Frame embedding brick, frame embedding body building and method for constructing the frame embedding body building

A brick body and inlay technology, which is applied in the field of frame inlay bricks, can solve the problems of poor energy saving and heat preservation effect, poor connection and pulling ability, and large loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

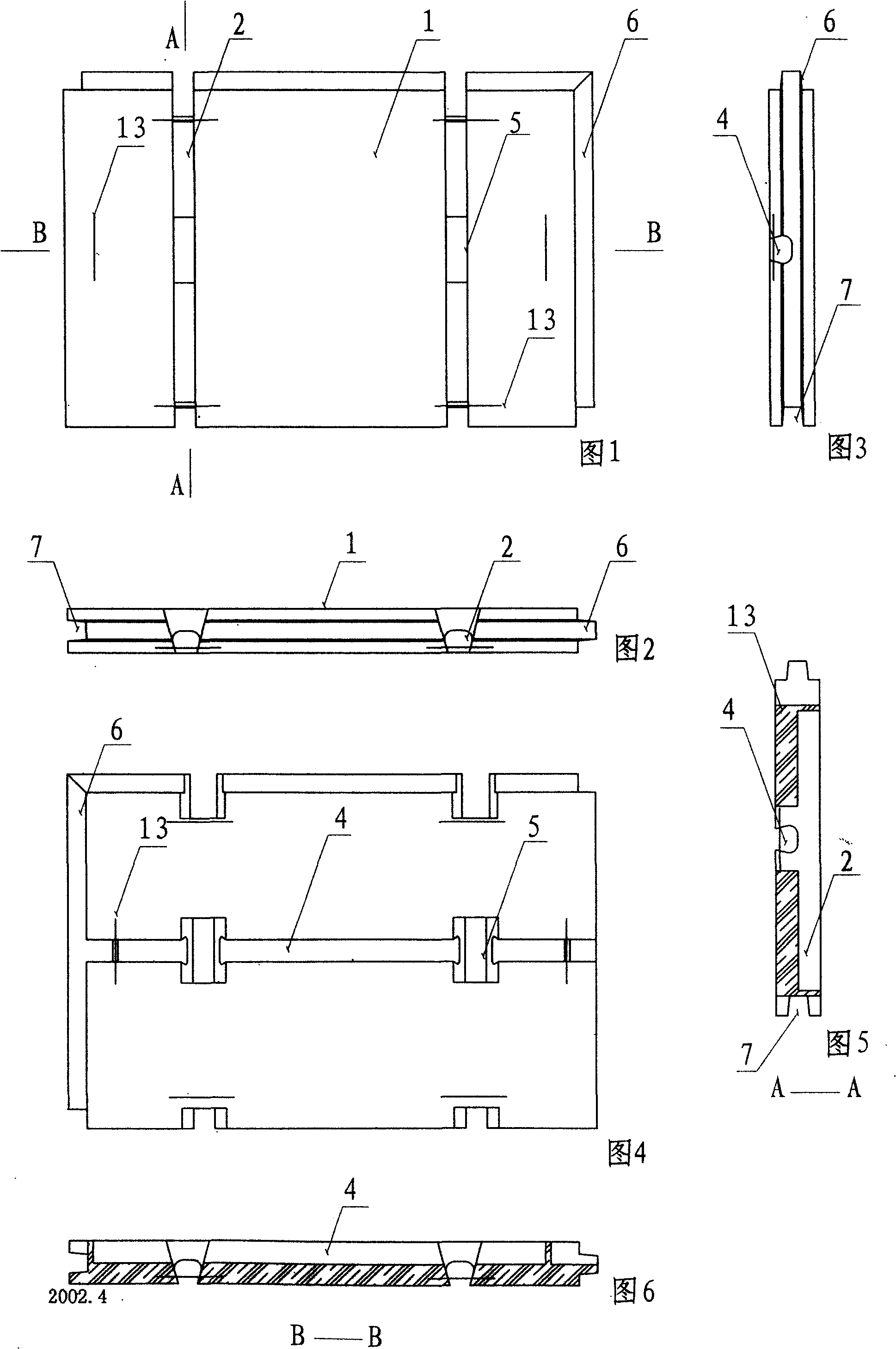

Embodiment 1

[0047] In Figures 1 to 6, the size and shape of the frame-embedded bricks are determined according to actual needs. Now take the frame-embedded bricks suitable for building one-skinned or double-skinned solid frame inlays, or enclosing inner cavity mold masonry for filling concrete and other filling materials as an example. On the front of the brick body 1, there are two auxiliary reinforcement embedding grooves 2 vertically and parallelly recessed into the brick body 1, and in the middle of the back of the brick body 1, there is a transverse main reinforcement embedding groove 4 recessed into the brick body 1, At the two ends of the auxiliary reinforcement embedding groove 2 and the corresponding intersection of the auxiliary reinforcement embedding groove 2 and the main reinforcement embedding groove 4, there are six transparent embedding reinforcement openings 5, and between the main reinforcement embedding groove 4 and the auxiliary reinforcement embedding groove 2, there ...

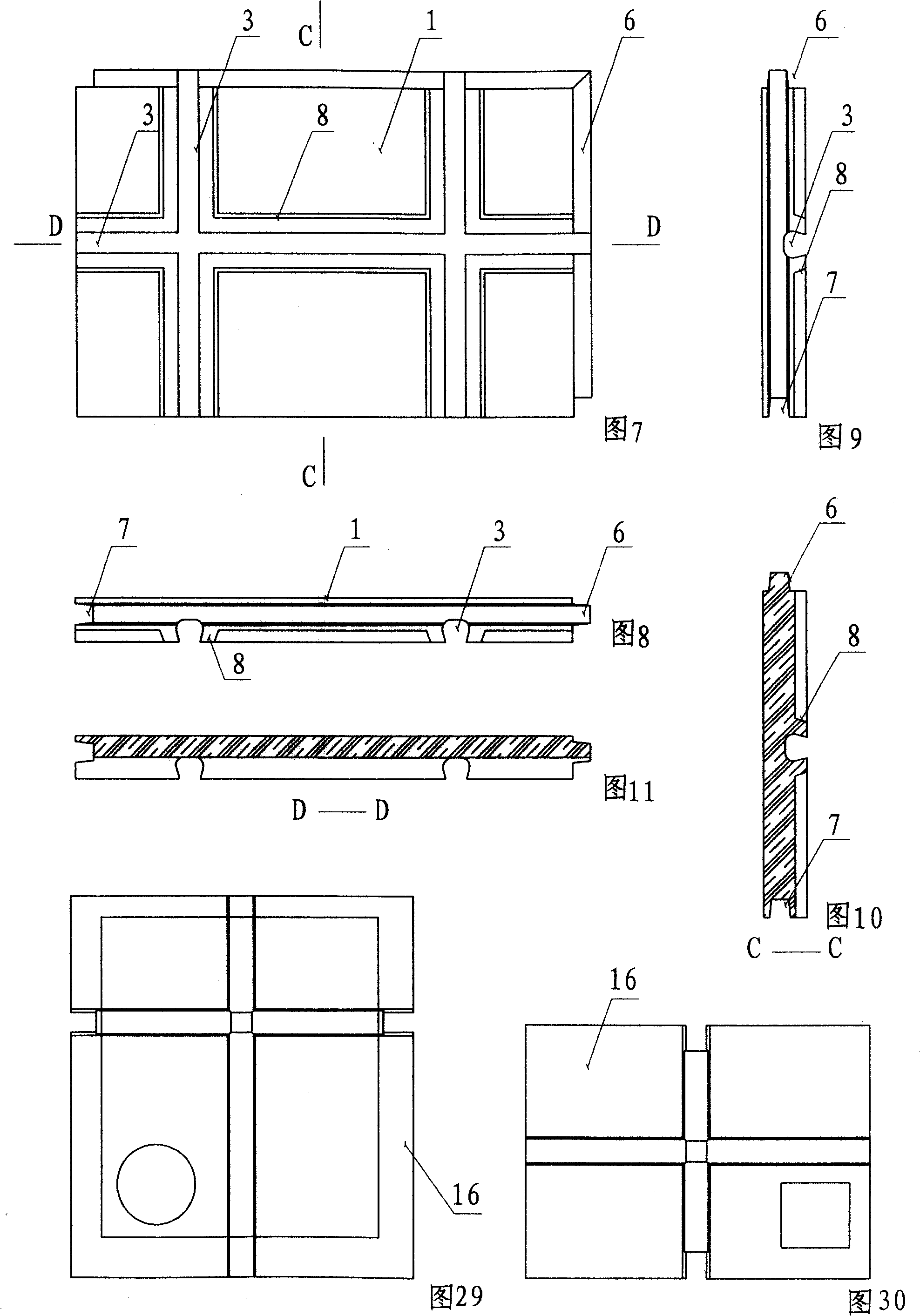

Embodiment 2

[0049] In Figures 7 to 11, the size and shape of the frame-embedded bricks are determined according to actual needs. Now take the frame-embedded brick suitable for building a thick-skinned frame-embedded wall and board after the frame-embedded brick is used as an example. On the large surface of one side of the brick body 1, there is a large horizontal boss 8 intersected with two longitudinal parallel bosses 8. shaped raised, in On the shaped bulge, there is a horizontal groove 3 with no distinction between primary and secondary reinforcement and two vertical grooves 3 with no distinction between primary and secondary reinforcement. shaped protrusions, forming an interconnected The shape does not distinguish between the primary and secondary reinforcement grooves 3 combinations, the other side of the brick body 1 is a plane, the upper and right sides of the brick body 1 have U-shaped side bosses 6, and the lower and left sides of the brick body 1 U-shaped side boss gr...

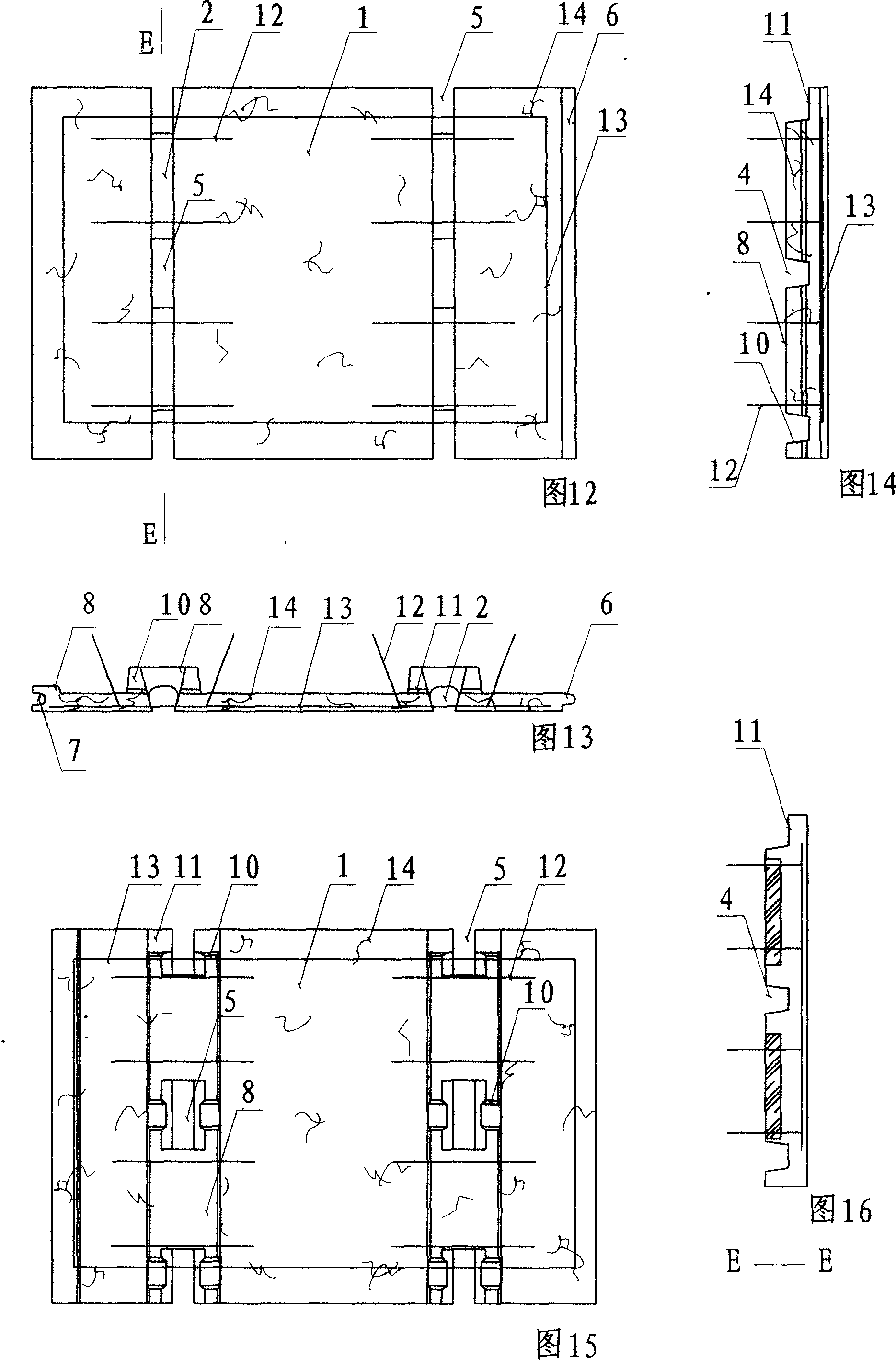

Embodiment 3

[0051] Fig. 12~14, among Fig. 16, the size and shape of frame inlaid bricks are determined according to actual needs. Now take the frame-embedded brick suitable for constructing the cavity mold frame inlay of the beam-column concrete member as an example. On the front of the brick body 1, there are two longitudinally parallel auxiliary reinforcement embedding grooves 2 recessed into the brick body 1. Inside the brick body 1 close to the mouth of the auxiliary reinforcement embedding groove 2, a frame-shaped reinforcement Connecting bars 13, and four pairs of anchoring tie bars 12 evenly distributed across the auxiliary bar buried bar ditch 2, penetrating the brick body 1 and hanging on the other side of the brick body 1, on the back of the brick body 1, there are two positions and The corresponding longitudinal large surface bosses 8 of the auxiliary reinforcement embedding grooves 2 have three transverse main reinforcement embedding grooves 4, Six parallel shelving caps 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com