Mini-type inversing manual arc welding machine

A miniature, arc welding machine technology, applied in the direction of arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of reduced reliability of welding machines, poor dustproof performance, increased manufacturing costs, etc., to solve the problem of grid resistance Poor voltage fluctuation ability, improve the ability to resist network voltage fluctuation, and solve the effect of short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

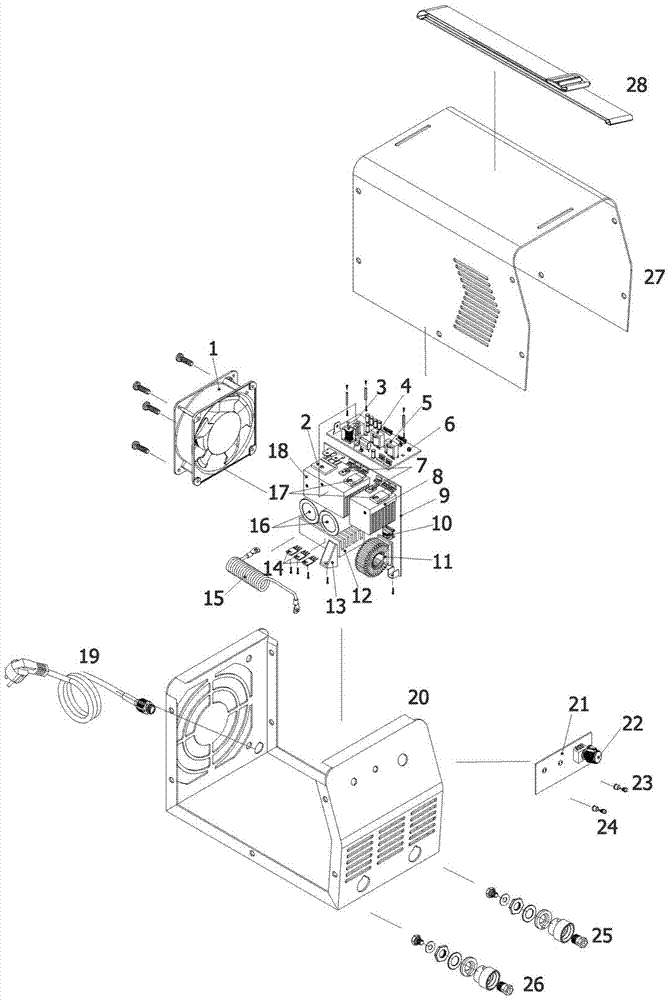

[0028] like Figure 1-8 Shown, main component of the present invention comprises:

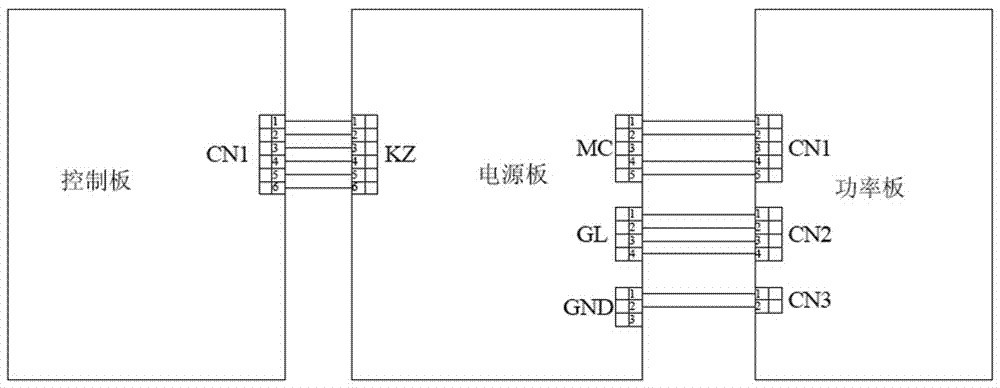

[0029] 1) Front panel part. There are mainly a positive output quick connector 26, a negative output quick connector 25, and a control panel 21. The control board 21 is installed on the front panel of the chassis bottom plate 20 . The power indicator light 24 on the control board 21 and the thermal protection indicator light 23, the current adjustment potentiometer knob 22, etc., the feature of the control board 21 is: on the control board, a UC3842 PWM pulse width modulation chip, a four operational amplifiers, Power indicator light, thermal protection indicator light, current adjustment potentiometer, and some resistors and capacitors, Zener tubes and diodes, etc. According to the function of the control circuit, it can be divided into UC3842 PWM output characteristic control, no-load voltage limit, overcurrent and overheat protection, and long-term output short circuit protection circuit....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com