Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Controlled sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loess tunnel construction method

InactiveCN102140918ASuitable construction methodEffective control of sinkingUnderground chambersTunnel liningTunnel constructionLoess

The invention relates to a loess tunnel construction method, which can lower the construction difficulty and ensure the construction safety and the structure stability. The method comprises the following steps: (1) rapidly excavating the tunnel; (2) immediately constructing a primary support; (3) erecting an invert trestle, and constructing a primary support invert in time to make the primary support form a closed integral body; (4) erecting an invert trestle, and carrying out invert backfilling and short wall construction as earlier as possible; and (5) constructing a secondary lining at a proper moment meeting the deformation rule of the loess tunnel.

Owner:CHANGAN UNIV

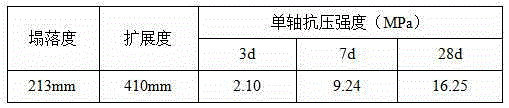

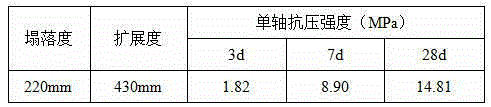

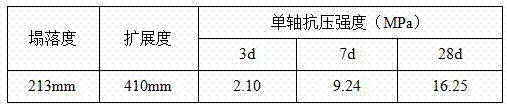

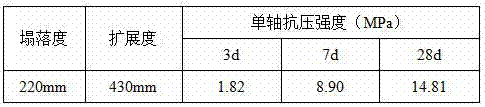

Preparation method of gangue base mine cemented filling material

ActiveCN105152601AImprove utilizationEfficient and reasonable useSolid waste managementMaterials scienceGangue

The invention discloses a preparation method of a gangue base mine cemented filling material, and belongs to the field of mine filling materials. Cementing activity hidden in gangue is stimulated in a compound stimulation way, cement is partially replaced with the cementing activity to serve as a cementing material for cemented filling mining, and then the material is mixed with fine particle size gangue to be prepared into the mine cemented filling material. The process for preparing the mine cemented filling material is simple, large proportion dosage of gangue powder and cement is realized, the filling material has excellent mechanical property and stable conveying property, no segregation or no bleeding exists, the application of gangue in mine filling is broadened, the mine filling cost is reduced, the material conveying property is improved, at the same time, the purpose of effective use of gangue is realized, and mine filling is promoted to develop forward.

Owner:TAIYUAN UNIV OF TECH

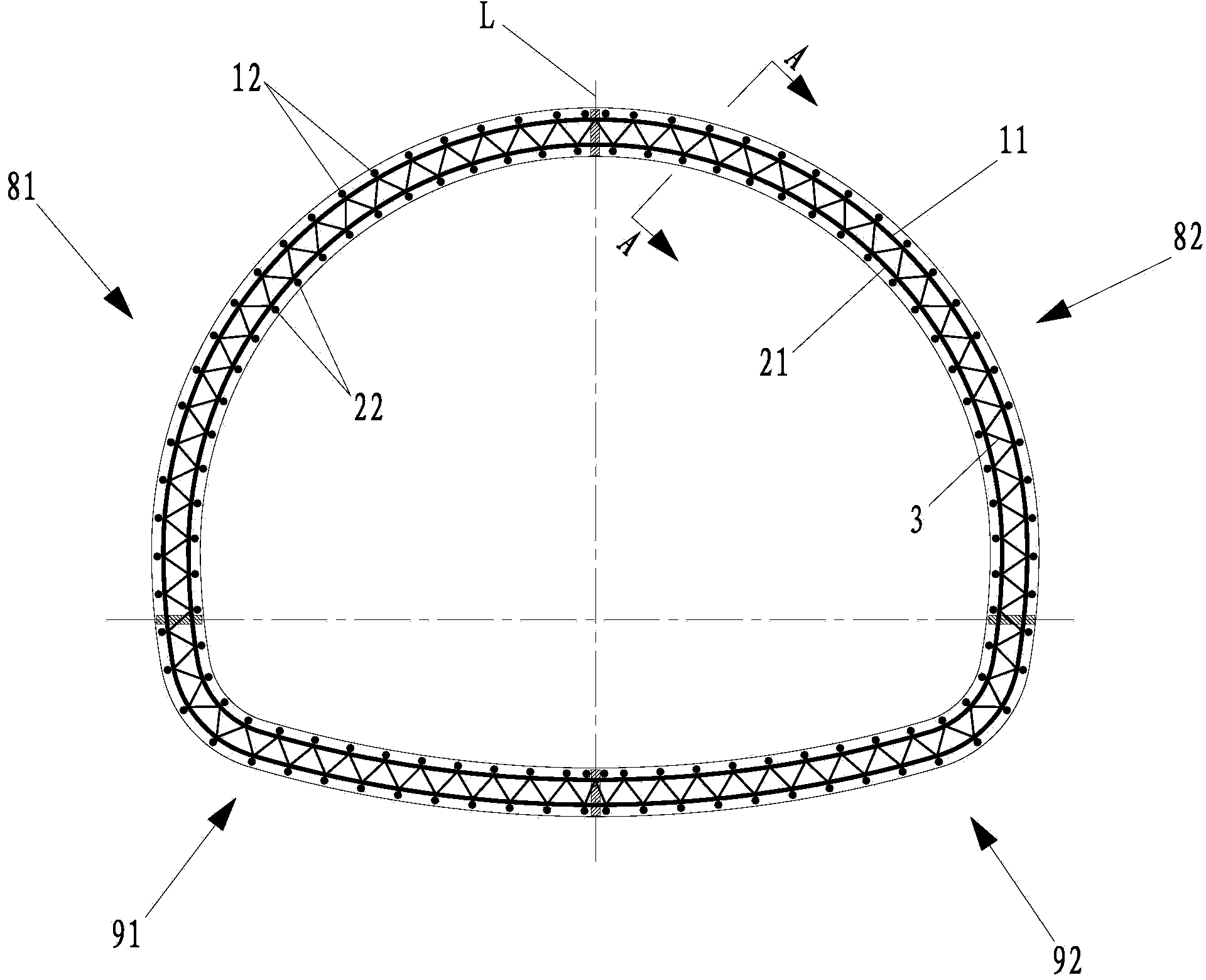

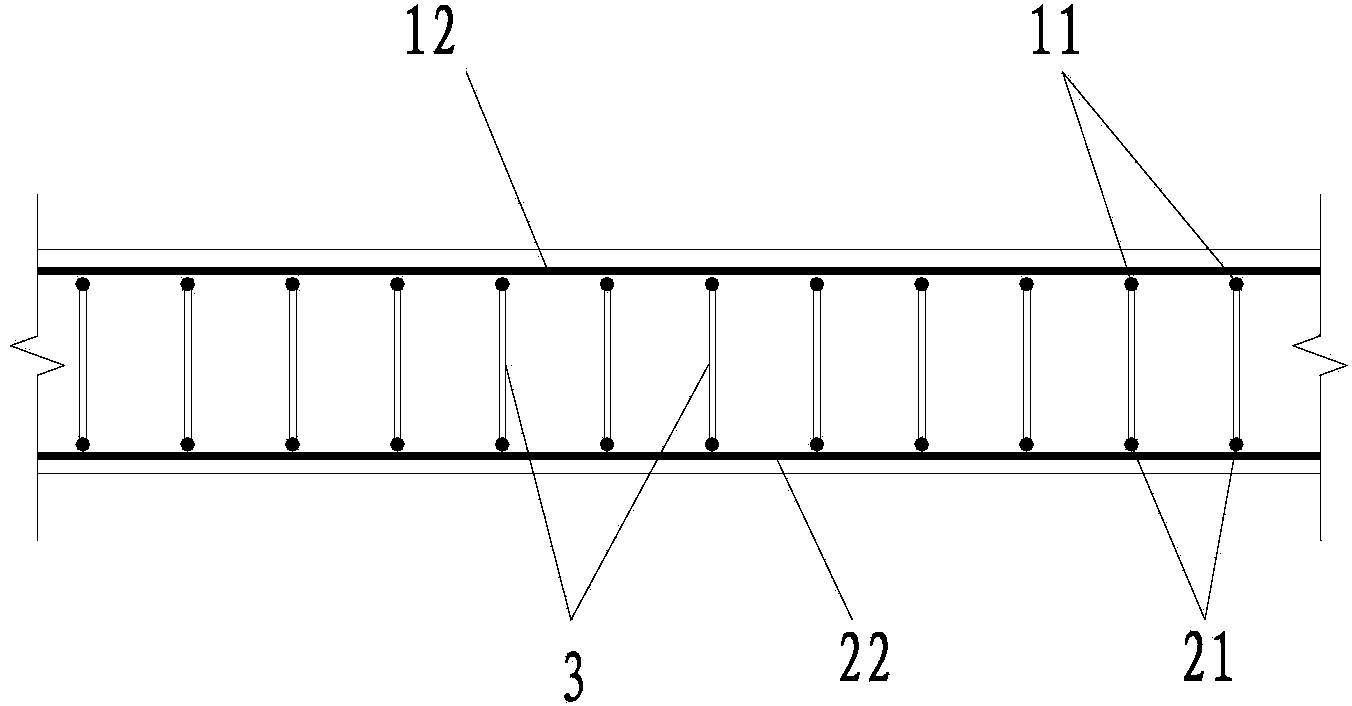

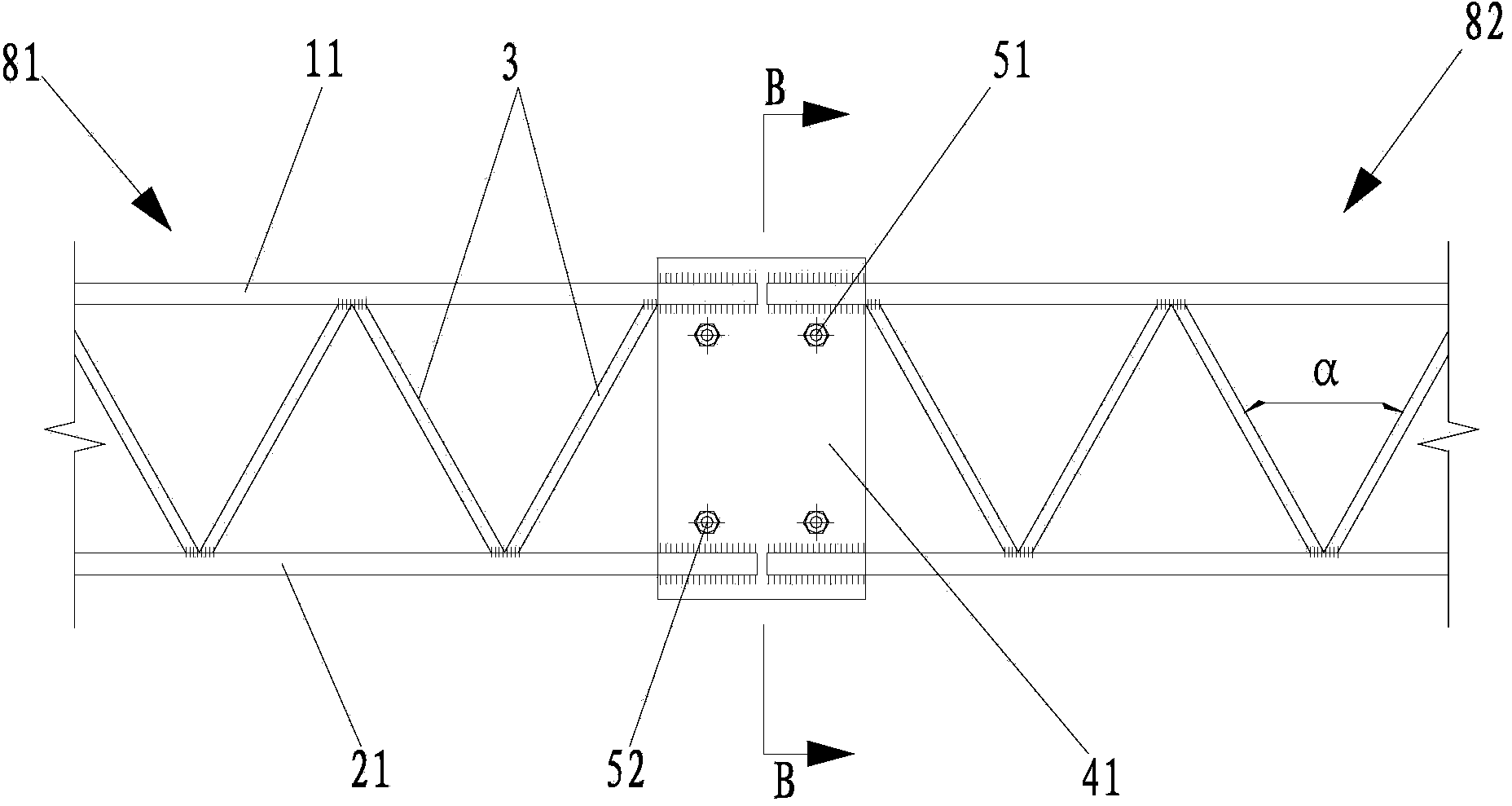

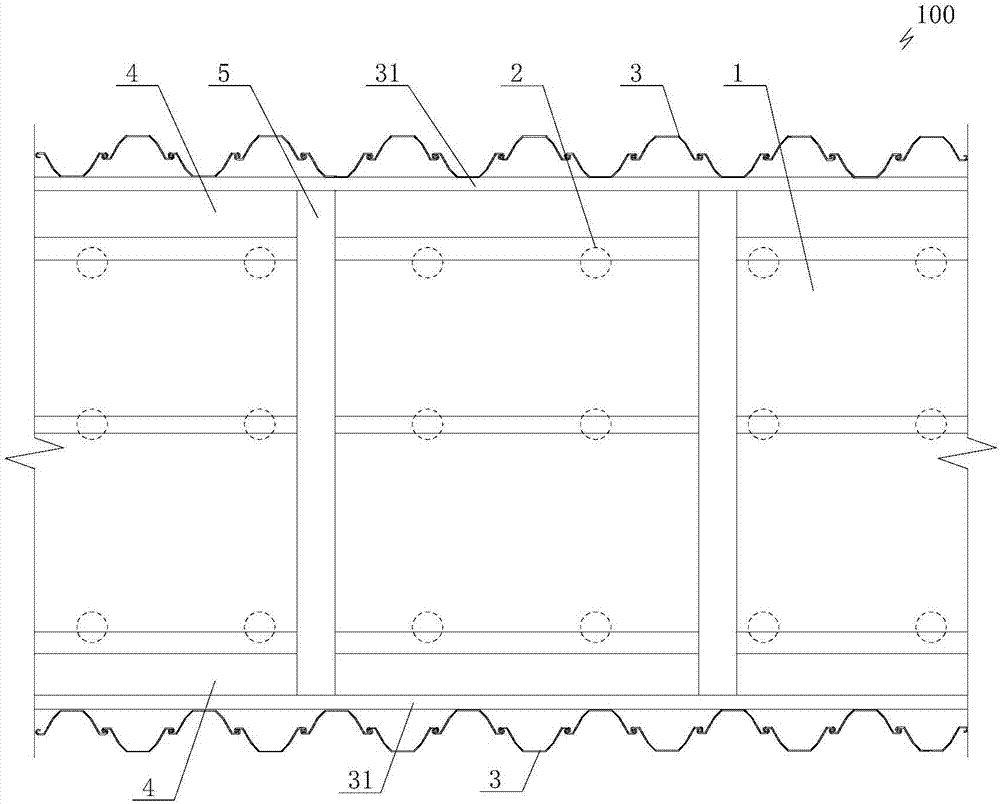

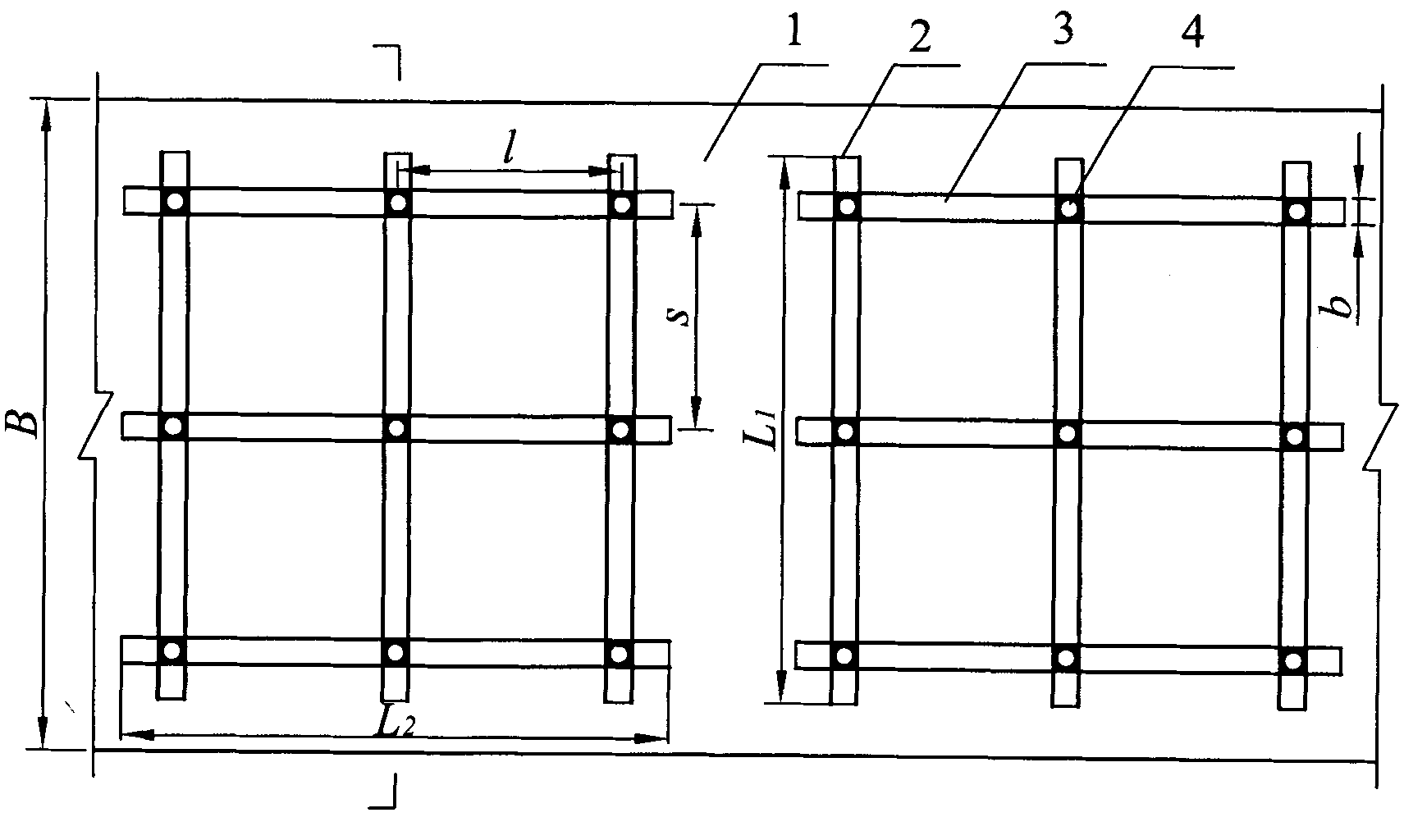

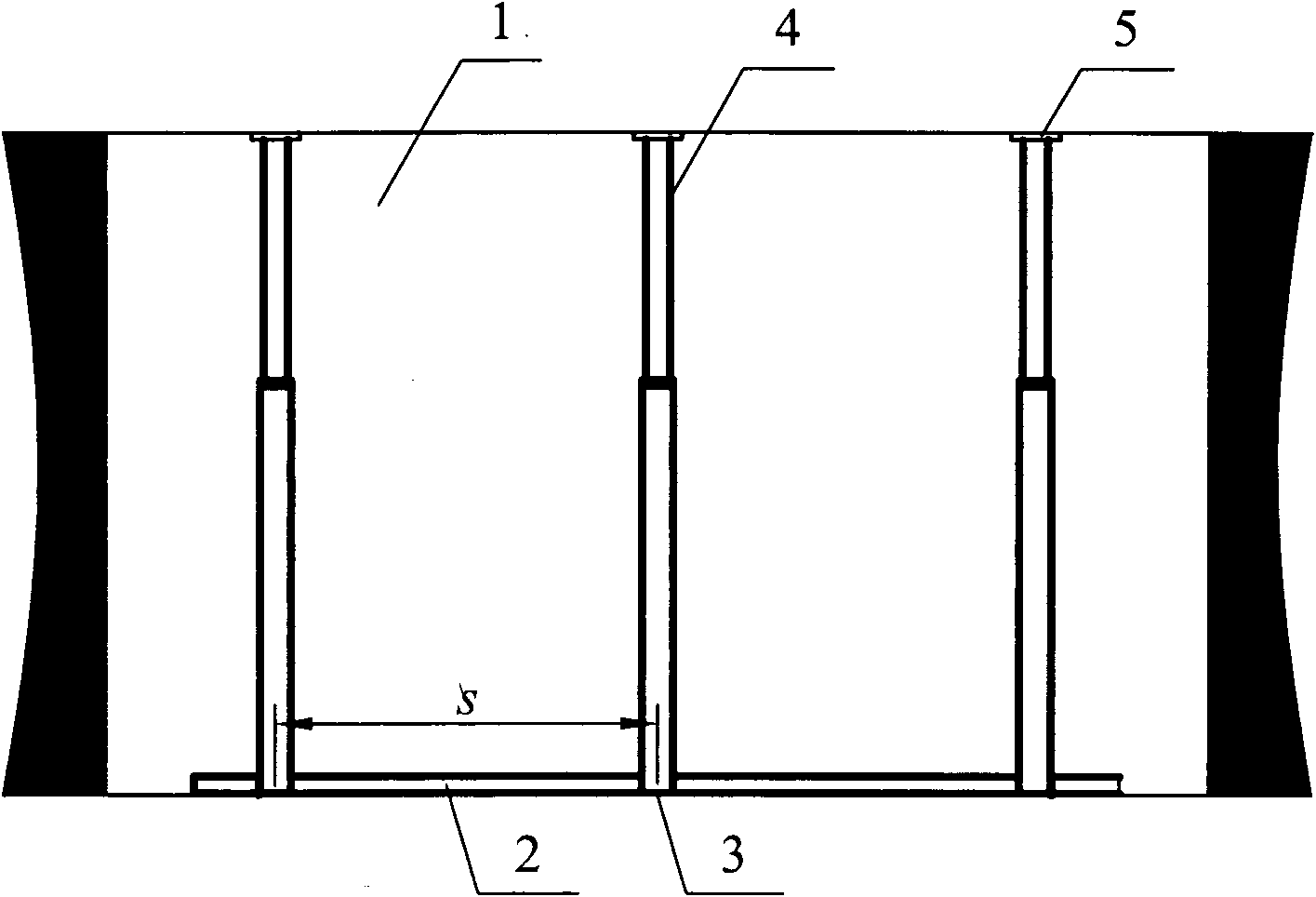

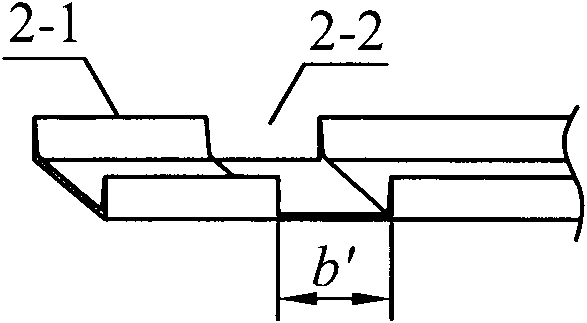

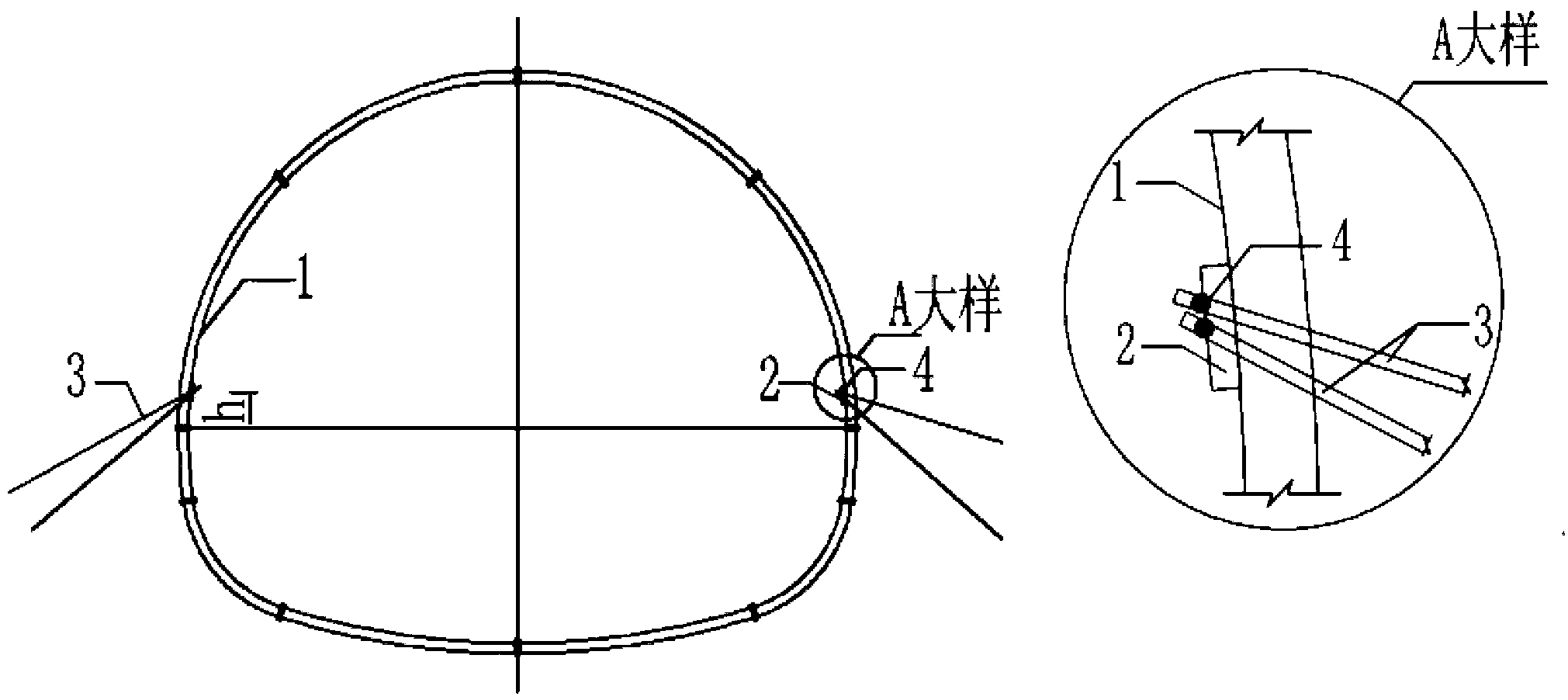

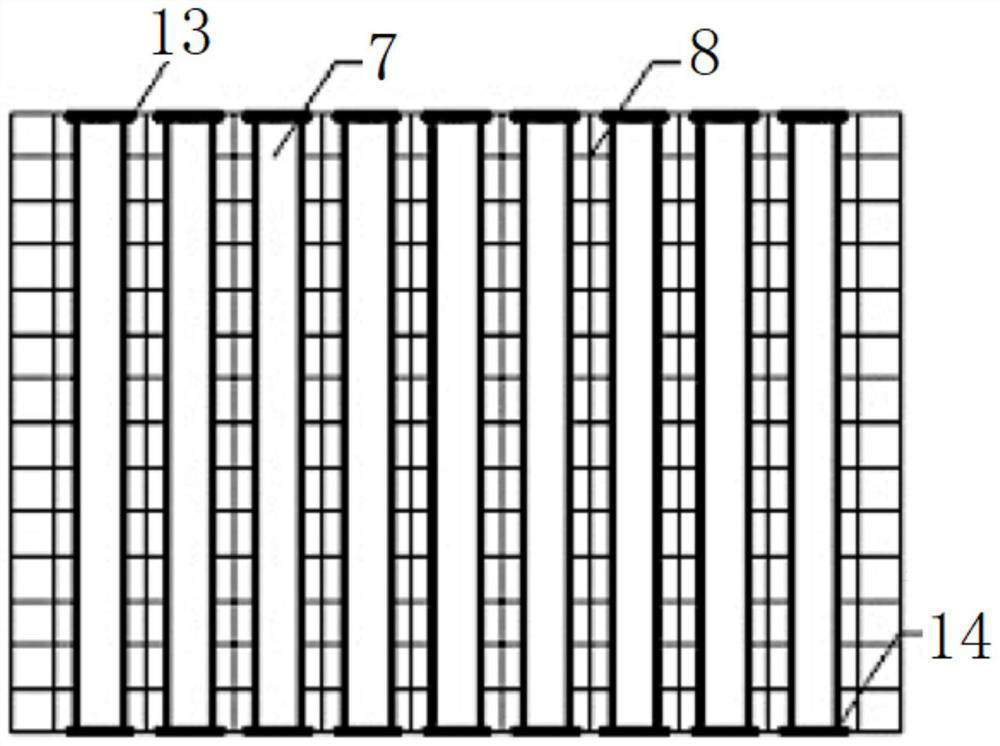

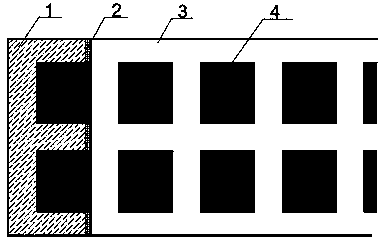

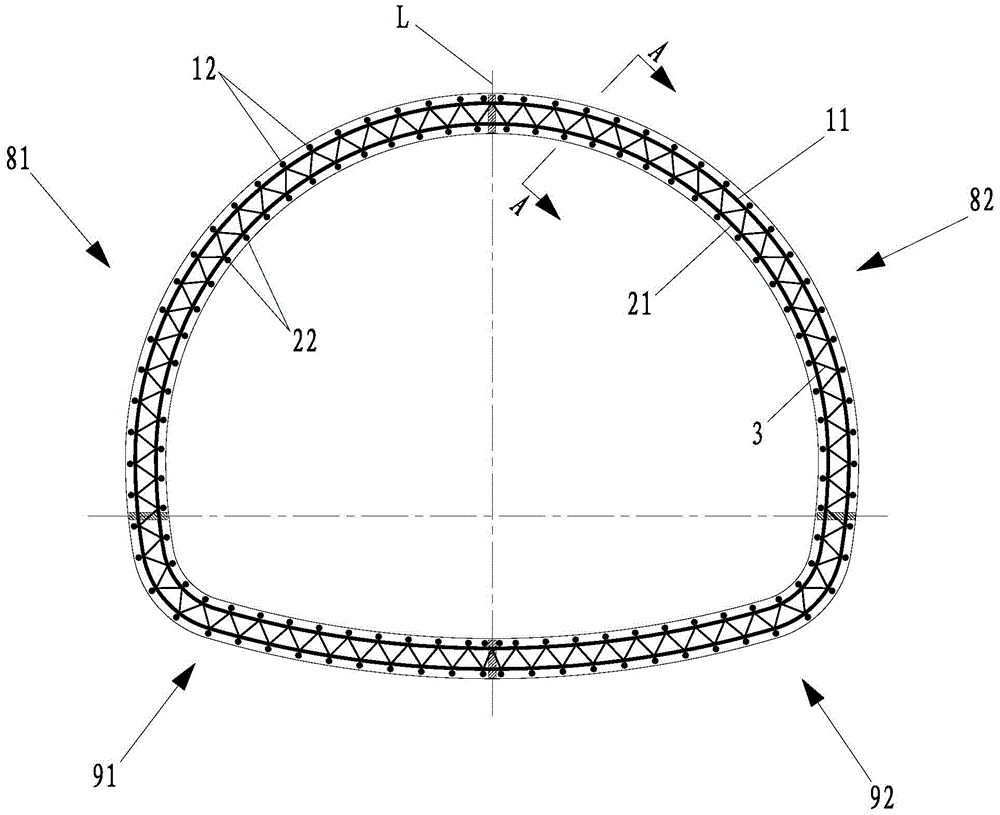

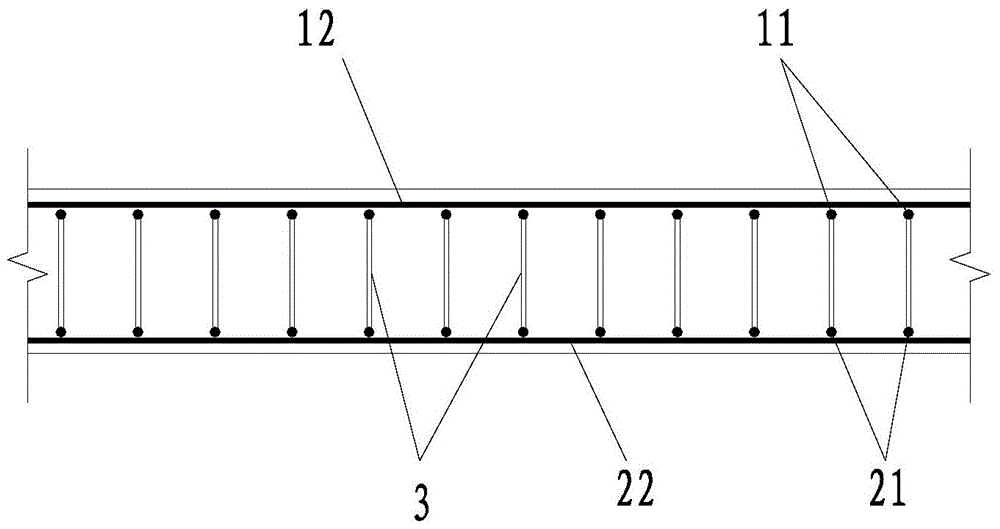

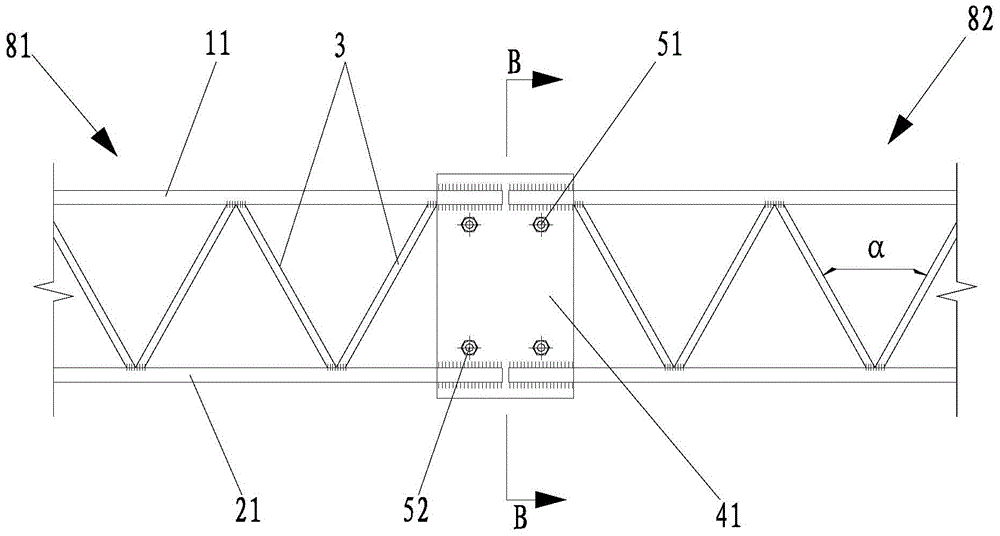

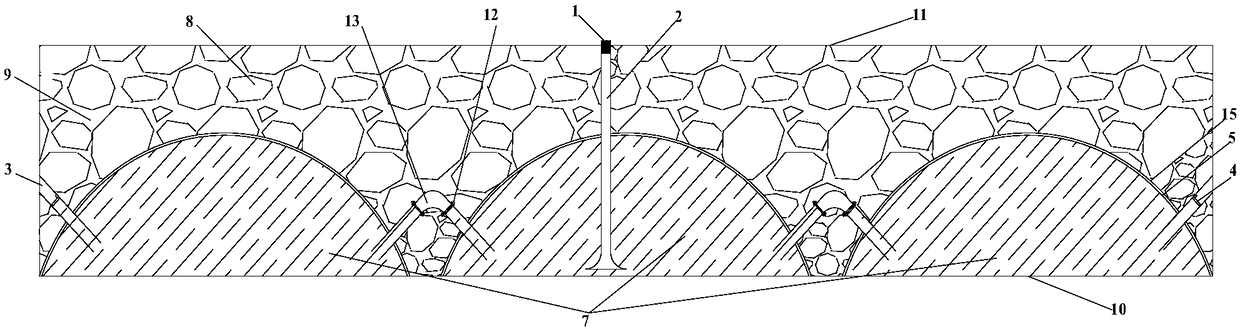

Steel bar construction for secondary lining of tunnel

InactiveCN104061004AEnsure safetyGuaranteed aestheticsUnderground chambersTunnel liningRebarProtection layer

The invention discloses a steel bar construction for secondary lining of a tunnel. The steel bar construction for the secondary lining of the tunnel comprises outer layer bar-mat reinforcement and inner layer bar-mat reinforcement, the outer layer bar-mat reinforcement comprises multiple outer layer annular main reinforcing bars which are laid in the longitudinal extending direction of the constructed tunnel and outer layer longitudinal connecting ribs which are bound to the outer layer annular main reinforcing bars, and the inner layer bar-mat reinforcement comprises multiple inner layer annular main reinforcing bars which are laid in the longitudinal extending direction of the constructed tunnel and inner layer longitudinal connecting ribs which are bound to the inner layer annular main reinforcing bars. The steel bar construction for the secondary lining of the tunnel further comprises interlayer connecting ribs connecting the outer layer bar-mat reinforcement with the inner layer bar-mat reinforcement, and each interlayer connecting rib is fixed between the corresponding outer layer annular main reinforcing bar and the corresponding inner layer annular main reinforcing bar of the same layer in a welding mode. Sinking of the outer layer bar-mat reinforcement and the inner layer bar-mat reinforcement can be effectively controlled by adding the interlayer connecting ribs which are fixed between the outer layer annular main reinforcing bars and the inner layer annular main reinforcing bars in the welding mode, the stability of the interval between an inner reinforcing steel bar layer and an outer reinforcing steel bar layer of a reinforcement cage is maintained, the thickness of a protection layer is guaranteed, safety and attractiveness of the tunnel structure are guaranteed, and working efficiency is improved.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

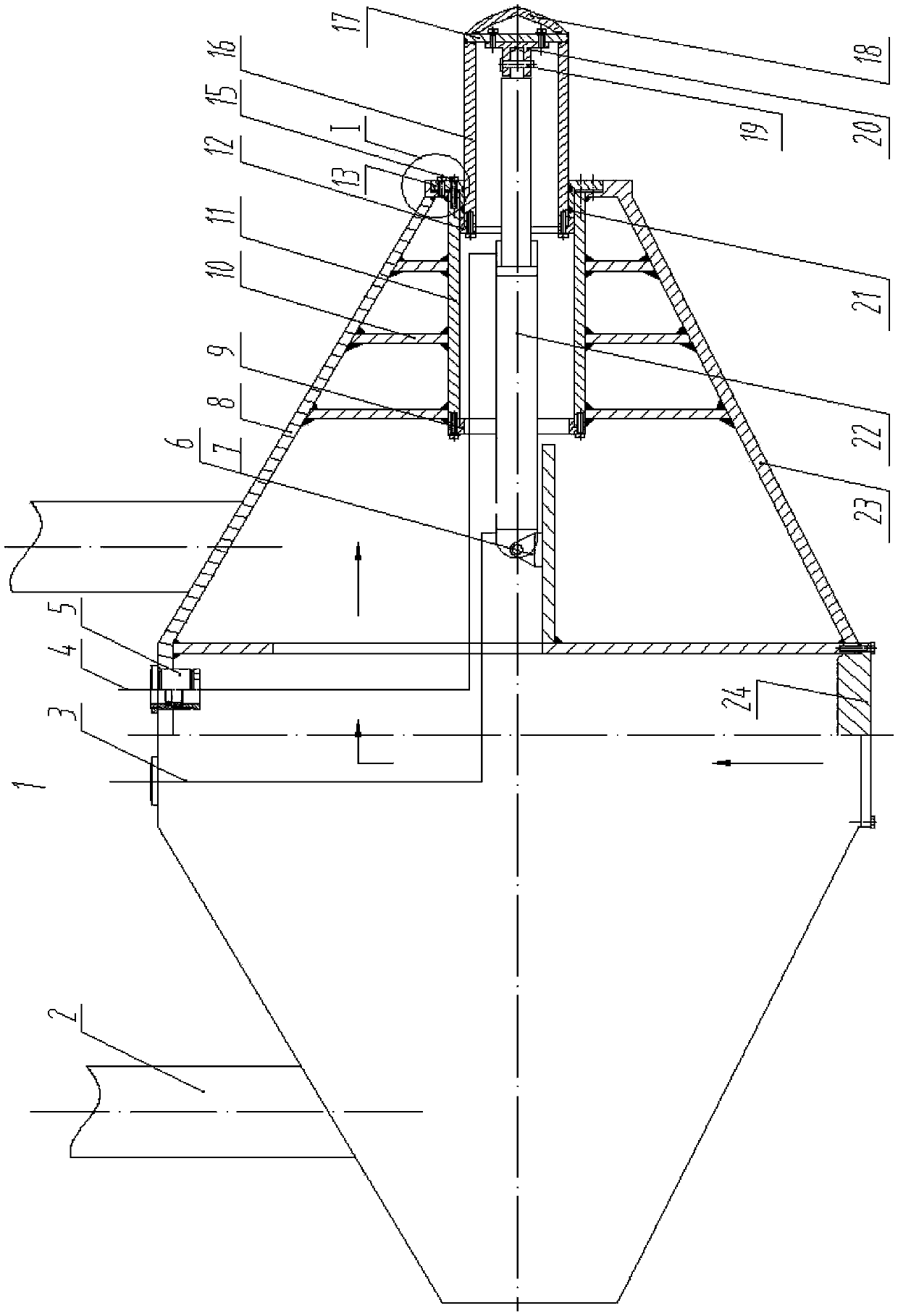

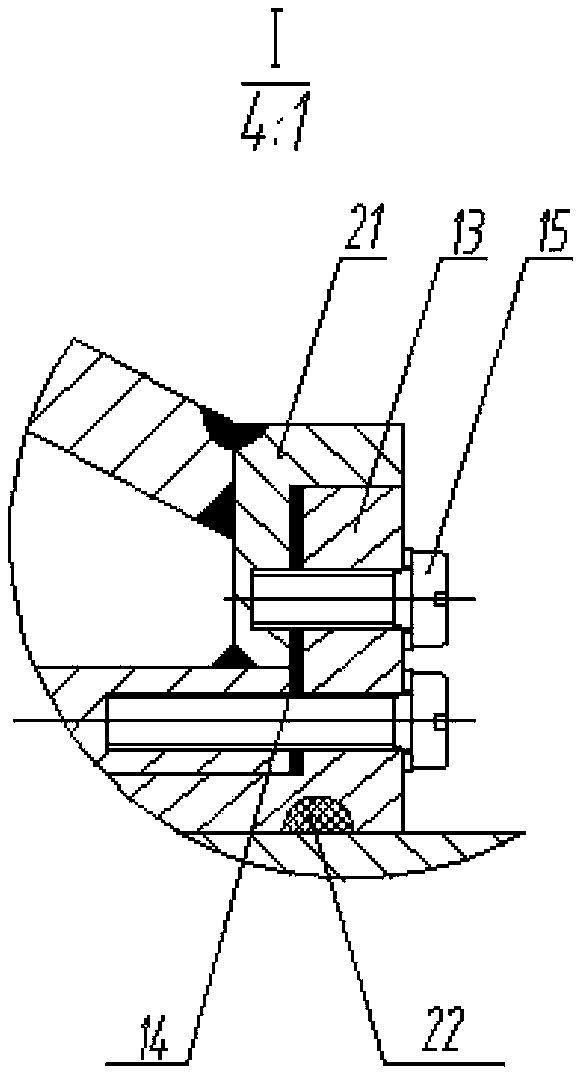

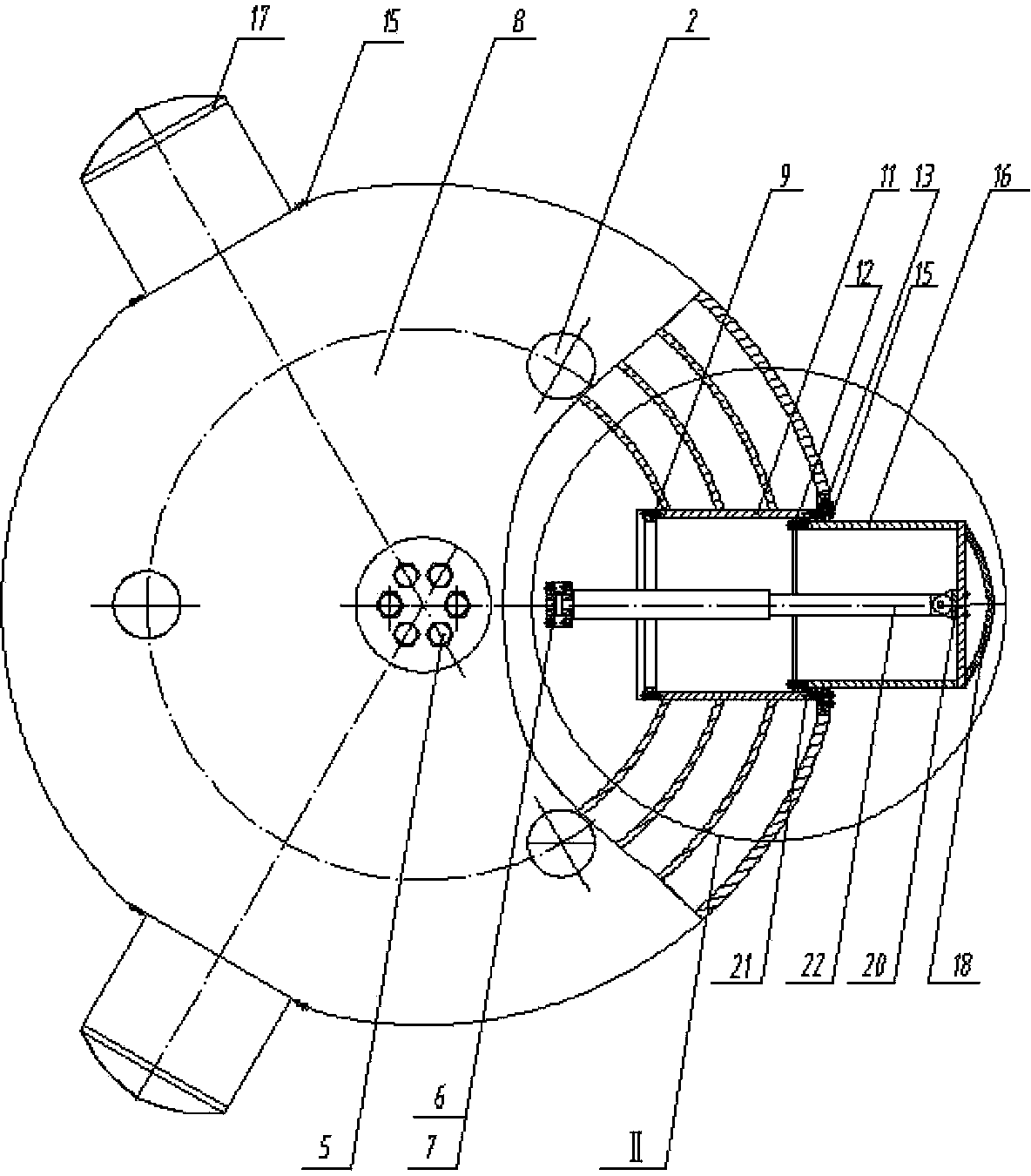

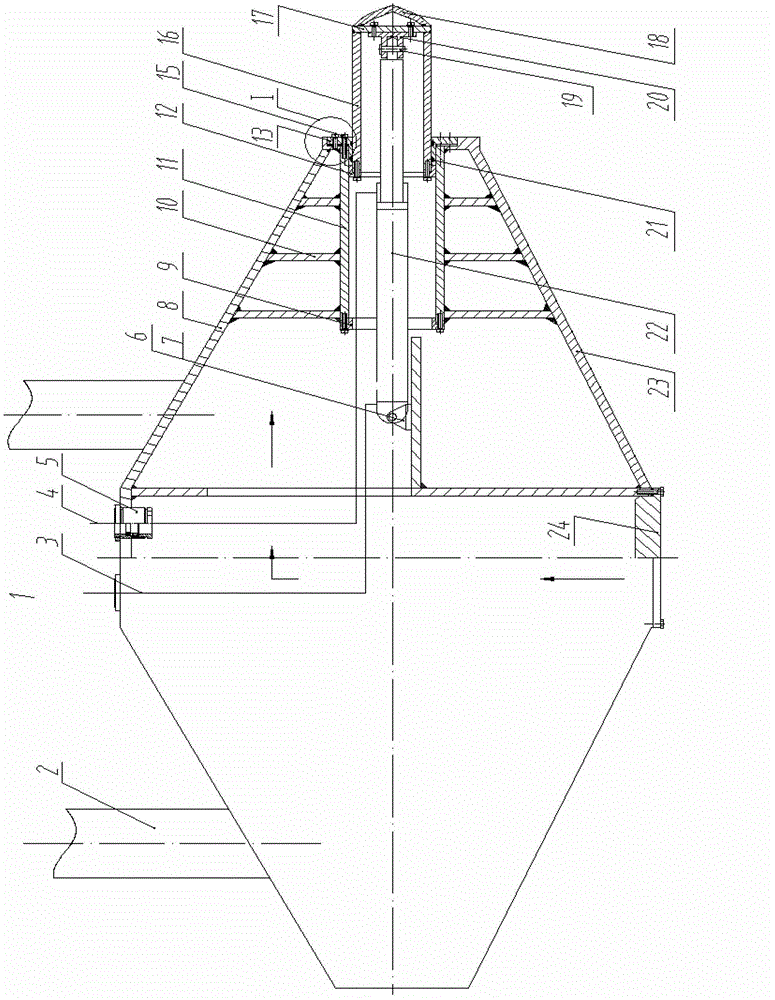

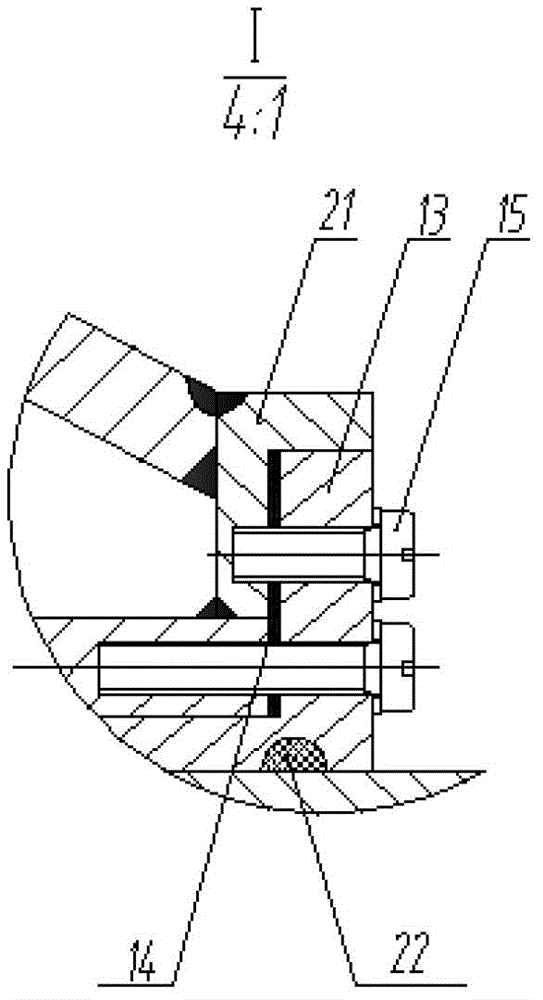

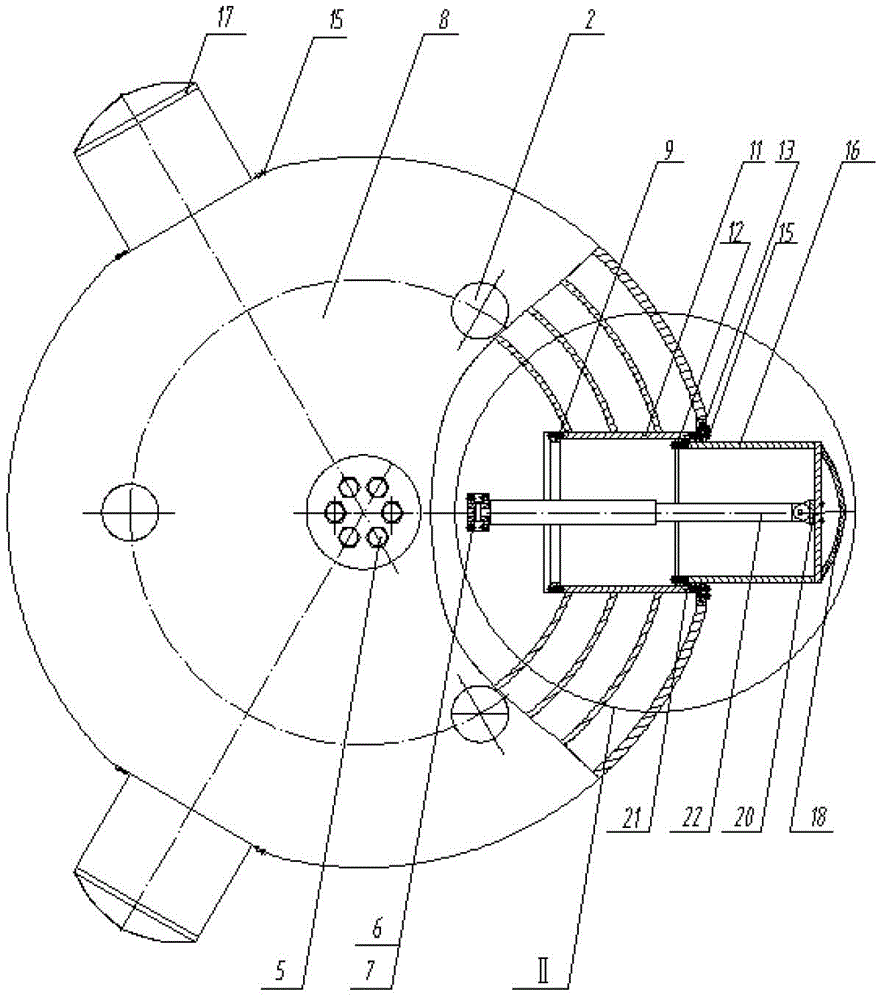

Overturn-resistant self-elevating platform pile shoe

InactiveCN103422500AFlexible operationIncrease the carrying areaArtificial islandsUnderwater structuresEngineeringHigh pressure

The invention discloses an overturn-resistant self-elevating platform pile shoe which comprises an iron-plate-shaped hollow flat circular shell body connected by an upper top board and a lower bottom board. At least three tubular sliding ways fixedly connected with the shell body are horizontally arranged along the circumference wall of the shell body in an equally spaced mode; the front end of each tubular sliding way is provided with a limiting ring and a sealing ring, the rear end of each tubular sliding way is provided with a flange, a hydraulic oil cylinder and at least one section of telescopic pipe are sequentially arranged from the rear end to the front end, one end of a piston rod of the hydraulic oil cylinder is connected with a reinforced bar inside the shell body, a rod head arranged at the other end of the piston rod is connected with the inner end face of the front end of the telescopic pipe, the front end of the telescopic pipe is closed, and the rear end of the telescopic pipe is provided with a flange; the upper top board of the shell body is further provided with a watertight stuffing box, a watertight door is arranged at the bottom of the lower bottom board, and the hydraulic oil cylinder is communicated with a hydraulic servo system installed on a self-elevating platform through a high-pressure oil pipe. The overturn-resistant self-elevating platform pile shoe has the advantages of being flexible in operation, safe, reliable, resistant to overturning and sliding and strong in puncturing capacity.

Owner:JIANGSU UNIV OF SCI & TECH

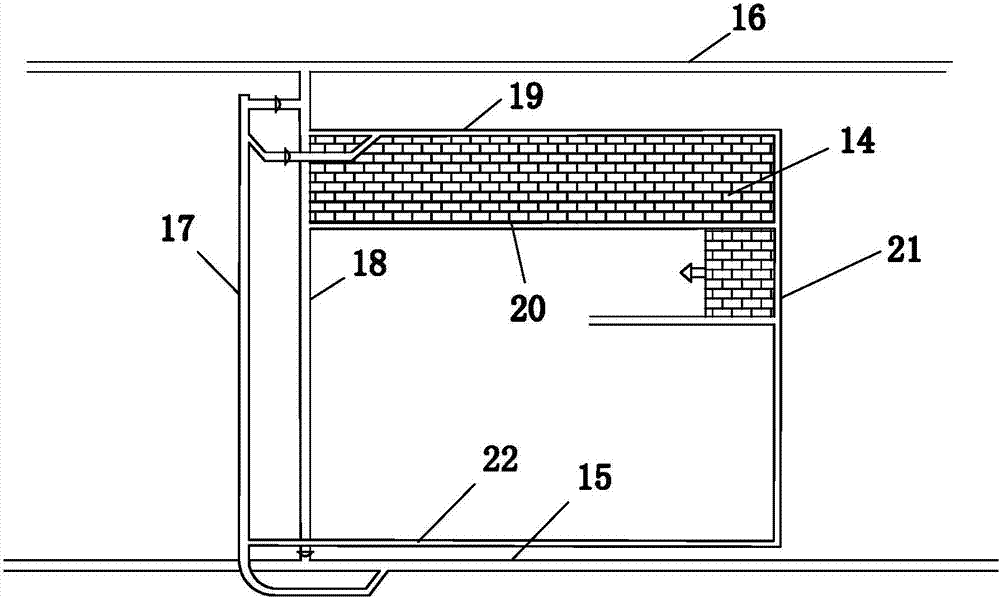

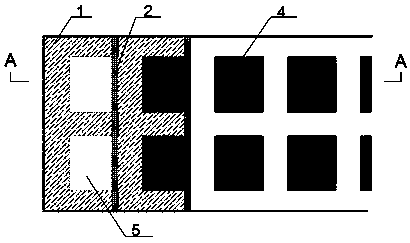

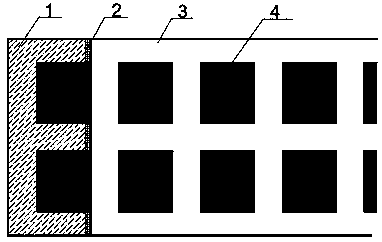

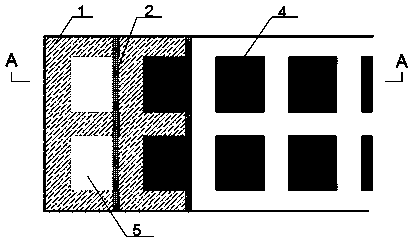

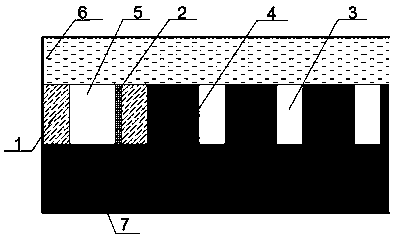

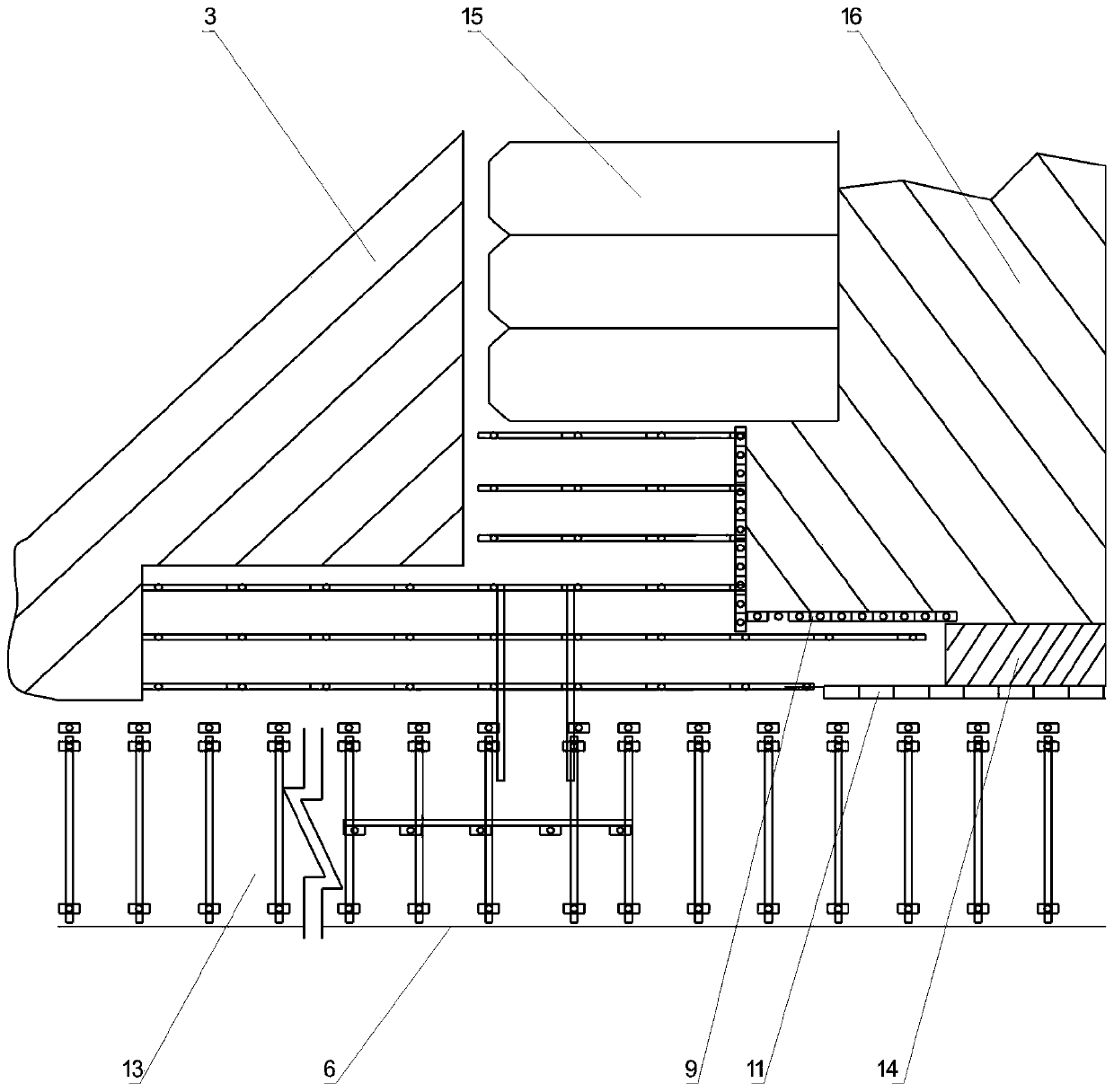

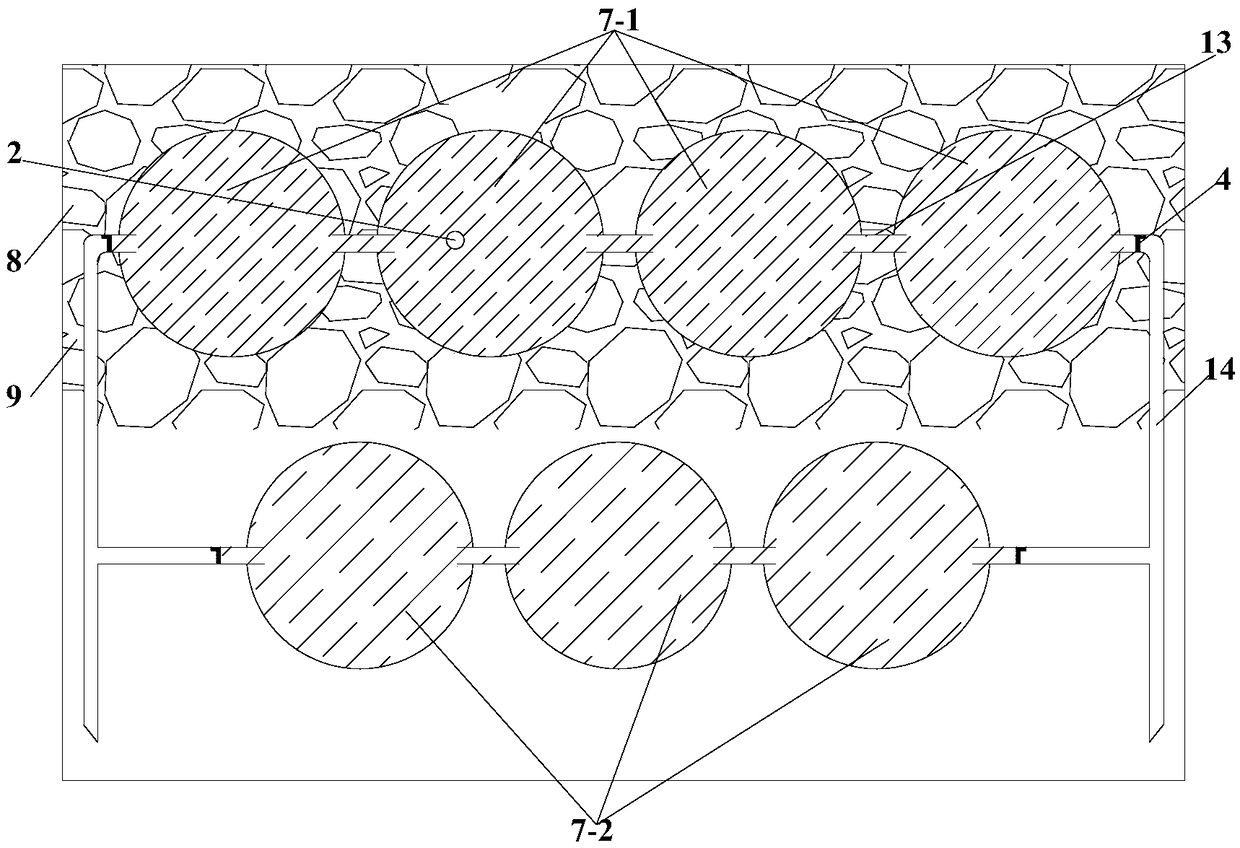

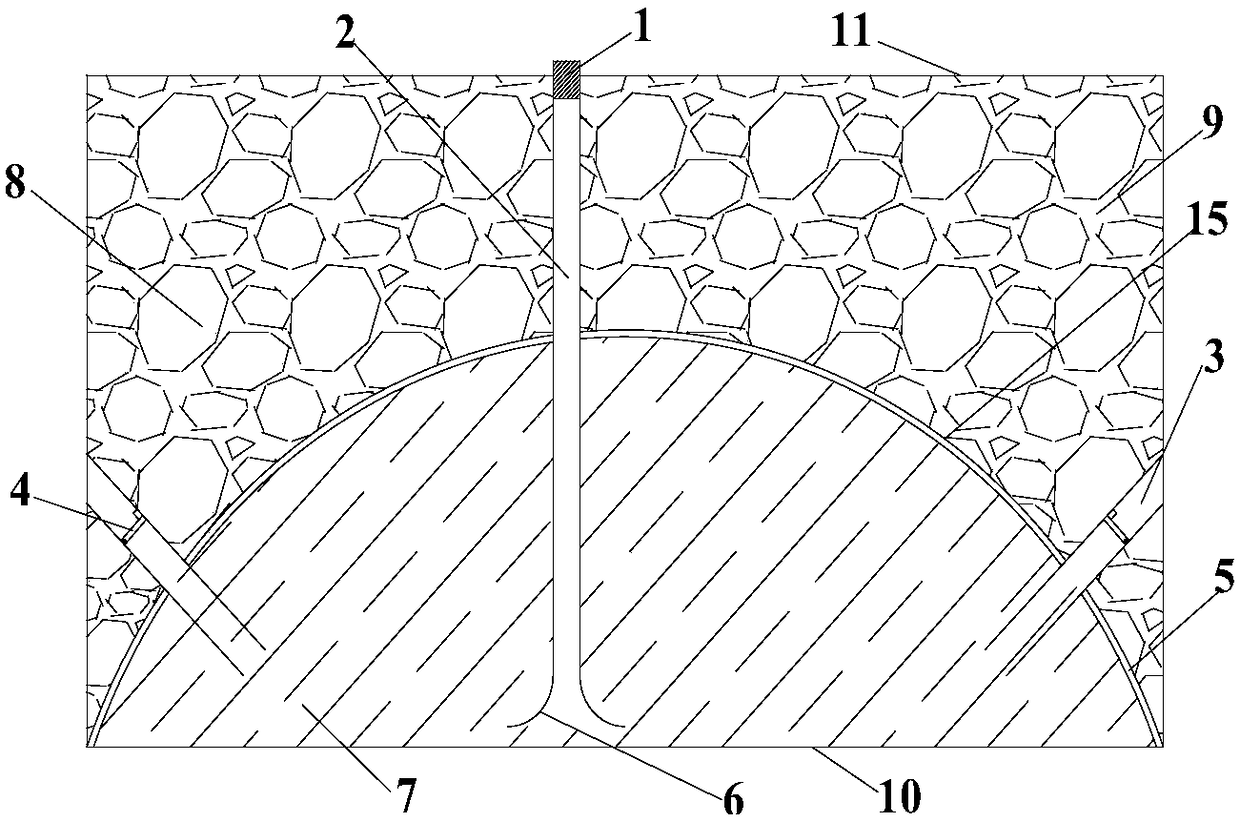

Soft soil foundation comprehensive pipe gallery and construction method thereof

The invention relates to a soft soil foundation comprehensive pipe gallery and a construction method thereof. The soft soil foundation comprehensive pipe gallery comprises a pipe gallery body. A plurality of prestressed reinforced concrete pipe piles are arranged at the bottom of the pipe gallery body. All the prestressed reinforced concrete pipe piles are arranged in a soil body at the bottom of the pipe gallery body. The top pile heads of all the prestressed reinforced concrete pipe piles are fixedly connected with a bottom plate of the pipe gallery body. Detachable Larson steel plate piles are arranged in soil bodies on the two sides of the pipe gallery body in the longitudinal direction of the pipe gallery body correspondingly. The Larson steel plate piles and the two sides of the pipe gallery body are arranged in a spaced mode. The Larson steel plate piles form a construction side supporting structure of the pipe gallery body. According to the soft soil foundation comprehensive pipe gallery and the construction method thereof, the large settlement and floating problems of soft soil foundation pipe galleries in the prior art are solved, failure of the comprehensive pipe gallery is avoided, and the stability of the comprehensive pipe gallery is effectively ensured.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

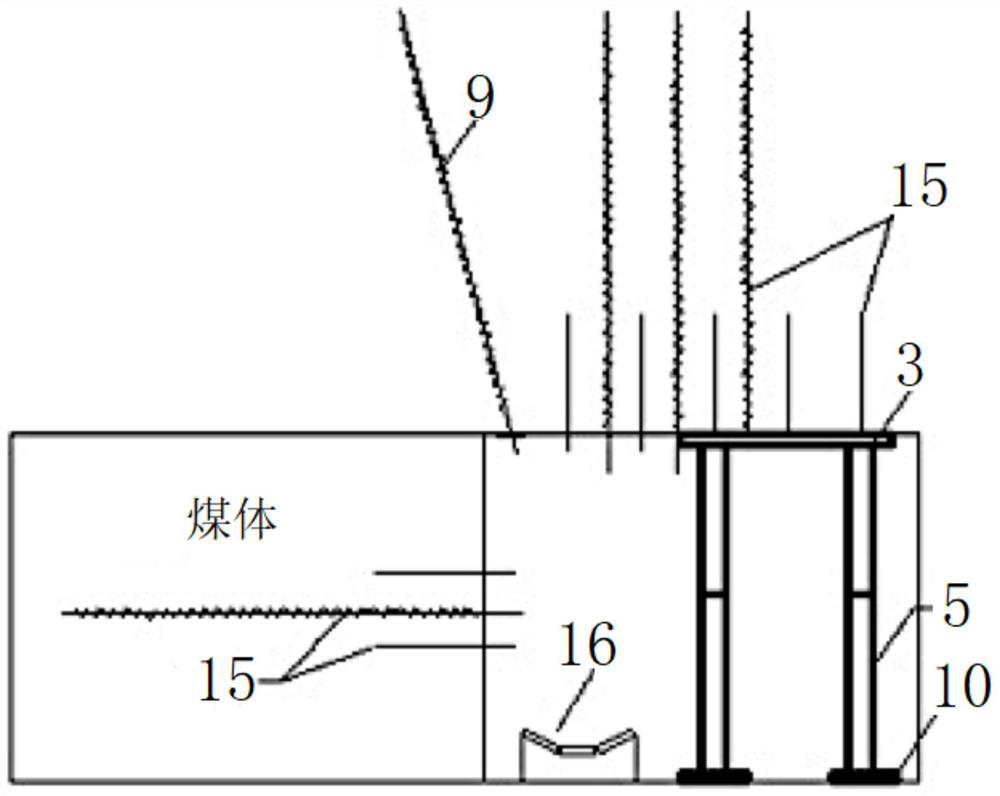

Shallow coal seam water protection mining method and application thereof

ActiveCN107542465APromote recoveryRealize the protective exploitation of water resourcesUnderground miningSurface miningSufficient timeFracture zone

The invention discloses a shallow coal seam water protection mining method and an application thereof and belongs to the technical field of coal mining. In a working face, a plurality of pre-excavation roadways are vertically or obliquely demarcated from a main transportation roadway, roadway excavation is conducted in a multipoint parallel operation mode, and the excavated roadways are filled intime. By controlling the roadway excavation width, the roadway interval width, the roadway excavation speed, the filling speed and the interval filling time, the fracture development of mining overburden rock and the falling capacity of roadway roofs are effectively controlled. By means of the method, continuous, stable and efficient coal production of the working face is guaranteed, sufficient time and effective space are provided for filling of the working face so as to make a filling body solidify and meet bearing strength requirements, evolution of the permeability of a water-resisting layer on a water flowing fracture zone of a shallow coal seam is controlled effectively, water protection mining of an occurrence area of the shallow coal seam is achieved, selection and application conditions of the water protection mining method are widened, and meanwhile safe, efficient and high-recovery-rate mining of coal resources is achieved.

Owner:陕西省地质环境监测总站 +1

Governance method of floor heave of mine roadway during mining

InactiveCN101936172AImprove support strengthThe supporting strength is sufficientProps/chocksEngineeringUltimate tensile strength

Owner:CHINA UNIV OF MINING & TECH

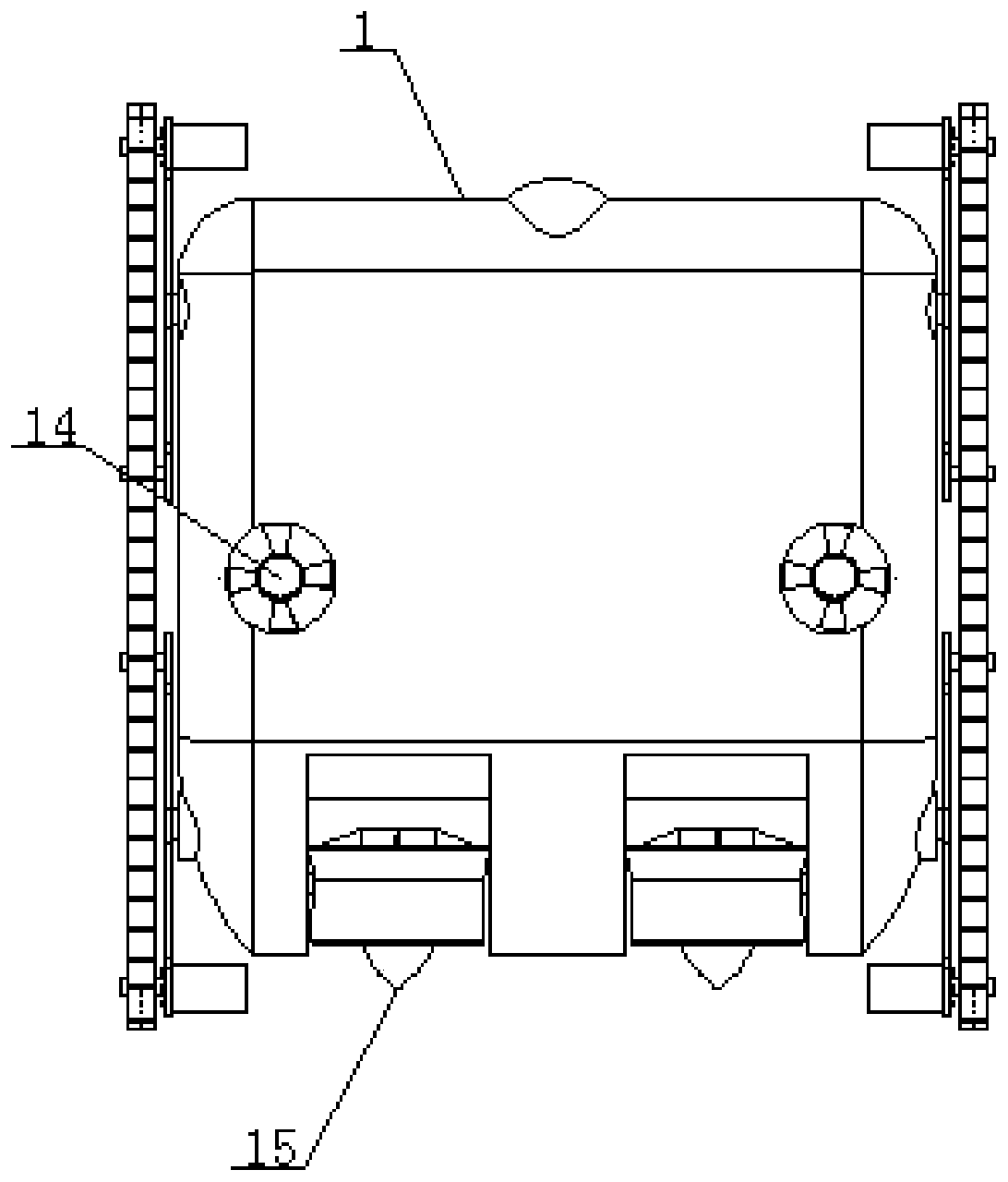

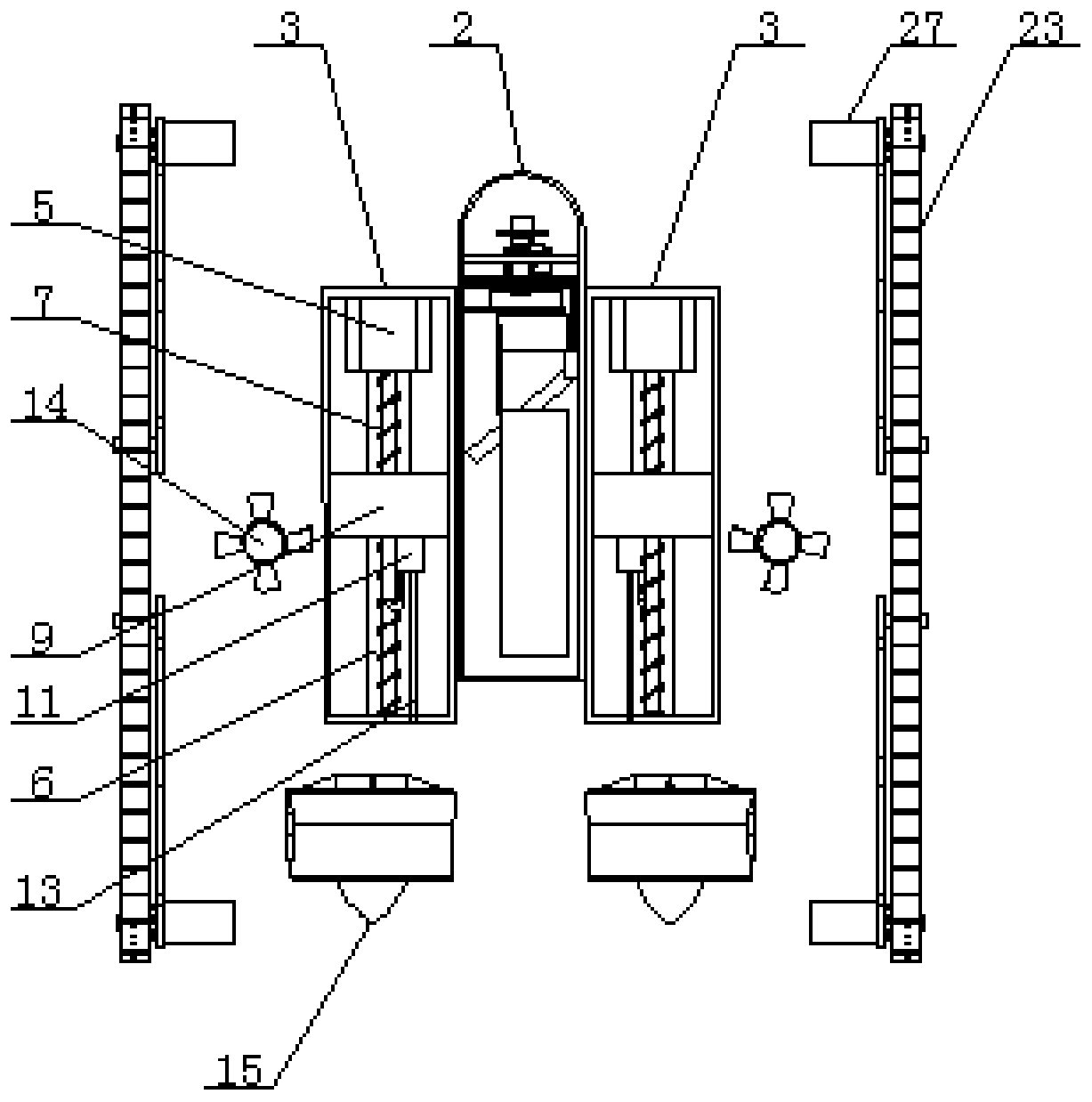

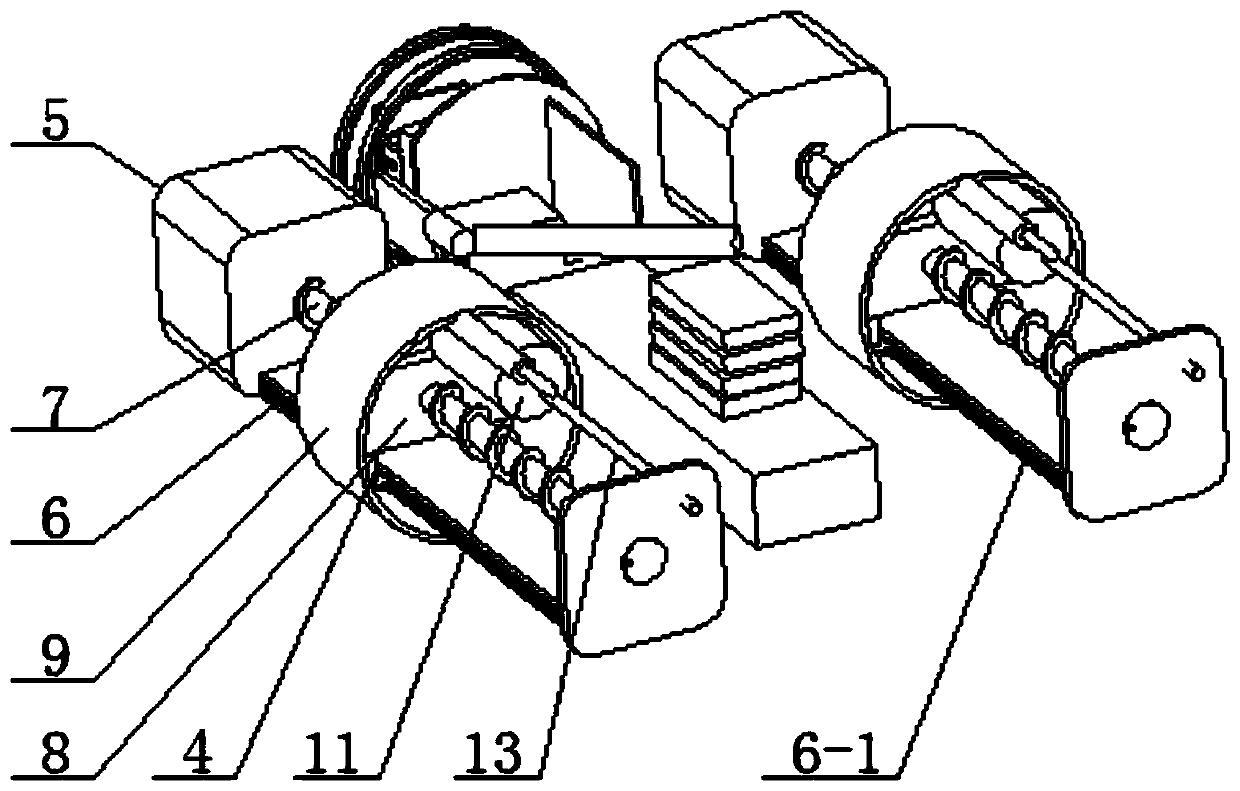

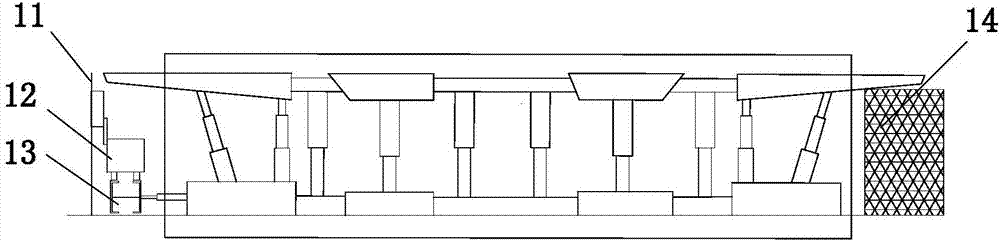

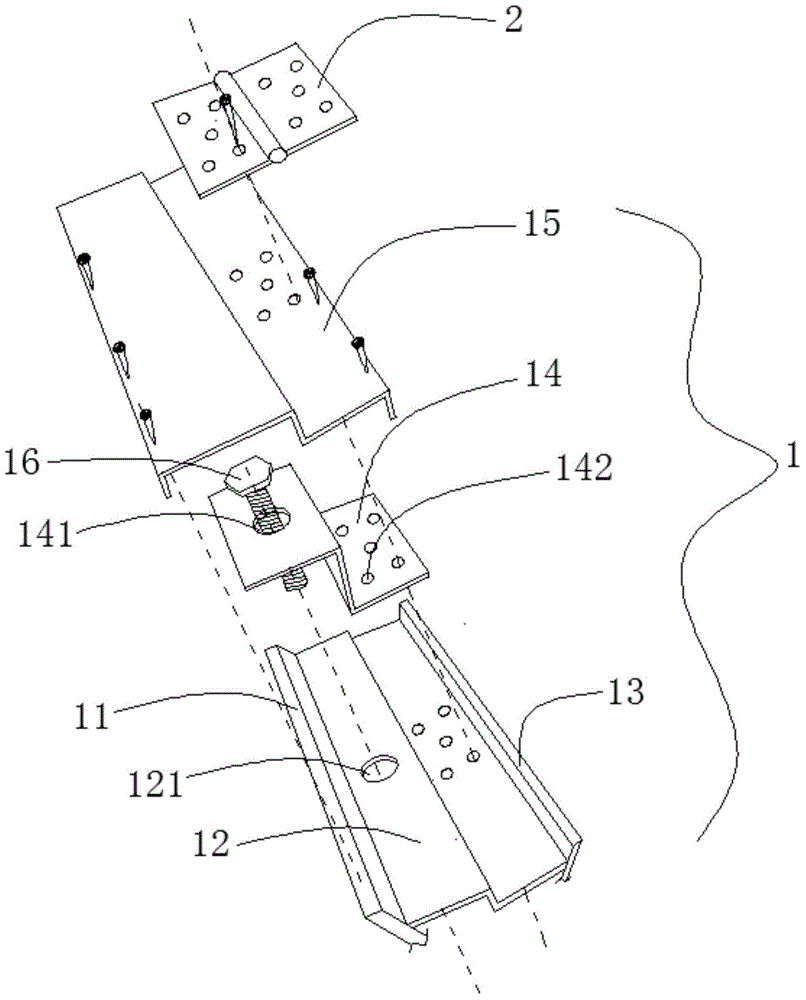

Crawler-type robot with underwater posture changing function

ActiveCN110125950ARealize multiple posture changesControlled sinkingManipulatorUnderwater equipmentPropellerEnergy consumption

The invention discloses a crawler-type robot with an underwater posture changing function, and belongs to the field of underwater robots. The crawler-type robot solves the problem that an existing underwater robot can flexibly operate in a complex underwater environment due to the fact that a propeller changes the working posture energy consumption and is unstable. The crawler-type robot comprisesa shell, a monitoring mechanism, a vertical propeller, a horizontal propeller, two sets of posture changing mechanisms and two sets of crawler walking mechanisms, wherein the monitoring mechanism isarranged at the front end of the shell and is used for underwater monitoring, the vertical propeller is arranged in through holes in the two sides of the upper part of the shell and is used for floating and transverse inclination of the underwater robot, and a horizontal propeller is arranged at the rear end of the shell and is used for advancing and retreating and turning of the underwater robot,each crawler walking mechanism is arranged on the side walls of the two sides of the shell and used for climbing the underwater robot, and the two sets of posture changing mechanisms are arranged onthe two sides inside the shell, and are used for changing the posture of the underwater robot. The crawler-type robot is used for underwater operation.

Owner:HARBIN ENG UNIV

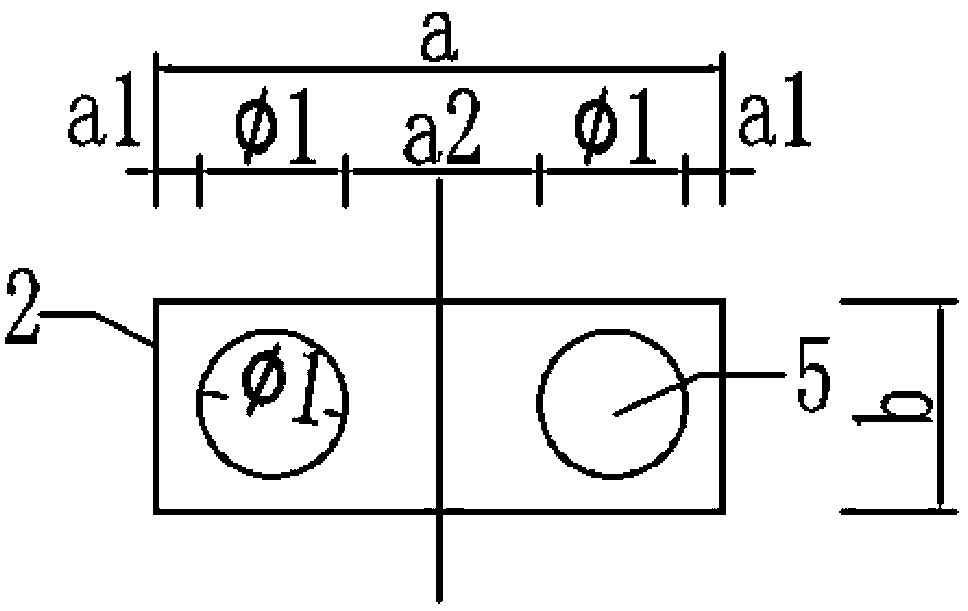

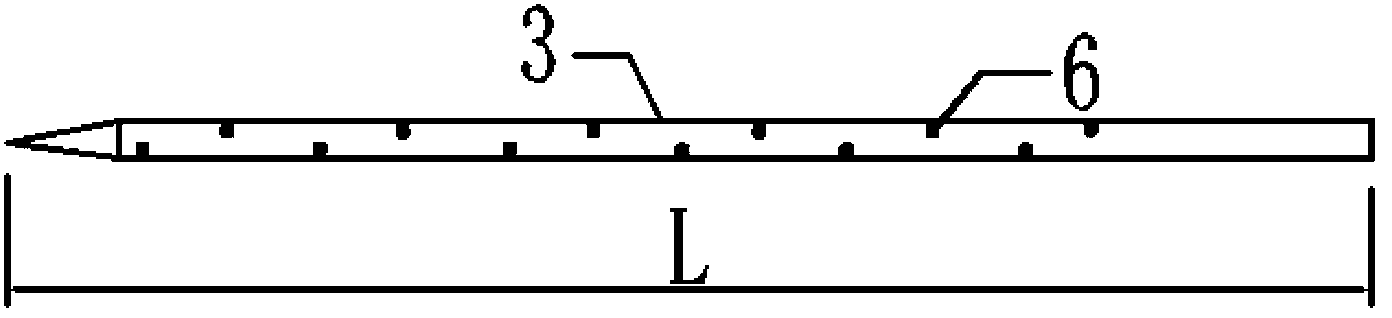

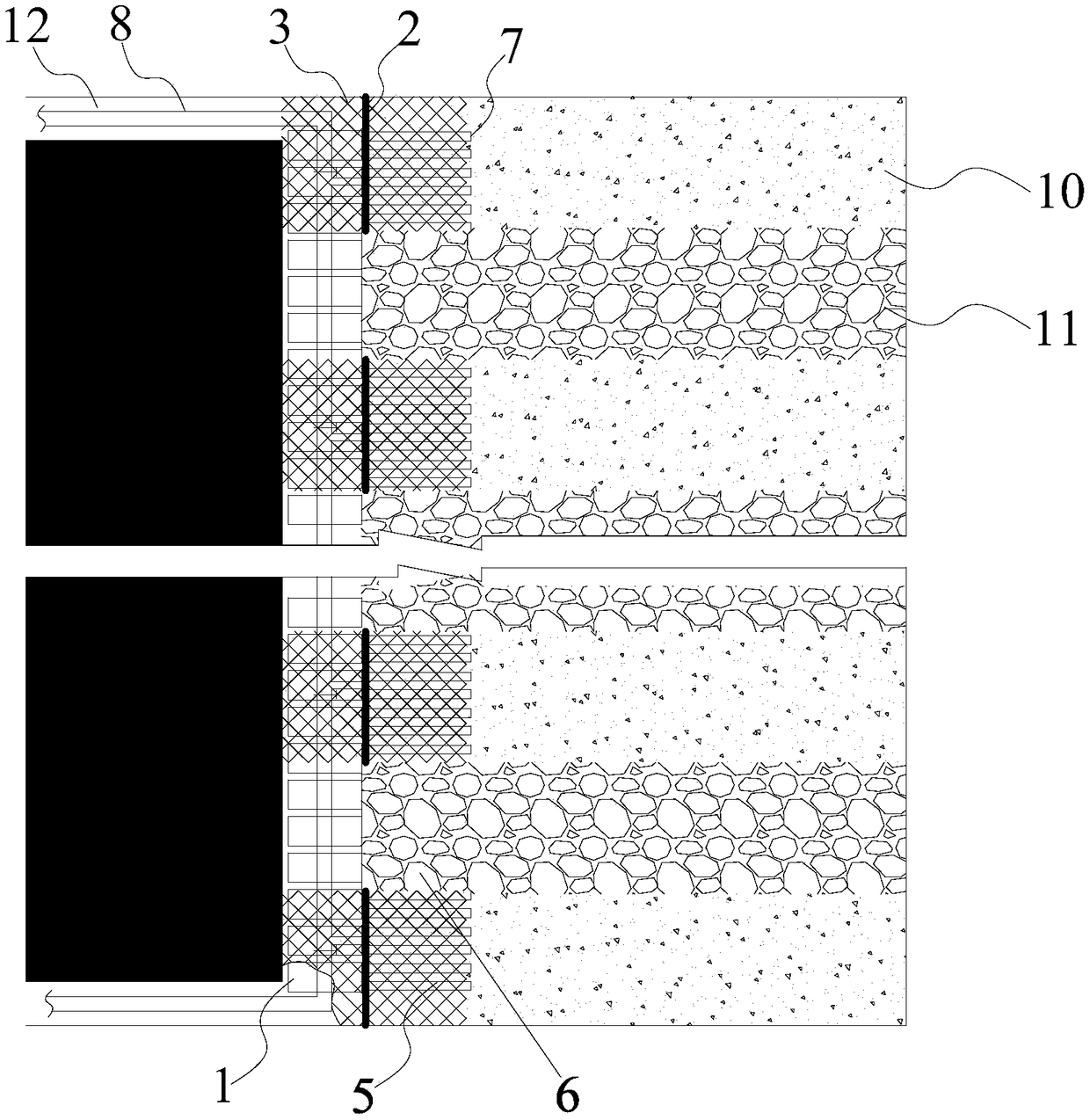

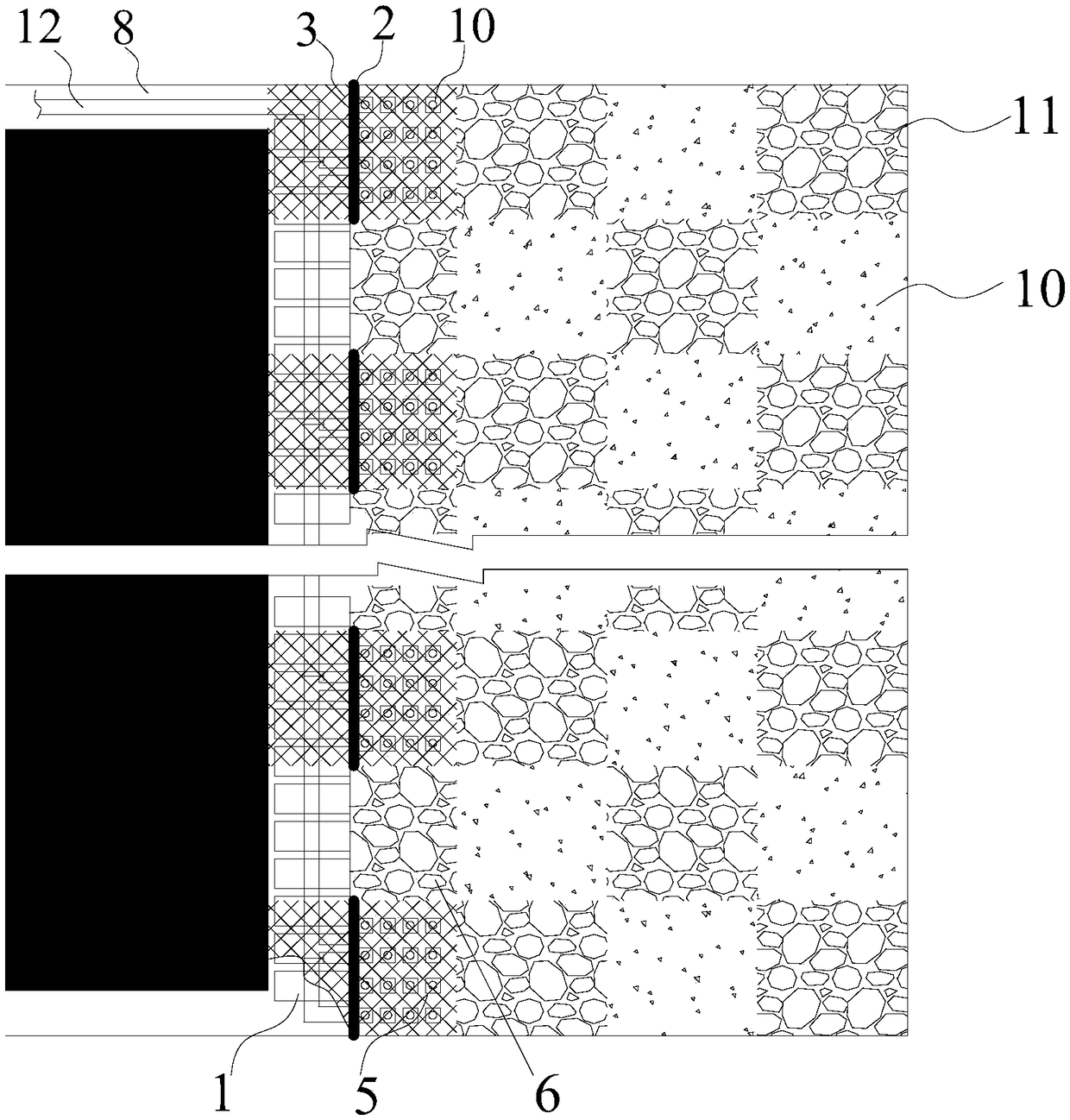

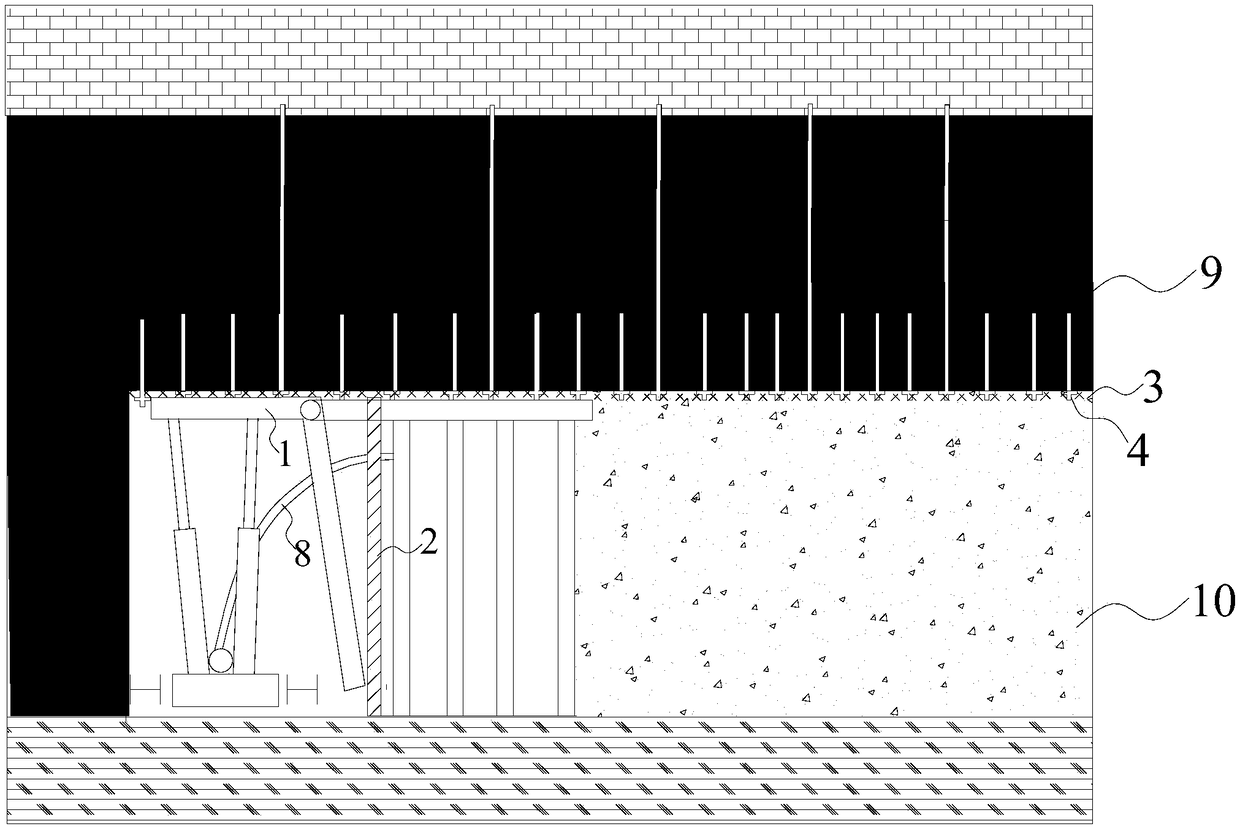

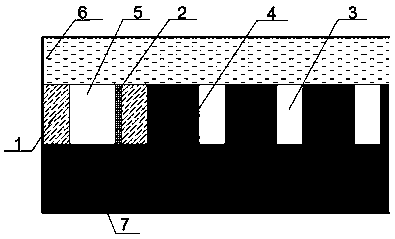

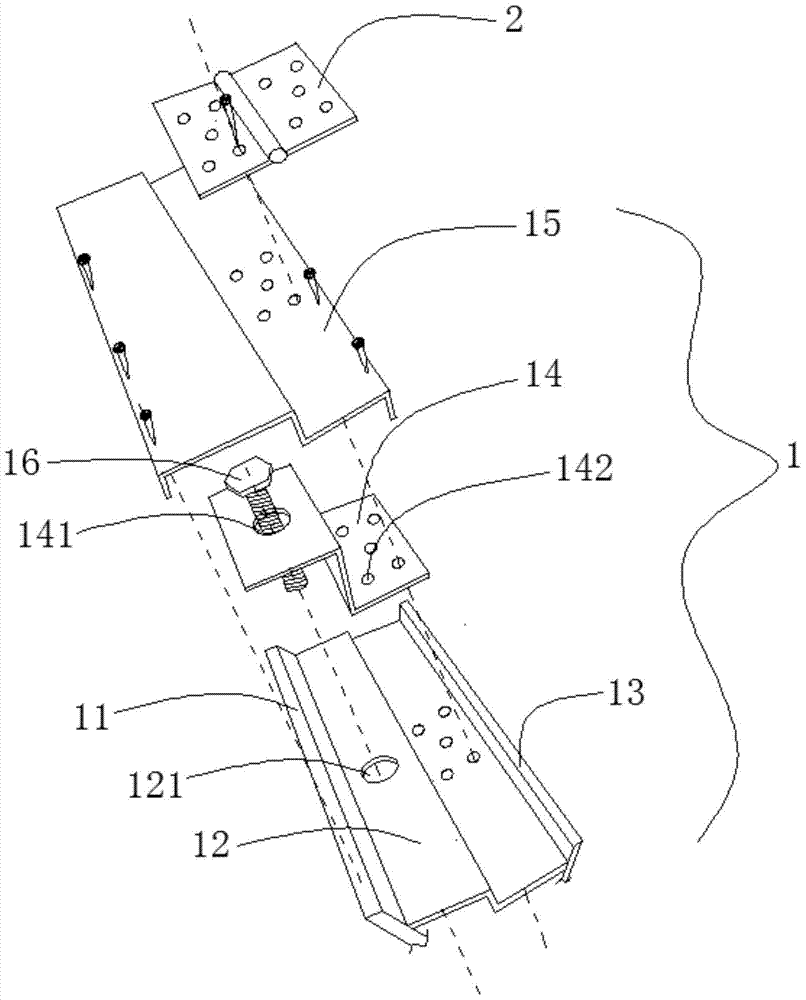

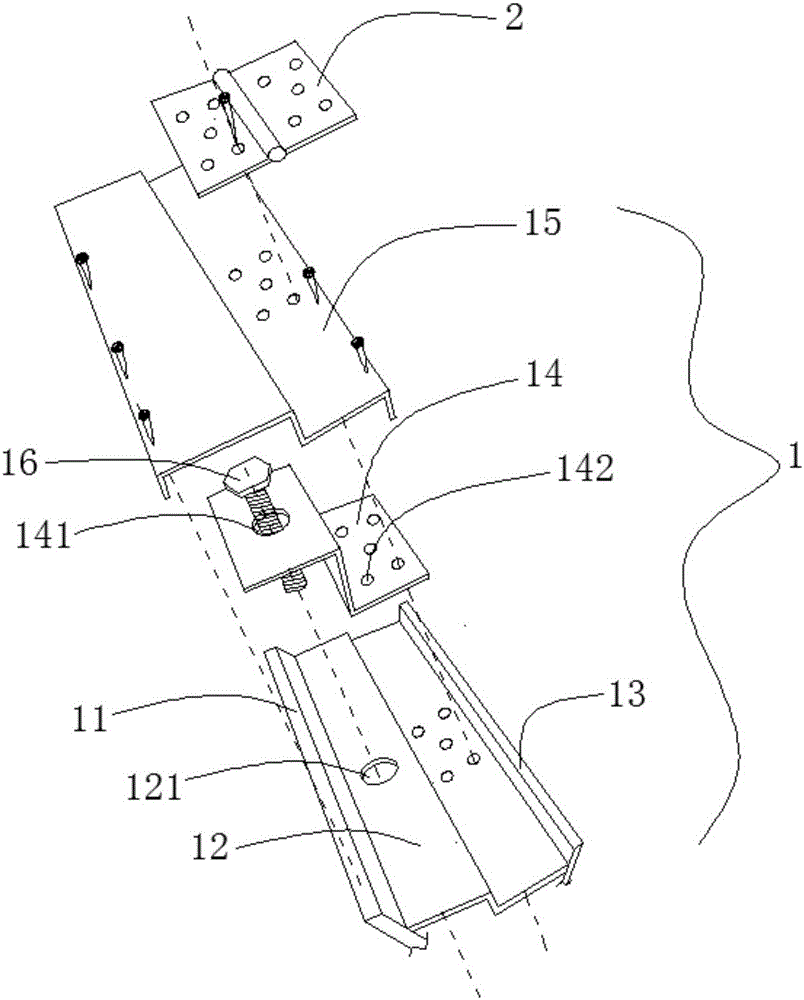

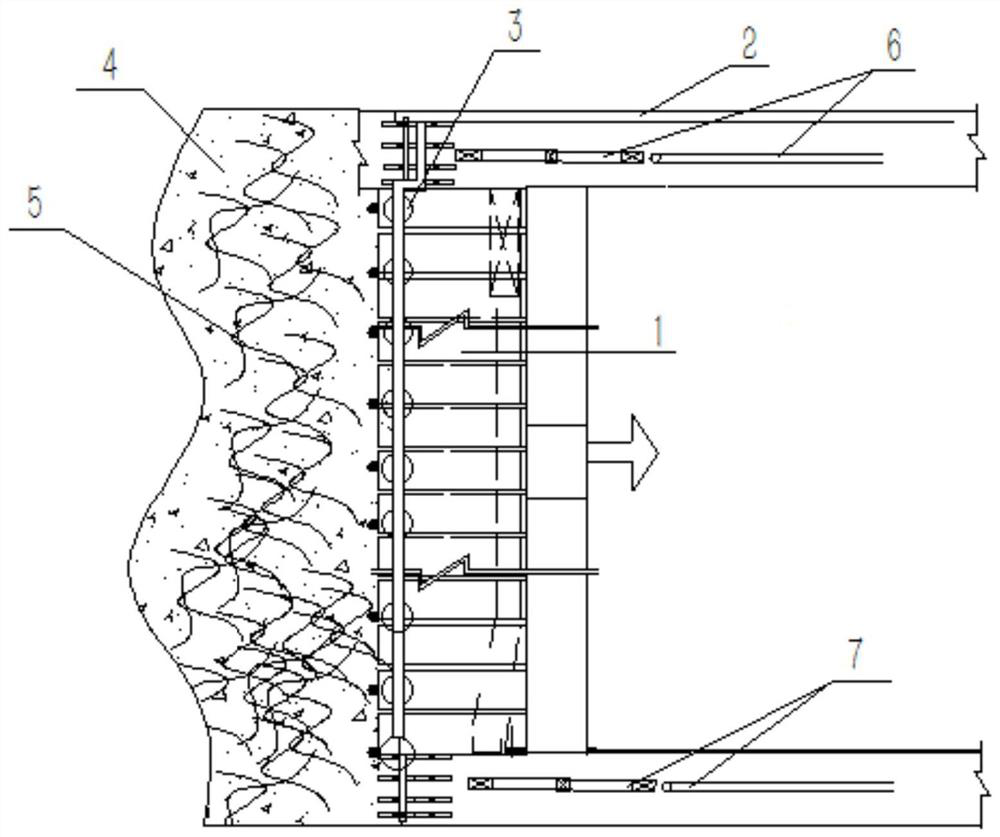

Small feet-lock guide pipe with steel plate connection

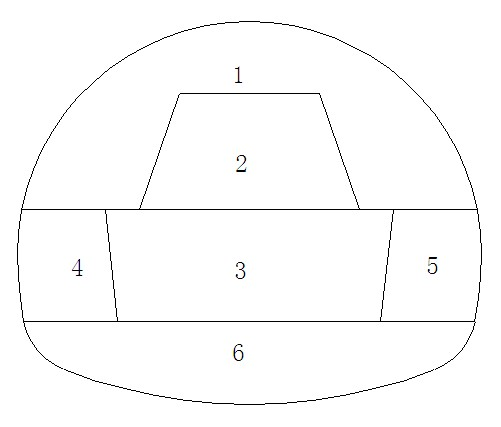

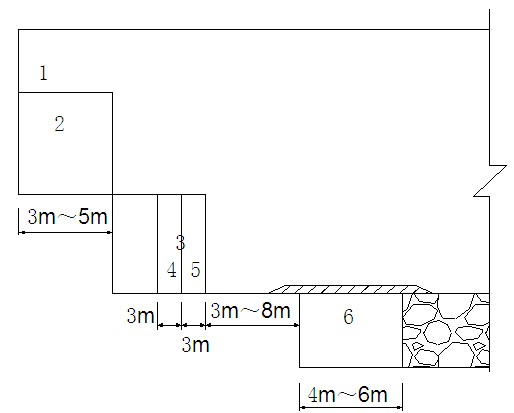

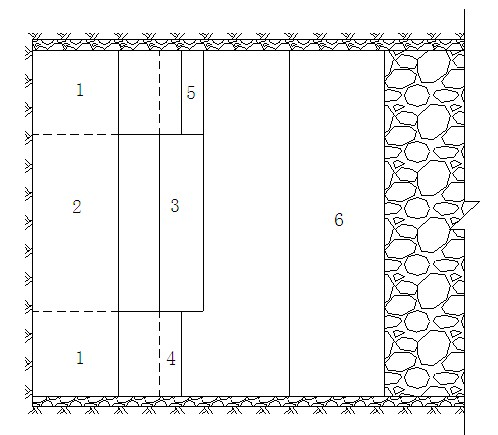

ActiveCN103277125AShorten construction timeImprove the construction environmentAnchoring boltsSteel platesClerestory

The invention relates to a small feet-lock guide pipe with steel plate connection. The small feet-lock guide pipe is characterized in that a feet-lock steel plate with two symmetric round holes is welded on H-shaped steel to be locked at feet, small feet-lock guide pipes drilled with mortar injection holes penetrate the round holes of the feet-lock steel plate to be hit into wall rock, a reinforcing steel bar limit ring is sleeved at one end of each small feet-lock guide pipe and used as a connector for welding and fixing the feet-lock steel plate and the small feet-lock guide pipes. By the small feet-lock guide pipe, the wall rock and the small feet-lock guide pipes can be tightly connected, the small feet-lock guide pipes are fixedly connected with the H-shaped steel in preliminary bracing, so that the purposes of controlling restraint, controlling arch and controlling integral submergence of the ground are achieved. Members can be processed and manufactured industrially, the steel plate and the H-shaped steel can be welded in advance outside a tunnel, construction time in the tunnels is shortened, construction progress and construction quality are improved, and construction environment inside the tunnel is improved. The small feet-lock guide pipe is safe, reliable and convenient to operate, and meets requirements of safety, quality, progress, economic benefits, social benefits and the like.

Owner:云南交投集团云岭建设有限公司

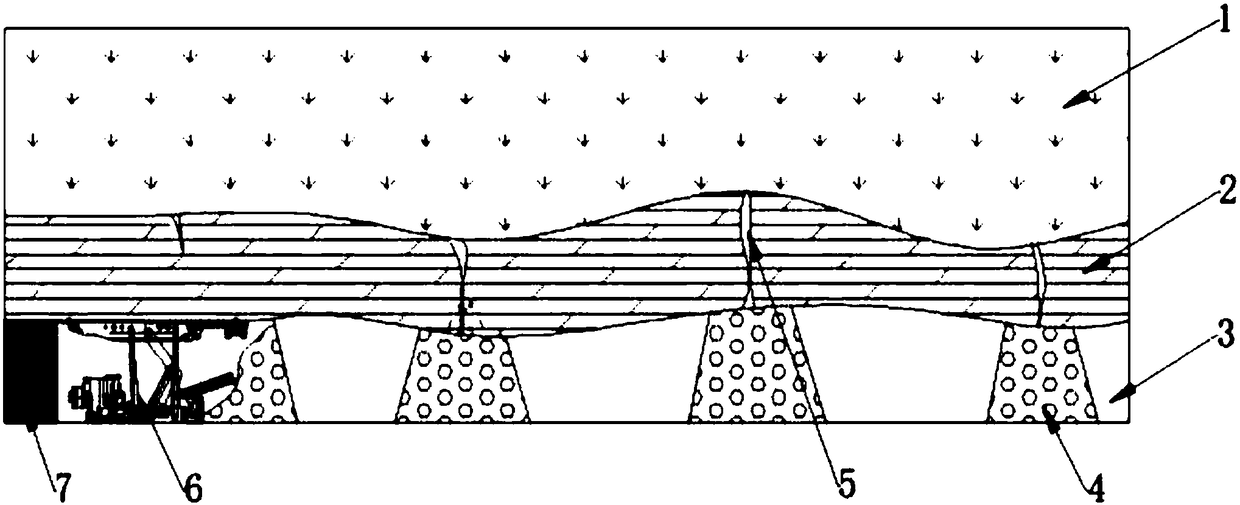

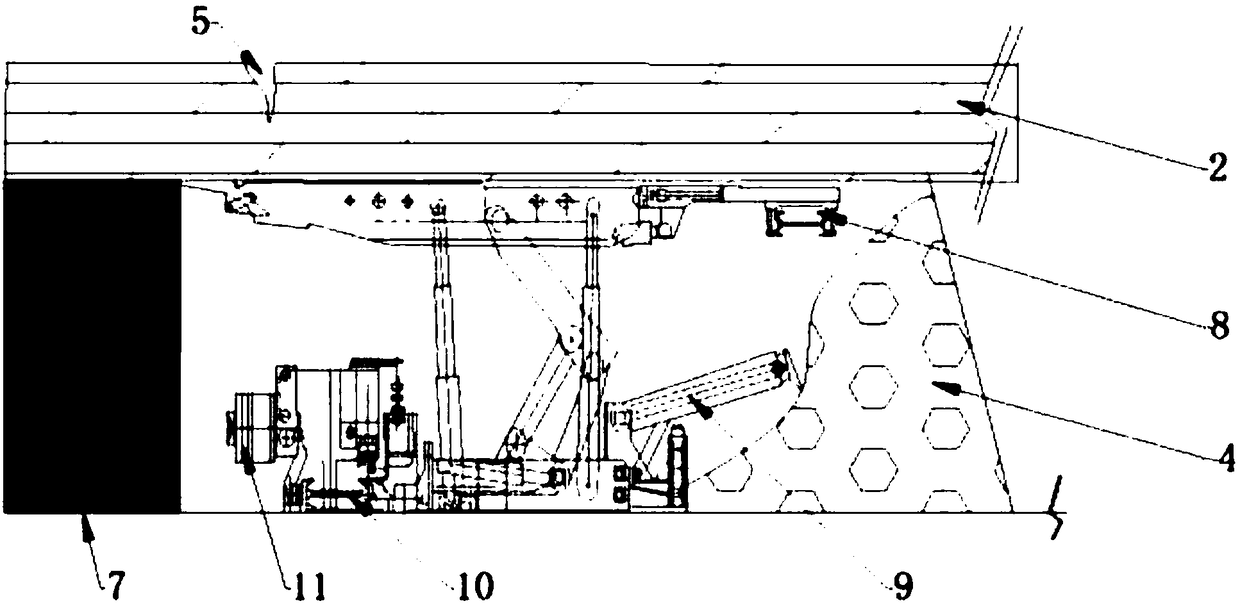

Filling mining method for fully mechanized top coal caving working face

ActiveCN109356582AControlled sinkingReduce settlementUnderground miningSurface miningEngineeringLarge deformation

The invention provides a filling mining method for a fully mechanized top coal caving working face, and relates to the technical field of mining engineering. The technical problems of control over a roof of the fully mechanized top coal caving working face and large deformation of a top coal caving mining surface are solved. The filling mining method comprises the steps that A, the fully mechanized top coal caving working face is divided in the extending direction of the working face into a filling area and a top coal caving area, or the working face is divided in the extending direction and the inclination direction into a filling area and a top coal caving area; B, a working face cycle step pitch is determined; C, the filling area in front of the working face is supported, and when coalcaving of the top coal caving area is completed, round wood supports are erected in the filling area; D, after the filling area reaches a filling step pitch, a filling tarpaulin is arranged behind a hydraulic support, and filling paste is pumped; and E, the steps C and D are repeated to complete the mining. The mining method of alternating coal caving and filling is provided to complete filling and mining of the top coal caving working face, a roof is effectively controlled, surface subsidence is reduced, and the method further has the advantages such as safety and high efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

Gangue spacing filling coal mining method

InactiveCN108204244AEffective control of pollution problemsPollution controlMaterial fill-upMining engineeringTransportation cost

The invention discloses a gangue spacing filling coal mining method, and relates to the technical field of coal mining methods. According to an existing gangue filling coal mining method, gangue needsto be utilized to completely fill a goaf, the mine auxiliary transportation cost is increased, coal mining work is greatly affected, the labor amount of filling workers is large, the gangue generatedduring mining of a thick coal seam is insufficient to completely fill the goaf, and the existing gangue filling coal mining method cannot be applied. According to the technical scheme, the gangue spacing filling coal mining method comprises the steps that the caving step pitch of roof strata is calculated according to the roof conditions of each coal mine, and precise filling is conducted on theposition where a roof is likely to caving by utilizing an ordinary gangue filling method, so that the to-be-caved roof strata is supported; as for precise filling, only the position where a roof is likely to caving is filled with a filling gangue belt which is parallel to a coal mining working face, so that the to-be-caved roof strata is supported; and as for the gangue belt, the bottom width is 10m-20 m.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

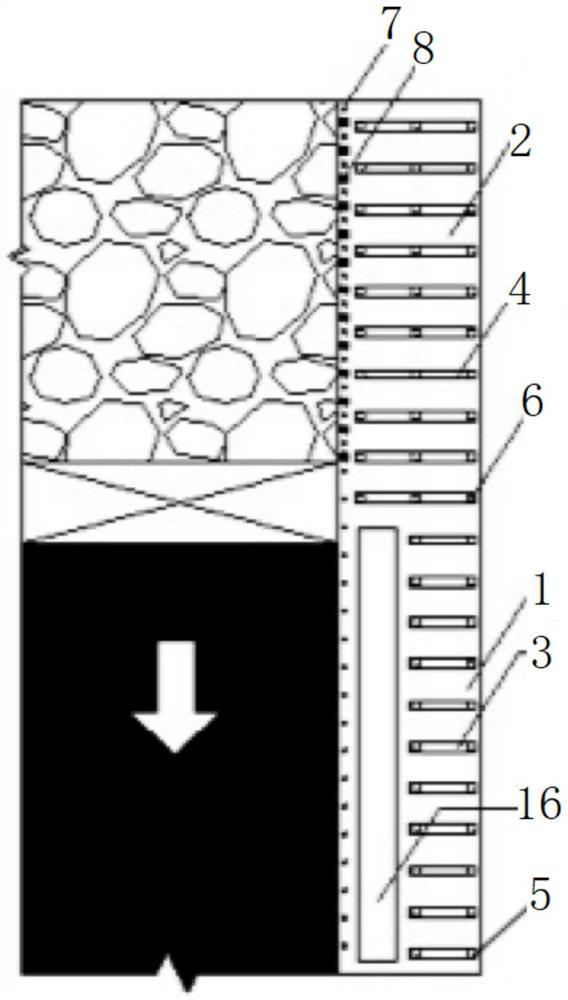

Coal pillar-free mining gob-side entry retaining roadway supporting system and method for three-soft-stratum coal seam

ActiveCN111734466AControl swing sinkingControl deformationMine roof supportsSupporting systemCoal pillar

The invention discloses a coal pillar-free mining gob-side entry retaining roadway supporting system and method for a three-soft-stratum coal seam. The system comprises a plurality of first pi-shapedbeams, wherein the plurality of first pi-shaped beams are uniformly arranged in an advancing roadway; a plurality of second pi-shaped beams are uniformly arranged in a lagging roadway; single props are arranged below the first and second pi-shaped beams; a plurality of gangue blocking pillars are uniformly arranged in the lagging roadway at intervals and are arranged close to a gob side; the sides, approaching the gob side, of the gangue blocking pillars are provided with a gangue blocking net; a top plate on the side wall of the advancing roadway is provided with a row of edge locking anchorropes; and the edge locking anchor ropes are located on a coal wall side of a working face. According to the system and the method, the support is strengthened by the edge locking anchor ropes; the reinforced support to the top plate approaching the gob side is realized; the sinking of the top plate is controlled in advance; by adopting the combination of the pi-shaped beams and the single props,the support to the top plate for a gob-side entry retaining roadway is realized; the support resistance is high; the lateral pressure and side bulging of a gangue side are effectively controlled by arranging the gangue blocking pillars and the gangue blocking net; and by using the system and the method, the rotatory sinking of the top plate for the gob-side entry retaining roadway and the deformation of the gob-side entry retaining roadway are effectively controlled.

Owner:SHAANXI COAL & CHEM TECH INST

Non-destructive mining method

ActiveCN107120117AControlled sinkingLandslide controlUnderground miningSurface miningNon destructiveResource recovery

The invention discloses a non-destructive mining method, which comprises the following steps on a whole: firstly, distributing a mining area tunnel including a coal mine transportation corridor and a material and equipment transportation corridor; installing a hydraulic support on a working plane, a scraper plate conveyor and a coal mining machine on the front side of the support, and a filling body transportation machine on the rear side of the support; and starting equipment, and supporting the coal mining space of a coal mining machine by the front part of the support and the filling operation space by the rear part of the support while the coal mining machine is propelled forward. A top plate is prevented from collapsing through the temporary supporting and timely filling modes of the support, so that a series of accidents or disasters caused due to collapse of the top plate can be avoided, the influence of coal recovering on the ambient environment of a mining field can be improved to the maximum extent, not only can the coal resource recovery rate be increased, but also the green and environment-friendly mining of the coal resources can be realized; the non-destructive mining method also has good multi-geological condition adaptability, and can increase the resource recovery rate while the mining safety is enhanced.

Owner:SHANDONG UNIV OF SCI & TECH

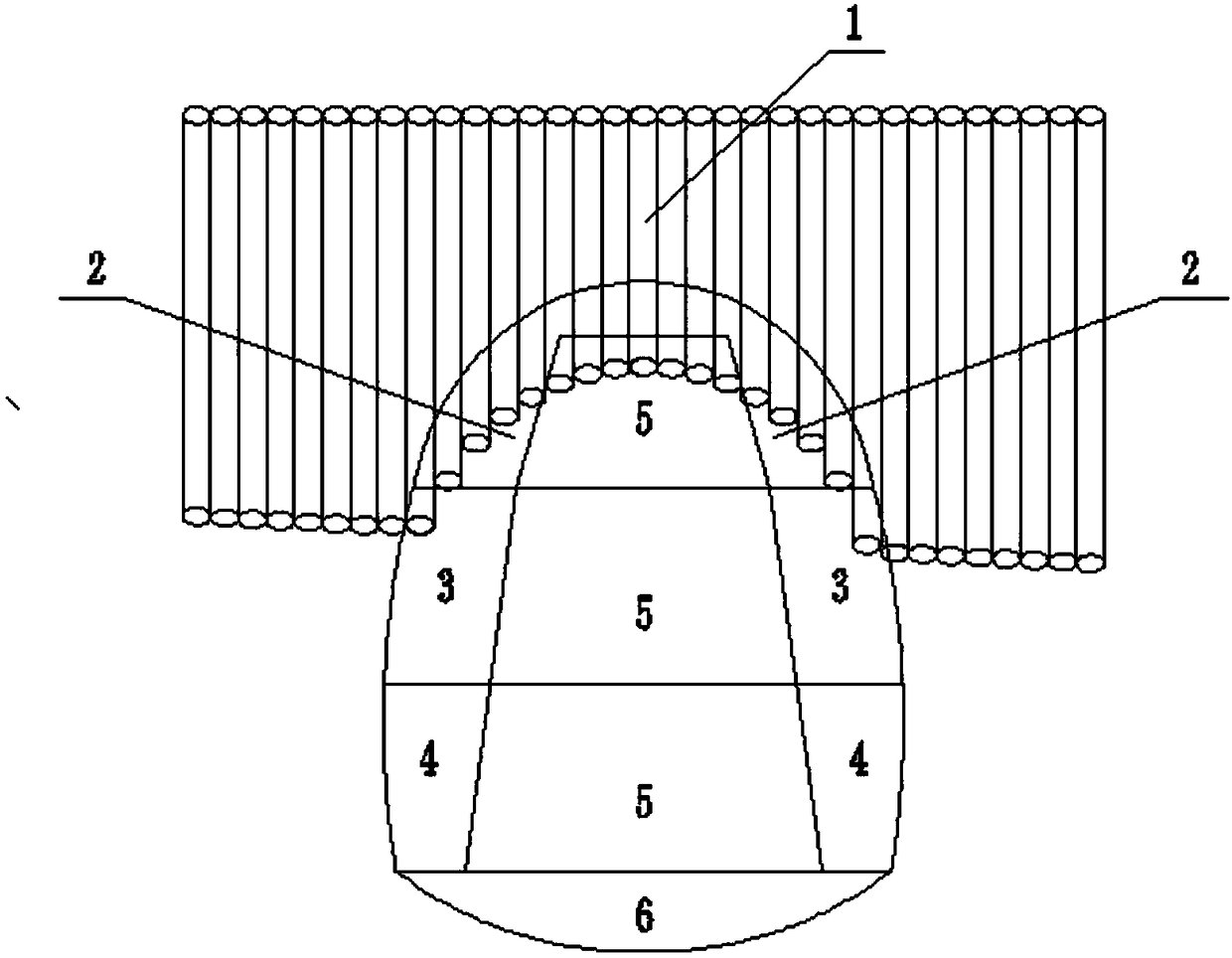

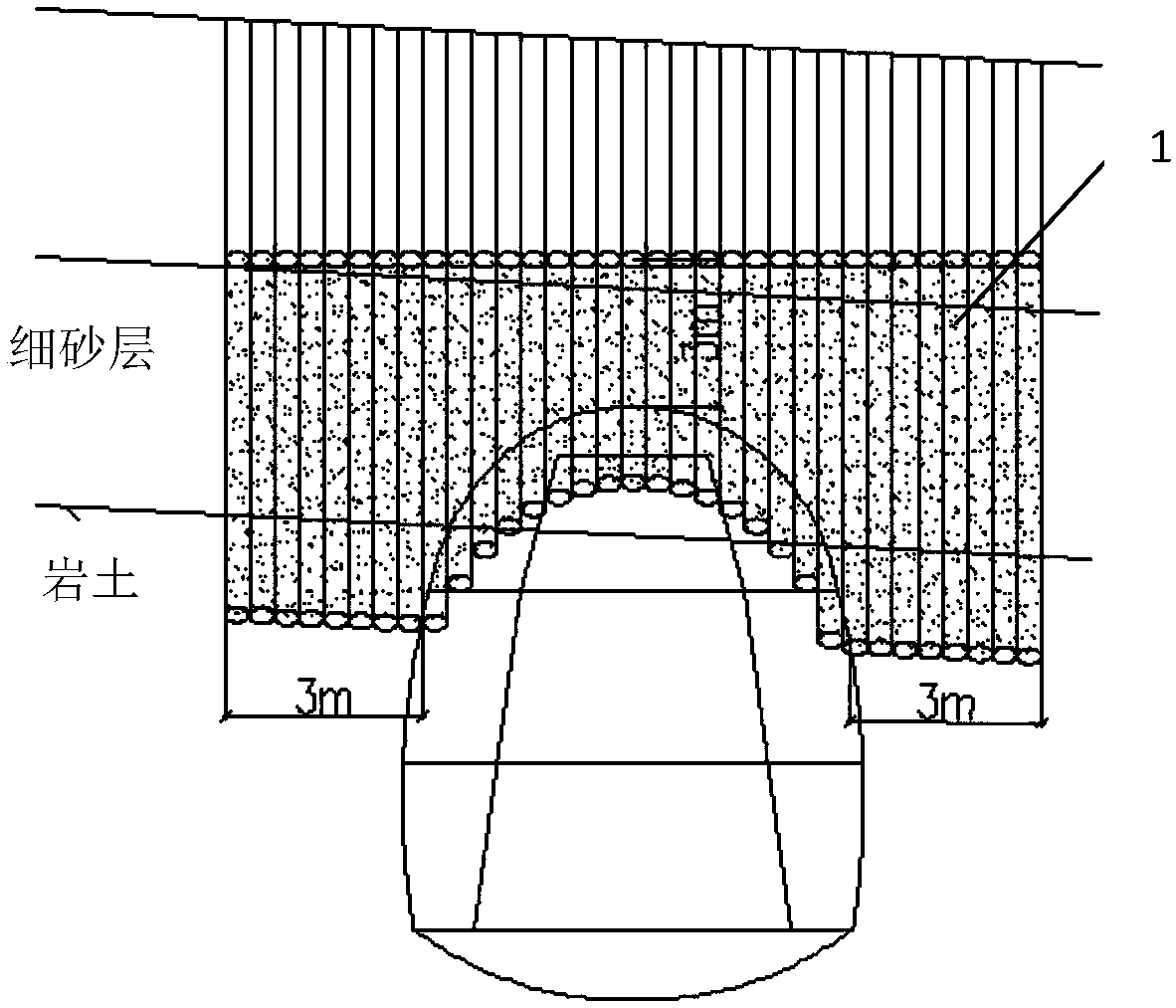

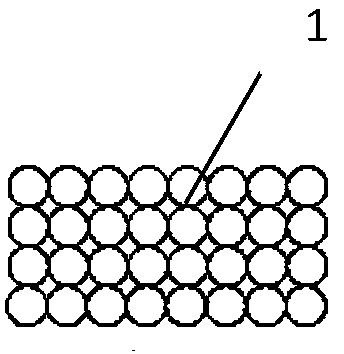

Construction method for soft surrounding rock section at tunnel portal passing through fine sand layer

PendingCN108222951AReduce disturbanceControl hazardsUnderground chambersTunnel liningClosed loopSteel frame

The invention discloses a construction method for a soft surrounding rock section at a tunnel portal passing through a fine sand layer. The construction method comprises the following steps that vertical high-pressure rotary jet grouting piles outside the tunnel are constructed; a top curved pilot tunnel of the tunnel section is excavated, and primary support is constructed in time after the excavation is completed; then left and right side middle steps are excavated, and the primary support is constructed in time after the excavation is completed; then left and right side lower steps are excavated, and the primary support is constructed in time after the excavation is completed; then reserved core soil of the upper, middle and lower steps is excavated; and finally, the bottom of the tunnel is excavated, an inverted arch steel frame is installed in time, and C25 concrete is sprayed, so that the primary support of the whole tunnel forms a closed loop as soon as possible. According to the entering-tunnel fine sand layer-passing construction method using an outside tunnel surface high-pressure jet grouting reinforcement undercutting method, sand bed hazards and vault sinking can be controlled effectively, and the construction method is suitable for entering-tunnel excavation construction of the tunnel portal passing through the sand section.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG +1

Extra-thick coal seam stratified non-integral filling mining method

ActiveCN108278113AReduce lossControlled sinkingUnderground miningSurface miningRoom and pillar miningMining engineering

The invention discloses an extra-thick coal seam stratified non-integral filling mining method. The extra-thick coal seam stratified non-integral filling mining method is used for mining "three-lower"extra-thick coal seam and stratifying synthetically by combing coal quality property and devices, and the stratified height is determined; then methods of upper room column non-integral filling recovering coal pillar and lower strip-type filling and mining are used, coal seams are sequentially mined by the two methods, and the upper layer is mined firstly then the lower layer is mined until the whole layer of coal are mined completely. The extra-thick coal seam stratified non-integral filling mining method makes good use of coal seam instead of artificial false roof, the material wastage is greatly reduced, a filling method realizes non-integral filling, and filling materials are saved; a method of combing mining and filling is realized in the process of mining, in the absence of a coal pillar, solid cemented filling materials are quickly used instead of the coal pillar, sharp change of overlying rock is strictly controlled, the safety of ground buildings is ensured, and the upper andlower structures are matched to control ground depression.

Owner:TAIYUAN UNIV OF TECH

Downward Horizontal Layered Dry Fill Mining Method

ActiveCN103061767BImprove recovery rateEfficient use ofUnderground miningSurface miningReinforced concreteEngineering

The invention relates to a mining method. The stoping sequence of the mining method is that layers are turned from top to bottom; each stoping layer is 2-2.2m; the bottoms of the stoping layers are filled with materials; mining and filling are performed simultaneously in the stoping process; the filling layer is taken as the roof of the next stoping layer; a working face is advanced from the roof to the floor; in the process of production, the maximal roof control distance of the stoping working face is 3.2m and the minimal roof control distance is 2.2m; one or two reinforced concrete water-resisting layers are arranged on each stoping layer; the water-resisting layers tilt to one side and drain water to a water sump at the next layer and water is drained out of a mine by a drainage system of the mine. By adopting the method, the traditional mining technology is changed. The downward horizontal-slice dry-type filling mining method has the advantages of improvement of stoping efficiency, simultaneousness in mining and filling, full utilization of wastes which are generated in the process of mining and smelting, lessened pollution of discharged pollutants to the environment, reduction of land occupation and basic eradication of roof fall accidents.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND

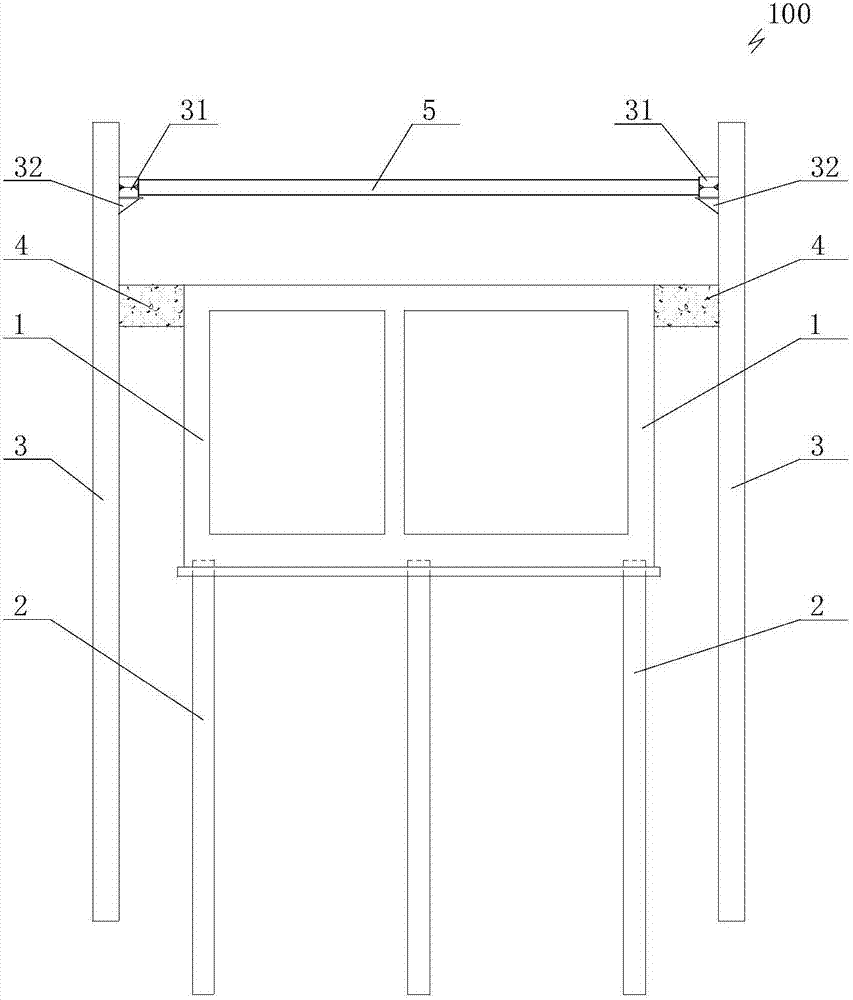

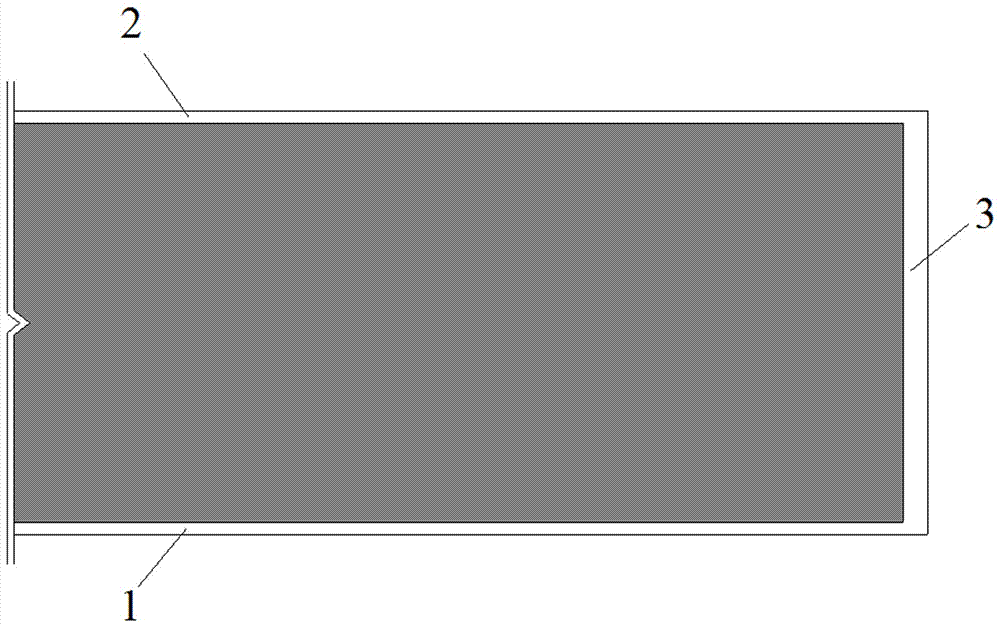

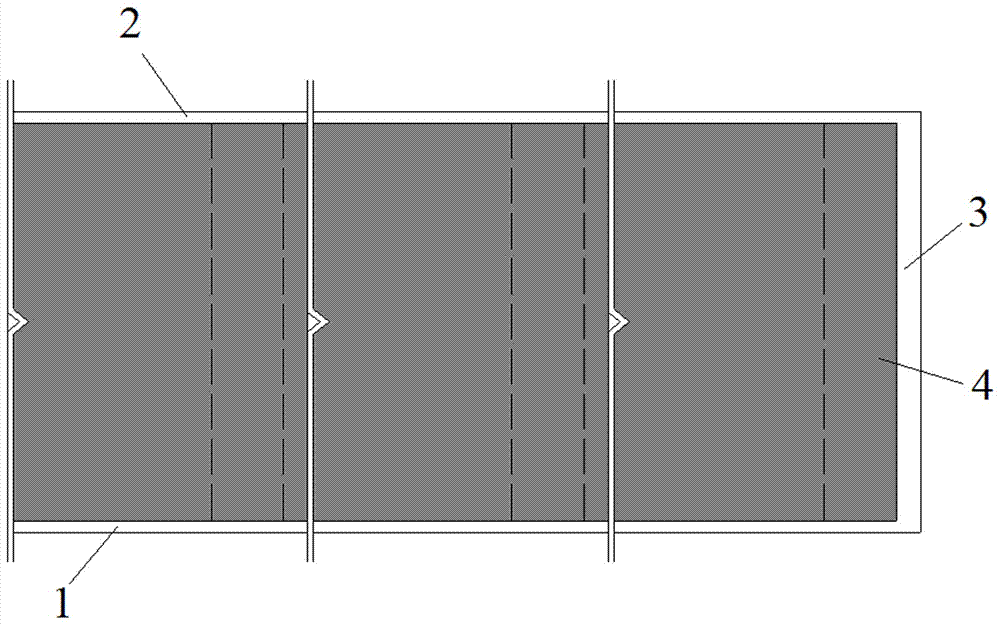

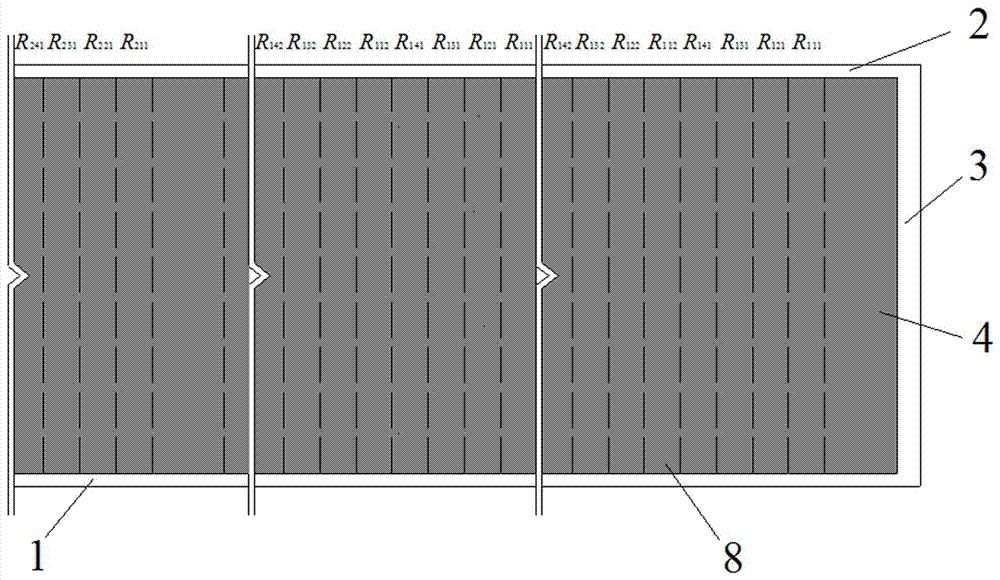

Anti-sinking door

ActiveCN105201350AReduce the chance of looseningReduce noiseBuilding braking devicesWing accessoriesEngineeringElectrical and Electronics engineering

The invention provides an anti-sinking door which comprises a door frame and a door leaf. The door frame comprises a connection column connected with the door leaf through hinges. The connection column is sequentially provided with a first panel, a rib and a second panel in the thickness direction. The first panel and the second panel are connected together through the rib. A fixing element is further arranged in the connection column. The two ends of the fixing element are connected with the first panel and the second panel respectively. One blade of each hinge is fixed to the side, close to a third panel, of the fixing element. Compared with the prior art and a common door, the fixing element is arranged in the door frame, besides, the fixing element is fixed to a wall through an expansion bolt, the gravity of the door leaf is transmitted to the fixing element through the hinges, the fixing element transmits the gravity to the wall through the expansion bolt, the probability that the hinges disengage from the door frame is reduced, and the door leaf is controlled to not sink. When the door leaf is opened and closed, noise is lowered, and the door is environmentally friendly and reliable.

Owner:安徽智扬门业股份有限公司

A filling mining method for fully mechanized top coal caving face

ActiveCN109356582BControlled sinkingReduce settlementUnderground miningSurface miningEngineeringMechanical engineering

The invention provides a filling mining method applied to fully mechanized top-coal caving working faces, relates to the technical field of mining engineering, and solves the technical problems of roof control of fully mechanized top-coal caving working faces and large surface deformation in top-coal caving mining. The method includes: A. Divide the fully mechanized mining top-coal caving working face into filling area and top-coal caving area along the direction of the working face, or divide the working face into filling area and top-coal caving area along the direction and inclination; B. Determine the circulation of the working face Step distance; C. Support the filling area in front of the working face, and set up log support in the filling area after the top coal caving area is completed; D. After the filling area reaches the filling step distance, set up filling behind the hydraulic support Tarpaulin, pump filling paste; E. Repeat steps C and D to complete mining. This method proposes a mining method of alternate coal caving and filling, completes the filling mining of the top coal caving face, effectively controls the roof, reduces surface subsidence, and has the advantages of safety and high efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

A preparation method of coal gangue-based mine cemented filling material

ActiveCN105152601BImprove utilizationEfficient and reasonable useSolid waste managementFilling materialsMechanical property

The invention discloses a preparation method of a gangue base mine cemented filling material, and belongs to the field of mine filling materials. Cementing activity hidden in gangue is stimulated in a compound stimulation way, cement is partially replaced with the cementing activity to serve as a cementing material for cemented filling mining, and then the material is mixed with fine particle size gangue to be prepared into the mine cemented filling material. The process for preparing the mine cemented filling material is simple, large proportion dosage of gangue powder and cement is realized, the filling material has excellent mechanical property and stable conveying property, no segregation or no bleeding exists, the application of gangue in mine filling is broadened, the mine filling cost is reduced, the material conveying property is improved, at the same time, the purpose of effective use of gangue is realized, and mine filling is promoted to develop forward.

Owner:TAIYUAN UNIV OF TECH

A layered non-integral filling mining method for extra-thick coal seams

ActiveCN108278113BReduce lossControlled sinkingUnderground miningSurface miningRoom and pillar miningStructure of the Earth

The invention discloses an extra-thick coal seam stratified non-integral filling mining method. The extra-thick coal seam stratified non-integral filling mining method is used for mining "three-lower"extra-thick coal seam and stratifying synthetically by combing coal quality property and devices, and the stratified height is determined; then methods of upper room column non-integral filling recovering coal pillar and lower strip-type filling and mining are used, coal seams are sequentially mined by the two methods, and the upper layer is mined firstly then the lower layer is mined until the whole layer of coal are mined completely. The extra-thick coal seam stratified non-integral filling mining method makes good use of coal seam instead of artificial false roof, the material wastage is greatly reduced, a filling method realizes non-integral filling, and filling materials are saved; a method of combing mining and filling is realized in the process of mining, in the absence of a coal pillar, solid cemented filling materials are quickly used instead of the coal pillar, sharp change of overlying rock is strictly controlled, the safety of ground buildings is ensured, and the upper andlower structures are matched to control ground depression.

Owner:TAIYUAN UNIV OF TECH

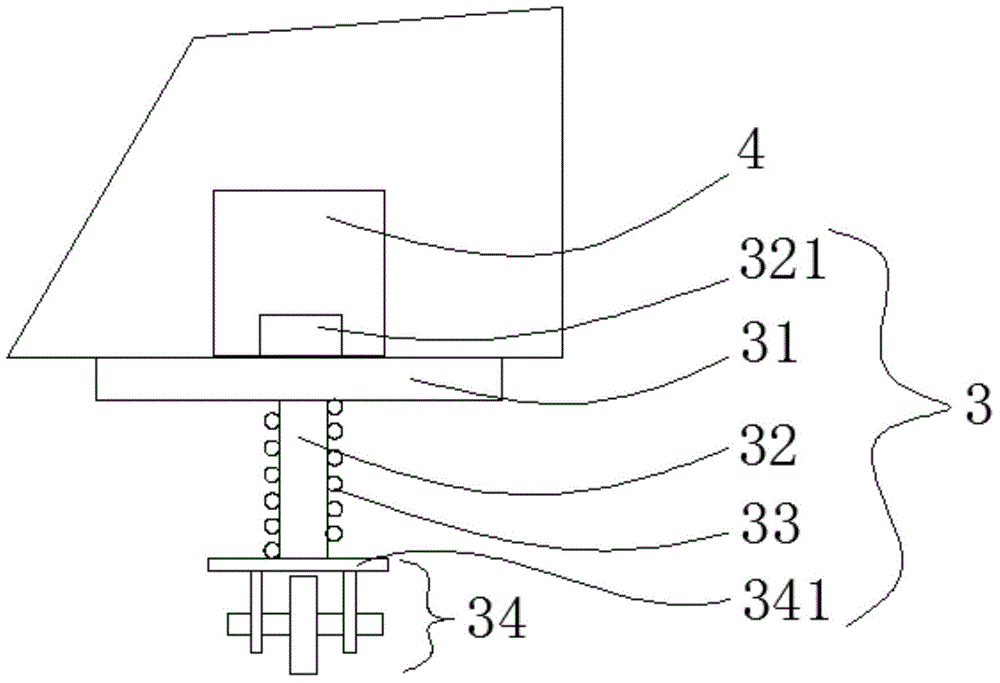

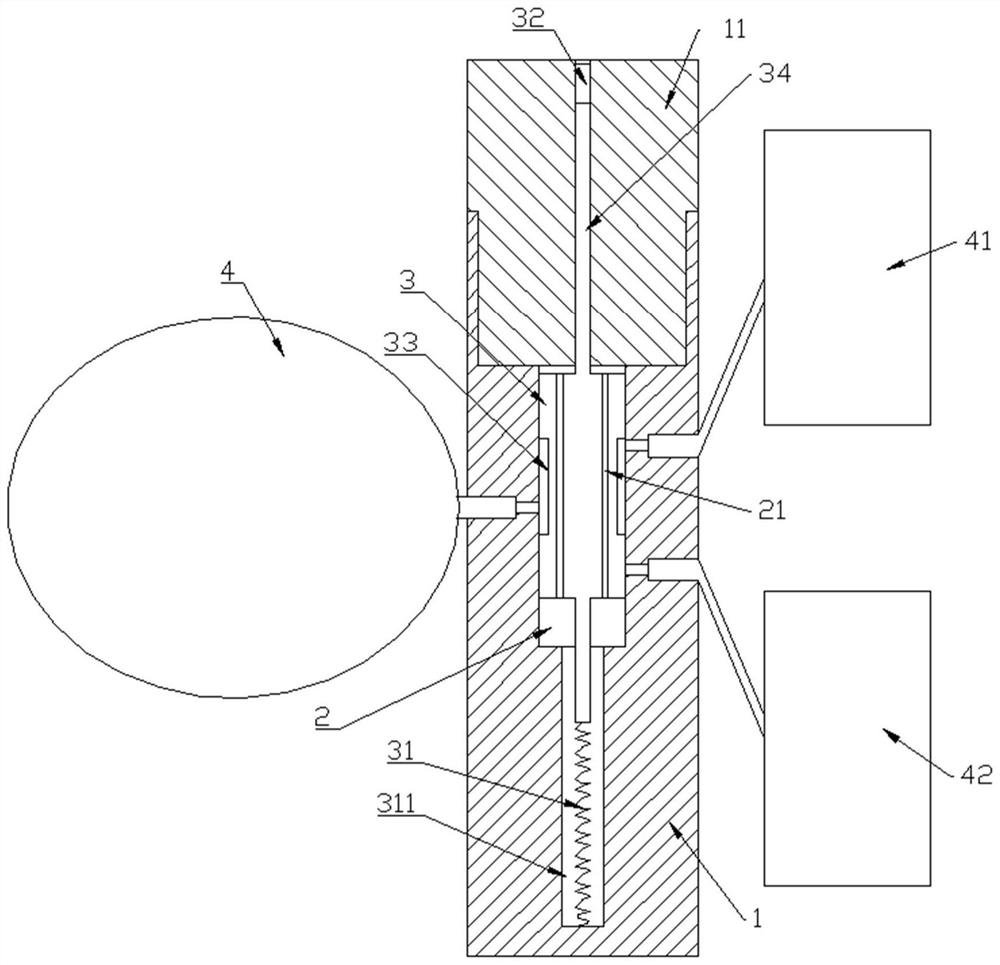

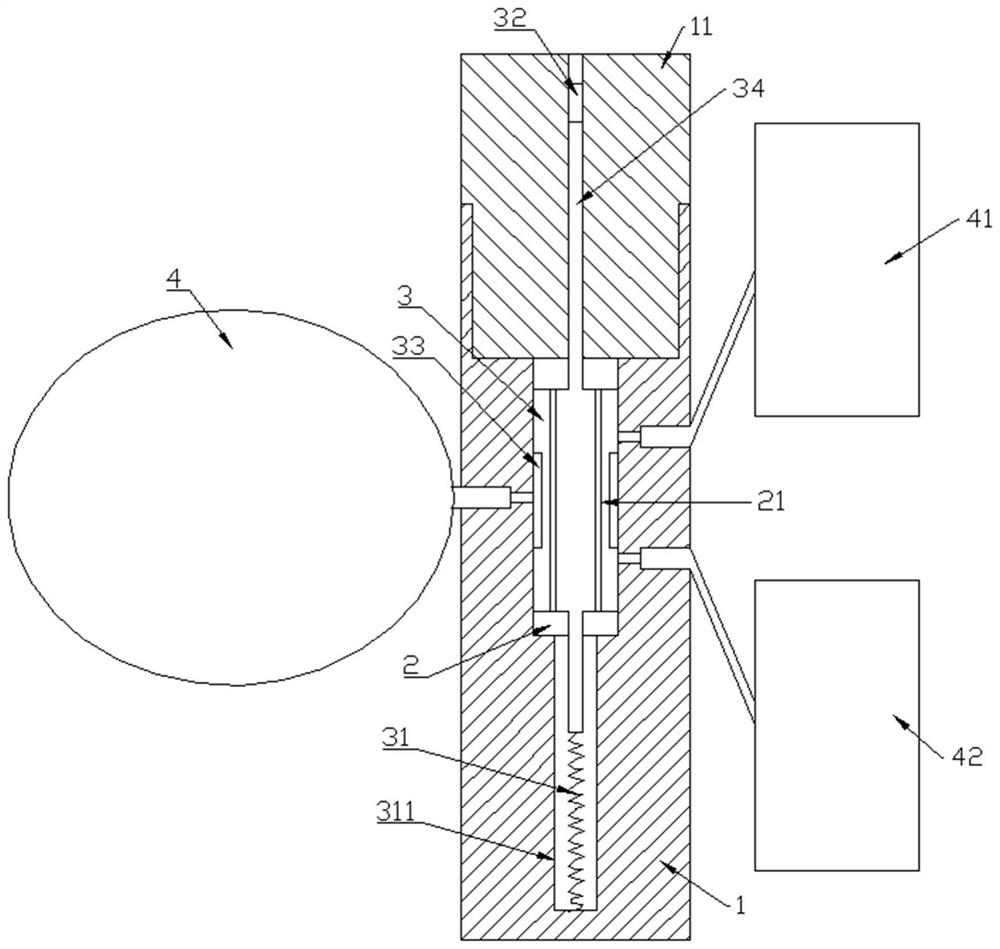

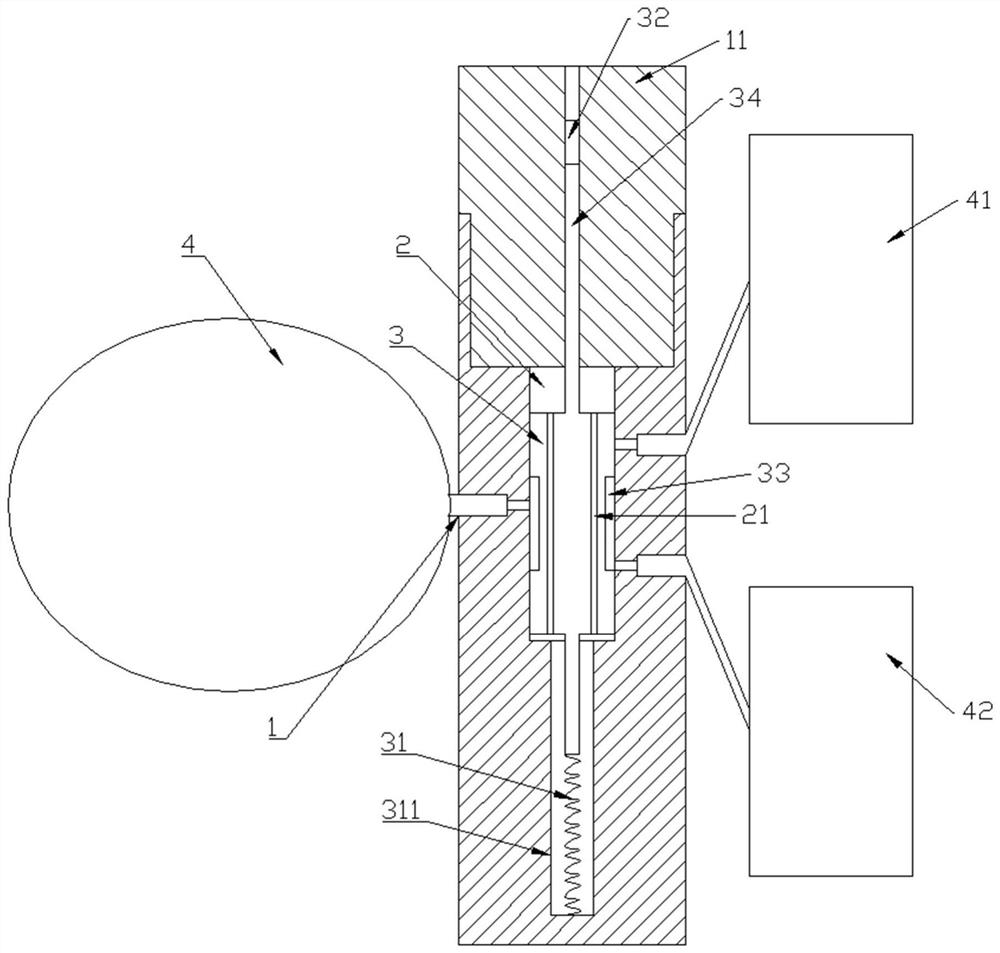

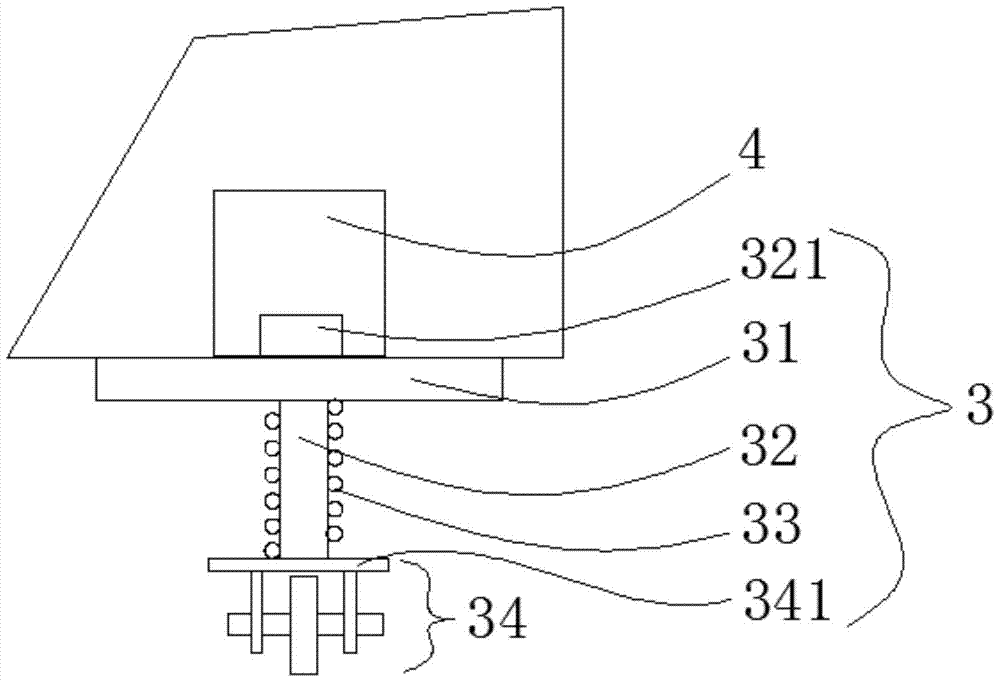

Pressure accumulation type deep sea suspension depth setting device

ActiveCN111959727AAutomatic control floatAutomatic sinkingUnderwater vesselsUnderwater equipmentPressure transmissionEngineering

A pressure accumulation type deep sea suspension depth setting device comprises a shell, and the shell is provided with a pressure transmission component and a buoyancy control structure; the pressuretransmission component comprises a sealed cavity formed in the shell, a piston is arranged in the cavity in a sliding mode, one end of the piston is fixed to the bottom of the cavity through a spring, the other end of the piston is connected with a pressure sensing unit penetrating out of the shell, the pressure sensing unit is connected with the shell in a sliding mode, and an annular groove isformed in the middle of the piston. The buoyancy control structure comprises an air bag, a high-pressure air bin and a low-pressure air bin, the high-pressure air bin is filled with high-pressure air,the air bag communicates with the middle of a cylinder sleeve, and the low-pressure air bin and the high-pressure air bin communicate with the two ends of the cylinder sleeve respectively. After thedepth position of the device is greatly changed due to the influence of marine environments such as internal waves, the device can be quickly and spontaneously adjusted to be within the preset depth range.

Owner:NAT UNIV OF DEFENSE TECH

anti sinking door

ActiveCN105201350BReduce looseningControl deformationBuilding braking devicesWing accessoriesElectrical and Electronics engineeringSurface plate

The invention provides an anti-sinking door which comprises a door frame and a door leaf. The door frame comprises a connection column connected with the door leaf through hinges. The connection column is sequentially provided with a first panel, a rib and a second panel in the thickness direction. The first panel and the second panel are connected together through the rib. A fixing element is further arranged in the connection column. The two ends of the fixing element are connected with the first panel and the second panel respectively. One blade of each hinge is fixed to the side, close to a third panel, of the fixing element. Compared with the prior art and a common door, the fixing element is arranged in the door frame, besides, the fixing element is fixed to a wall through an expansion bolt, the gravity of the door leaf is transmitted to the fixing element through the hinges, the fixing element transmits the gravity to the wall through the expansion bolt, the probability that the hinges disengage from the door frame is reduced, and the door leaf is controlled to not sink. When the door leaf is opened and closed, noise is lowered, and the door is environmentally friendly and reliable.

Owner:安徽智扬门业股份有限公司

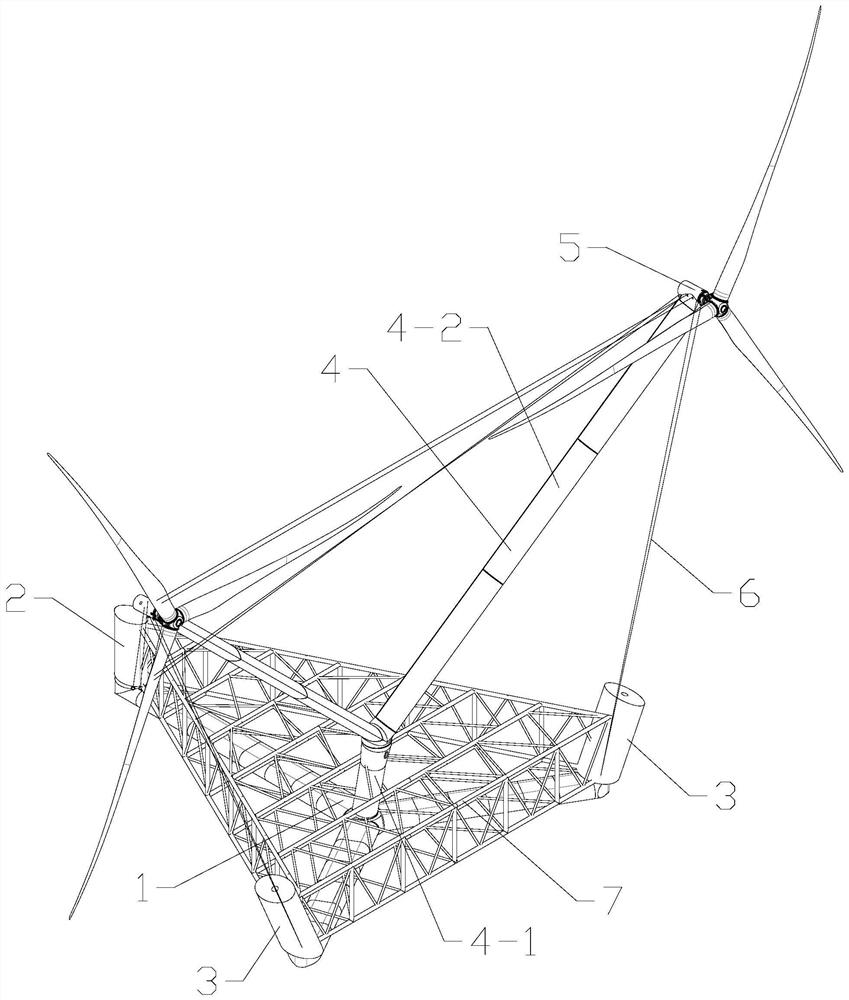

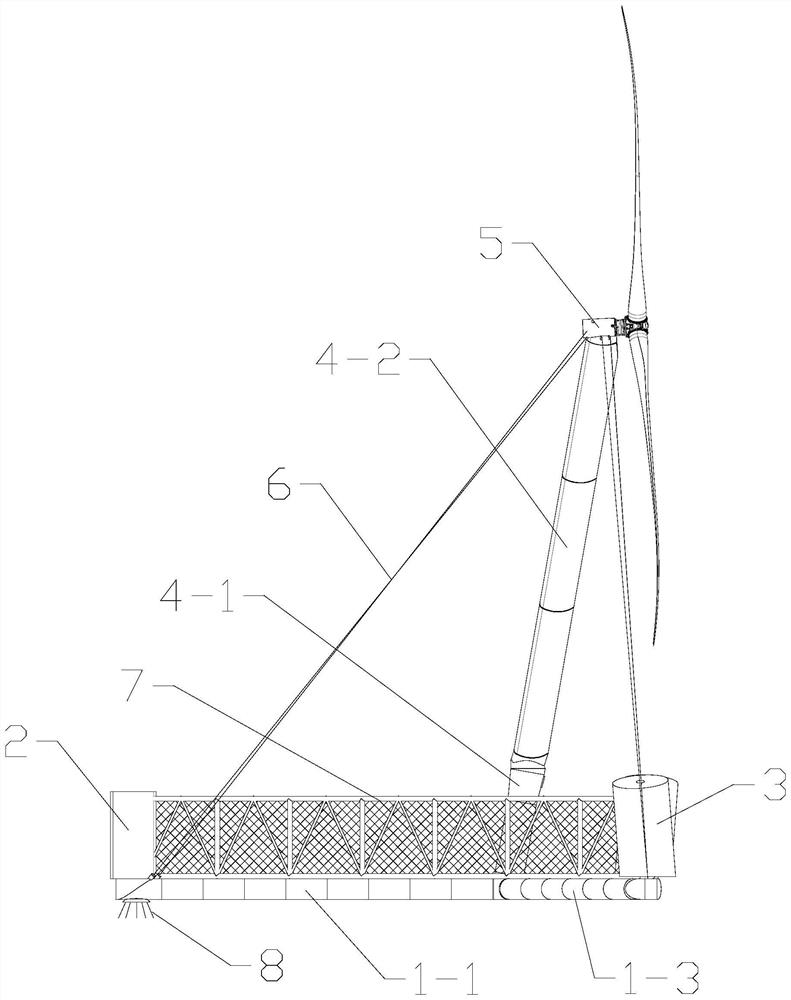

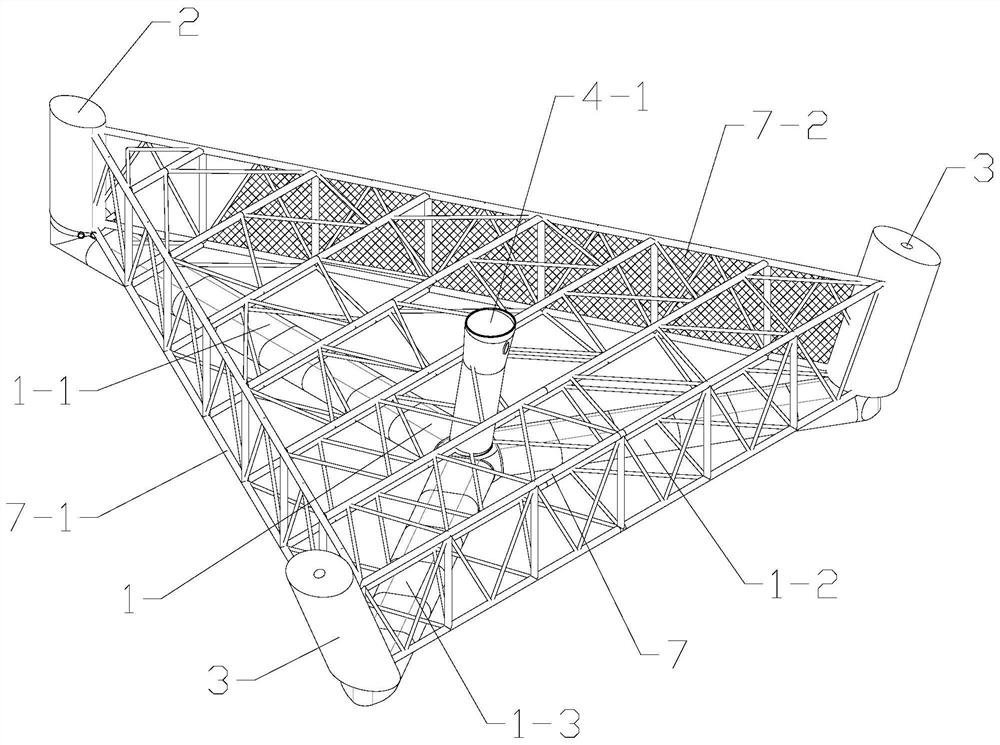

Floating platform combining wind power generation and mariculture

PendingCN112706889AEfficient use ofIncrease incomeWind motor controlWind motor supports/mountsMaricultureSea waves

The invention relates to the technical field of wind power generation, in particular to a floating platform combining wind power generation and mariculture; the platform comprises a floating foundation and a mariculture device, a tower is arranged on the floating foundation, a wind generating set is arranged on the tower, the mariculture device is arranged on the floating foundation, and the tower penetrates through the mariculture device. The wind driven generator and the mariculture device are integrated on the same floating platform; on the floating platform, wind power generation and mariculture can be synergistically carried out, marine energy can be effectively and comprehensively utilized, and comprehensive benefits are improved; according to the aquaculture net cage, an original floating foundation is fully utilized, and the aquaculture net cage and the floating foundation share one anchoring system, so that the construction cost of mariculture is greatly reduced; the aquaculture net cage is located below the sea level, the influence of sea waves can be avoided, the aquaculture net cage moves along with the Y-shaped floating foundation, seawater flowing in the aquaculture net cage is accelerated, and fish aquaculture is facilitated.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Door frame

The invention provides a door frame. The door frame comprises a connection column connected with a door leaf through a hinge. The connection column sequentially comprises a first face plate, a rib and a second face plate in the thickness direction. The first face plate and the second face plate are connected into a whole through the rib. A fixing part is arranged in the connection column. The two ends of the fixing part are connected with the first face plate and the second face plate respectively. One leaf of the hinge is fixed to the side, close to a third face plate, of the fixing part. Compared with the prior art and compared with an ordinary door, a Z-shaped plate is arranged in the door frame and fixed to a wall through expansion bolts, the gravity of the door leaf is transmitted to the Z-shaped plate through the hinge and is transmitted to the wall body through the expansion bolts by means of the Z-shaped plate, and therefore the probability that the hinge is disengaged from the door frame is lowered, and sinking of the door leaf is controlled. In the door leaf opening and closing process, no extra noise can be generated, and the door frame is environmentally friendly and reliable.

Owner:安徽智扬门业股份有限公司

Combined gob-side entry retaining method of wedge-shaped regenerated wall and single-leg shed beam in coal mining roadway

ActiveCN108979638BHigh strengthSimple structureUnderground chambersUnderground miningShotcreteMining engineering

The invention discloses a composite gob-side entry retaining method using mining roadway wedge-shaped regeneration wall and single-leg shed beam. The method is characterized in that after the coal bedis cut off in the mining process, an advance notch is communicated with a mining working face to form a wedge-shaped notch, a concrete masonry wall is built at the lower section of the wedge-shaped notch, the collapsing gangue in a gob is naturally and downwards stacked to fill the wedge-shaped notch to form a filling body, and the concrete is sprayed to the filling body in the wedge-shaped notch, so as to complete the gob-side entry retaining. The method has the advantages that by fully utilizing the characteristic of the gangue naturally sliding down after a top plate of the inclined miningworking face collapses, support rods are densely installed to block the gangue in the early stage, then the gangue naturally falls down, and the concrete is sprayed to strengthen the gangue filling body, so that the structure of the gangue filling body is enhanced, and the strength of the filling body is improved; by adopting the wedge-shaped notch, the gangue automatically slides down to extrudeinto the wedge-shaped notch, and then the gangue is densely filled into the wedge-shaped notch to form the filling body.

Owner:四川达竹煤电(集团)有限责任公司金刚煤矿

Tunnel secondary lining reinforced structure

InactiveCN104061004BEnsure safetyGuaranteed aestheticsUnderground chambersTunnel liningSteel frameRebar

The invention discloses a secondary lining reinforcement structure for a tunnel, which comprises an outer reinforcement mesh and an inner reinforcement mesh. The outer reinforcement mesh includes a plurality of outer circumferential main reinforcements arranged along the longitudinal extension direction of the constructed tunnel and bound on The outer longitudinal connecting bars on the outer circumferential main reinforcement, and the inner steel mesh includes a plurality of inner circumferential main bars arranged along the longitudinal extension direction of the constructed tunnel and inner longitudinal connections bound on the inner circumferential main bars It also includes the interlayer connecting bars connecting the outer layer steel mesh and the inner layer steel mesh. The welding method is used to fix the interlayer connecting bars between the outer ring main reinforcement and the inner ring main reinforcement, which can effectively control the sinking of the outer reinforcement mesh and the inner reinforcement mesh, maintain the stability of the inner and outer reinforcement layer spacing of the steel skeleton, and ensure The thickness of the protective layer ensures the safety and beauty of the tunnel structure, while improving work efficiency.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

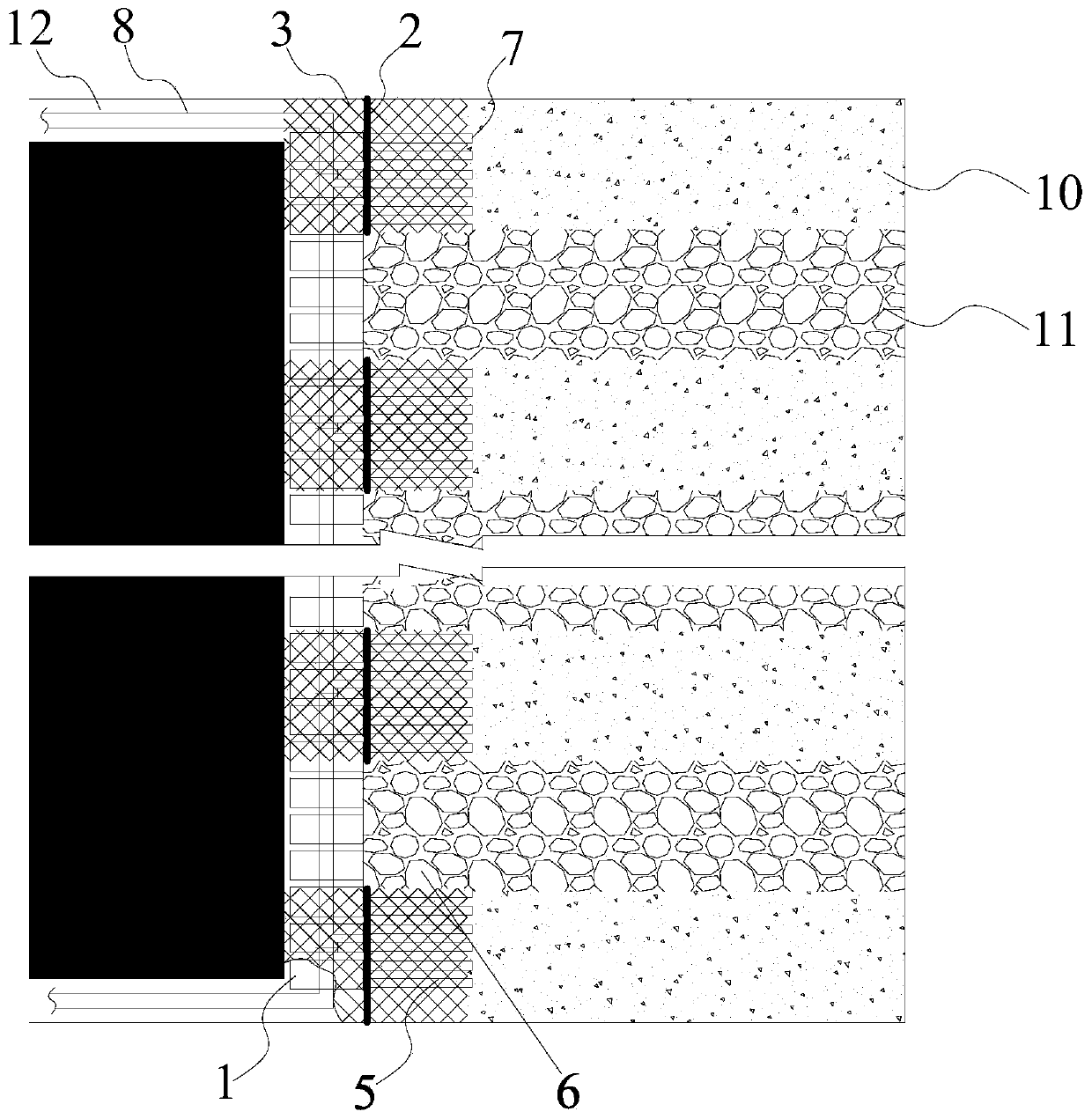

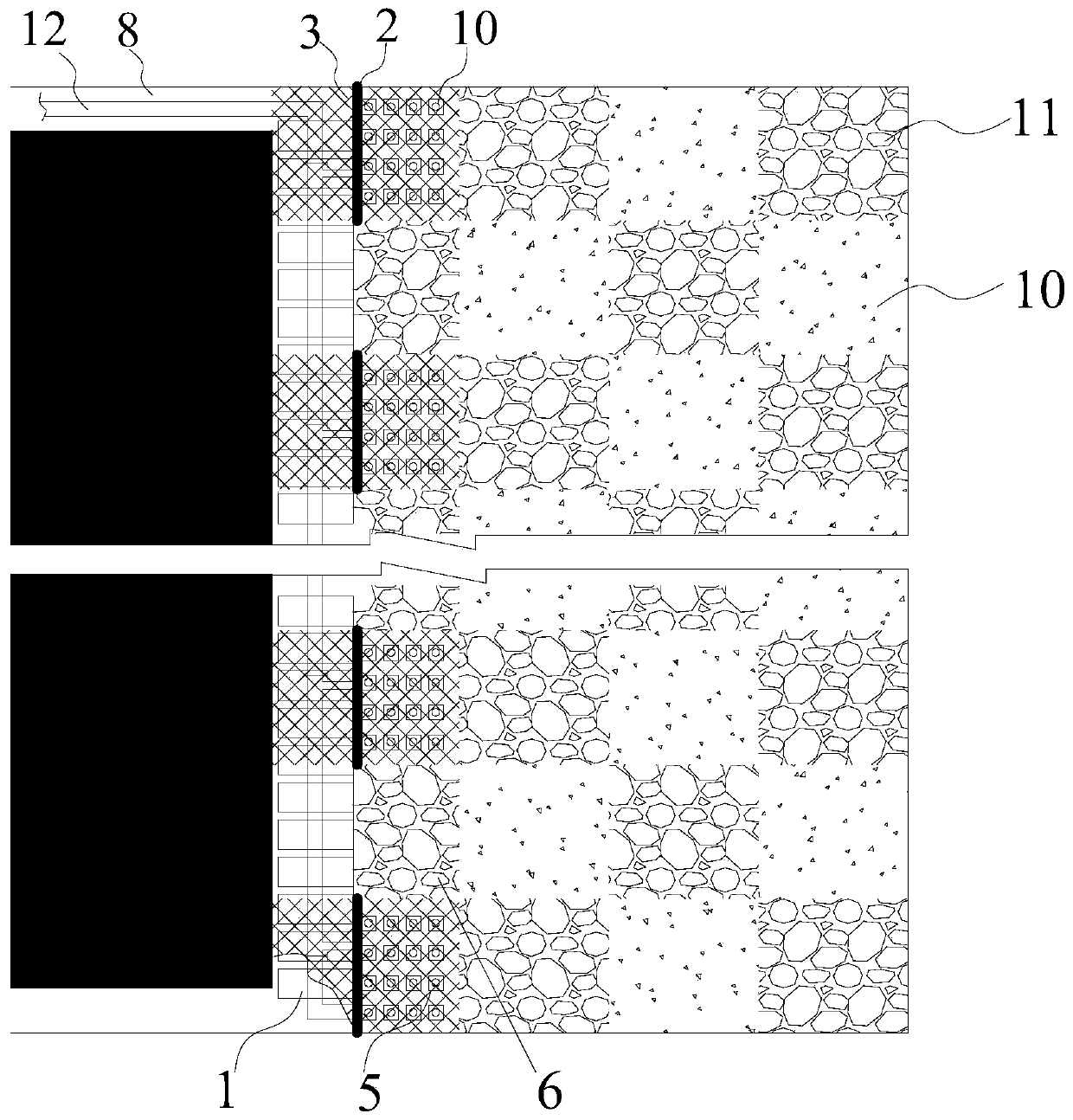

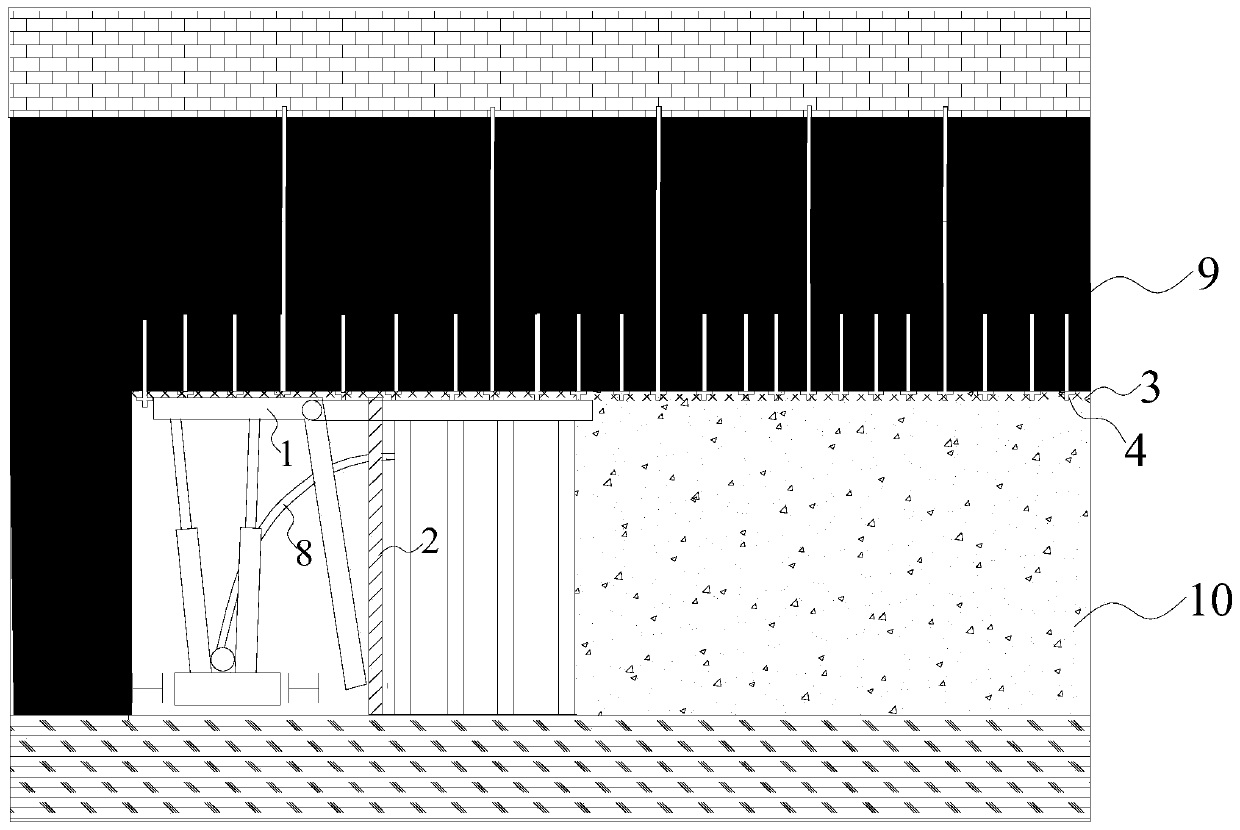

Water rock combined grouting filling stope sedimentation control and water control method

ActiveCN108518241AControlled sinkingHarm reductionMaterial fill-upDrainageWater retention curveCrushed stone

The invention discloses a water rock combined grouting filling stope sedimentation control and water control method. The method comprises the steps that an overlying strata is born by depending on a combined structure formed by water, slurry and falling rocks; in the exploitation process of mineral resources in stope, accumulated water is pumped into a temporary water warehouse with certain strength in the stope; after exploitation, a roof strata collapses, stope strata gravel is settled around the temporary water warehouse, slurry grouting is conducted, and the gravel is coagulated together to form a similar dome-shaped supporting body. Accordingly, the accumulated water in the exploitation process is stored for application specially for the condition that a water-bearing stratum is destroyed; meanwhile, by means of the bearing capacity of the water and the temporary water warehouse, the similar dome structure is formed in the strata gravel collapsing space, and the sedimentation control effect on the earth surface is achieved. Accordingly, the method has the effects of water retention, water proofing, sedimentation reducing and the like, filling materials are low in dosage, the cost is low, operation is easy, the engineering effect is significant, the method is suitable for the stratum with the small inclined angle, and the method can be applicable to west water retention exploitation and anti-settlement exploitation of a mining area.

Owner:NORTHEASTERN UNIV LIAONING

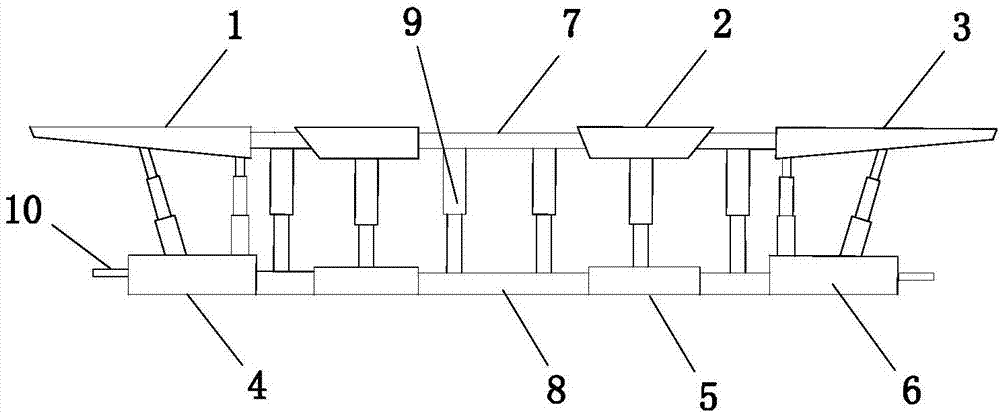

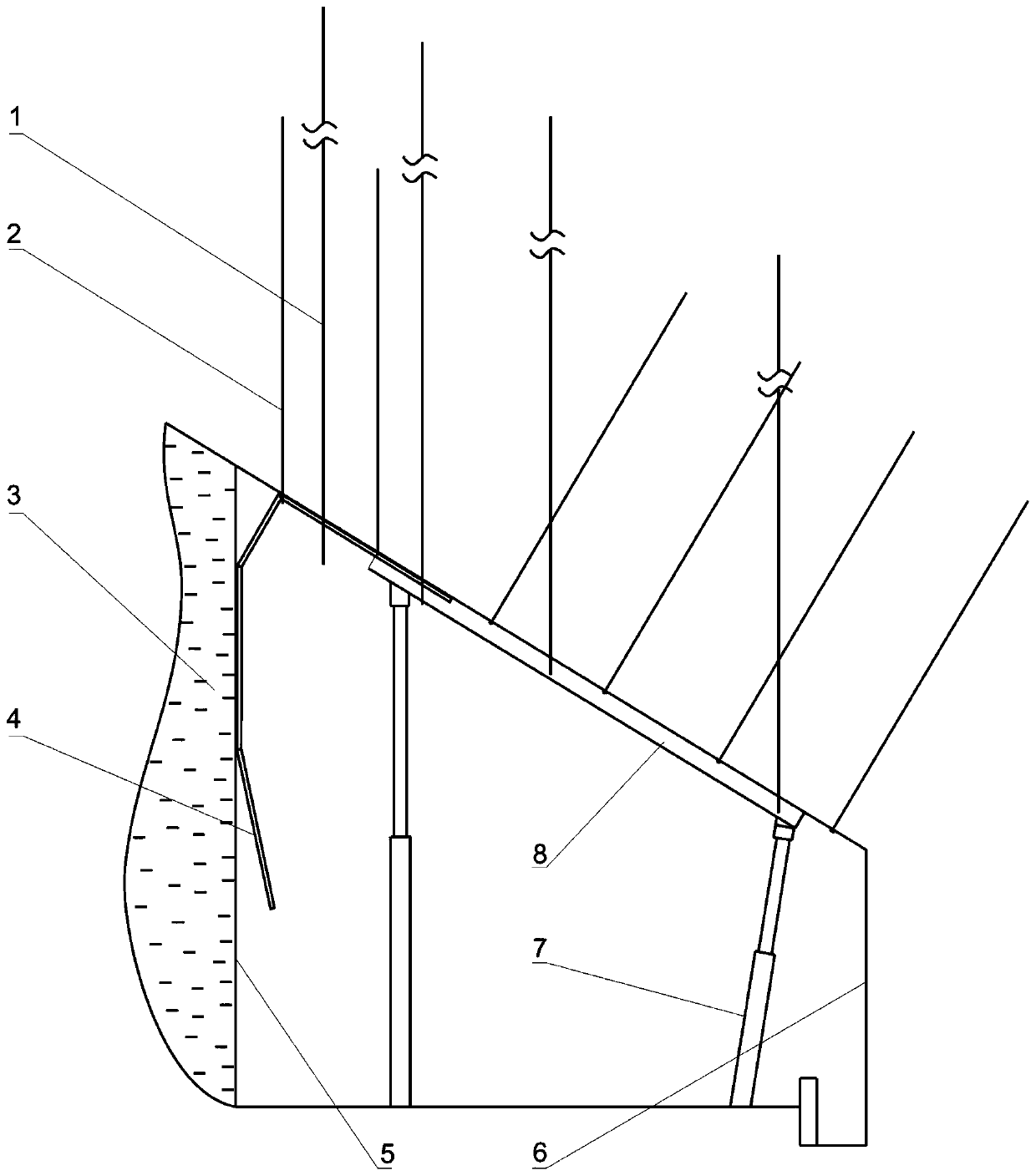

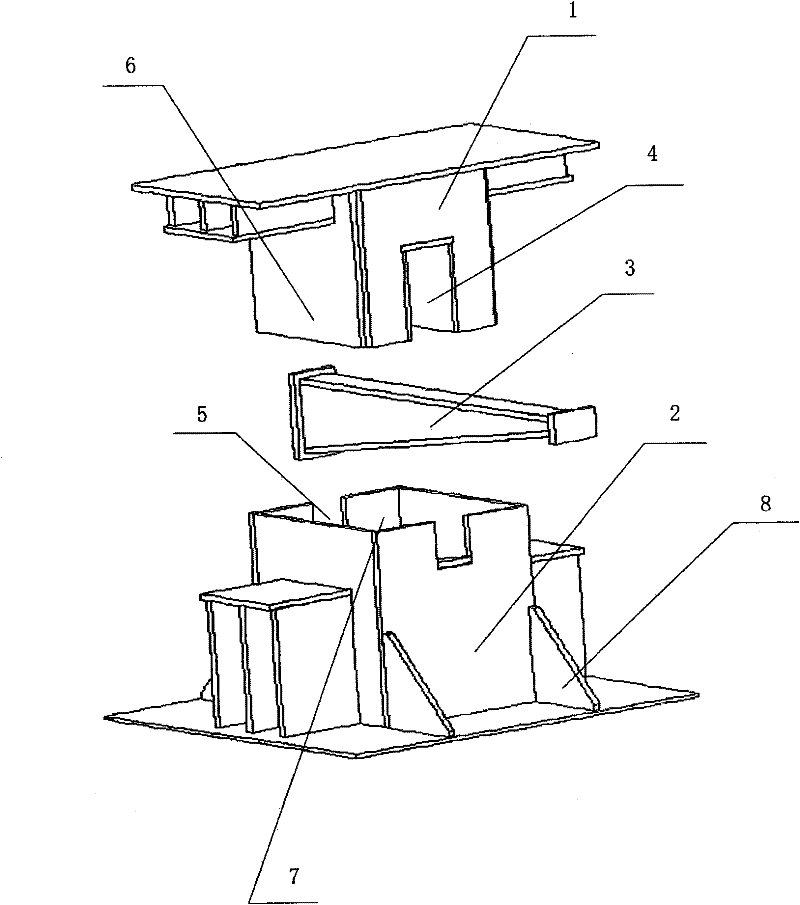

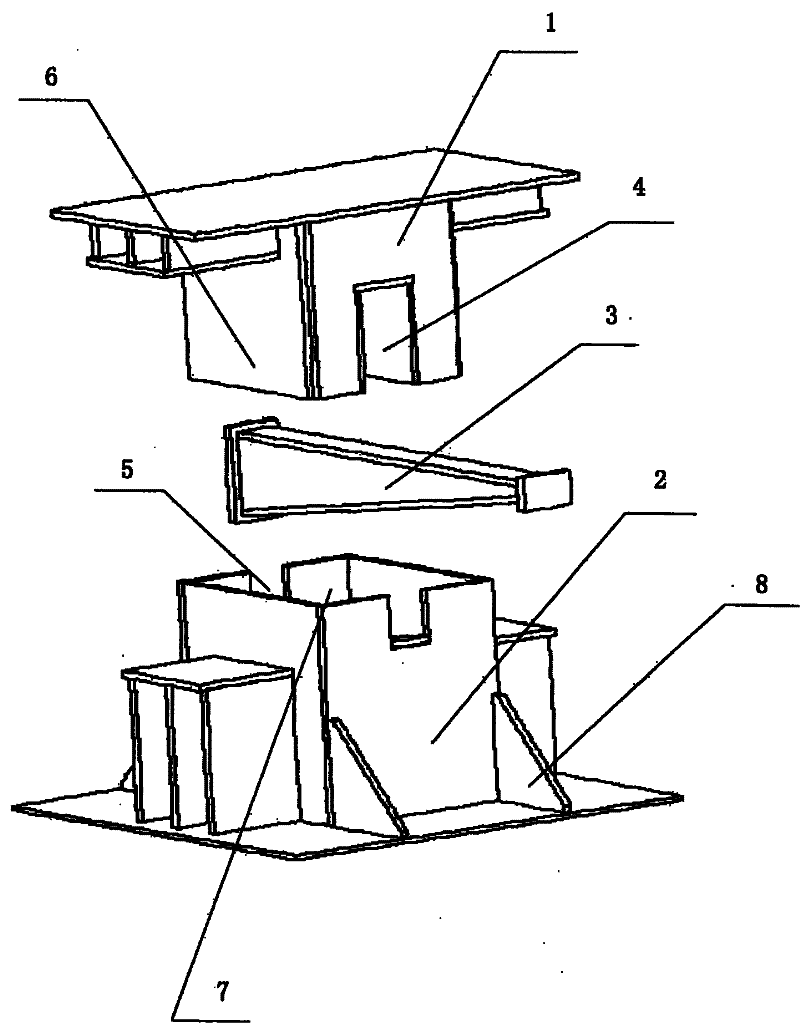

Rapid pier arranging device for ship

The invention discloses a rapid pier arranging device for a ship. The device comprises an upper pier body (1) and a lower pier body (2), wherein an insertion piece (3) is arranged between the upper pier body (1) and the lower pier body (2); the upper pier body (1) and the lower pier body (2) are inserted into each other; an upper slot (4) is arranged at the lower part of the upper pier body (1); a lower slot (5) is arranged at the upper part of the lower pier body (2); the upper slot (4) corresponds to the lower slot (5); and after the upper pier body (1) and the lower pier body (2) are inserted into each other, the insertion piece is located in the upper slot (4) and the lower slot (5). Through the invention, the requirement for rigidity in support can be improved, and the sinking of the ship during the slipway joining is effectively controlled; and moreover, rapid disassembly can be realized in ship launching, thus the reliability of the ship launching is ensured.

Owner:杨春

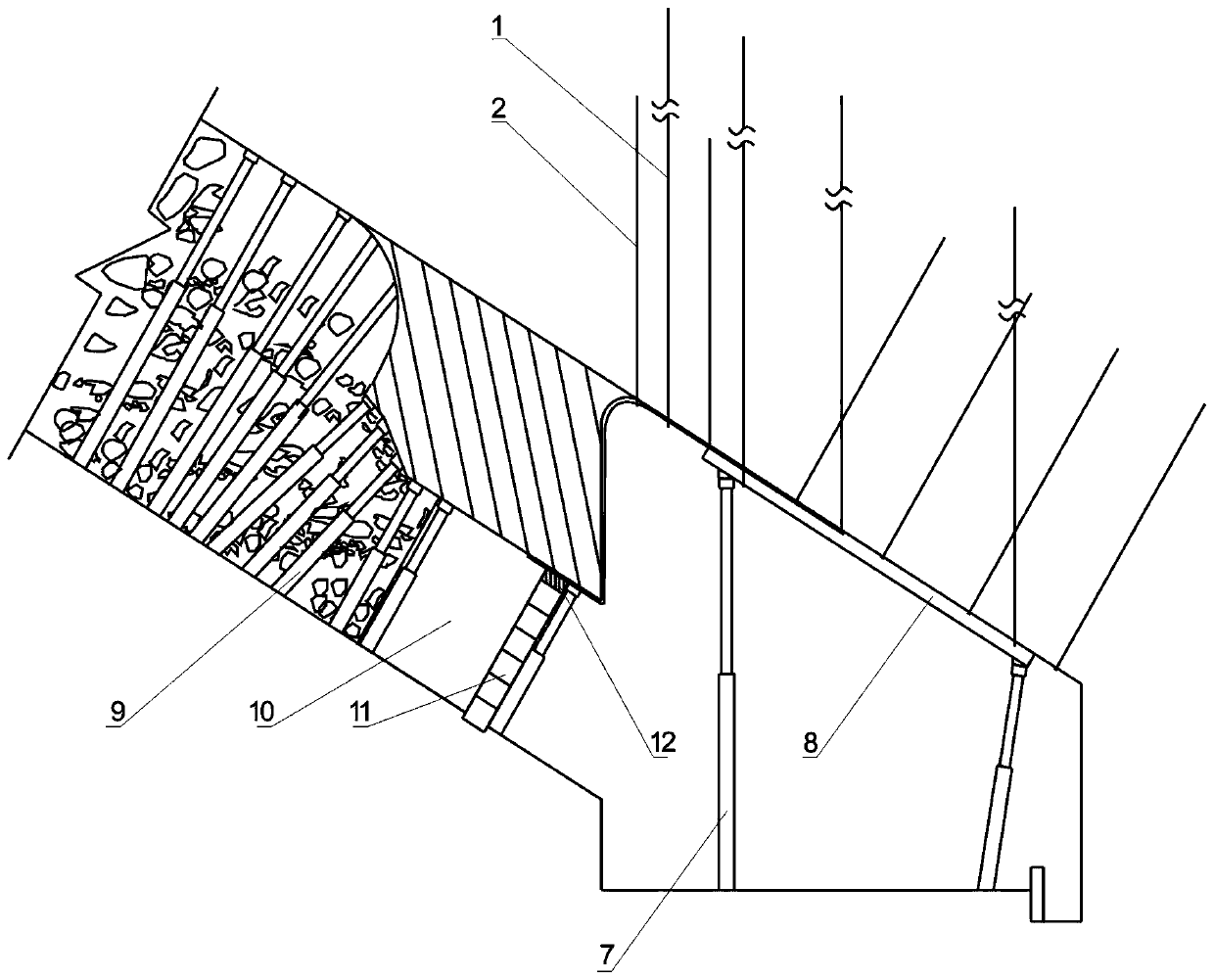

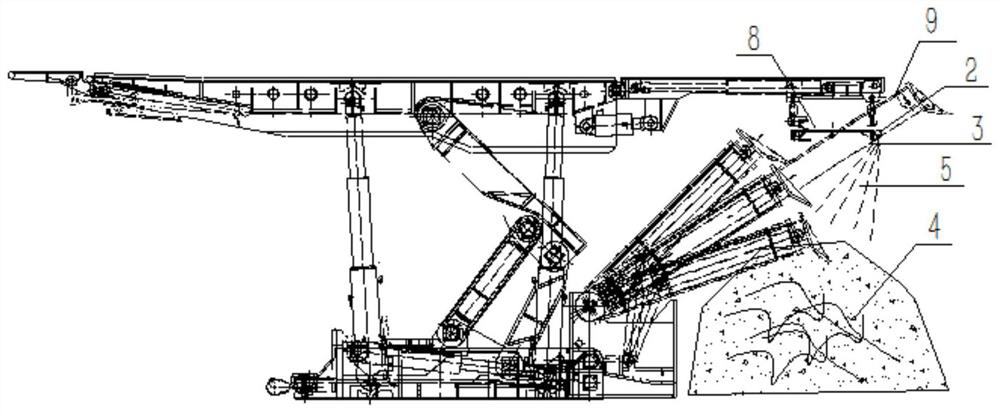

Back waste rock throwing guniting filling system and method based on fully-mechanized mining frame

The invention provides a rear waste rock throwing, guniting and filling system and method based on a fully-mechanized coal mining frame, and belongs to the field of coal mining. The rear waste rock throwing, guniting and filling system comprises at least one fully-mechanized coal mining waste rock throwing support capable of being arranged in a coal mining working face, and a tamping assembly is arranged on the side, close to a space to be filled, of each fully-mechanized coal mining waste rock throwing support; a scraper conveyor is arranged at the lower end of a rear beam of each fully-mechanized coal mining waste rock throwing support, a spray head is arranged on one side, close to a space to be filled, of each scraper conveyor, and each spray head is communicated with a slurry conveying pipeline; the method has the beneficial effects that the filling efficiency and the roof contact rate of the filling process of the original waste rock behind the fully-mechanized mining frame can be improved.

Owner:XINWEN MINING GROUP

An anti-overturning self-elevating platform spud shoe

InactiveCN103422500BIncrease the carrying areaControlled sinkingArtificial islandsUnderwater structuresAgricultural engineeringHigh pressure

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com