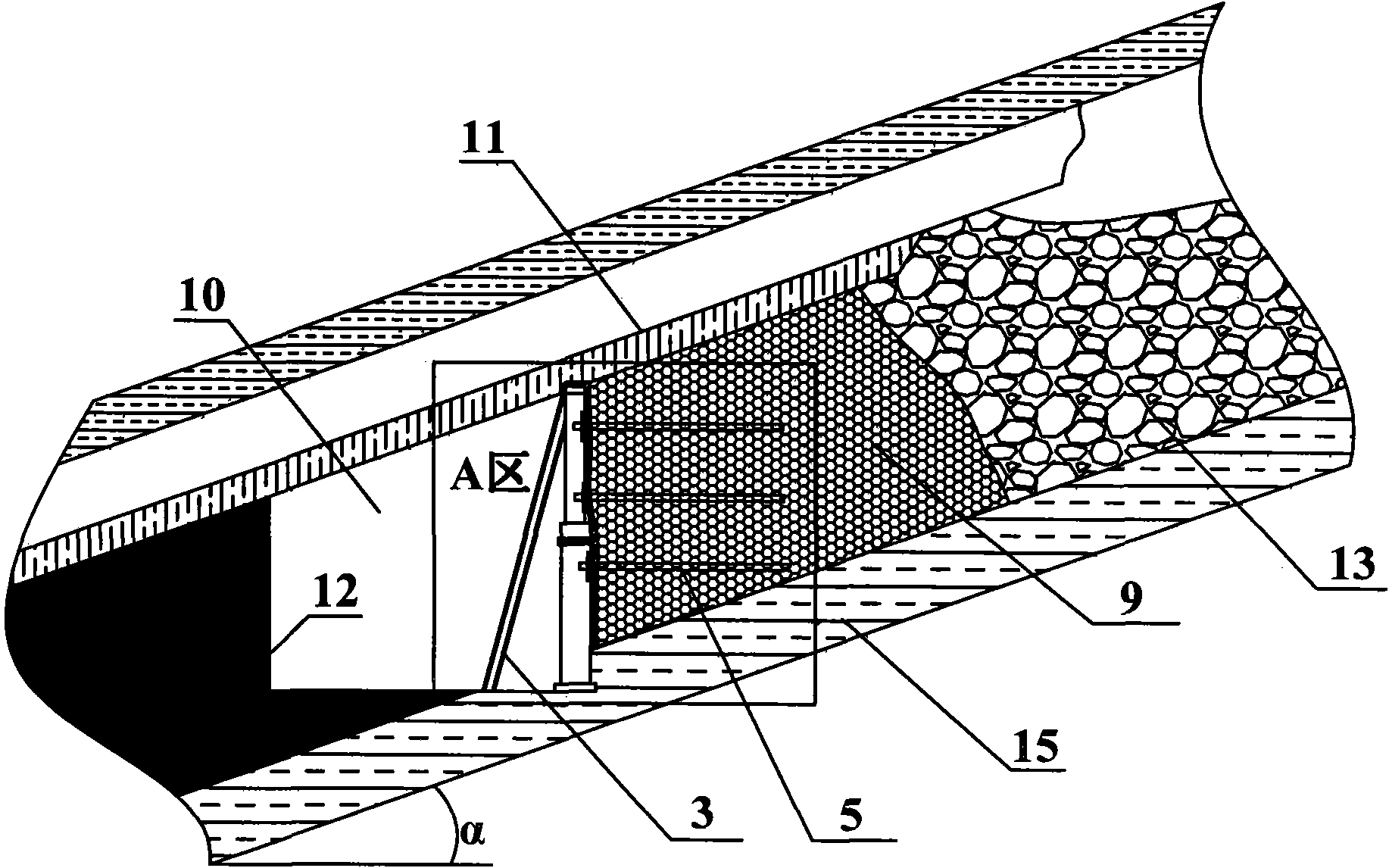

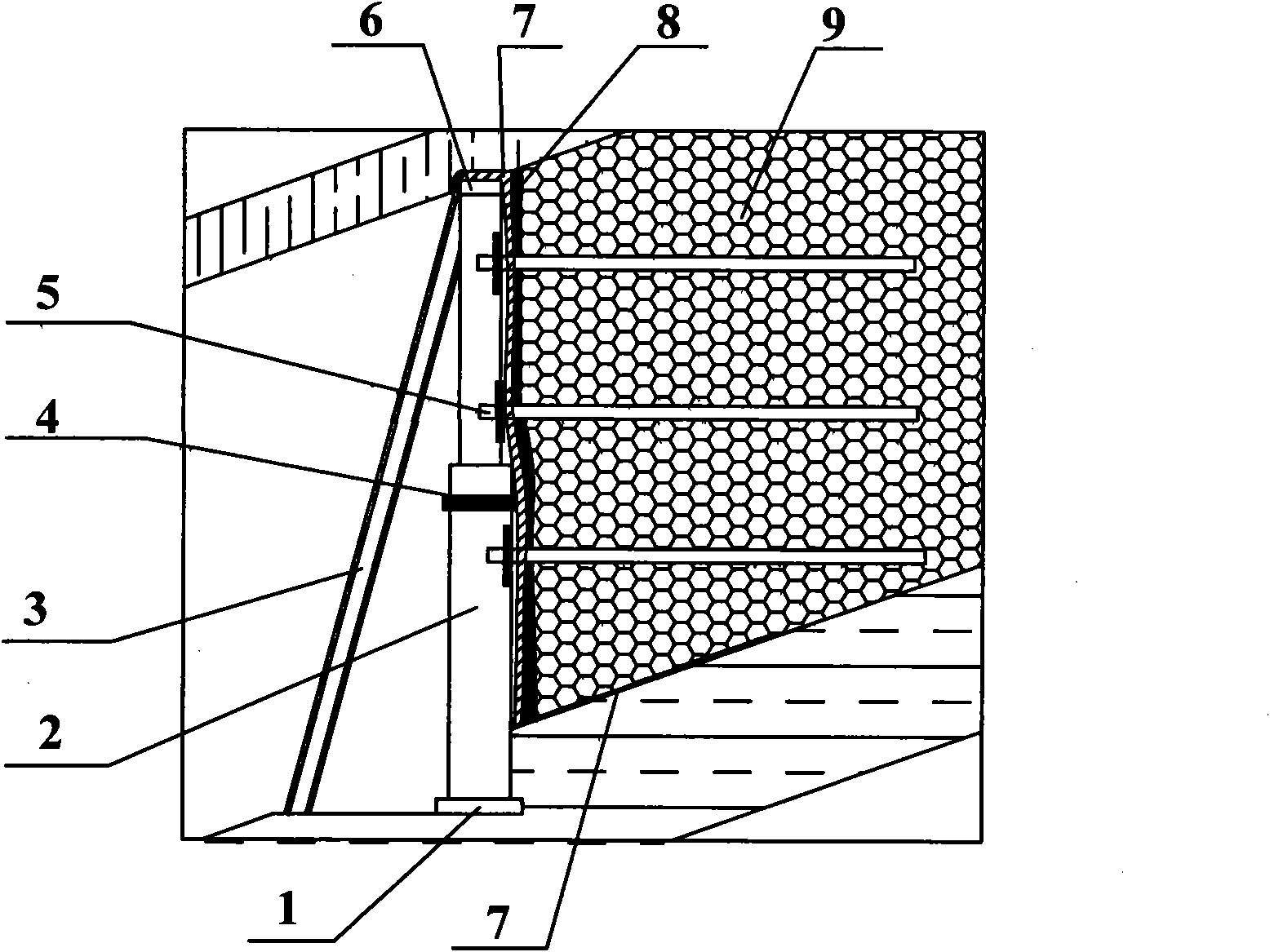

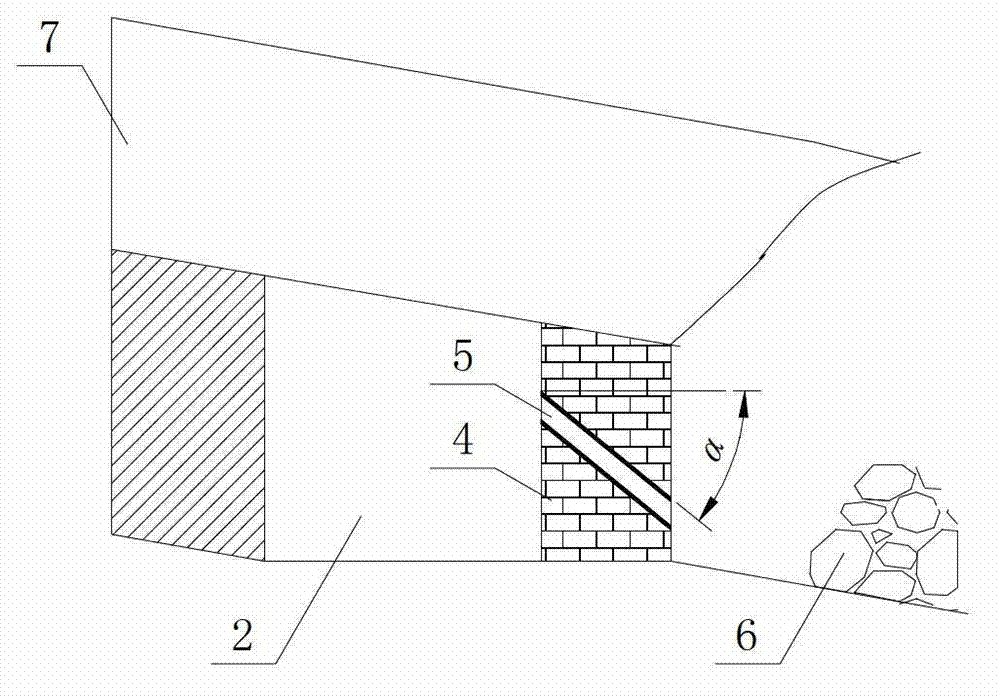

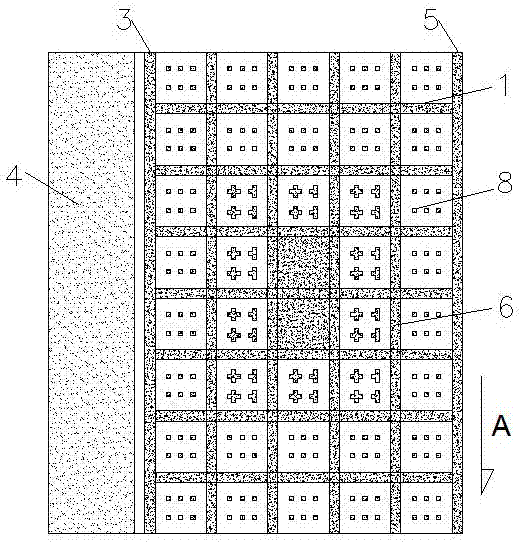

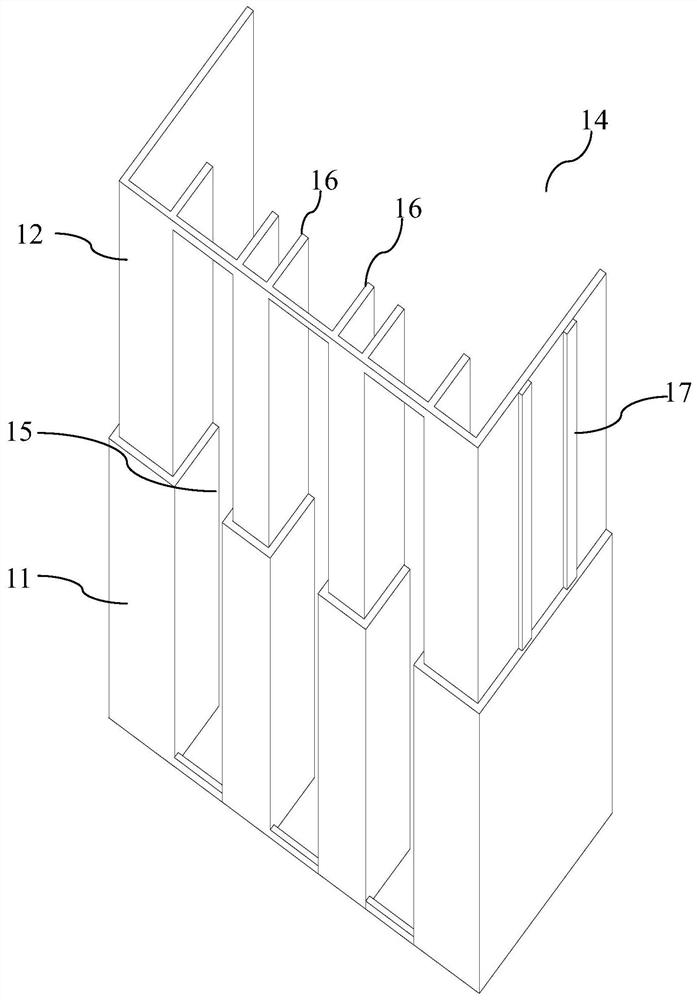

Building method of filled wall body for gob-side entry retaining of large-inclination coal seam

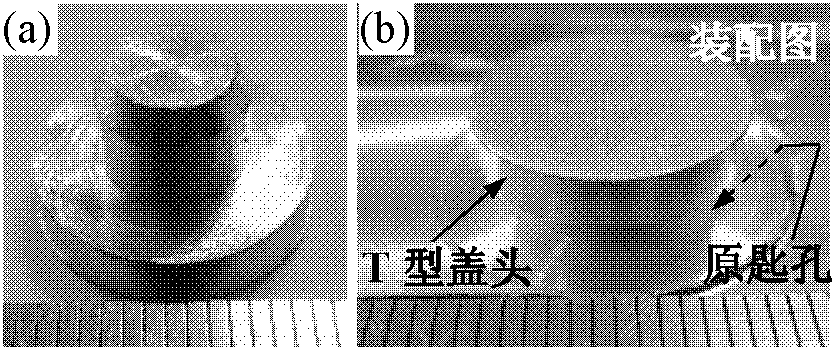

The invention relates to a building method of a filled wall body for gob-side entry retaining of a large-inclination coal seam, which comprises the following steps: erecting dense individual props on the entry retaining side on the rear part of a heading stope to retain roadway space on the rear part of the heading stope, erecting anti-tilting side supports along the dense individual props, laying reinforcing fabric and high-strength fiber cloth on the side of the dense individual props close to the gob, and building a structure used for intercepting waste rocks in the gob; and when the dropped waste rocks in the gob automatically slide along the large-inclination footwall to the waste rock blocking structure formed by the reinforcing fabric and the high-strength fiber cloth under the effect of the dead weight and pile up to a certain degree, grouting and cementing part of the dropped waste rocks near the entry retaining side for consolidation, thereby forming the filled wall body, and repeating the steps in sequence along with the advancement of the heading stope until the whole filled wall body for gob-side entry retaining. The invention has the advantages of simple method and high working efficiency, the filled wall body built in the method is of high strength and is also economical and practical, and the method is suitable for the building of the filled wall body for gob-side entry retaining under the high-inclination condition.

Owner:CHINA UNIV OF MINING & TECH

Method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of welding keyhole

InactiveCN103071911AAvoid smallImprove liquidityNon-electric welding apparatusFilling materialsBraze alloy

The invention discloses a method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of a welding keyhole. The method comprises the following steps that brazing alloy is preset in a keyhole, then a stuffing block is added in the keyhole, a T-typed stuffing block is subjected to rotation and friction through a needleless stirring head and is compressed down, the brazing alloy is heated to be softened, liquid brazing alloy is extruded and stirred by the stuffing block in an enclosed environment formed by the keyhole and the stuffing block, the liquid brazing alloy is stuffed in a driving and flowing way, and the liquid brazing alloy is enabled to be filled into a gap on the bottom of the keyhole; and due to the property of non-compression of the liquid brazing alloy, the liquid brazing alloy back flows along a side wall interface upward to stuff the remaining gap of the side wall, the side wall interface is dissolved, and compact alloying of the side wall and the bottom interface is realized. When the welding keyhole is repaired in batches, the replacement of tools is not needed, reduction of a welded keyhole does not exist or is extremely small, stuffing materials are saved, preset operation of the brazing alloy and the stuffing block is convenient, and the shaping of a surface of a stirring area is smooth.

Owner:XI AN JIAOTONG UNIV

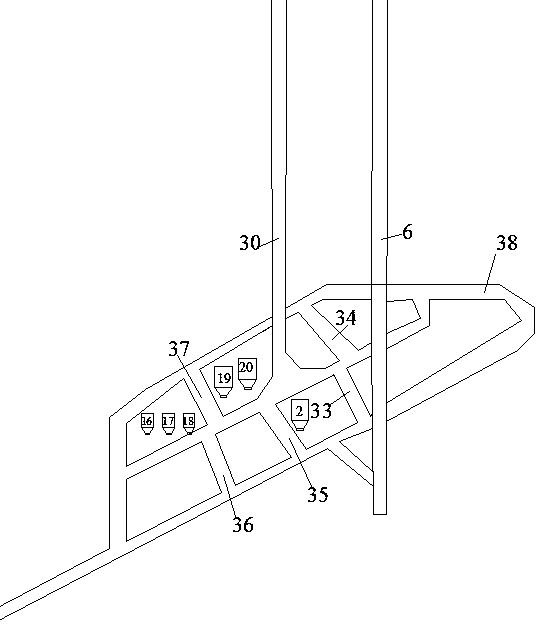

Interval skip-mining type filling coal mining method

InactiveCN103883350AIntegrity guaranteedReduce exerciseUnderground miningSurface miningFilling materialsSequential mining

The invention provides an interval skip-mining type filling coal mining method and belongs to the technical field of coal mine filling coal mining methods. The interval skip-mining type filling coal mining method comprises the steps that a first open-off cut is dug at the tail end of a butt entry, a second open-off cut is dug a certain distance away from the first open-off cut, and mining is conducted at the position of the second open-off cut with the wall type system coal mining method after the second open-off cut is well dug; a third open-off cut is dug a certain distance away from the second open-off cut, a gob formed after mining is conducted at the position of the second open-off cut is filled while the third open-off cut is dug, and the rest operation is conducted by analogy till mining is conducted on a mining stopping line. By the adoption of the interval skip-mining type filling coal mining method, mining can be conducted under the condition that the two ends are supported, sequential mining and sequential filling are achieved, the integrity of a base plate of a roof is guaranteed, movement of overlying rock is reduced, and the purpose of surface subsidence control is achieved; after mining with filling is completed, coal pillars left after mining do not need to be filled, filling materials are reduced, and filling cost is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

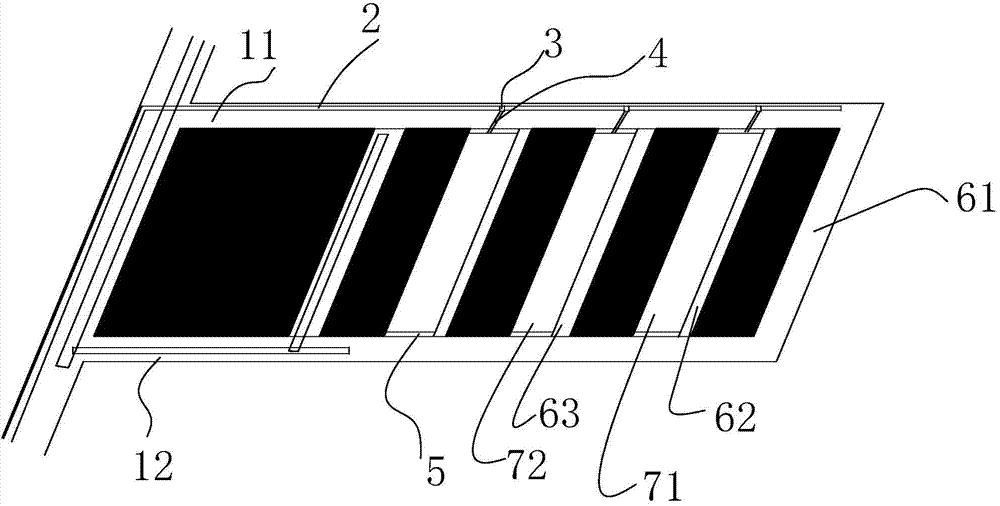

Gob-side entry retaining method using high-water material filling columns

InactiveCN102852551AAuxiliary transport volume is smallEasy constructionMaterial fill-upFilling materialsSlurry

A gob-side entry retaining method using high-water material filling columns belongs to the field of mine supports. With advancing of actual mining working faces, filling column structures are produced near end hydraulic supports at designed intervals, and two to three single hydraulic supports are fixed on the periphery of each filling column structure to assist forming of filling columns; and evenly-mixed high-water material slurry is filled into constructed filling column structures, and the single hydraulic supports are removed 4 hours after the filled slurry solidifies to finish construction of the filling columns. Road-side supports are formed by the filling columns in a row, the roadway is retained, and gob-side entry retaining is achieved. By the method, a huge amount of filling materials is saved, downhole auxiliary transport amount is low, and cost is low. The constructed filling columns are simple in construction and high in bearing capacity. An operator can operate below a top plate supported by bolt-mesh-cable in the roadway without entering a gob, and accordingly safety and reliability are high.

Owner:CHINA MINING & CIVIL NEW MATERIAL SCI & TECH LTD

Obligate cavity channel gob-side entry retaining wall filling method

ActiveCN103089299APlay a supporting roleSupport does not affectMaterial fill-upUltimate tensile strengthRetaining wall

An obligate cavity channel gob-side entry retaining wall filling method is characterized in that a cylinder hole is obligated on a formwork, a thin-wall steel cylinder penetrates through the formwork, a lane is located on the high position, a goaf area us located on the low position, a filling wall with a cavity is formed after filling, wall using materials are reduced, and wall strength is not influenced. An open-close door is installed at the hole opening, when the lane deforms, cannot normally use and needs to conduct dinting, a large quantity of gangue produced after lane dinting can be thrown to the inside by opening the door, and the lane is distributed in an air return along groove. Due to existence of a coal bed pitch, inbreak gangue surges up the goaf area of the transportation along grooves under the effect of gravity, in addition, side direction breaking is carried out on the top plate during caving, a lateral breaking angle is formed, a space at a button angle of the filling wall enables the inbreak gangue to be unable to achieving a filling area, a great quantity of spaces are left on the filling wall side, throwing gangue directly enters the goaf area under the effect of gravity, and deposit spaces are provided for processing undercover gangue.

Owner:CHINA UNIV OF MINING & TECH

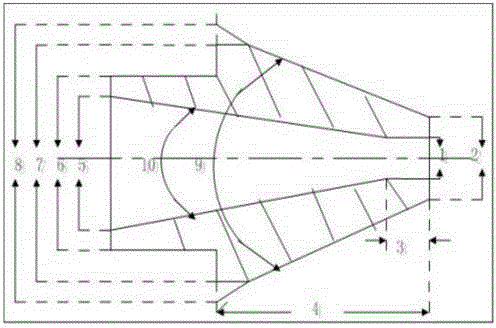

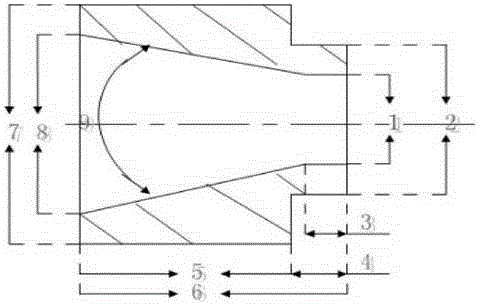

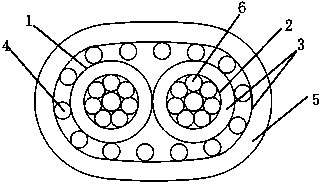

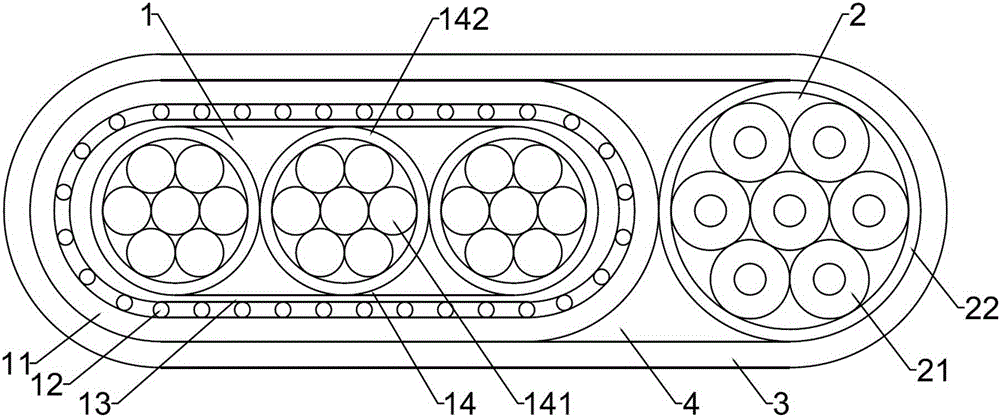

Extrusion-type mold and method for preparing special-shaped conductor cable by extrusion-type mold

InactiveCN103600481ALow costReduce the cost of qualityInsulated cablesDetails of conductive coresElectrical conductorEngineering

The invention discloses an extrusion-type mold for rubber insulated cable extrusion and a method for preparing a special-shaped conductor cable by the extrusion-type mold, and belongs to the technical field of wire cable manufacture. Through the extrusion-type mold, five types of special-shaped conductor insulated cable cores are processed to form the round special-shaped conductor cable so that unwrapping of the cable cores in compound stranding extrusion is avoided and the problem that the molded conductor cable fed to a take-up reel is easily unwrapped, so that a cable quality cost is reduced.

Owner:BAIYIN NONFERROUS GROUP

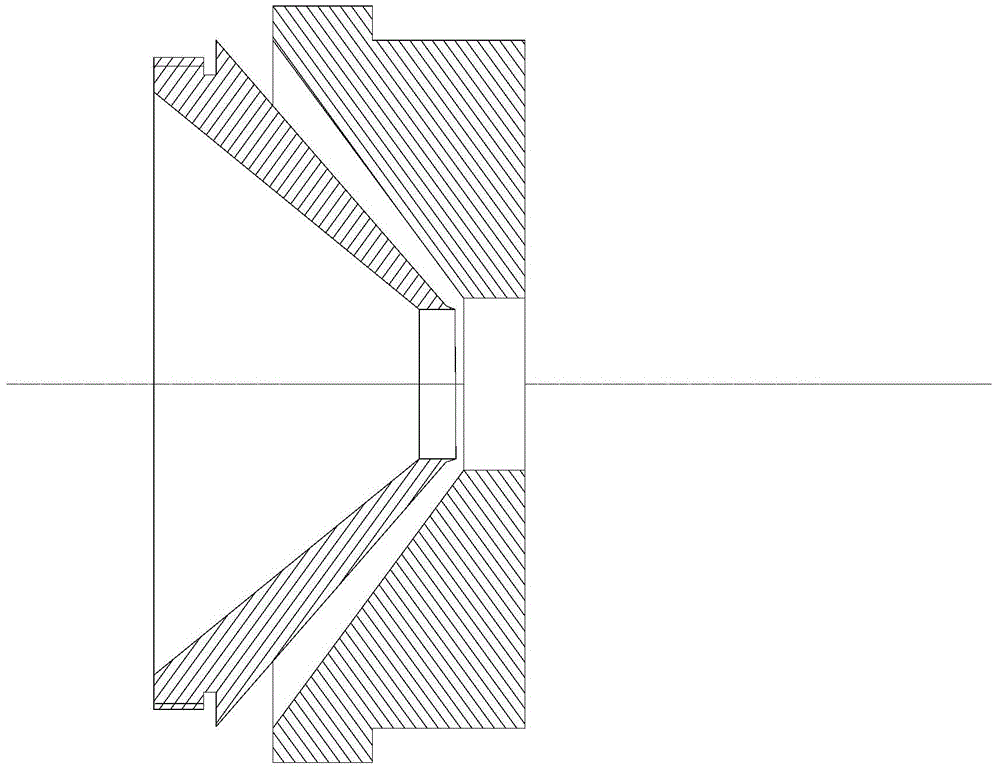

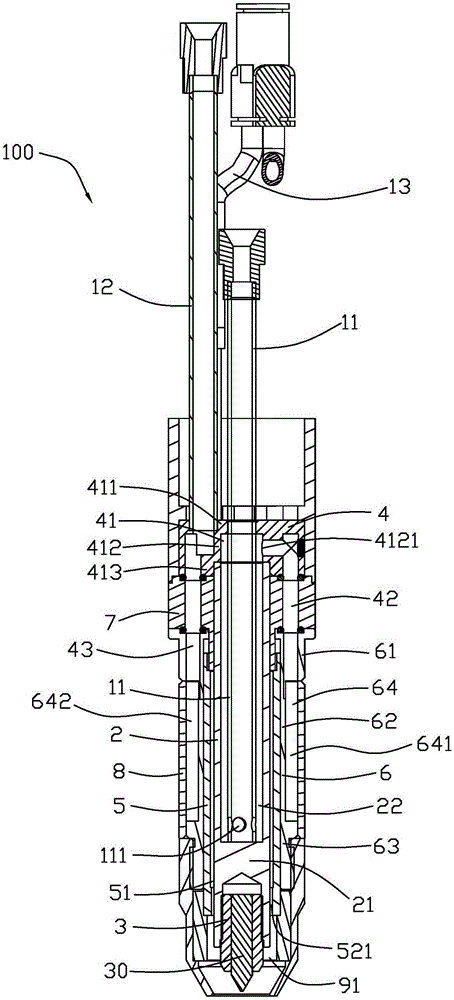

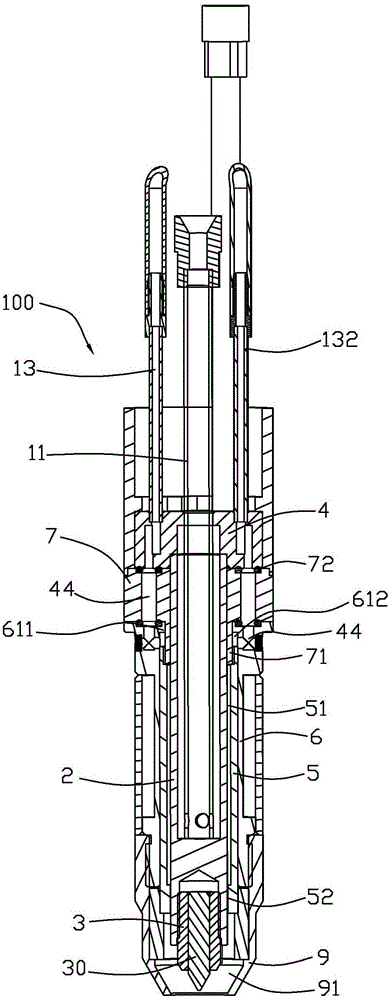

TIG welding gun

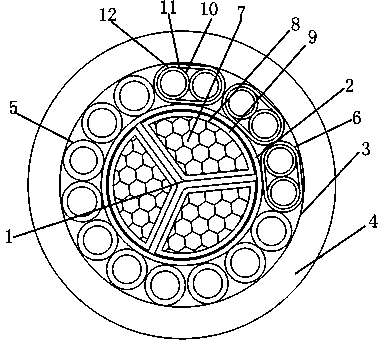

ActiveCN105171209AHigh duty cycleImprove welding qualityCooled electrode holdersElectrode accessoriesEngineeringWater cooling

The invention provides a TIG welding gun. The TIG welding gun comprises a water electric pipe positioned in the axis position, a core rod arranged at the outer periphery of the water electric pipe, a tungsten electrode clamp fixed at one end of the core rod, an electric conducting connection base fixed at the other end of the core rod and connected with the water electric pipe, a water cooling jacket arranged at the outer side of the core rod, an insulation block fixedly connected between the water cooling jacket and the electric conducting connection base in the axial direction, a shell fixed at the outer periphery of the water cooling jacket, and a water outlet pipe fixed on the electric conducting connection base. An isolation part is arranged in the core rod near the tungsten electrode clamp. The water electric pipe extends to the position of the isolation part, and is provided with a first water outlet hole penetrating through in the radial direction. A first water cavity communicated with the first water outlet hole is formed between the core rod and the water electric pipe. The electric conducting connection base is provided with a first water inlet communicated with the first water cavity. A second water cavity is formed between the water cooling jacket and the shell. The electric conducting connection base and the insulation block are formed with a first communication hole for communicating the first water inlet with the second water cavity and a second communication hole for communicating the second water cavity with the water outlet pipe.

Owner:HUAHENG WELDING

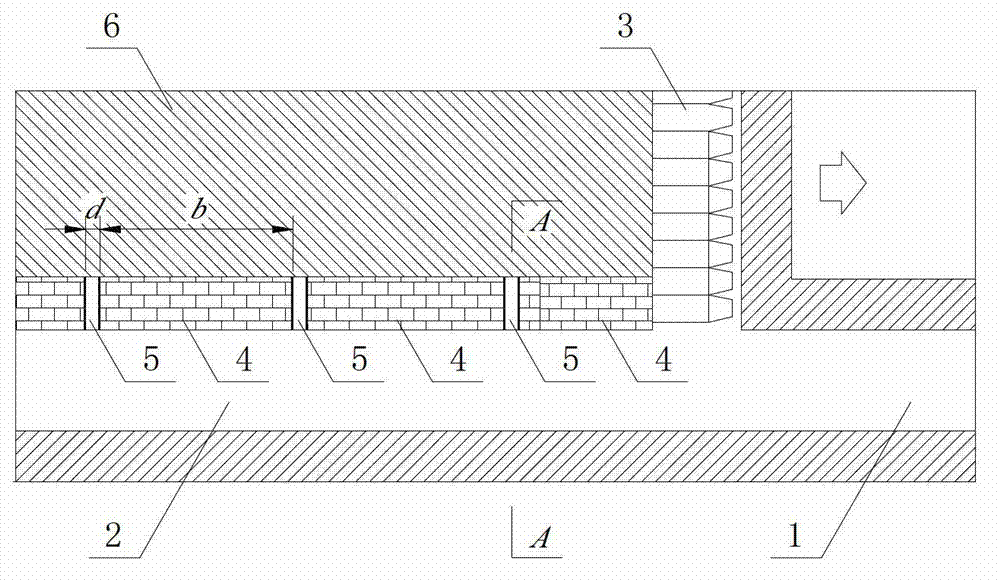

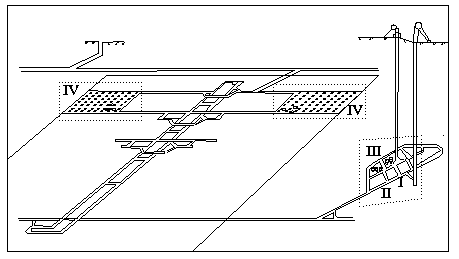

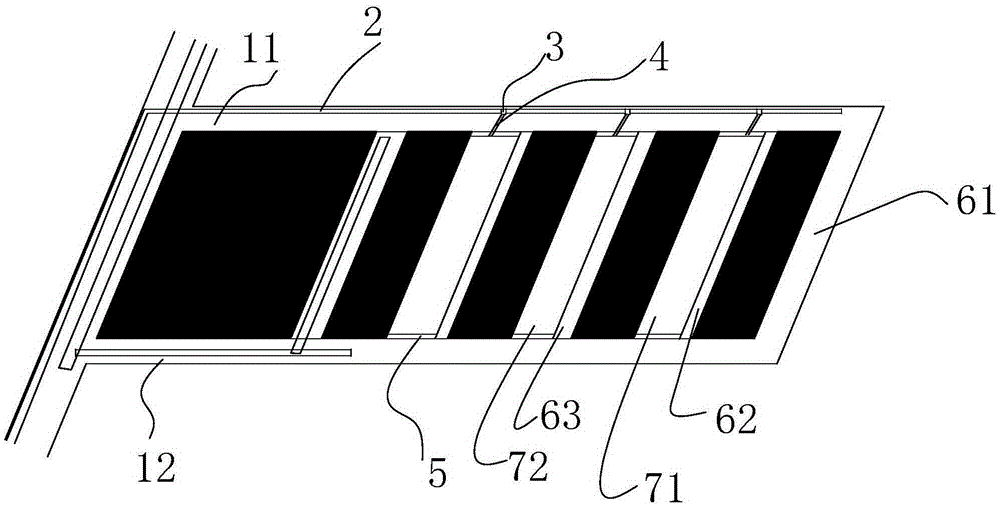

Extra-thick coal seam strip-type filling and mining method relying on steel mould trolleys

ActiveCN110259449AImprove completenessHigh degree of integrationUnderground chambersUnderground miningFilling materialsCoal pillar

The invention discloses an extra-thick coal seam strip-type filling and mining method relying on steel mould trolleys. The extra-thick seam strip-type filling and mining method is used for 'three-under' extra-thick coal seam mining. After coal seam mining, an upper layer hard roof forms a cantilever plate structure, under the cover of the stable cantilever structure, a row of steel mould trolleys arranged parallel to the stope face jointly form a strip filling template to fill a goaf closely adjacent to the stope face. According to the extra-thick coal seam strip-type filling and mining method, the traditional steel mould trolley for tunnel lining is modified, the construction technology is simplified, the planned filling space of the goaf is filled at full height at one time, and false roof laying of slicing filling is avoided; a partition wall is not needed to be constructed, partial filling can be achieved, and filling materials are saved; a mode of combining filling and mining is adopted, filling and mining are pushed forwards simultaneously, coal pillars are not needed to be reserved and arranged, secondary disturbance caused by recovering the coal pillars is avoided, the subsidence of an overlying rock is strictly controlled, and the safety of ground buildings is ensured; and standardized and high modular steel mould trolleys are selected, and can be adapted to filling spaces with various sections and reused.

Owner:TAIYUAN UNIV OF TECH

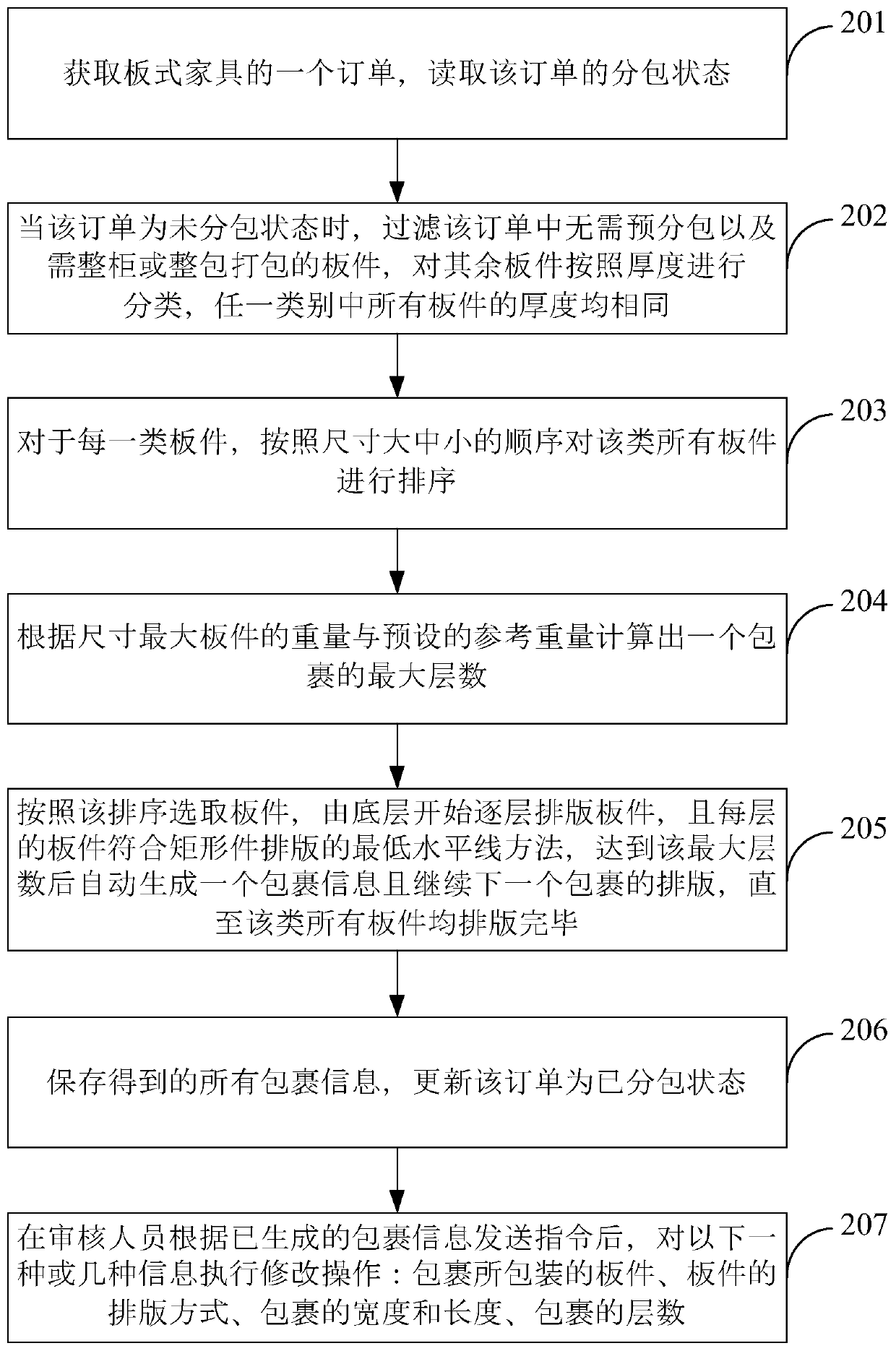

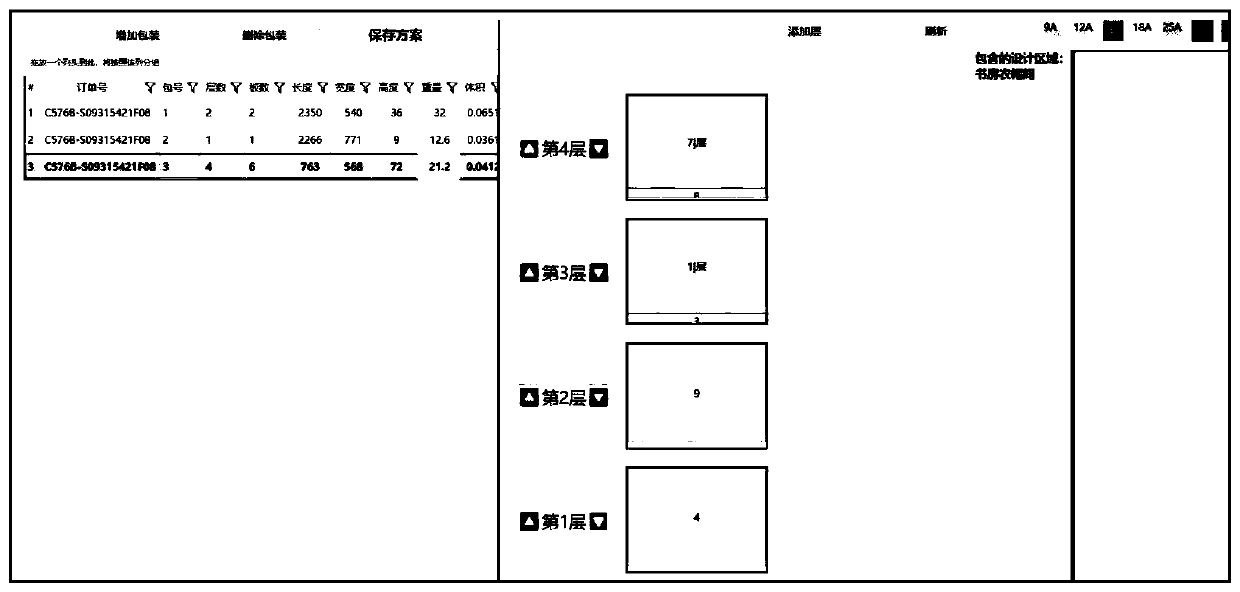

Plate intelligent subpackaging method and device

ActiveCN109795751AQuality improvementIncrease production capacityPackaging automatic controlInstrumentsOrder formIndustrial engineering

The invention discloses a plate intelligent subpackaging method and device, and belongs to the field of plate-type furniture packaging. The plate intelligent subpackaging method comprises the steps: an order of plate-type furniture is obtained, and the subpackaging state of the order is read; when the order is in an un-subpackaged state, plates not needing to be pre-subpackaged and needing to be packaged in a whole cabinet or whole package mode in the order are filtered, the rest of plates are classified according to the thickness, and all the plates in any category are the same in thickness;the plates of each type are arranged and subpackaged sequentially according to the large, middle and small size sequence till each package meets the reference weight and all the plates are arranged; and all obtained package information is preserved, and the order is updated to be in the subpackaged state. The plate intelligent subpackaging device comprises an acquisition module, a classification module, a subpackaging module and an updating module. The working difficulty and burden of packaging workers of a plate-type furniture workshop are greatly relieved, the productivity of the packaging workshop is improved, and the package quality after the plates are packaged is improved.

Owner:司空定制家居科技有限公司

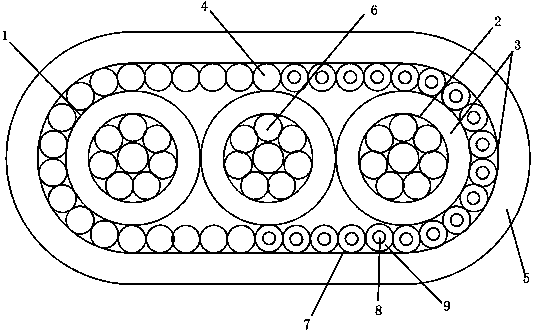

Anti-burn and anti-distortion cable based on flame-retardant inert gas

ActiveCN110942858AReduce feverEvenly dispersedFlexible cablesFlexible conductorsElectric cablesInert gas

The invention provides an anti-burn and anti-distortion cable based on flame-retardant inert gas, and relates to the technical field of cables. The invention discloses an anti-burn and anti-distortioncable based on flame-retardant inert gas. The device comprises an outer package, an inner cavity is formed in the outer package, a first fireproof coating is fixedly installed on the inner side of the outer package, an inner package is fixedly installed in the outer package, a connecting rod is fixedly connected between the inner package and the outer package, and a second fireproof coating is fixedly installed on the periphery of the inner package. The invention discloses an anti-burn and anti-distortion cable based on flame-retardant inert gas. Concentrated heating of internal wires is avoided, torsion generated by twisting can be buffered, the phenomenon that the wires are broken due to long-time excessive twisting is avoided, internal filling materials are saved, the flexibility of the cable is improved, the effect of fire on the cable is relieved, fusing of the internal wires is relieved, and time is bought for cutting off a cable power source.

Owner:QINGDAO CABLE

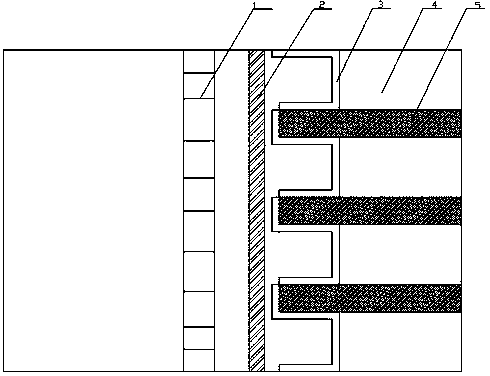

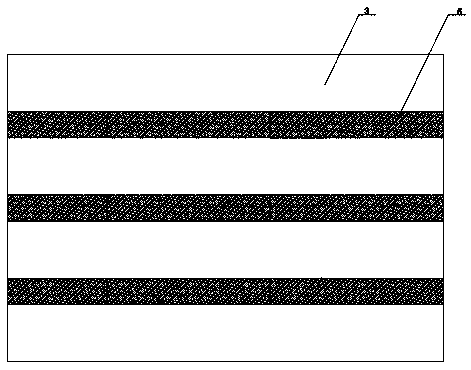

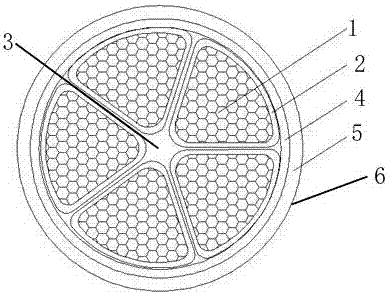

An inorganic mineral insulation metal sheath fireproof and waterproof cable

InactiveCN107017040ASimple structureSave filling areaNon-insulated conductorsConductive materialCopper conductorMaterials science

The invention discloses an inorganic mineral insulation metal sheath fireproof and waterproof cable comprising a cable core. The cable core is formed by intertwisting a plurality of fan-shaped wire cores. Each fan-shaped wire core is composed of a fan-shaped copper conductor and a fan-shaped inorganic mineral insulating layer wrapping the fan-shaped copper conductor in an extruded mode. Ointment is filled in gaps in the cable core. A ceramic silicone rubber lapped-wrapping band is arranged outside the cable core. A corrugated metal sheath is arranged outside the ceramic silicone rubber lapped-wrapping band. A polyisobutylene waterproof film is arranged outside the corrugated metal sheath. The inorganic mineral insulation metal sheath fireproof and waterproof cable of the invention has advantages such as superior fireproof performance, a good waterproof effect, relatively good overall flexibility, safety, pro-environment, high corrosion resistance, convenient installation, simplicity in manufacturing, etc.

Owner:WUXI NEW SUNSHINE CABLE

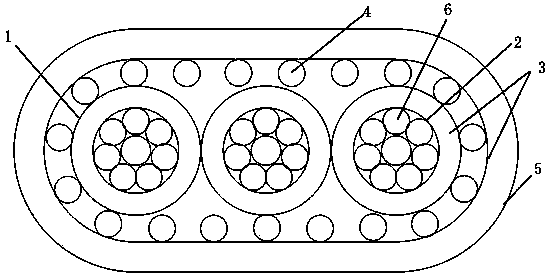

Bent type five-core flat cable

InactiveCN103680703AEasy to identifyEasy to use and maintainPower cables with screens/conductive layersFlat/ribbon cablesStructural engineeringNeutral line

The invention discloses a bent type five-core flat cable. The cable is of a flat structure, three paratactic phase wire cores are arranged in the center of the cable, a half circle of ground wire core conductors and a half circle of neutral wire cores are arranged outside the phase wire cores side by side, a wrapping tape is wrapped around the ground wire core conductors and neutral wire cores, and a protecting sleeve is wrapped around the wrapping tape in an extruded mode. The five-core flat cable has the advantages of being capable of being repeatedly moved, bent and vertically used, compact in structure, small in diameter and easy to machine, achieving convenient construction and the like.

Owner:WUXI JIANGNAN CABLE

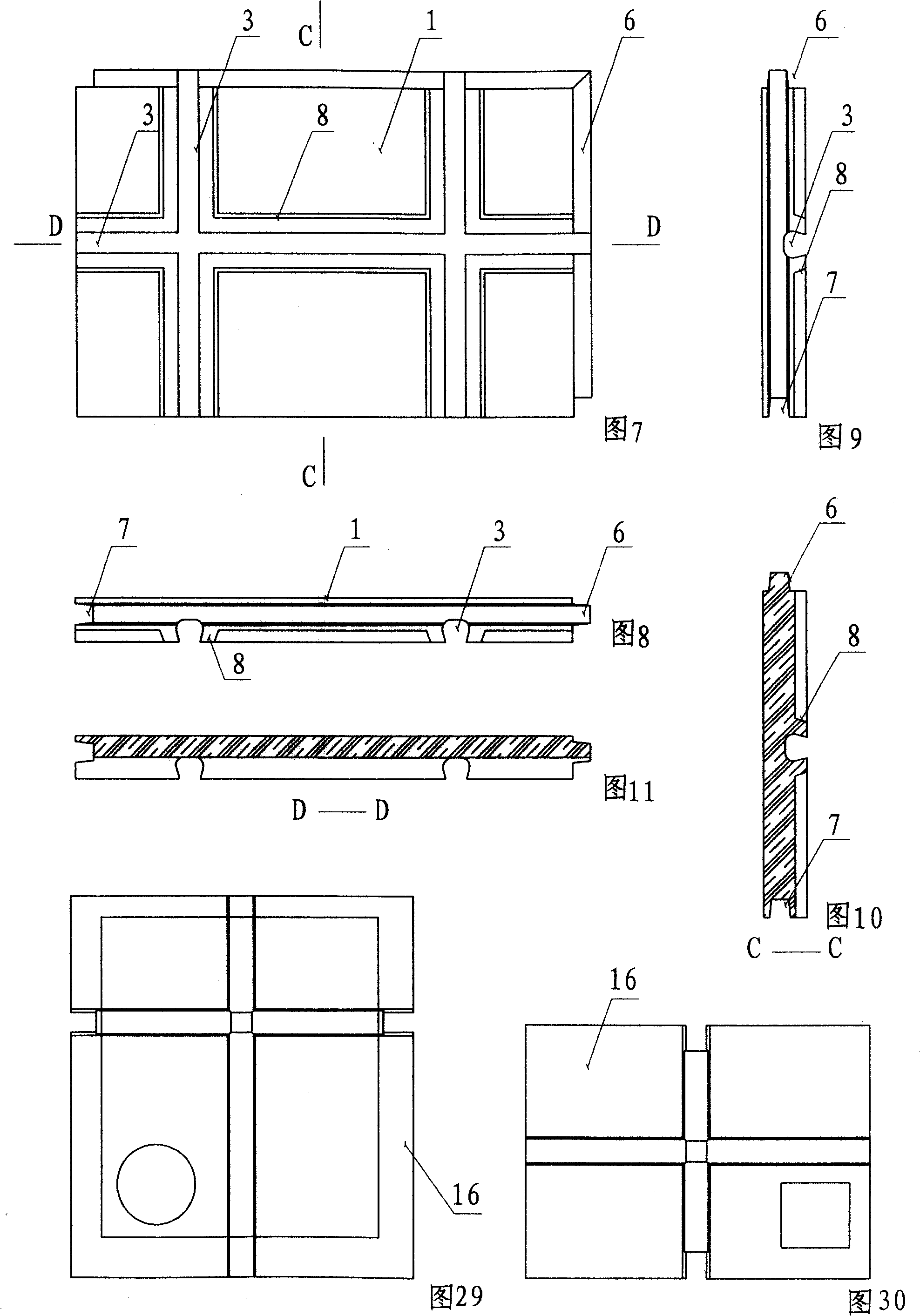

Frame embedding brick, frame embedding body building and method for constructing the frame embedding body building

InactiveCN100434631CLight weightImprove sound insulationSingle unit pavingsCoastlines protectionBrickMechanical engineering

The invention relates to a casing inlay that the brick, assistant tendon burying slot, side protruding table and protruding table slot form the basic section. The large surface protruding table, main tendon burying slot, anchor fixed pulling tendon and brick material form the adjusting section. The basic section and the adjusting section combine together and form the casing inlay.

Owner:杨新生

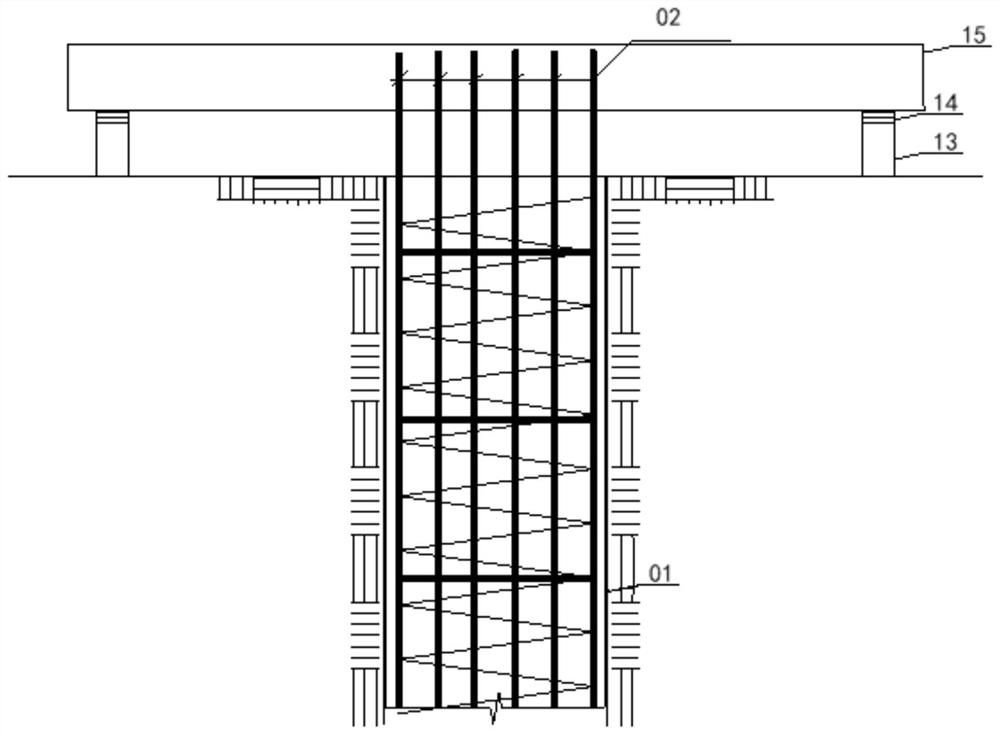

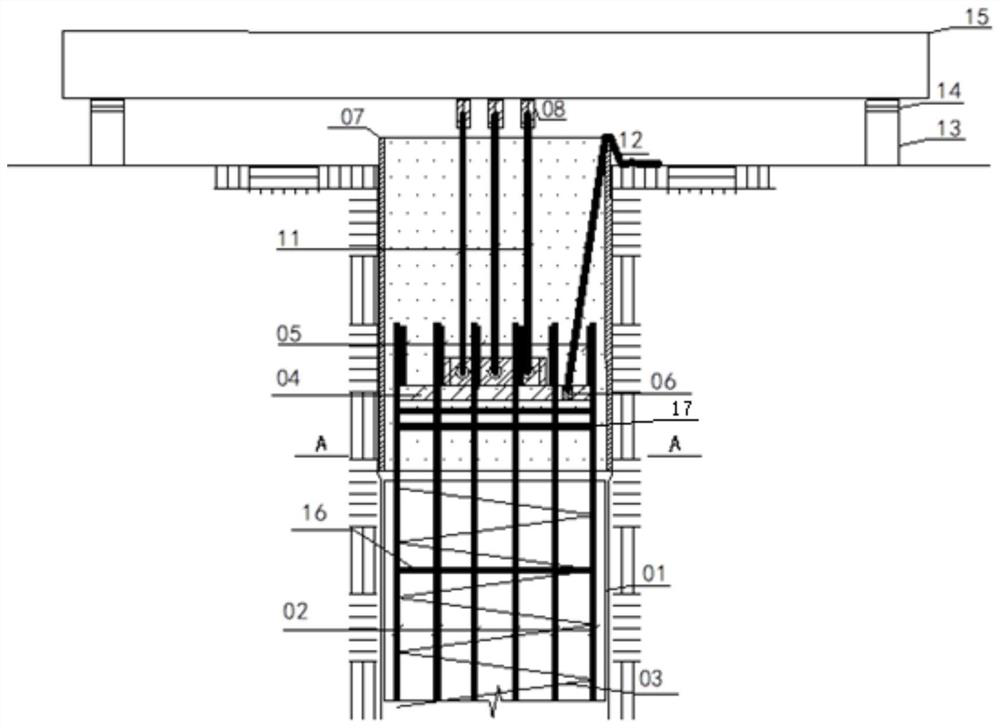

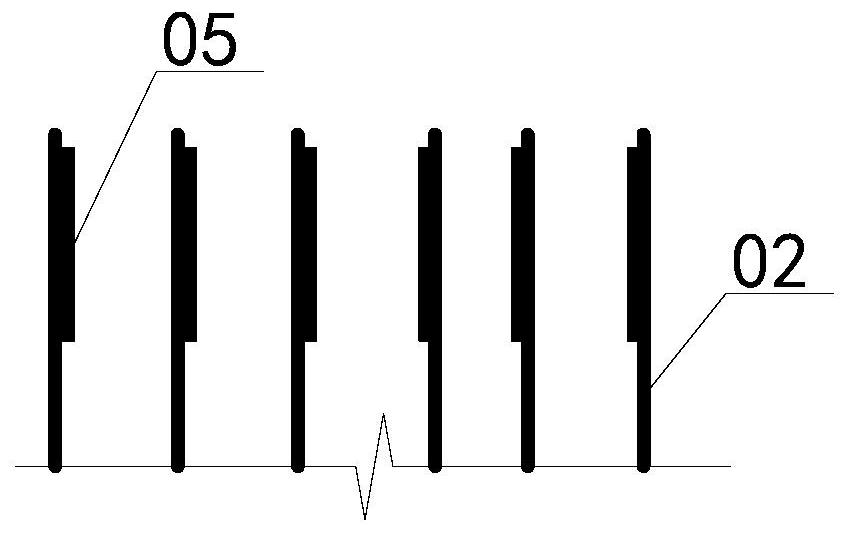

Uplift pile uplift force detection method

InactiveCN112459141AEasy to useSolve the problem of negative friction resistance affecting test resultsFoundation testingTest beamJackscrew

The invention discloses an uplift pile uplift force detection method. A detection device comprises an uplift pile, a steel plate, a force transmission member and a test beam, wherein the uplift pile is poured in a pile hole, a plurality of main reinforcements exposed out of the upper end of the uplift pile are arranged in the uplift pile, a hooking and pulling member is welded to one end, exposedout of the uplift pile, of each main reinforcement, the two ends of the force transmission member are detachably connected with the bottom face of the test beam and the top face of the steel plate respectively, the test beam is placed on supporting piers and separated from the ground outside the pile hole at intervals, a jack for applying pile pulling force to the uplift pile is arranged between the test beam and the ground, and the uplift pile is hung on the steel plate through the hooking and pulling members. During construction, a perfect detection state that the upper non-effective pile length is a hollow pile is reserved, and the problem that the negative friction resistance of the non-effective pile length influences a detection result is effectively solved; and meanwhile, the recyclable force transmission member is adopted for detecting the pulling resistance of the effective pile length, compared with an existing solution in the market, construction is convenient, the engineering cost can be greatly saved, and pile body filling materials in an empty hole area are effectively saved.

Owner:WUHAN CONSTR ENG

Three-core flat cable with small outer diameter

InactiveCN103680705AEasy to identifyEasy to use and maintainPower cables with screens/conductive layersFlat/ribbon cablesElectrical conductorEngineering

The invention discloses a three-core flat cable with a small outer diameter. The cable is of a flat structure, two paratactic phase wire cores are arranged in the center of the cable, a circle of ground wire core conductors are arranged outside the phase wire cores side by side, a wrapping tape is wrapped around the ground wire core conductors, and a protecting sleeve is wrapped around the wrapping tape in an extruded mode. The three-core flat cable has the advantages of being capable of being repeatedly moved, bent and vertically used, compact in structure, small in diameter and easy to machine, achieving convenient construction and the like.

Owner:WUXI JIANGNAN CABLE

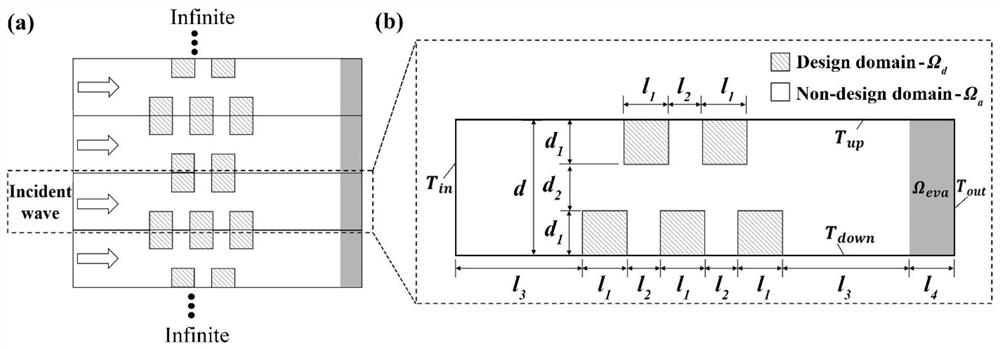

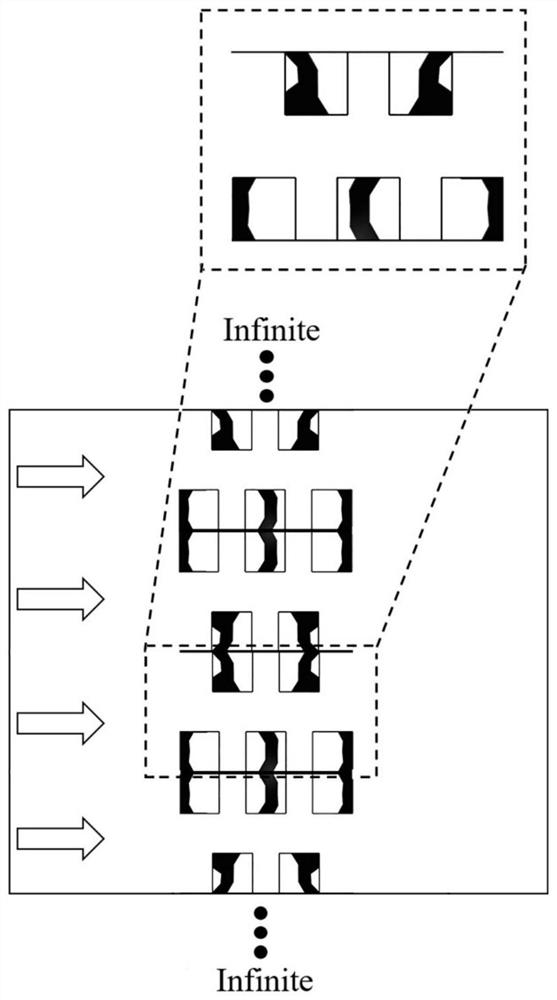

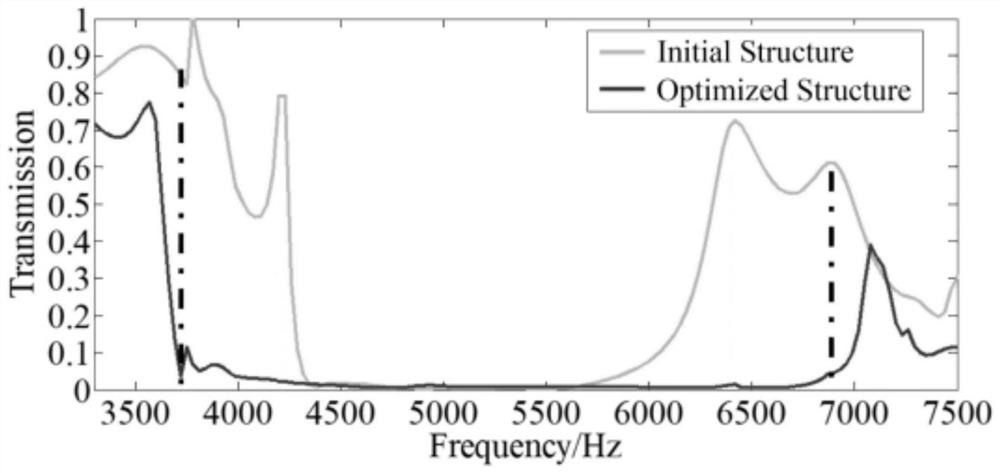

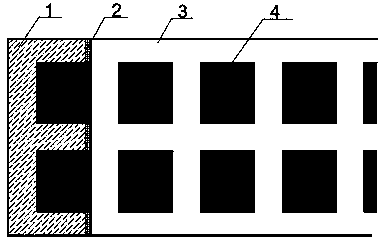

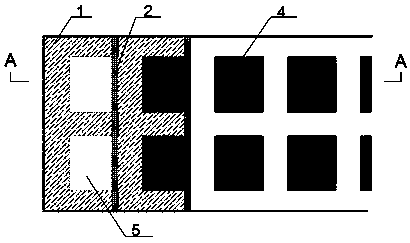

Topological optimization method for interval contraction sound insulation structure

PendingCN112182941AStrong designabilityHigh bandwidthDesign optimisation/simulationSpecial data processing applicationsSound barrierConfined space

The invention discloses a topological optimization method for an interval contraction sound insulation structure, which comprises the following steps of performing acoustic modeling on the interval contraction sound insulation structure according to a Helmholtz equation, and proposing a new interpolation function for continuous material interpolation of density and volume modulus by adopting a topological optimization method based on a variable density method. A constraint condition of the volume fraction of the material in the design domain is introduced, sensitivity analysis is carried out on an objective function and the constraint function by using an adjoint method by taking the minimized quadratic sum of the transmission sound pressure of the target frequency band in the evaluation domain as the objective function, and the objective function is optimized by using a moving asymptotic line method to obtain the optimal distribution of the solid material in the design domain; and finally, broadband sound insulation of the ventilation sound barrier in a limited space is realized. The method gets rid of the traditional thought of designing sound insulation structure parameters by experience, takes sound insulation frequency band widening as a target, and reversely designs material distribution by means of a topological optimization algorithm to obtain the optimal sound barrierwith the characteristics of broadband, ventilation, light weight and the like.

Owner:NANJING UNIV

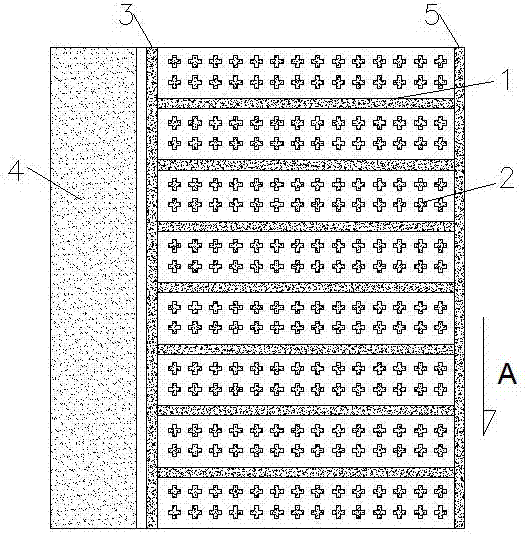

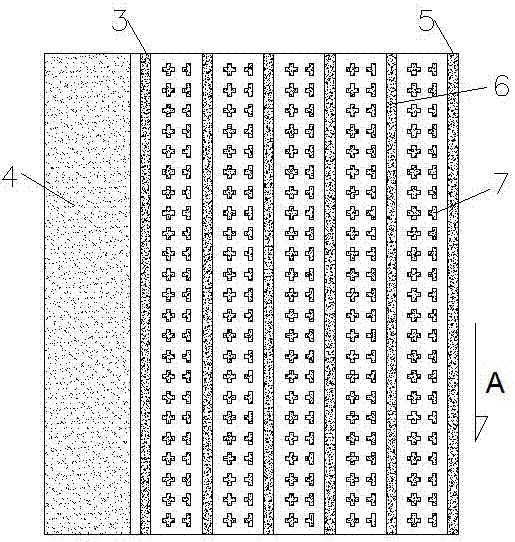

Extra-thick coal seam stratified non-integral filling mining method

ActiveCN108278113AReduce lossControlled sinkingUnderground miningSurface miningRoom and pillar miningMining engineering

The invention discloses an extra-thick coal seam stratified non-integral filling mining method. The extra-thick coal seam stratified non-integral filling mining method is used for mining "three-lower"extra-thick coal seam and stratifying synthetically by combing coal quality property and devices, and the stratified height is determined; then methods of upper room column non-integral filling recovering coal pillar and lower strip-type filling and mining are used, coal seams are sequentially mined by the two methods, and the upper layer is mined firstly then the lower layer is mined until the whole layer of coal are mined completely. The extra-thick coal seam stratified non-integral filling mining method makes good use of coal seam instead of artificial false roof, the material wastage is greatly reduced, a filling method realizes non-integral filling, and filling materials are saved; a method of combing mining and filling is realized in the process of mining, in the absence of a coal pillar, solid cemented filling materials are quickly used instead of the coal pillar, sharp change of overlying rock is strictly controlled, the safety of ground buildings is ensured, and the upper andlower structures are matched to control ground depression.

Owner:TAIYUAN UNIV OF TECH

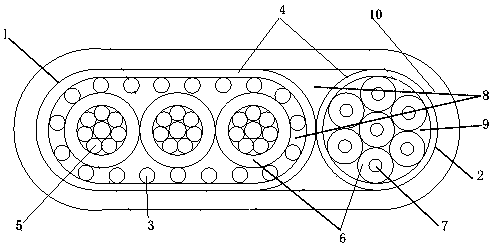

Four-core flat cable with control cable core

InactiveCN105336407ASave padding and strappingReduce material wastePower cables including communication wiresPower cables including electrical controlCompound (substance)Electrical conductor

The invention discloses a four-core flat cable with a control cable core. Power and a control signal can be transmitted at the same time without dependency. The cable comprises a power cable core and the control cable core, wherein the power cable core and the control cable core are arranged in parallel in a towed mode, and soft plastic or chemical fiber materials are adopted for the hollow part between the power cable core and the control cable core. Three phase line cores are arranged in parallel in the center of the power cable core in a towed mode, multiple ground wire core conductors are arranged in parallel on the peripheries of the three phase line cores, an insulating layer is arranged between the phase line cores and the ground wire core conductors, and the ground wire core conductors are wrapped with a master sheath in an extruded mode. The cable is compact in structure, small in outer diameter, capable of being moved repeatedly, bent and used perpendicularly, easy to machine and convenient to construct, and occupies less space.

Owner:WUXI JIANGNAN CABLE

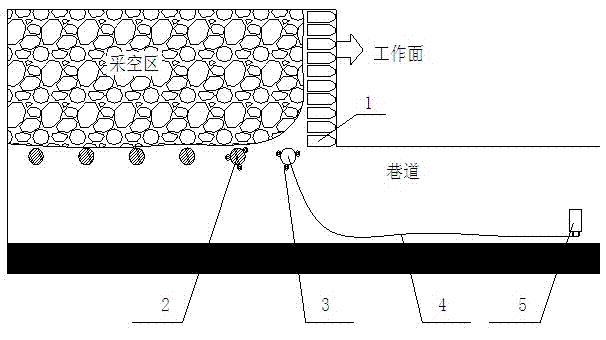

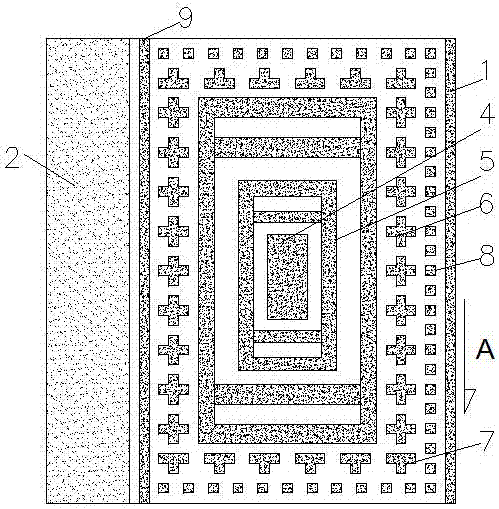

A Method for Partial Filling of Gobs According to the Characteristics of Roof Caving

ActiveCN106150545BControl deformation damagePromote recoveryMaterial fill-upStress concentrationEngineering

The invention discloses a method for conducting goaf partial filling according to roof caving characteristics. The method comprises the steps that high-strength filling strips which are perpendicular or parallel to the mining direction are arranged in a goaf according to an initial caving pace of an immediate roof of the goaf to control caving of the immediate roof; multiple rows of high-strength filling monomers with different shapes are arranged among the filling strips at intervals according to the bending deflection of the immediate roof to control deformation of the immediate roof; large-range filling is conducted on positions with special geological structures to control stress concentration points; a high-strength filling body-immediate roof structure control system is formed, and an upper overlying strata is supported by the high-strength filling body and the immediate roof; narrow filling strip goaf-side retained roadways are arranged, the roadway driving workload of the next working face is reduced, and the goaf is filled in a sealed mode. According to the method for conducting goaf partial filling according to the roof caving characteristics, filling materials are saved, and the filling cost is reduced; the filling structure bodies with different shapes are arranged on key positions, the control effect on the roof is good, and a whole-region chain reaction caused by destruction of partial filling bodies is prevented; a large amount of underground space formed through filling can be reused.

Owner:TAIYUAN UNIV OF TECH

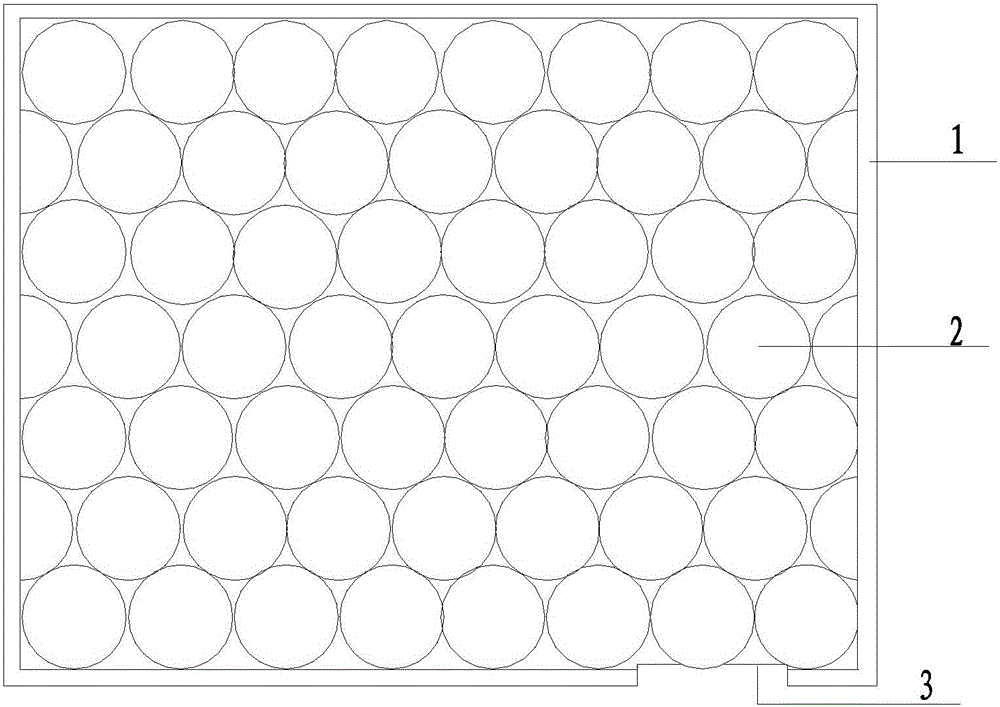

Insulation and explosion-proof system for aircraft fuel tank and installation technology and application thereof

InactiveCN106494630ACutting costsFilled tightlyPower plant fuel tanksCombustion systemForeign matter

The invention discloses an insulation and explosion-proof system for an aircraft fuel tank and the installation technology and application thereof; the insulation and explosion-proof system comprises a box body and insulation and explosion-proof material units arranged in the box body; the oil outlet on the bottom of the box body is provided with a steel mesh sheet so as to prevent foreign matters from flowing into the combustion system through a pipeline; the insulation and explosion-proof system is good in filling uniformity and compaction, uses less materials, thus saving engineering construction time, and reducing construction cost and discharge and disassemble difficulty; more importantly, the insulation and explosion-proof system can effectively save oil gas losses, can reduce pollutions on the atmosphere environment, and can better improve the box body safety.

Owner:JIANGSU ZHONGDING ENVIRONMENTAL PROTECTION EQUIP TECH +3

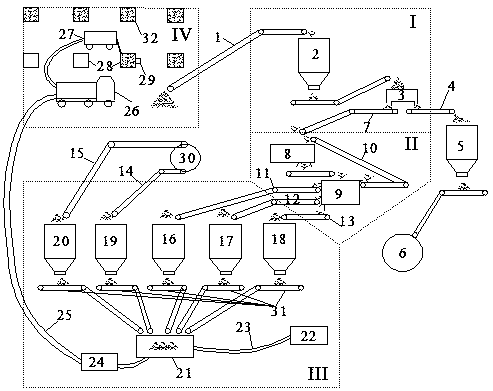

Downhole mining, screening, mixing and filling integrated gangue cement structure filling system and method

ActiveCN107246279BRealize the balance of mining and chargingHigh liftMaterial fill-upFilling materialsSlurry

The invention discloses an underground selection, screening and stirring integrated gangue cementation construction filling system and method. The system comprises an underground coal and gangue separating device, an underground gangue crushing and screening device, an underground filling material weighing and stirring device, an underground filling material slurry conveying device, an underground filling material slurry casting device and a PLC control device. The filling method comprises the steps that raw coal mined from a driving working face and a mining working face is transported to a raw coal bunker of a mining area, separated clean coal is transported to a clean coal bunker and is lifted by a main well, separated gangues are fed into a gangue crushing machine, and the gangues undergoing secondary smashing are fed into a gangue screening device; various raw filling materials are respectively fed into a burdening hopper, and filtered mine water is added to obtain filling material pulp through stirring after even and drying stirring; the filling material pulp is transported to a filling working face by a stirring transportation truck, then is cast into a filling formwork by a movable filling pump truck and is evenly vibrated by using a vibration device. By adopting the system and method, the mine transportation and lifting pressure is reduced, the working efficiency is improved, and the mining-filling balance of coal mine waste is achieved.

Owner:TAIYUAN UNIV OF TECH

Method for filling friction stir welding keyhole by using T-shaped filling block and bitless stirring head

InactiveCN102500915BSimple designPreset operation is convenientWelding/cutting media/materialsSoldering mediaFilling materialsEngineering

Owner:XI AN JIAOTONG UNIV

A layered non-integral filling mining method for extra-thick coal seams

ActiveCN108278113BReduce lossControlled sinkingUnderground miningSurface miningRoom and pillar miningStructure of the Earth

The invention discloses an extra-thick coal seam stratified non-integral filling mining method. The extra-thick coal seam stratified non-integral filling mining method is used for mining "three-lower"extra-thick coal seam and stratifying synthetically by combing coal quality property and devices, and the stratified height is determined; then methods of upper room column non-integral filling recovering coal pillar and lower strip-type filling and mining are used, coal seams are sequentially mined by the two methods, and the upper layer is mined firstly then the lower layer is mined until the whole layer of coal are mined completely. The extra-thick coal seam stratified non-integral filling mining method makes good use of coal seam instead of artificial false roof, the material wastage is greatly reduced, a filling method realizes non-integral filling, and filling materials are saved; a method of combing mining and filling is realized in the process of mining, in the absence of a coal pillar, solid cemented filling materials are quickly used instead of the coal pillar, sharp change of overlying rock is strictly controlled, the safety of ground buildings is ensured, and the upper andlower structures are matched to control ground depression.

Owner:TAIYUAN UNIV OF TECH

Downhole filling equipment, downhole filling system and downhole filling method

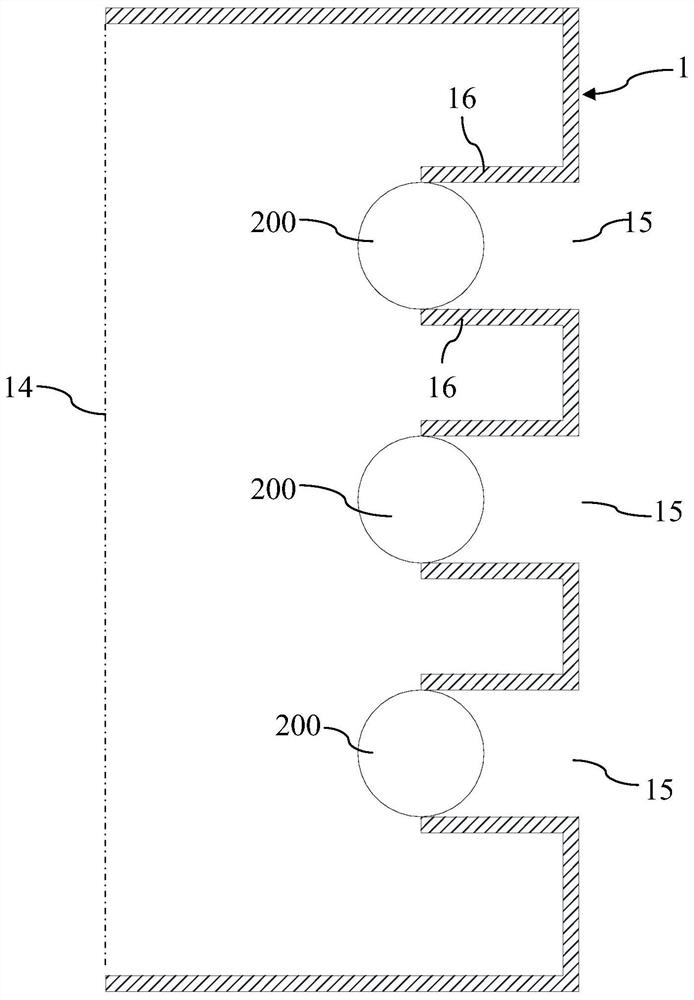

ActiveCN112377250ASave filling materialLower filling costsMining devicesMaterial fill-upMechanical engineeringElectrical and Electronics engineering

The invention discloses underground filling equipment, an underground filling system and an underground filling method. The underground filling equipment comprises a filling mold frame and an inflatable bag supply device used for supplying inflatable bags into the filling mold frame; the rear portion of the filling mold frame is provided with a mold frame rear opening, and the front portion of thefilling mold frame is provided with at least one mold frame front opening used for clamping the inflatable bags; the inflatable bag supply device is located on the front side of the filling mold frame; and the inflatable bag supply device can process non-inflated and continuous bag barrels into the inflatable bags and push the inflatable bags into the mold frame front opening, and the inflatablebags can seal the mold frame front opening. According to the underground filling equipment, the underground filling system and the underground filling method, the inflatable bags can be added into a filling body, so that a hole is formed in the filling body, the filling material is saved, and the filling cost is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Compact four-core ribbon cable

InactiveCN103680695AEasy to identifyEasy to use and maintainFlat/ribbon cablesFlexible cablesRibbon cableStructural engineering

The invention discloses a compact four-core ribbon cable which is of a flat structure. The center of the cable is provided with three parallel phase cable cores. A plurality of ground cable core conductors are distributed outside the phase cable cores in parallel. Wrapping tape wraps the ground cable conductors. Protecting sleeves wrap the wrapping tape in an extruding mode. The compact four-core ribbon cable has the advantages of being capable of being moved repeatedly, bent and vertically used, compact in structure, small in outer diameter, easy to process, convenient to construct and the like.

Owner:WUXI JIANGNAN CABLE

Four-core compound cable with control line core pairs

InactiveCN103680747AReduce wasteReduce signal interferencePower cables with screens/conductive layersElectricityControl signal

The invention discloses a four-core compound cable with control line core pairs. The four-core compound cable with the control line core pairs comprises a cable core, wherein the cable core is formed by intertwisting three fan-shaped phase line cores in the center and a wrapping belt layer wrapping the phase line cores, a cable core layer wraps the cable core, an outer sheath is arranged outside the cable core in an extrusion mode, and the cable core layer is composed of a plurality of ground wire cores and at least one control line core pair which are concentrically distributed outside the cable core side by side. The four-core compound cable with the control line core pairs is small in signal interference, can simultaneously transmit electricity and control signals, enables wires to be arranged more reasonably and more compactly, and is compact in structure, small in outer diameter, easy to process and convenient to construct.

Owner:WUXI JIANGNAN CABLE

Flat four-core composite mineral fire-proof control cable

InactiveCN107945942AReduce wasteReduce electromagnetic interferenceFlat/ribbon cablesFlexible cablesGlass fiberElectrical conductor

The invention discloses a flat four-core composite mineral fire-proof control cable comprising an insulated cable core and a control cable core that are arranged in parallel. Three insulating wire cores are arranged in parallel at the center of the insulated cable core; a plurality of ground wire core conductors are distributed in parallel at the peripheries of the three insulating wire cores; andthe outsides of the ground wire core conductors and the three insulating wire cores are extruded by an inner inorganic mineral metal sheath. A plurality of control wire cores are twisted and then aninner inorganic mineral metal sheath extrudes the outsides of the plurality of control wire cores to form the control cable core. The gap between the insulated cable core and the control cable core isfilled with glass fiber filaments. The outsides of the insulated cable core and the control cable core are extruded by an outer flat inorganic mineral metal sheath. The cable having advantages of compact structure, small outer diameter, and reduced occupied space can be moved repeatedly, be bent, and be used vertically and is also easy to process and convenient to construct.

Owner:WUXI JIANGNAN CABLE

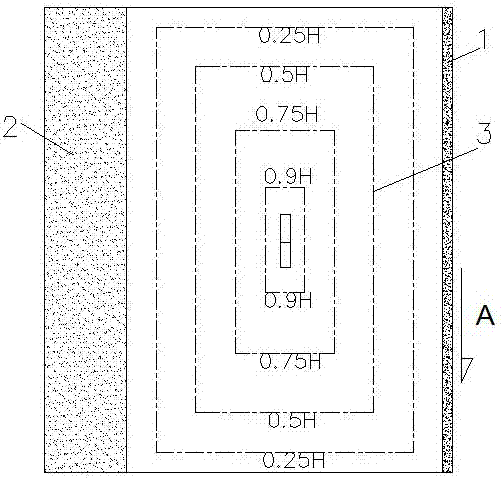

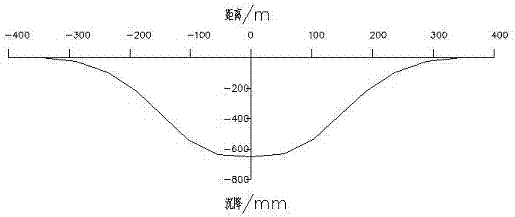

A Method for Partial Filling of Gob Area According to Surface Subsidence Characteristics

ActiveCN106150546BControl deformation damagePromote recoveryMaterial fill-upMining engineeringStructural engineering

The invention discloses a method for conducting goaf partial filling according to ground surface subsidence characteristics. The method comprises the steps that the positions of filling bodies are designed according to a ground surface subsidence contour map; complete filling is conducted within a central area range, and a subsidence center is controlled; multiple circles of filling strips are arranged outside the complete filling range, and a larger subsidence region is controlled; multiple rows of filling monomers are arranged outside the filling strips, and a subsidence edge region is controlled; the filling bodies with different shapes are arranged in a goaf in a targeted mode, deformation destruction and ground surface subsidence of a roof are controlled, a filling body-roof structure control system is formed, and deformation destruction and ground surface subsidence of an upper overlying strata are controlled; narrow filling strip goaf-side retained roadways are arranged, the roadway driving workload of the next working face is reduced, and the goaf is filled in a sealed mode. According to the method for conducting goaf partial filling according to the ground surface subsidence characteristics, deformation destruction and ground surface subsidence of the roof can be effectively controlled, the recovery rate of coal mining under buildings, railways and water bodies is increased, and the environment is protected; filling materials are saved, the filling cost is reduced, and a large amount of underground space formed through filling is reused.

Owner:TAIYUAN UNIV OF TECH

A filling coal mining method with skip mining at intervals

InactiveCN103883350BIntegrity guaranteedReduce exerciseUnderground miningSurface miningFilling materialsSequential mining

The invention provides an interval skip-mining type filling coal mining method and belongs to the technical field of coal mine filling coal mining methods. The interval skip-mining type filling coal mining method comprises the steps that a first open-off cut is dug at the tail end of a butt entry, a second open-off cut is dug a certain distance away from the first open-off cut, and mining is conducted at the position of the second open-off cut with the wall type system coal mining method after the second open-off cut is well dug; a third open-off cut is dug a certain distance away from the second open-off cut, a gob formed after mining is conducted at the position of the second open-off cut is filled while the third open-off cut is dug, and the rest operation is conducted by analogy till mining is conducted on a mining stopping line. By the adoption of the interval skip-mining type filling coal mining method, mining can be conducted under the condition that the two ends are supported, sequential mining and sequential filling are achieved, the integrity of a base plate of a roof is guaranteed, movement of overlying rock is reduced, and the purpose of surface subsidence control is achieved; after mining with filling is completed, coal pillars left after mining do not need to be filled, filling materials are reduced, and filling cost is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com