Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

262results about "Welding coupling means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

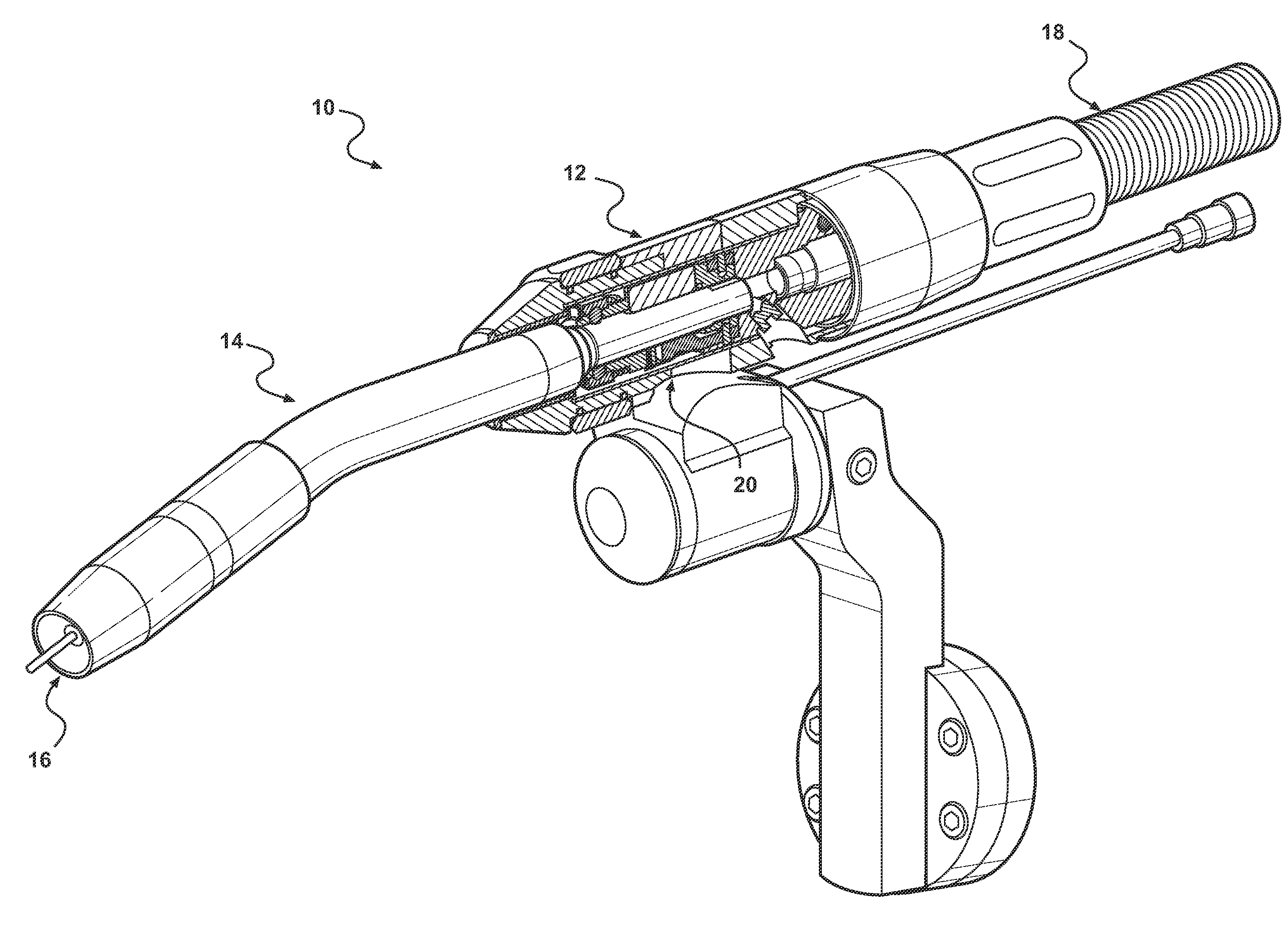

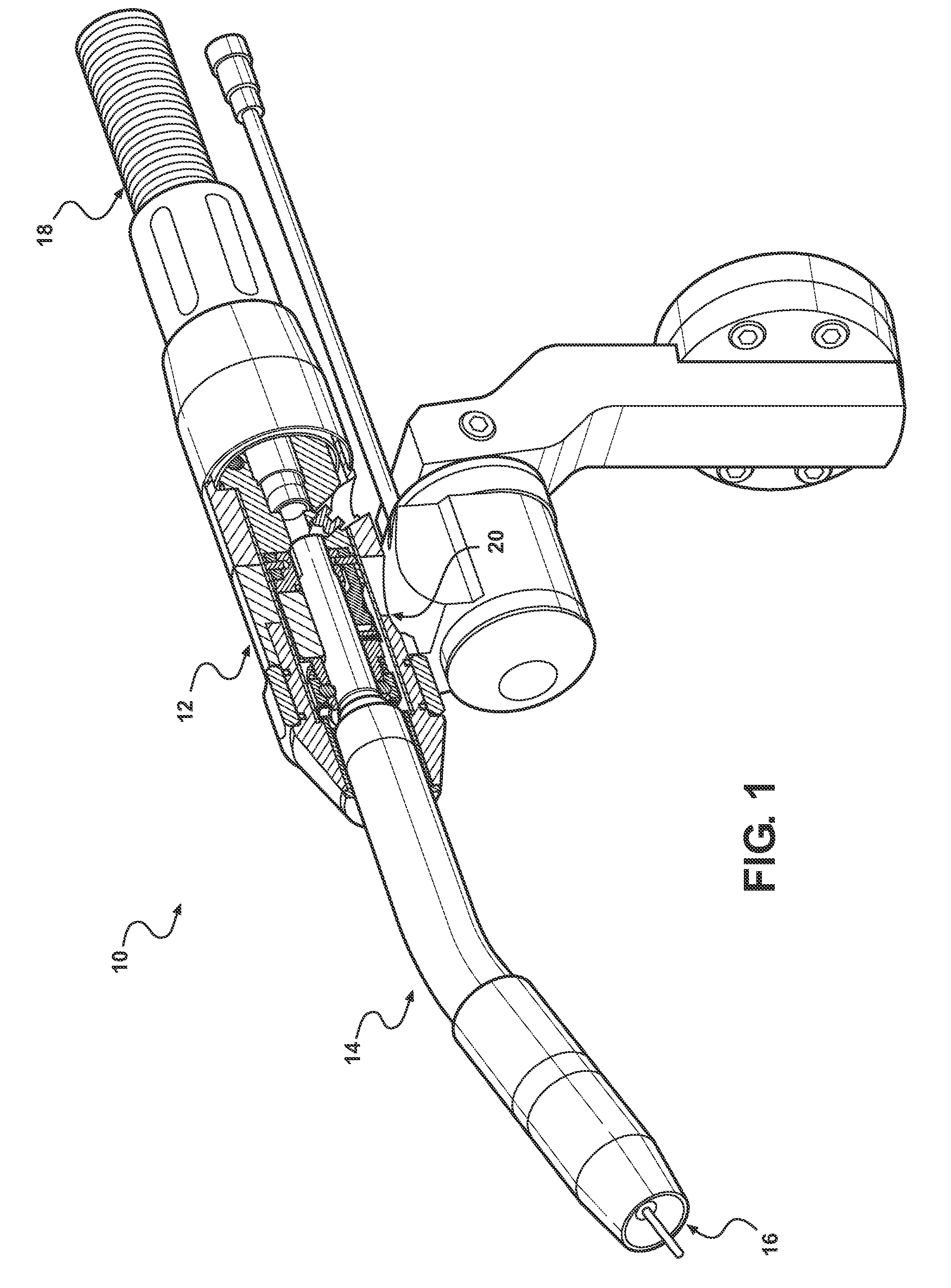

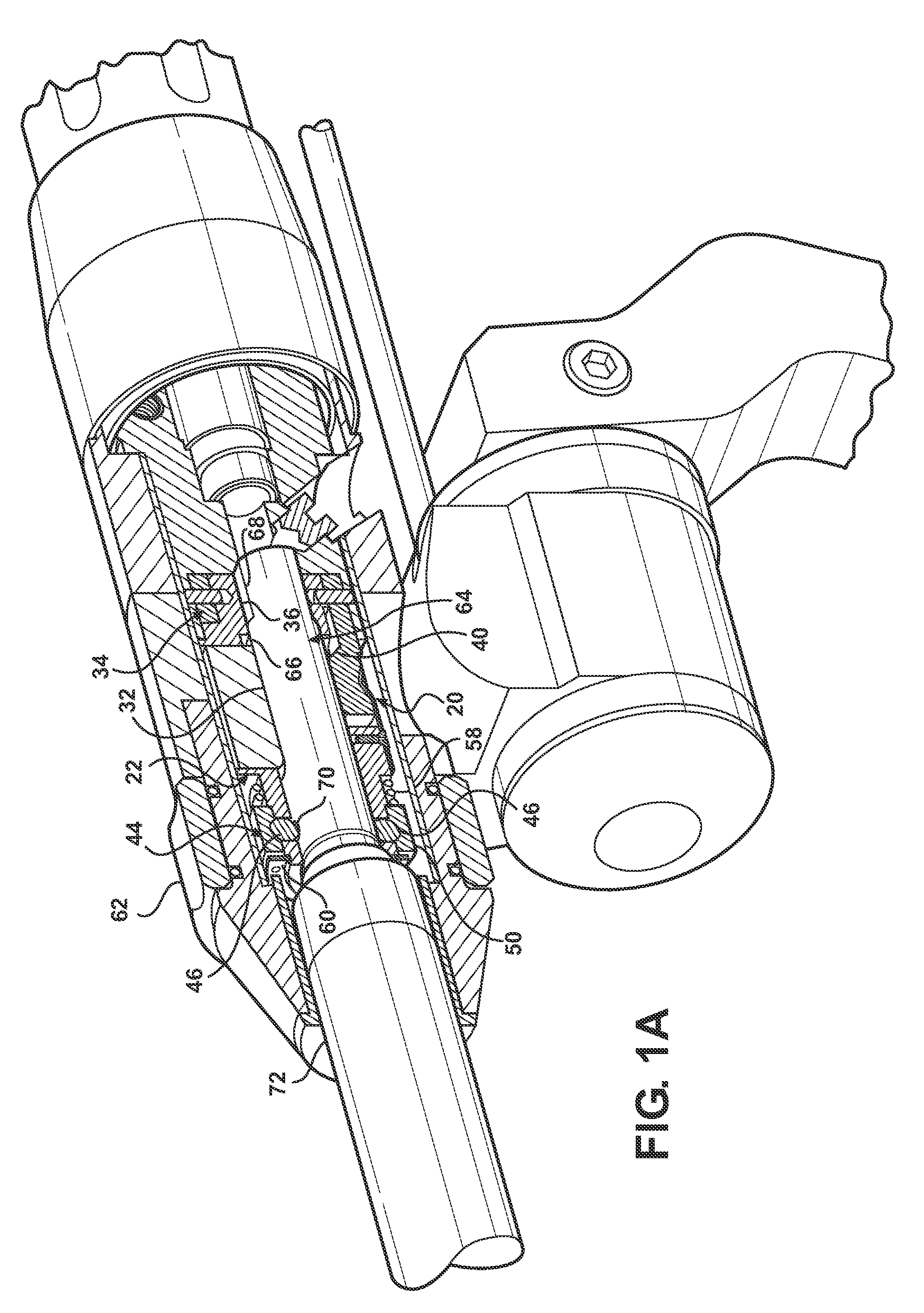

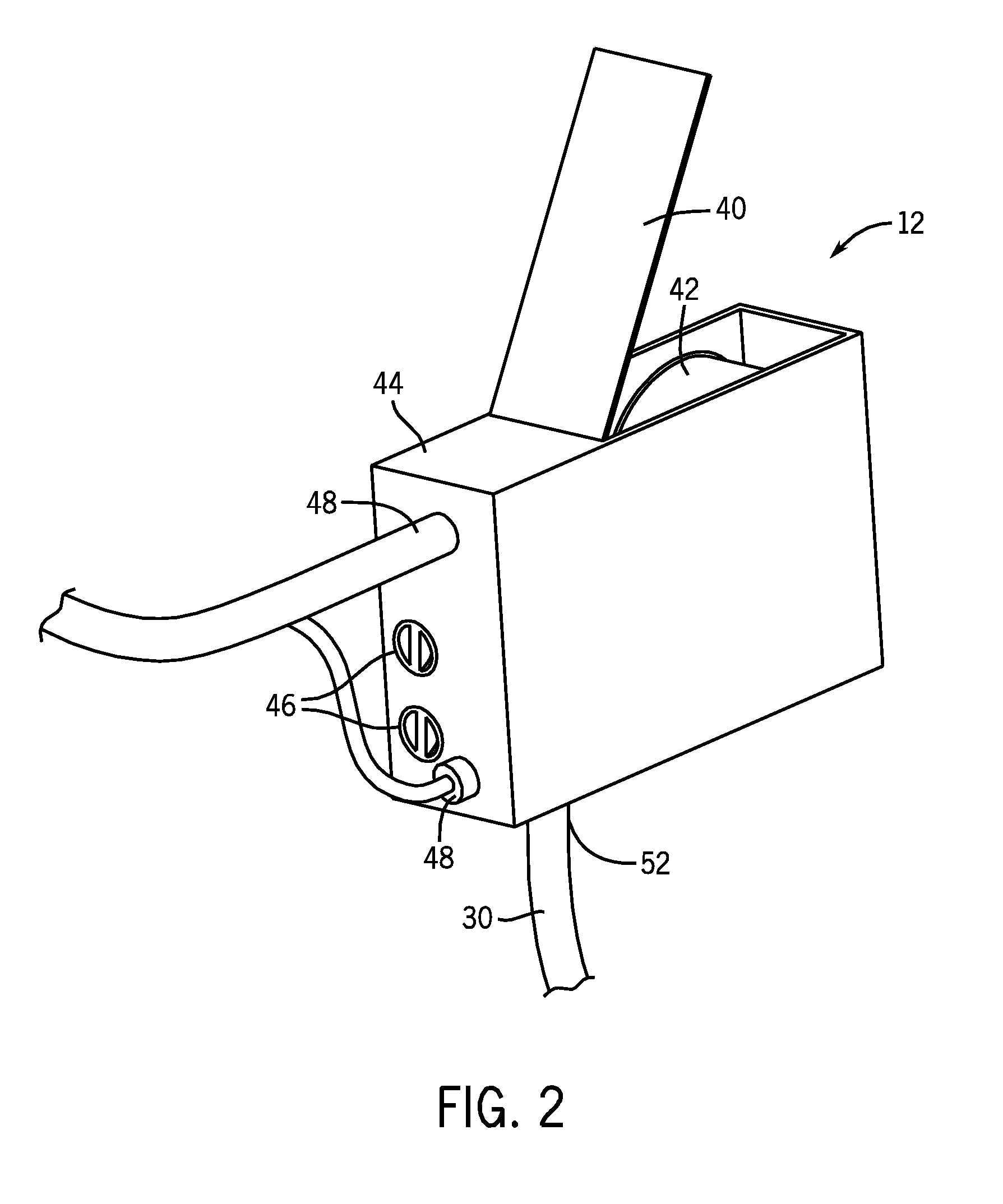

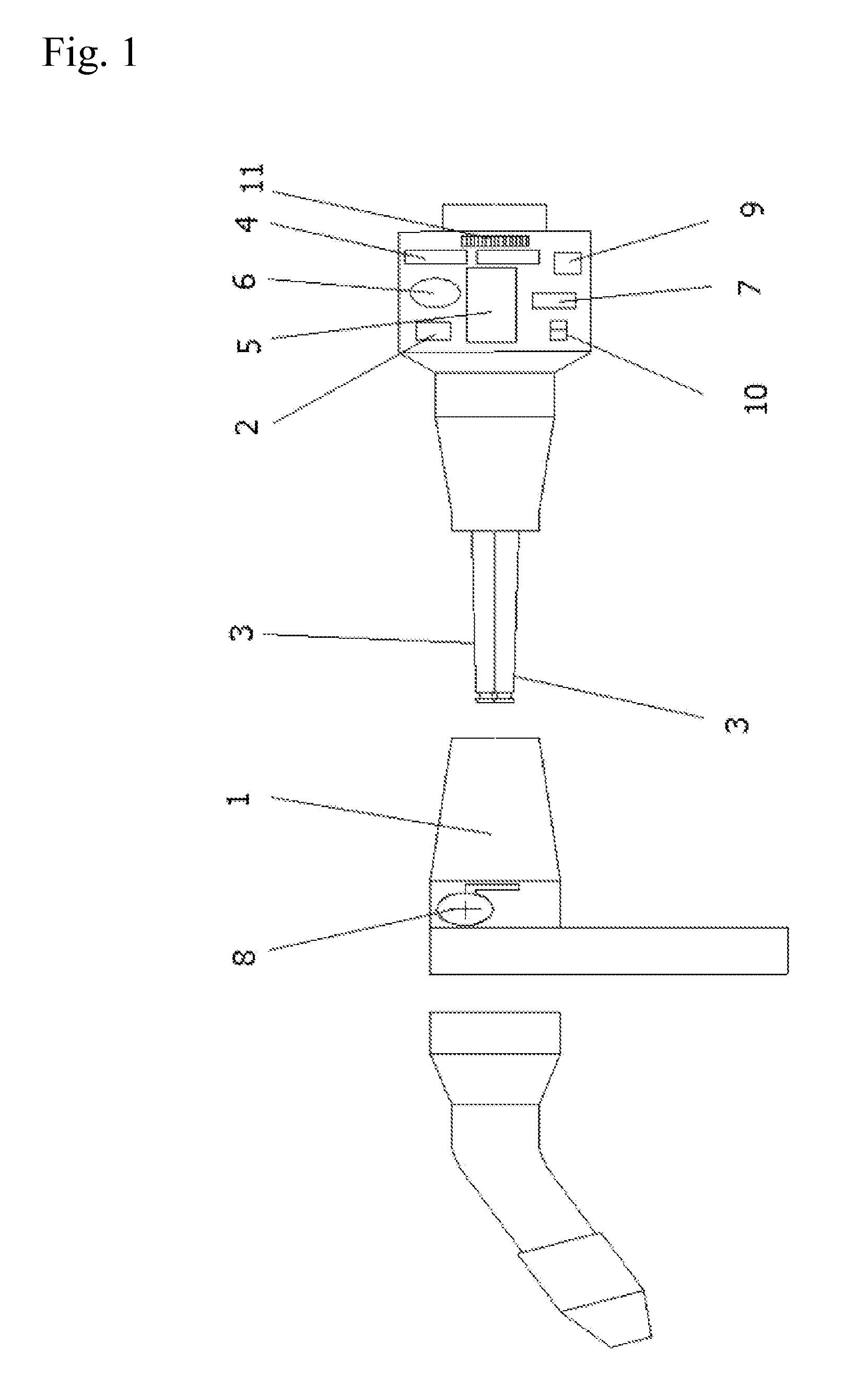

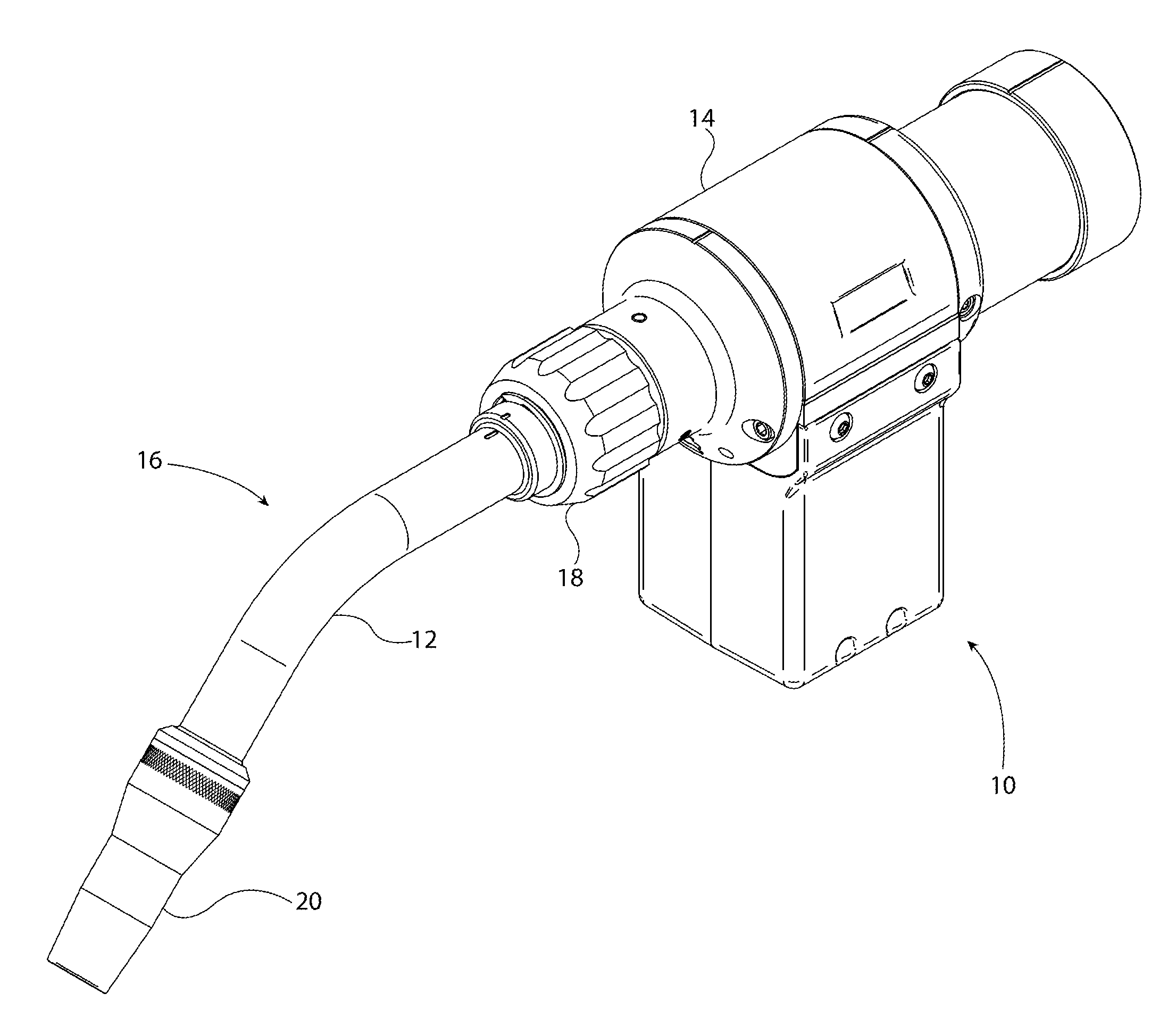

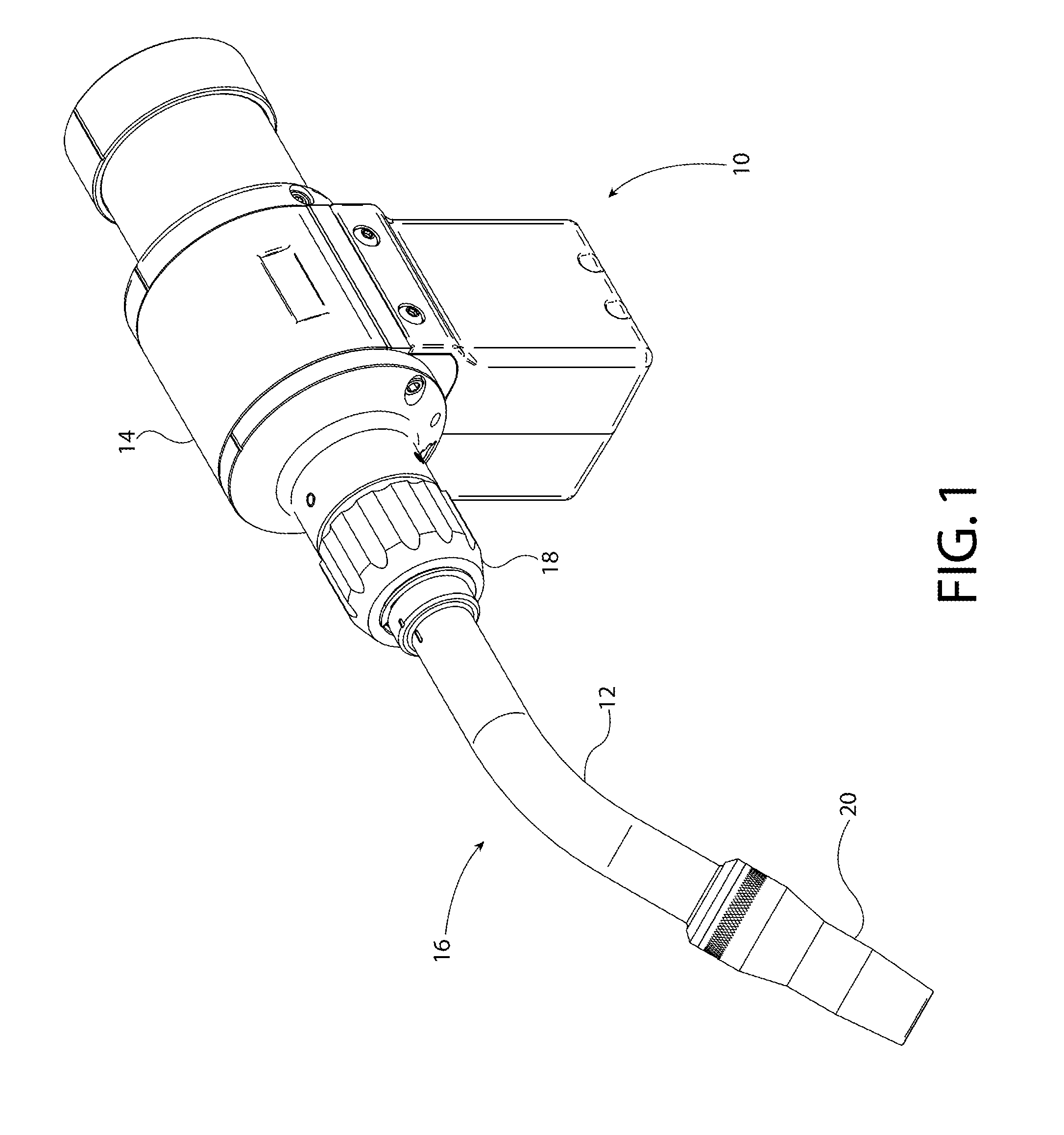

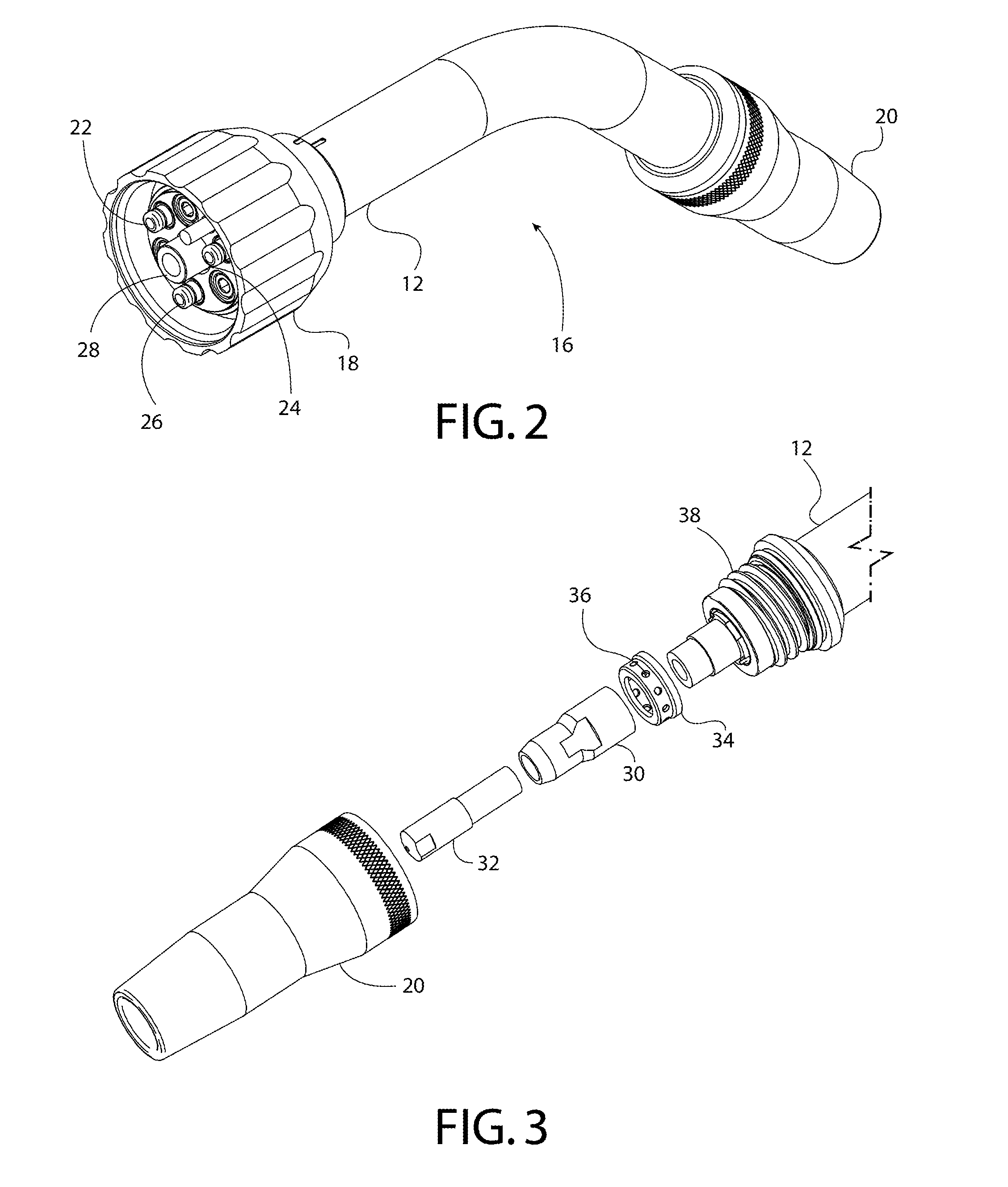

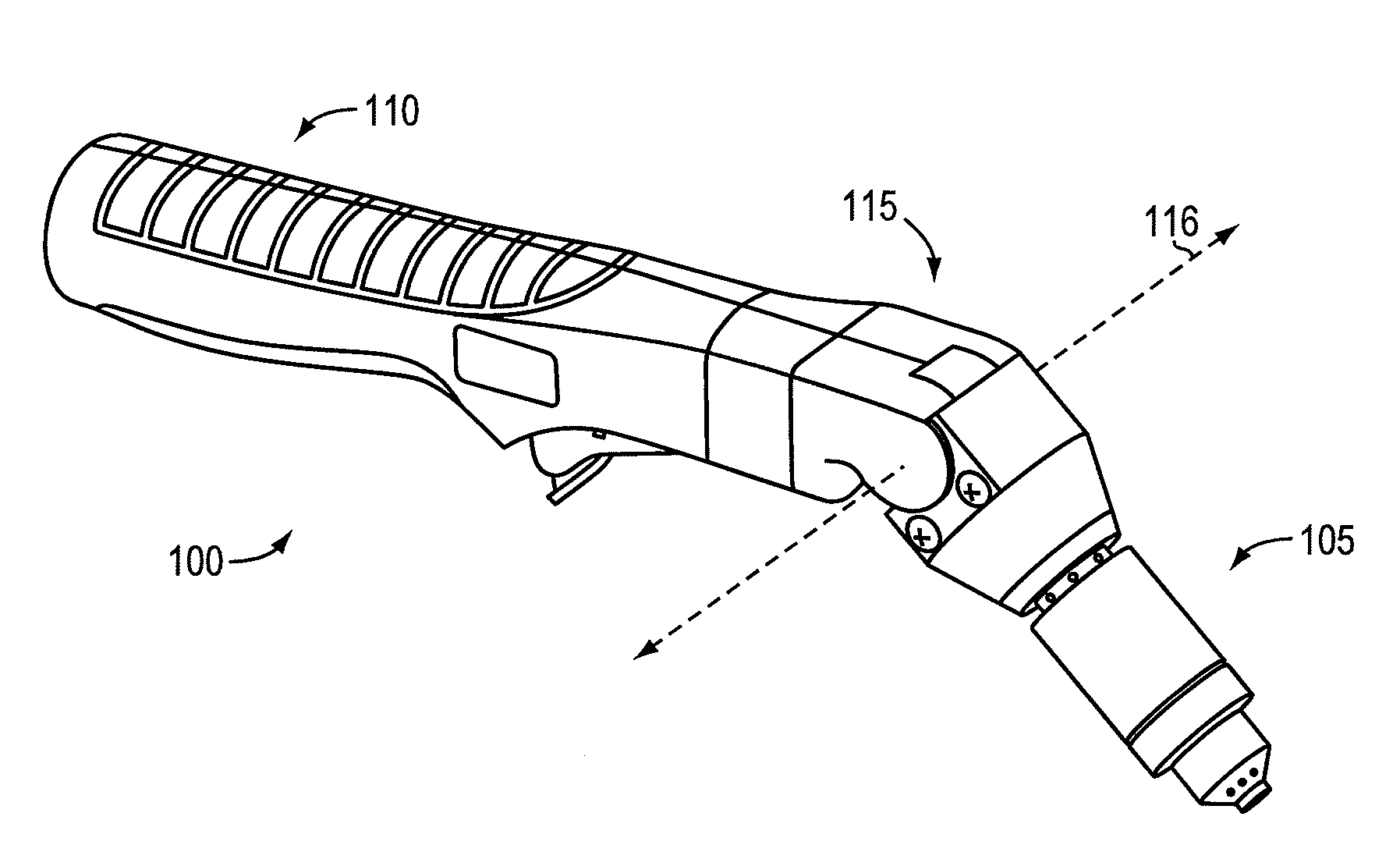

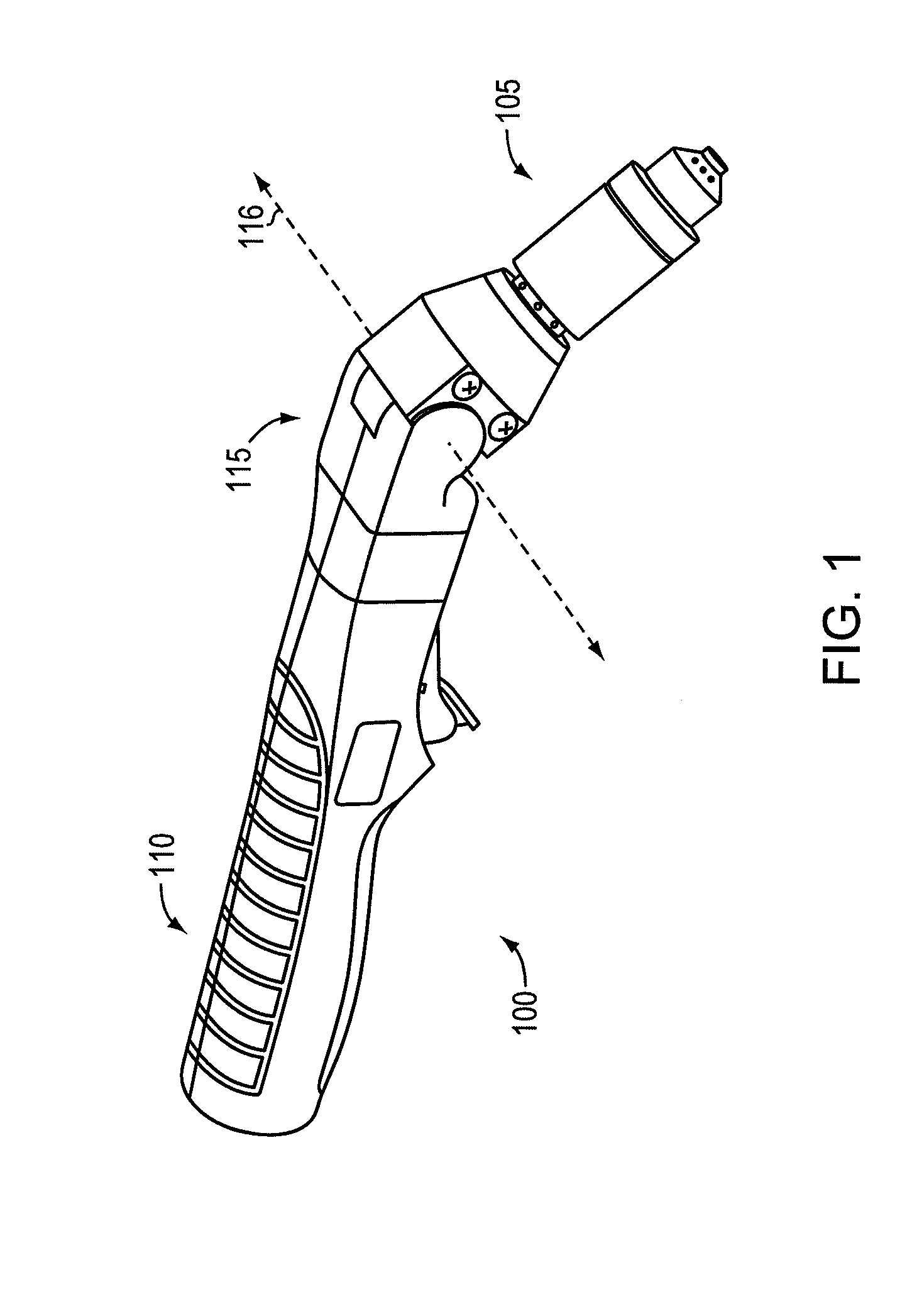

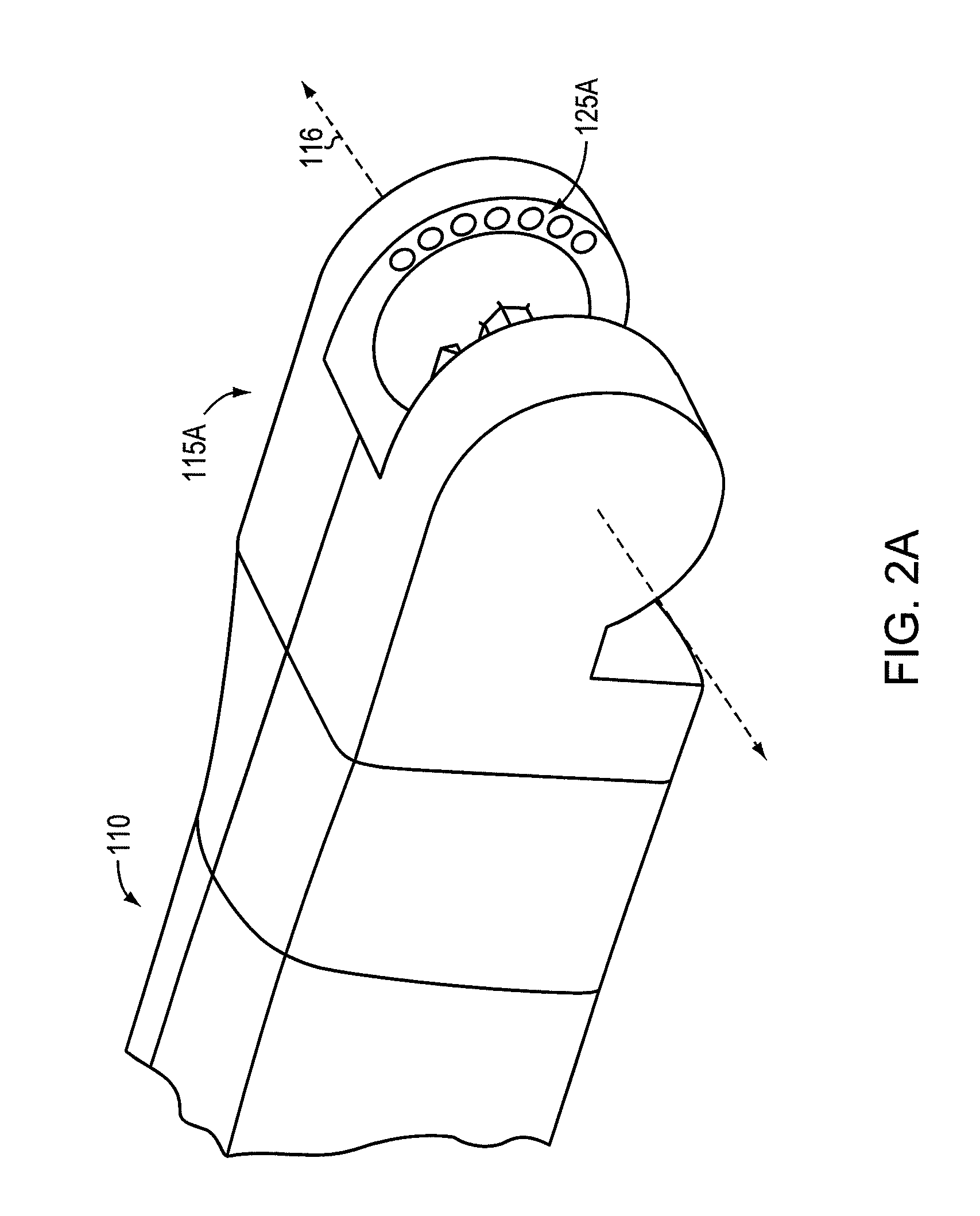

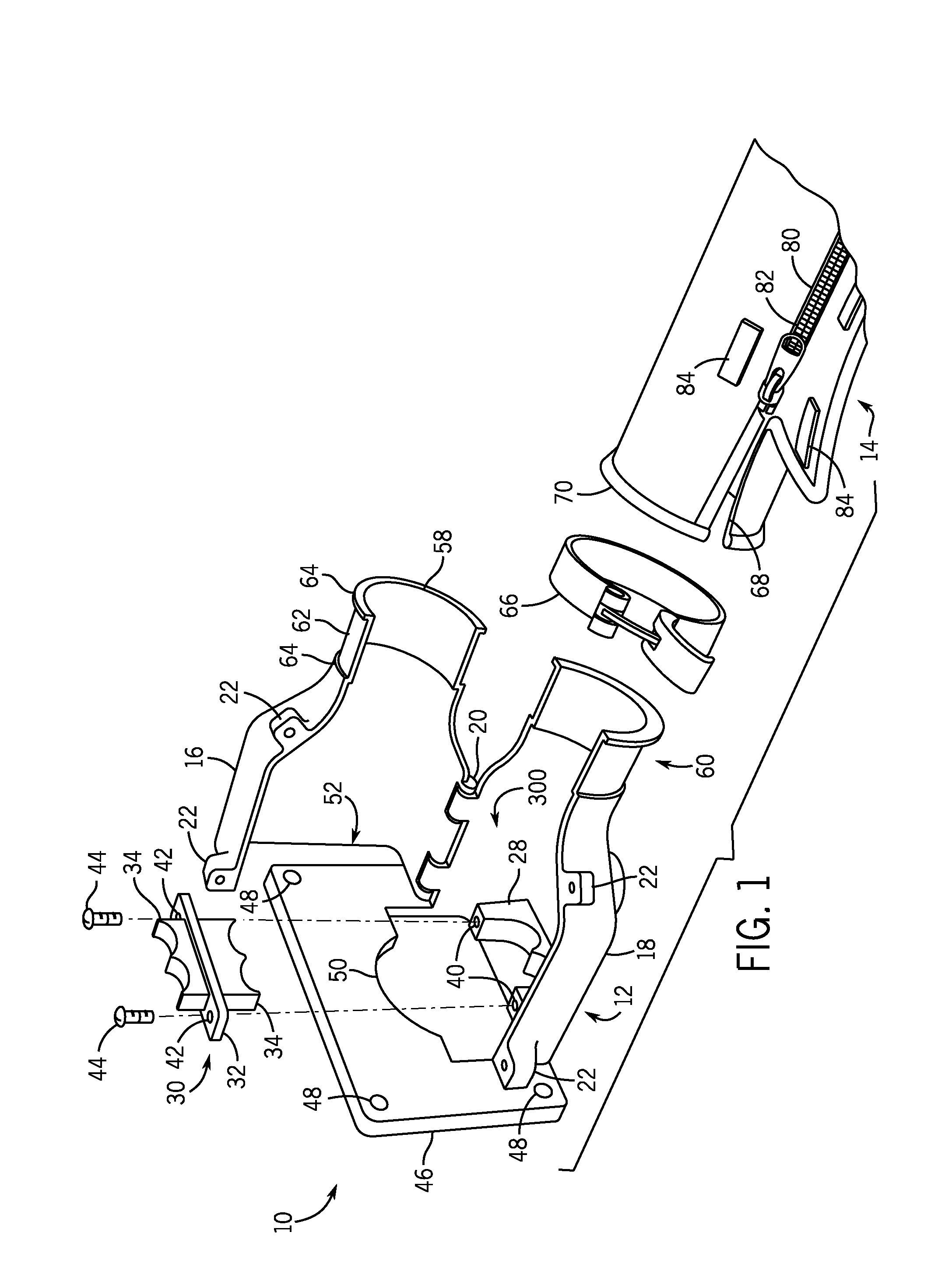

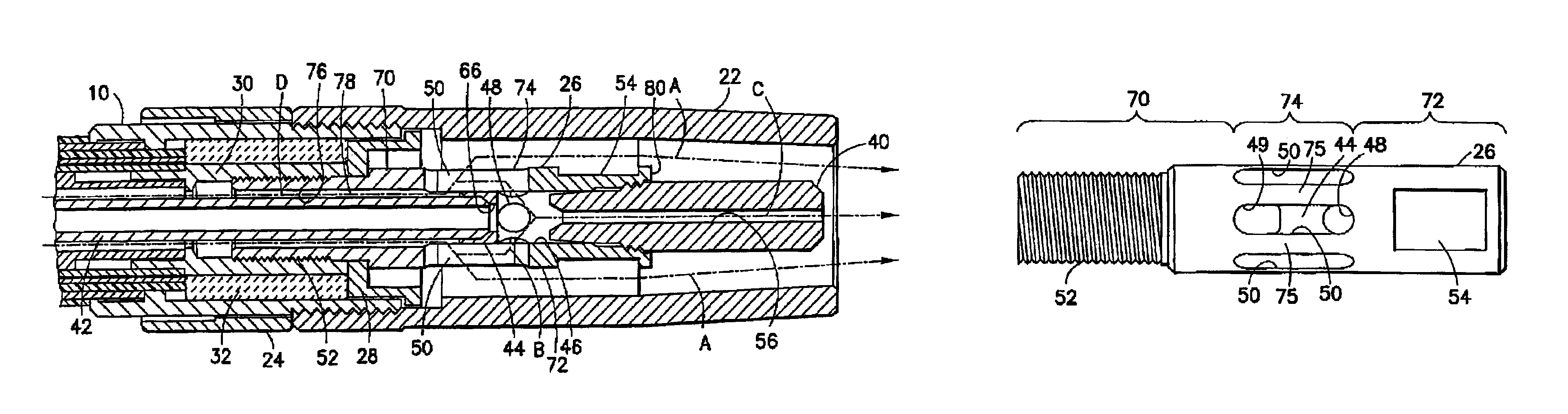

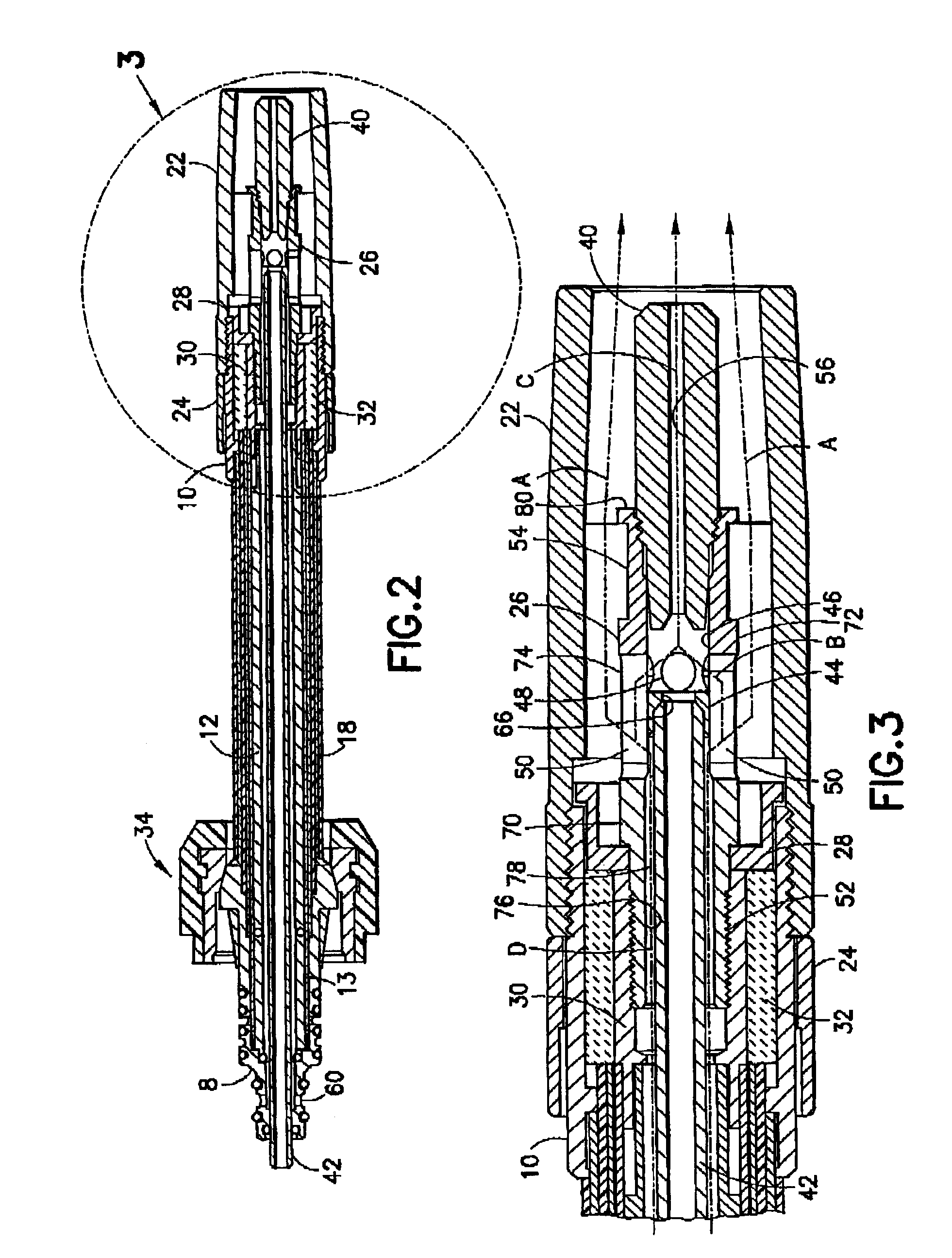

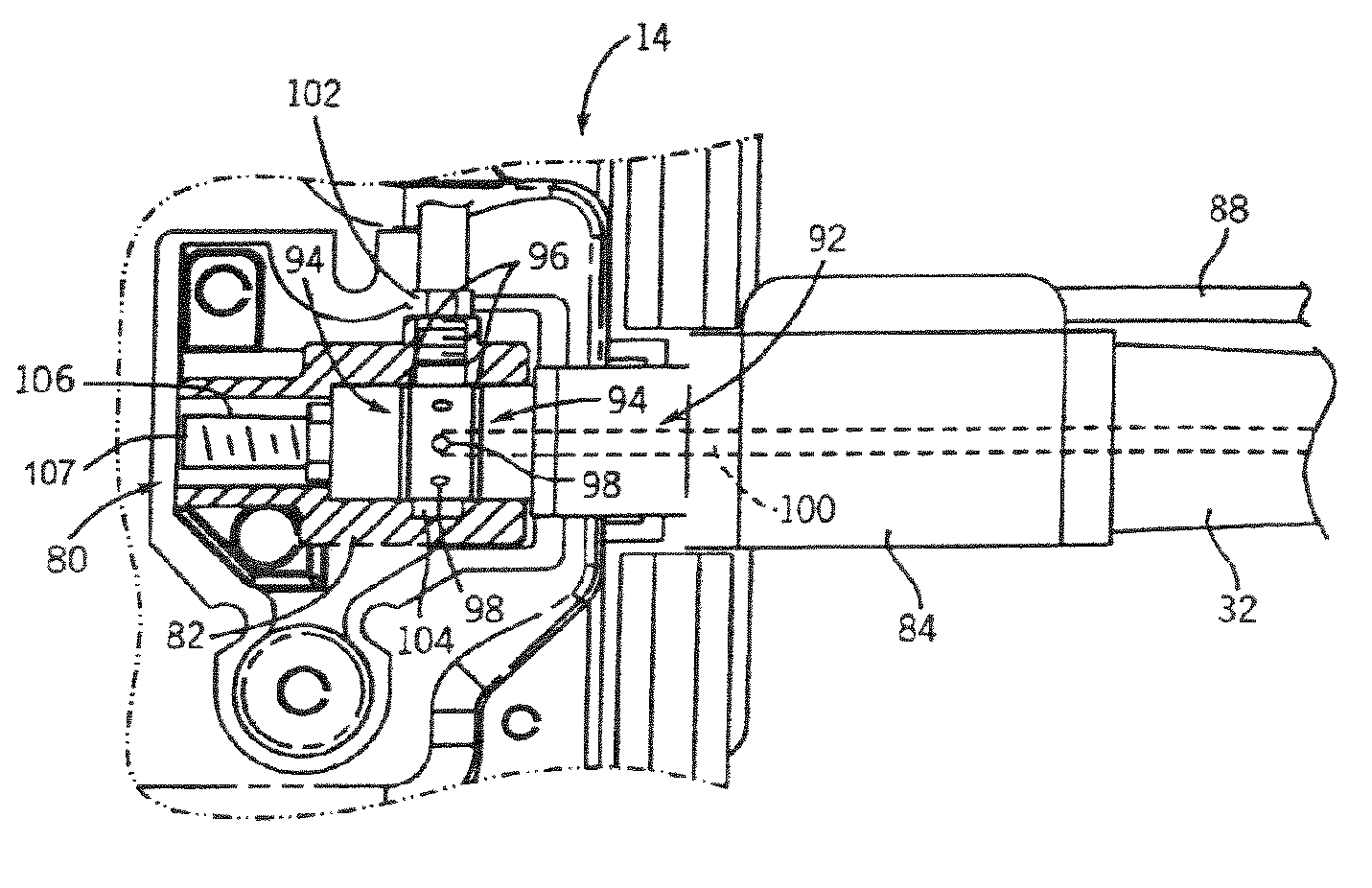

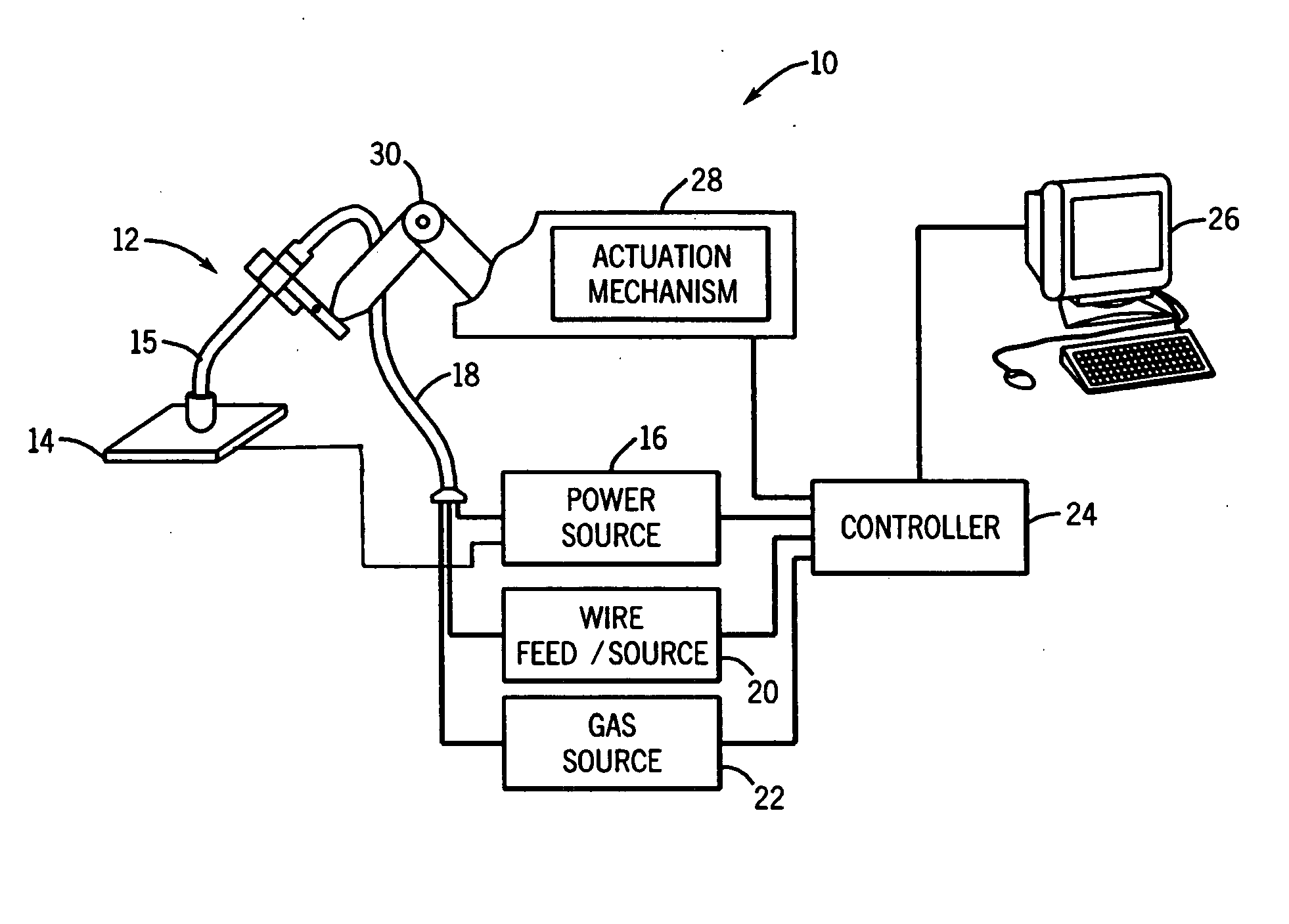

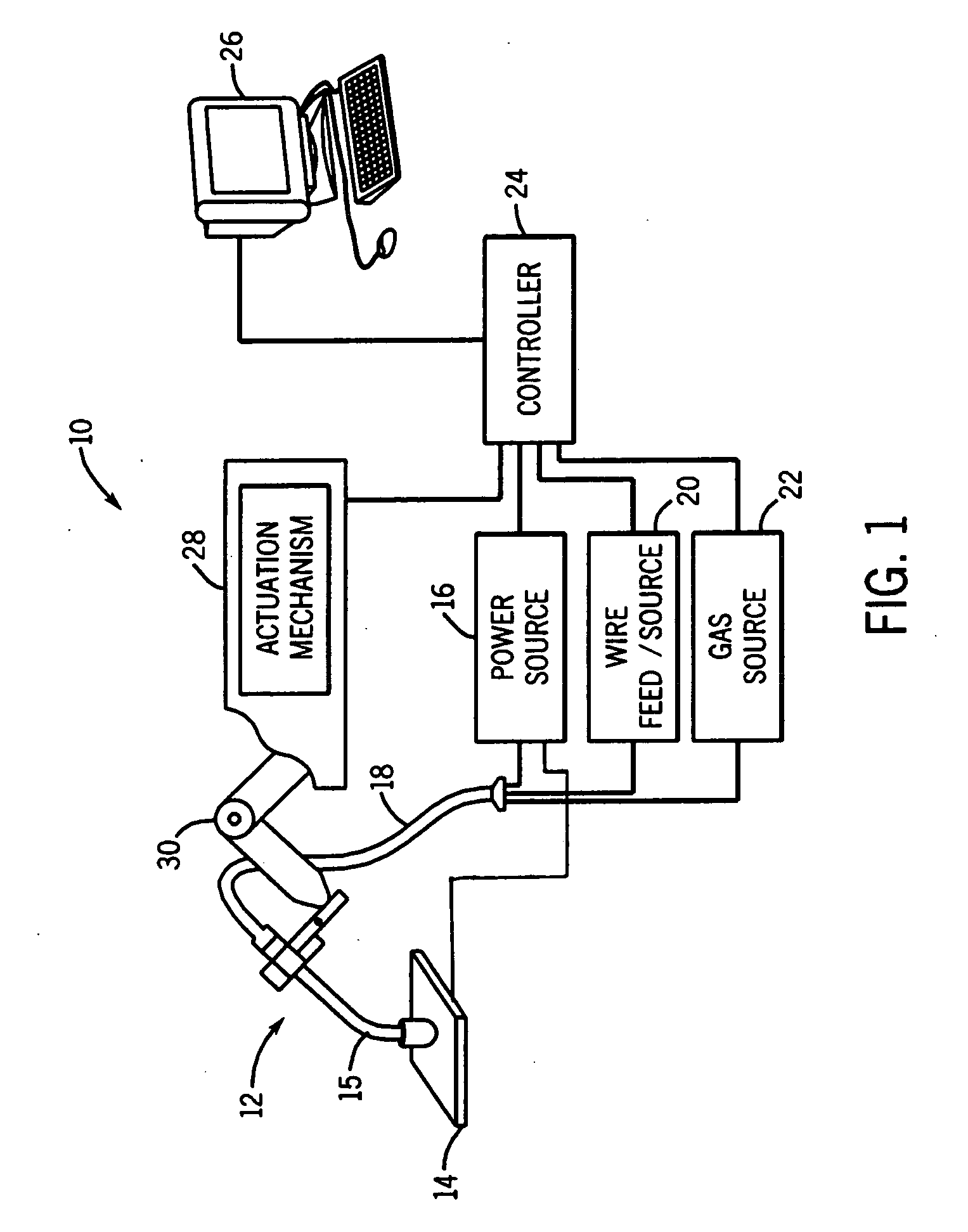

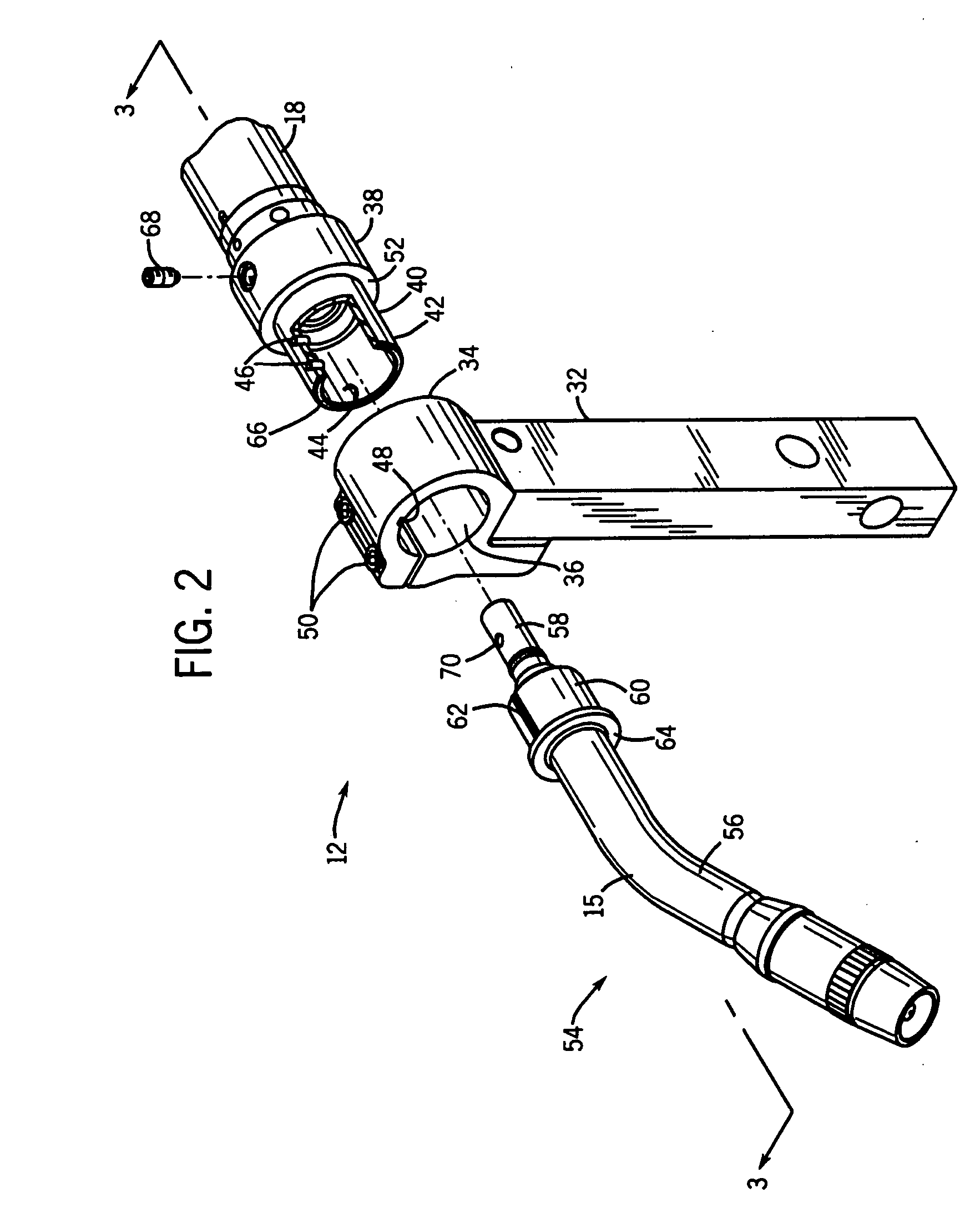

Robotic gmaw torch with quick release gooseneck locking mechanism, dual alignment features, and multiple electrical contacts

InactiveUS20100012637A1Increased durabilityImprove consistencyShielding gas supply/evacuation devicesSupport devices with shieldingLocking mechanismDetent

A gooseneck locking mechanism for a robotic GMAW torch having a torch body and a gooseneck includes a connector receiver disposed in the torch body. The connector receiver includes longitudinal ends and a passageway extending between the longitudinal ends. An indexing feature is disposed in the passageway. An elongated connector is mountable on a proximal end of the gooseneck. The connector includes a cooperable indexing feature. The locking mechanism further includes a detent for joining the connector receiver and the elongated connector. The indexing features align the gooseneck relative to the torch body, and the detent secures the connector in the connector receiver for quick release. The locking mechanism may include a plurality of electrical contacts in the connector receiver that are engageable with the connector to provide flow of electrical current through the connector receiver to the gooseneck.

Owner:ILLINOIS TOOL WORKS INC

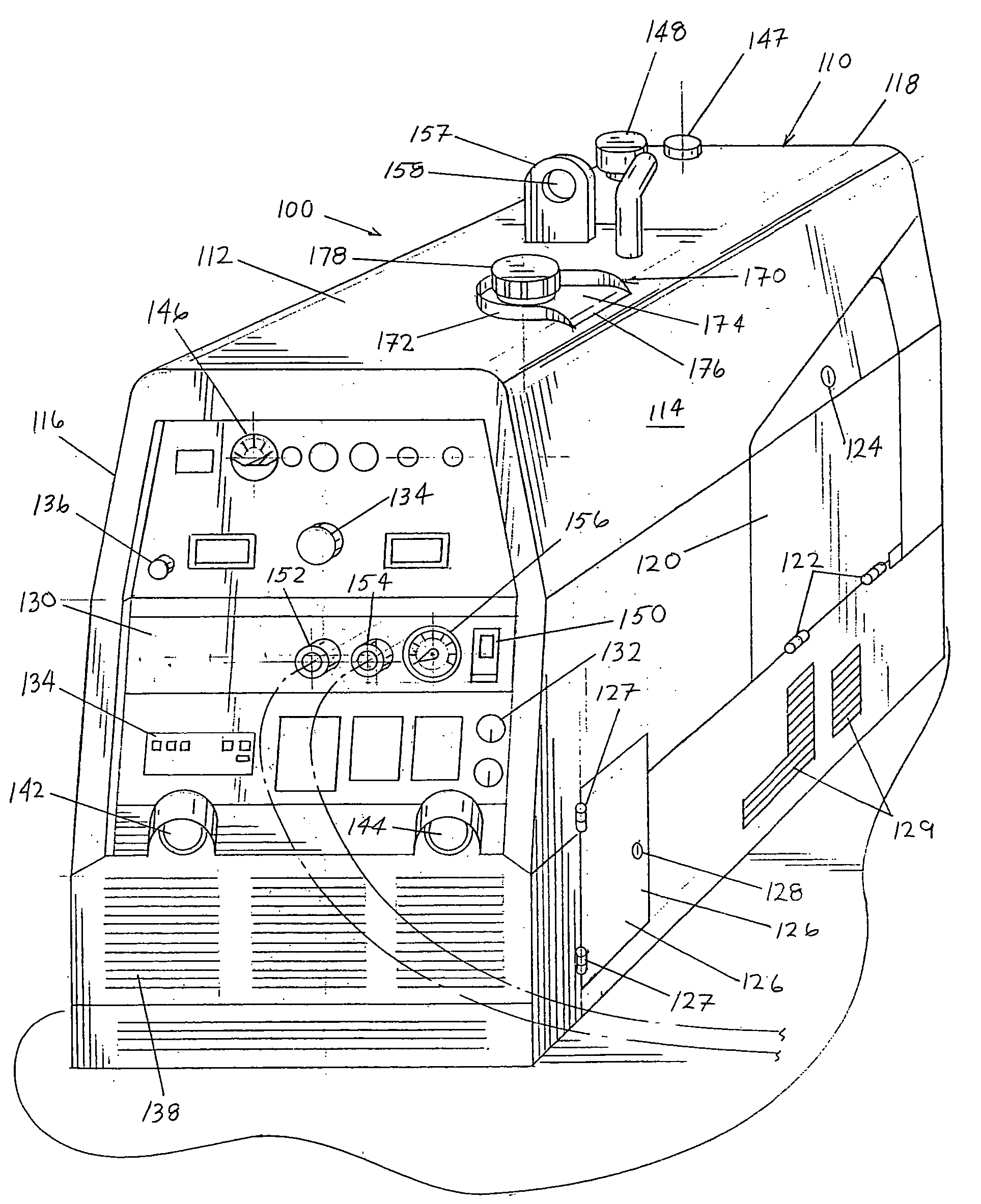

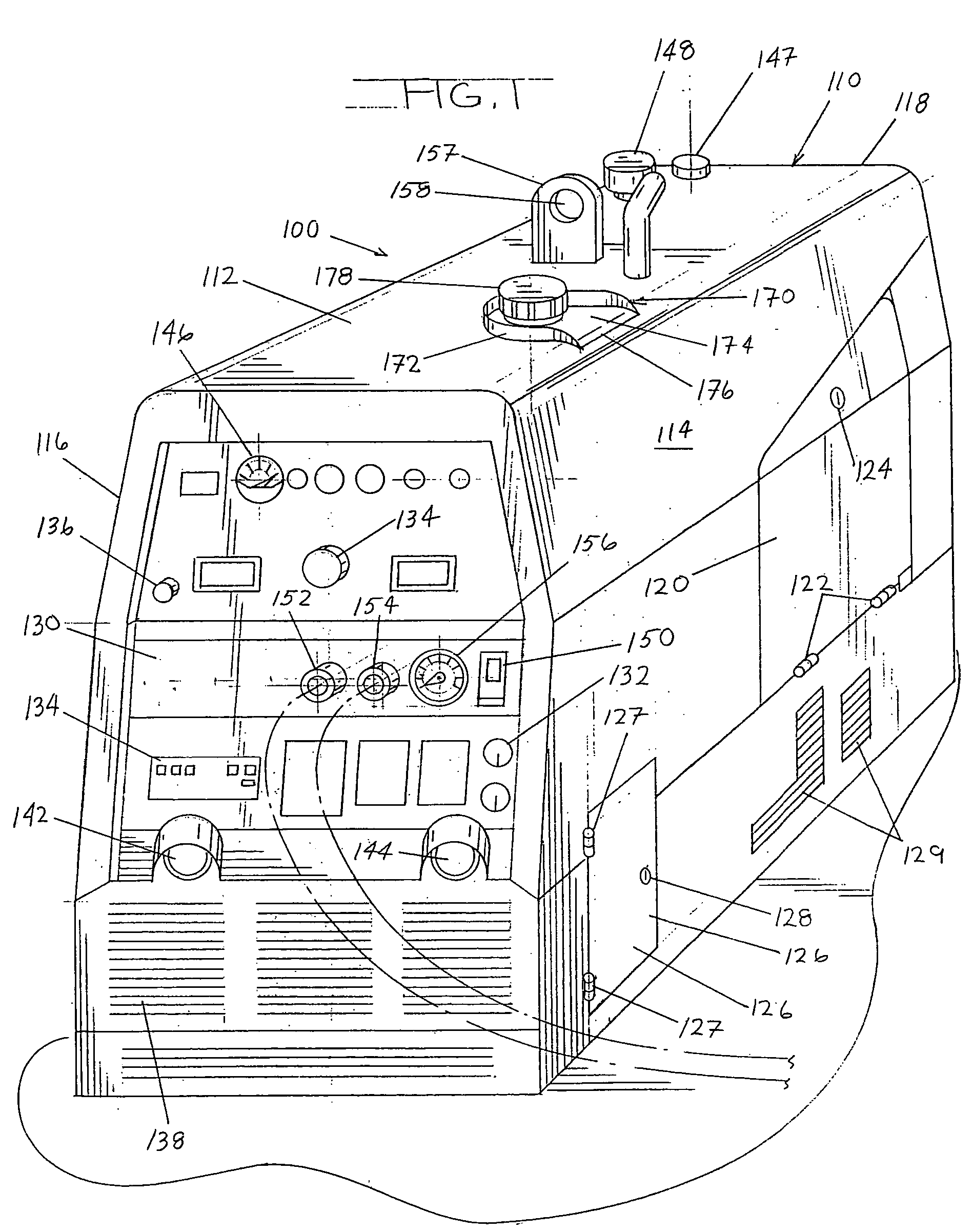

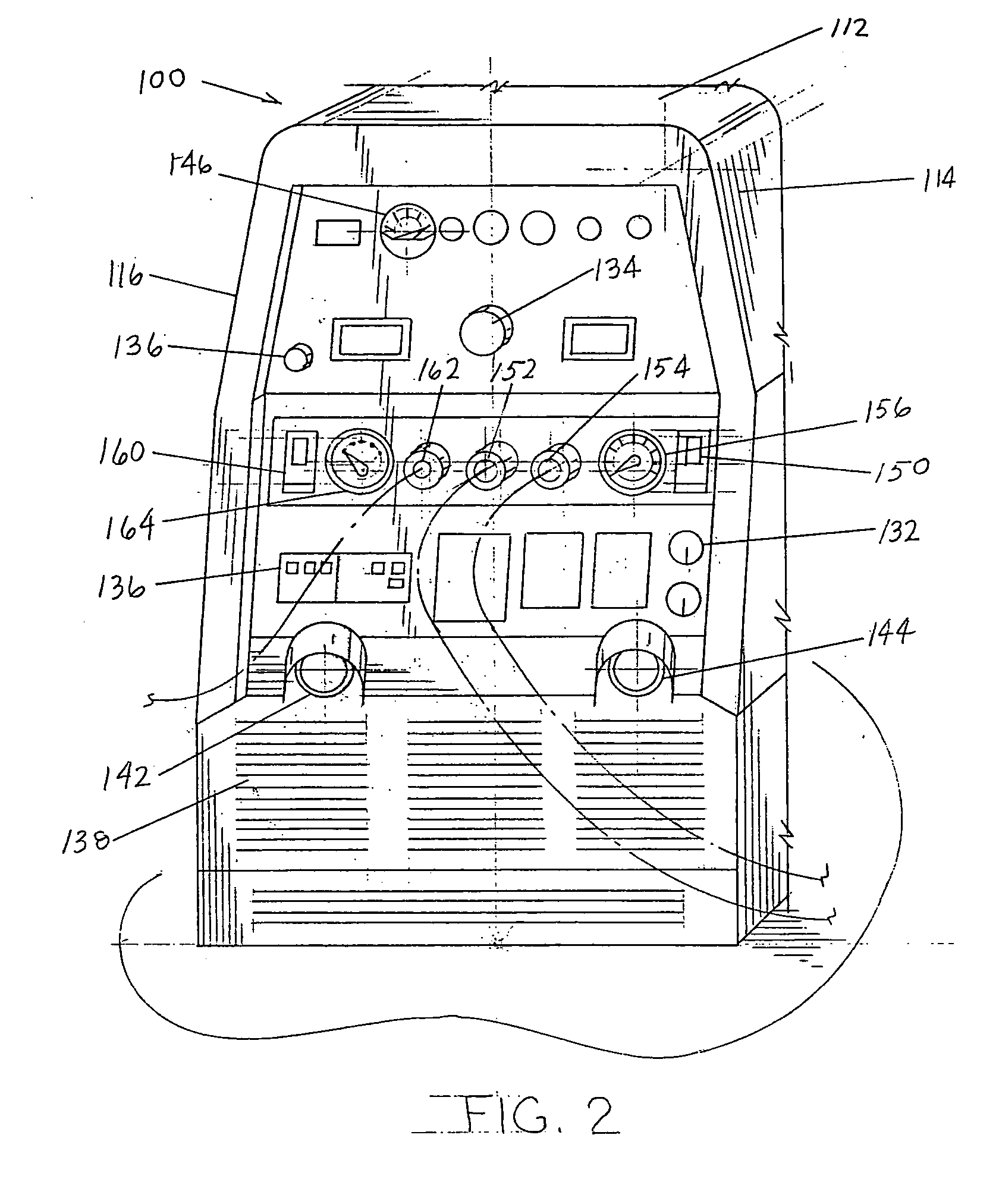

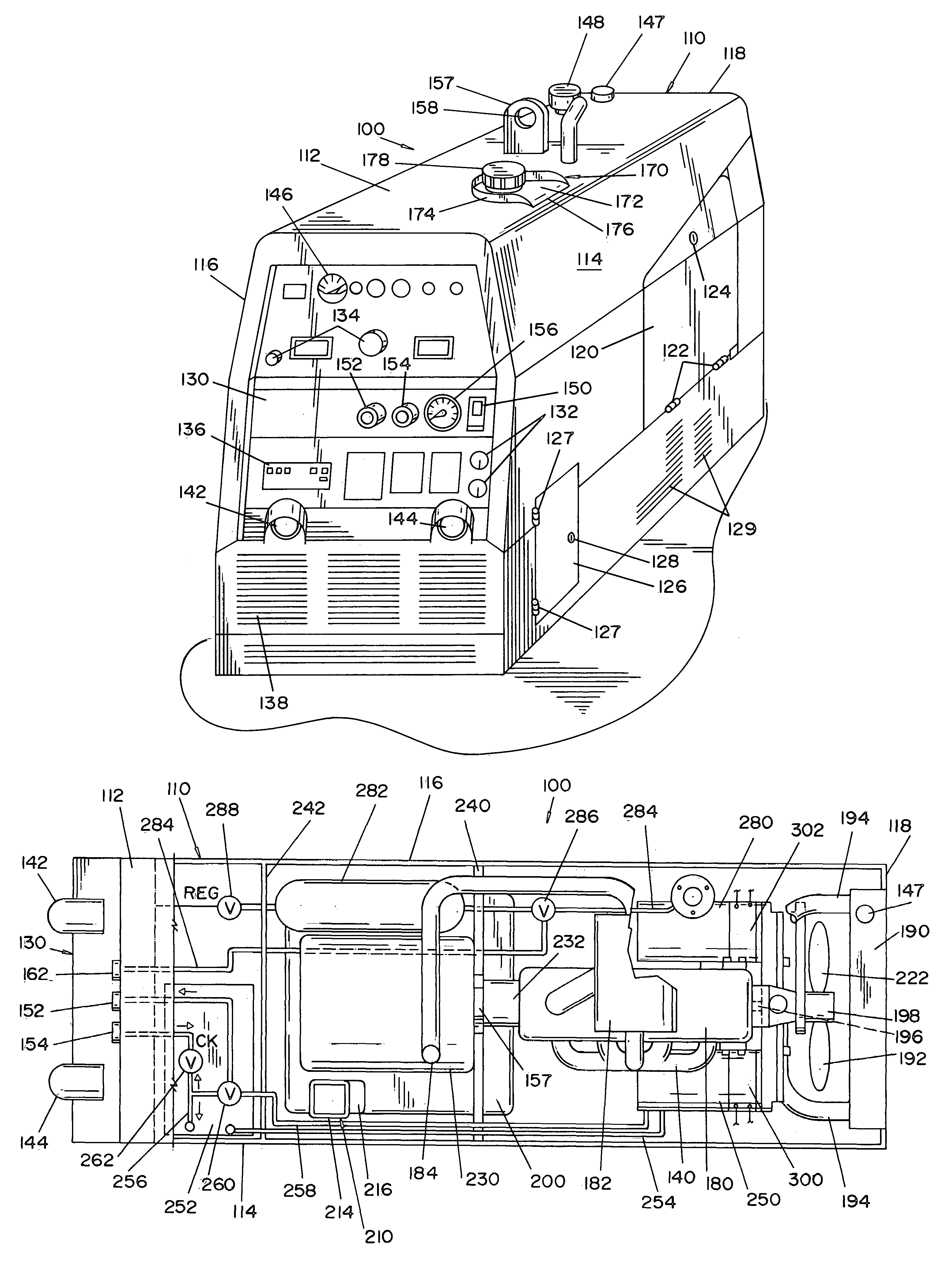

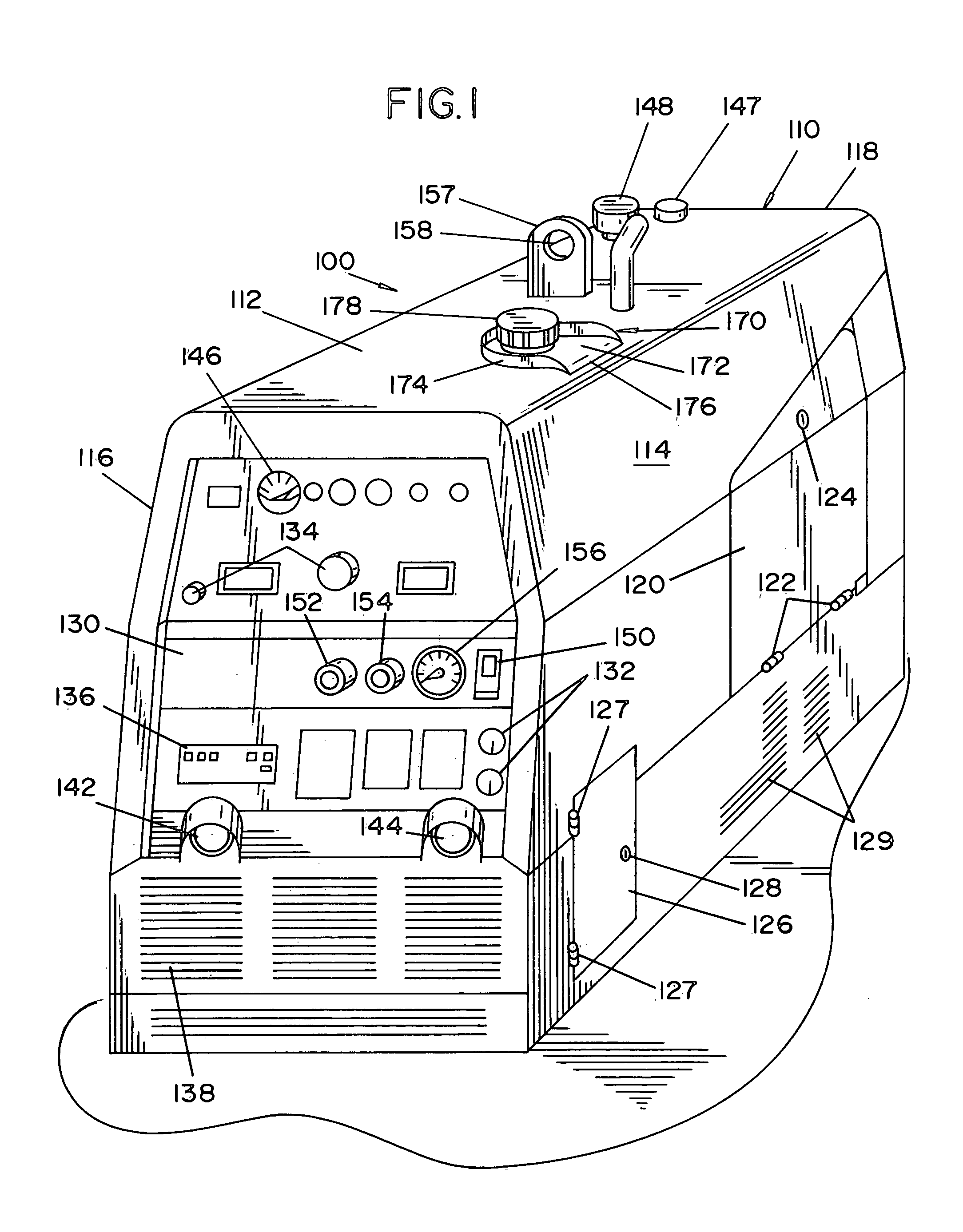

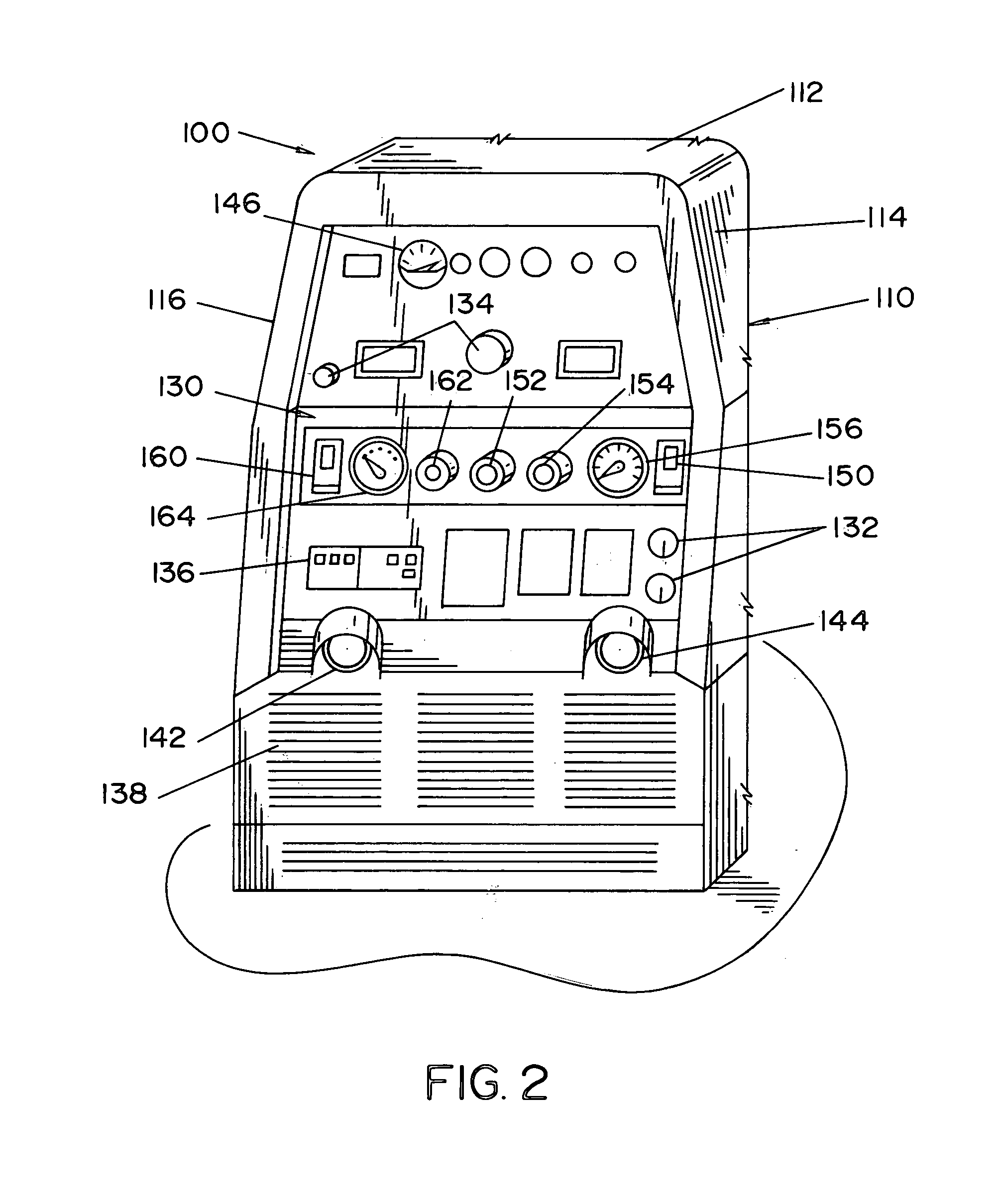

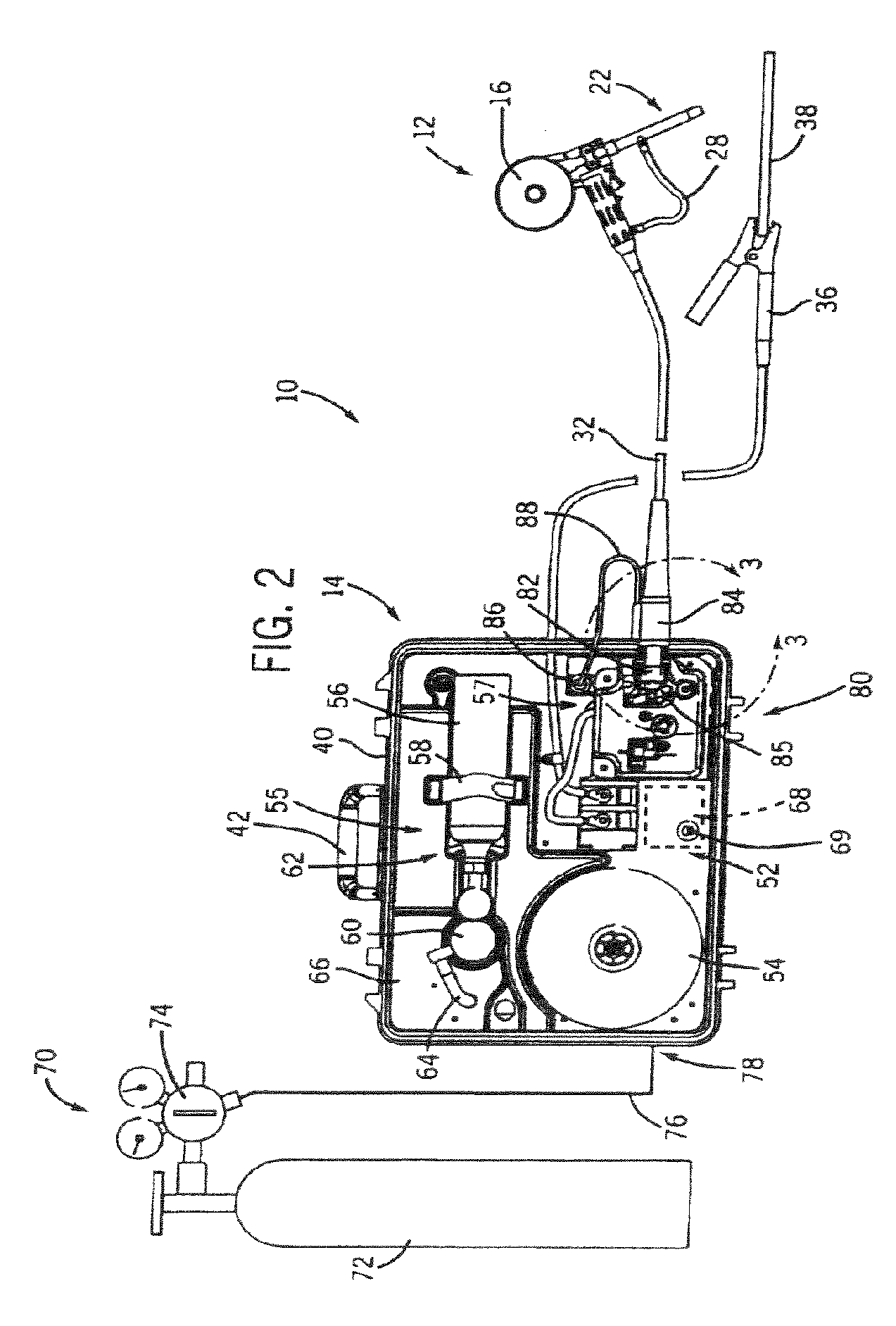

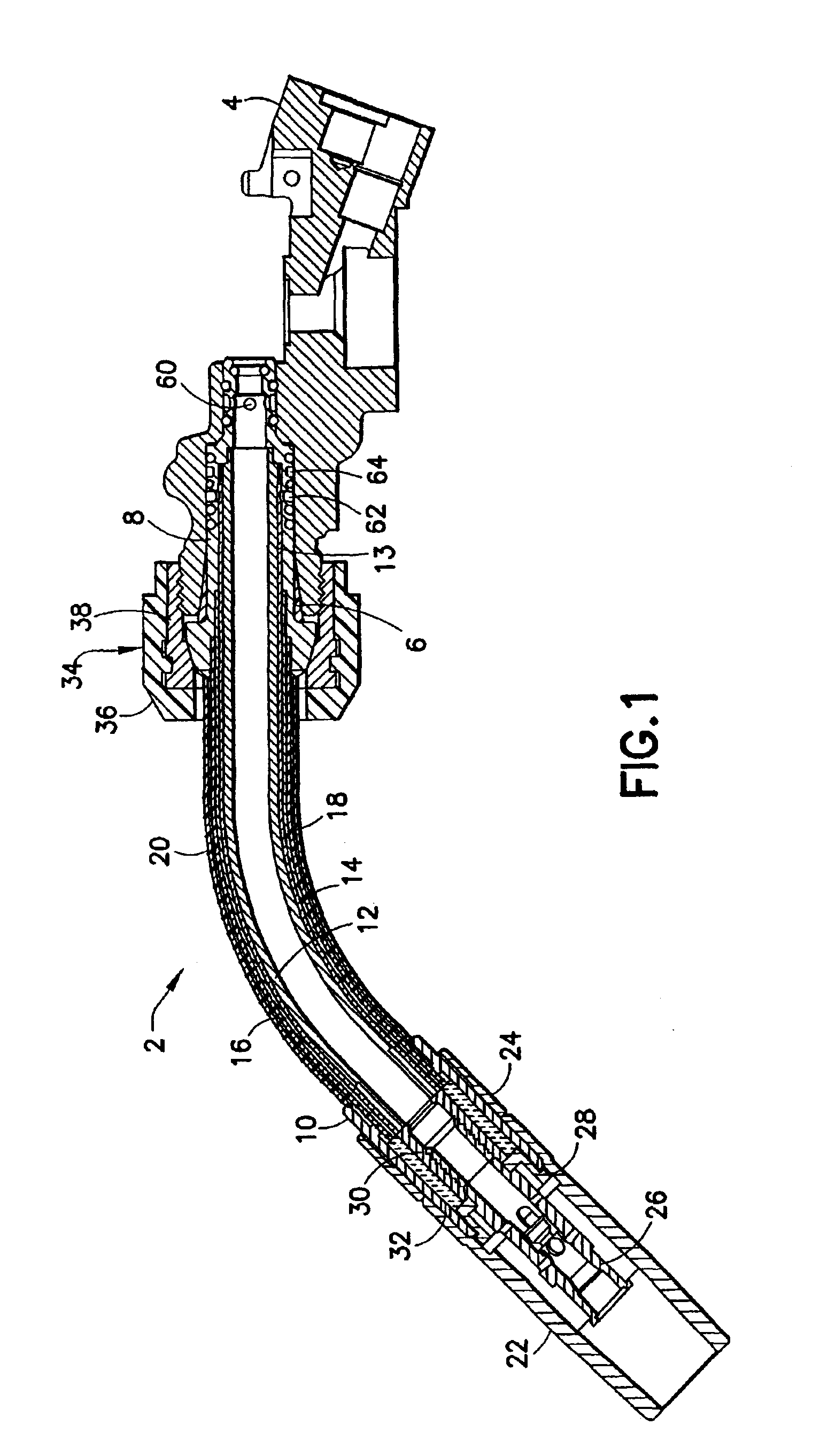

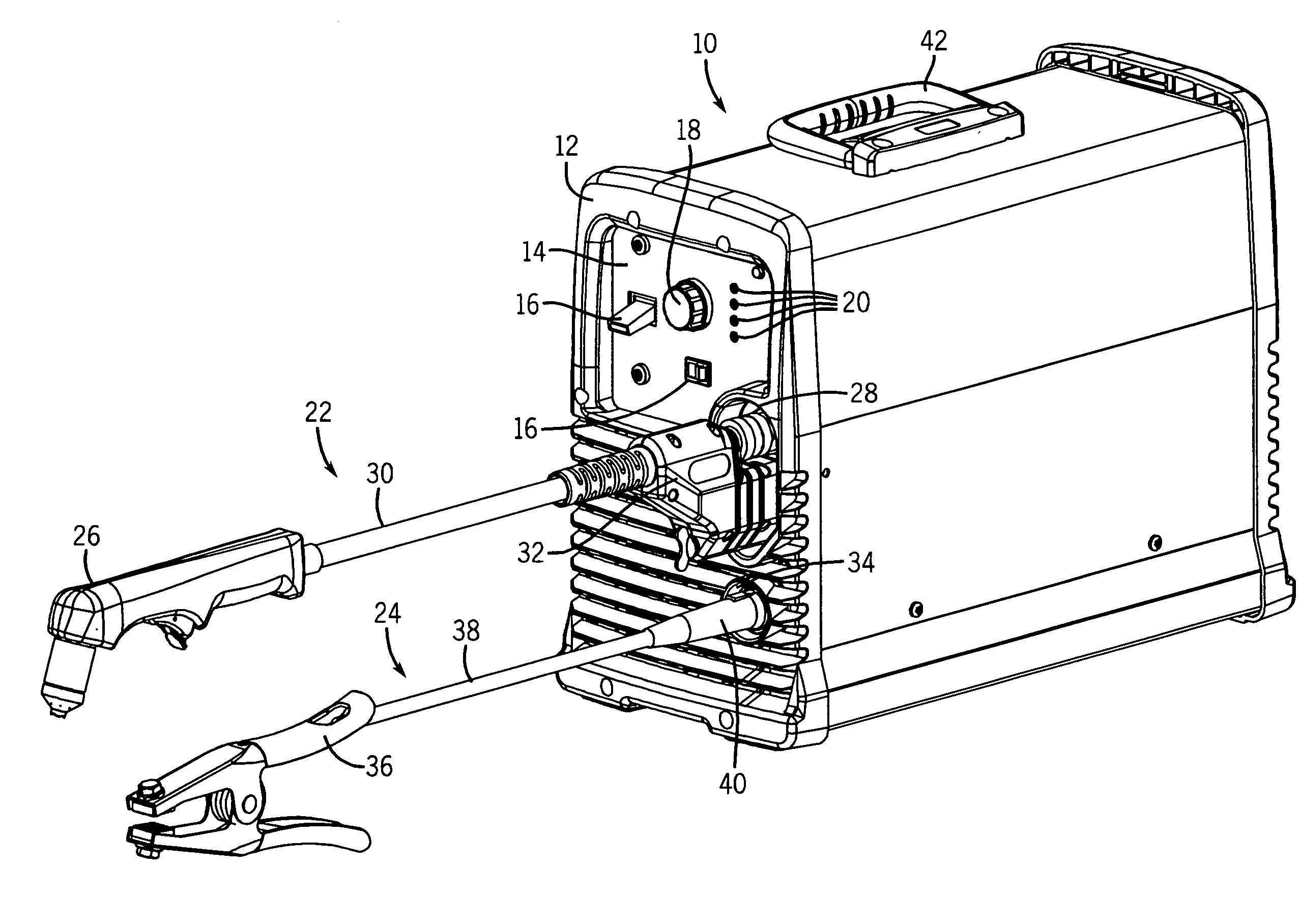

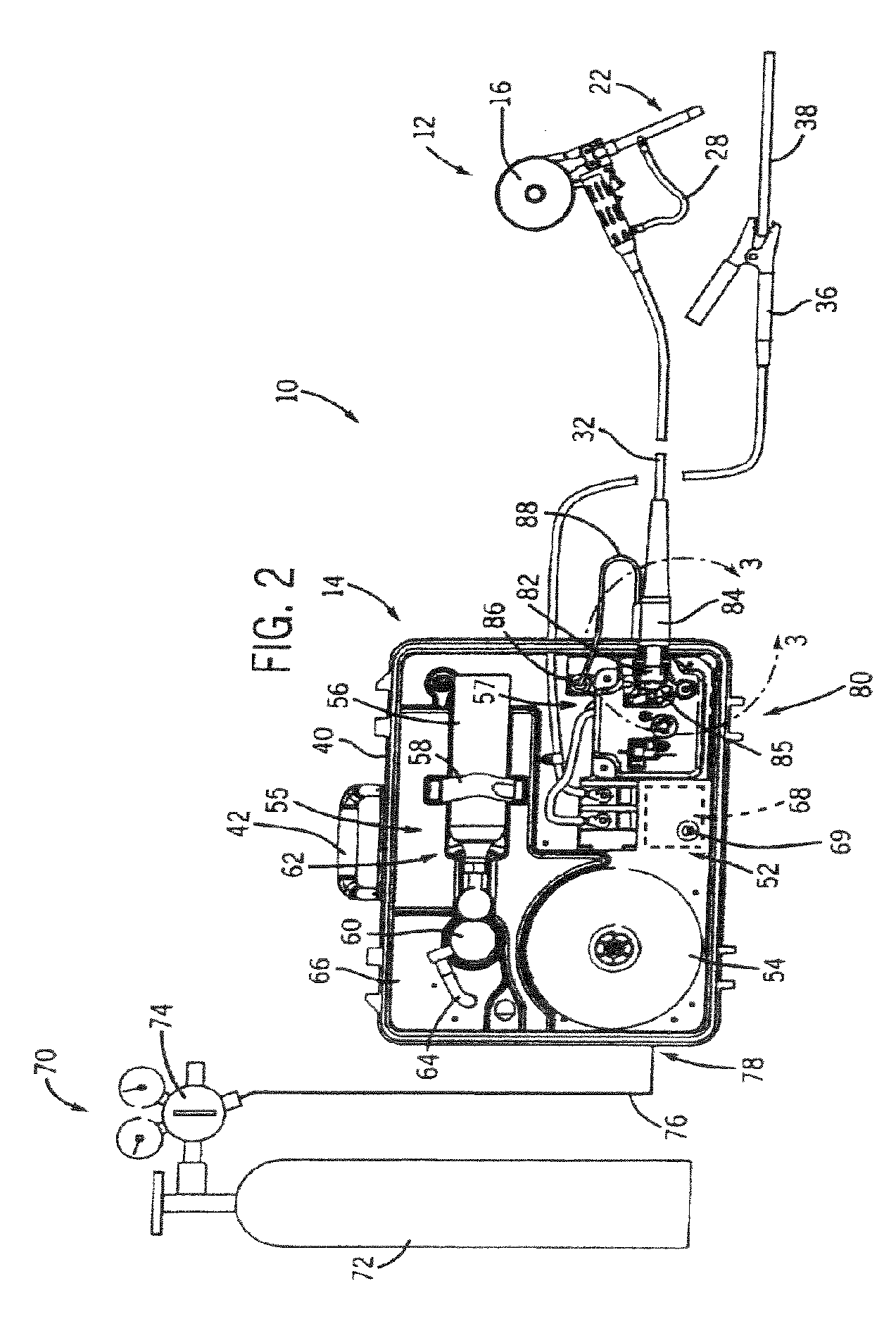

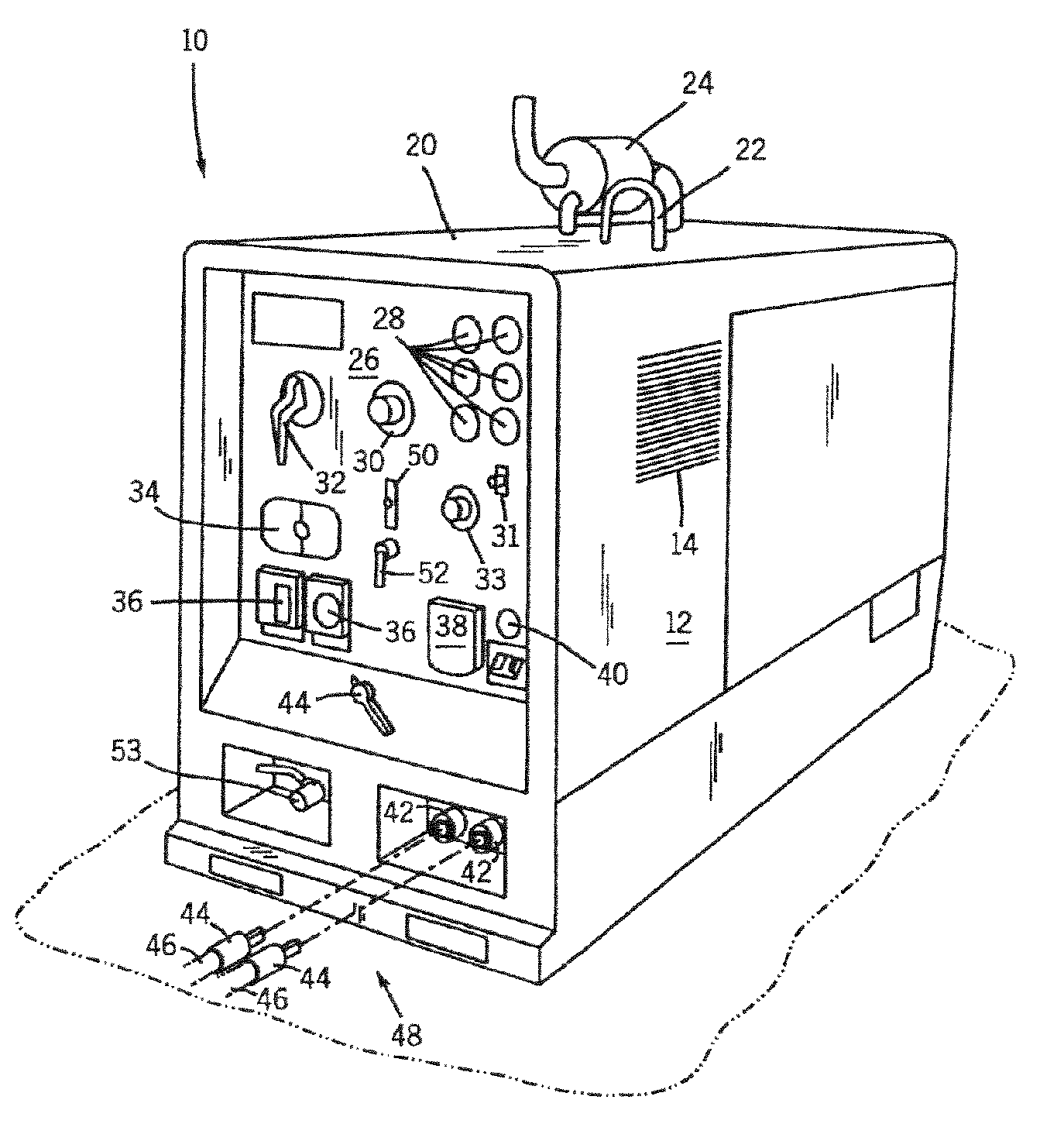

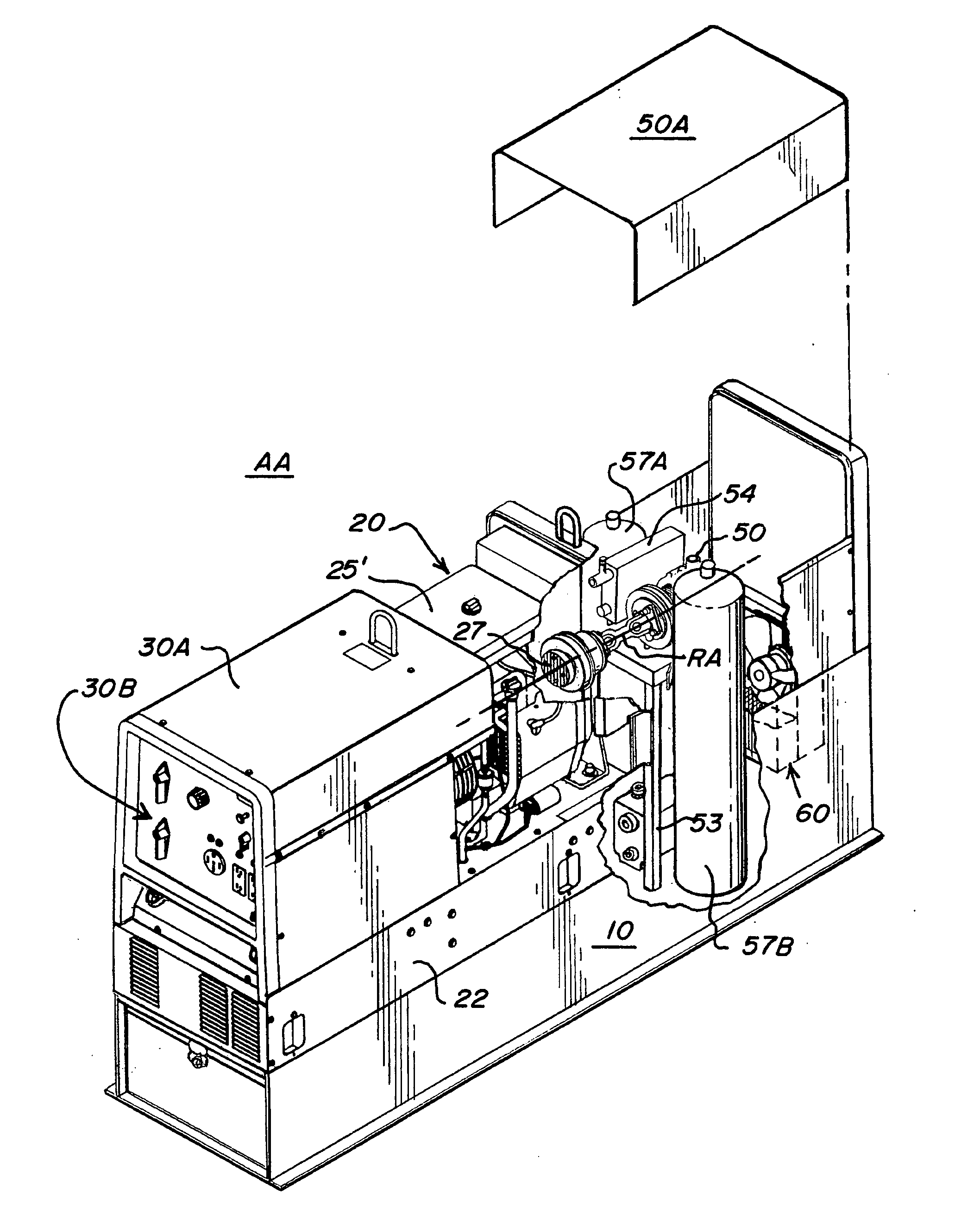

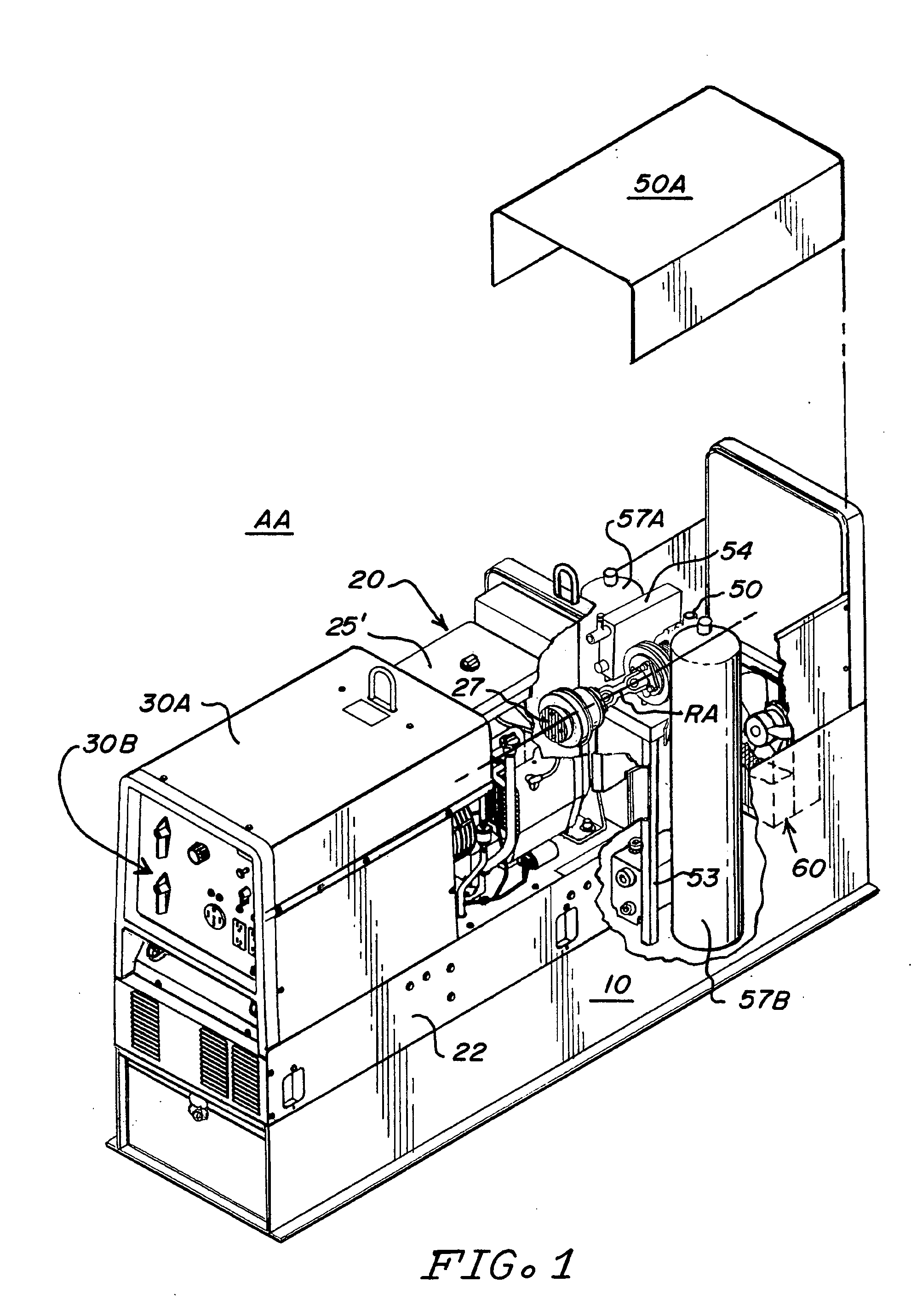

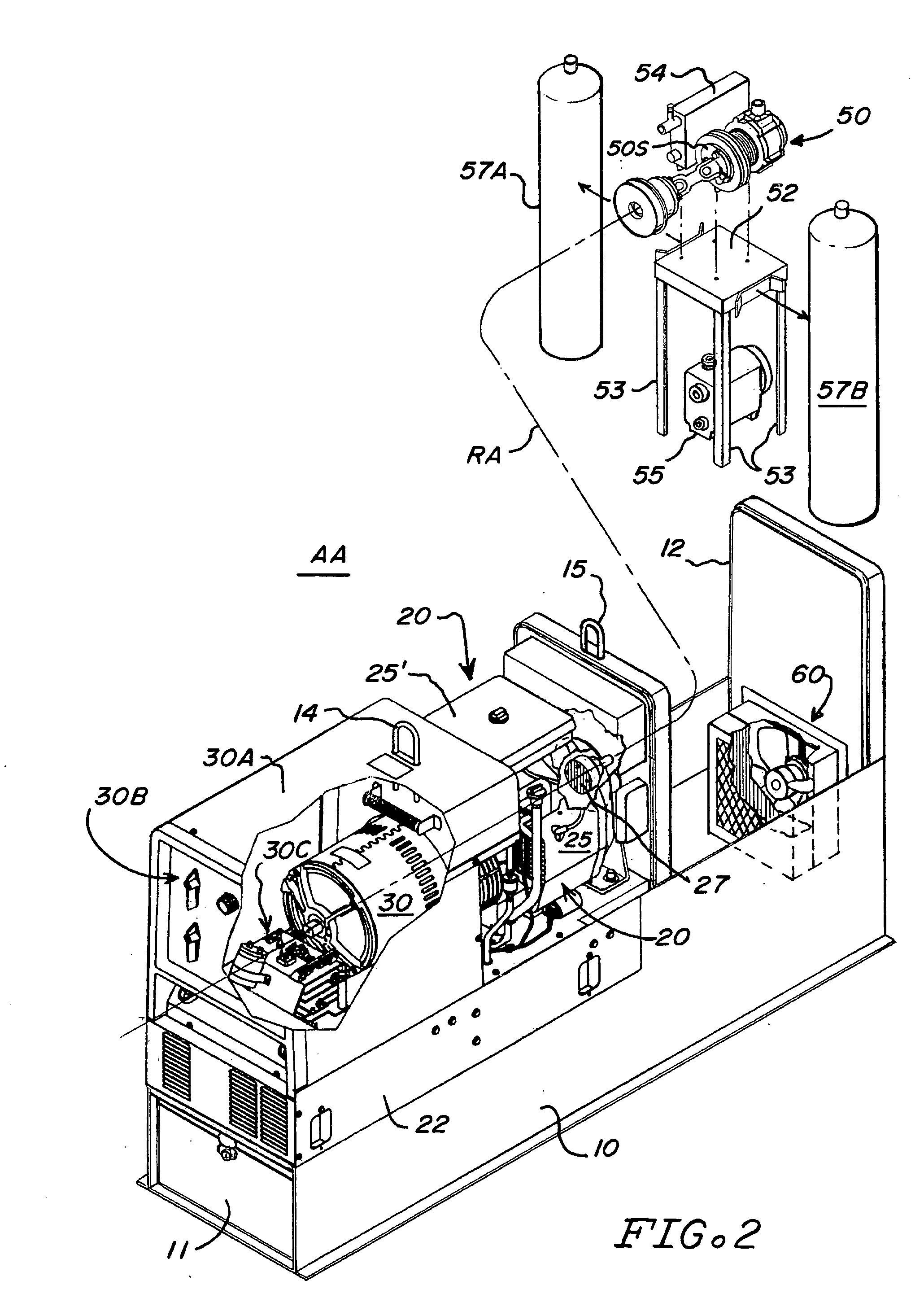

Integrated engine welder and hydraulic pump

InactiveUS20060027547A1Easy to transportImproves ease of designElectric discharge heatingWelding coupling meansHydraulic pumpAir compressor

An integrated welder, generator and hydraulic unit that includes a housing that at least partially contains components of a welder, generator and a hydraulic pump. An engine, an electric current generator, and a hydraulic pump are at least partially mounted in the housing. The electric current generator is at least partially connected to the engine to be at least partially driven thereby. The hydraulic pump can be at least partially powered by the electric current generator or the fuel powered engine during the operation of the engine. The integrated welder, generator and hydraulic unit can also include an air compressor.

Owner:LINCOLN GLOBAL INC

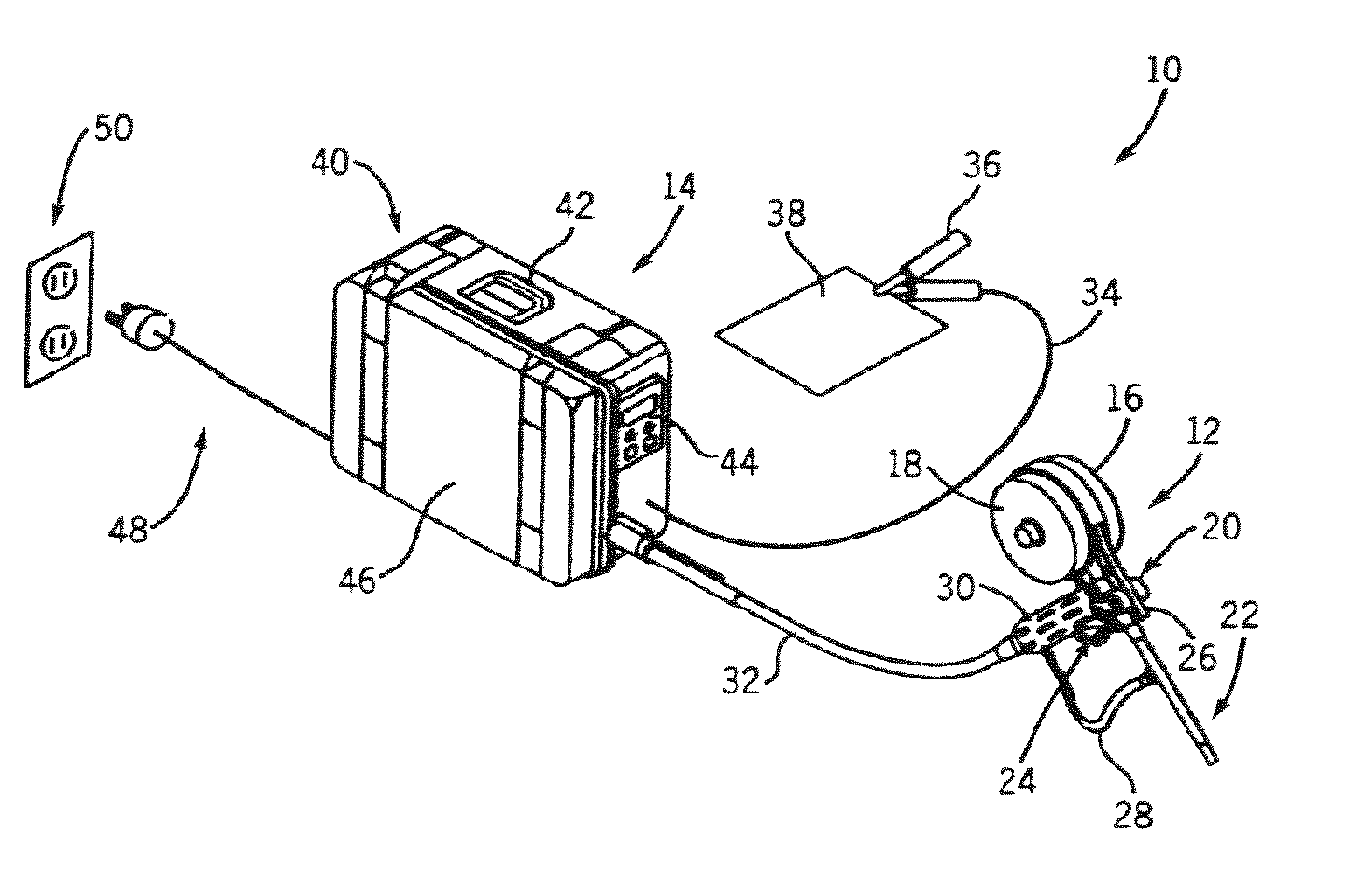

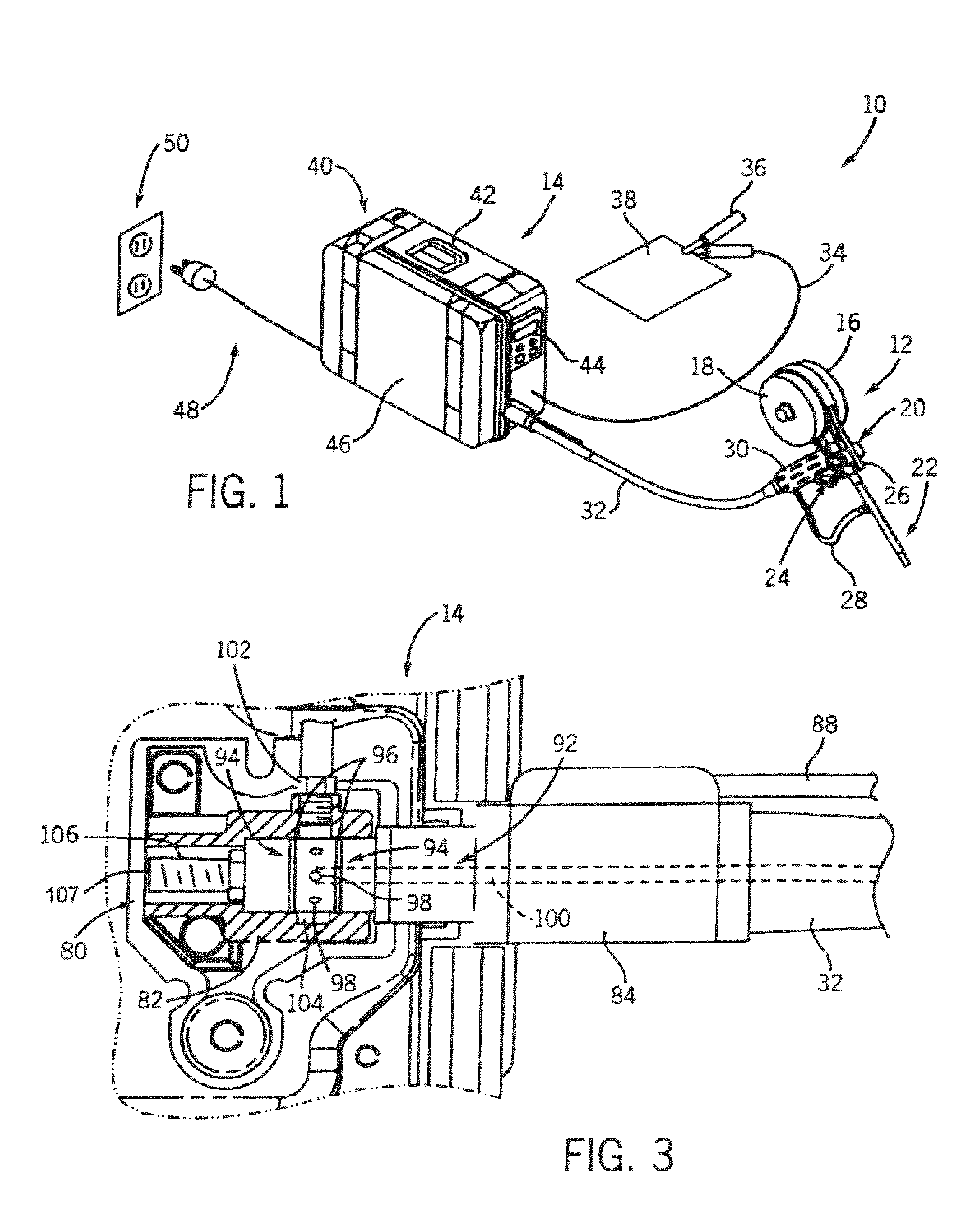

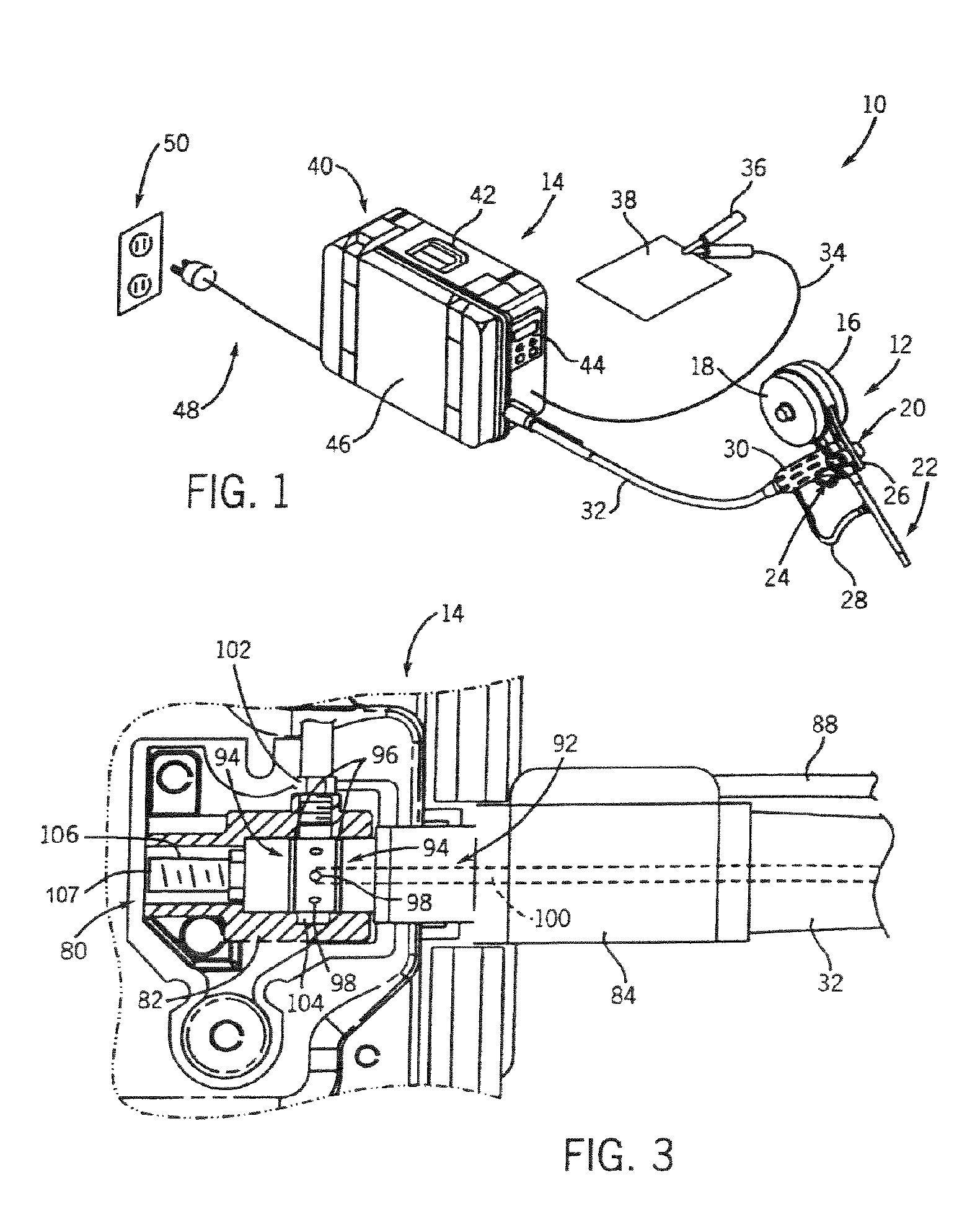

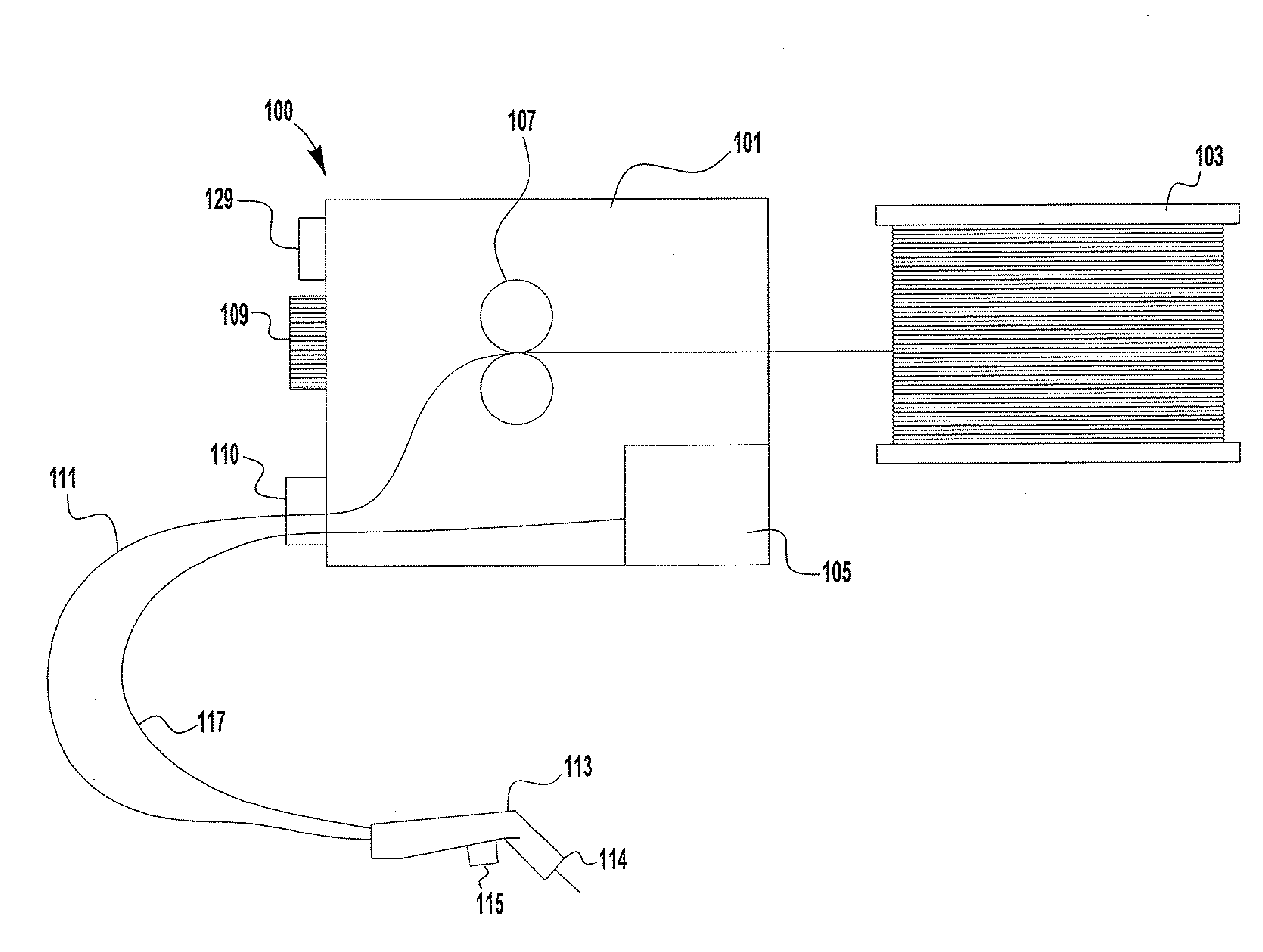

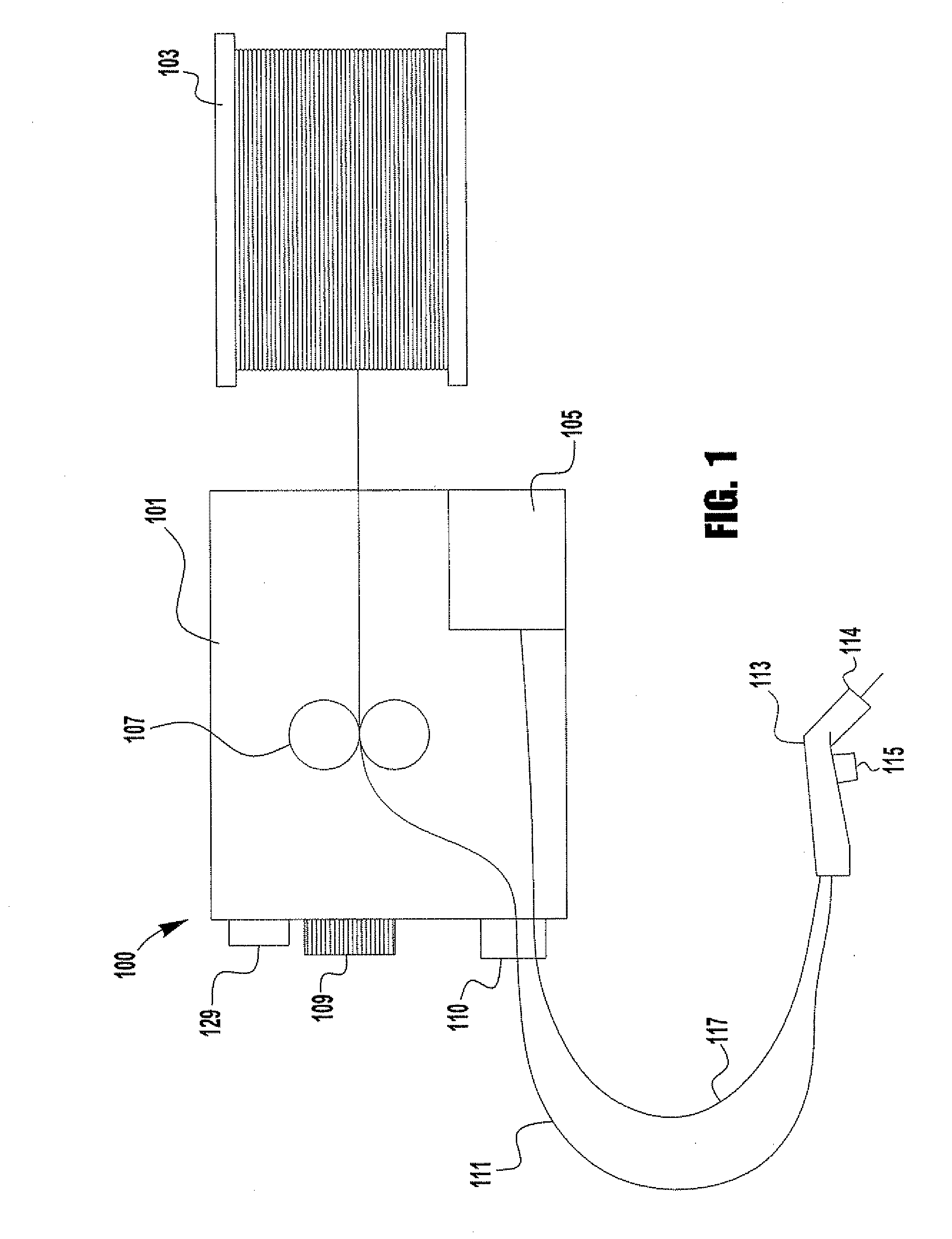

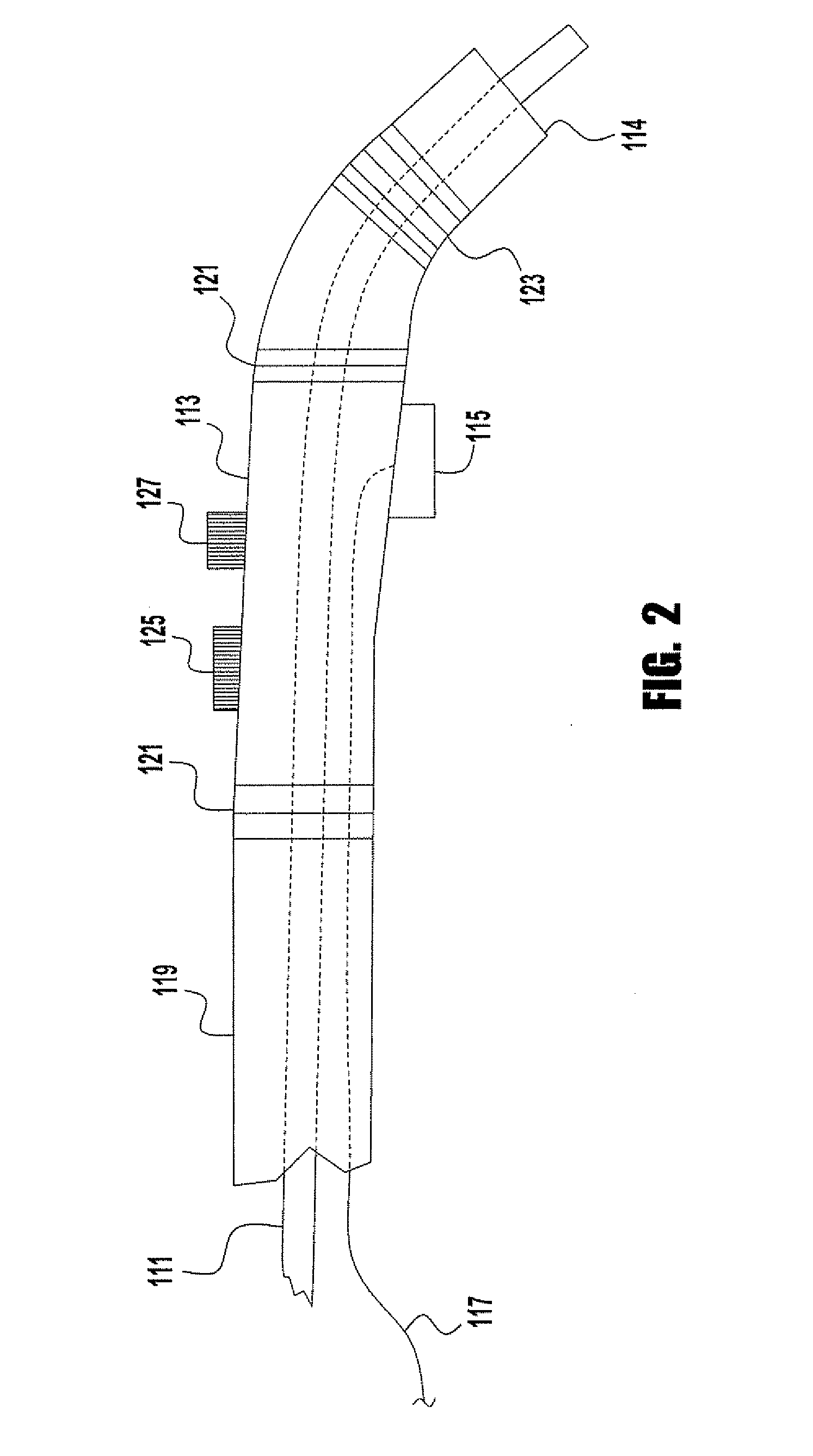

Portable welding wire feed system and method

A welding system is provided that includes a wearable wire feeder having a wire drive motor that is responsive to a control signal received directly from a power unit. Another welding system is provided that includes a wearable wire feeder that is configured to couple to a constant voltage power unit and does not include a voltage sensor. Another welding system is provided that includes a power unit, a wearable wire feeder separate from the power unit, a cable extending directly from the power unit to the wearable wire feeder and a welding torch coupled to and separate from the wire feeder. A method is provided that includes receiving a control signal from a power unit at a wearable wire feeder and driving a welding wire from the wearable wire feeder to a welding torch in response to the control signal, wherein the wearable wire feeder is separate from the torch.

Owner:ILLINOIS TOOL WORKS INC

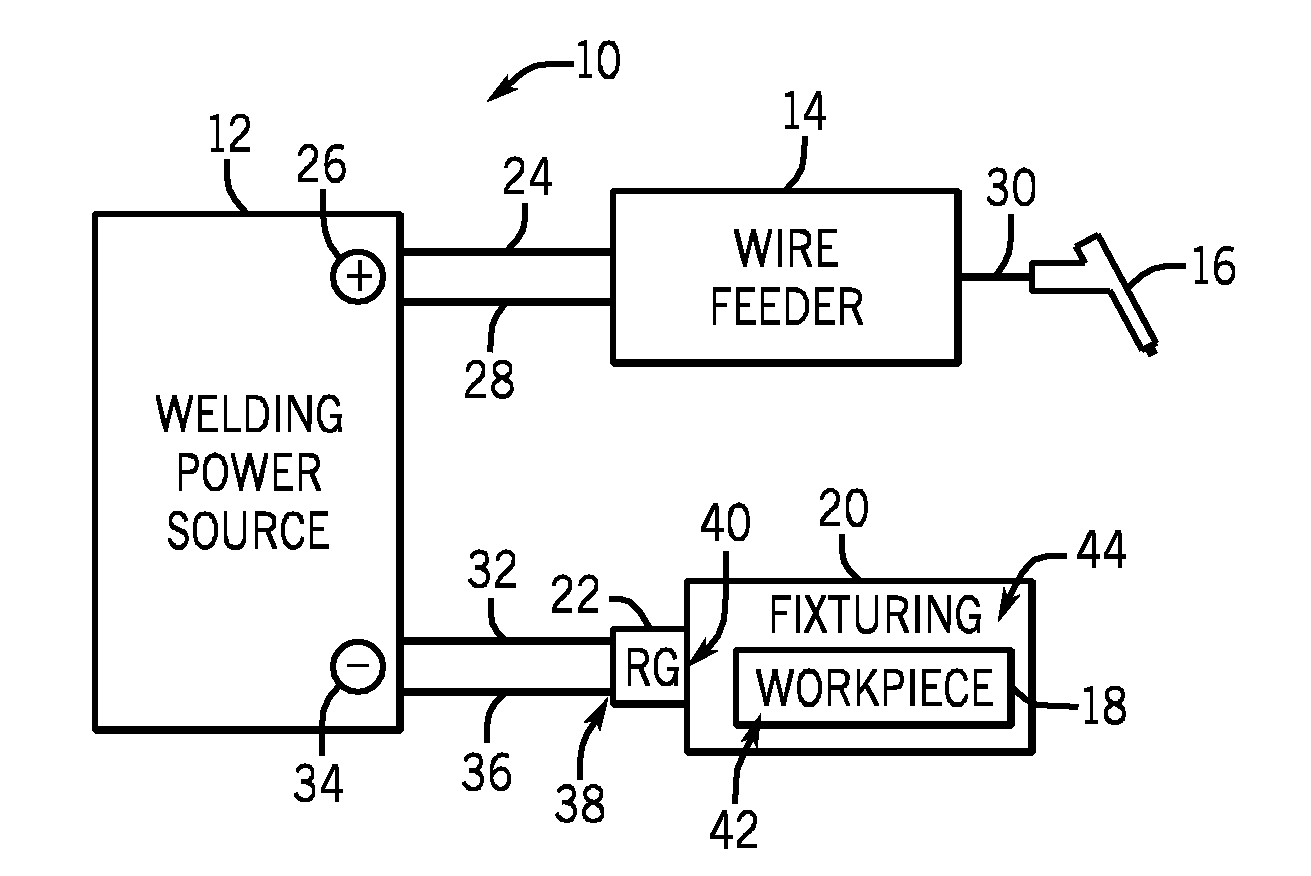

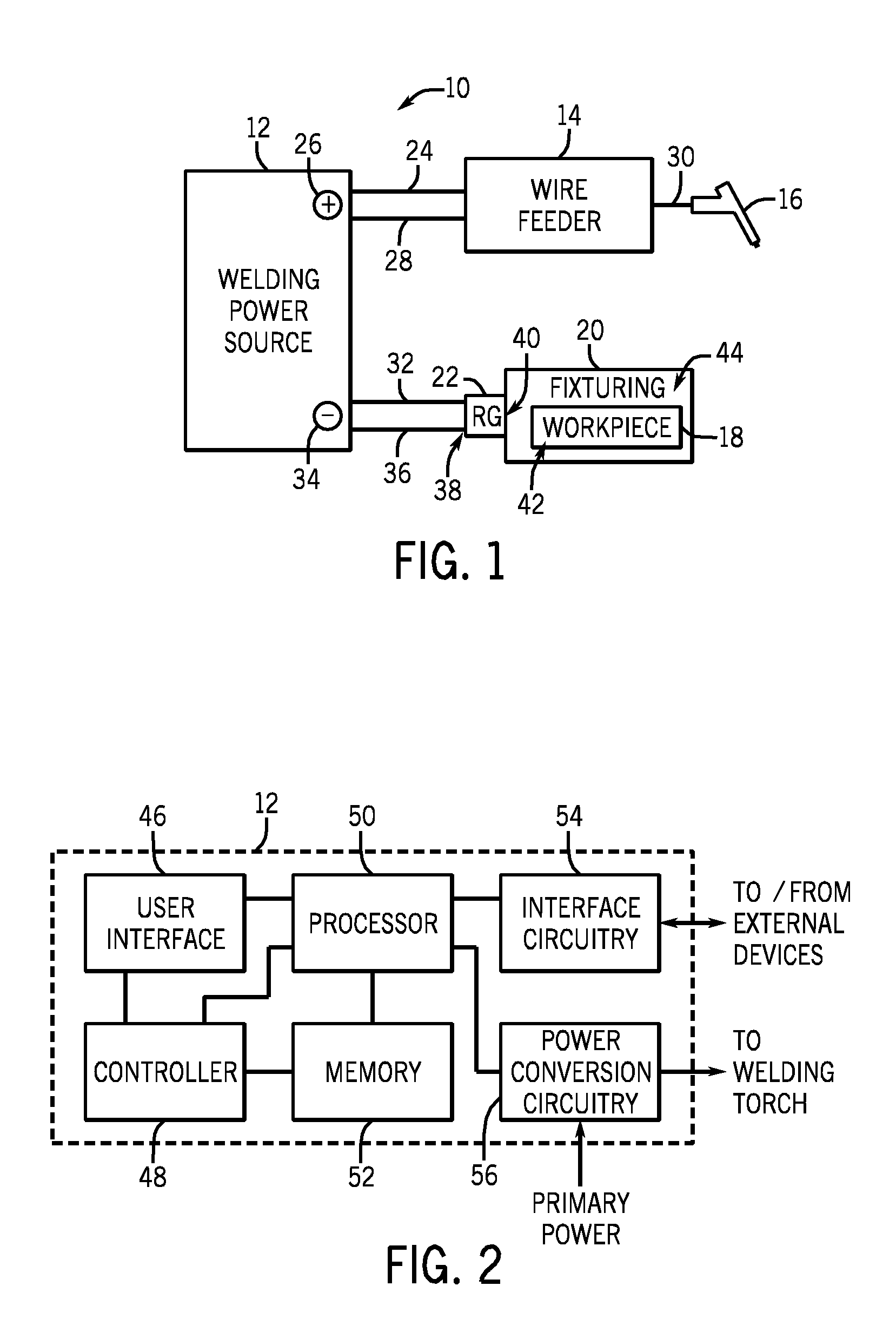

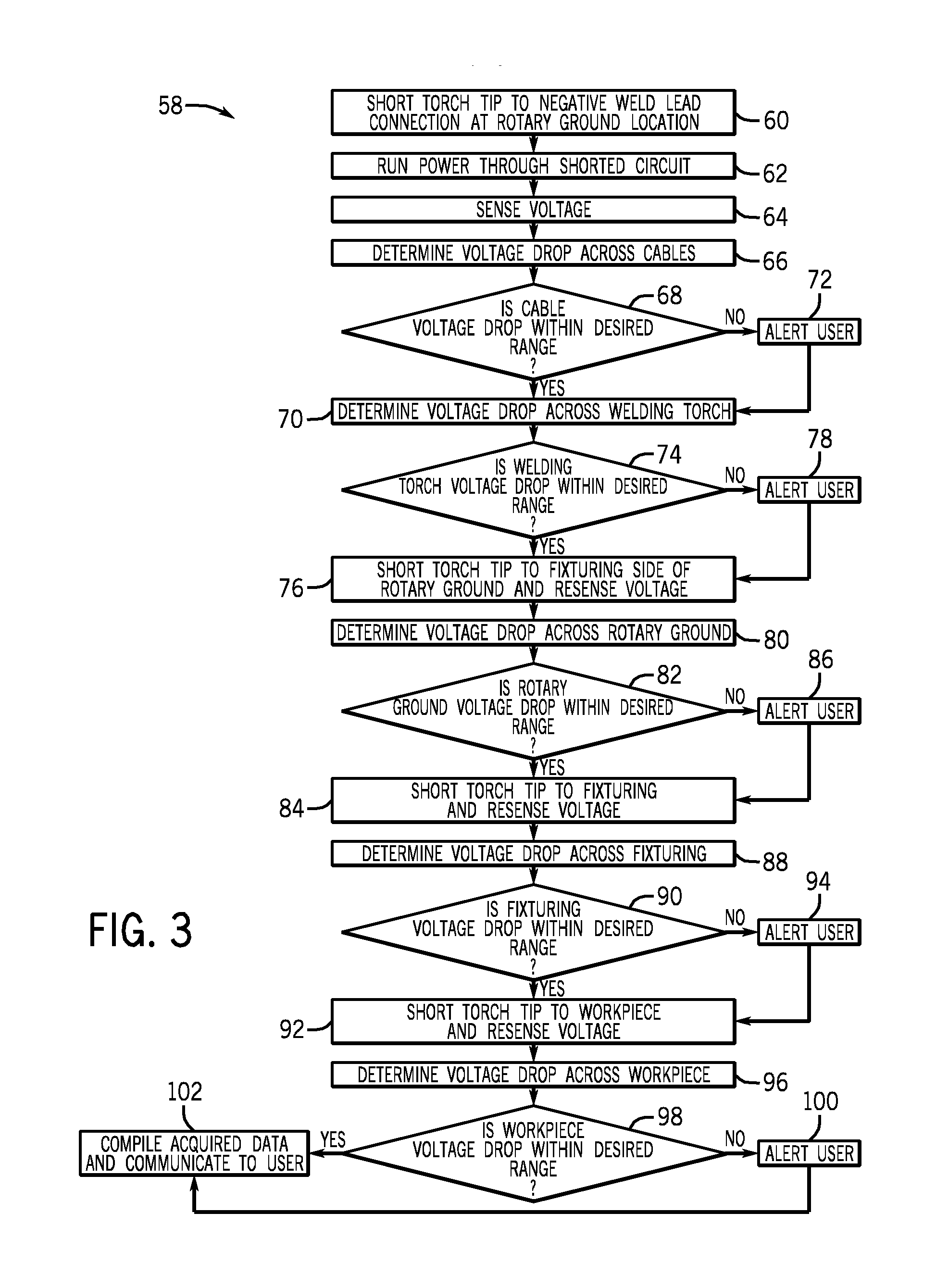

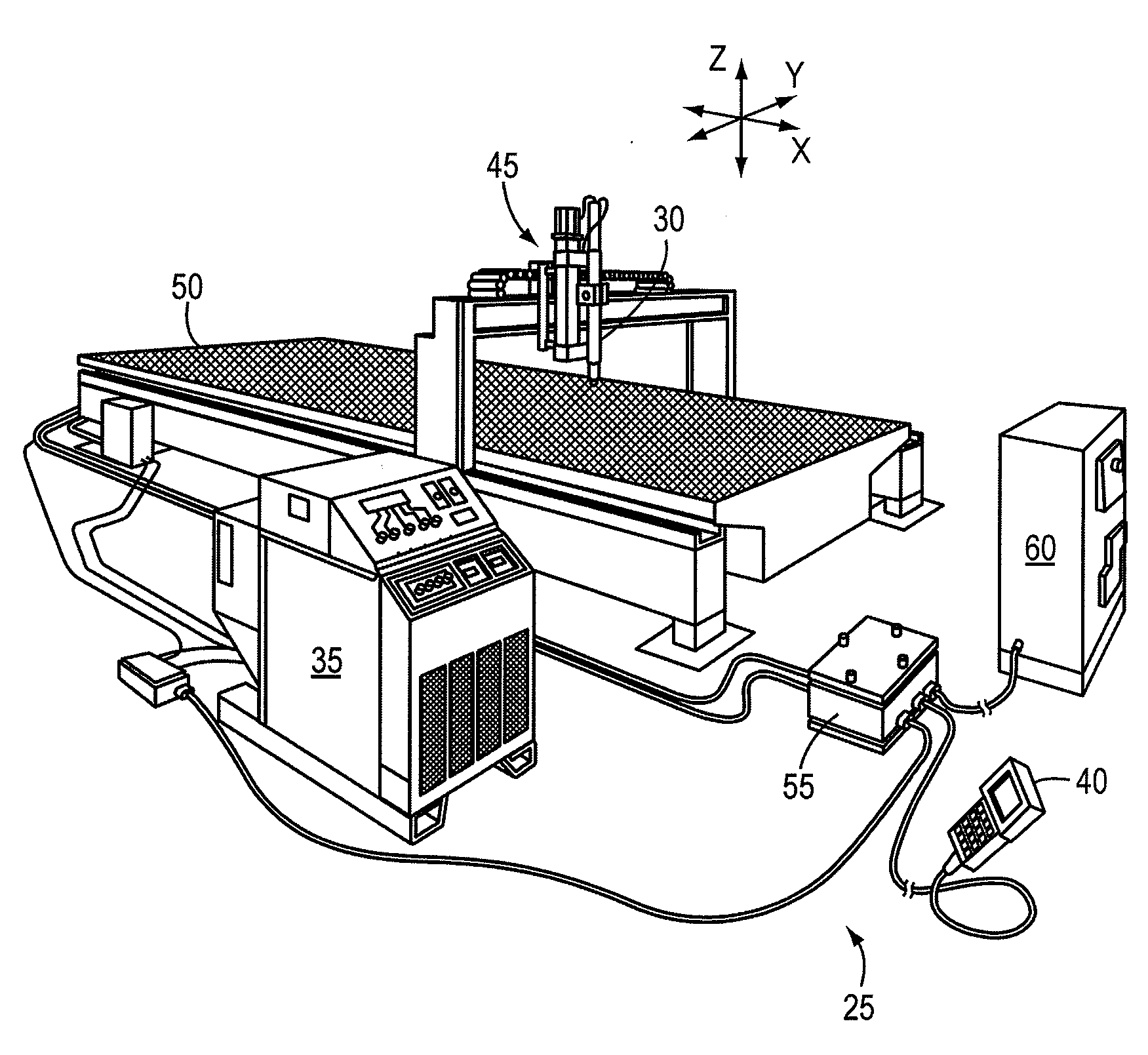

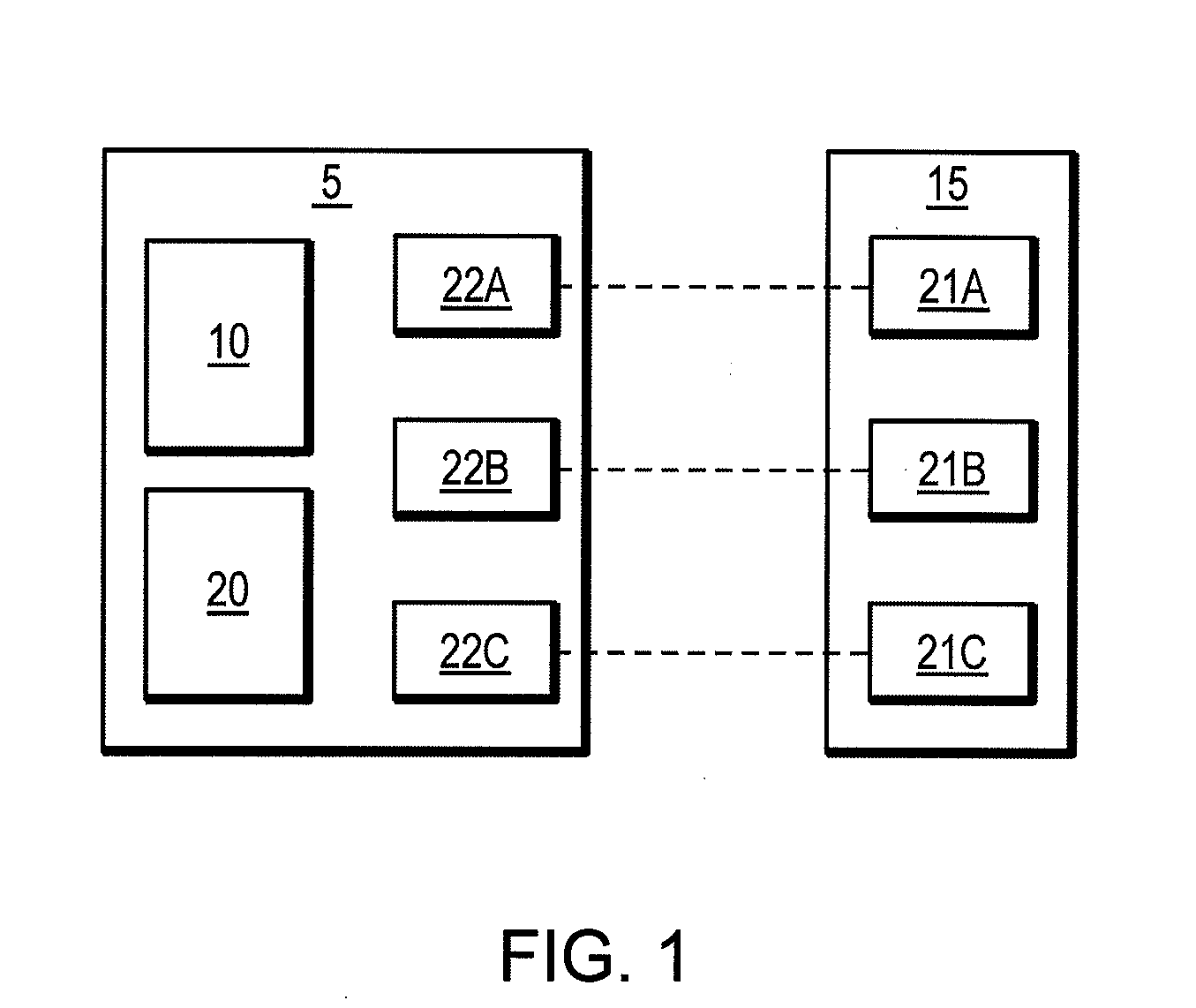

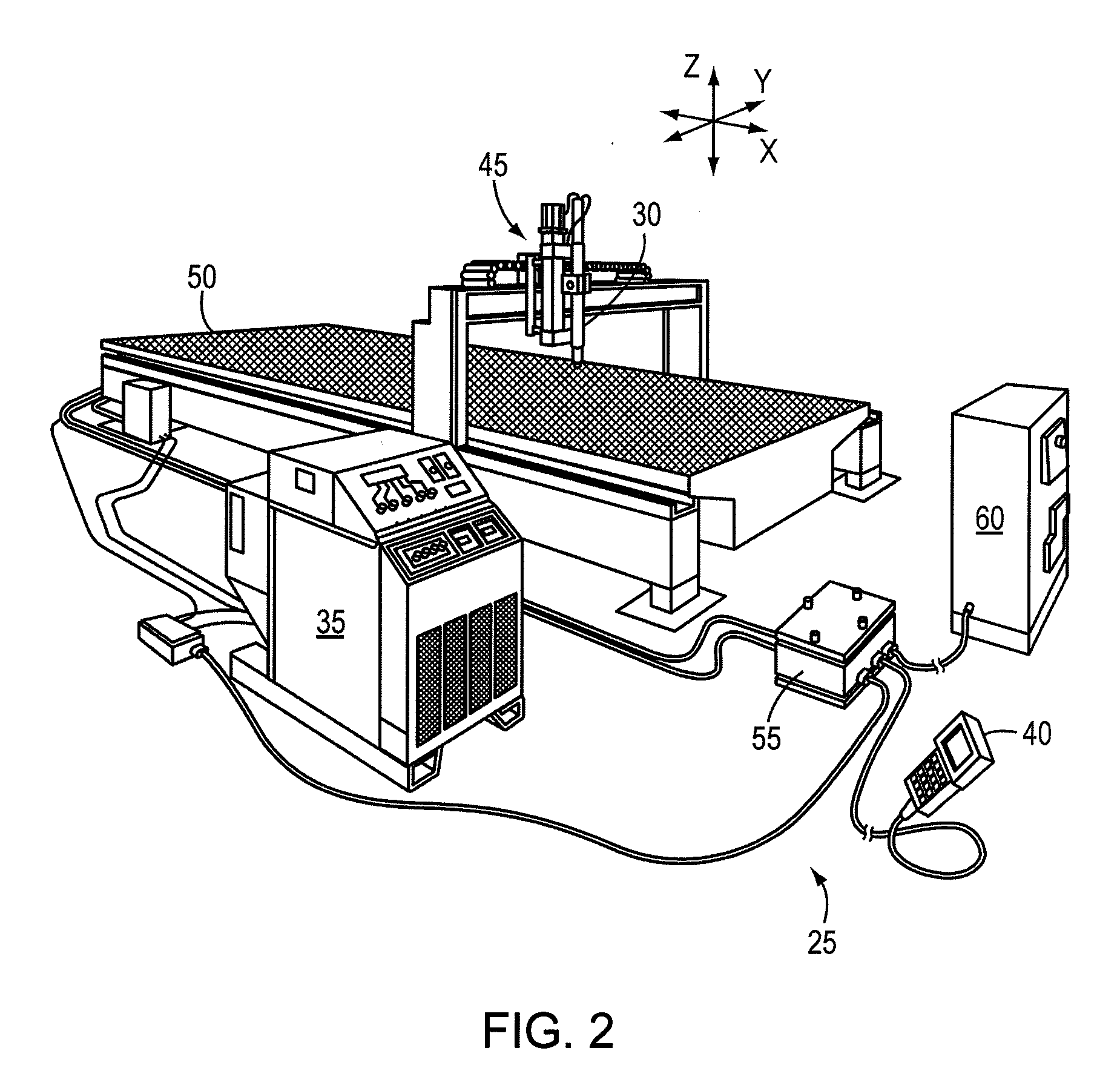

Systems and methods for diagnosing secondary weld errors

ActiveUS20100314371A1Electrode supporting devicesWelding coupling meansSecondary componentReference range

A controller for a welding system adapted to determine a value of a weld secondary parameter across a weld secondary component based on a sensed parameter is provided. The controller may also be adapted to compare the determined value to a reference value range and to alert a user to a presence and location of a weld secondary error when the determined value is outside the referenced value range.

Owner:ILLINOIS TOOL WORKS INC

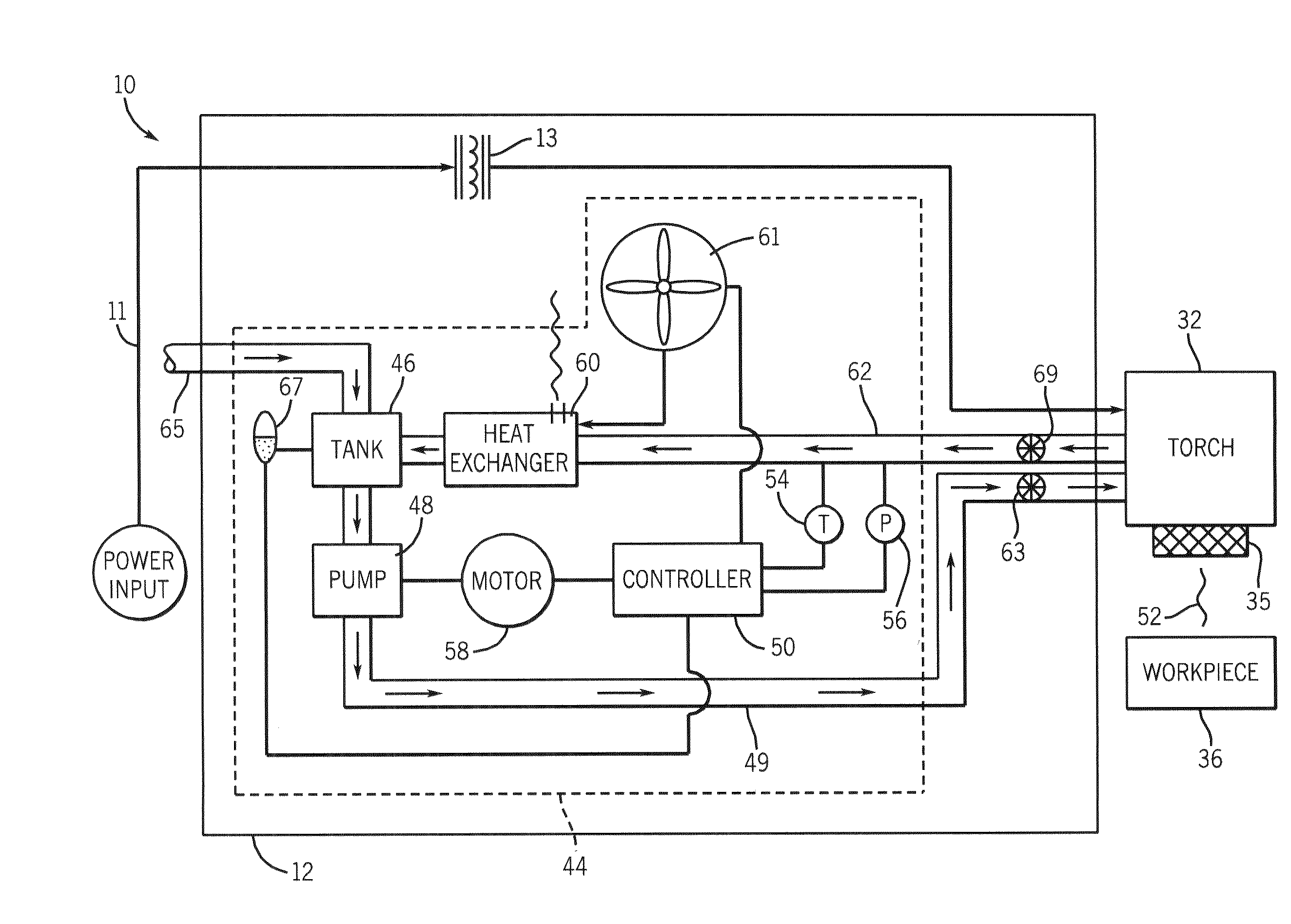

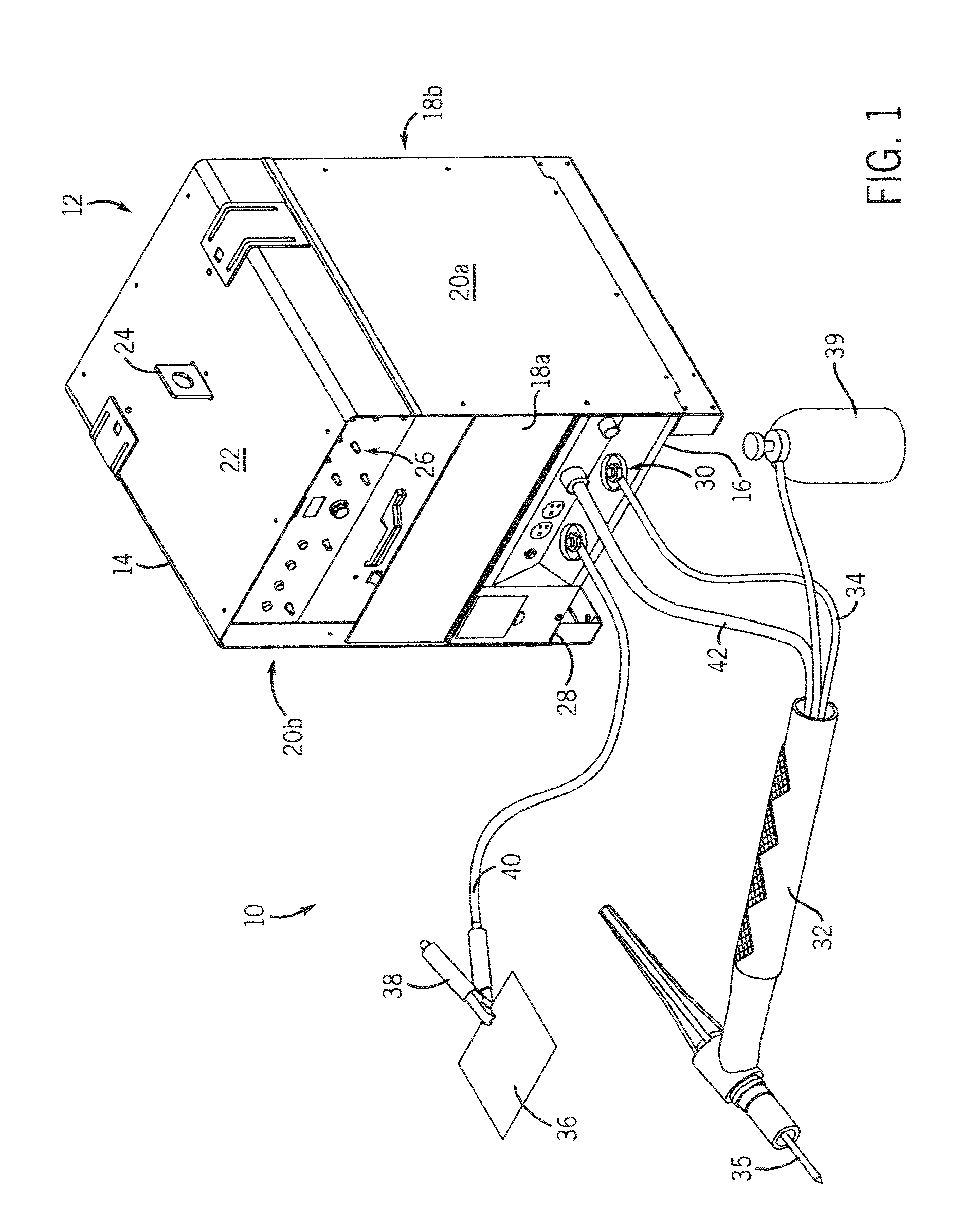

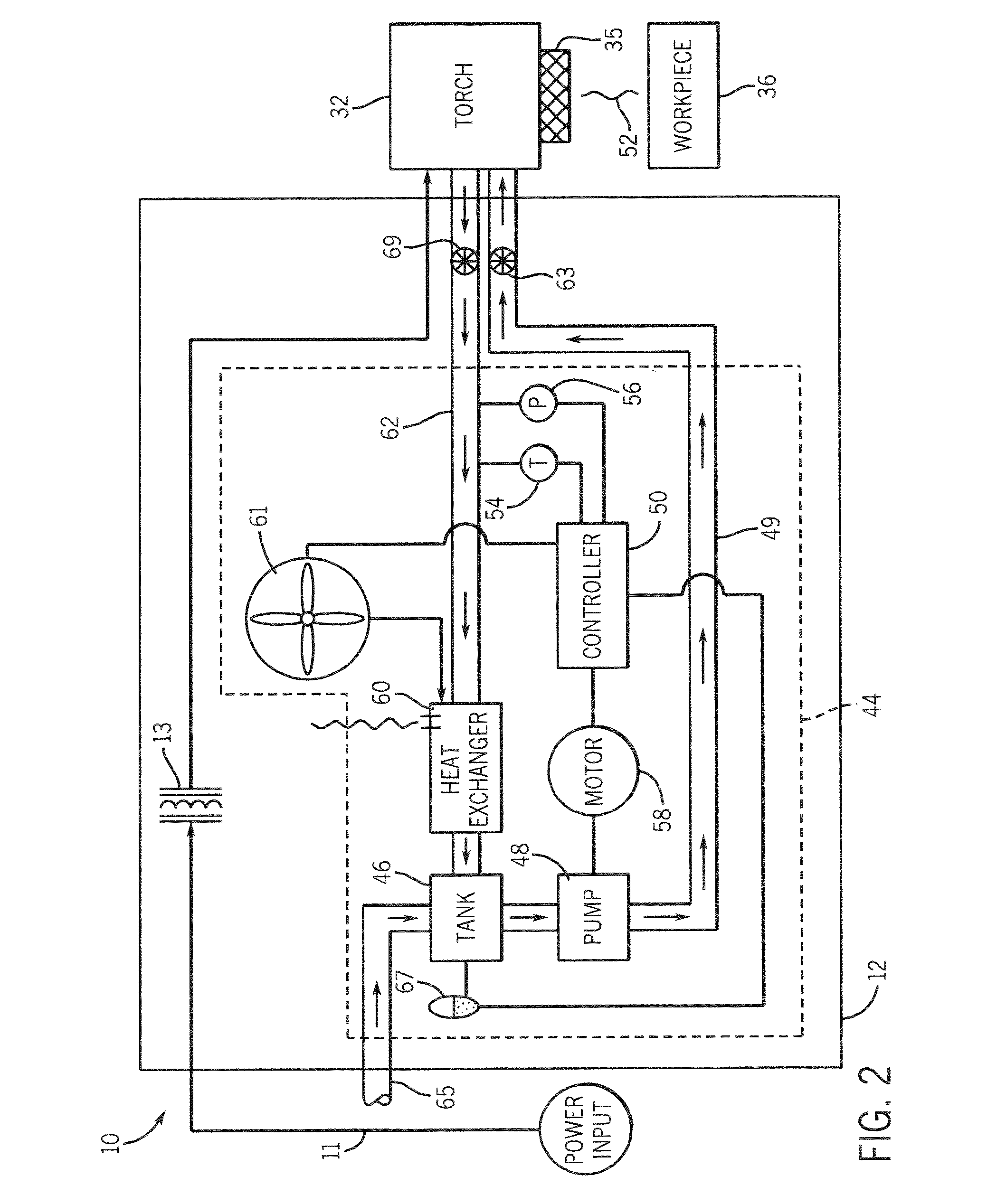

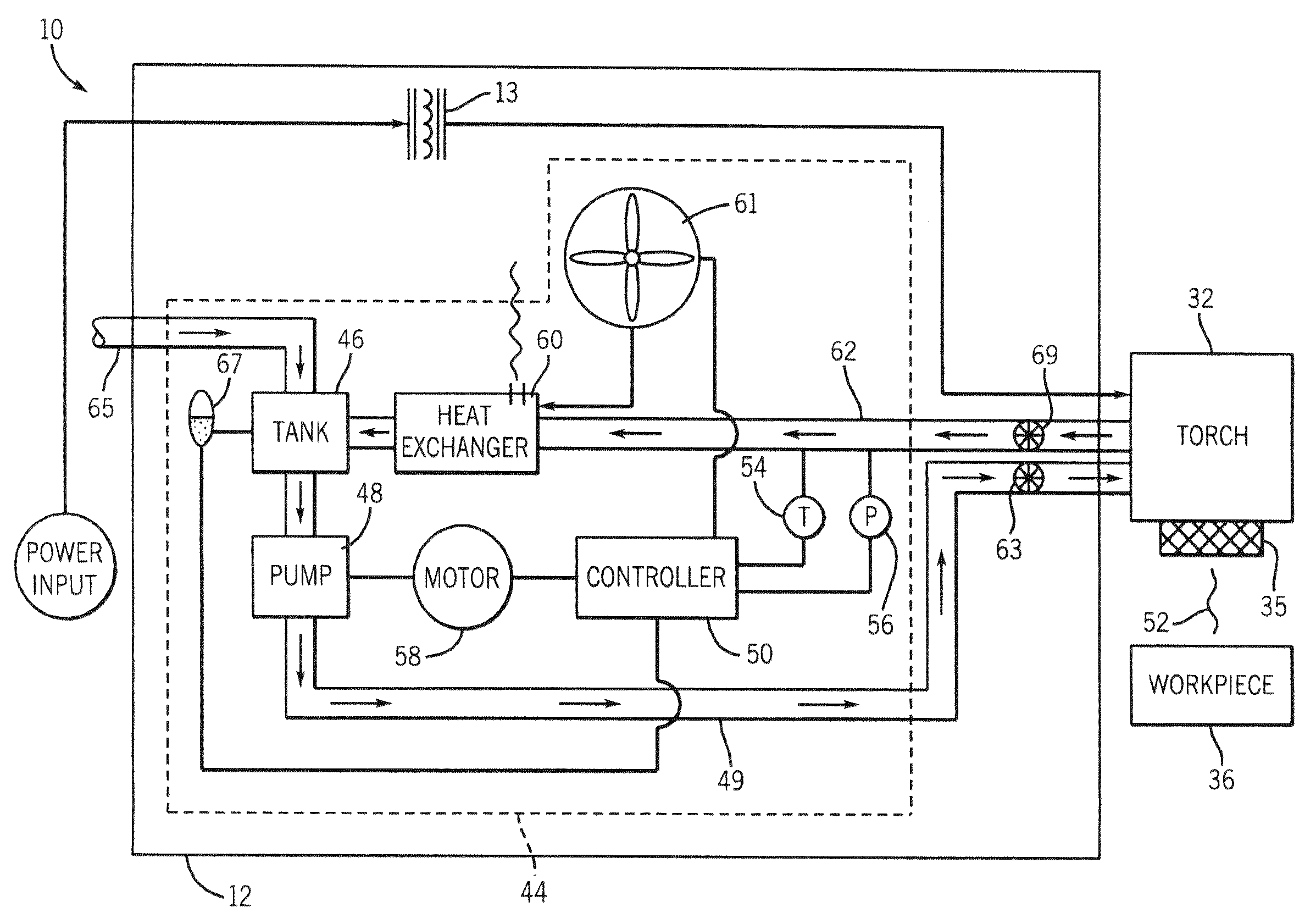

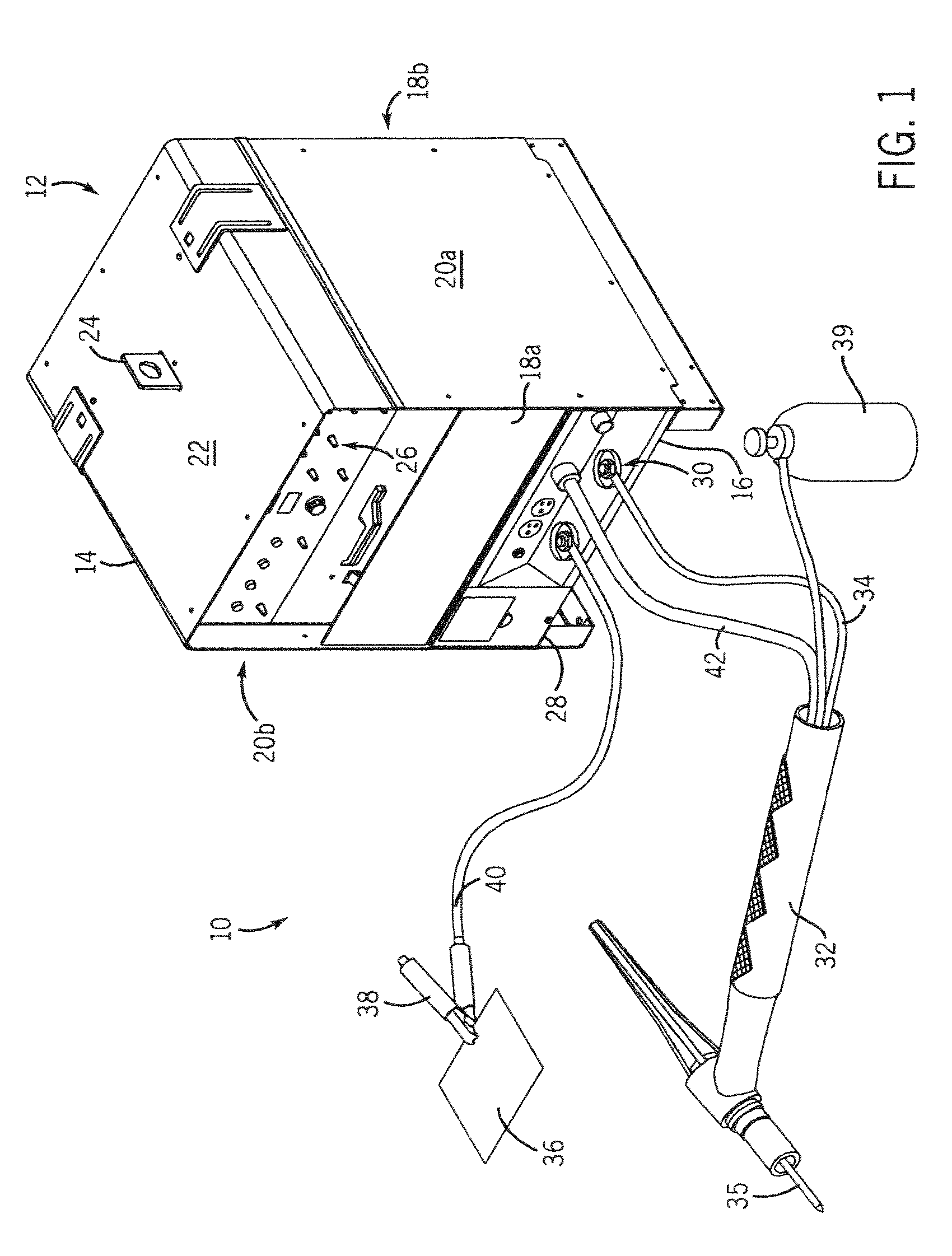

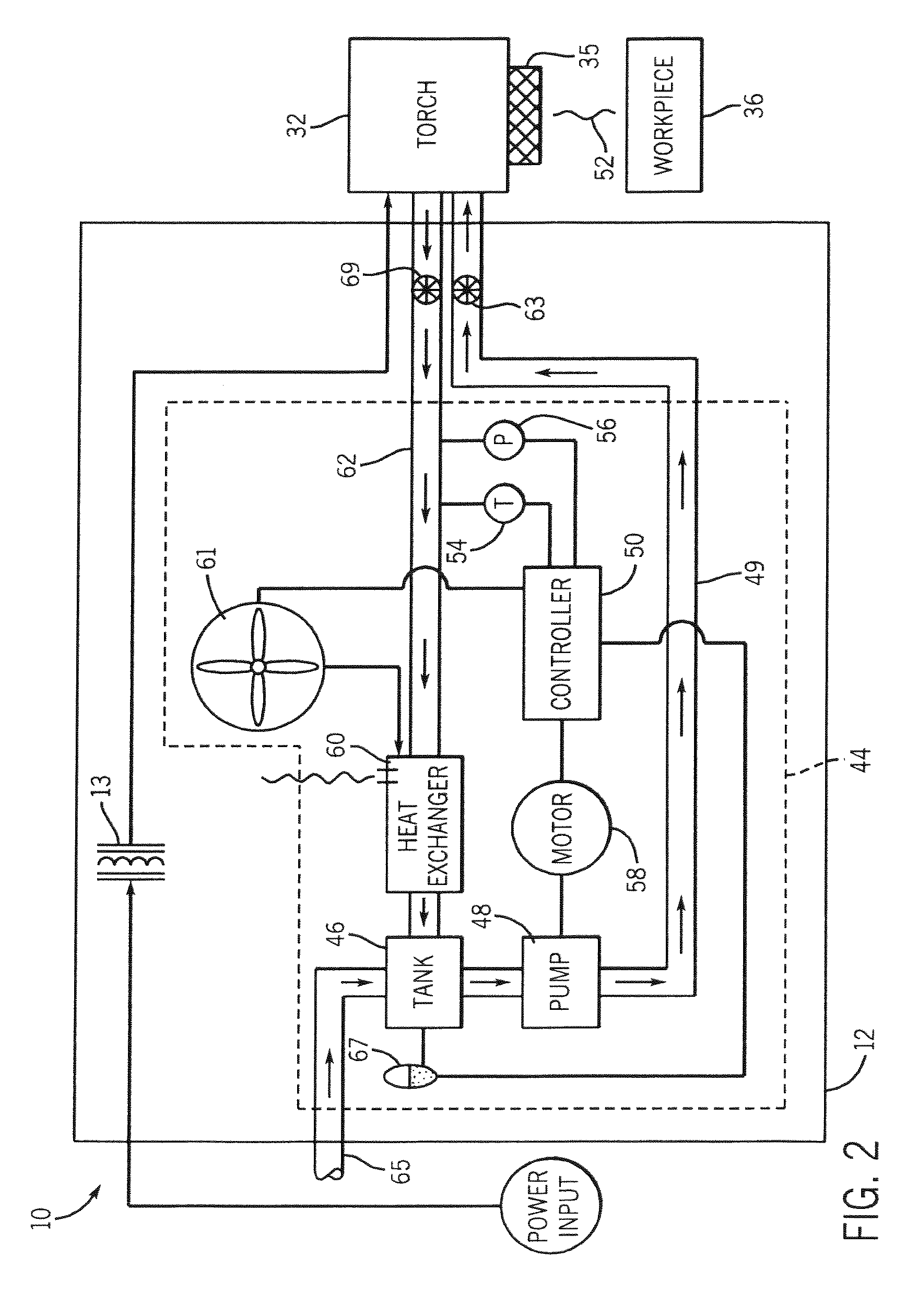

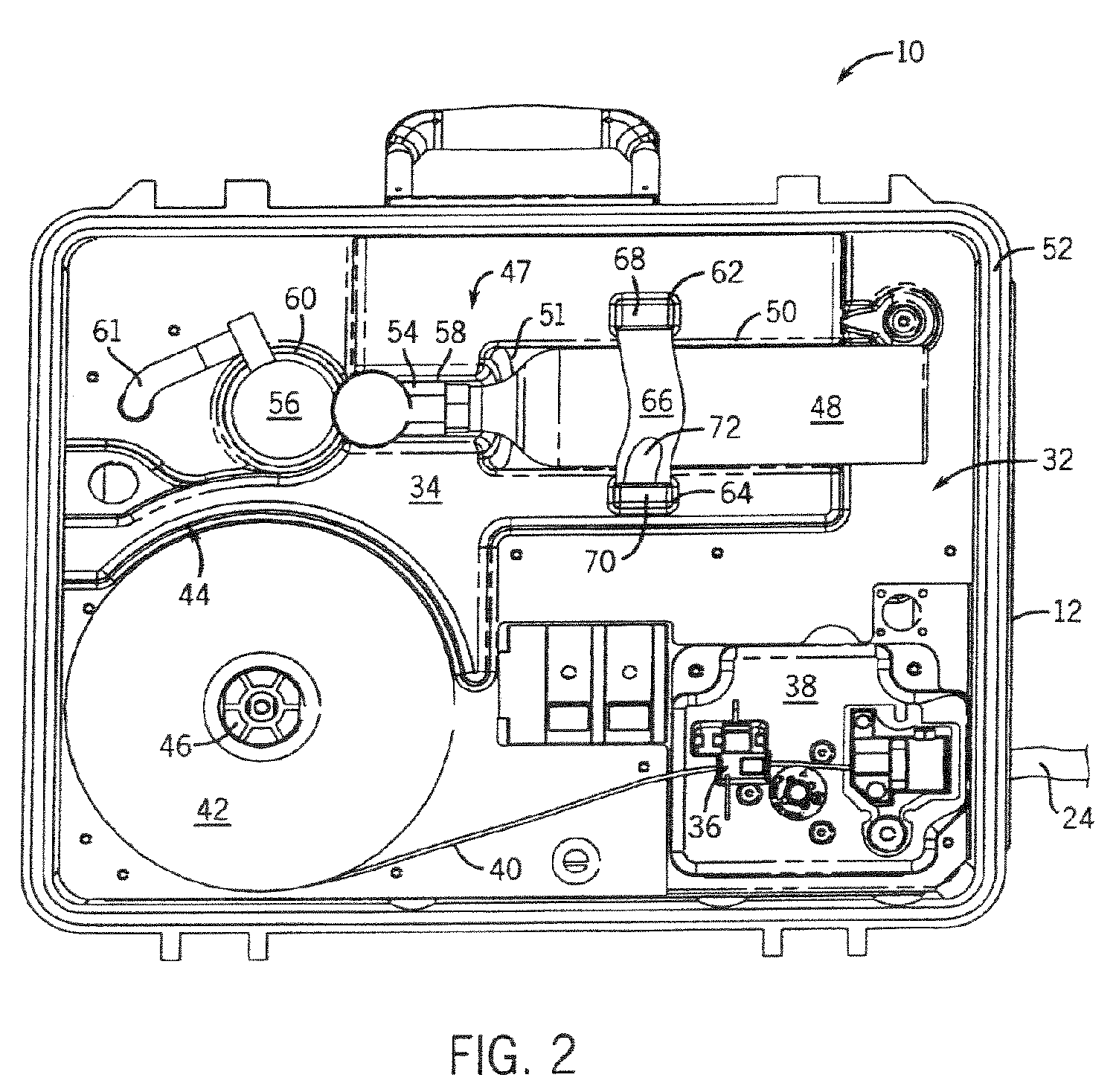

Method and apparatus to adaptively cool a welding-type system

ActiveUS20050016979A1Support devices with shieldingCooled electrode holdersEngineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired.

Owner:ILLINOIS TOOL WORKS INC

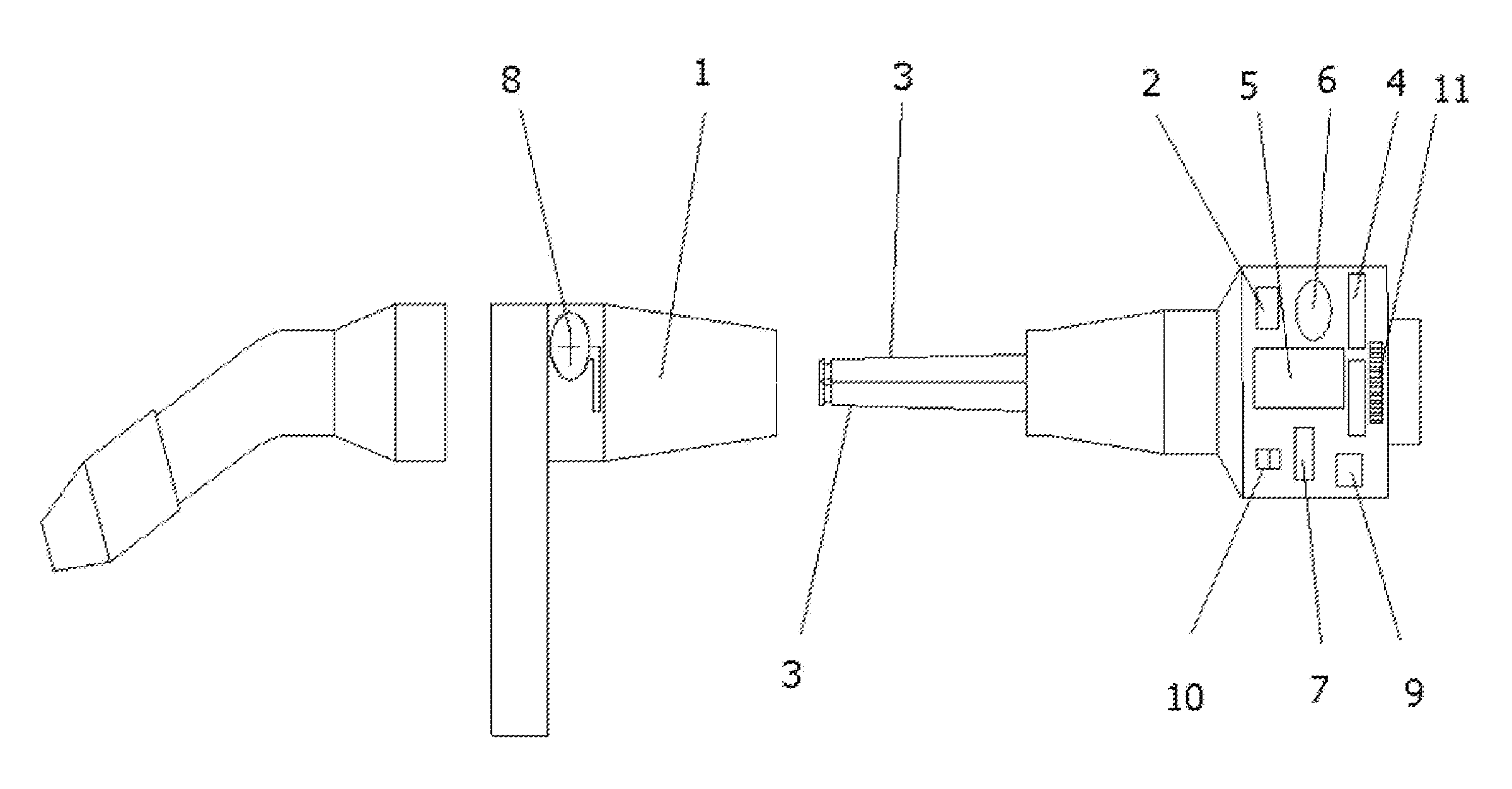

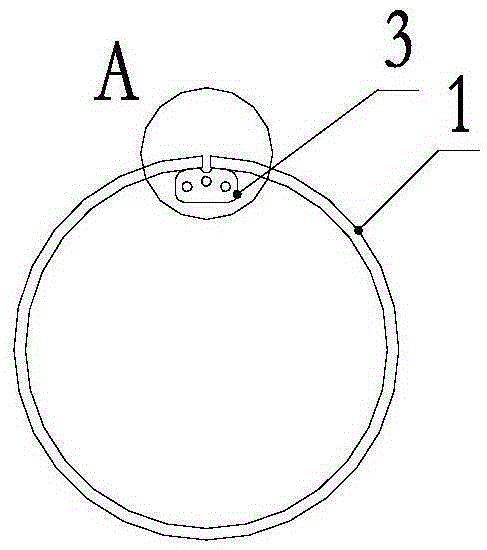

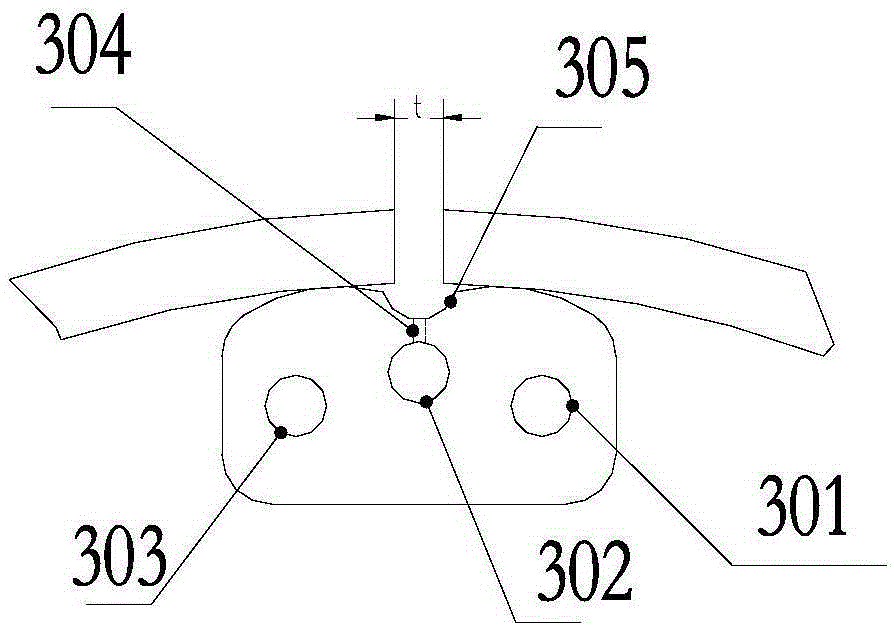

Dual-conductor welding gun

InactiveUS20090236325A1Reduce demandReduce the total massElectric discharge heatingWelding/cutting auxillary devicesMicrocontrollerElectrical conductor

Welding gun with double conductor composed by a torch body (1) and electronic scales (2) to measure the intensity of the sensors (6) located in each conductor (3) and with mechanisms to trigger an alarm when there is an imbalance of the intensities circulating through both conductors. To this end, a microcontroller (5) connected to intensity (6) and temperature (8) sensors in the conductors is used, with indicators of failure or anomaly. The microcontroller (5) program calculates the difference between the magnitudes of both intensity signals and determines which of the two is higher, and, based on predefined parameters, triggers the corresponding alarm signal.

Owner:MORENO GOZALBO JOSE CARLOS

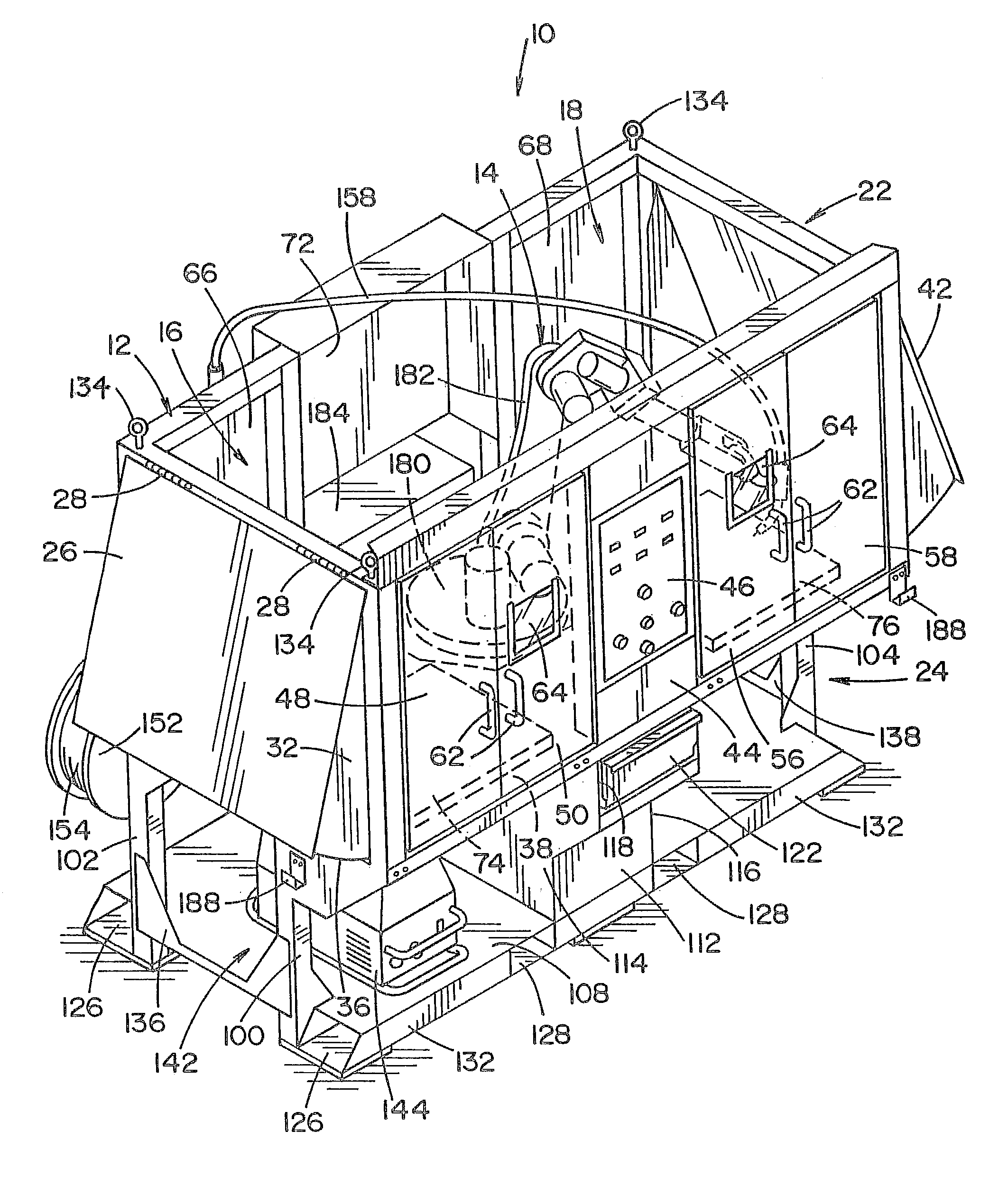

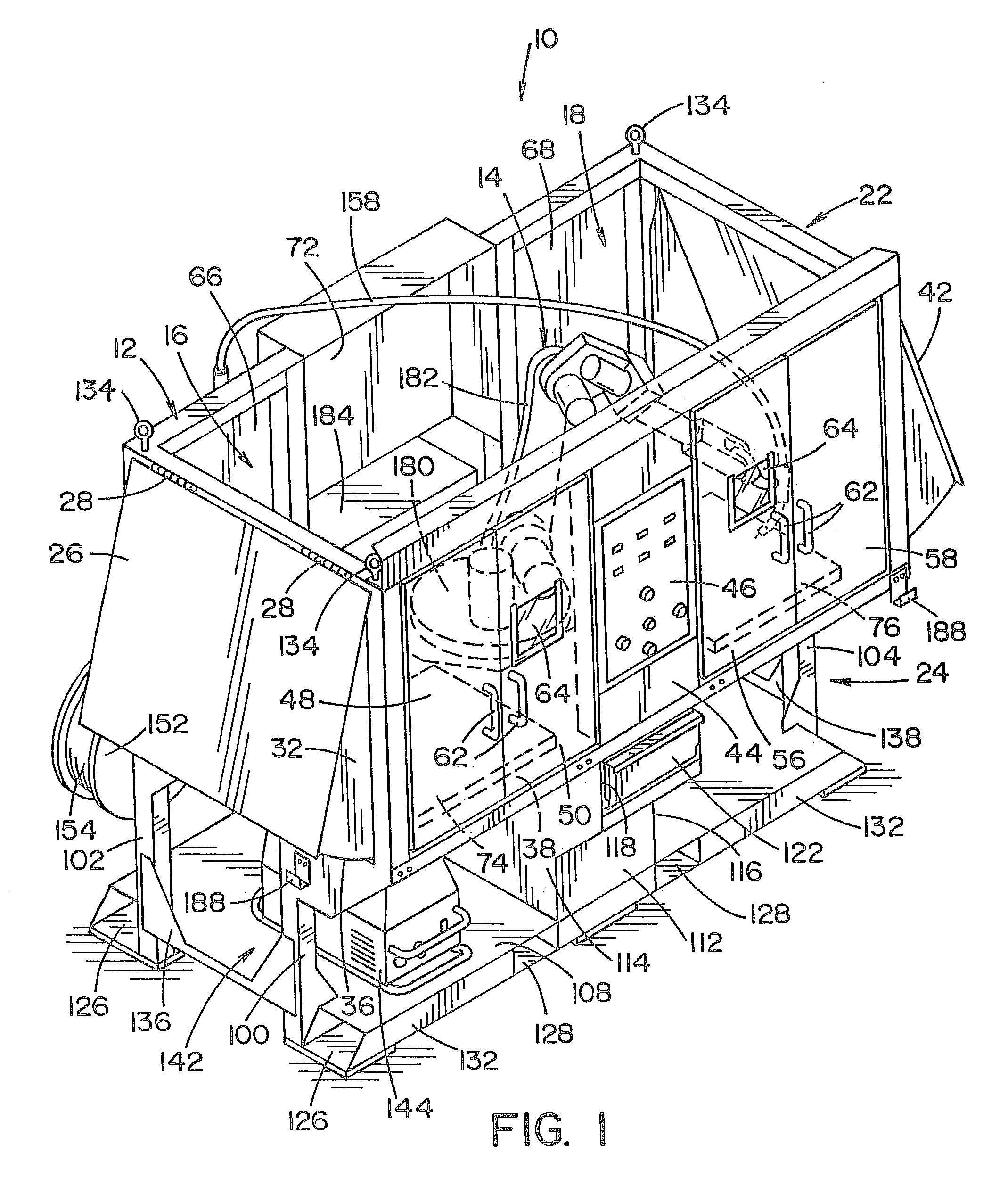

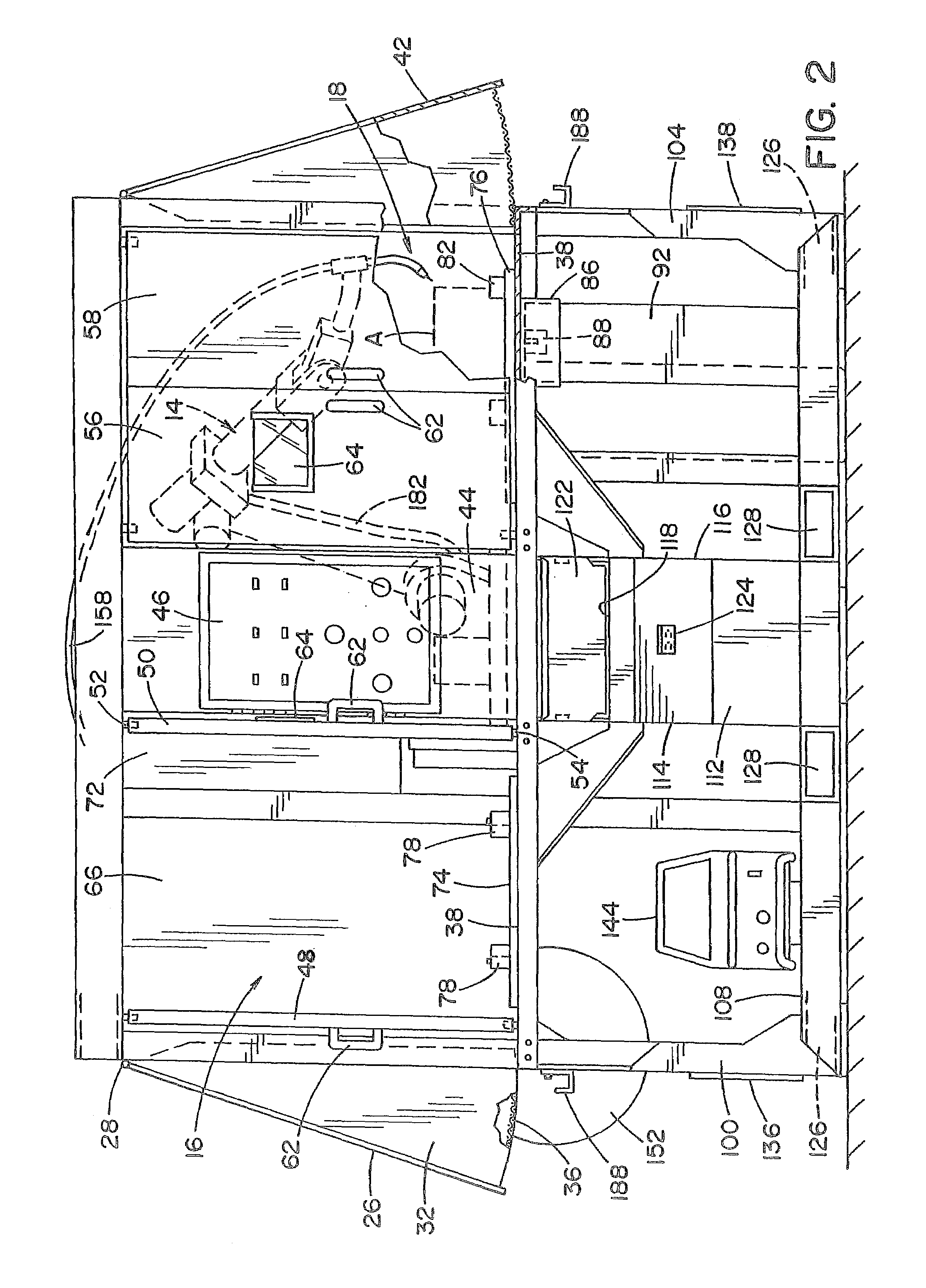

Robotic welding cell unit

InactiveUS7238916B2Easily fitted into bedMore freedom of movementElectric heatingForging/hammering/pressing machinesRobot weldingEngineering

Owner:LINCOLN GLOBAL INC

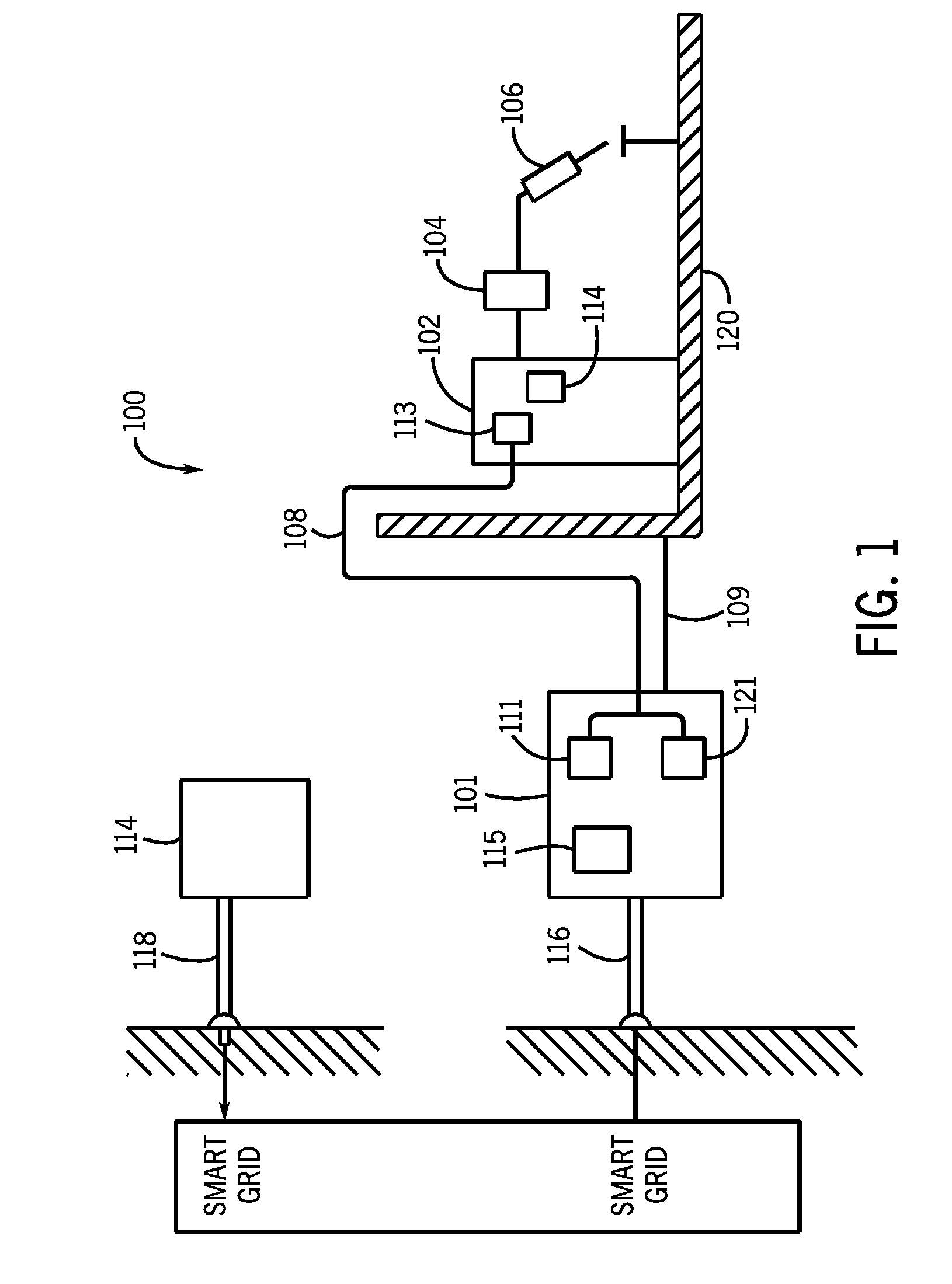

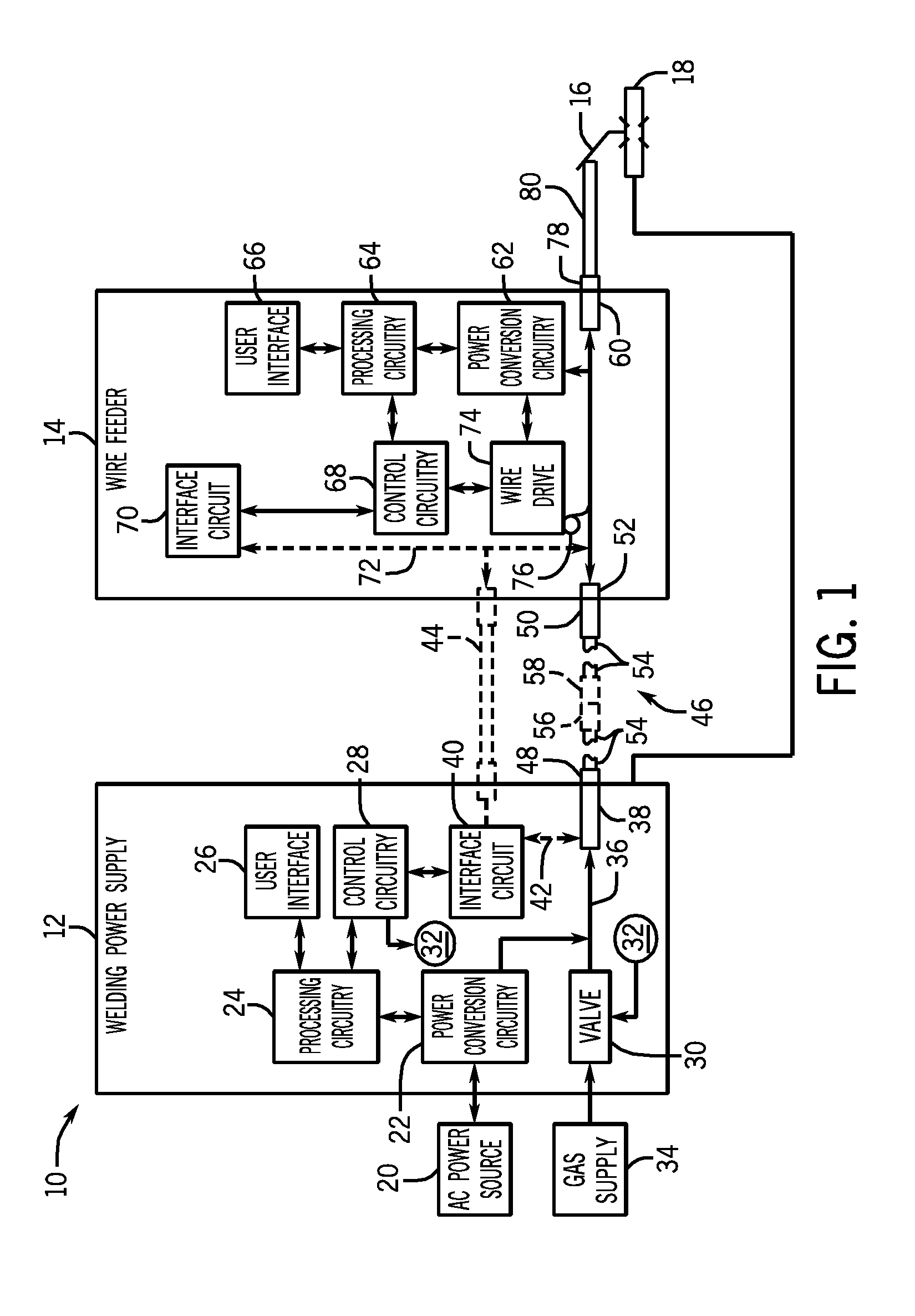

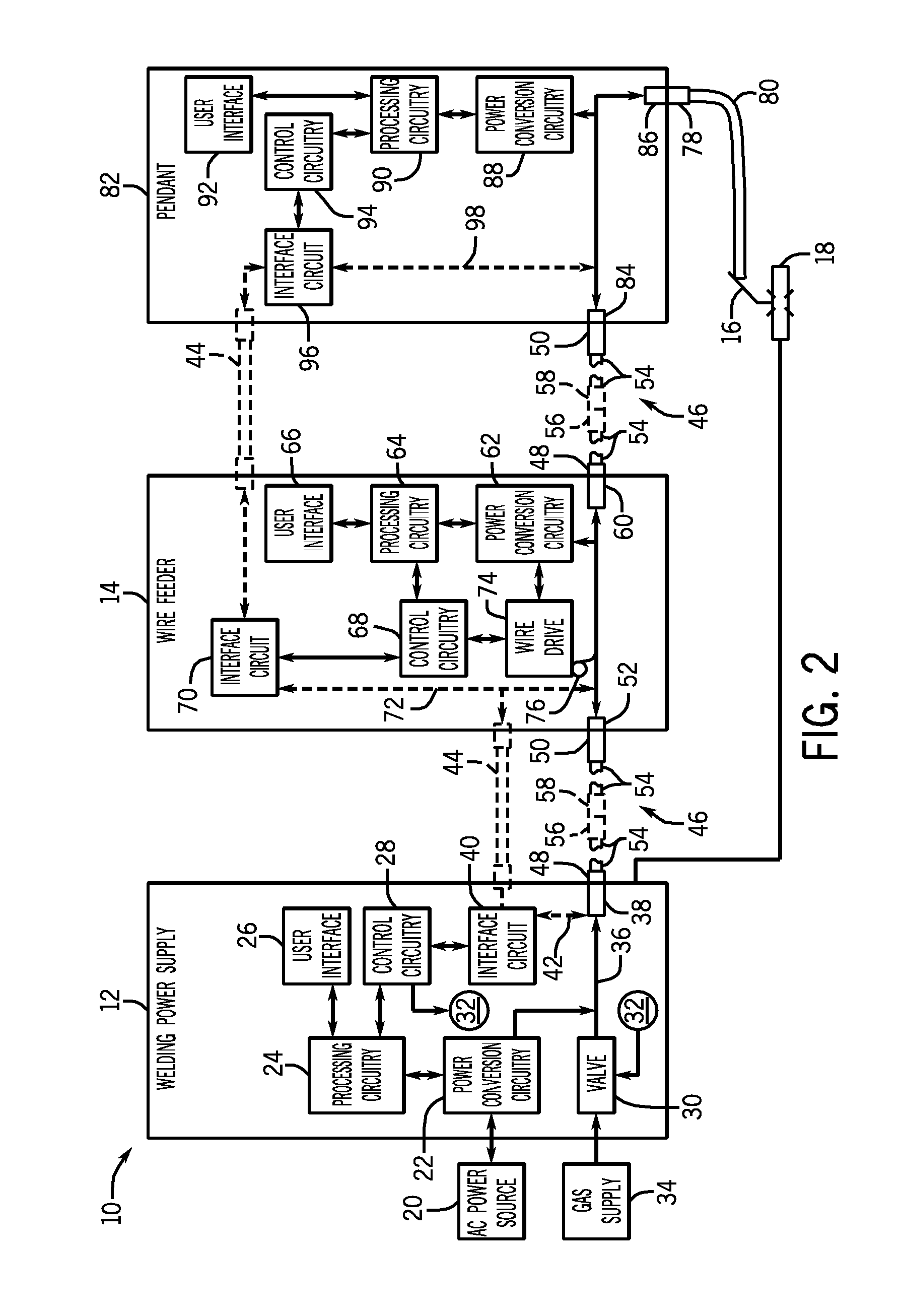

Weld Cell System With Communication

A method and apparatus for providing welding-type power is disclosed and includes a means for communicating.

Owner:ILLINOIS TOOL WORKS INC

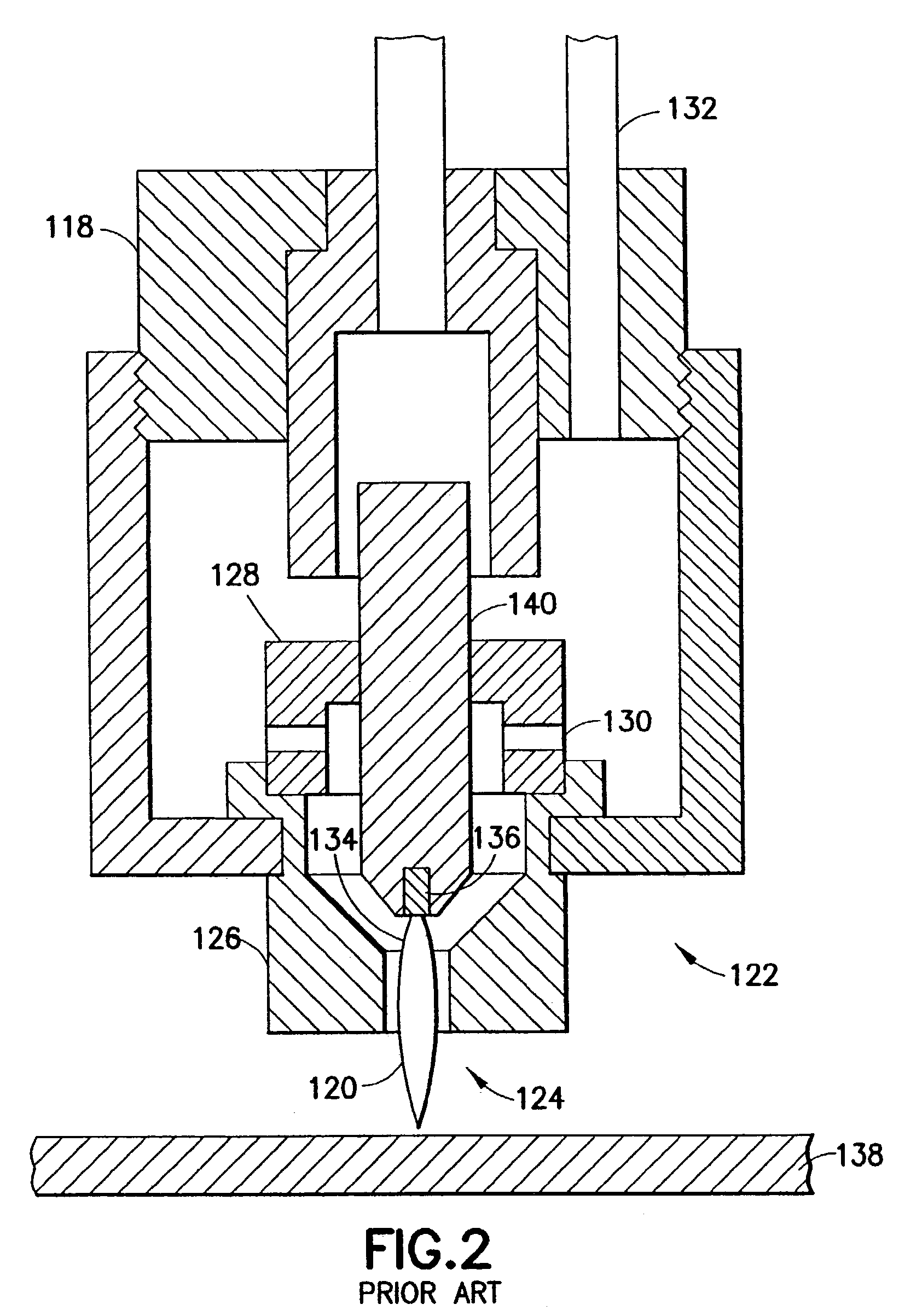

Electric arc torch with cooling conduit

ActiveUS20160074973A1Well formedWelding/cutting auxillary devicesCooled electrode holdersTorchEngineering

An electric arc torch includes a torch base, and a cooling conduit having a conduit wall forming a central axial bore and having a plurality of longitudinal cooling channels spaced circumferentially around the bore. The cooling channels extend through the conduit wall from a first end portion to a second end portion of the conduit. The cooling channels include both a plurality of cooling liquid distribution channels and a plurality of cooling liquid return channels alternately arranged within the conduit wall. The conduit includes a circumferential cooling liquid manifold in fluid communication with each of the cooling liquid distribution channels, a circumferential return manifold in fluid communication with each of the cooling liquid return channels, and a circumferential recirculation manifold in fluid communication with each of the cooling liquid distribution and return channels such that the cooling liquid distribution and return channels are in fluid communication through the circumferential recirculation manifold.

Owner:LINCOLN GLOBAL INC

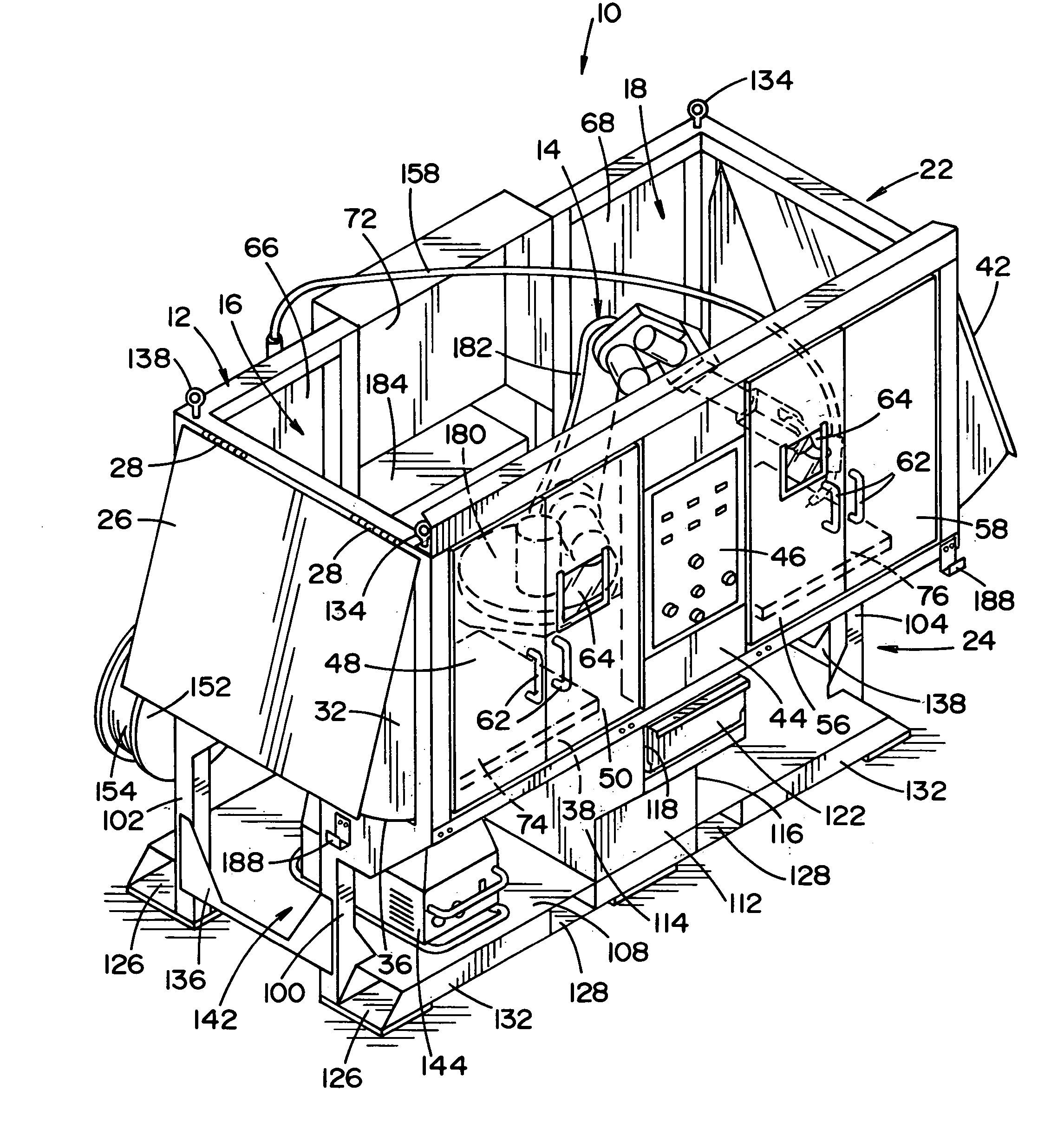

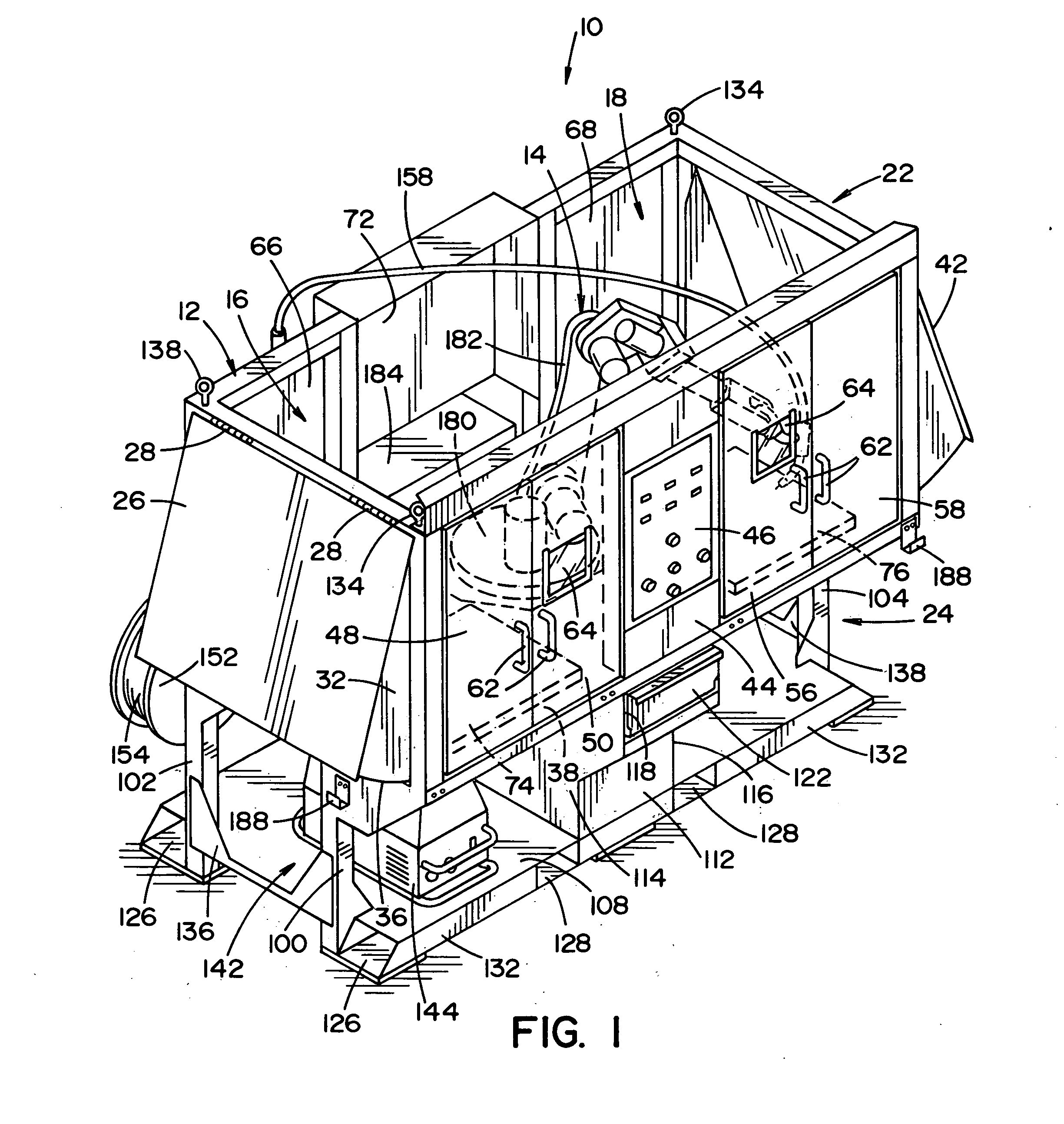

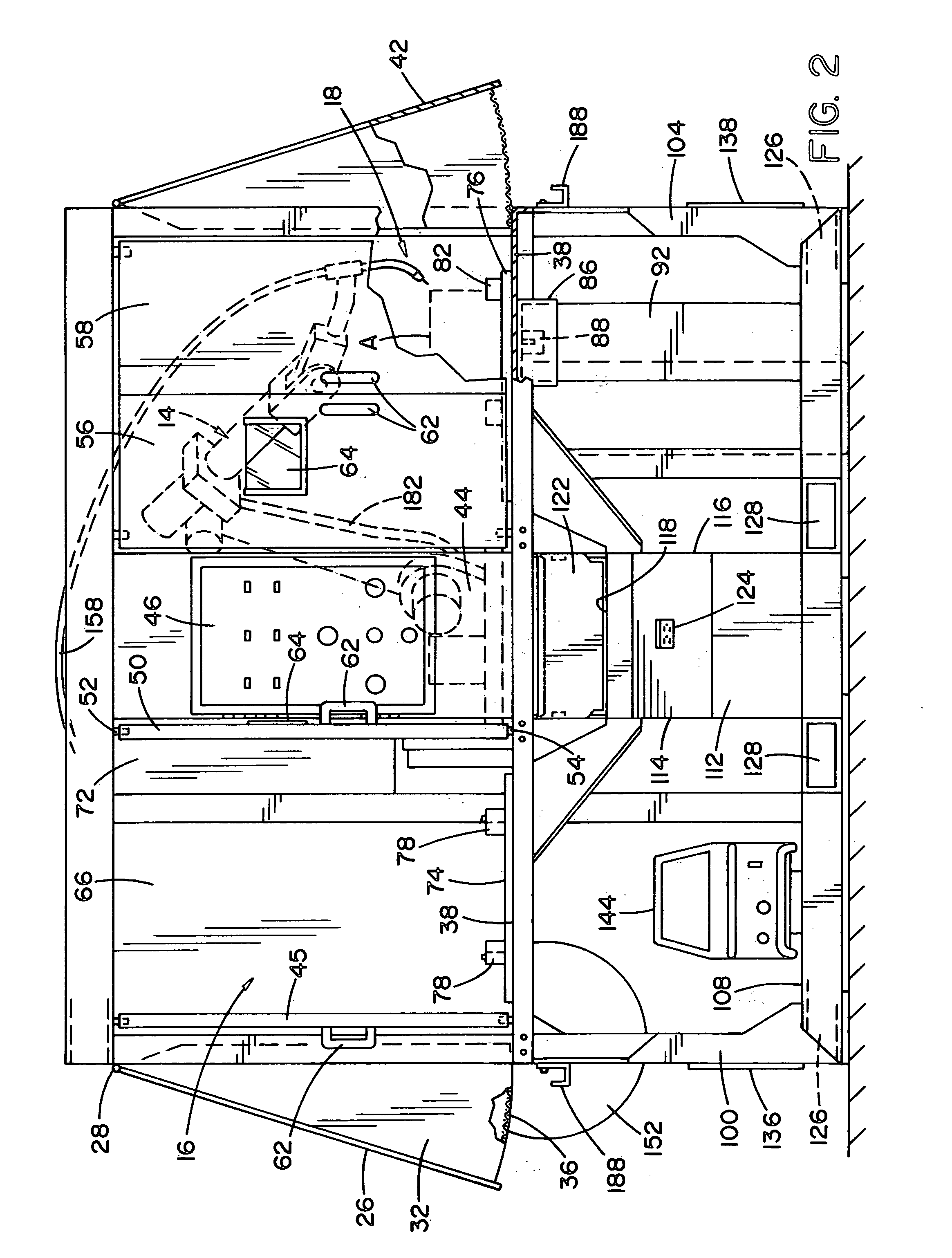

Robotic welding cell unit

InactiveUS20060108342A1Easily fitted into bedMore freedom of movementElectric heatingForging/hammering/pressing machinesRobot weldingEngineering

A portable welding cell unit includes a frame structure in which first and second welding stations are disposed. A robot arm is also provided within the frame. The robot arm can pivot between the first and second welding stations such that a work piece can be welded in the first welding station while a work piece is being loaded into or unloaded from the second welding station.

Owner:LINCOLN GLOBAL INC

Integrated engine welder and hydraulic pump

InactiveUS7642487B2Easy to transportImproves ease of designElectric discharge heatingMachines/enginesPower flowHydraulic pump

An integrated welder, generator and hydraulic unit that includes a housing that at least partially contains components of a welder, generator and a hydraulic pump. An engine, an electric current generator, and a hydraulic pump are at least partially mounted in the housing. The electric current generator is at least partially connected to the engine to be at least partially driven thereby. The hydraulic pump can be at least partially powered by the electric current generator or the fuel powered engine during the operation of the engine. The integrated welder, generator and hydraulic unit can also include an air compressor.

Owner:LINCOLN GLOBAL INC

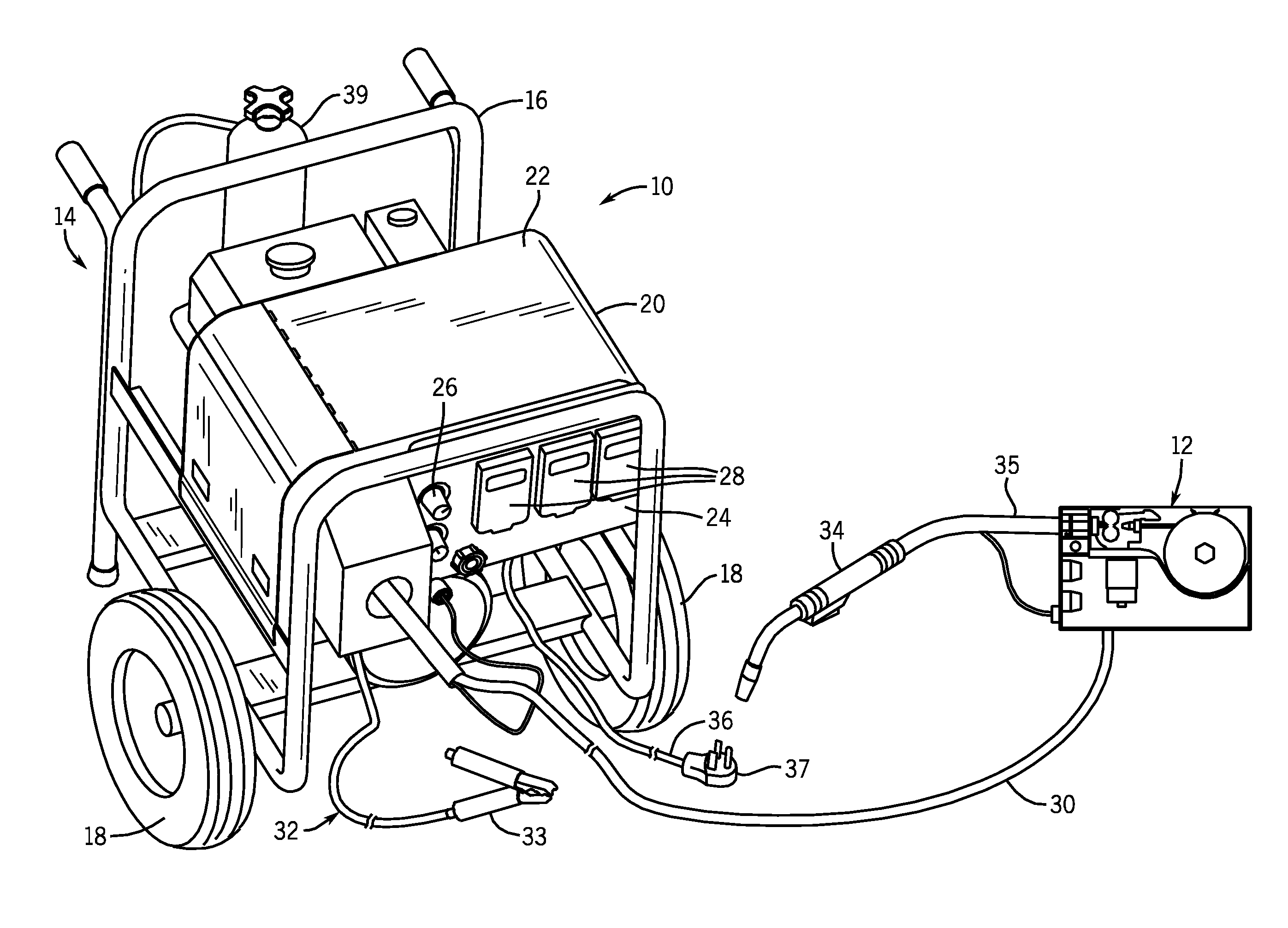

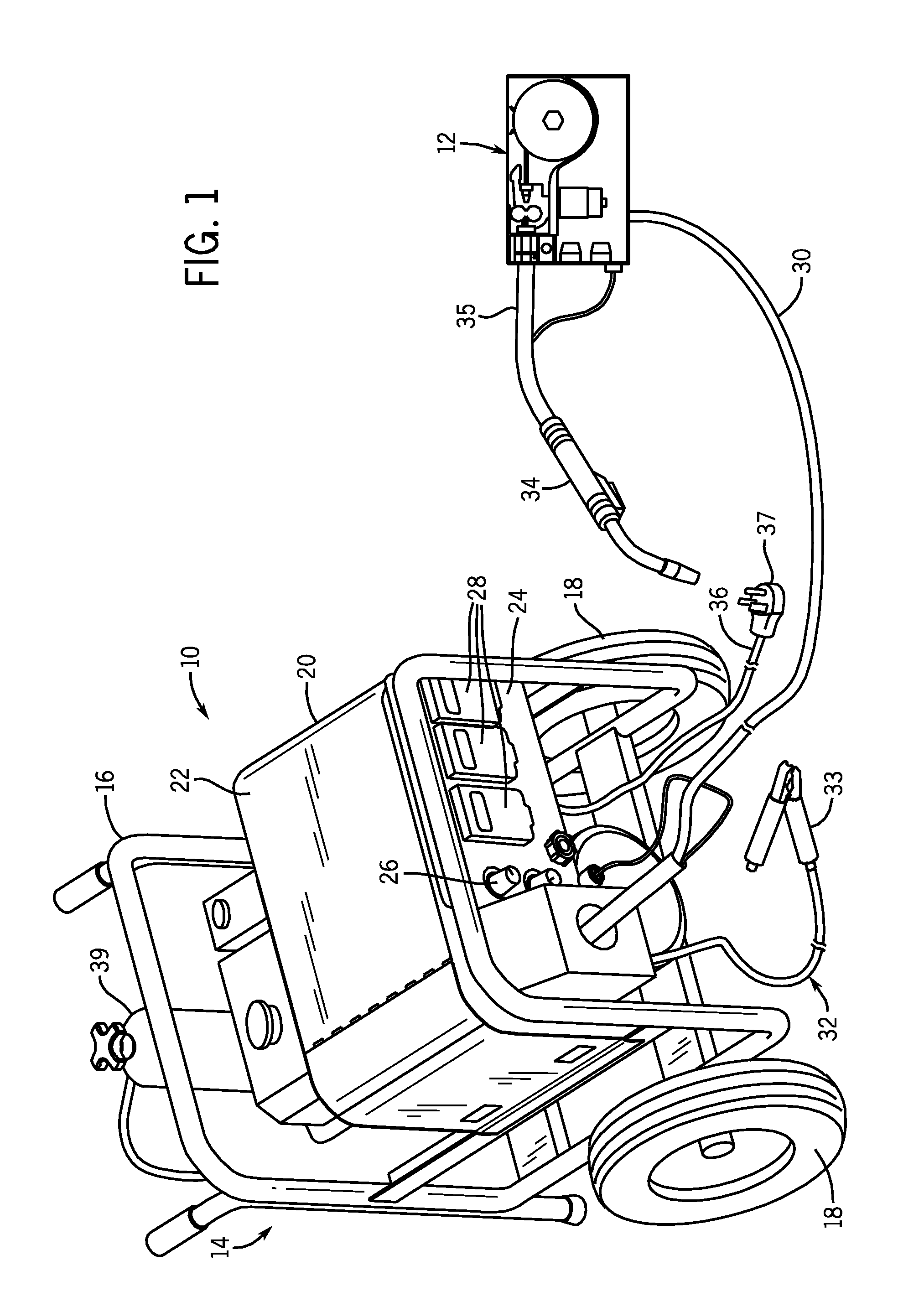

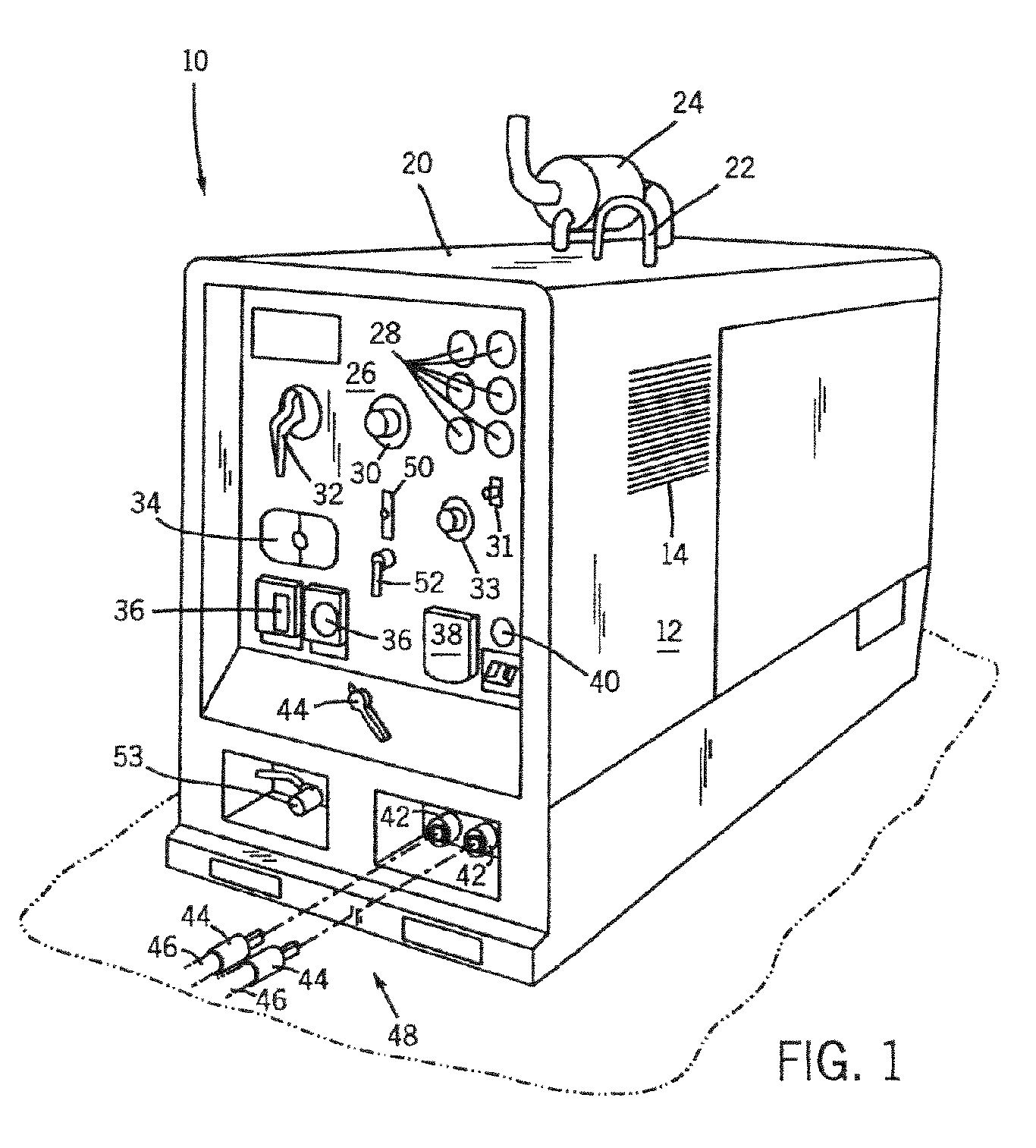

Spool gun having unitary shielding gas and weld power connector

A spool gun having a quick connector connectable to an electrical power source and a gas source is disclosed. A connection line extends from the spool gun and is attached to a connector. The connector both fluidly connects the spool gun to a shielding gas source and electrically connects the spool gun to a power source constructed to generate a welding-type power. Such a spool gun is quickly and efficiently connectable to the gas and power systems required for performing welding processes.

Owner:ILLINOIS TOOL WORKS INC

Articulated Thermal Processing Torch

A thermal processing torch can include a torch housing having a head portion pivotally coupled relative to a body portion with a joint portion. The torch also can include a pivotal connector simultaneously pivoting about a common axis with the joint portion of the torch housing. The pivotal connector can include an electrically conductive wall conducting an electrical current between the body portion of the torch housing and the head portion of the torch housing. The pivotal connector can also include a passage provide a processing gas between the body portion of the torch housing and the head portion of the torch housing.

Owner:HYPERTHERM INC

Binary Signal Detection

A system and method for identifying a torch assembly associated with a thermal processing system can include a detector that detects a multi-bit binary signal based on a plurality of open circuits or closed circuits with the thermal processing system. Each representative binary signal can comprise an individual physical component. The system can also include a control mechanism in communication with the detector, the control mechanism identifying at least one characteristic of the torch assembly based upon the multi-bit binary signal.

Owner:HYPERTHERM INC

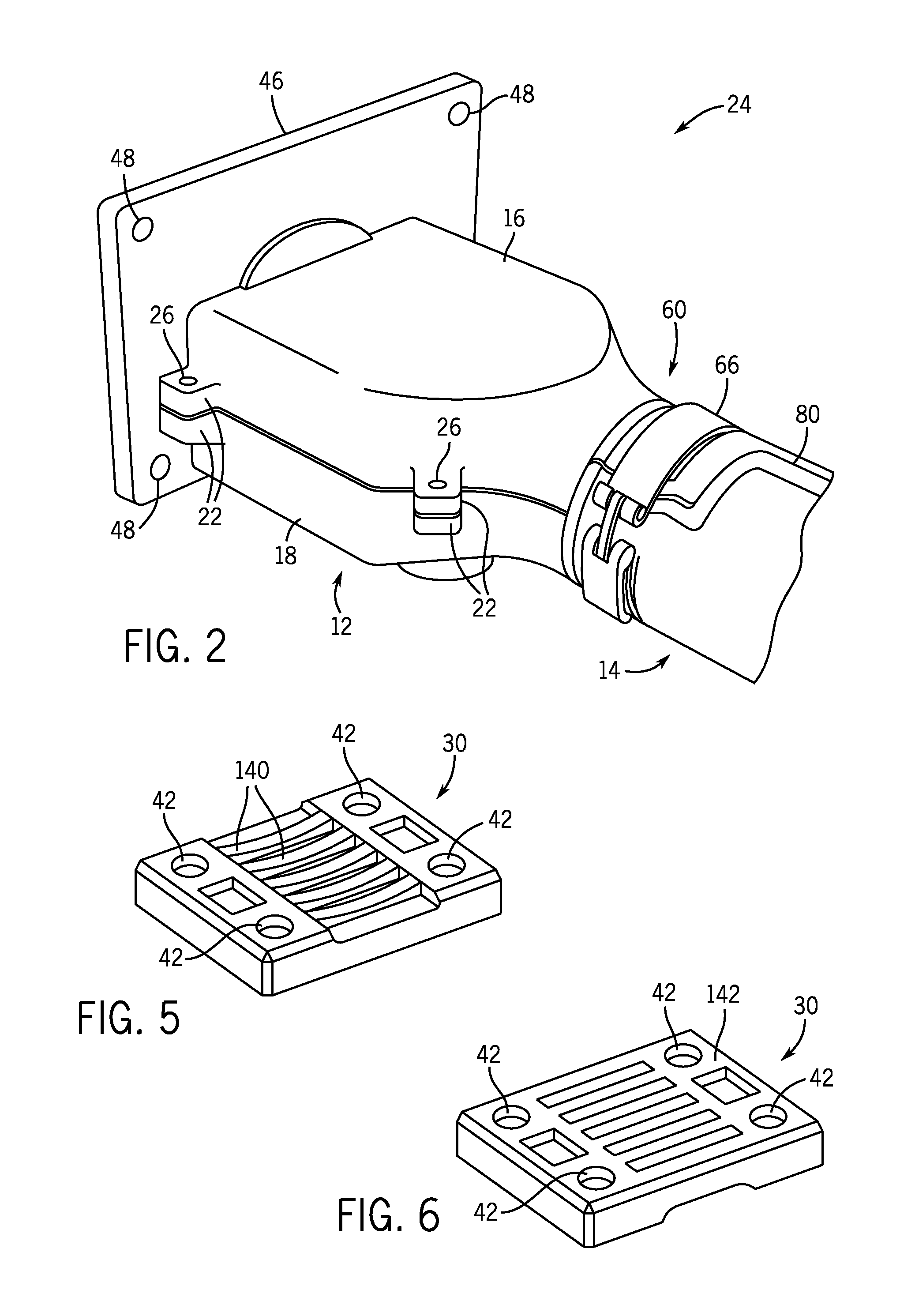

System and method for welding system cable management

ActiveUS20140069904A1Restrict movementWelding electric supplyCouplings bases/casesManagement systemCable management

Embodiments of the present disclosure include a cable management system with a housing comprising a first shell and a second shell configured to couple together about welding system cabling such that a portion of the welding system cabling is contained by the housing. The first and second shells form openings at ends of the housing such that the welding system cabling is capable of extending through the openings and such that edges of the openings enclose a perimeter of the welding system cabling when the first and second shells are coupled together about the welding system cabling. A cradle receives a weld cable of the welding system cabling. A cable clamp engages the weld cable and cooperates with the cradle to restrict movement of the weld cable when the weld cable is disposed in the cradle and the cable clamp is engaged.

Owner:ILLINOIS TOOL WORKS INC +1

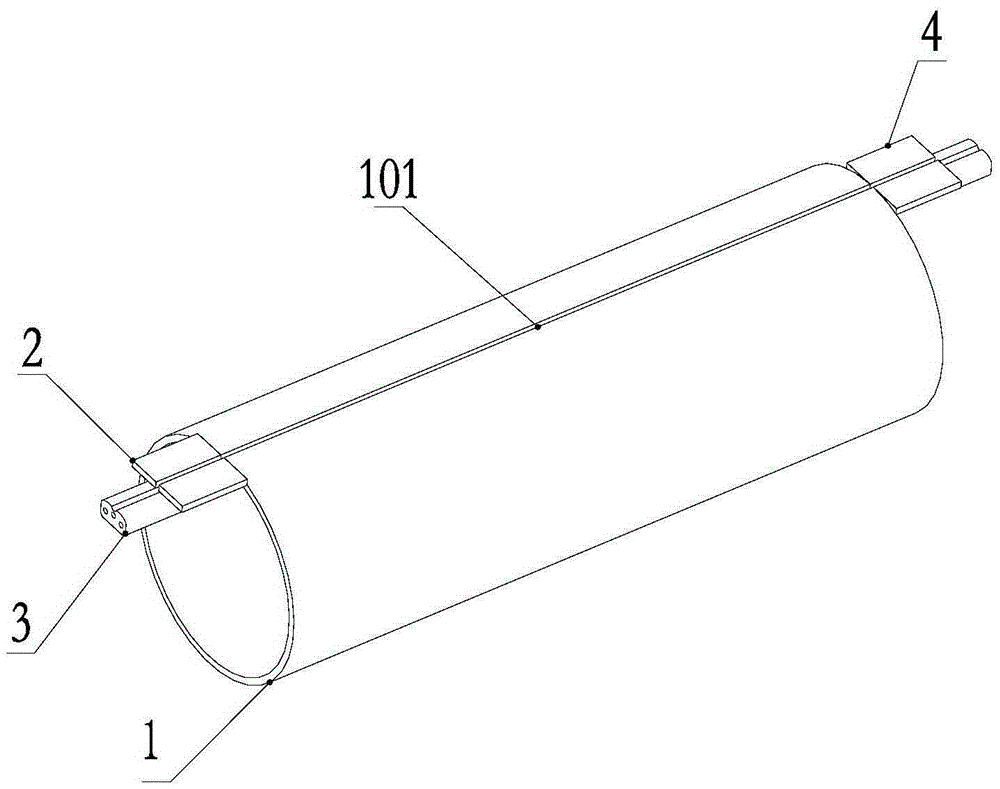

Circulating water cooling liner device for welding and application method of liner device

ActiveCN103586622ARapid coolingExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesWater storage tankStructural engineering

The invention discloses a circulating water cooling liner device for welding. The liner device comprises a liner device body an a circulating water cooling device. The grooves of two to-be-welded plates are oppositely fixed on the upper side of the liner device body. The circulating water cooling device is connected with the liner device. A recessed longitudinal arc-shaped forming groove is formed in each of the four sides of a copper liner which is longitudinally positioned through a retaining plate. A water pump water outlet pipe is connected with a cooling water circulating hole of the copper pad and is connected with a water return pipe of a water storage tank through a water return hose. The invention further discloses an application method of the circulating water cooling liner device. The method includes: fixing a liner seat; selecting the width W1 of each longitudinal arc-shaped forming groove of the copper liner; tightly pressing the copper liner through the retaining plate; connecting water pipes at two ends of the copper liner; fixing the two to-be-welded plates; starting a water pump to feed water so as to cool the copper liner, and welding the two to-be-welded plates. By the longitudinal arc-shaped forming grooves in the copper liner, utilization rate of the copper liner is increased by three times, welding of plates of different thicknesses can be satisfied, and application cost is lowered.

Owner:中外合资沃得重工(中国)有限公司

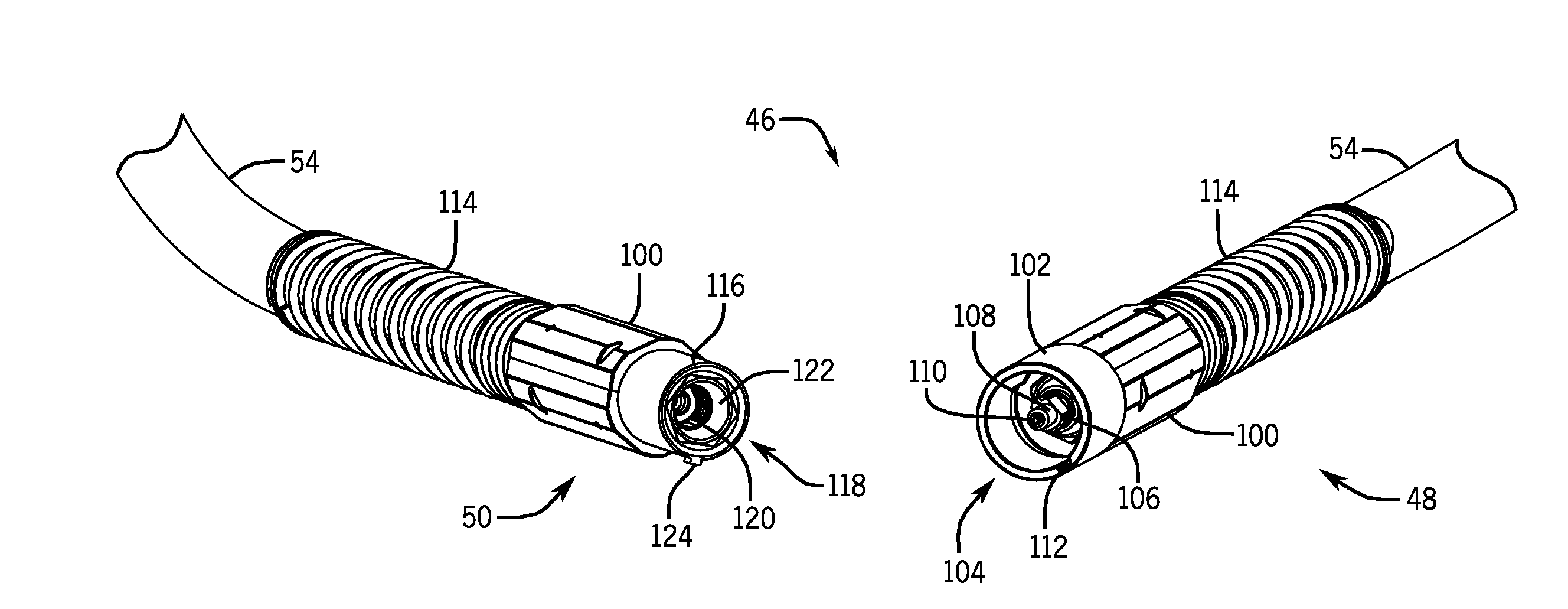

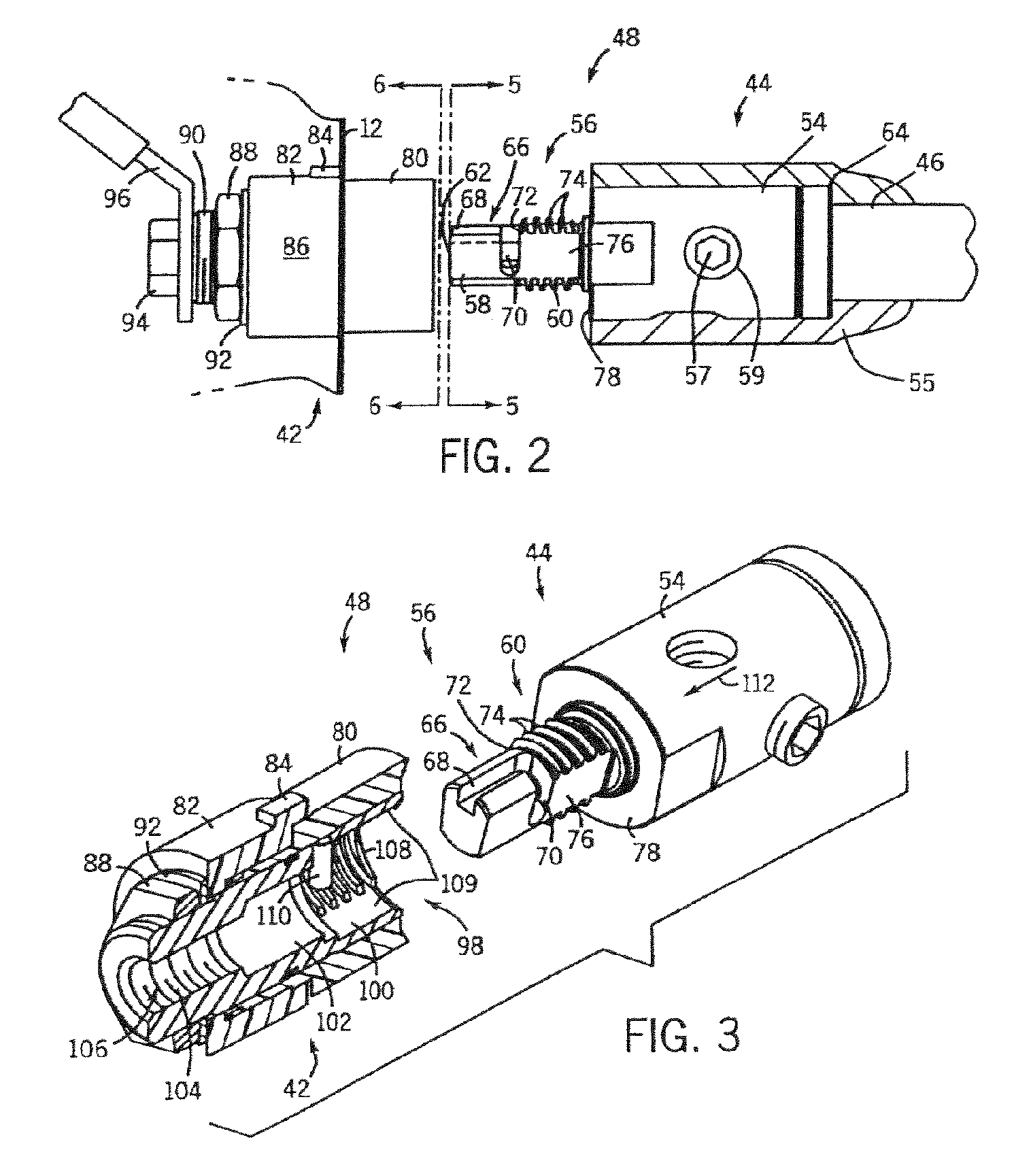

Weld electrical and gas connector with sealed gas flow

ActiveUS20110247999A1Welding/cutting media/materialsSoldering mediaCarbon Dioxide / HeliumShielding gas

A weld electrical and gas connector with sealed gas flow is provided. In an exemplary embodiment, a welding cable connector system includes a male connector having a conductive body for conveying welding power. The male connector includes a sealed passageway disposed coaxially of the conductive body for conveying shielding gas, and a gas sealing valve configured to seat to stop flow of shielding gas when the male connector is not engaged. The system also includes a female connector having a conductive body for conveying welding power. The female connector includes a sealed passageway disposed coaxially of the conductive body for conveying shielding gas, and a gas sealing valve configured to seat to stop flow of shielding gas when the female connector is not engaged. The male and female connectors are mutually engageable to conduct welding power and shielding gas therethrough.

Owner:ILLINOIS TOOL WORKS INC

Gas diffuser for head tube assembly of welding gun

InactiveUS6924461B2Improve shielding effectLess complexWelding coupling meansAtmospheric airEngineering

A gas diffuser for a welding gun in which atmospheric air in the interior of the liner is substantially prevented from entering the contact tip hole. The gas diffuser includes a cradle having a hole and a section of a concave surface disposed around a periphery of the hole, and an outer peripheral body having a first axial bore on one side of the cradle and a second axial bore on the other side of the cradle. The outer peripheral body includes one or more generally axial slots, each slot having one end that opens into the first axial bore and another end that opens into the second axial bore. Each slot is open to the exterior of the diffuser along its length and is disposed radially outward of the cradle. The first and second axial bores communicate via the hole in the cradle and via the slots.

Owner:ILLINOIS TOOL WORKS INC

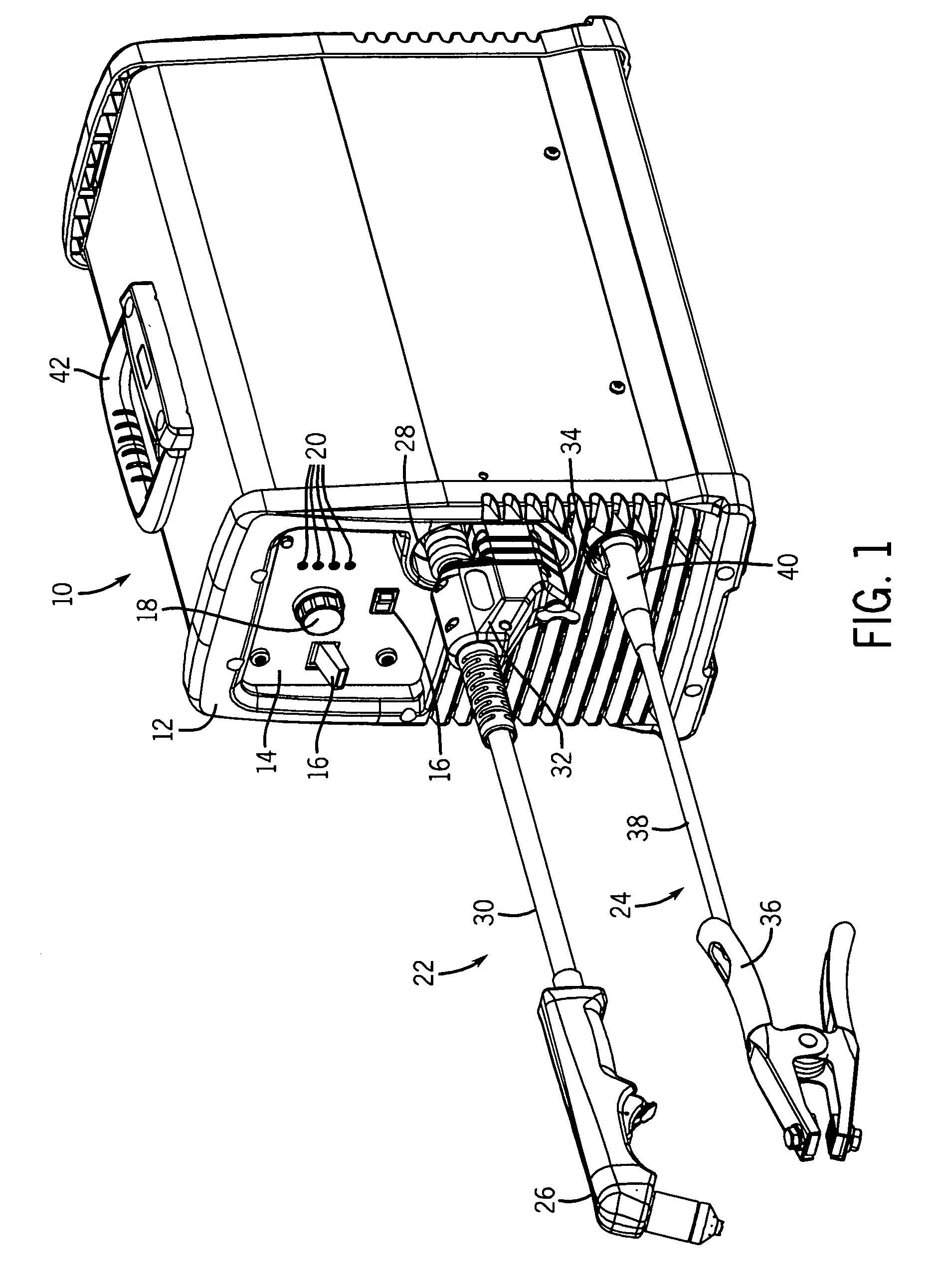

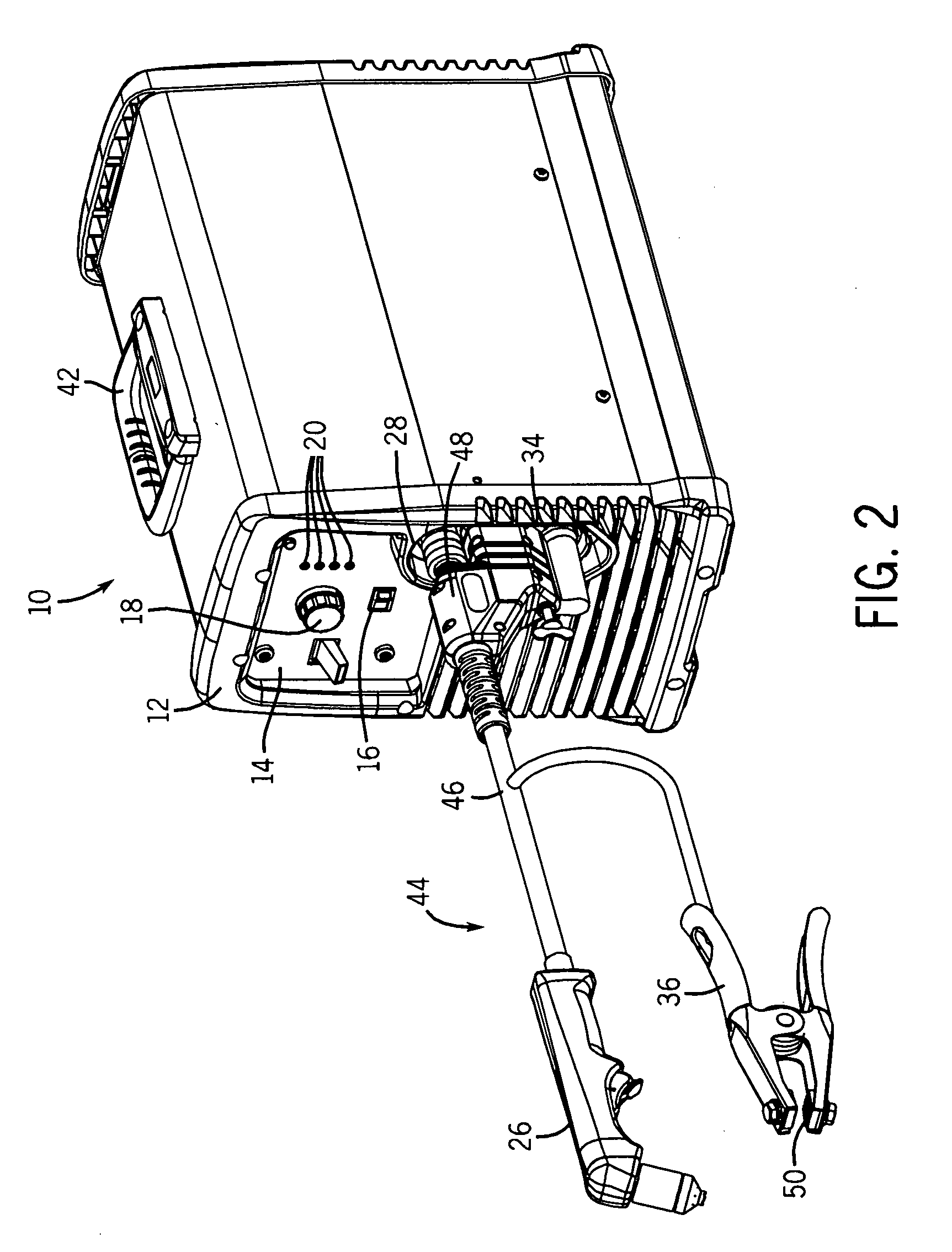

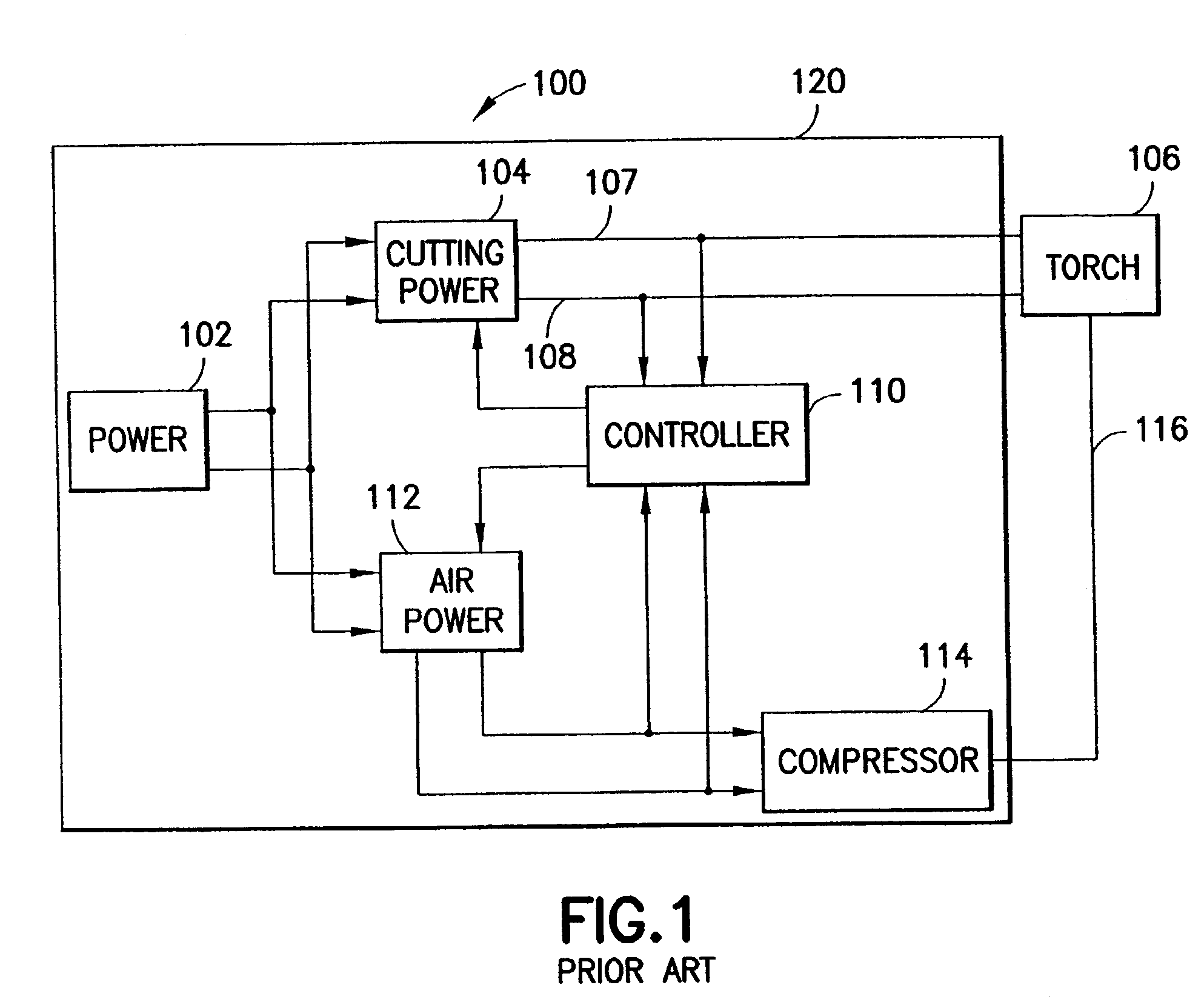

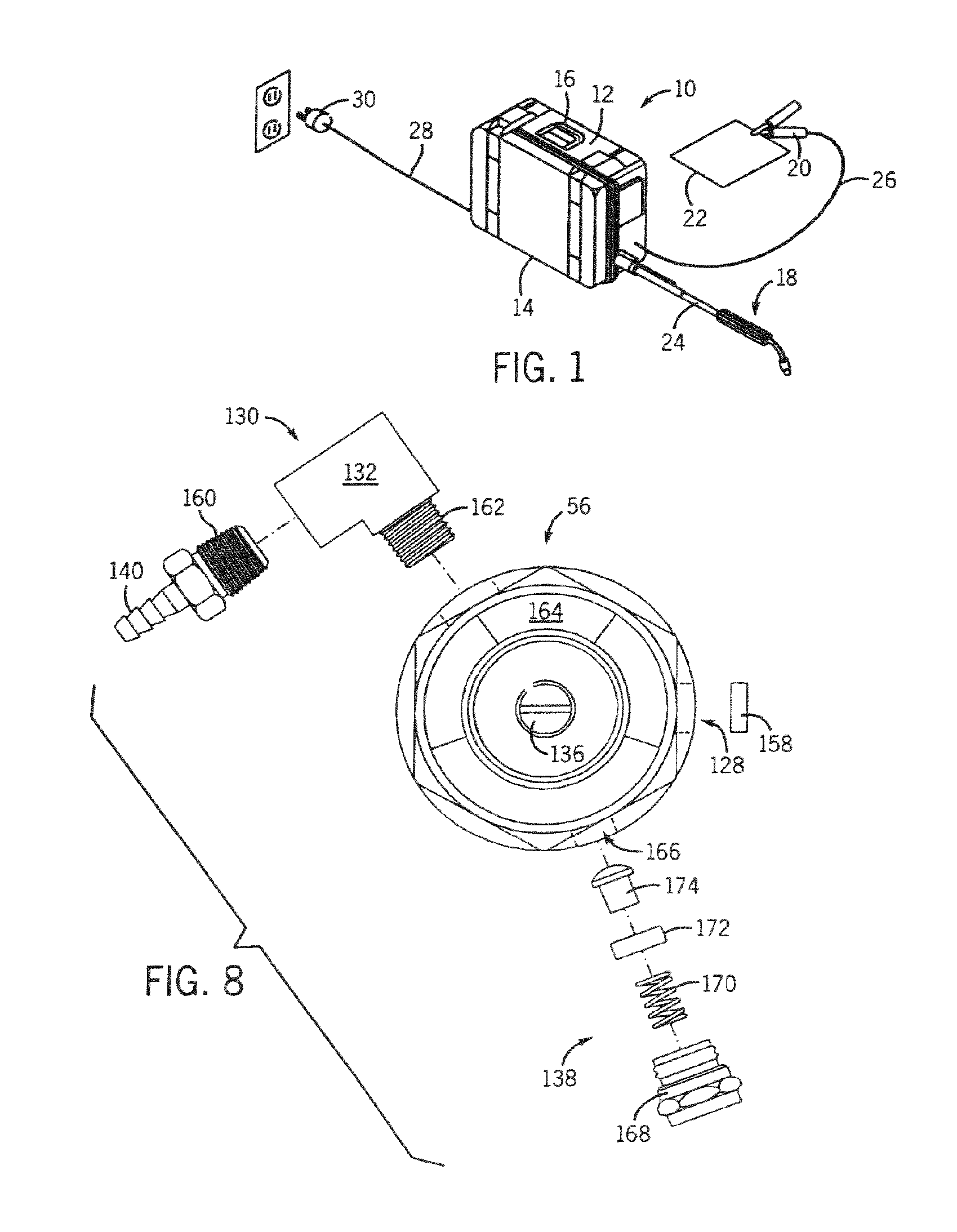

Plasma cutter with disconnectable torch and work assemblies

ActiveUS20090277881A1Good adhesionEasy to removeOhmic-resistance heating detailsPlasma welding apparatusEngineeringTorch

Systems and methods relating to securing a torch assembly and a work lead assembly to a plasma cutting power supply are provided. The present disclosure relates to a system and method that allows the torch assembly and the work lead assembly to be readily replaced by the user since the power supply unit need not be opened or disassembled for removal. The present disclosure provides methods and systems for removably securing both the torch assembly and the work lead assembly to the plasma cutting power supply. In one embodiment, the torch assembly and the work lead assembly may be communicatively coupled to the plasma cutting power supply unit via a single cable and a single connector. The connection between the first connector and the first port may be of the quick disconnectable type. The connection between the second connector and the second port may be of the twist lock type, such as a dinse style connector.

Owner:ILLINOIS TOOL WORKS INC

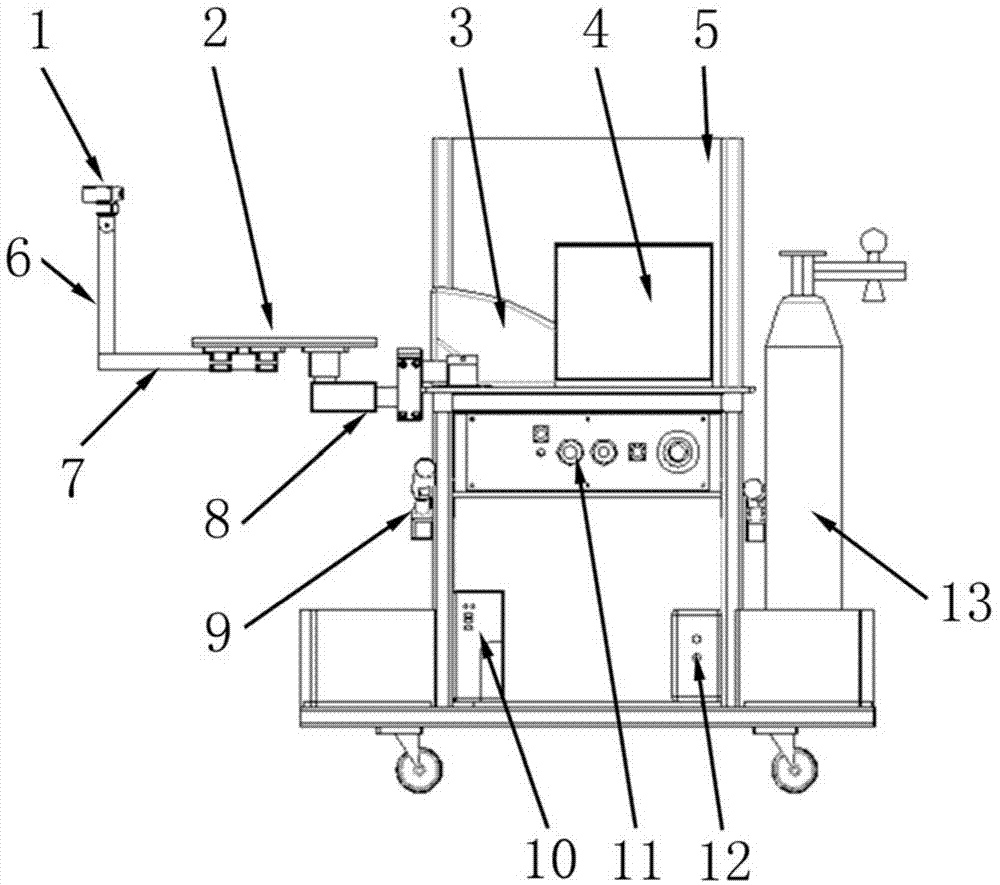

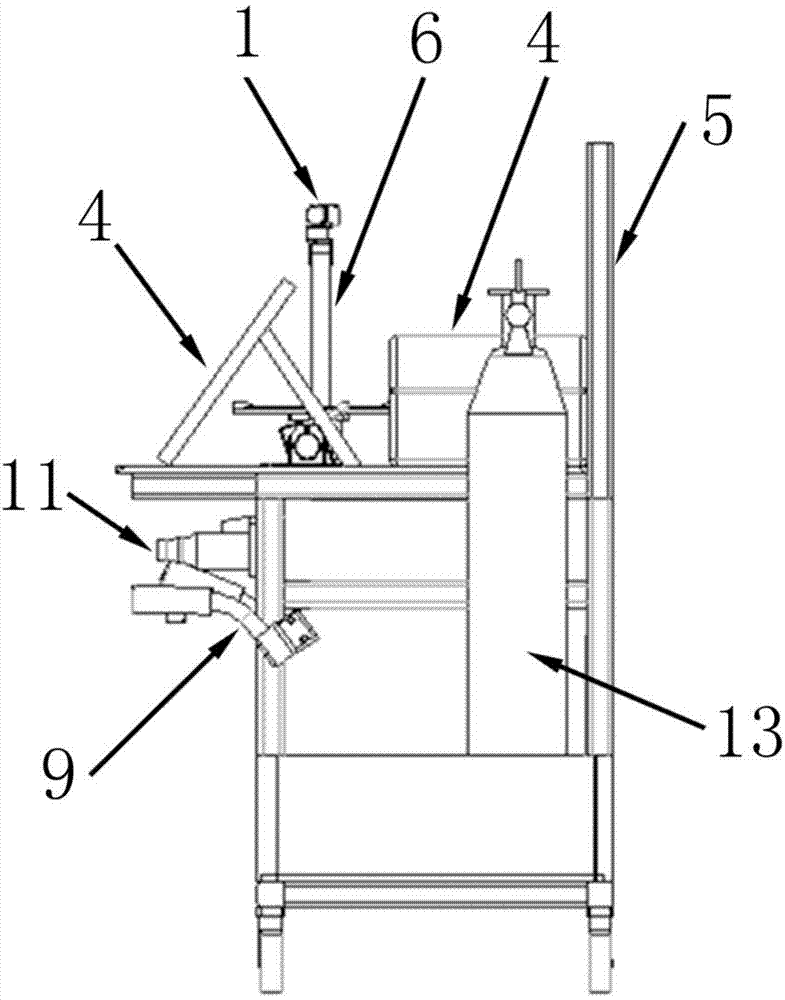

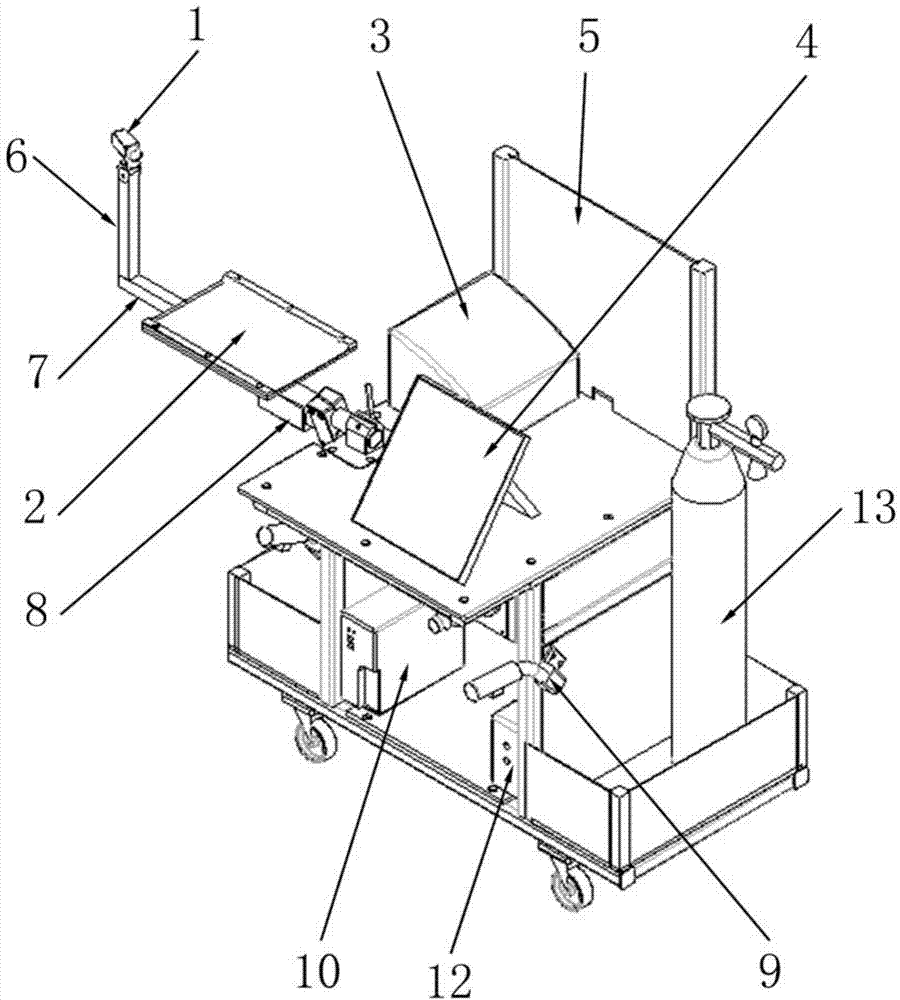

Welding simulation trainer

InactiveCN104708174ASmall footprintImprove resource utilizationEducational modelsWelding coupling meansResource utilizationTeaching tool

The invention belongs to the technical field of teaching tools, and discloses a welding simulation trainer which comprises a trainer body. The trainer body is provided with a welding platform, a welding machine, gas sources, at least two welding guns and at least two welding gun plugs. The welding platform is provided with a test panel for welding. The welding gun plugs correspond to the welding guns. Welding gun connectors are connected with the welding machine / or the gas source. The welding gun connectors are used for being connected with the welding guns and providing power sources / or the gas sources for the welding guns. According to the welding simulation trainer, a plurality of welding gun plugs are arranged, all the welding gun plugs are connected with different gas sources or power sources so as to be connected with different welding guns, multiple kinds of welding simulation training can be achieved on the same trainer body, the occupied space of the trainer is small, and the resource utilization rate is high.

Owner:北京竞业达沃凯森科技有限公司

Spool gun having unitary shielding gas and weld power connector

A spool gun having a quick connector connectable to an electrical power source and a gas source is disclosed. A connection line extends from the spool gun and is attached to a connector. The connector both fluidly connects the spool gun to a shielding gas source and electrically connects the spool gun to a power source constructed to generate a welding-type power. Such a spool gun is quickly and efficiently connectable to the gas and power systems required for performing welding processes.

Owner:ILLINOIS TOOL WORKS INC

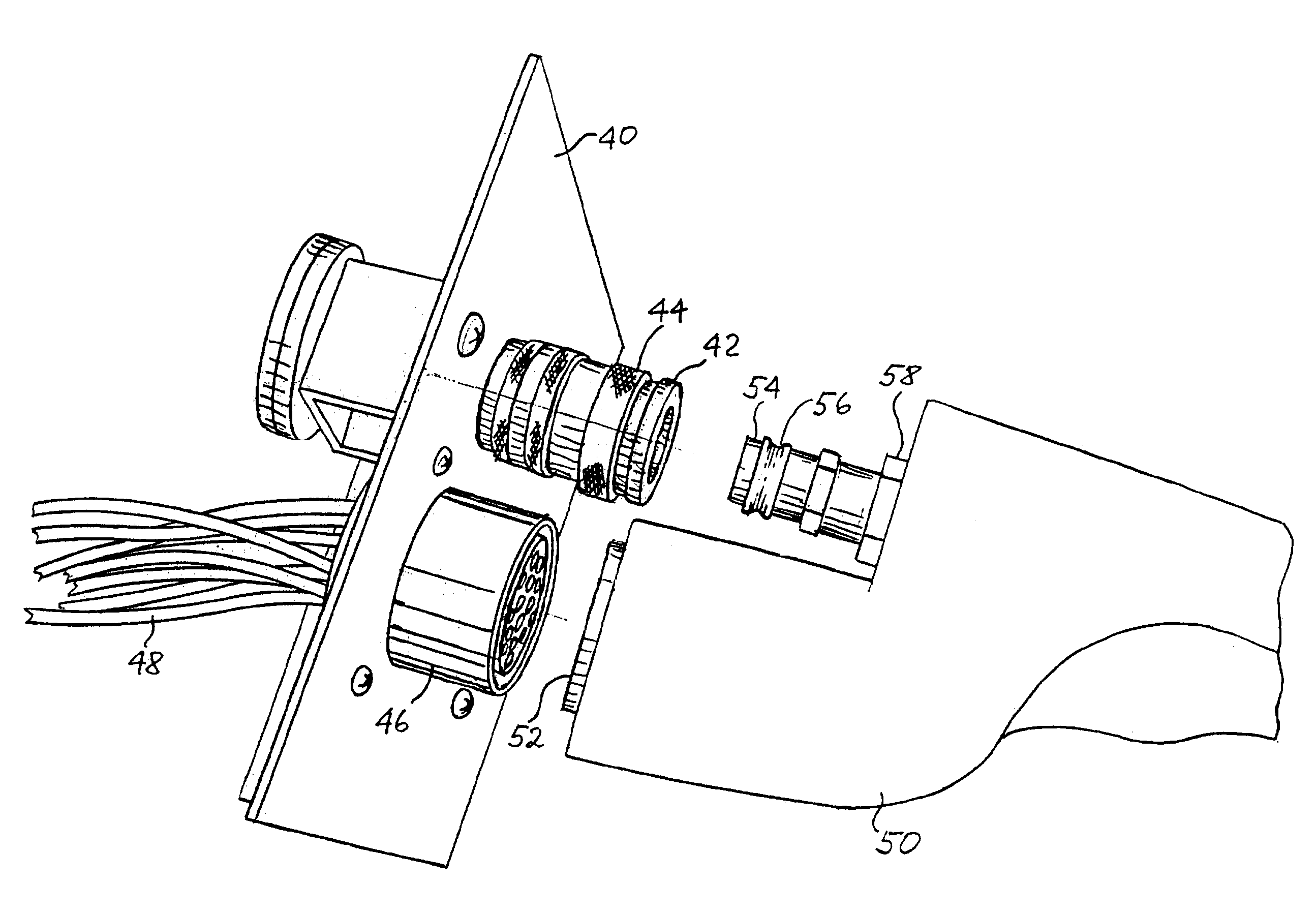

System for quick disconnect of torch from power and gas supply unit

InactiveUS7176404B2Simple and inexpensivePlasma welding apparatusWelding coupling meansElectricityOff the shelf

A torch cable in which both the electrical connection and the pneumatic connection can be made concurrently in one motion by coupling the end of the torch cable to the exterior of the supply unit. The coupling further includes a quick disconnect feature. The torch cable coupling is simple and inexpensive, using standard off-the-shelf components. The end of the cable comprises various components that are overmolded to form an electrically insulative body, e.g., made of urethane rubber compound. This molded body incorporates strain relief, is water resistant, protects the electrical plug, and stabilizes the electrical contacts. Gas, power and control are combined in one assembly. The pneumatic quick disconnect coupling is used as a latching mechanism for the entire assembly. The torch cable can be disconnected from the supply unit by simply releasing the quick disconnect coupling and then pulling the end of the torch cable away from the supply unit. The pneumatic connector and the electrical plug form keying means by their orientation.

Owner:ILLINOIS TOOL WORKS INC

Welding structure for inner container longitudinal seam of stainless steel gas cylinder and welding method

ActiveCN105252121AReduce one-time input costsLow input costShielding gas supply/evacuation devicesWelding/cutting media/materialsButt weldingGas cylinder

The invention discloses a welding structure for an inner container longitudinal seam of a stainless steel gas cylinder and a welding method. The welding structure comprises a strip-shaped auxiliary board, wherein a main gas guide hole and a gas guide groove are formed in the strip-shaped auxiliary boar in the length direction; the main gas guide hole and the gas guide groove are arranged in parallel; a plurality of gas guide small holes are formed between the main gas guide hole and the gas guide groove; the two ends of the gas guide small holes are respectively communicated with the main gas guide hole and the gas guide groove; and the cross section of the gas guide groove and the cross section of the longitudinal seam to be welded are positioned in the same plane. The welding method comprises the following steps: rolling round; carrying out butt welding and spot welding; carrying out spot welding on run-on plates and run-off plates; clamping; and welding. According to the invention, an MIG automatic welding process is adopted, so that the primary input-cost of welding equipment is low; in a later using process, the input using and maintenance costs are relatively low and the working efficiency is improved greatly. By adopting the process in the invention, the qualification rate of nondestructive testing reaches 99.4% or above in an actual longitudinal seam welding process of an insulated gas cylinder and a cylinder for an LNG vehicle; and physical and chemical test projects completely meet standard requirements.

Owner:ANHUI DAPAN SPECIAL EQUIP VEHICLE CO LTD

Method and apparatus to adaptively cool a welding-type system

InactiveUS20050016978A1Support devices with shieldingCooled electrode holdersNuclear engineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired. The cooling system is constructed to be integrally disposed within a power source housing.

Owner:ILLINOIS TOOL WORKS INC

Alignment mechanism for a welding torch

InactiveUS20060226134A1Facilitate securementEasy alignmentWelding coupling meansEngineeringMechanical engineering

In accordance with one exemplary embodiment, the present invention provides a welding torch that includes features facilitating aligned assembly of various components of the welding torch with respect to one another. For example, the welding torch includes a nipple that carries a pin member extending from both an inner peripheral surface and an outer peripheral of a sleeve of the nipple. This pin engages with a slot on a coupling member and a slot on a neck assembly, thereby facilitating proper alignment of the neck assembly, coupling member, and nipple with respect to one another. Moreover, the engagement between the pin member and the slots block pivotal displacement of neck assembly, coupling member, and neck assembly with respect to one another. Advantageously, the use of a single pin member for both slots presents a more judicious construction, leading to reduced manufacturing costs, for instance.

Owner:ILLINOIS TOOL WORKS INC

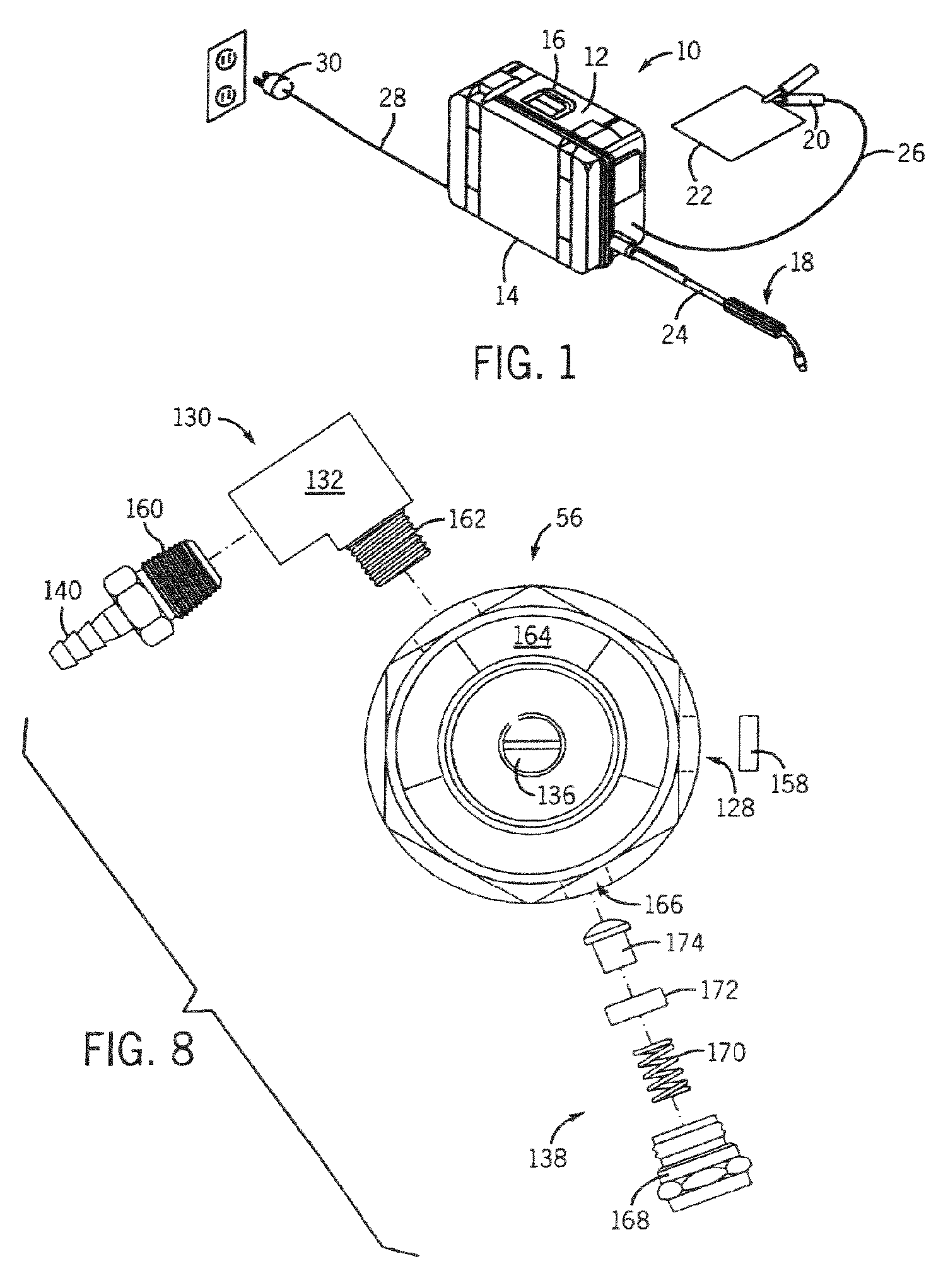

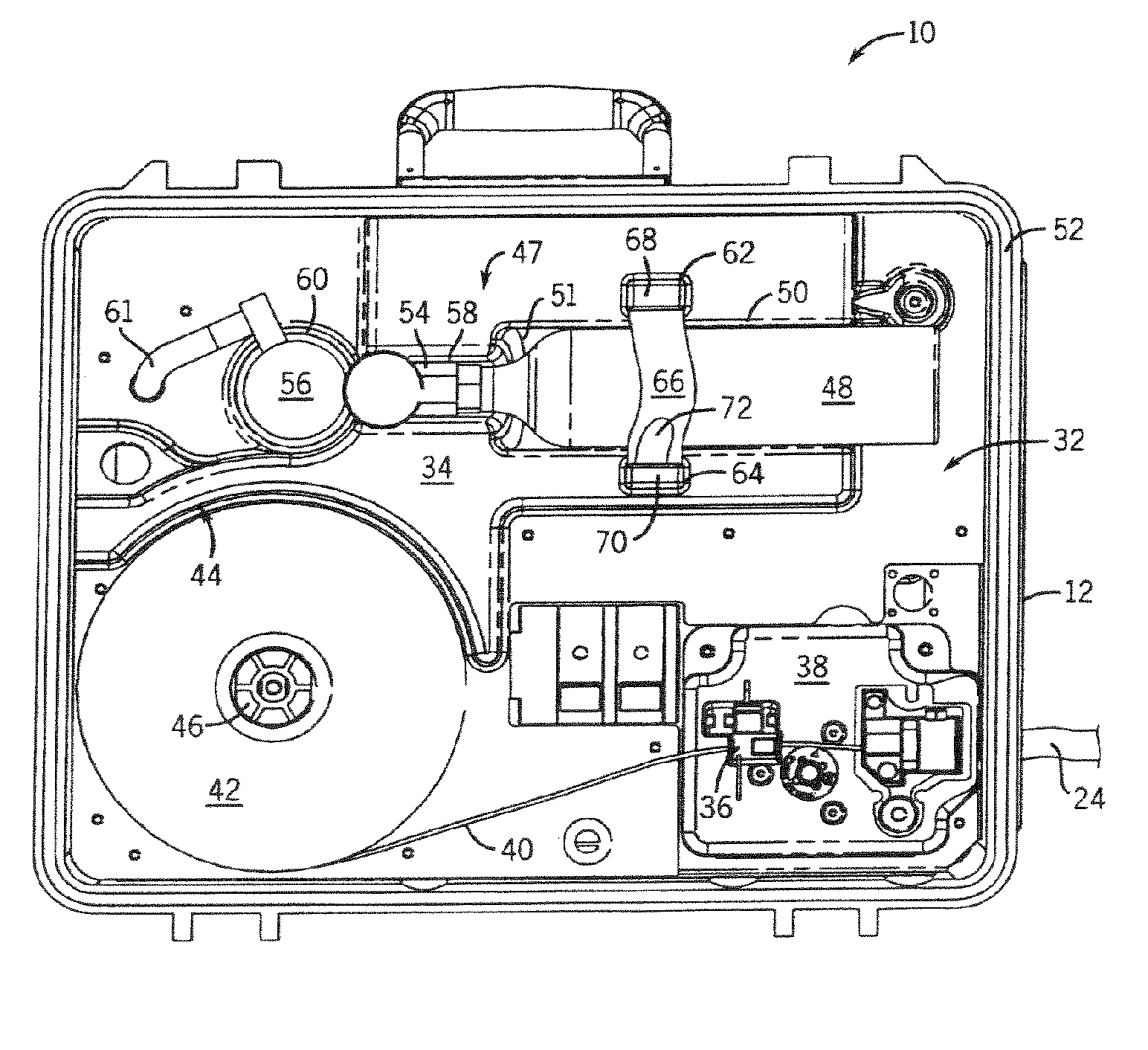

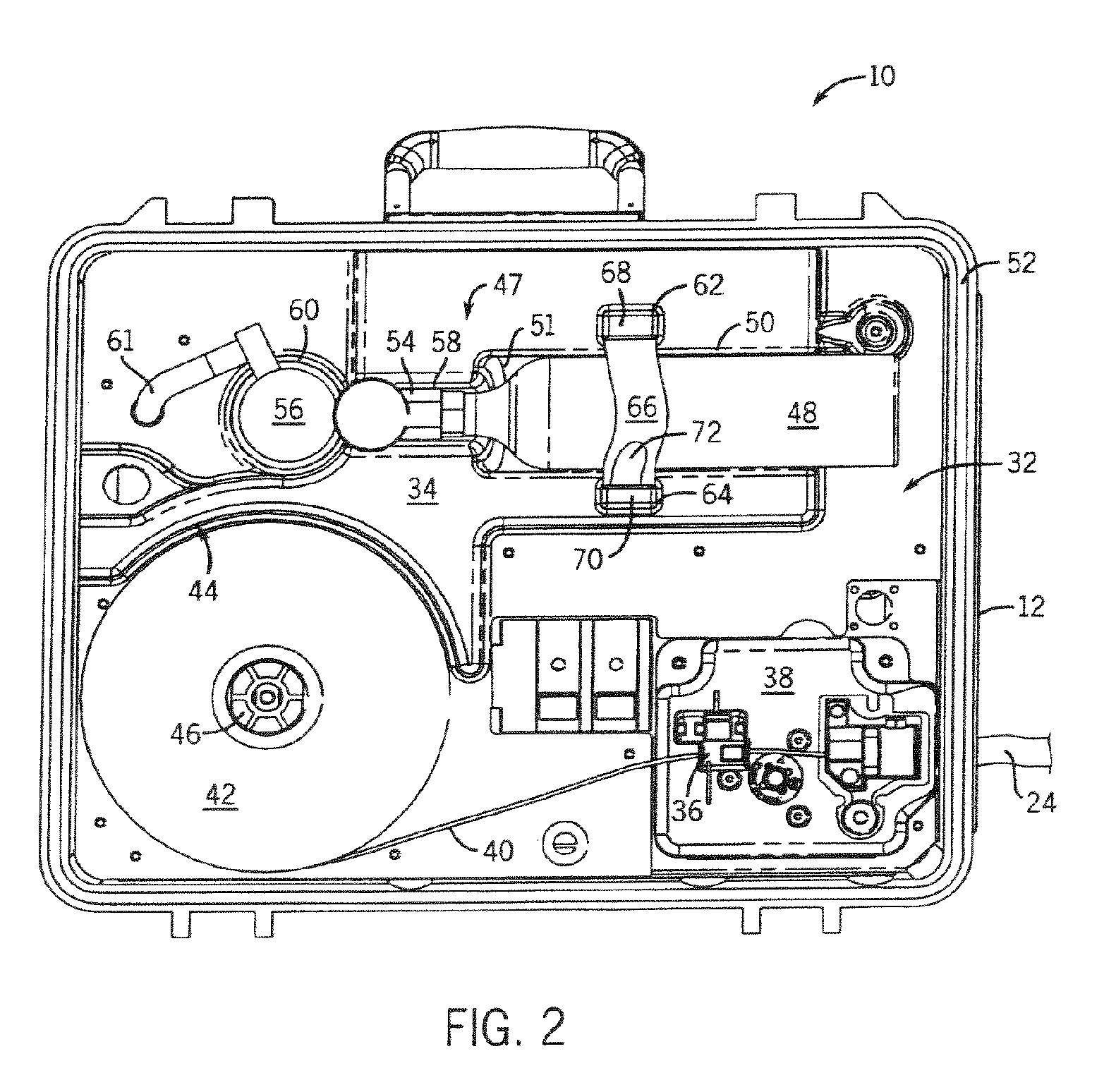

Gas system for wire feeding devices

ActiveUS7423238B2Efficiently and conveniently transportable by a single personSecure supportElectrode supporting devicesWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A wire feeder and gas system for use therewith is shown. The gas system of the wire feeder includes a canister that is constructed to contain a shielding gas therein and is connectable to the wire feeder. The canister is supported by the wire feeder when it is connected thereto such that the wire feeder can be efficiently and conveniently transported from one location to another with the source of shielding gas securely connected thereto.

Owner:ILLINOIS TOOL WORKS INC

High-Power Electrical Quick Connector

ActiveUS20060063396A1Less surface areaRotary current collectorCoupling contact membersElectrical connectionEngineering

A quick connector assembly for high power electrical applications and method of manufacturing a high-power quick connector assembly are disclosed. The quick connector assembly has a first connector and a second connector constructed to form an electrical connection that can be quickly coupled and decoupled. The first connector has a collar portion connectable to a welding cable and a stem portion having a shank section and a threaded section. The second connector has a recess constructed to receive the stem portion of the first connector and electrically engage both the shank portion and the threaded portion of the first connector.

Owner:ILLINOIS TOOL WORKS INC

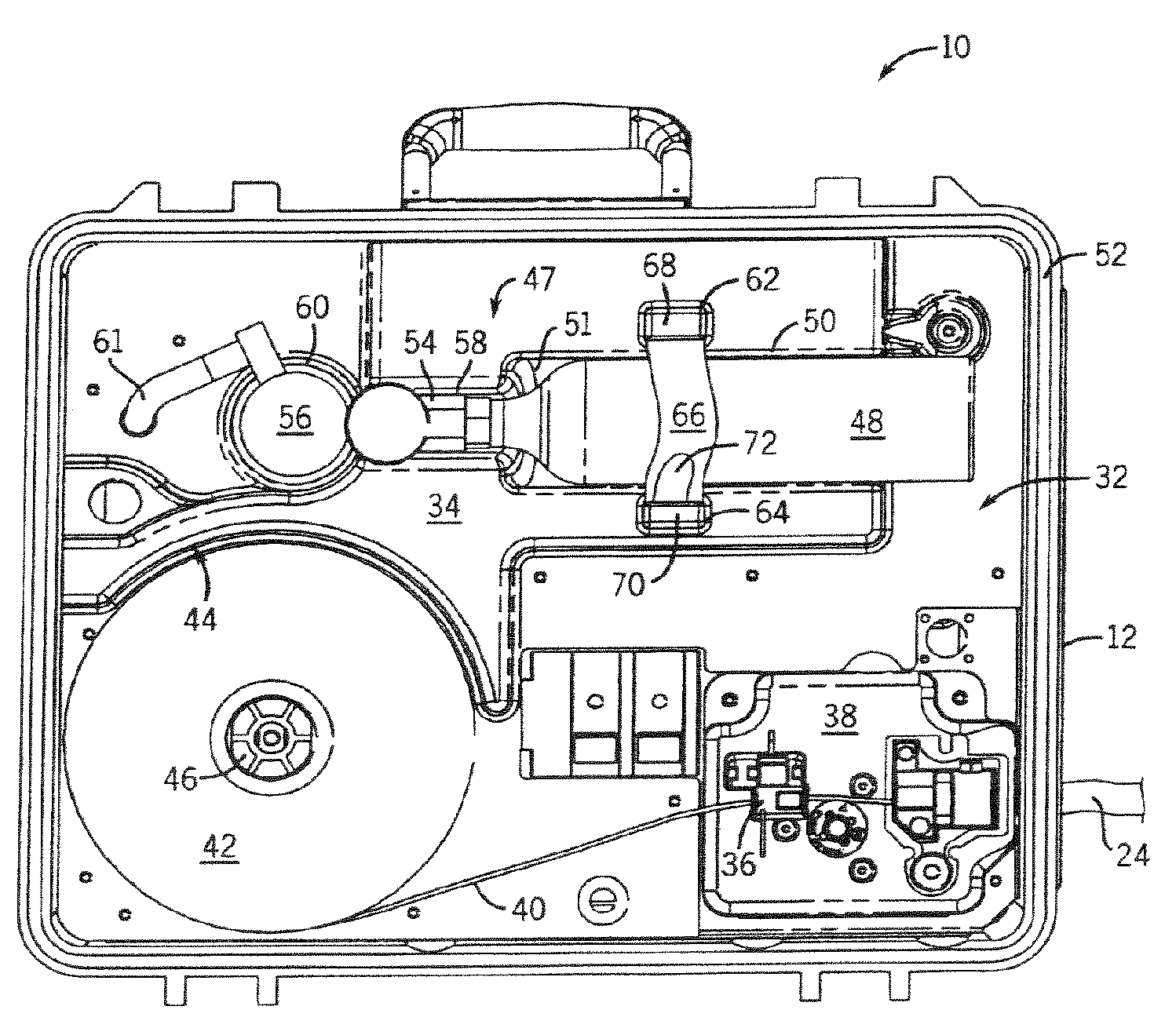

Multi-function integrated portable power and utility apparatus

InactiveUS20050151374A1High maintenance costMinimal start-up loadingMachines/enginesMechanical energy handlingElectricityPortable power

An integrated multi-function, portable power and utility apparatus comprises a single prime mover means having a single engine means having at least two opposite extending rotary output means. An electric generator means is directly connected to one of the two rotary output means, and has a plurality of electric output means. A fluid pumping means is directly connected to the other rotary output means. The fluid pumping means is preferably a rotary screw-type air compressor.

Owner:CARTER GARY SR

Gas system for wire feeding devices

ActiveUS20050252899A1Improve portabilityEfficiently and conveniently transportable by a single personElectrode supporting devicesWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A wire feeder and gas system for use therewith is shown. The gas system of the wire feeder includes a canister that is constructed to contain a shielding gas therein and is connectable to the wire feeder. The canister is supported by the wire feeder when it is connected thereto such that the wire feeder can be efficiently and conveniently transported from one location to another with the source of shielding gas securely connected thereto.

Owner:ILLINOIS TOOL WORKS INC

Semi-automatic brazing device

A semi-automatic brazing apparatus having a brazing wire feeding apparatus containing a brazing wire feed mechanism a controller, and a user input device. The brazing wire from a brazing wire source is continuously drawn from the source through the apparatus via the feeding mechanism and is directed towards a brazing gun for a semi-automatic brazing operation.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com