Uplift pile uplift force detection method

A detection method and a technology of pull-out resistance, which are applied in construction, foundation structure tests, foundation structure engineering, etc., can solve problems affecting detection results, etc., and achieve the effects of saving filling materials, facilitating construction, and saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

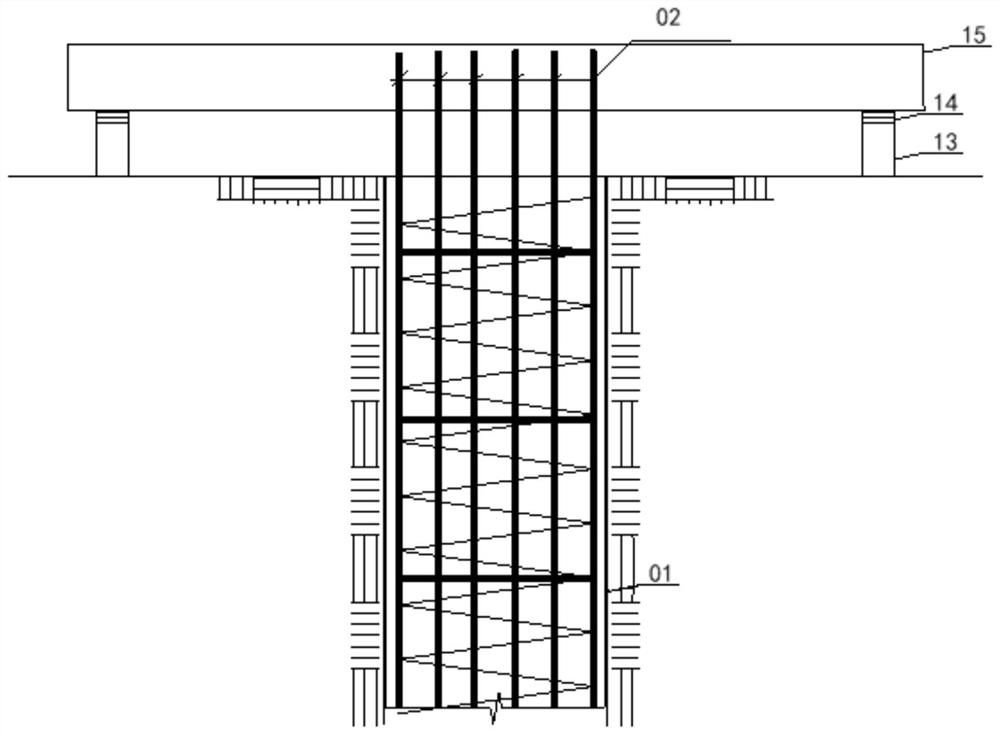

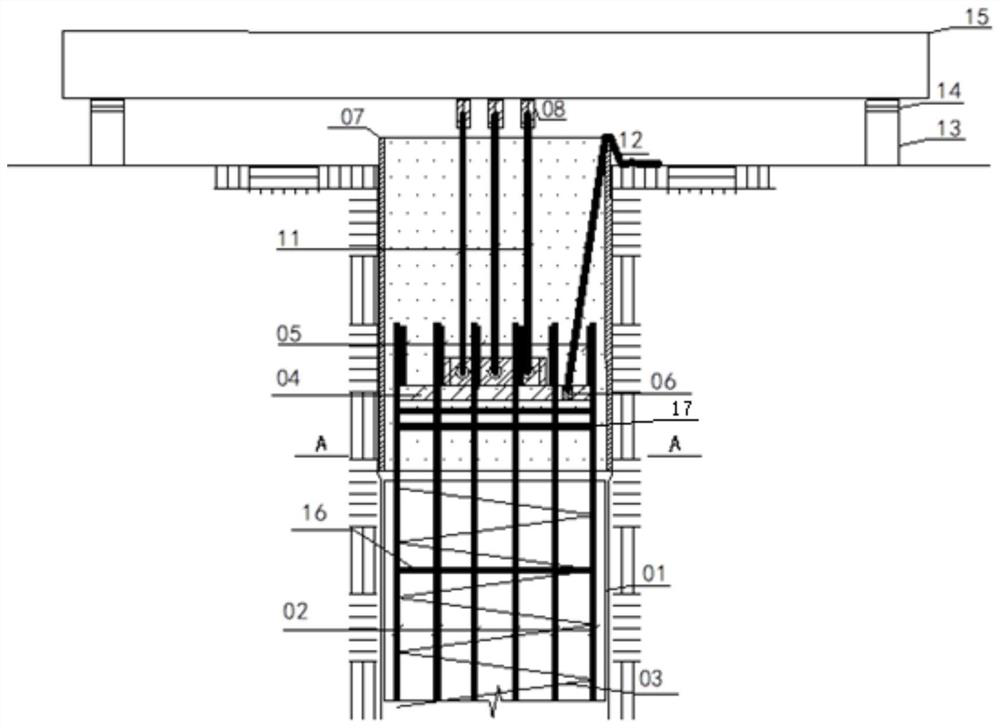

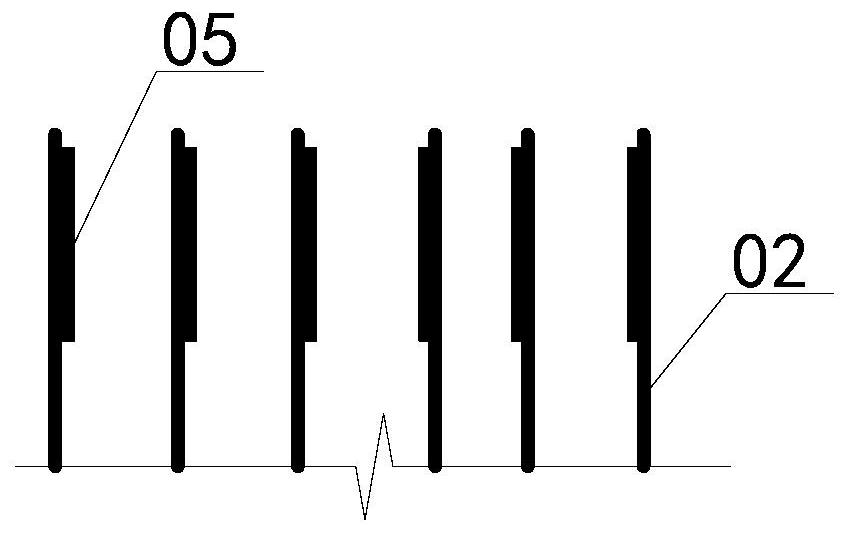

[0027] Such as Figure 2-Figure 5 , the connection member for testing the pullout force of the uplift pile, including the uplift pile 1, the steel plate 4, the force transmission member, and the test beam. The uplift pile 1 is poured in the pile hole, and the uplift pile 1 is arranged with an exposed uplift pile A plurality of main tendons 2 at the upper end, one end of the main tendons 2 exposed to the uplift pile 1 is welded with a hook pull member 5, and the two ends of the force transmission member 4 are detachably connected to the bottom surface of the test beam 15 and the top surface of the steel plate 4 respectively, and the test beam 15 It is placed on the support pier 13 and separated from the ground outside the pile hole. A jack is provided between the test beam 15 and the ground to apply pile pulling force to the uplift pile 1. The uplift pile 1 is suspended on the steel plate 4 through the hook pull member 4. superior. The outer periphery of the main reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com