A filling mining method for fully mechanized top coal caving face

A fully mechanized roof caving and mining method technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of large surface deformation, etc., and achieve the effects of increased density, strong stability, and enhanced filling and support effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

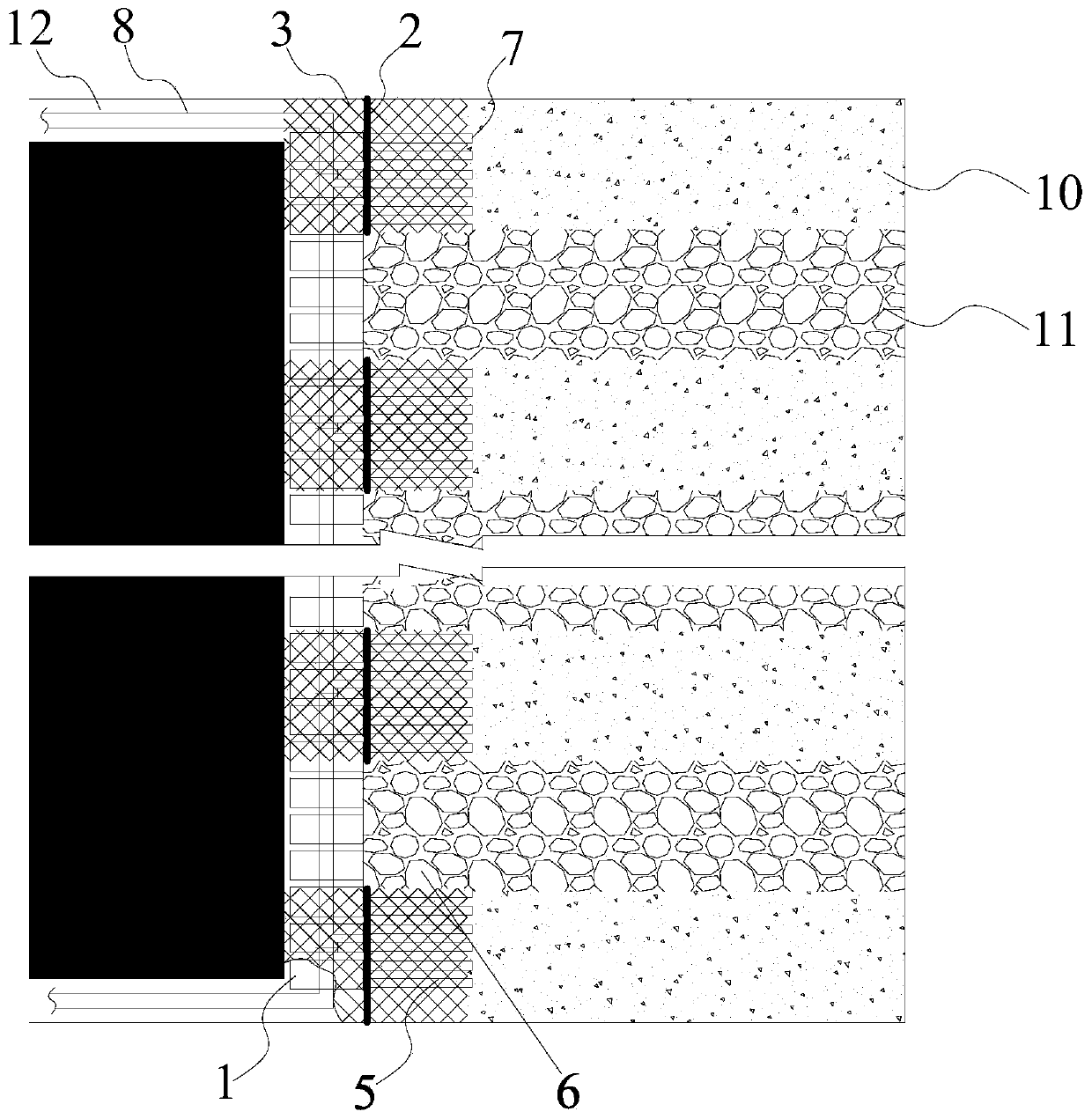

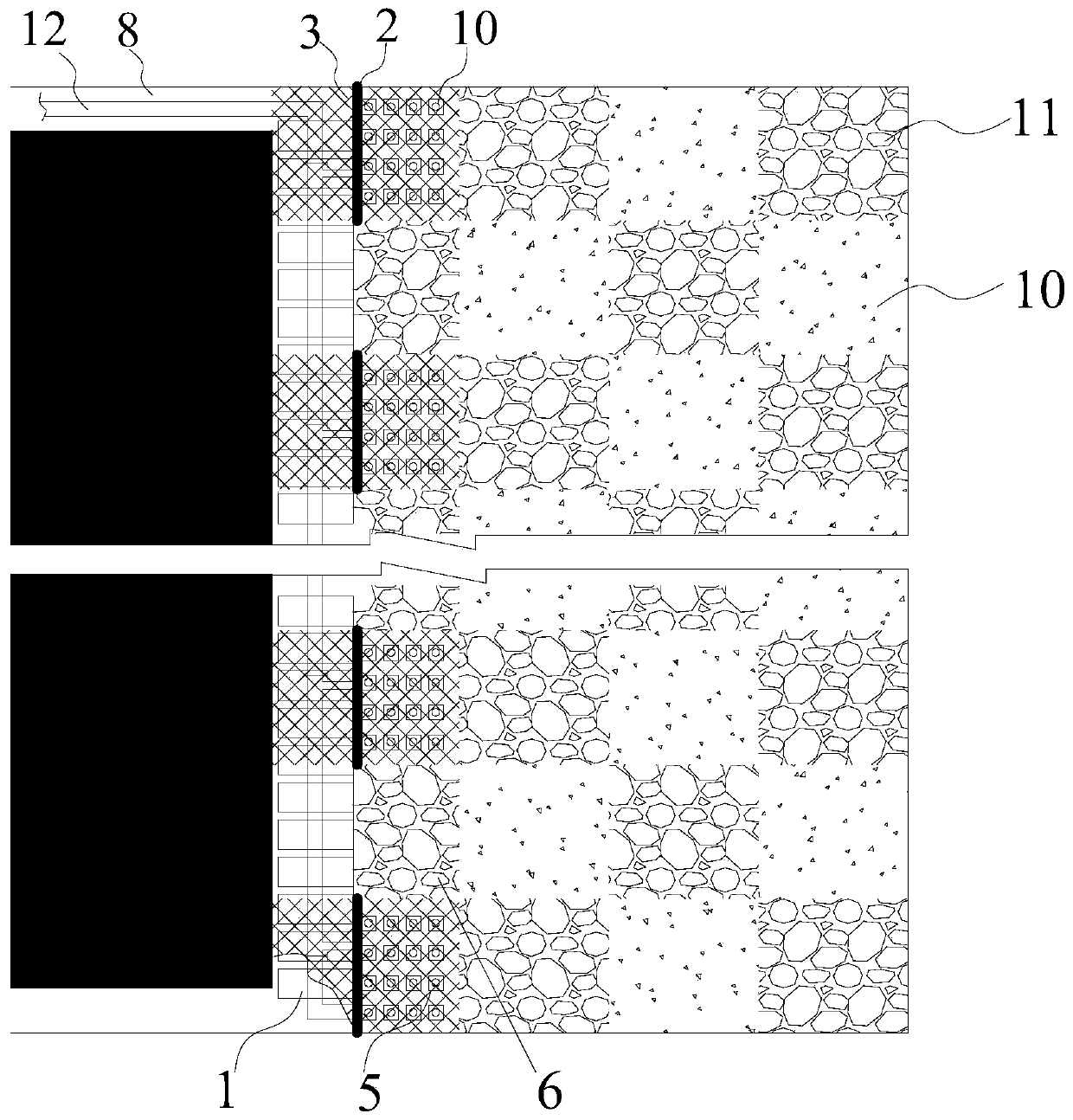

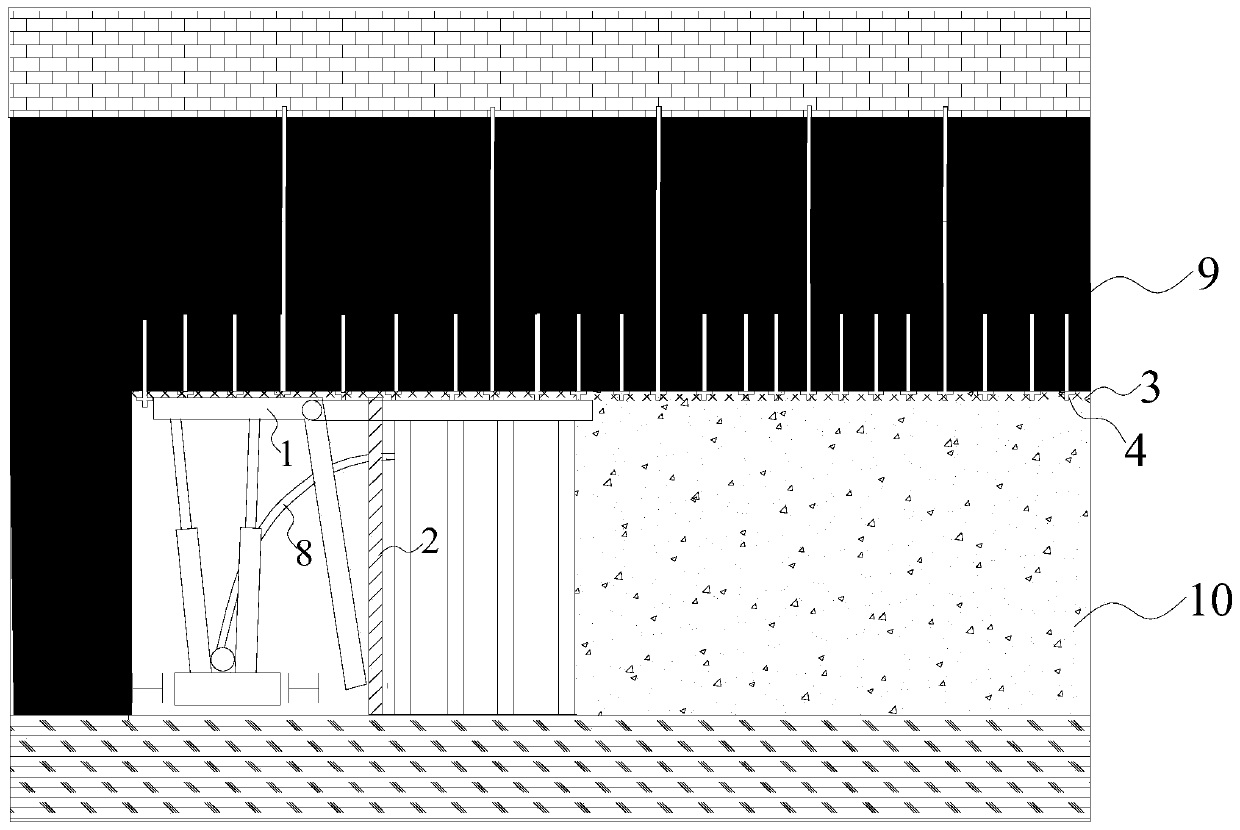

[0034] Such as figure 1 with image 3 As shown, a filling mining method applied to fully mechanized top coal caving face specific construction steps include:

[0035] Step A. When the fully-mechanized top-coal caving face is arranged in a hard coal seam with uniform thickness and there are no large faults in the face, divide the fully-mechanized top-coal caving face along the direction of the face into filling area 5 and top-caving Coal area 6. The length of the filling area 5 and the top-coal caving area 6 is equal to the length of the working face, the sum of the width of the filling area 5 and the top-coal caving area 6 is equal to the width of the working face, and the length and width of the top-coal caving area are guaranteed to be less than the initial pressure of the basic top-coal The step distance, where the filling area 5 and the top-coal caving area 6 are adjacent. The fully mechanized top-coal caving working face is divided into several filling areas 5 and top-...

Embodiment 2

[0047] On the basis of Example 1, combined with an engineering example, the filling mining method applied to the fully mechanized top coal caving face will be further explained. The underground elevation of the fully mechanized top coal caving face of a mine is -241.3m, and the main coal seam is the 3rd coal seam of the Shanxi Formation. The 3rd coal seam has a simple structure, no bifurcation phenomenon, and is thick and stable. The strike length of the working face is 700m, the inclination length is 150m, the average thickness of the coal seam is 8.5m, the inclination angle is 5-8°, and the bulk density is 1.38t / m 3 . The immediate roof is dark gray siltstone, generally 2-3m thick, relatively stable, with a compressive strength of 40.53-62.81MPa; the old roof is thick medium-grained sandstone, 10-30m thick, with a hard rock formation, and a compressive strength of 91.20-131.7MPa.

[0048] Step A. According to the above-mentioned stope geological conditions and surrounding r...

Embodiment 3

[0054] On the basis of Example 1, combined with an engineering example, the filling mining method applied to the fully mechanized top coal caving face will be further explained. In the fully mechanized top coal caving face of a mine, the strike length of the face is 800m, and the inclination length is 200m. The average thickness of the coal seam in the working face is 9m, which is a stable coal seam. The average inclination angle of the coal seam is 9°. The immediate roof is mudstone with an average thickness of 1.4m, and the average unidirectional compressive strength is 47.7MPa. The basic roof is fine sandstone with an average thickness of 3.0m and an average unidirectional compressive strength of 119.8MPa. The immediate bottom is mudstone with an average thickness of 2.4m, with an average unidirectional compressive strength of 47.7MPa, and the basic bottom is fine sandstone with an average thickness of 3.9m, with an average unidirectional compressive strength of 119.8MPa. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com