Gob-side entry retaining method using high-water material filling columns

A high-water material, empty entry retaining technology, applied in the fields of backfill, earthwork drilling, safety devices, etc., can solve the problems of difficult roof connection, low supporting strength of piers, etc., and achieves small underground auxiliary transportation and simple construction. , good for ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

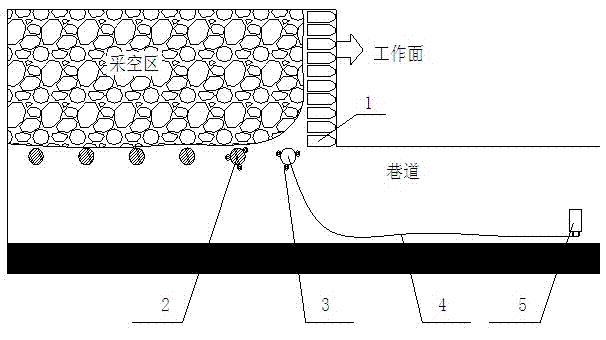

[0014] Such as figure 1 Shown, the construction steps of the present invention are as follows:

[0015] a. After the mining face is advanced, near the end hydraulic support 1, clean the floating coal and scum on the floor near the filling space to the solid floor, then build a high-water material filling column 2 at the predetermined position, and inject the high-water material slurry 2~3 single hydraulic props 3 are installed close to the filling column 2 in front.

[0016] b. Inject the homogeneously mixed high-water material slurry into the filling column 2 through the filling pump 5 and the delivery pipe 4 .

[0017] c. 4 hours after the high-water material slurry in the filling column is solidified, remove the corresponding single hydraulic prop 3.

[0018] d. Repeat the above steps, and make the next filling column after the working face advances for a certain distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com