A layered non-integral filling mining method for extra-thick coal seams

A technology of extra-thick coal seam and mining method, which is applied in the direction of filling, special mining, ground mining, etc., can solve the problems of increased freight costs, serious cost of money and time, and poor solutions, so as to reduce material loss and save filling Material, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

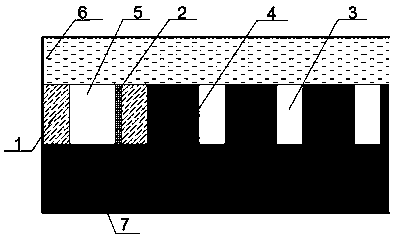

[0036] A layered non-integral filling coal mining method in an extra-thick coal seam, the specific steps are as follows:

[0037] a. According to the overlying rock structure, mining equipment height and ground building protection level when mining the "three lower" coal seams, the coal seam is layered at a height of 3-4.5m, and the number of layers of the coal seam is determined, and then layered and separated in sequence , the first layer adopts the room-and-pillar type non-complete filling recovery coal pillar, the second layer adopts strip filling mining, and the upper and lower mining methods are carried out in sequence.

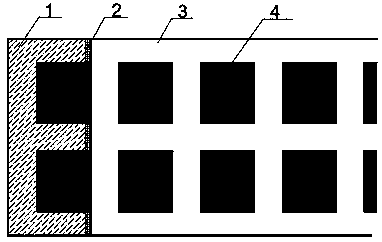

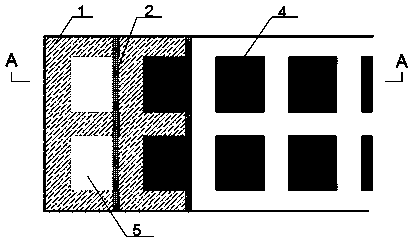

[0038] b. First, arrange the equipment according to the traditional room-and-pillar mining method, and extract the coal room 3 on the first floor according to the traditional room-and-pillar mining method (such as figure 1 As shown), usually a group of 4-5 or more coal houses is excavated at the same time, the coal house 3 is 5-7m wide, and the room coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com