Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

519results about "Welding protection means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

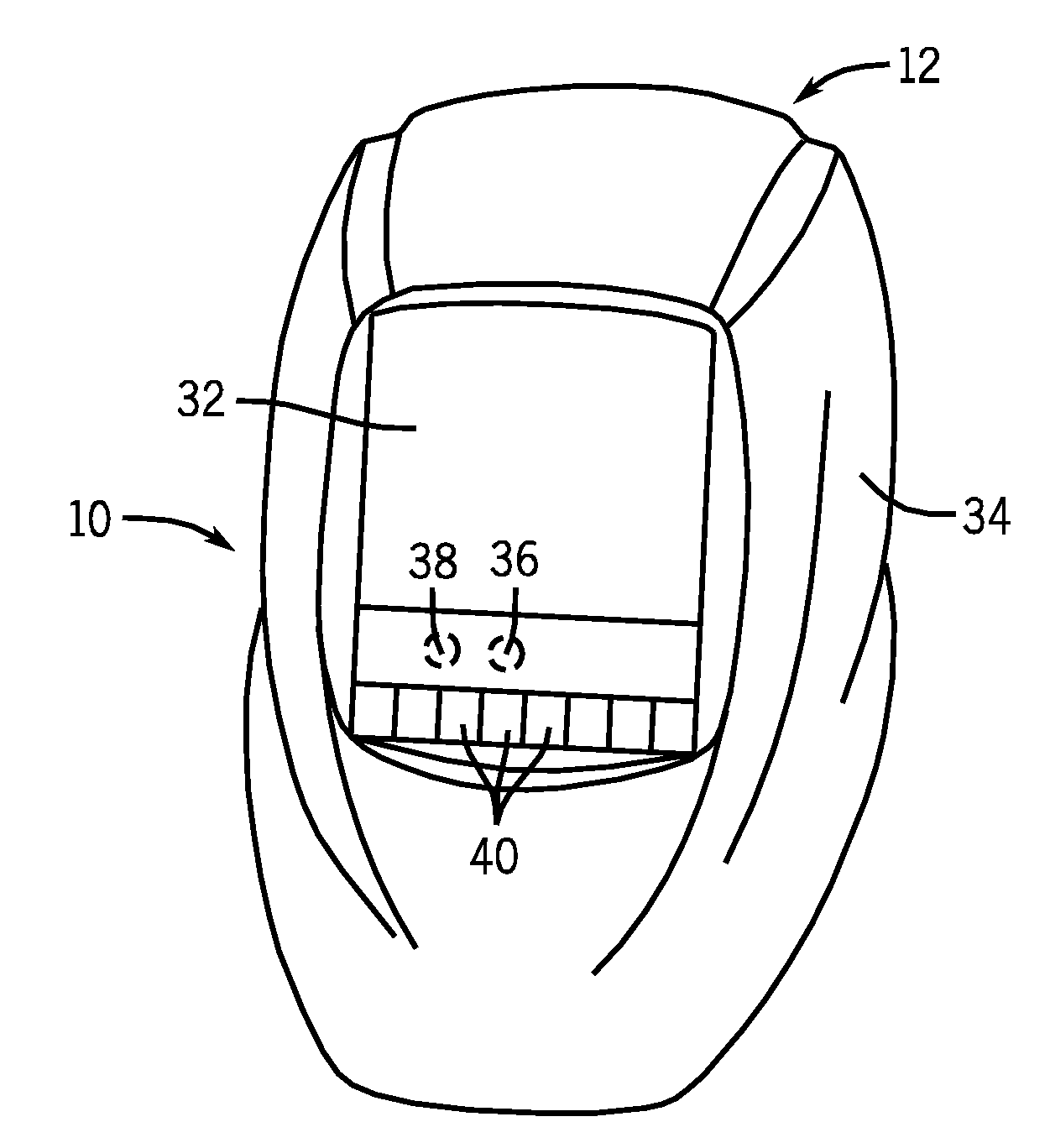

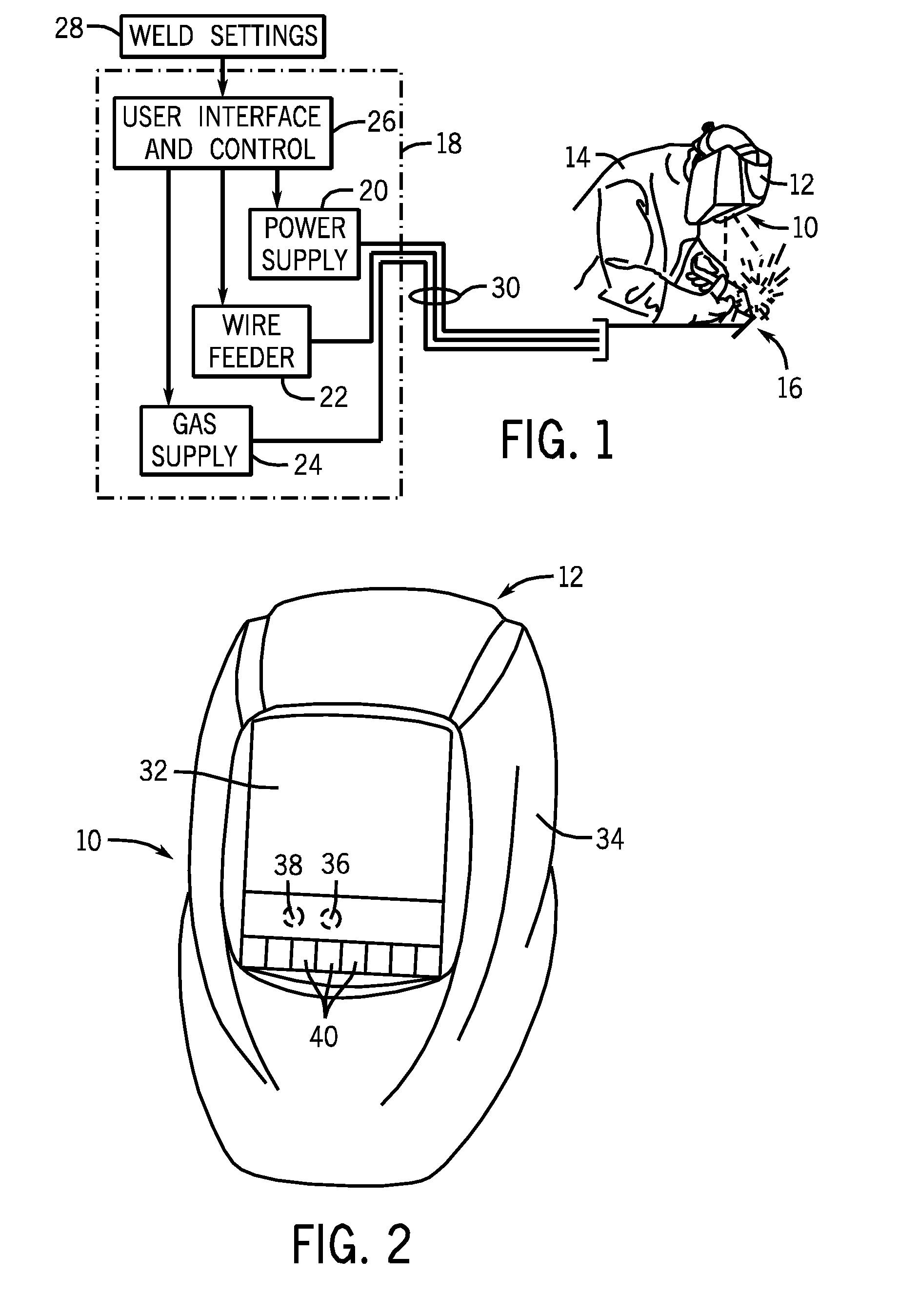

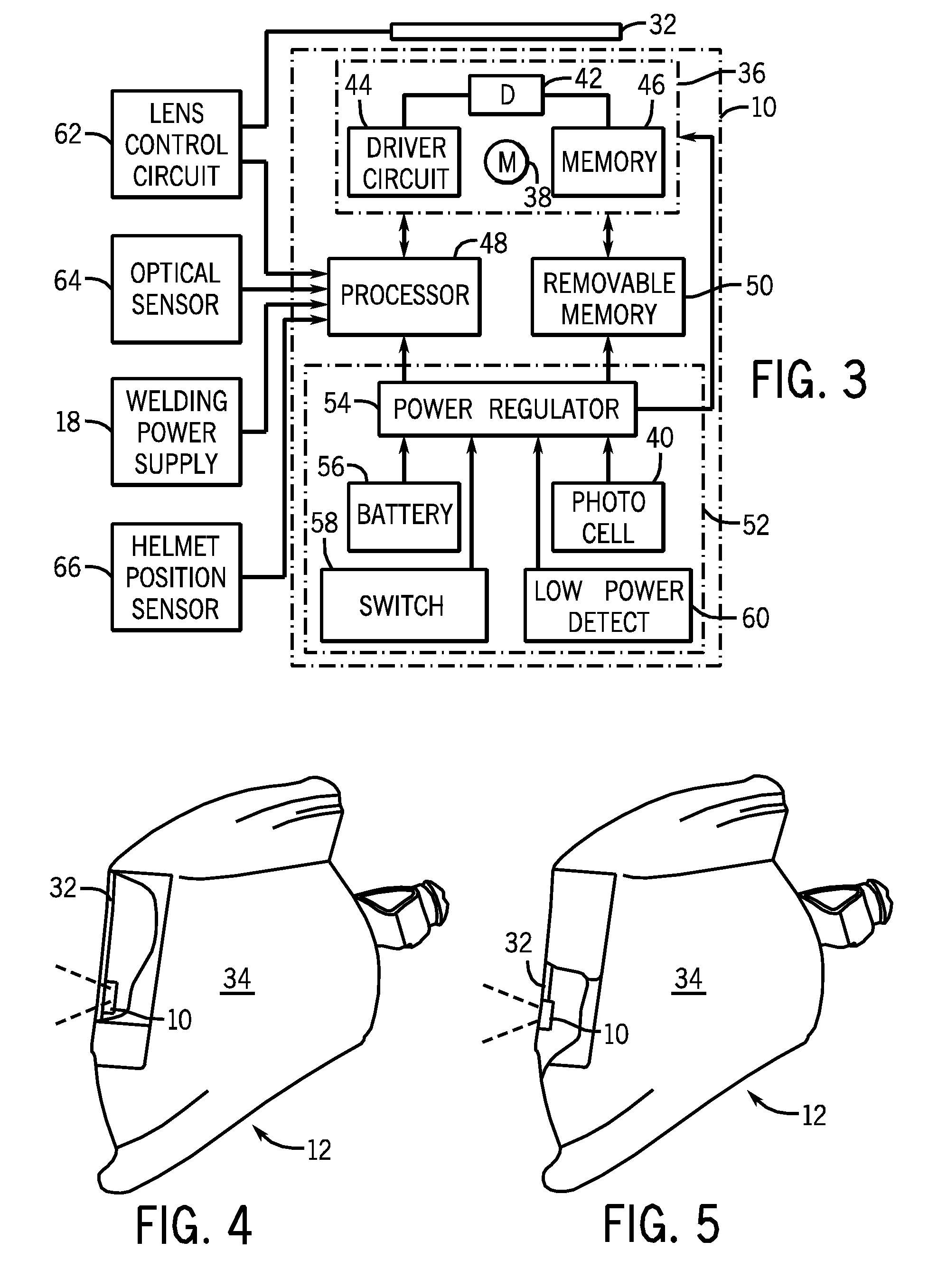

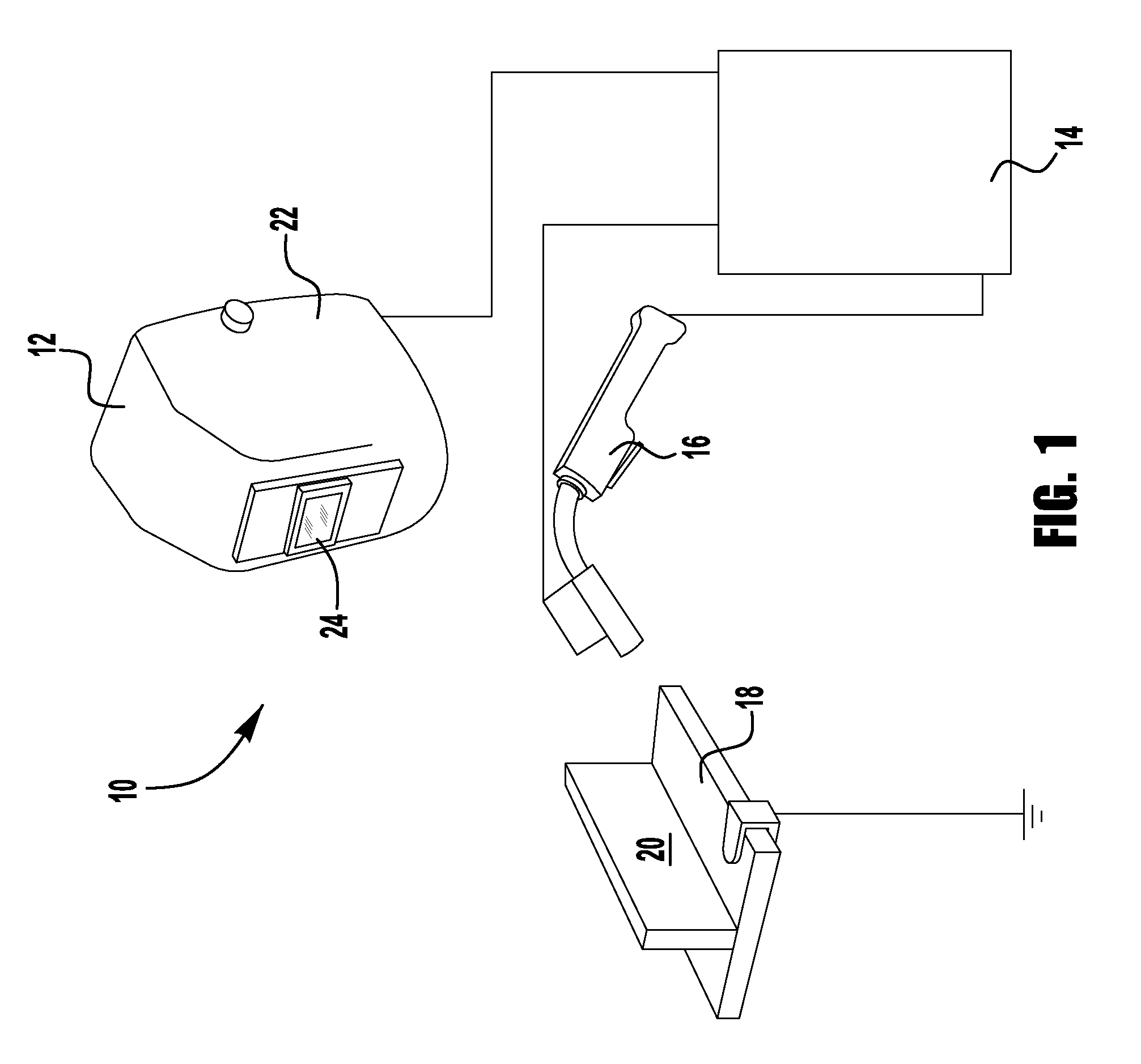

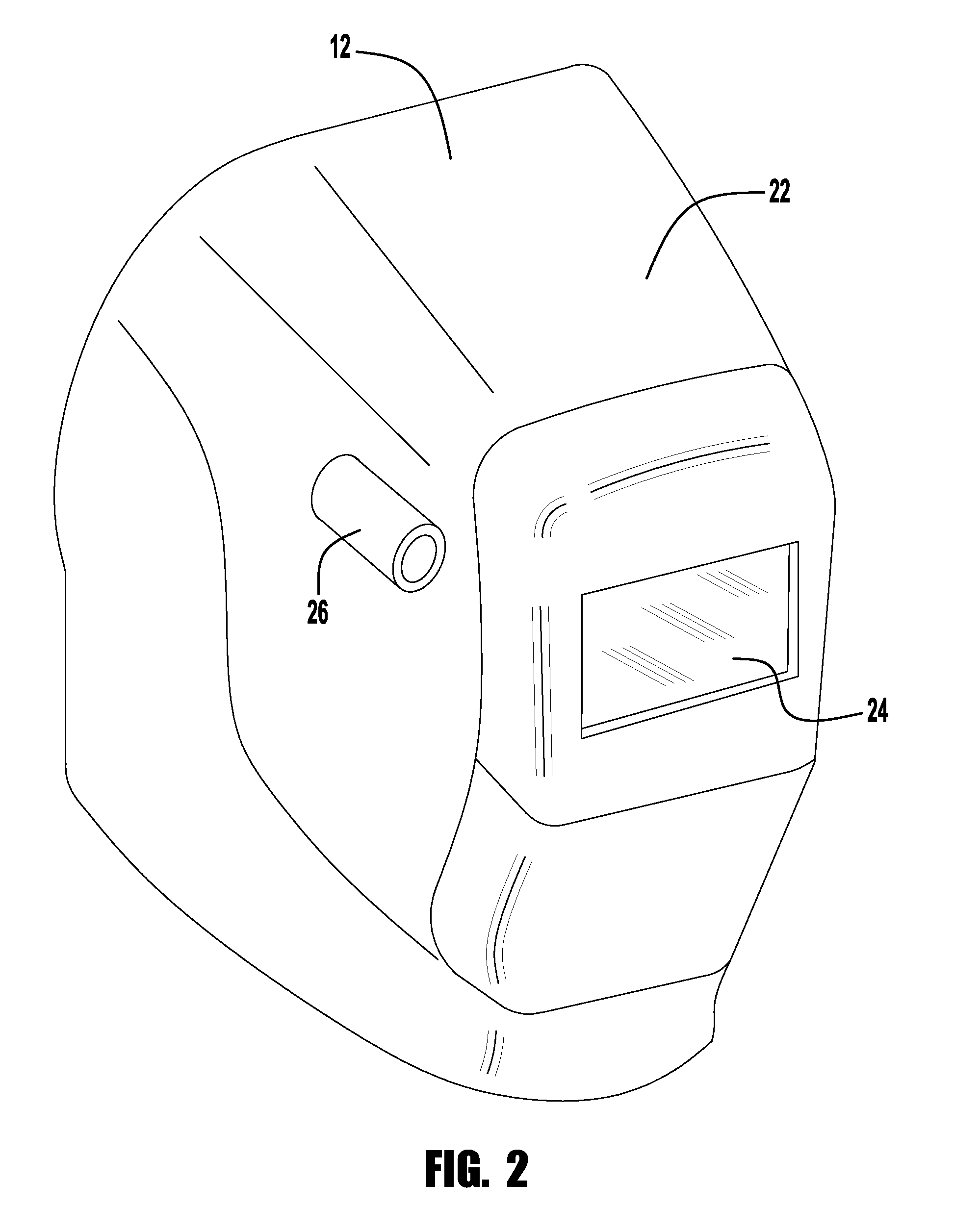

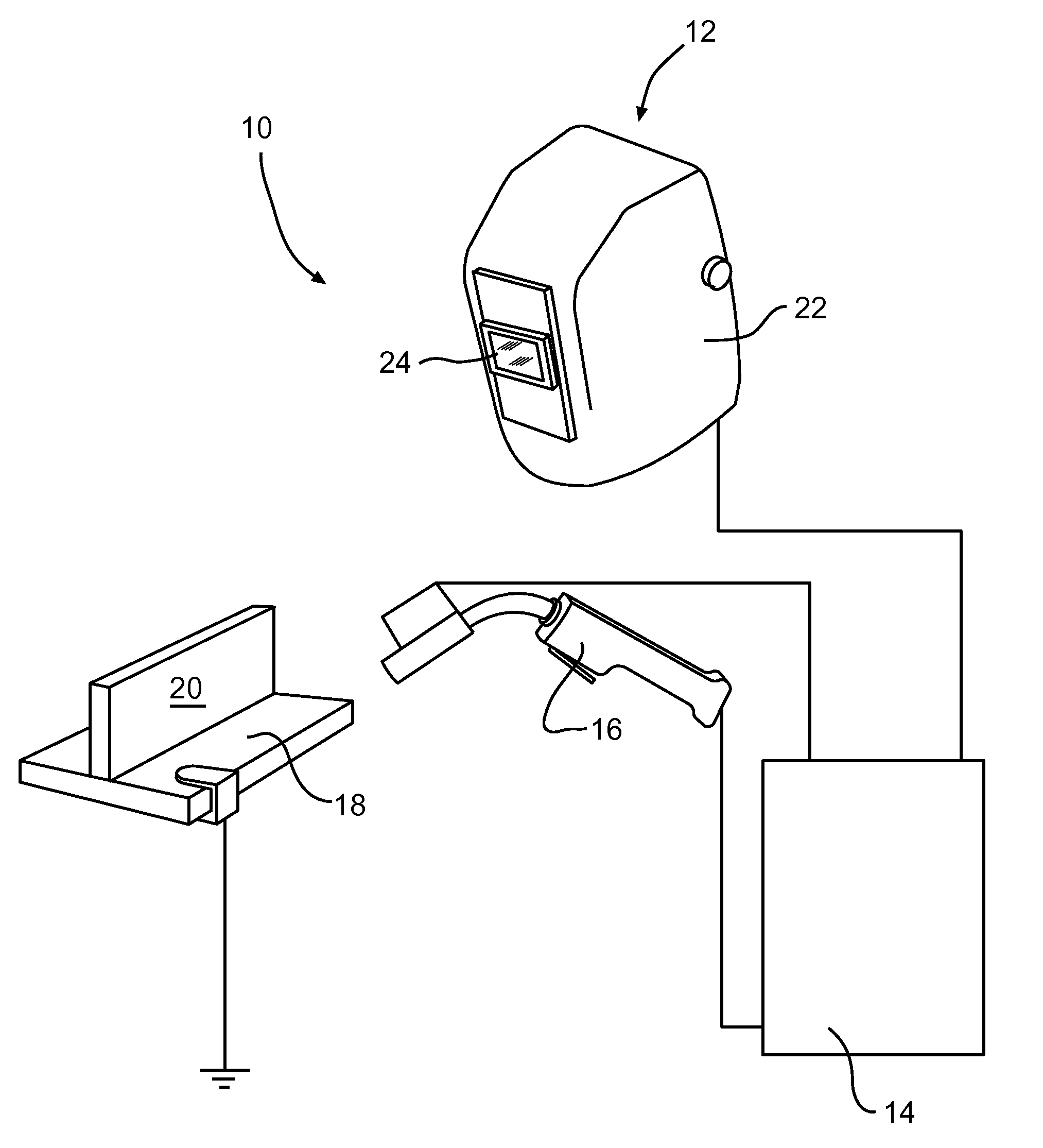

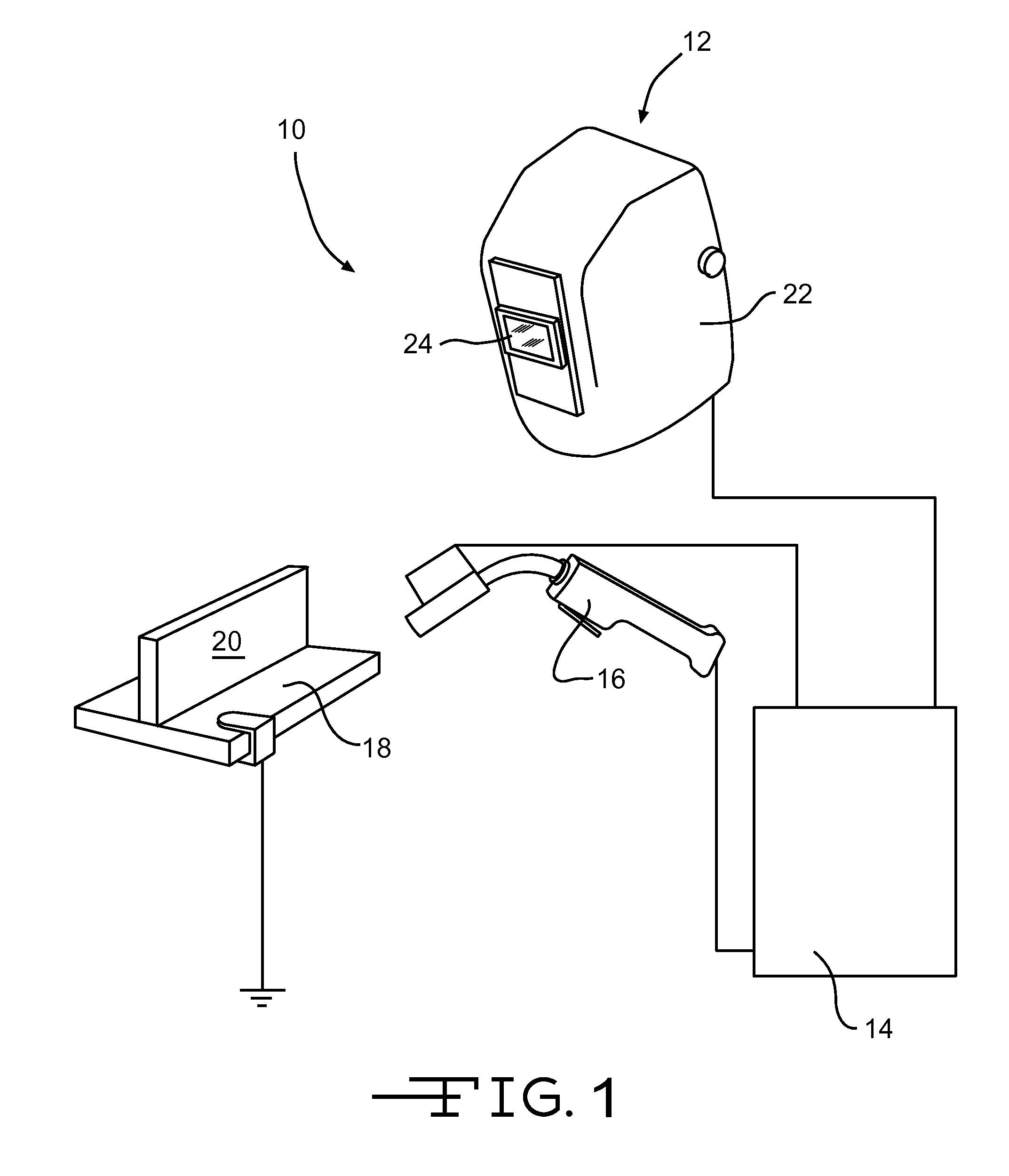

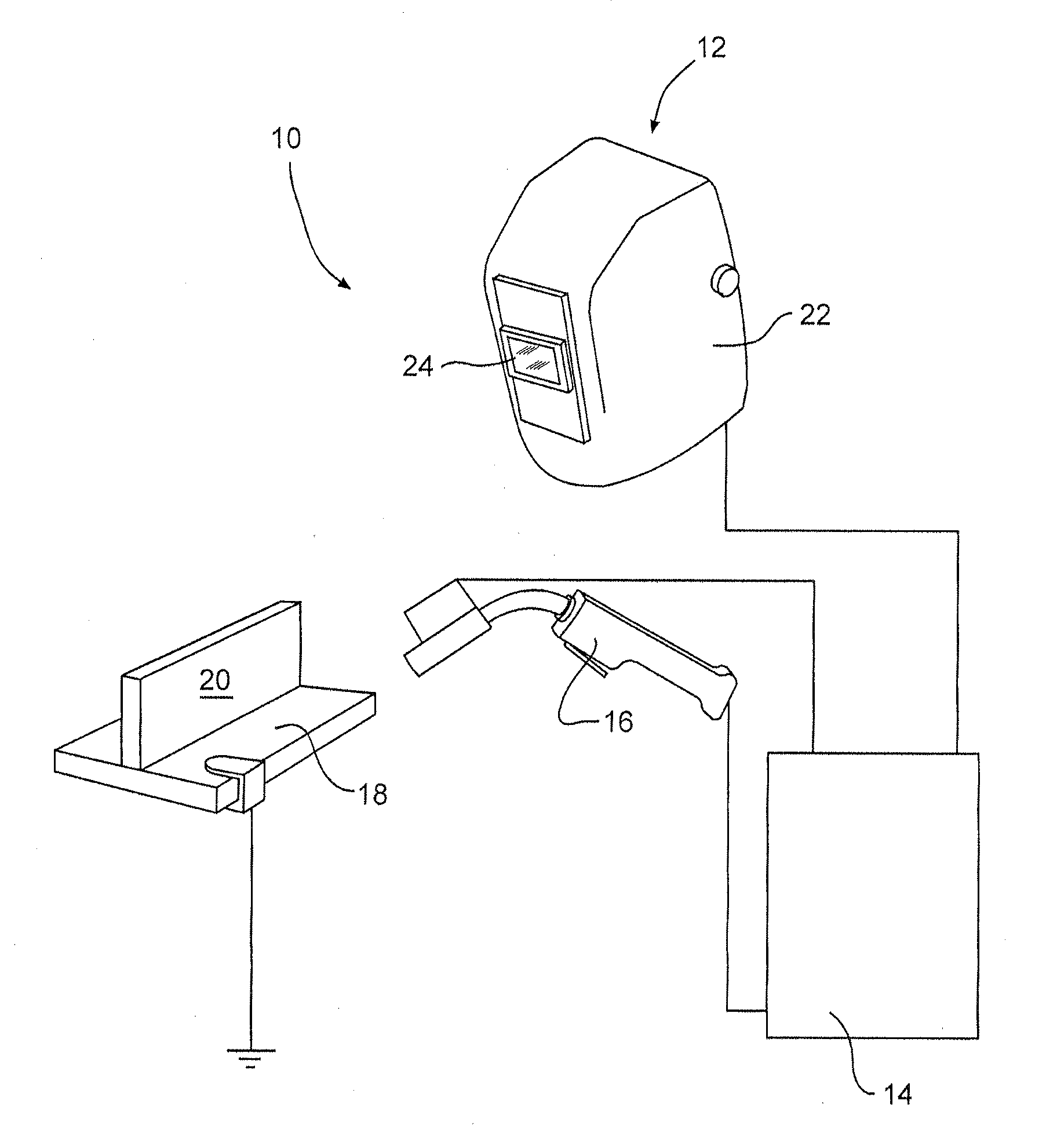

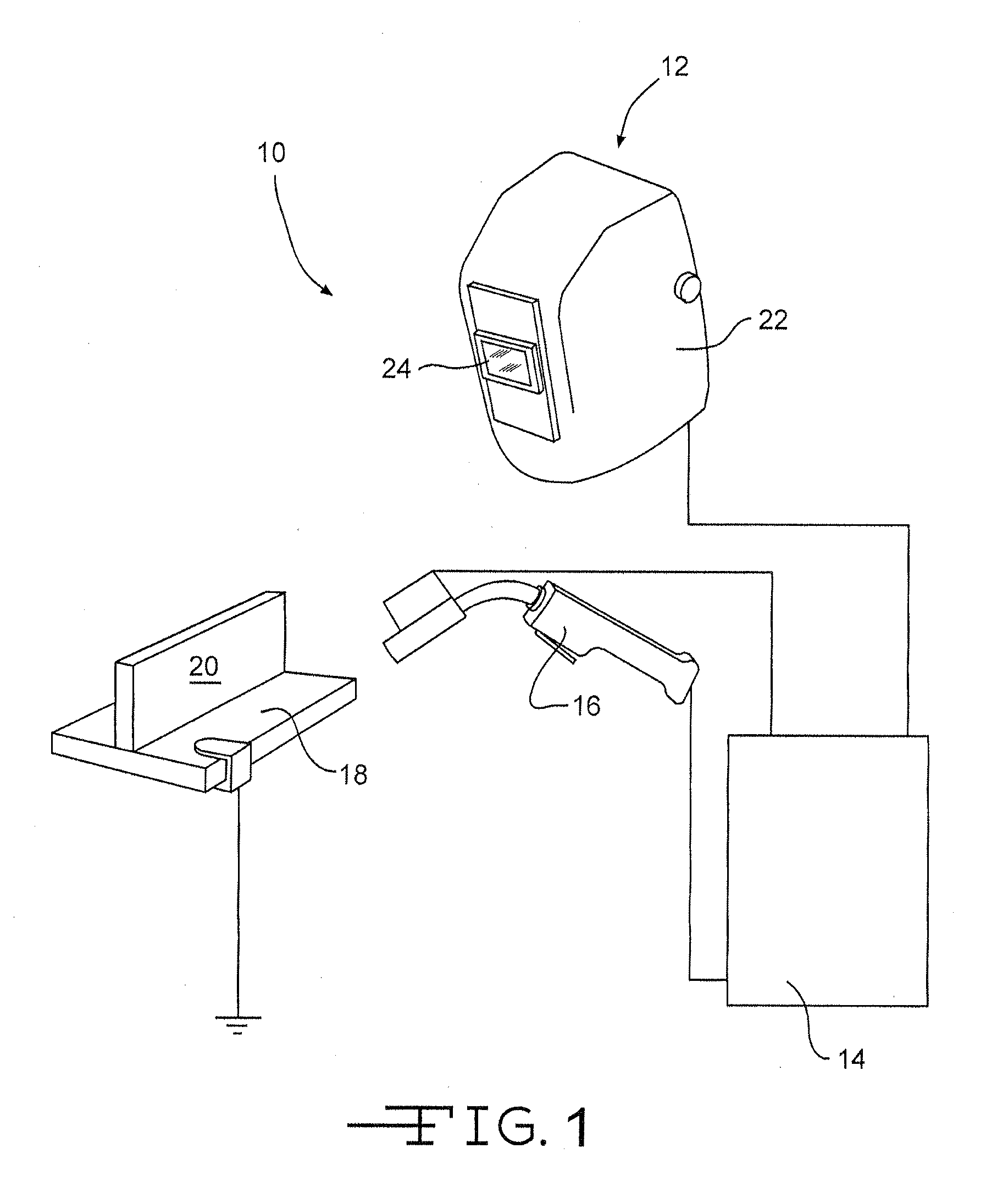

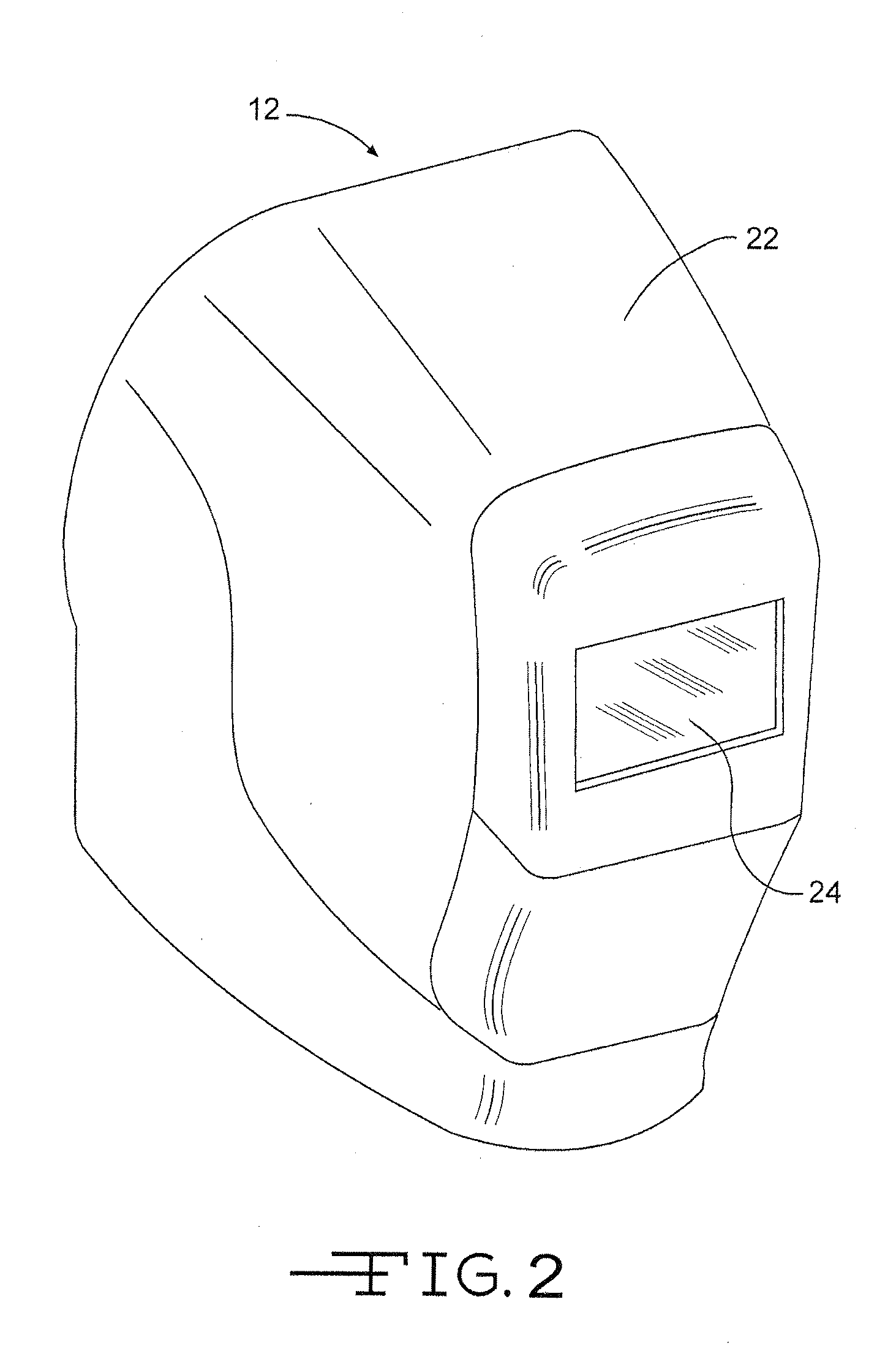

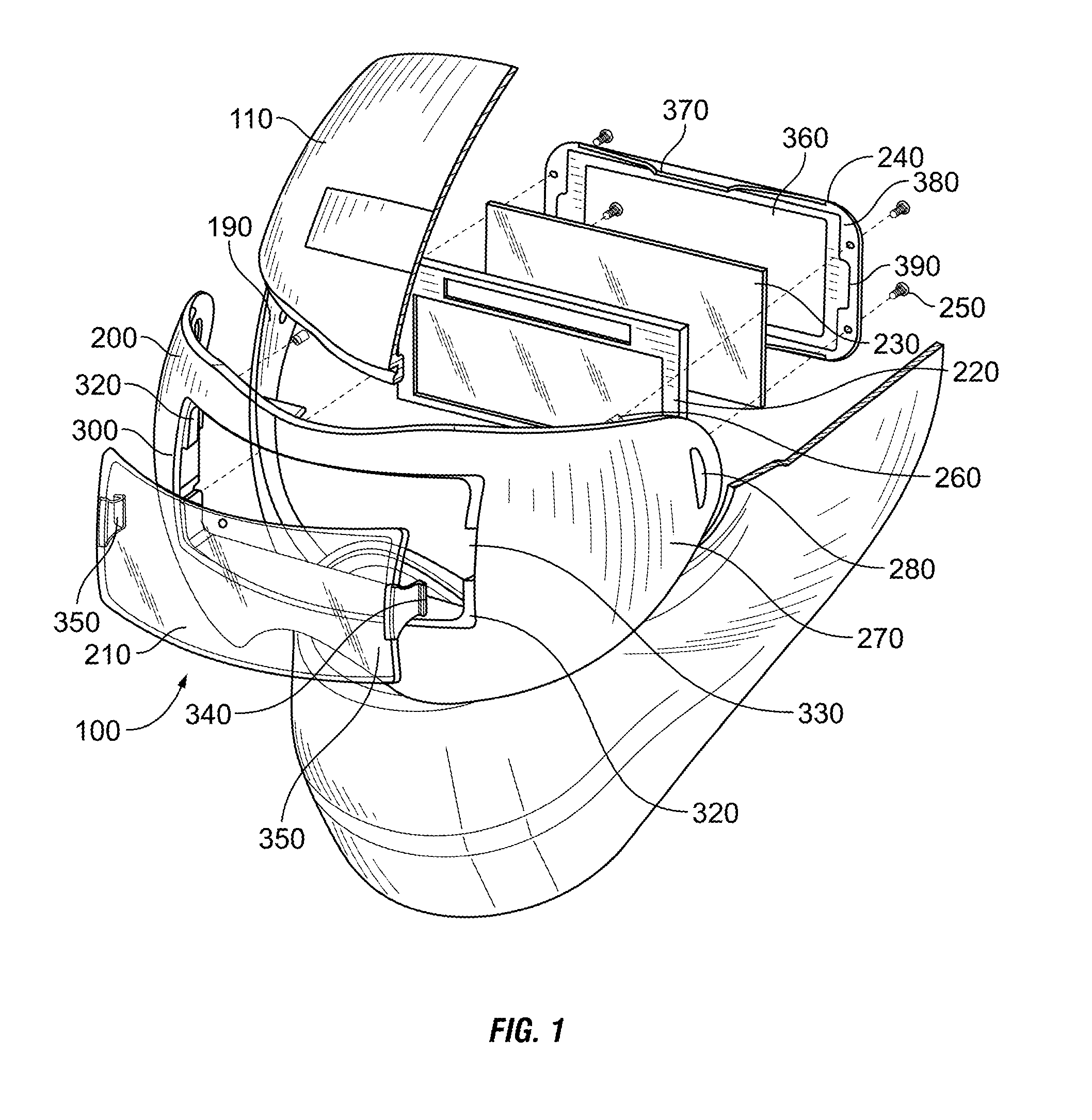

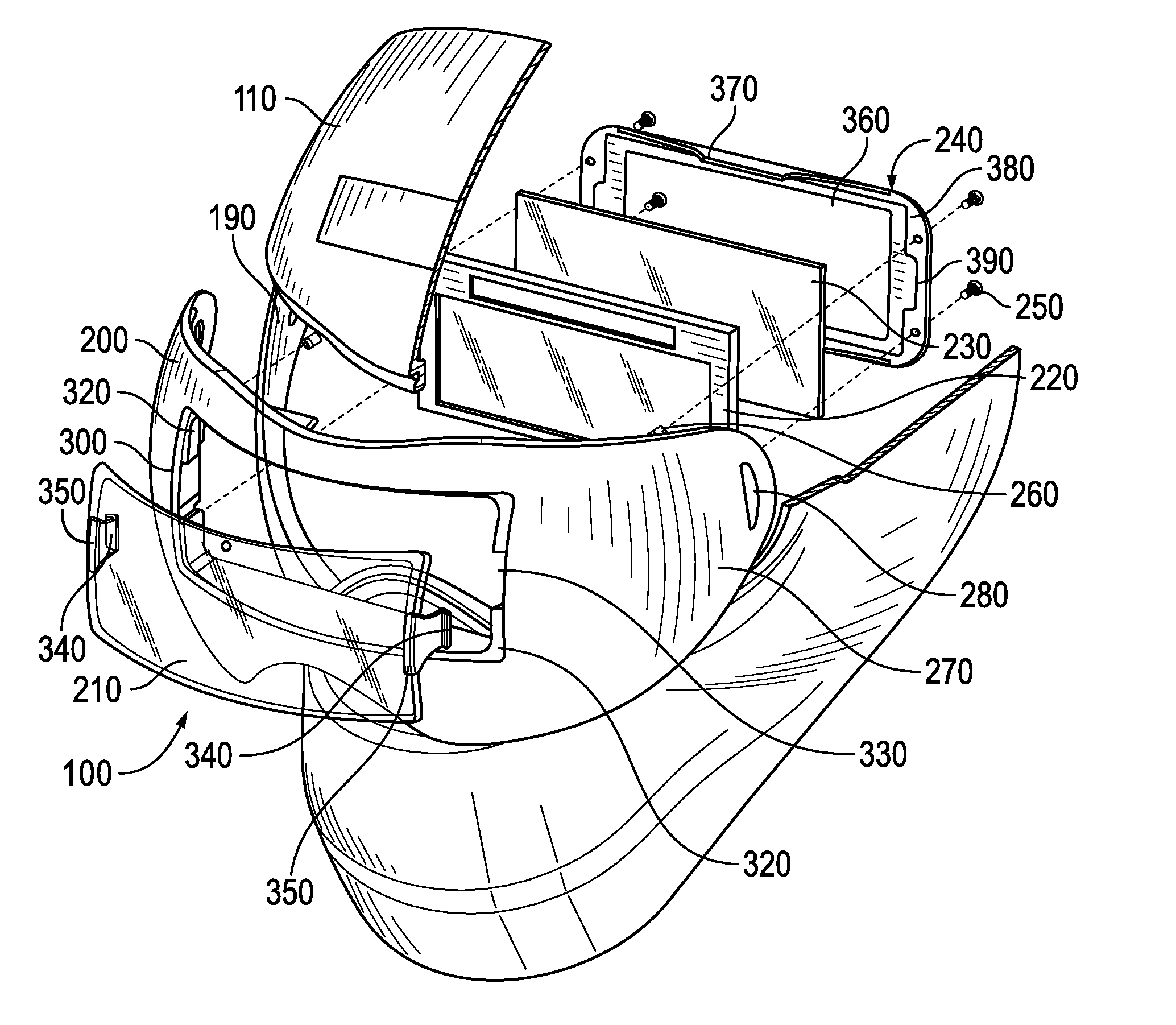

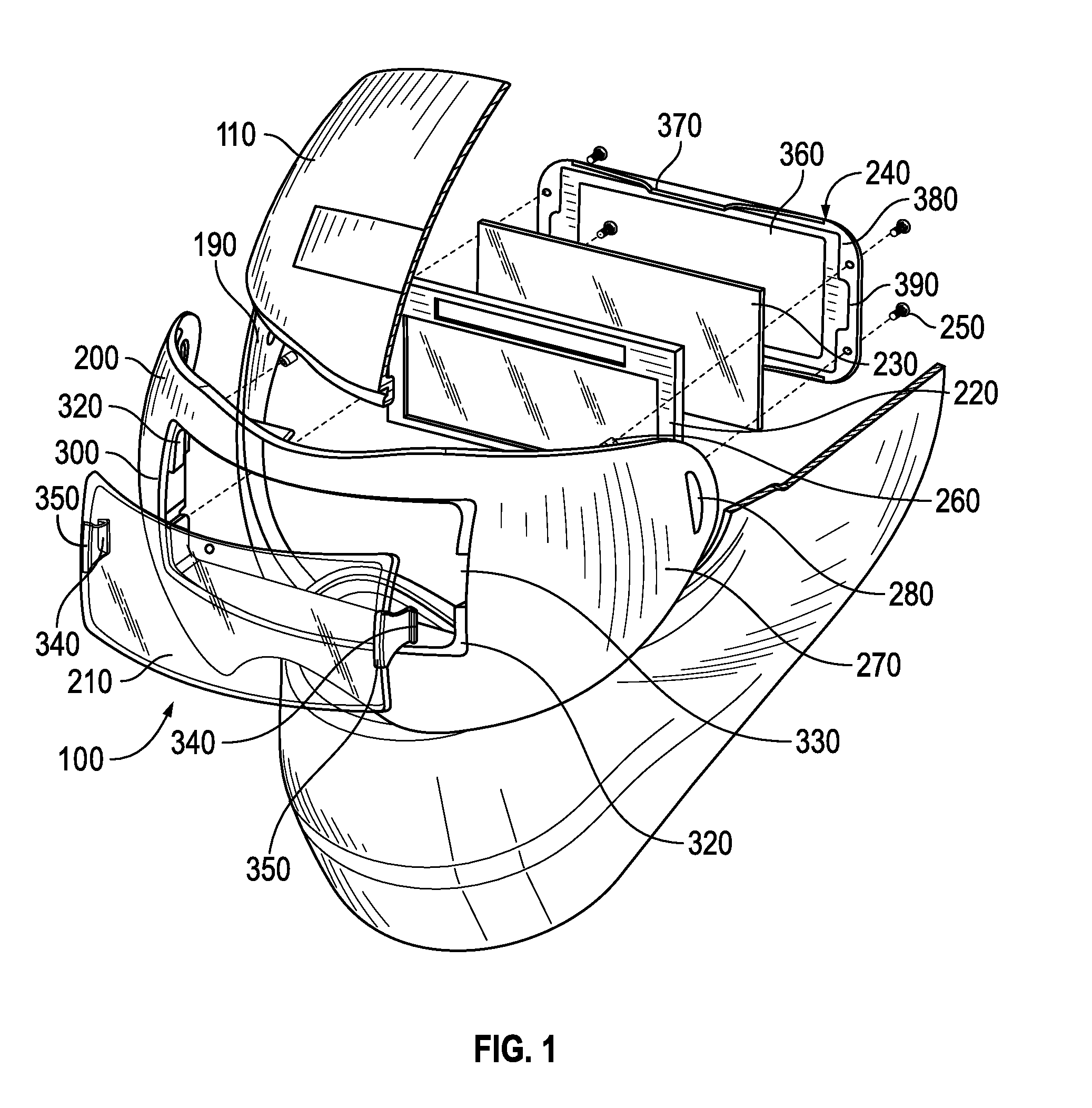

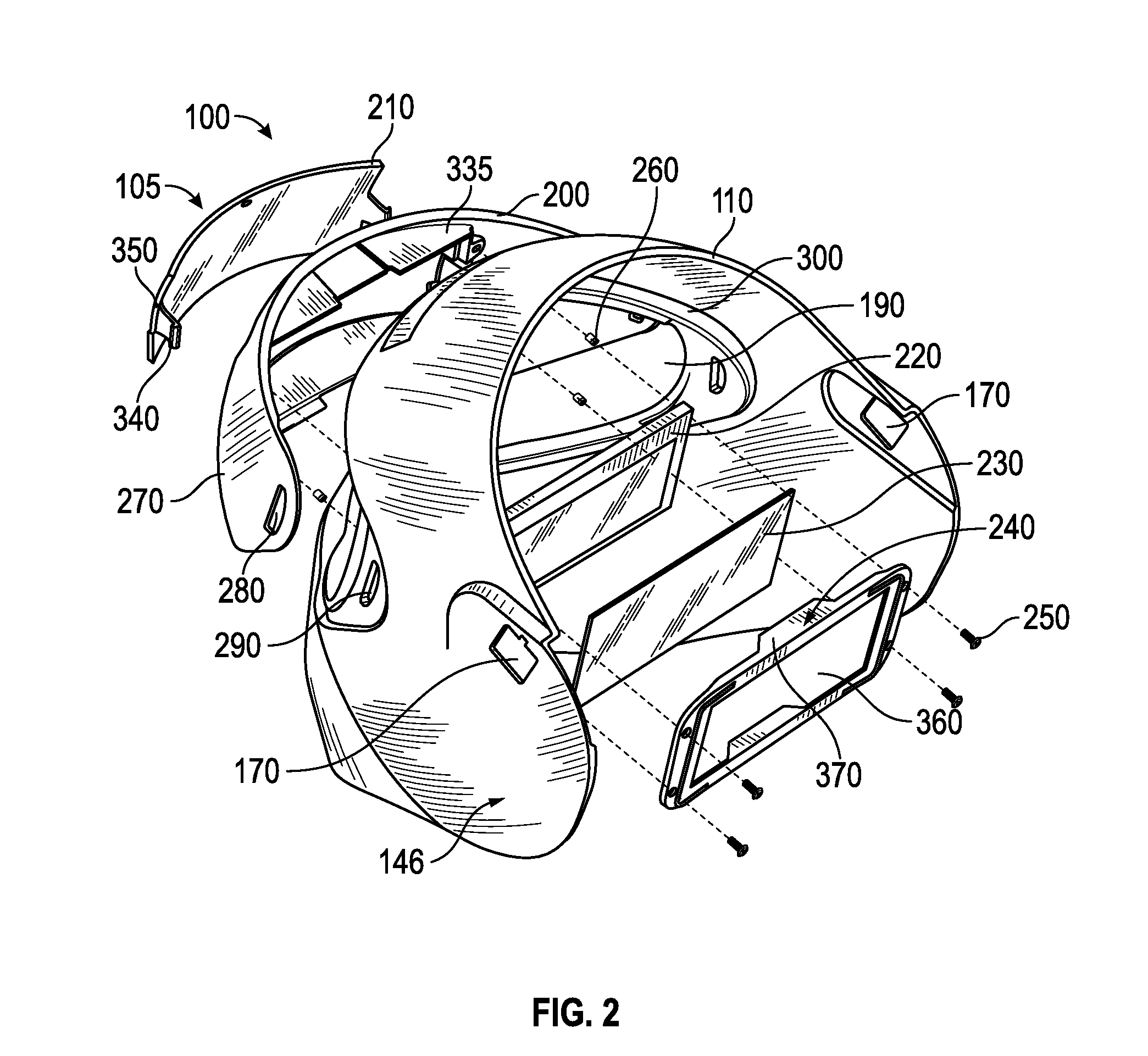

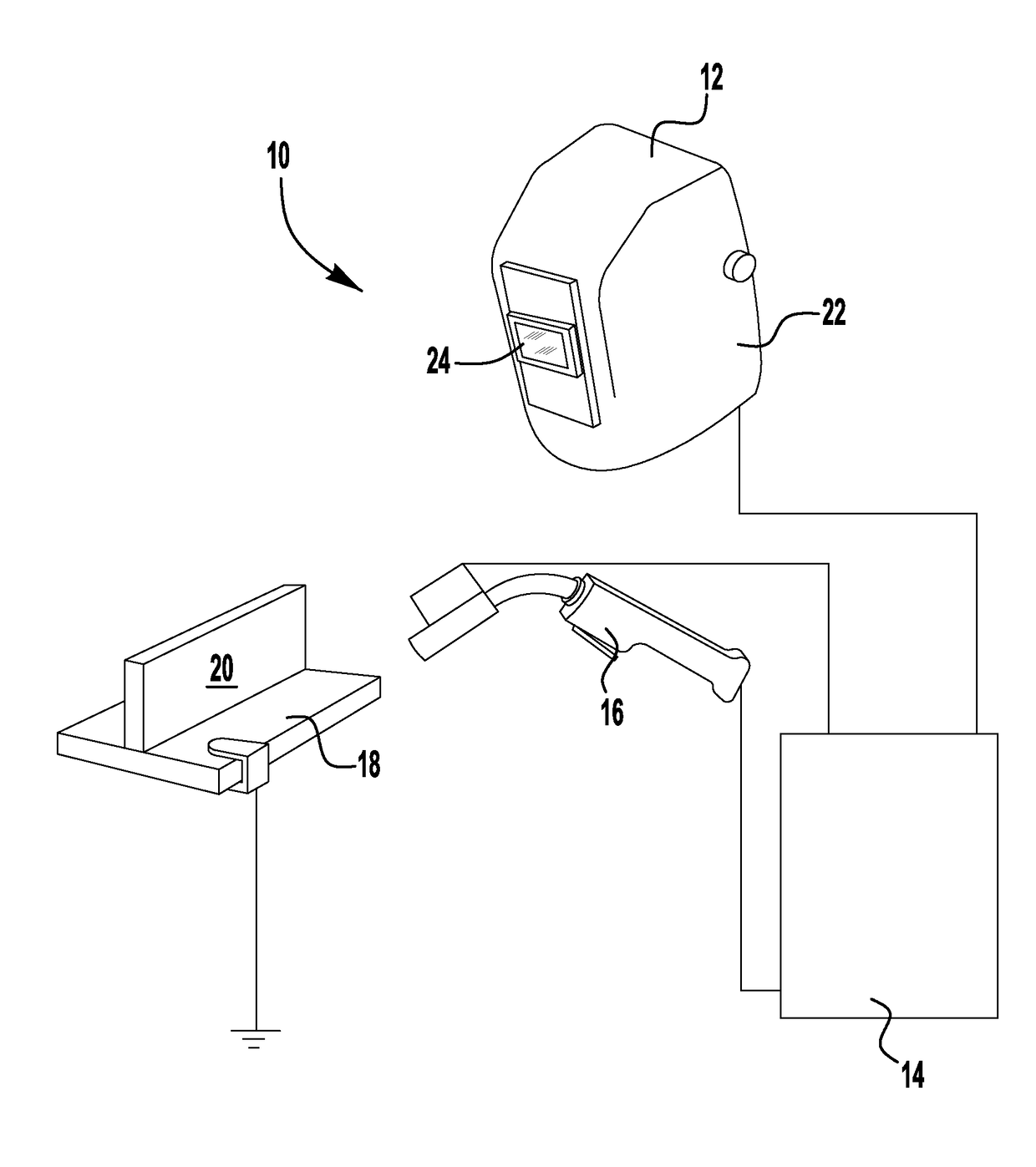

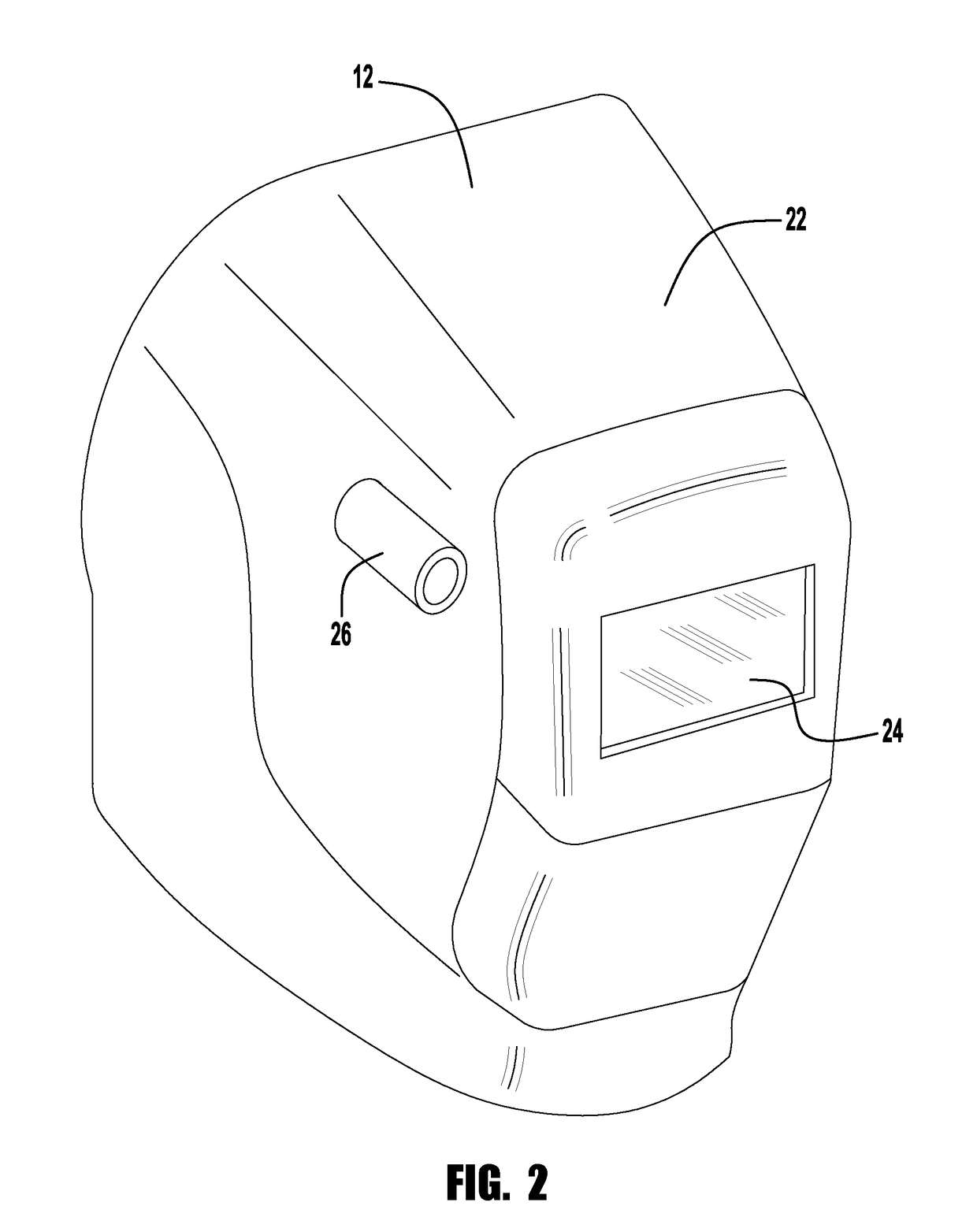

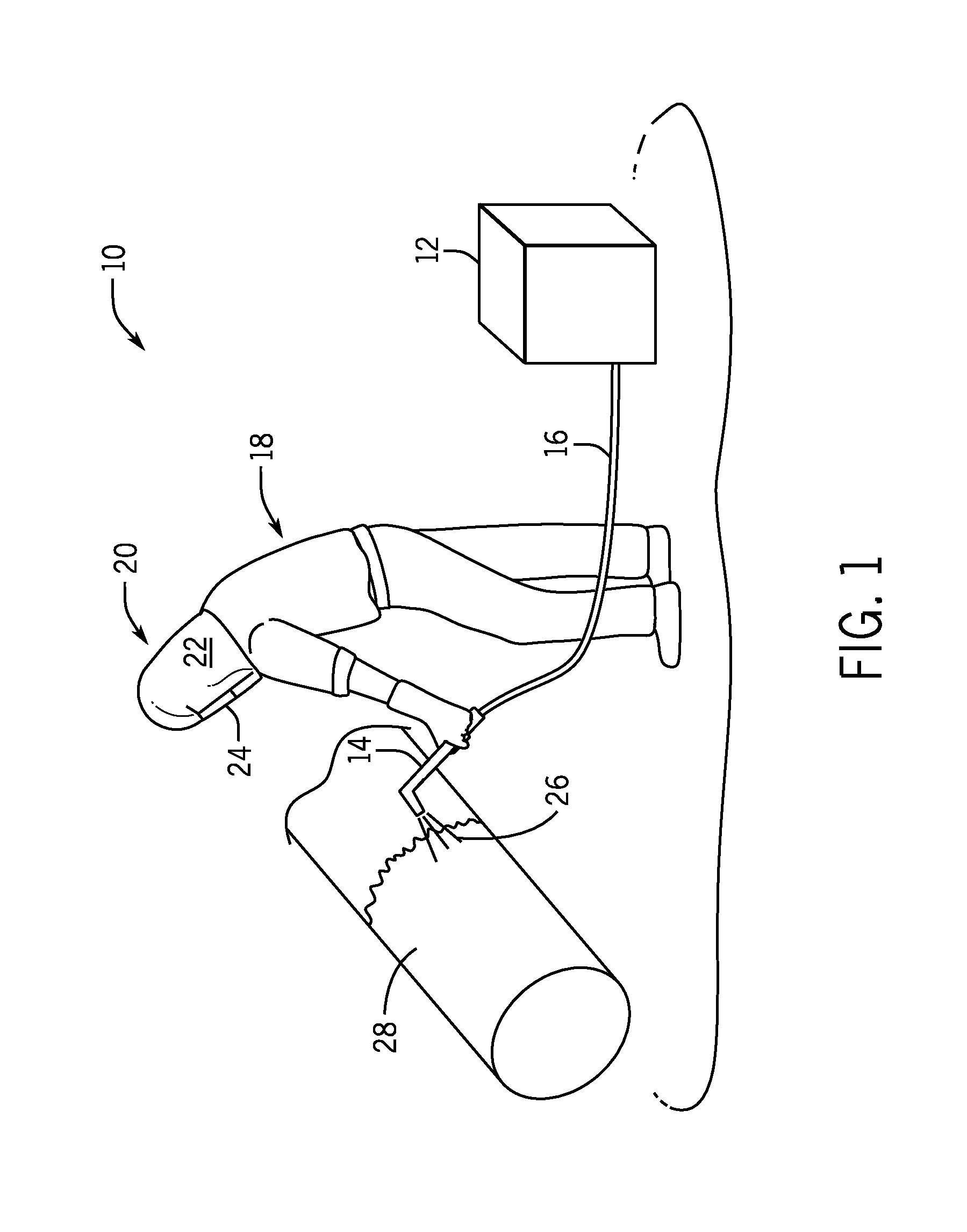

Video recording device for a welder's helmet

ActiveUS20090231423A1Television system detailsColor television signals processingComputer hardwareVideo record

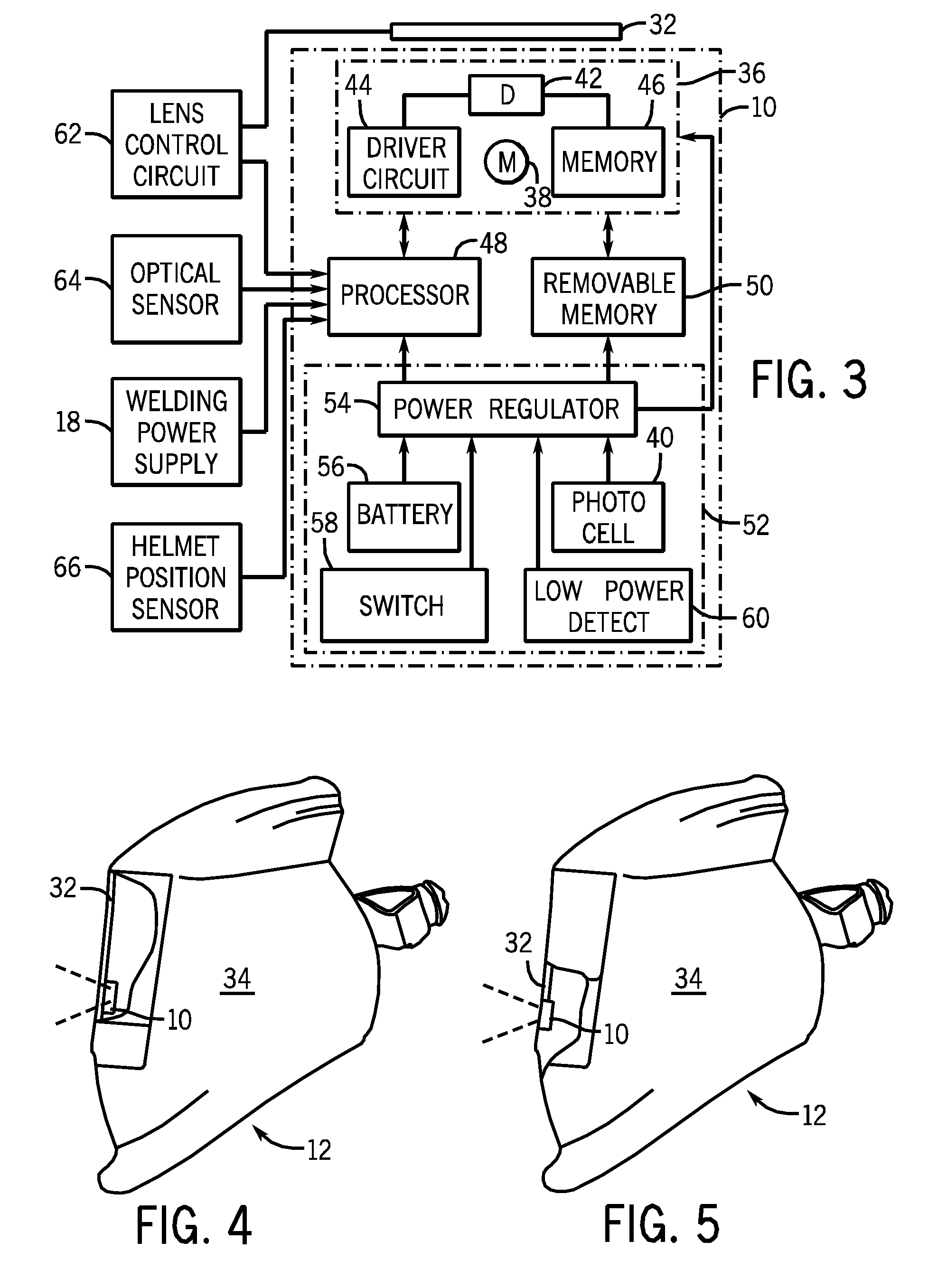

A weld recording system mounted in or on a welding helmet is provided. The weld recording system includes a camera assembly unit, a power supply unit, a processor, and removable memory. The weld recording system interfaces with lens control circuitry, an optical sensor, a welding power supply, and a helmet position sensor. Logic is provided for the triggering and recording of video and audio signals, which are eventually stored in a file for future reference. Transmission of signals from one or more welders to a monitoring station for eventual display is presented. An image processing algorithm is provided to combine multiple images with varied exposure times into a visual image of the weld and its surroundings.

Owner:ILLINOIS TOOL WORKS INC

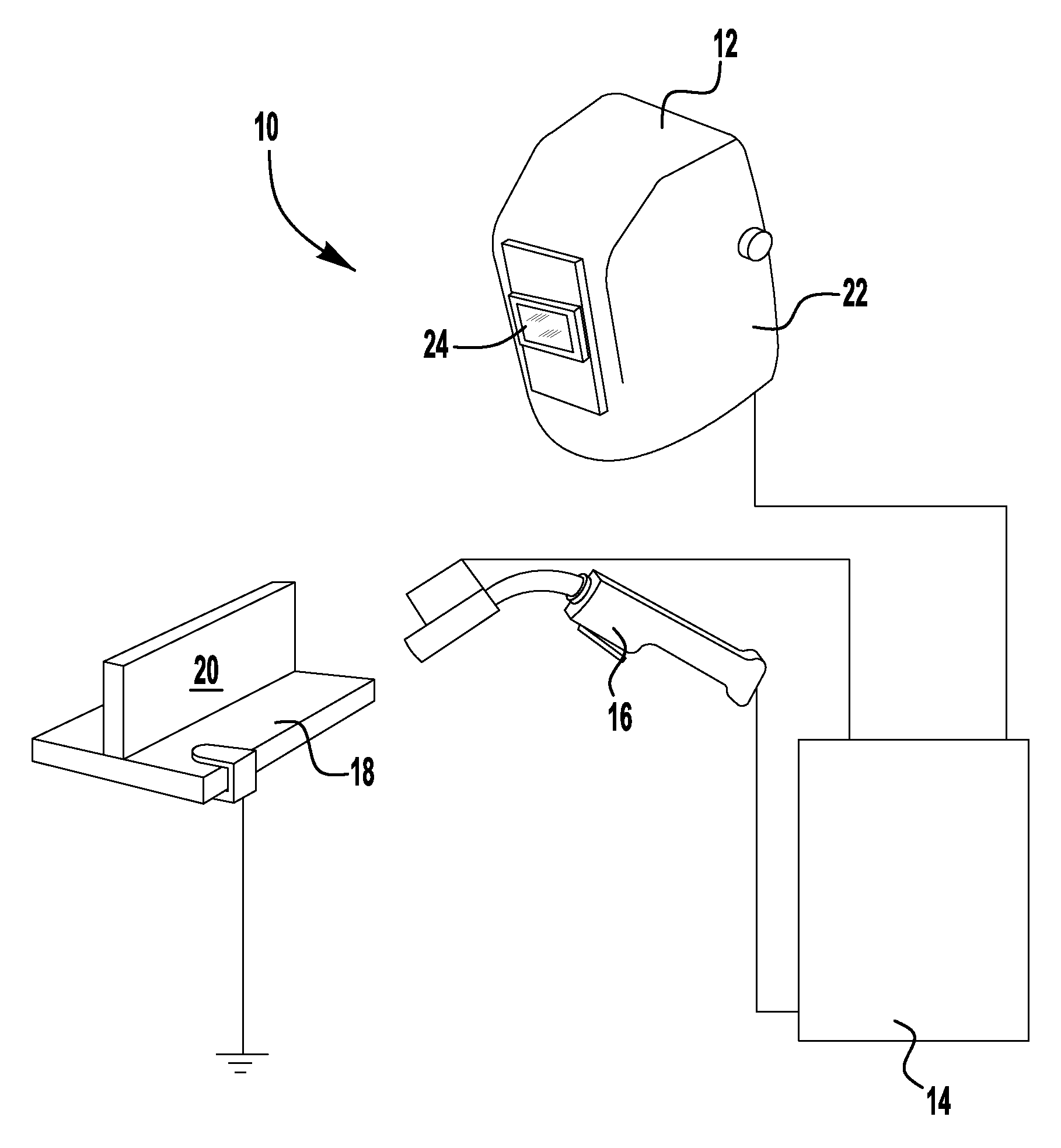

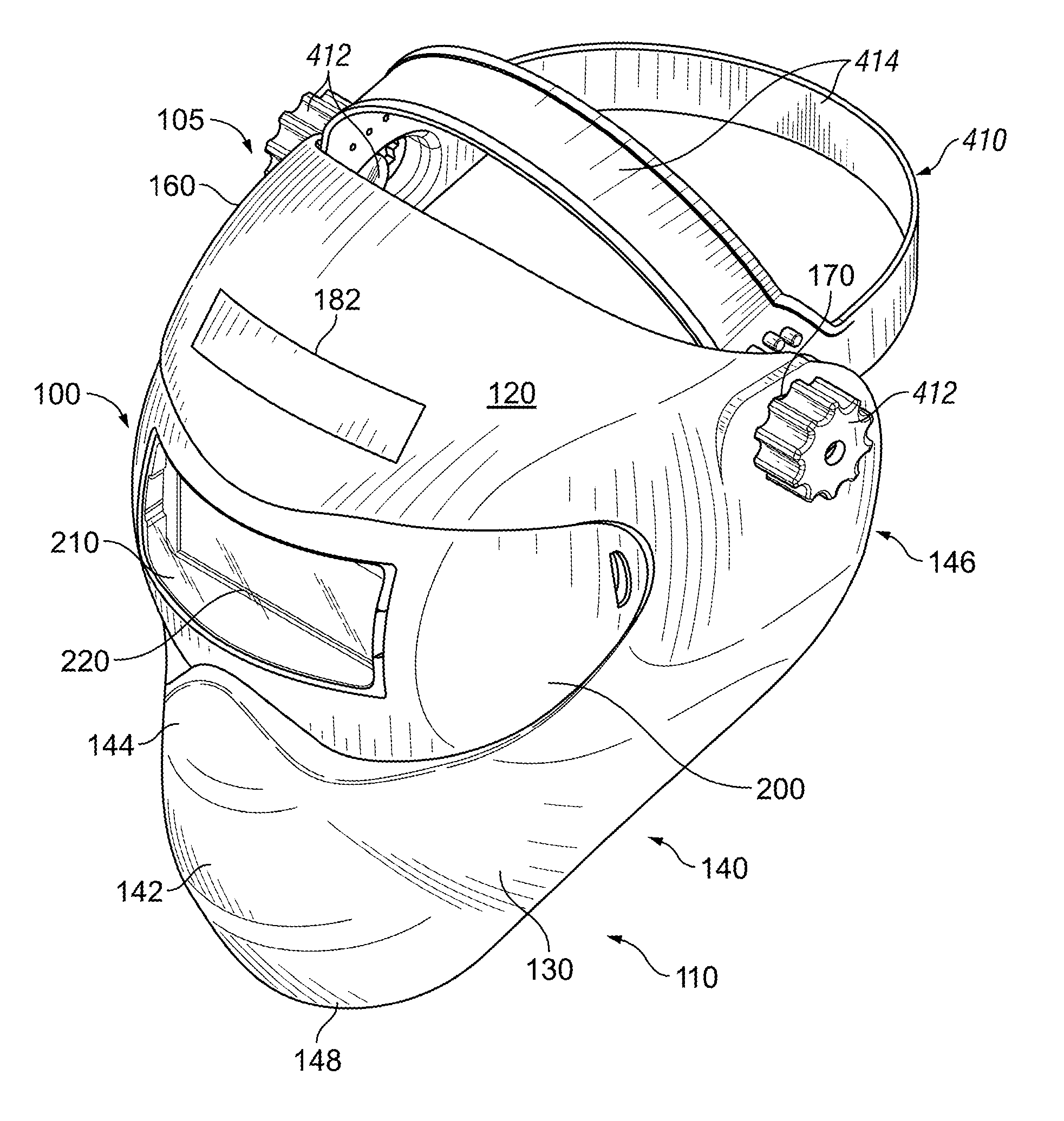

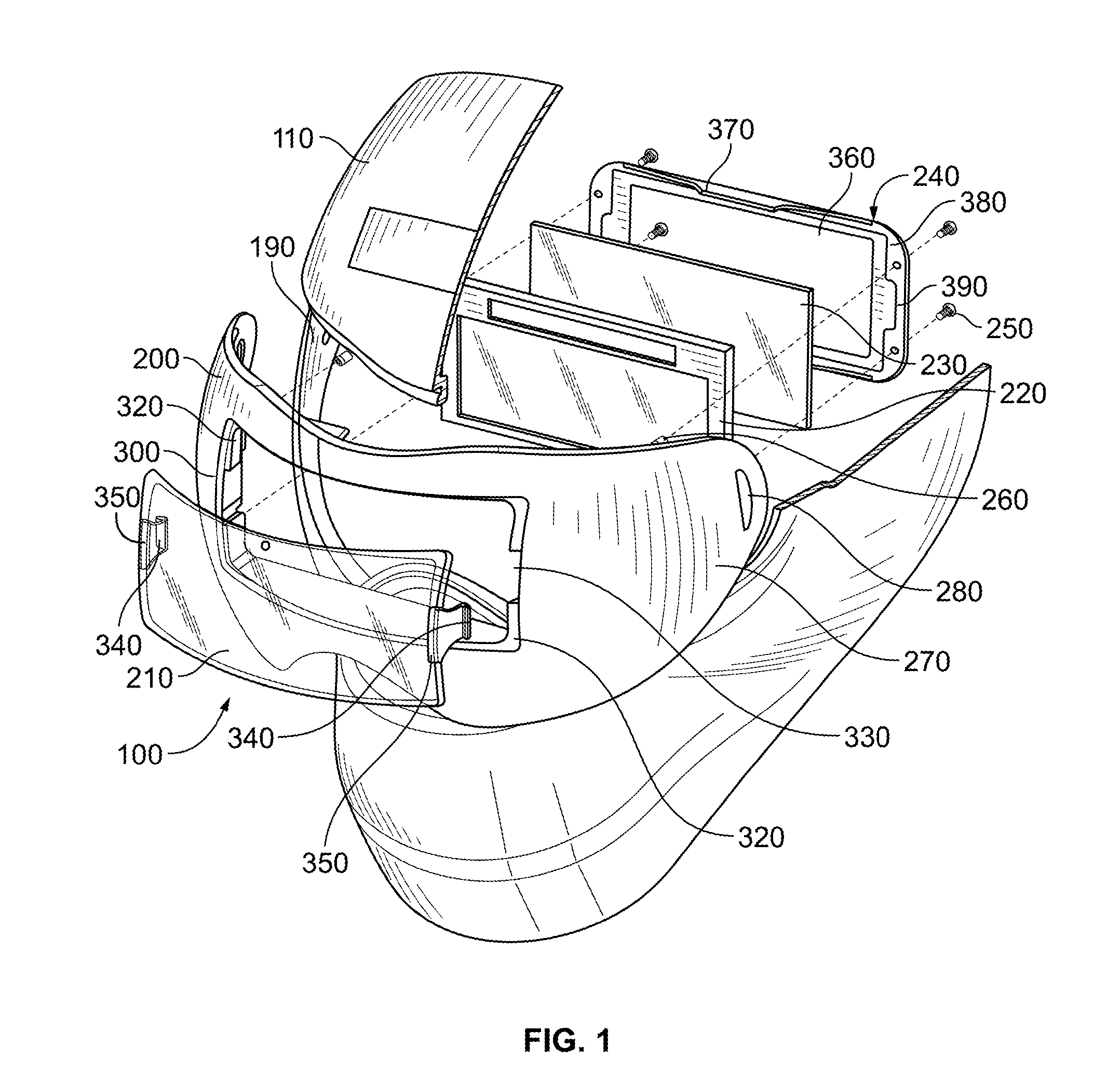

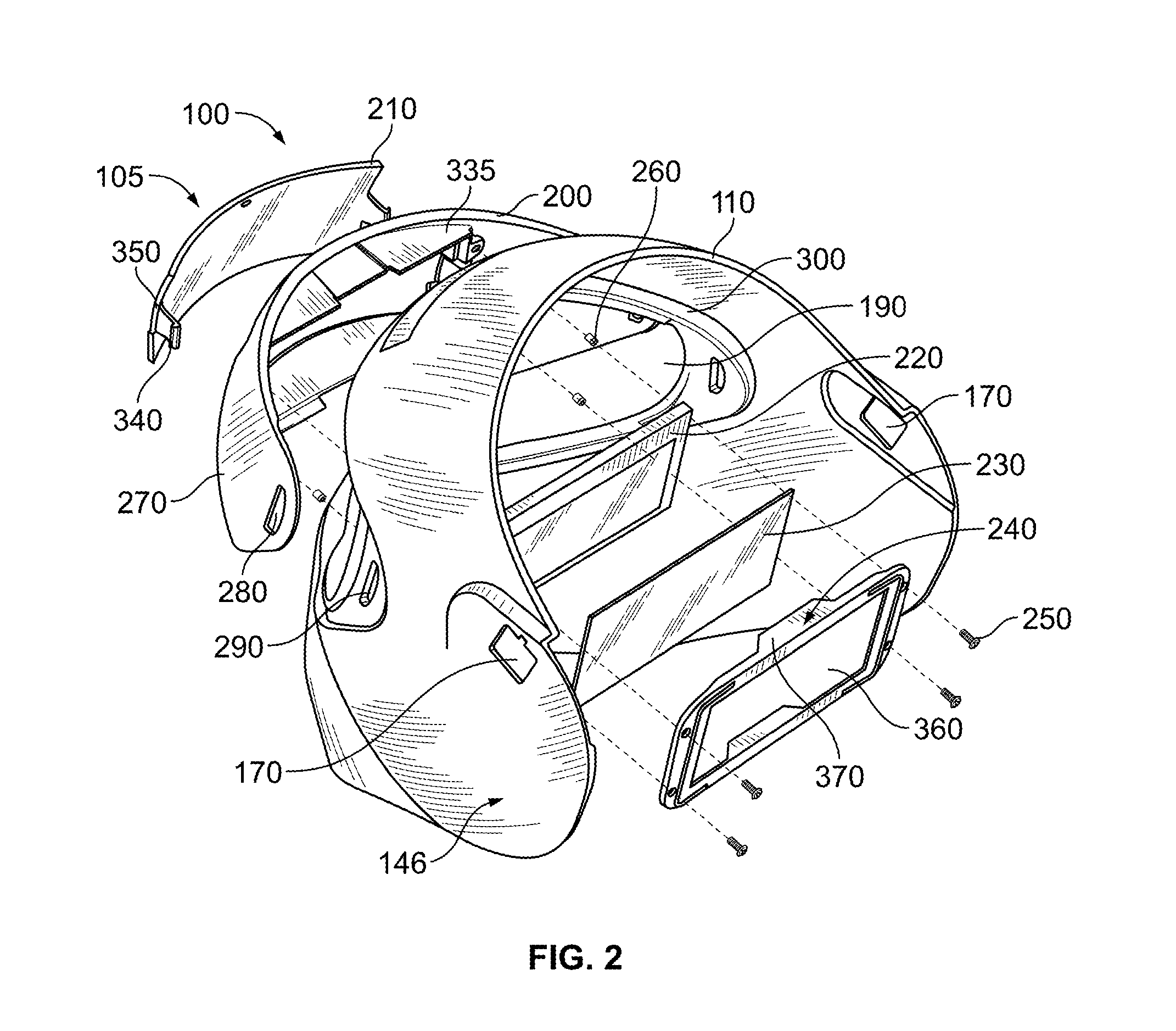

Welding helmet with heads up display

A welding system and welding helmet is provided, where the welding helmet is capable of providing an image representative of information from an associated welding operation where the image appears as a head-up display (HUD) in the welding helmet. The helmet displays the information at a focal point which coincides with a working distance of a welding operation so that a user need not change his / her focus during a welding operation.

Owner:LINCOLN GLOBAL INC

Video recording device for a welder's helmet

A weld recording system mounted in or on a welding helmet is provided. The weld recording system includes a camera assembly unit, a power supply unit, a processor, and removable memory. The weld recording system interfaces with lens control circuitry, an optical sensor, a welding power supply, and a helmet position sensor. Logic is provided for the triggering and recording of video and audio signals, which are eventually stored in a file for future reference. Transmission of signals from one or more welders to a monitoring station for eventual display is presented. An image processing algorithm is provided to combine multiple images with varied exposure times into a visual image of the weld and its surroundings.

Owner:ILLINOIS TOOL WORKS INC

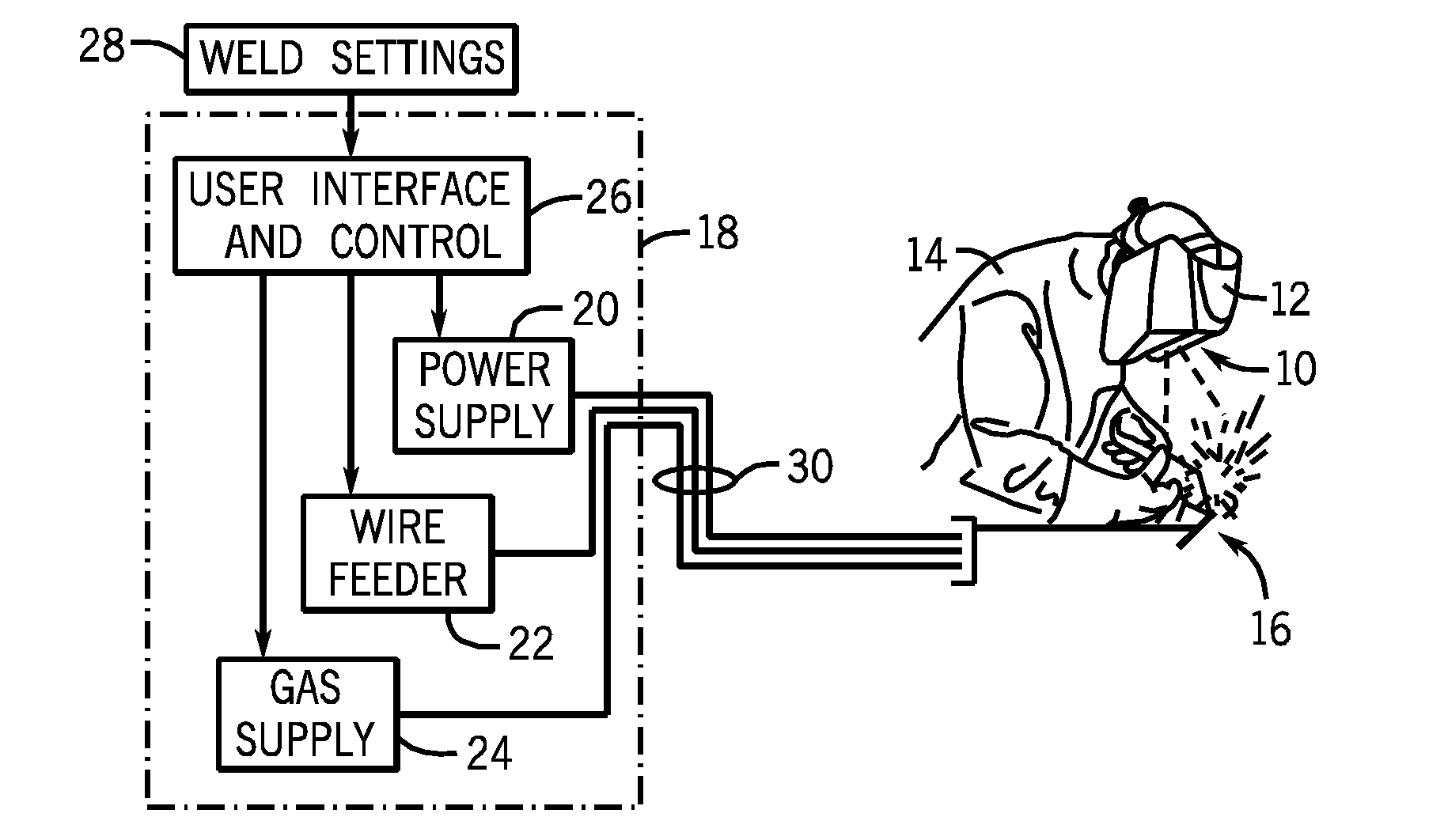

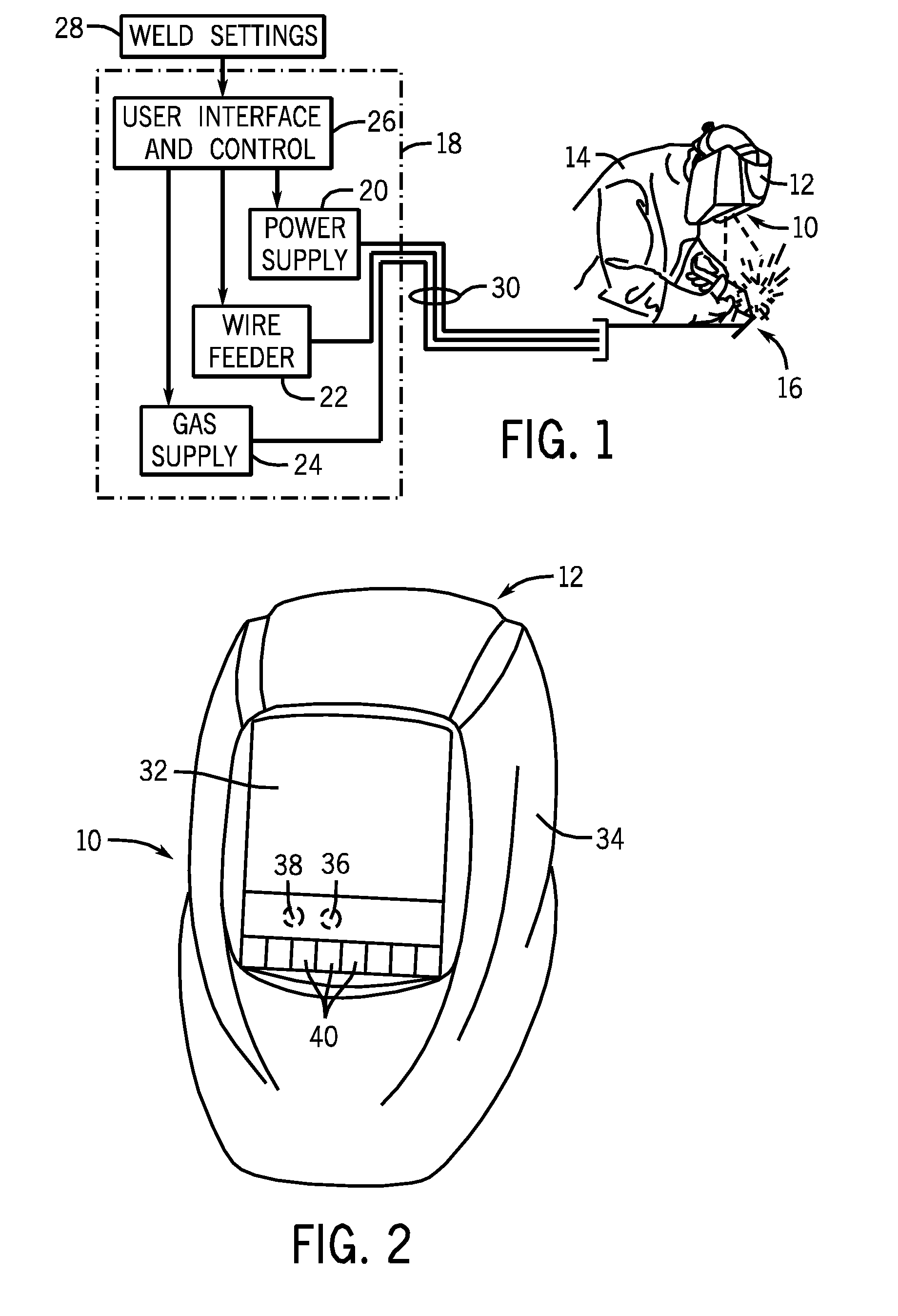

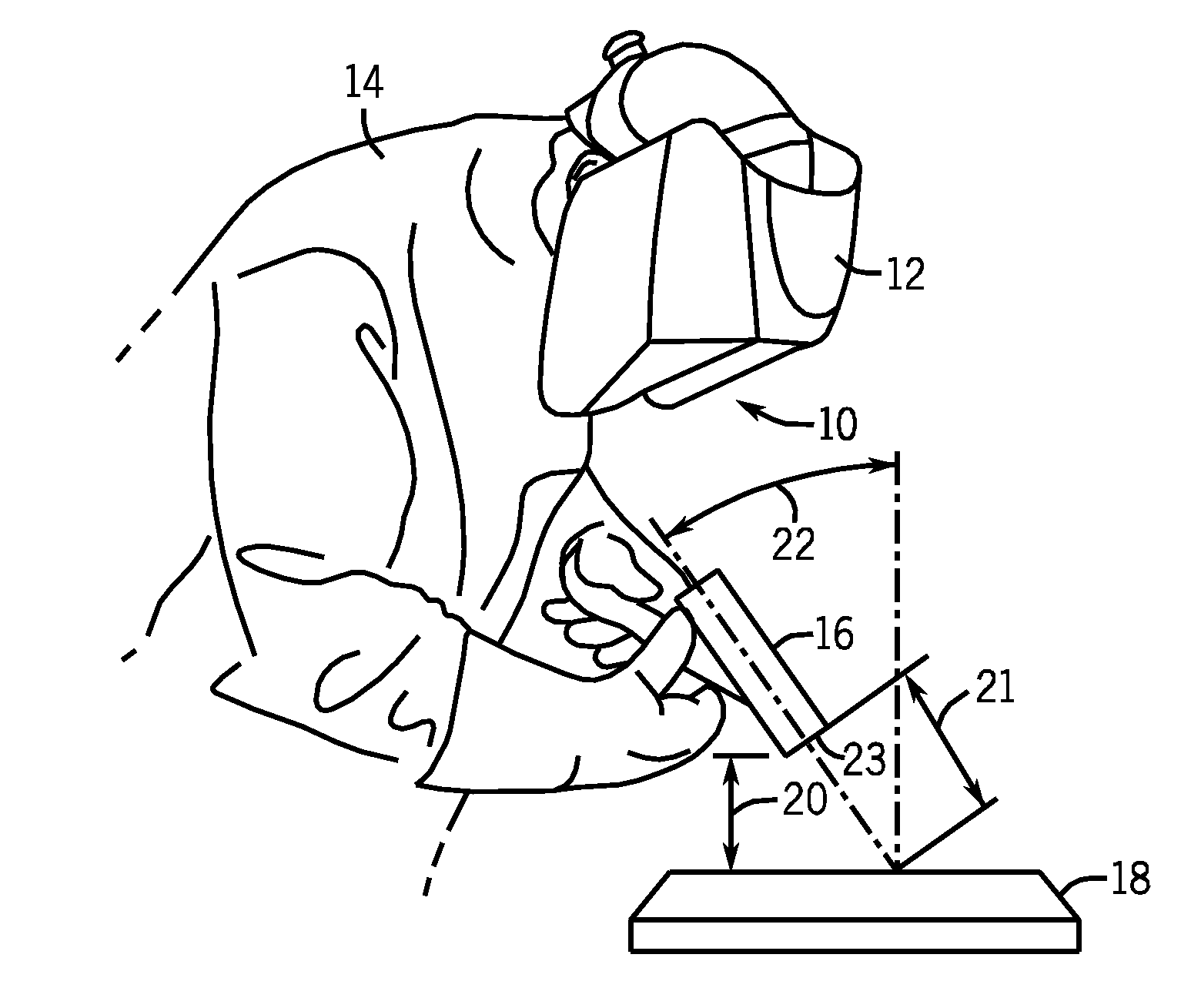

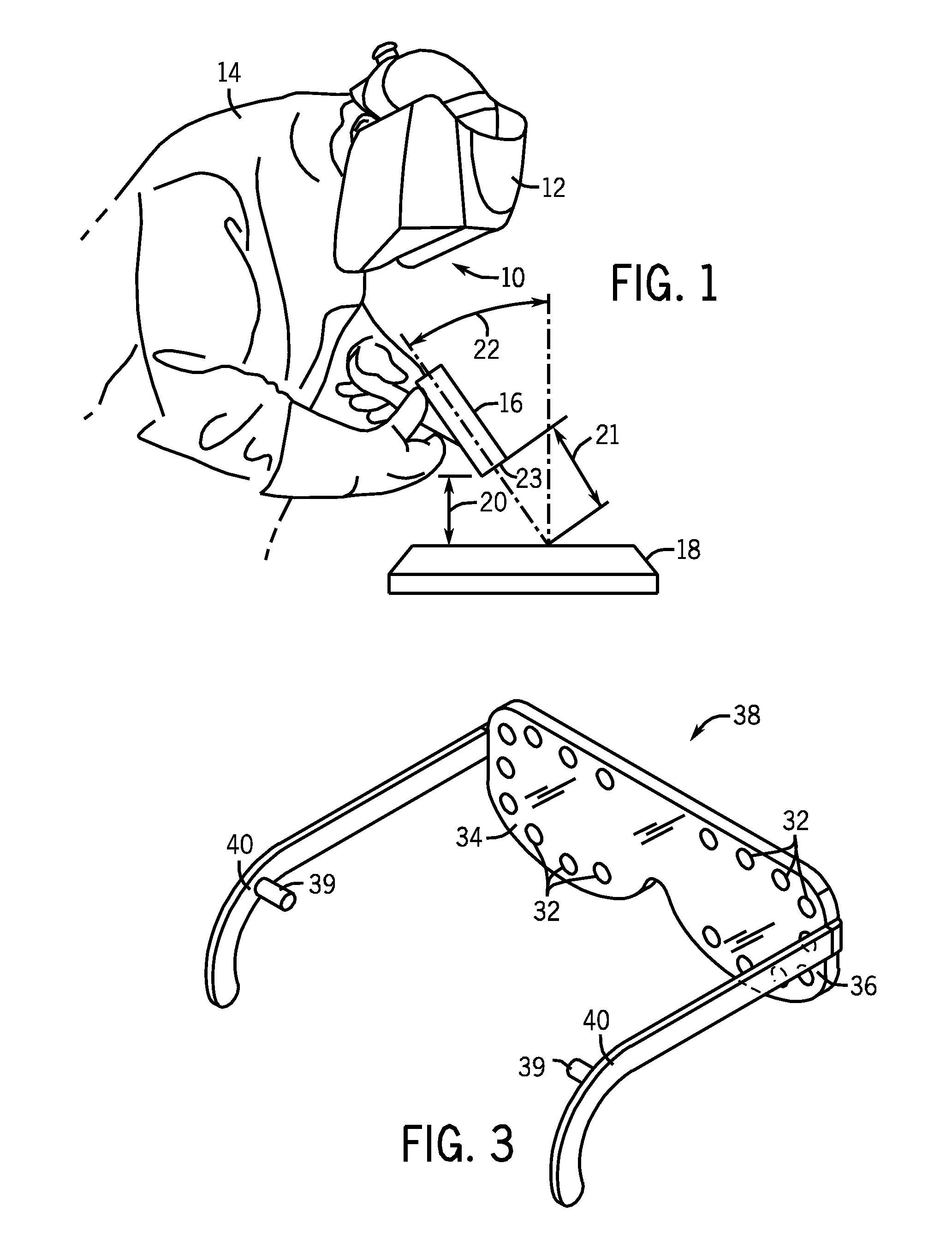

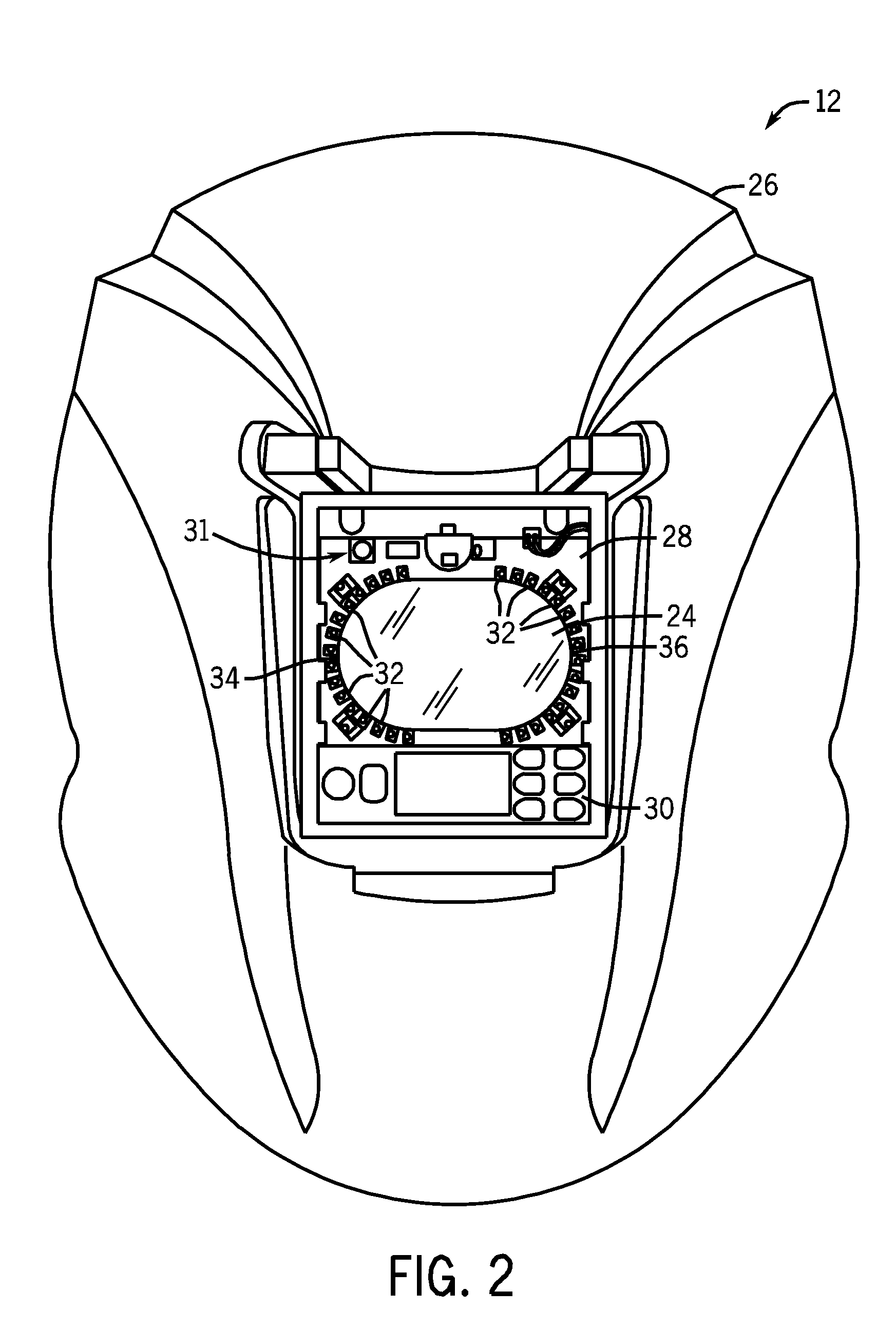

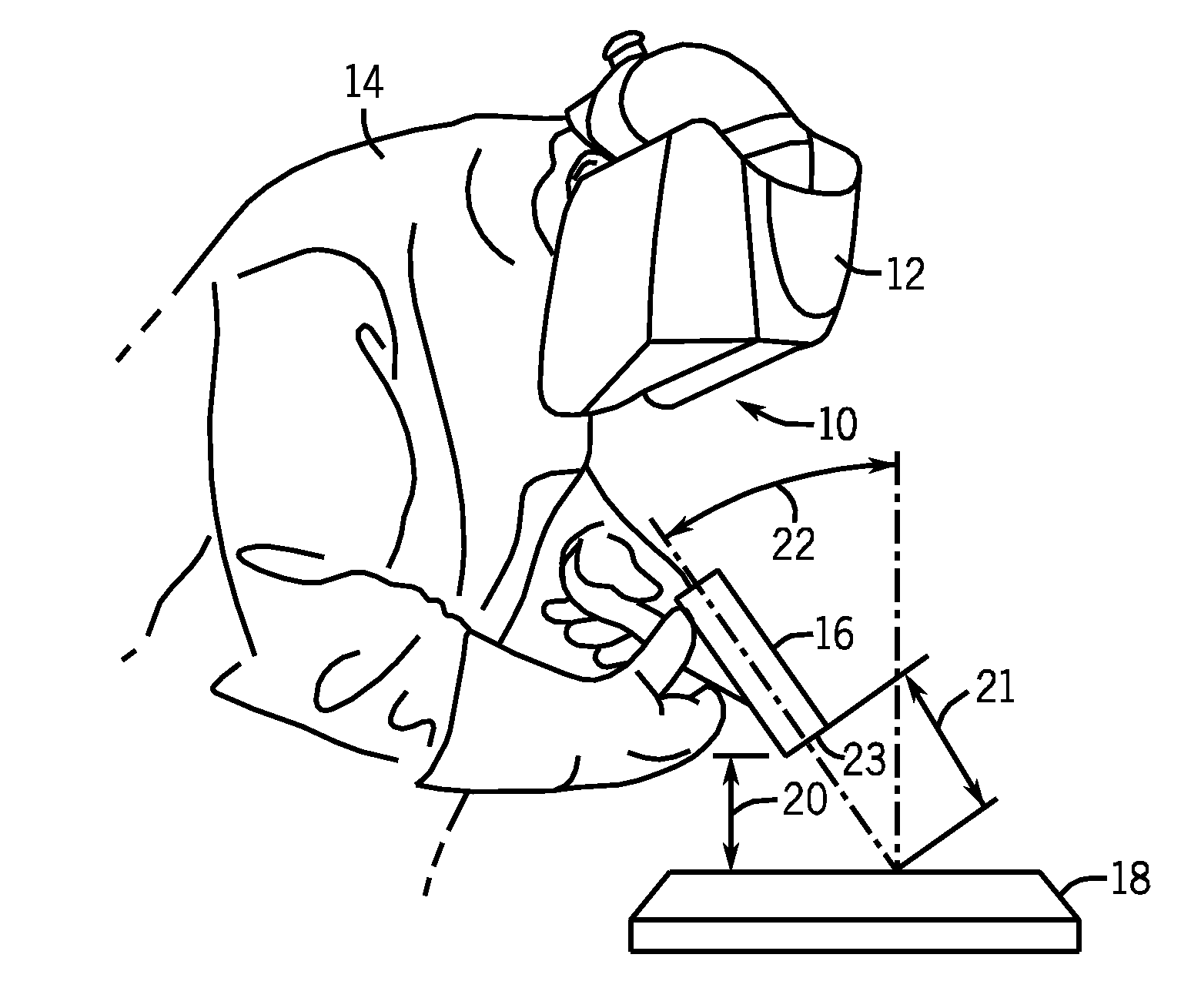

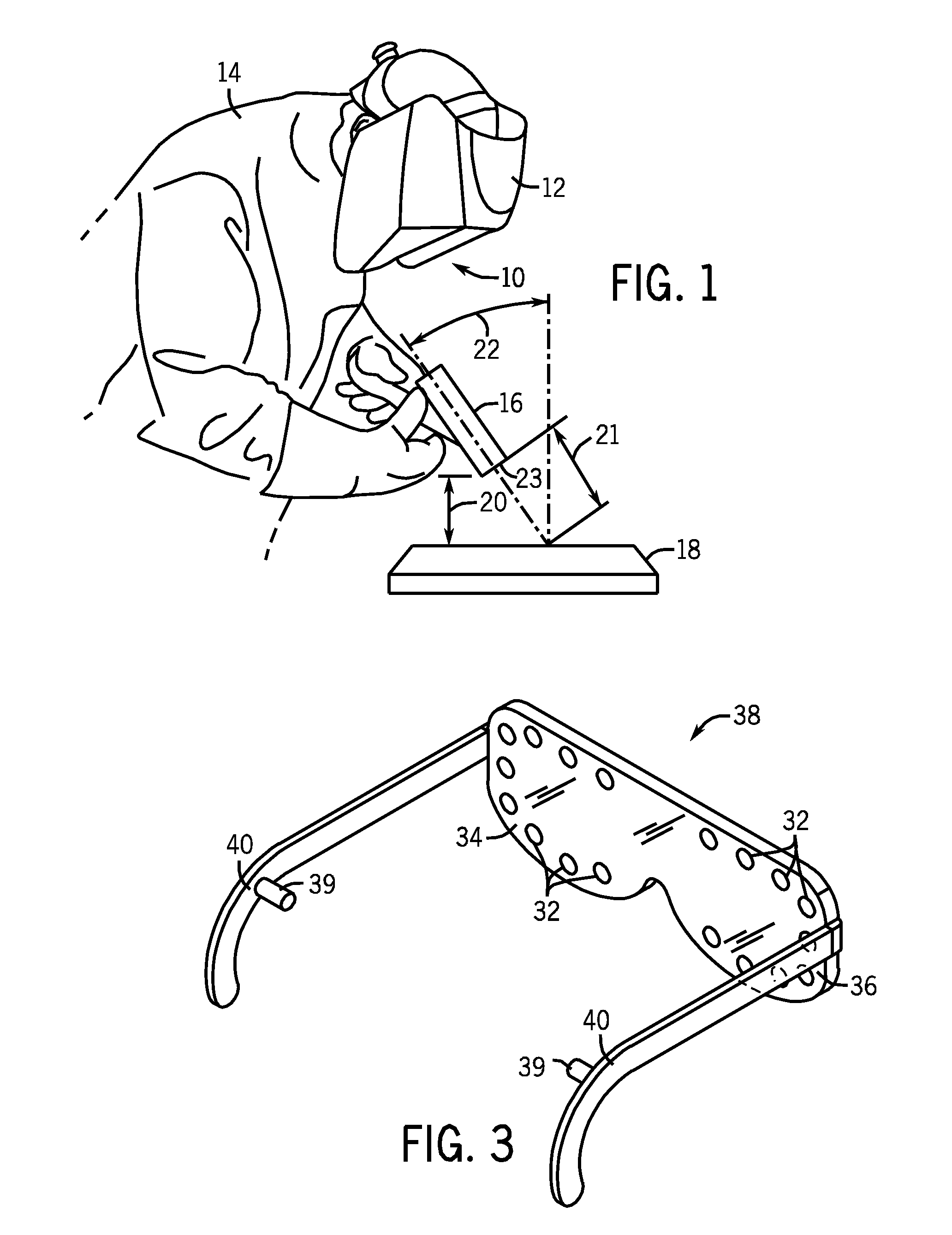

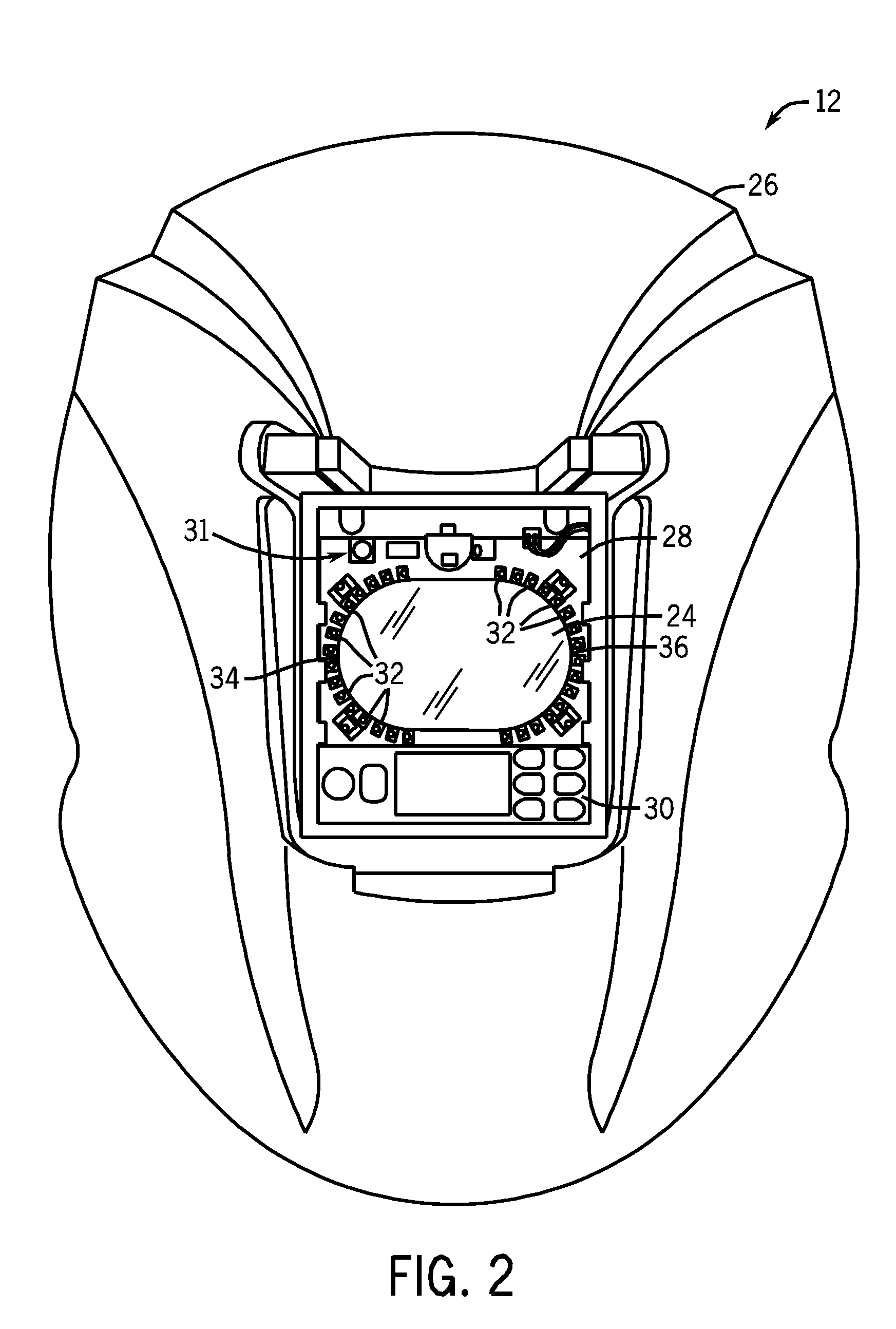

Weld characteristic communication system for a welding mask

Methods and systems for transmitting a torch angle and / or a torch-to-workpiece distance error to a welding operator when these parameters are outside of a preset optimal range via real time visual and / or audio cues are provided. One embodiment of the present disclosure relates to weld characteristic communication via intuitive arrays of visual indicators located on the periphery of a lens, which indicate to the welding operator the direction and severity of the torch angle error. In one embodiment, audio cues, such as pulsed or continuous tones may be used to communicate torch-to-workpiece distance to the welding operator. In certain embodiments, vertical visual indicator arrays may be used to indicate additional weld or auxiliary information, such as battery charge state, torch speed and so forth, to the welding operator. All the components of the communication system may be located in or on the welding helmet or the components may be split between the helmet and a belt pack.

Owner:ILLINOIS TOOL WORKS INC

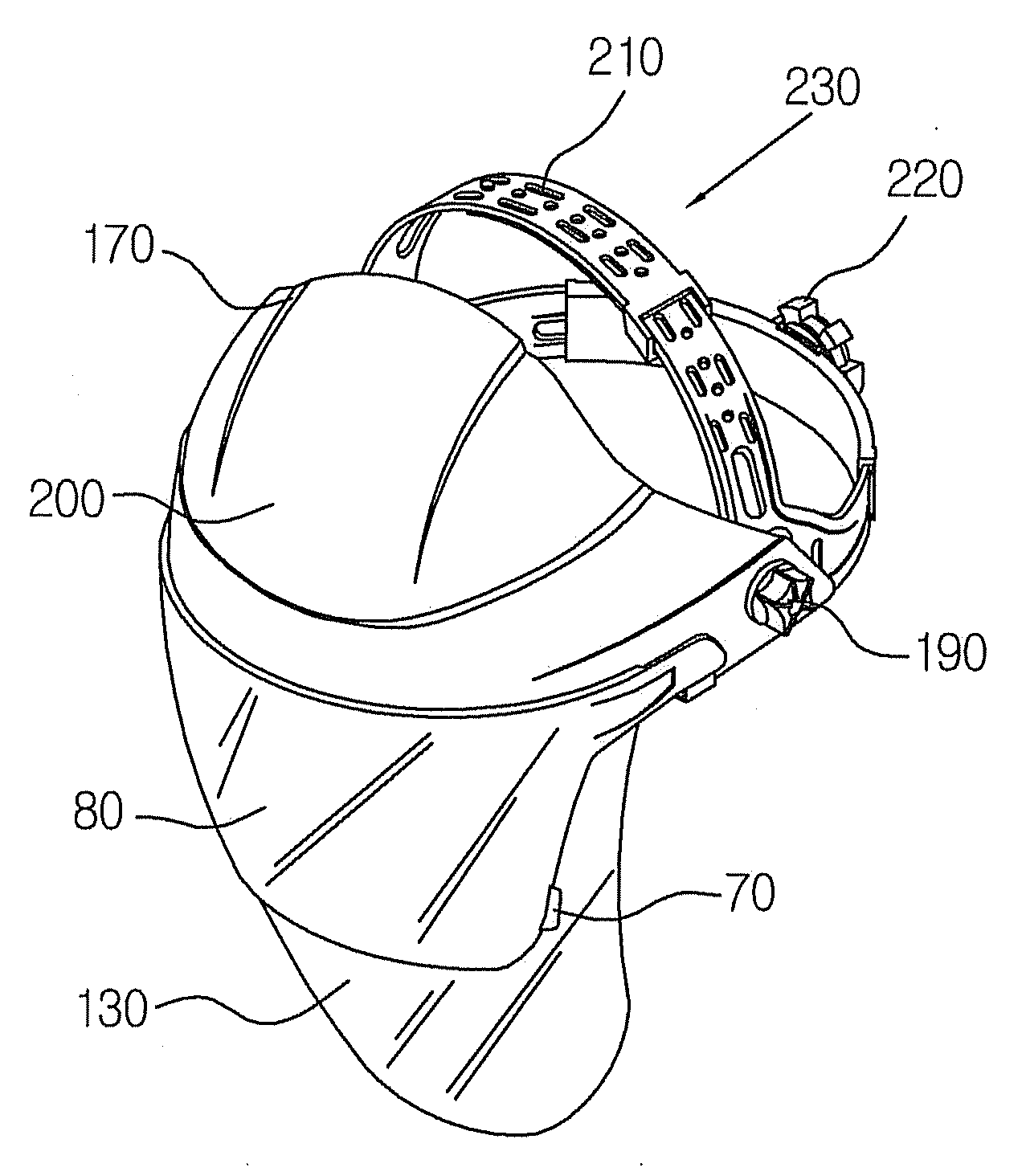

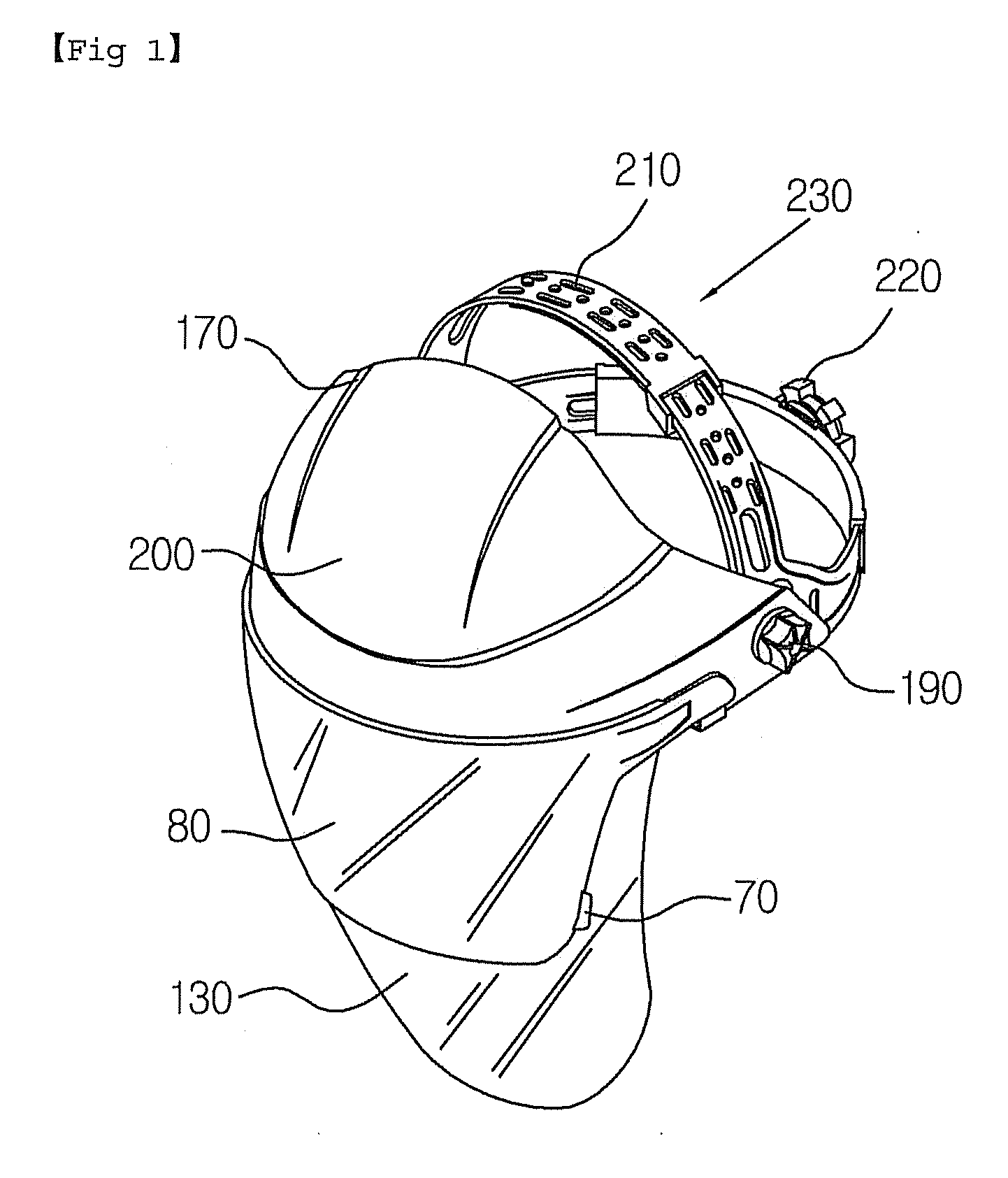

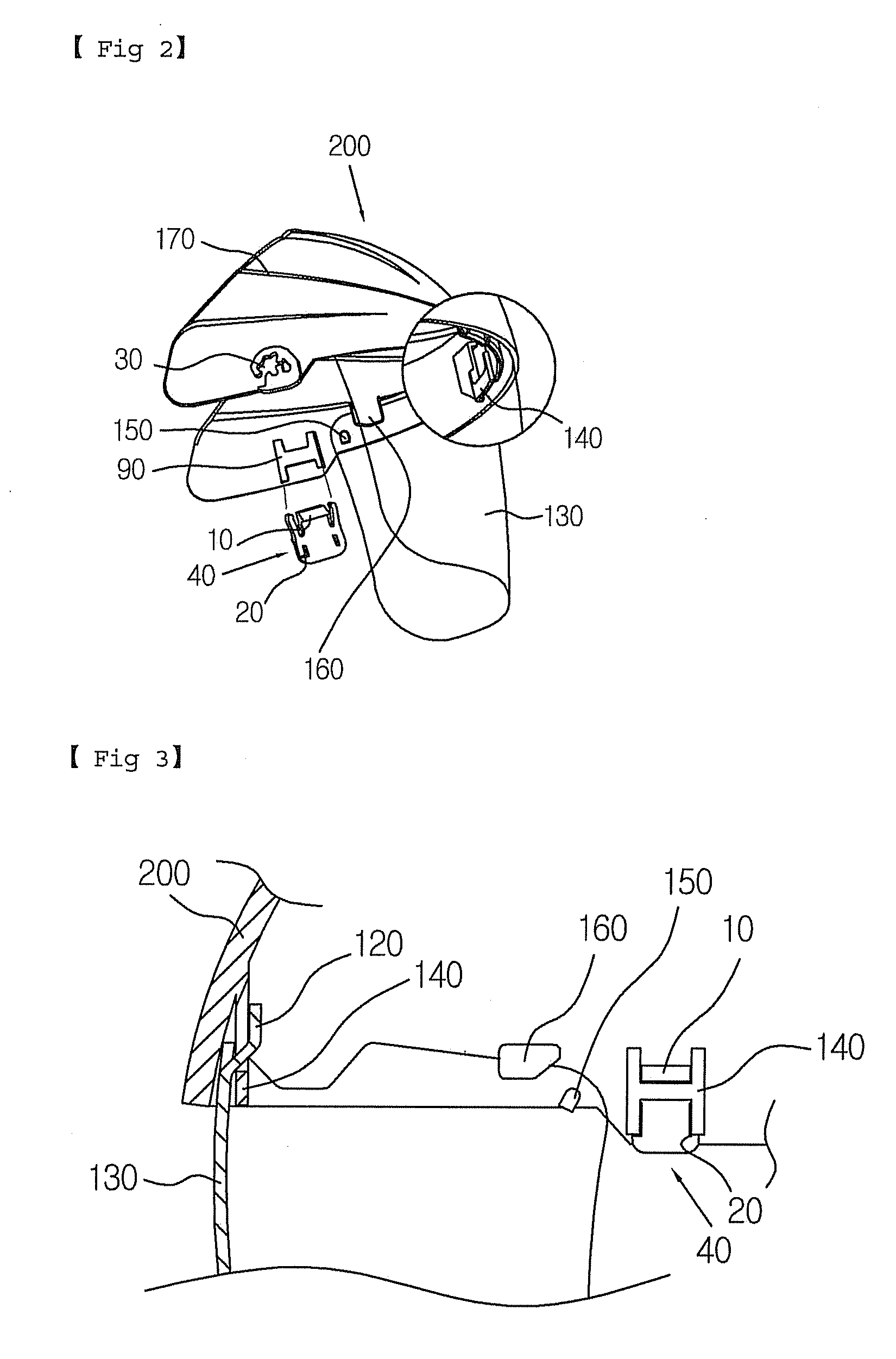

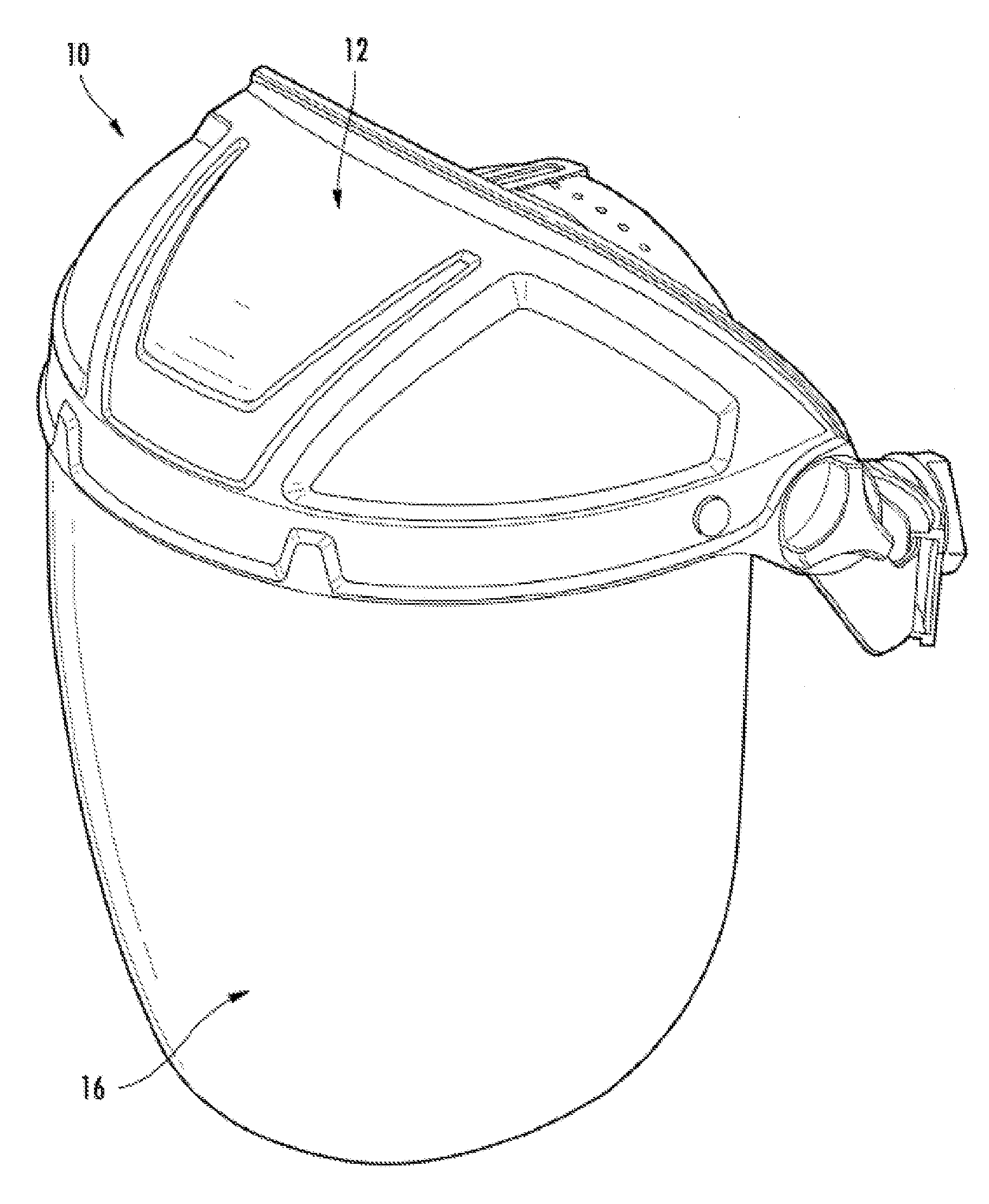

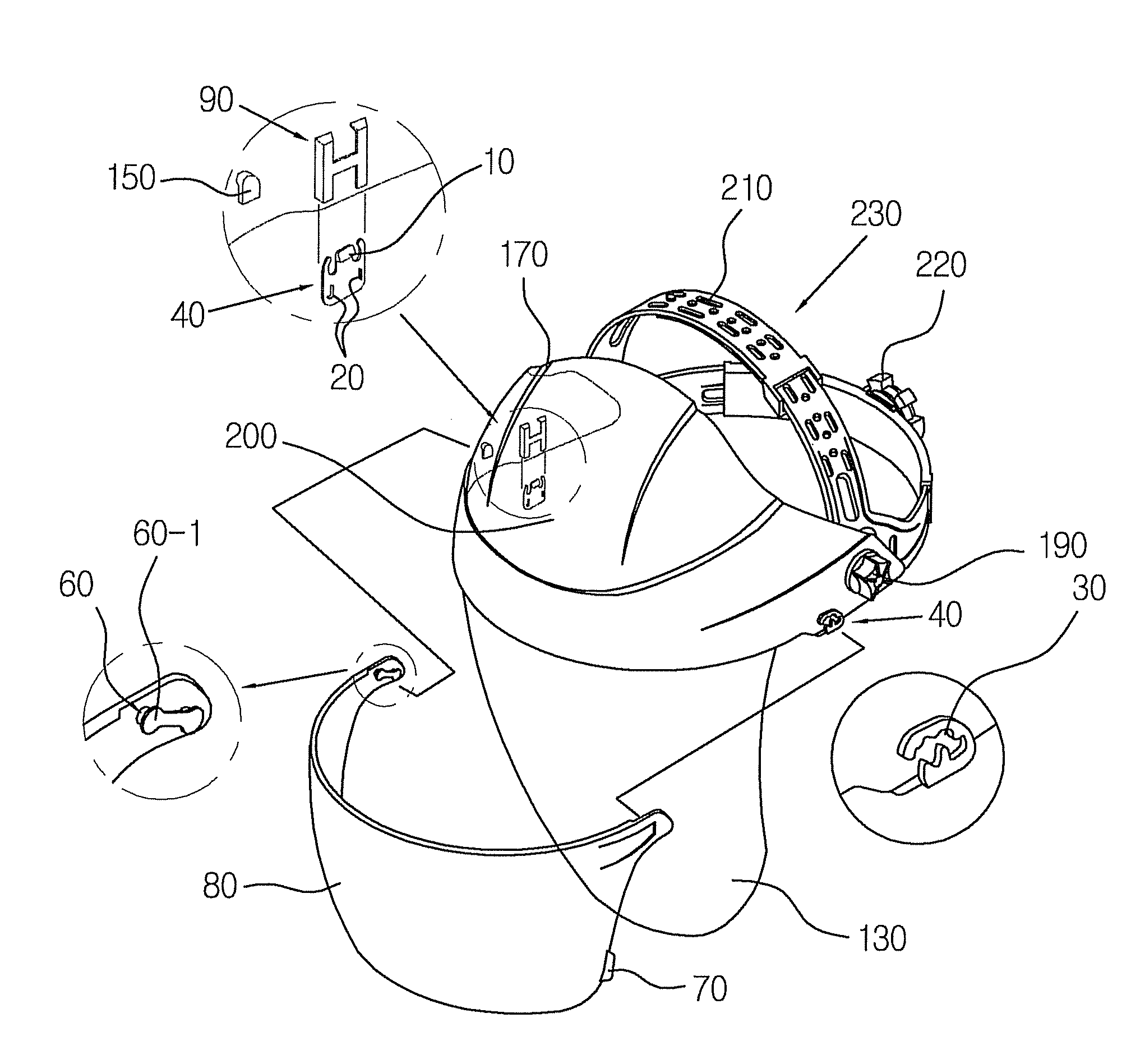

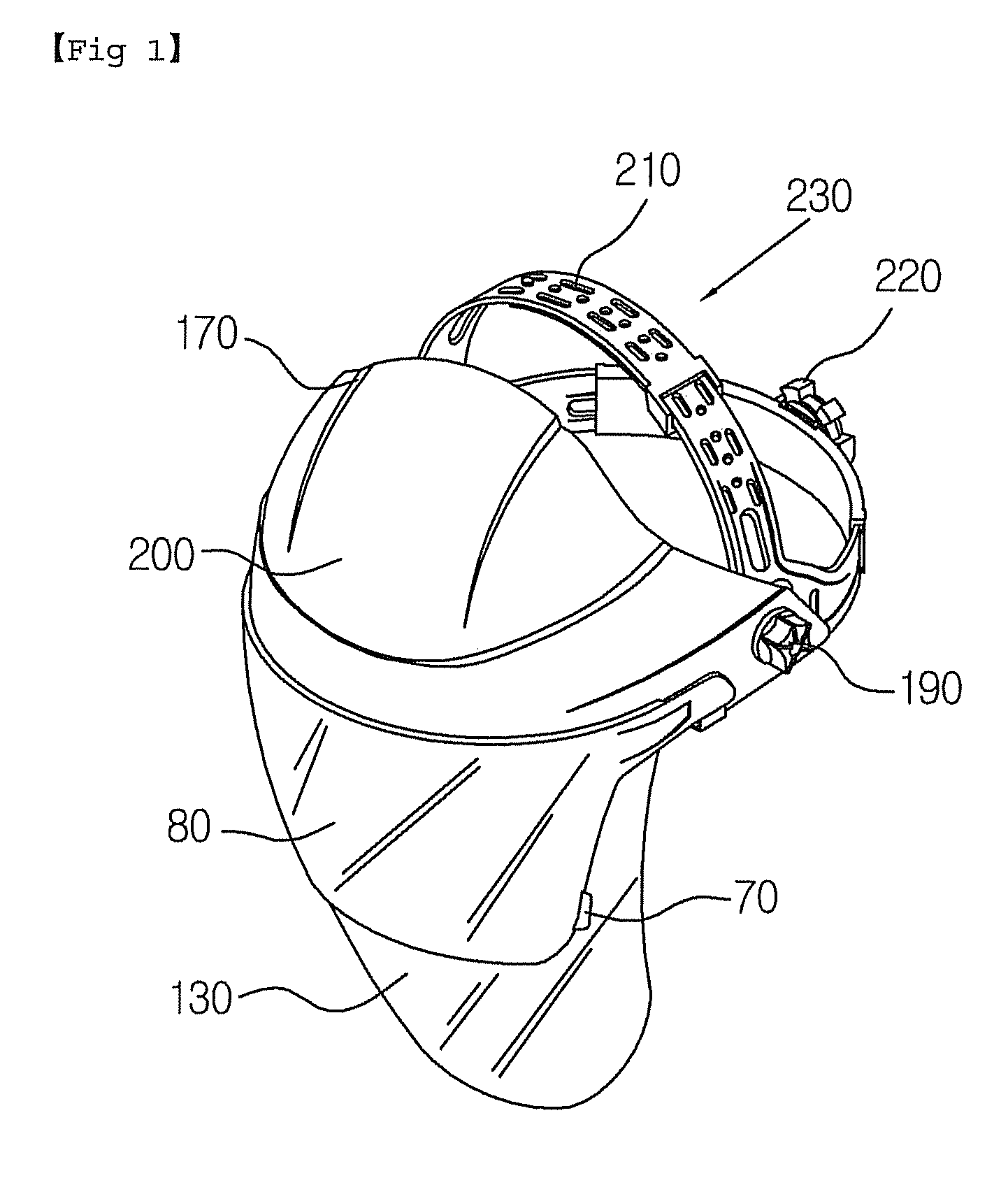

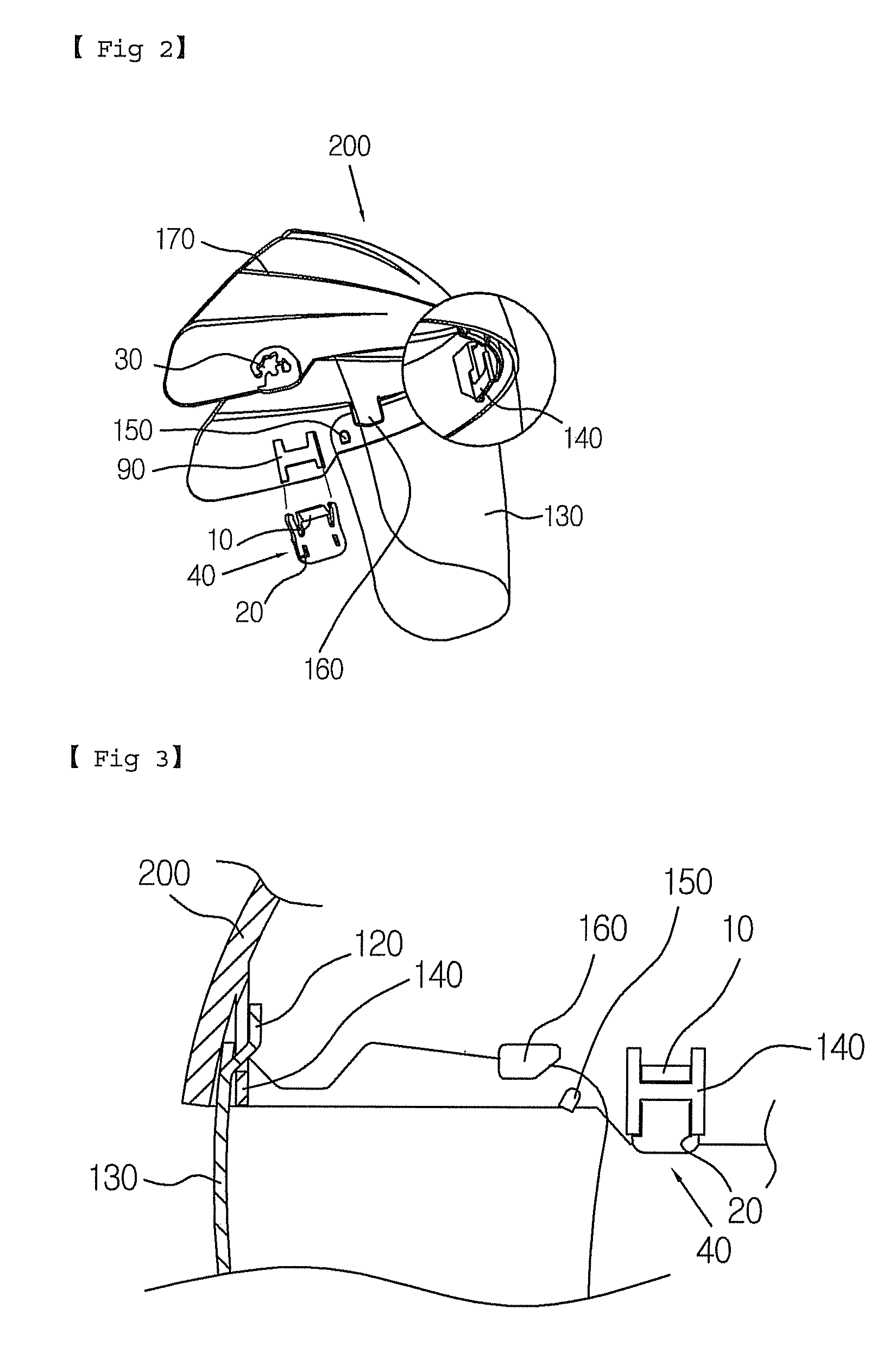

Multi-function face protector

Disclosed herein is a face protector having a protective shade that enables the worker to perform welding as well as grinding while wearing the multi-function face protector and that can be used with safety glasses, goggles and a mask. The multi-function face protector includes a head band, a forehead cover, and a face shield. The face shield comprises resilient hooks formed at its upper central portion, and engaging portions formed at its opposite ends respectively. The forehead cover comprises shield couplings formed at the central portion of its inner surface, and projections formed at the opposite ends of its inner surface respectively. The resilient hooks of the face shield are engaged with the respective shield couplings of the forehead cover.

Owner:OTOS TECH

Welding arc apparel with UV activated images

A welding accessory and a system for detecting UV radiation exposure during welding operations are disclosed. The welding accessory may have a surface exposed to UV radiation generated by electric arc welding, a first image visible without exposure to the UV radiation, and a second image formed from UV activated dye that is visible only after exposure to UV radiation generated by the electric welding arc. A system may include a UV exposure indicator with a first state and at least a second state, and include UV activated dye adapted to provide a reversible or persistent visual indication upon exposure to UV radiation. The visual indication may include any combination of symbols, logos, images, text, or other decorative or informational designs as desired.

Owner:LINCOLN GLOBAL INC

Welding arc apparel with UV or themochromic activated images

A welding accessory and a system for detecting thermal and / or UV radiation exposure during welding operations are disclosed. The welding accessory may have a surface exposed to thermal and / or UV radiation generated by electric arc welding, a first image visible without exposure to the thermal and / or UV radiation, and a second image formed from either a UV activated dye that is visible only after exposure to UV radiation generated by the electric welding arc or a thermochromic dye that is visible only after exposure to a predetermined level of thermal radiation generated by the welding arc. A system may include either a thermal or UV exposure indicator with a first state and at least a second state, and include either a thermochromic or UV activated dye adapted to provide a reversible or persistent visual indication upon exposure to radiation. The visual indication may include any combination of symbols, logos, images, text, or other decorative or informational designs as desired.

Owner:LINCOLN GLOBAL INC

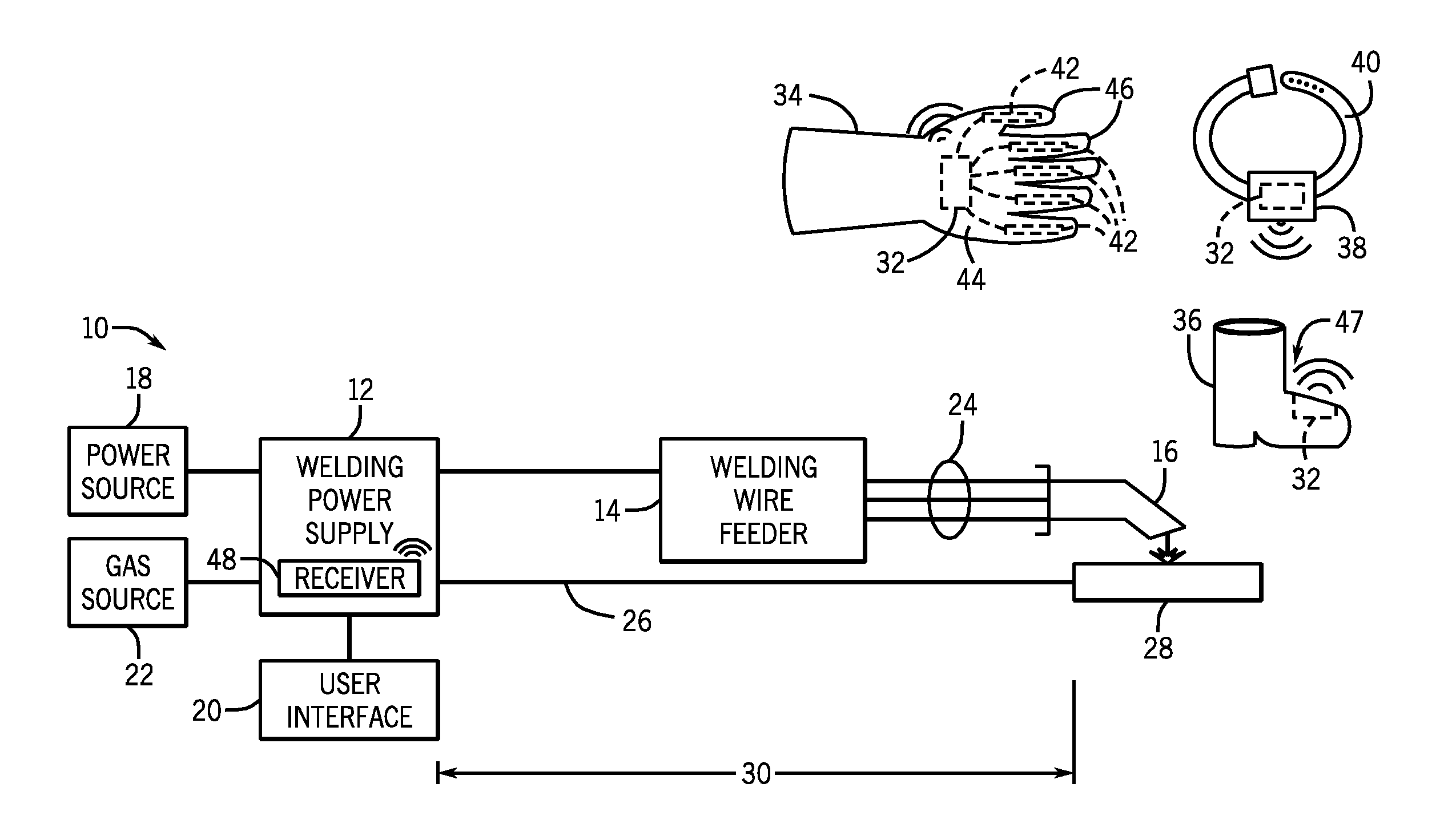

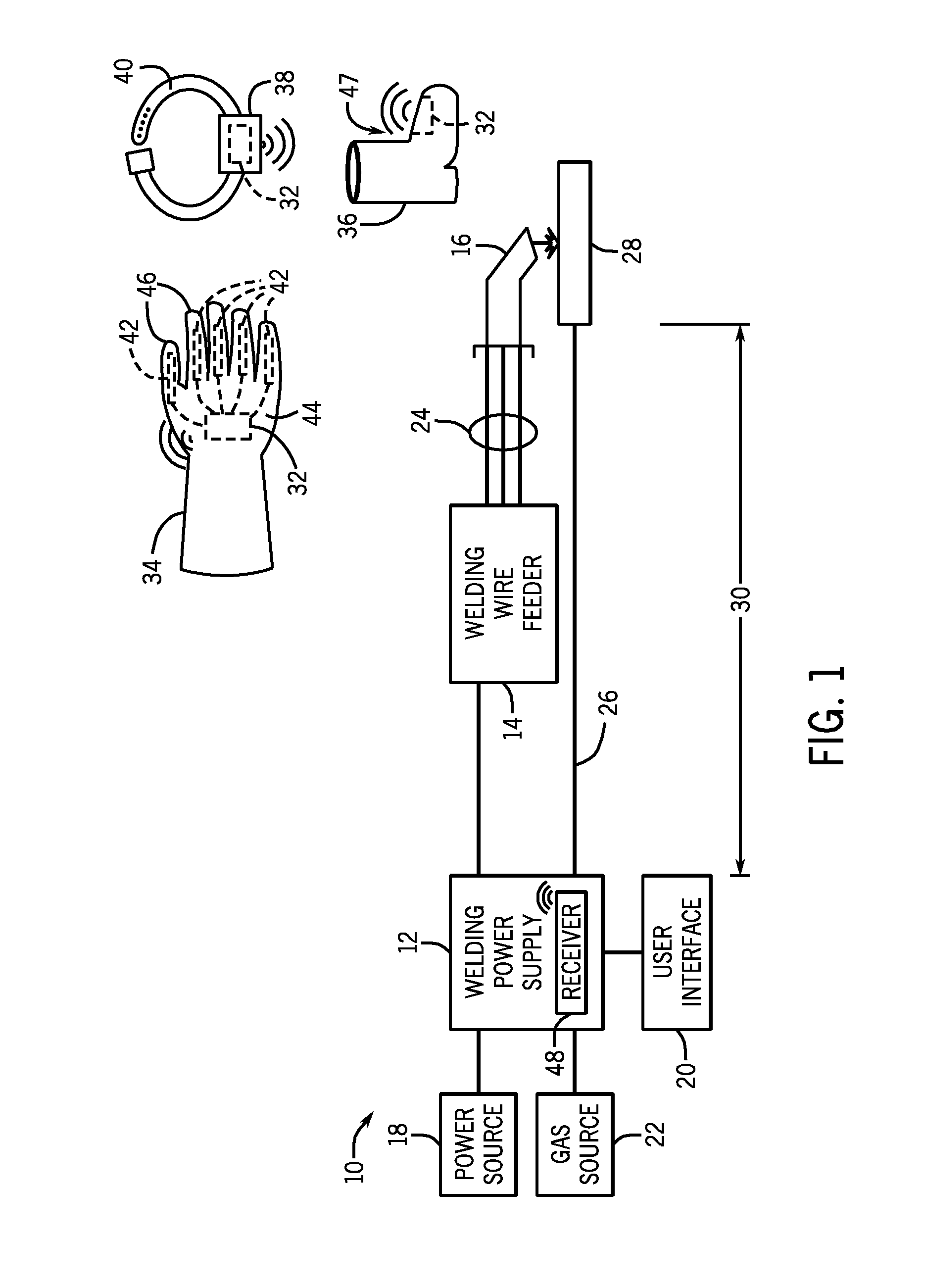

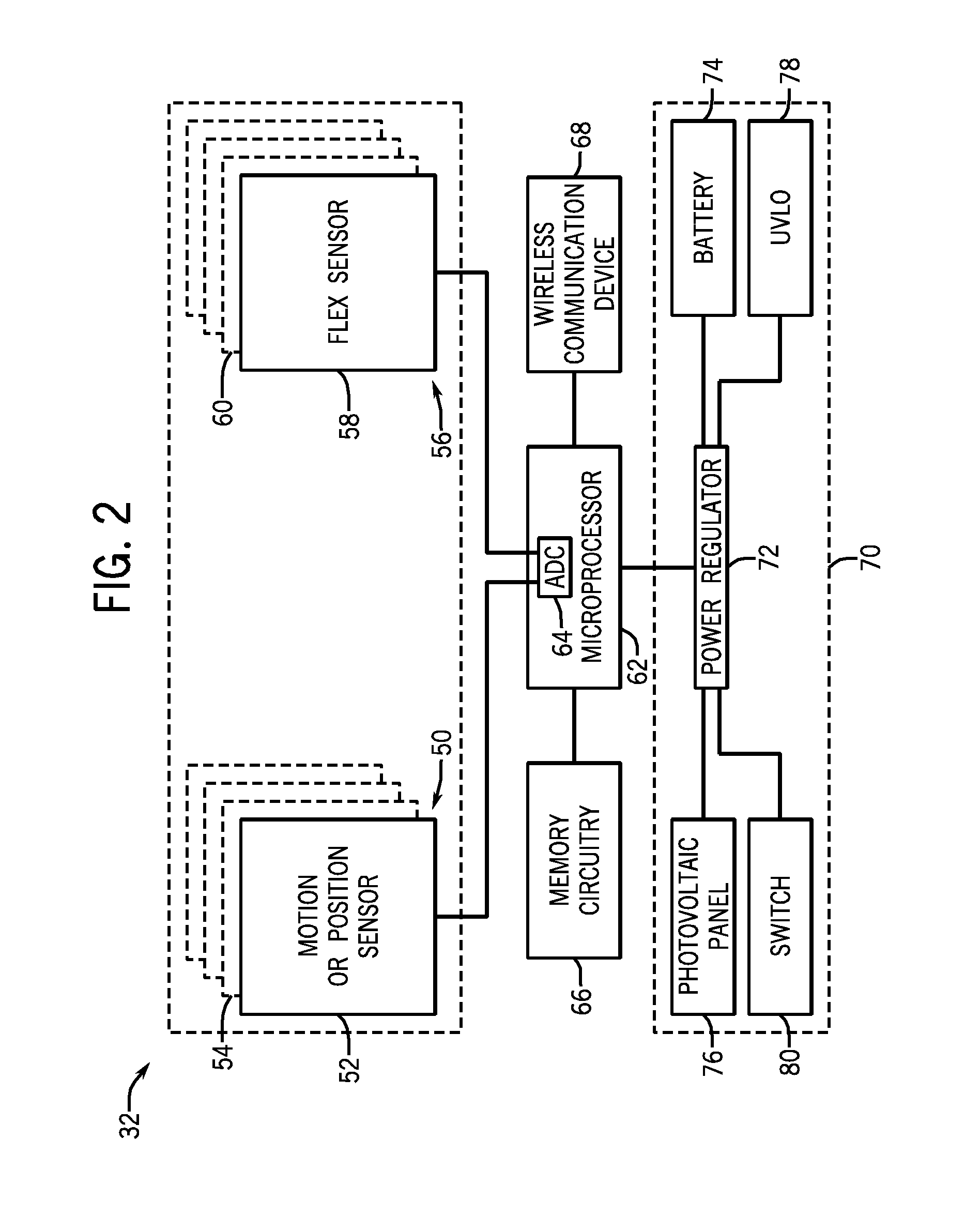

Welding parameter control

In certain embodiments, a wireless sensor module includes a motion or position sensor configured to detect a defined motion or position of a welding operator. The wireless sensor module also includes memory circuitry configured to store the defined motion or position and an adjustment of an operating parameter of a welding system which corresponds to the defined motion or position. A processor of the wireless sensor module is coupled to the motion or position sensor and the memory circuitry, where the processor is configured to retrieve the adjustment of the operating parameter from the memory circuitry upon detection of the defined motion or position by the motion or position sensor. The wireless senor module further includes a wireless communication device coupled to the processor and configured to transmit the adjustment of the operating parameter to the welding system.

Owner:ILLINOIS TOOL WORKS INC

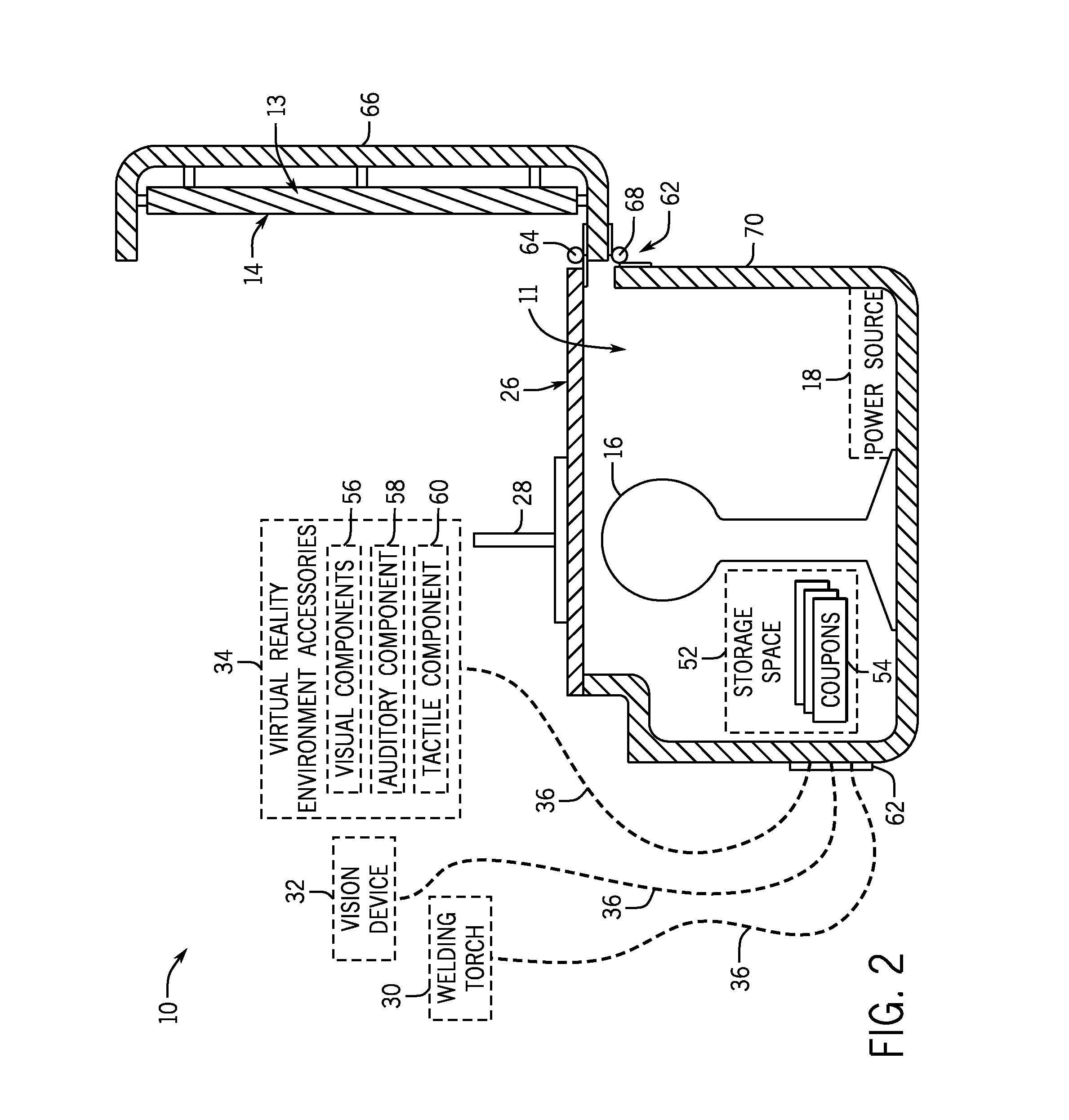

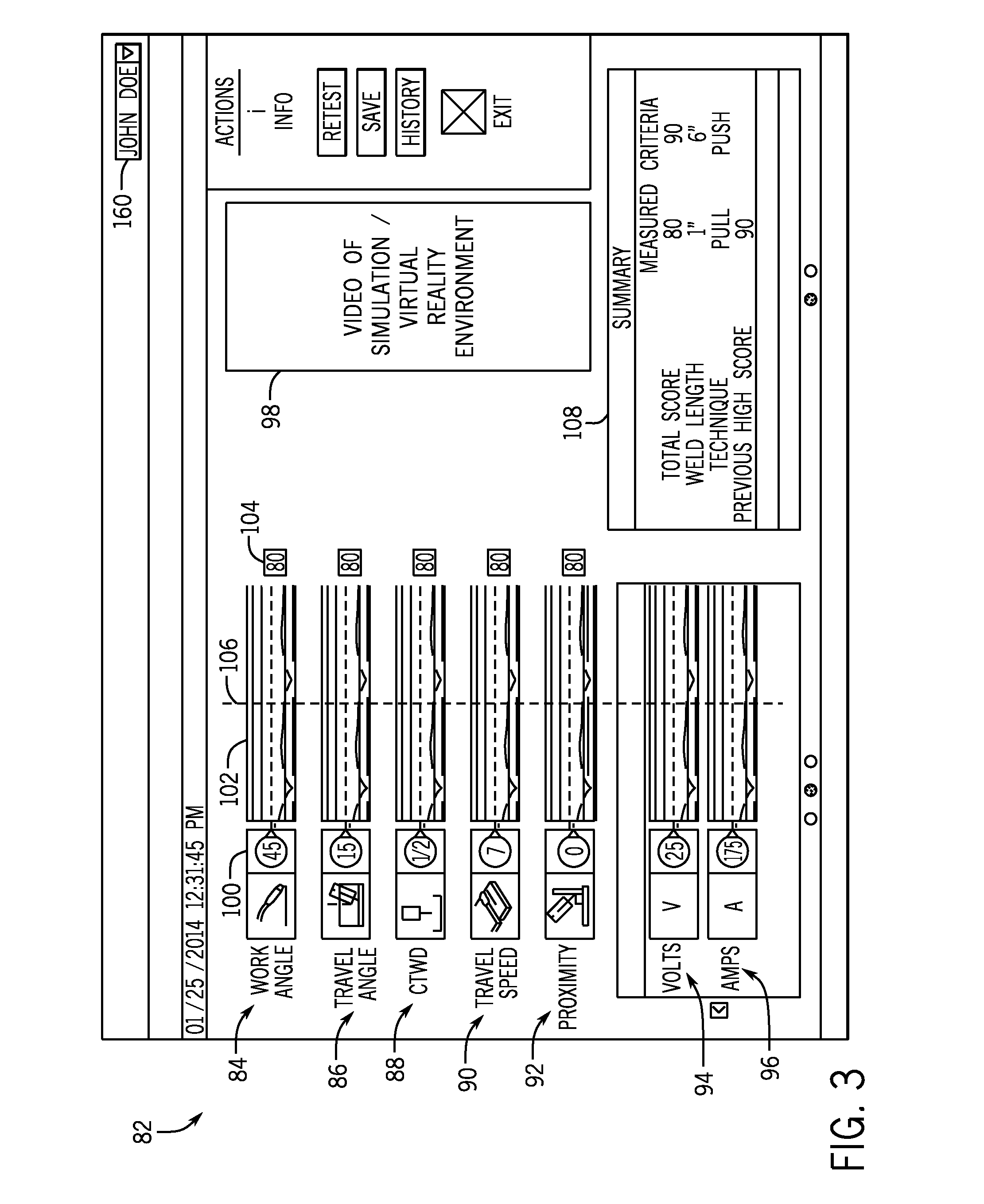

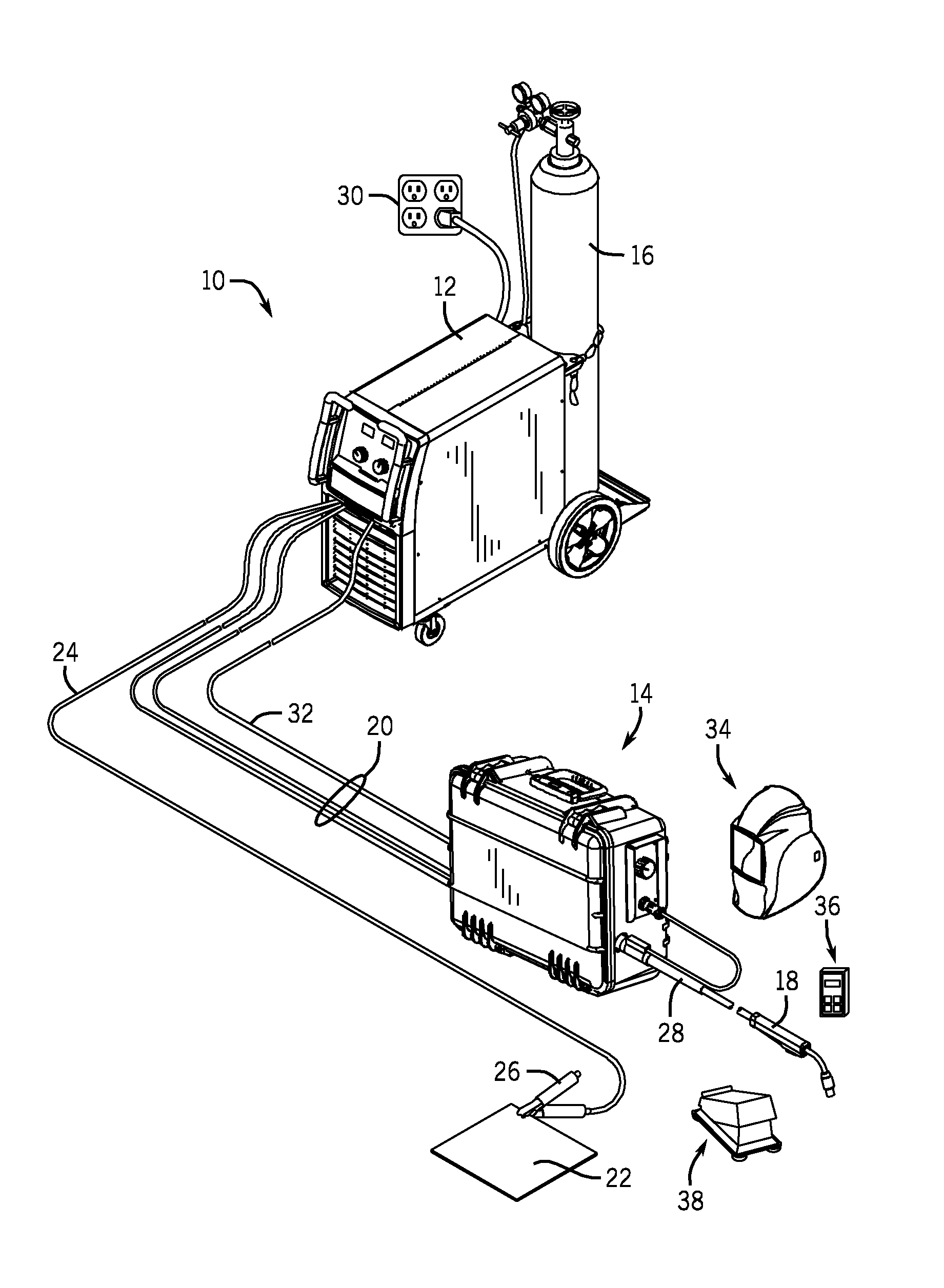

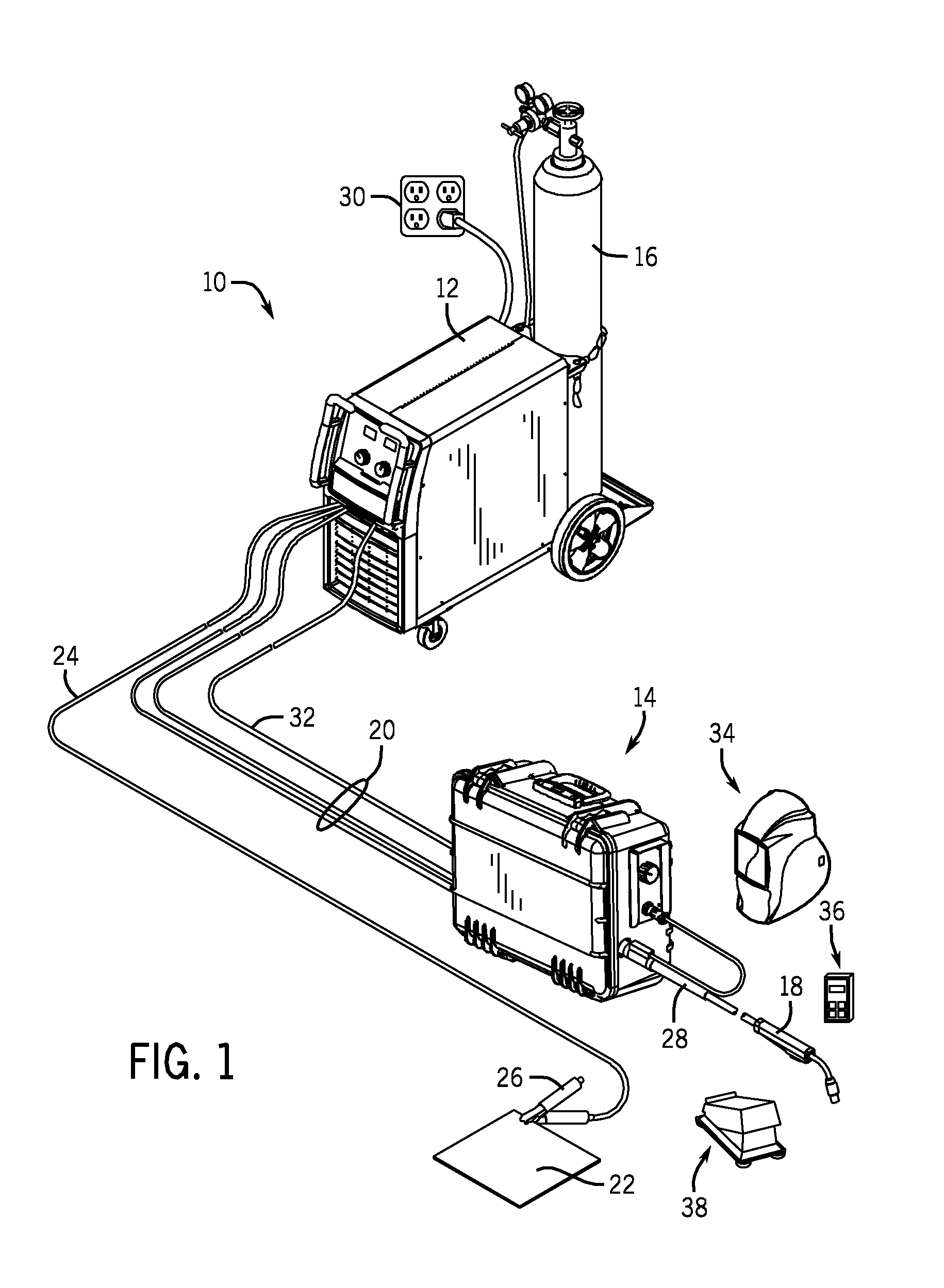

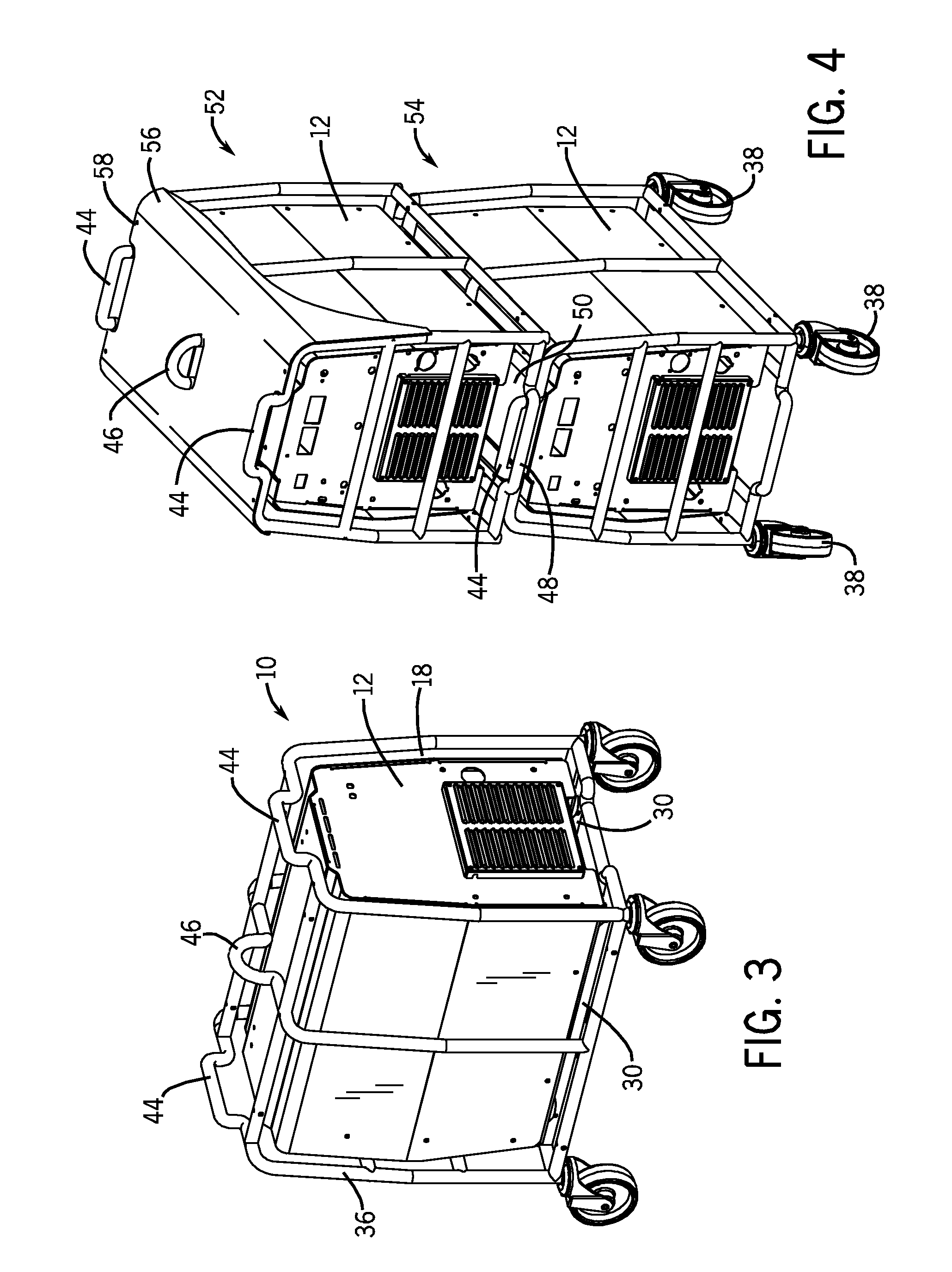

Weld training system and method

Systems and methods for a weld training system are provided. In particular, components of the weld training system may be removably disposed within an interior volume of a portable enclosure. The portable enclosure may be easy to transport by a welding operator from various training and / or recruiting locations. In some embodiments, the components of the weld training system include a weld training device, a work surface, a sensing device, a virtual reality interface, and processing circuitry.

Owner:ILLINOIS TOOL WORKS INC

Weld characteristic communication system for a welding mask

Methods and systems for transmitting a torch angle and / or a torch-to-workpiece distance error to a welding operator when these parameters are outside of a preset optimal range via real time visual and / or audio cues are provided. One embodiment of the present disclosure relates to weld characteristic communication via intuitive arrays of visual indicators located on the periphery of a lens, which indicate to the welding operator the direction and severity of the torch angle error. In one embodiment, audio cues, such as pulsed or continuous tones may be used to communicate torch-to-workpiece distance to the welding operator. In certain embodiments, vertical visual indicator arrays may be used to indicate additional weld or auxiliary information, such as battery charge state, torch speed and so forth, to the welding operator. All the components of the communication system may be located in or on the welding helmet or the components may be split between the helmet and a belt pack.

Owner:ILLINOIS TOOL WORKS INC

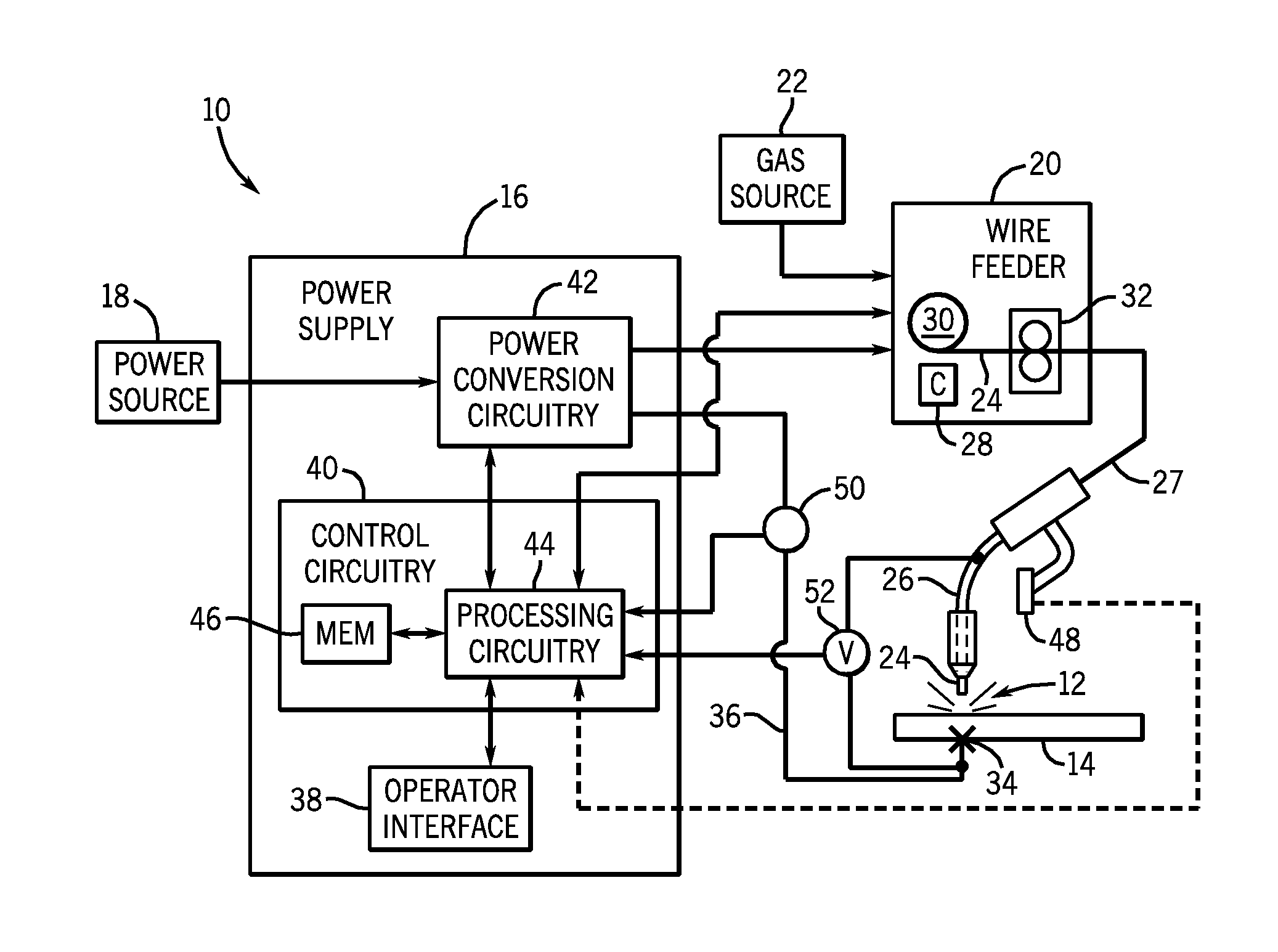

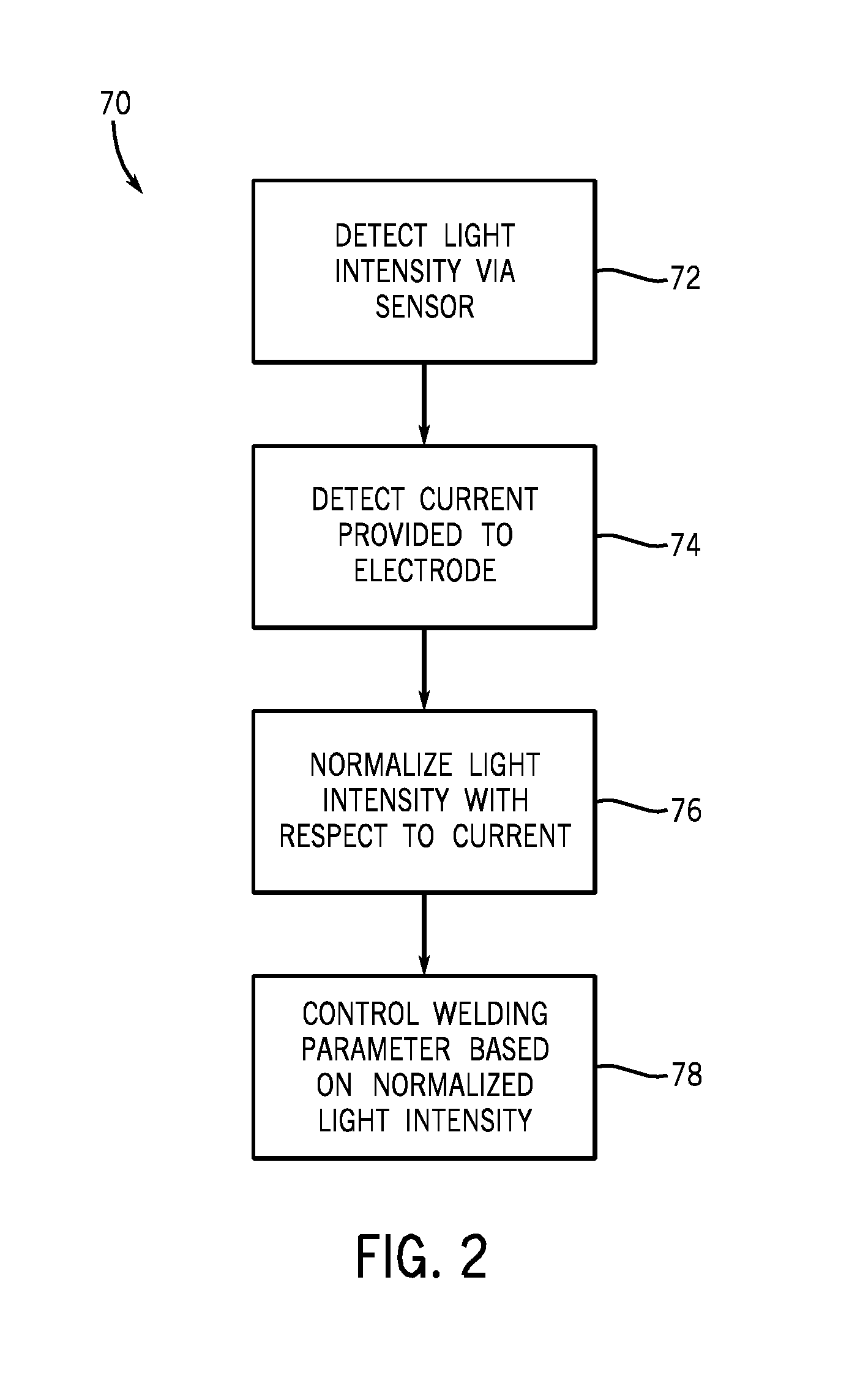

System and method for controlling an arc welding process

A welding system includes an electrode configured to be advanced toward a workpiece and a power supply configured to provide a flow of electricity to the electrode for generating a welding arc between the electrode and the workpiece. The welding system also includes a first sensor configured to sense a light intensity of the welding arc and a second sensor configured to sense a current provided to the electrode via the power supply. In addition, the welding system includes a controller communicatively coupled with the first and second sensors and configured to modify the light intensity with respect to the current. The controller is configured to control a welding parameter of the welding system based on the modified light intensity.

Owner:ILLINOIS TOOL WORKS INC

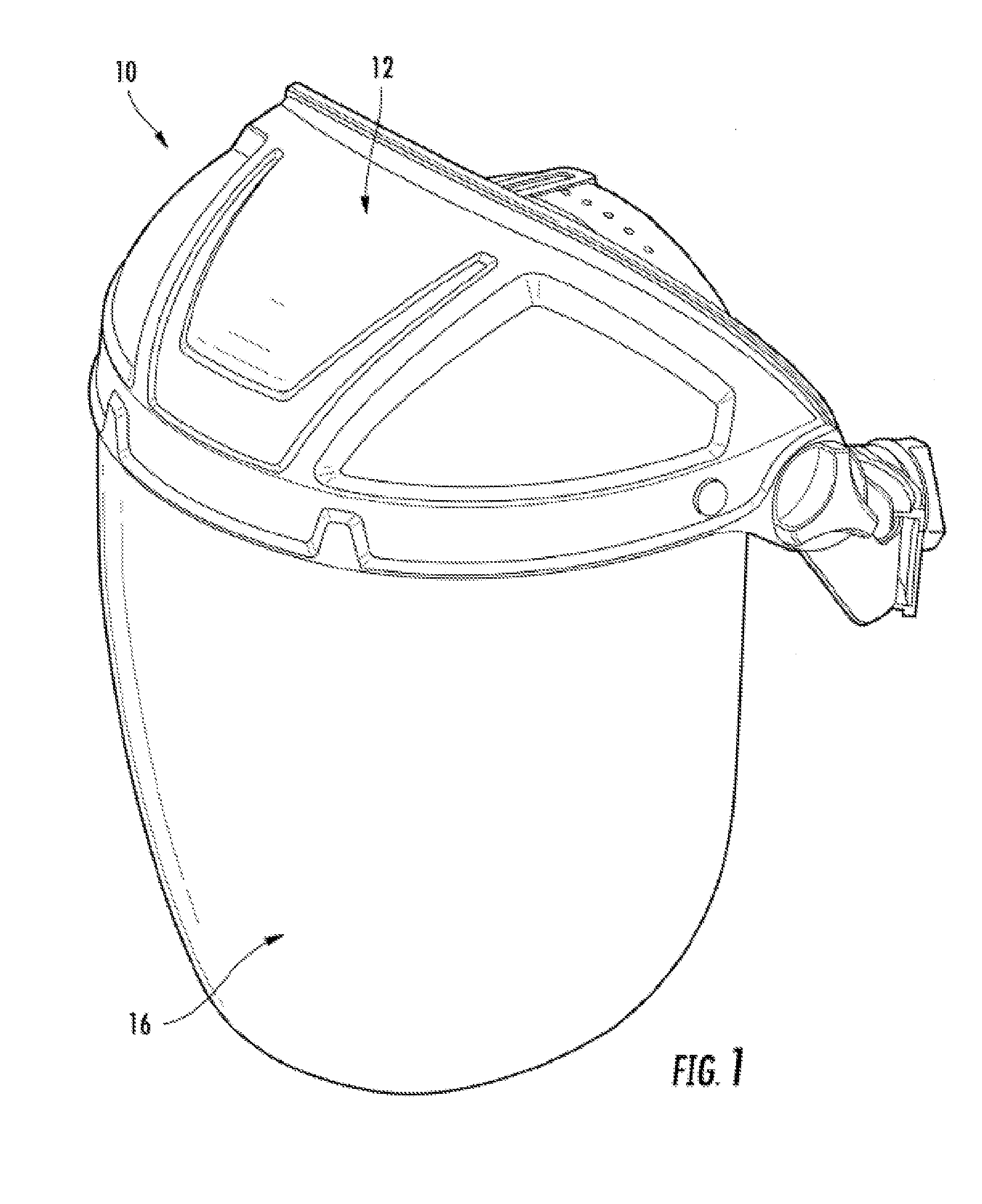

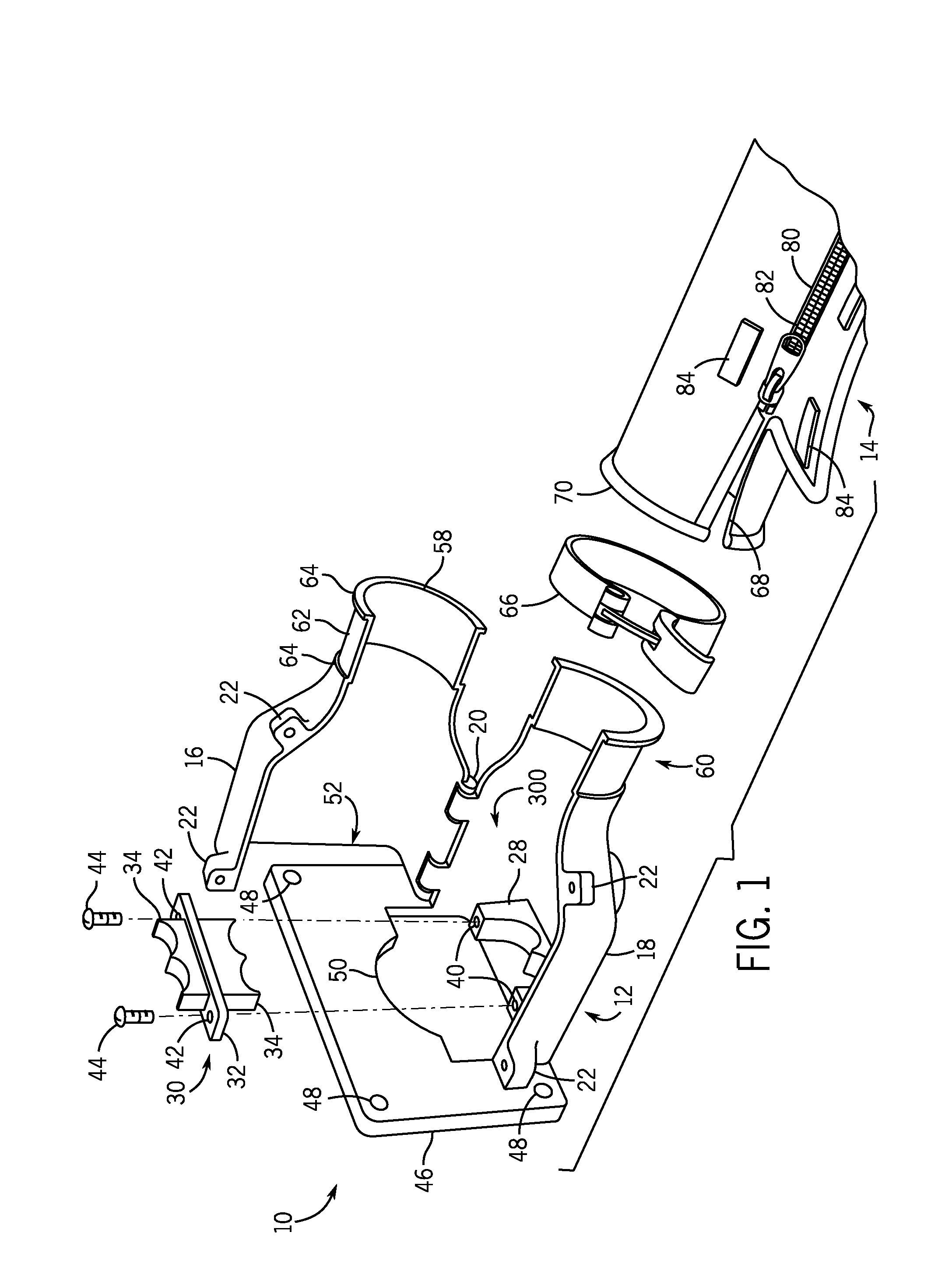

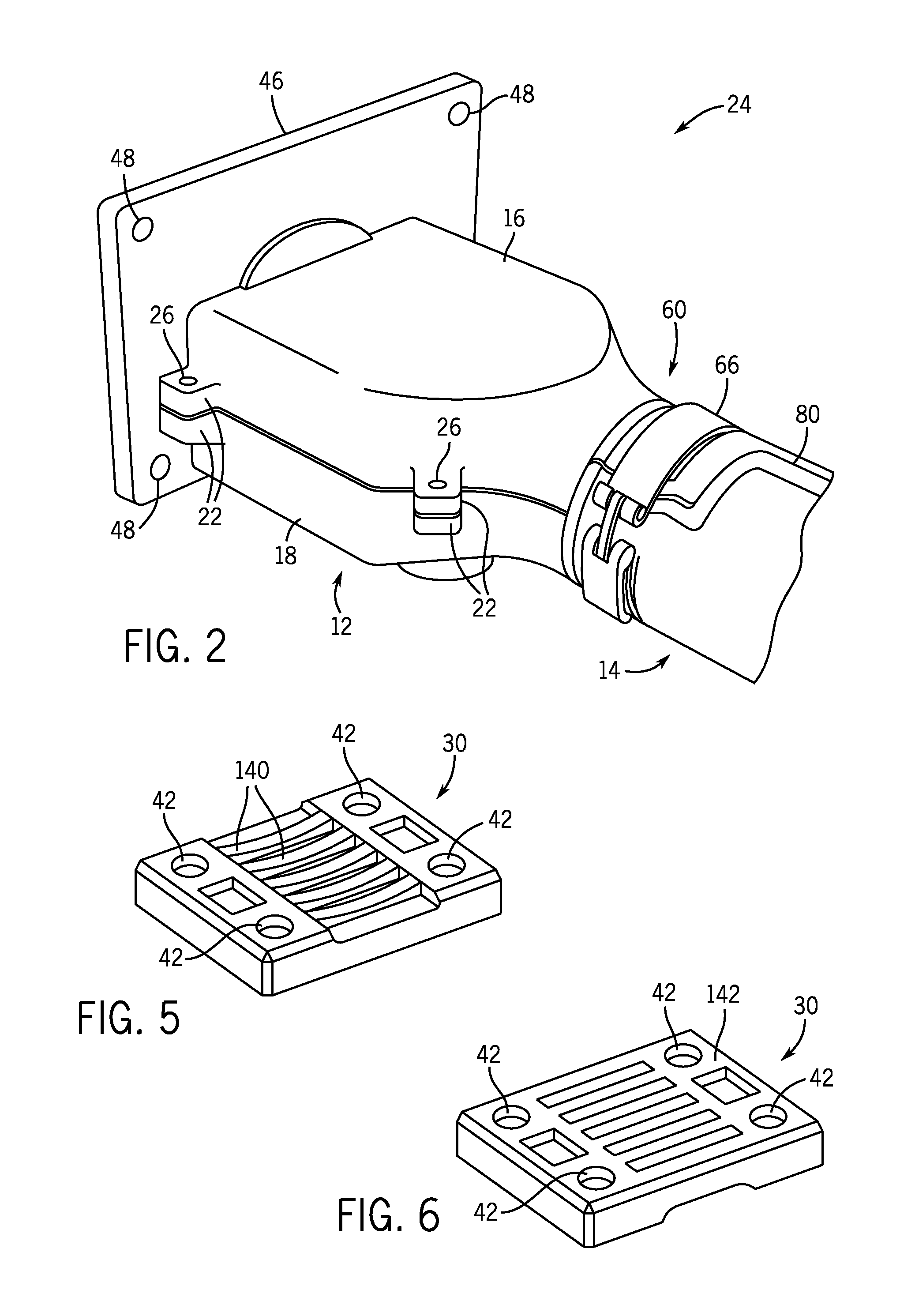

Face Protector Lens Assembly and Method of Use

A lens assembly for securing in an opening in a face plate of a face protector has a first, retainer lens of shape and dimensions configured to be secured in the front opening of a face plate and having a curvature substantially matching the curvature of the face plate. A second lens of smaller dimensions is secured behind the first lens to provide a lens-in-a-lens configuration. The second lens extends across a wearer's eyes when the face protector is worn and the first lens has side portions which extend around at least part of the opposite sides of the face to provide peripheral vision. The lens assembly may be releasably secured in the face plate opening and one or both lenses may be interchangeable with sets of lenses having different properties such as lens shade.

Owner:MENTA PATENT PARTNERS LLC +1

Face Protector Lens Assembly and Method of Use

ActiveUS20140007312A1Easy to replaceReplaceable quickly and easilyEngineering safety devicesEye-masksCamera lensWindow opening

A retainer lens of shape and dimensions configured to be releasably secured in the front opening of a face plate or helmet has a window opening configured for positioning in front of the eyes of a wearer of the face plate or helmet. An outer protective cover is configured to be secured over the window opening by means of scrap-book like frame corners located on the front surface of the retainer lens and spaced outwardly from respective corners of the window opening. The corners of the outer protective cover are releasably engaged with respective frame corners, so that the cover can be removed from the outside of the face plate as needed for replacement with a new outer protective cover, simply by removing the corners of the current outer protective cover from the respective frame corners, and then engaging a new outer protective cover into the frame corners.

Owner:MENTA PATENT PARTNERS LLC +1

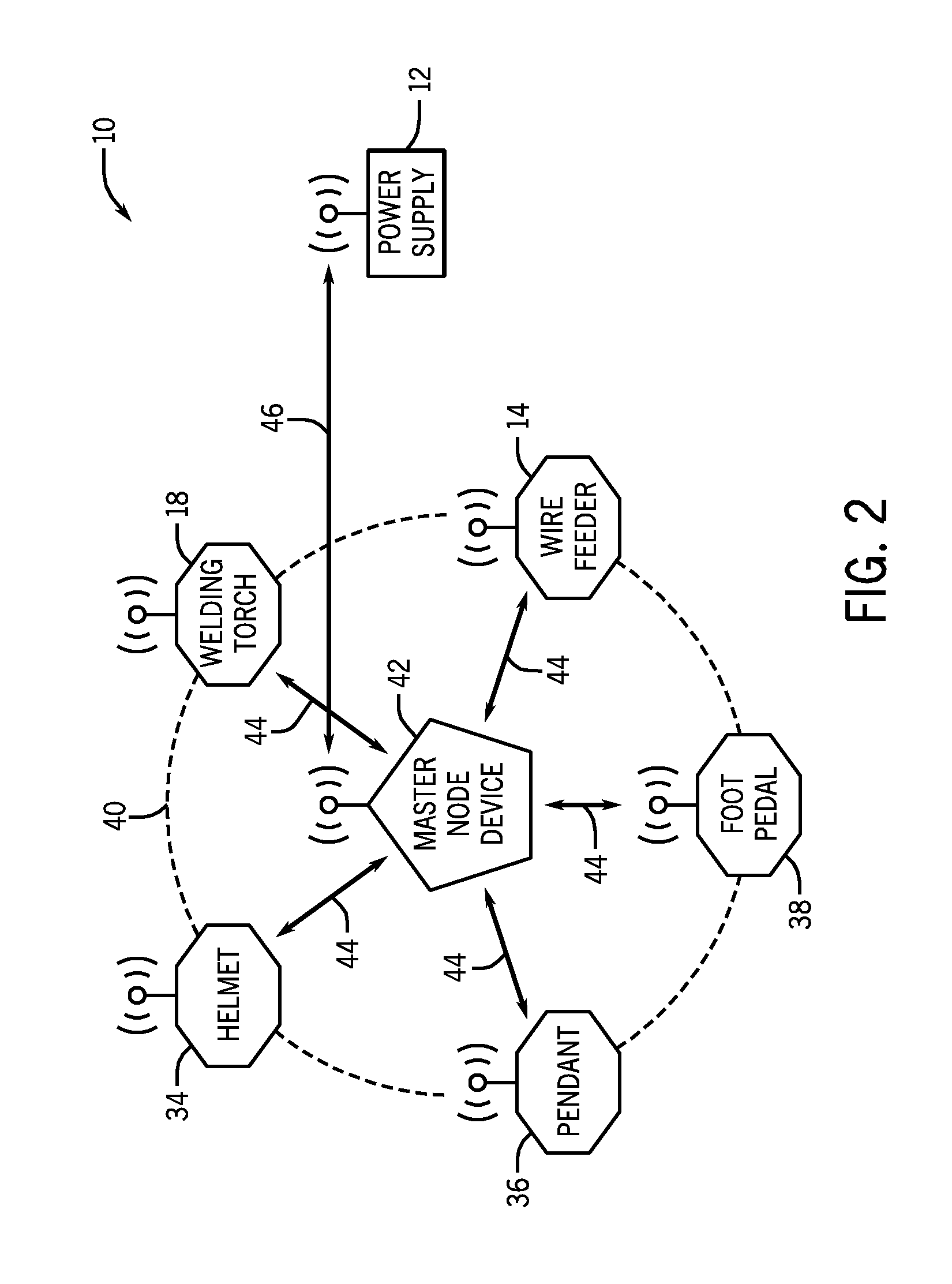

Wireless communication network association and security for control of industrial equipment in harsh environments

In certain embodiments, a system includes a master node device. The master node device includes communication circuitry configured to facilitate communication with a welding power supply unit via a long-range communication link, and to facilitate wireless communication with one or more welding-related devices via a short-range wireless communication network. The master node device also includes control circuitry configured to associate the one or more welding-related devices with the short-range wireless communication network. The master node device further includes means for manually initiating association of the one or more welding-related devices with the short-range wireless communication network.

Owner:ILLINOIS TOOL WORKS INC

Face Protector Lens Assembly and Method of Use

A lens assembly for securing in an opening in a face plate of a face protector has a first, retainer lens of shape and dimensions configured to be secured in the front opening of a face plate and having a curvature substantially matching the curvature of the face plate. A second lens of smaller dimensions is secured behind the first lens to provide a lens-in-a-lens configuration. The lens assembly may be releasably secured in the face plate opening and the second lens is interchangeable with sets of lenses having different properties such as lens shade. The retainer assembly has a back cover and a gasket or spacer between the back cover and second lens to allow second lenses of different depths to be secured in the assembly.

Owner:WRIGHT STACI +1

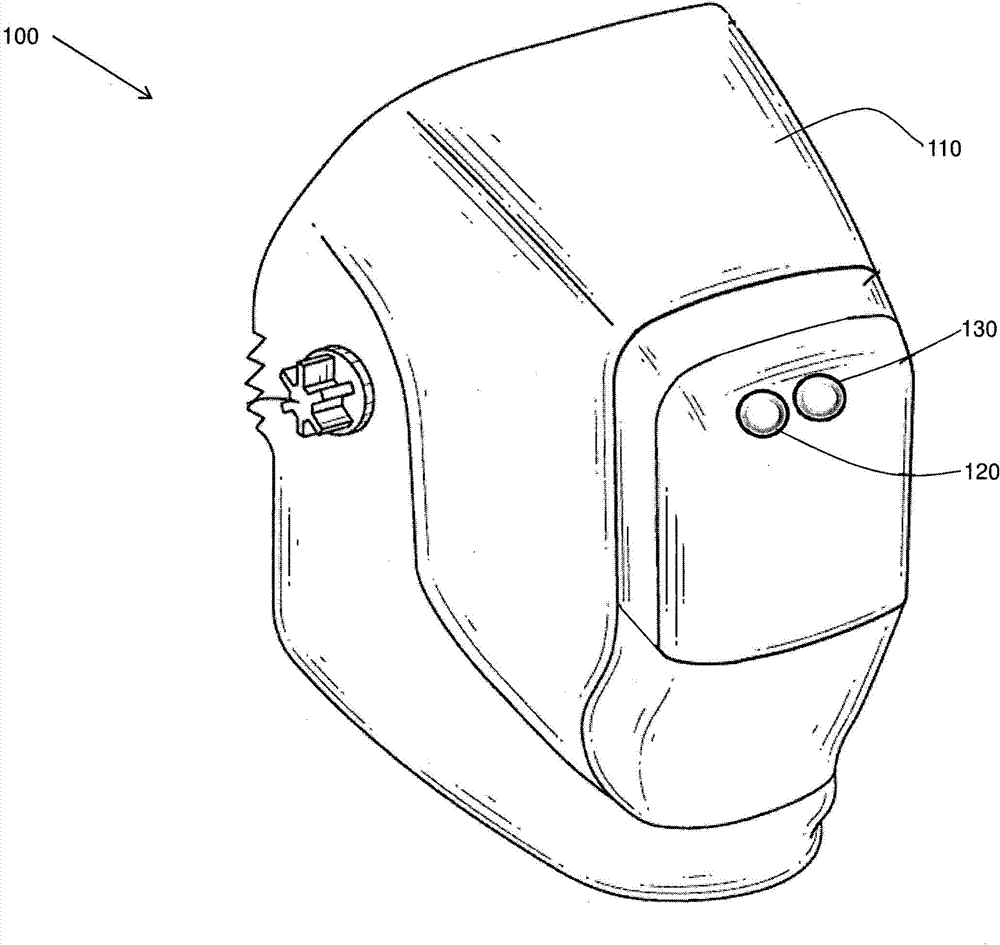

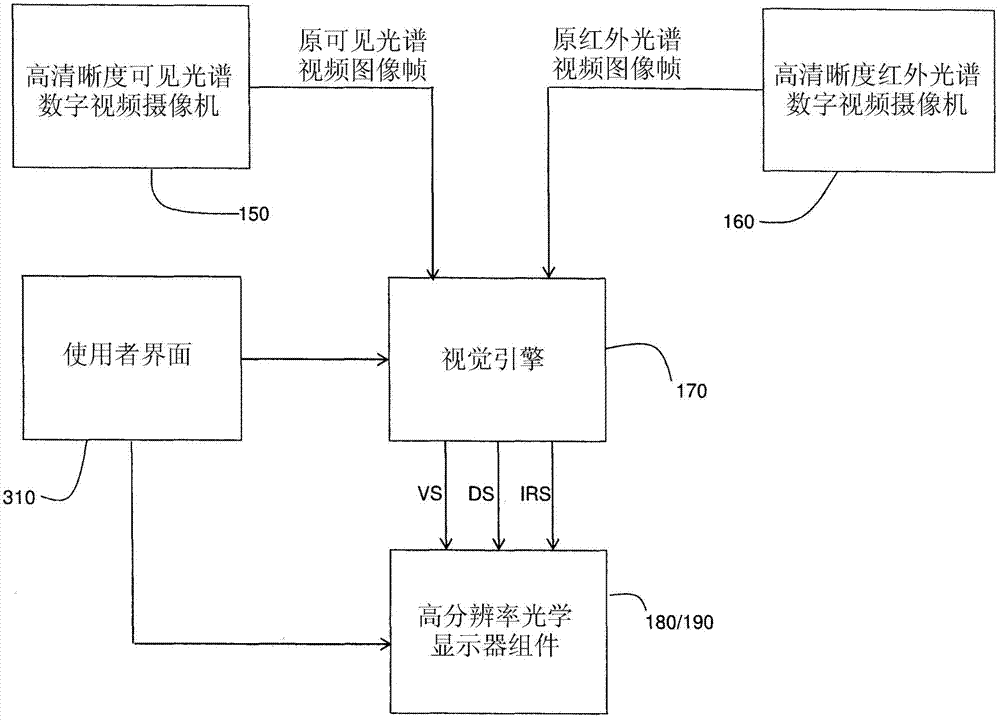

Dual-spectrum digital imaging welding helmet

Arc welding systems, methods, and apparatus that provide dual-spectrum, real-time viewable, enhanced user-discrimination between arc welding characteristics during an arc welding process. Welding headgear (110) is configured to shield a user from harmful radiation and to include a digital camera or cameras (150, 160) to provide dual-spectrum (i.e., both visible spectrum and infrared spectrum) real-time digital video image frames. The welding headgear (110) is also configured with an optical display assembly for displaying real-time digital video image frames to the user while wearing the headgear (110) during an arc welding process. Image processing is performed on the visible and infrared spectrum video image frames to generate dual-spectrum video image frames providing an integrated and optimized view of both the visible and thermal characteristics of the arc welding process which can be viewed by the user on the optical display assembly in real time.

Owner:LINCOLN GLOBAL INC

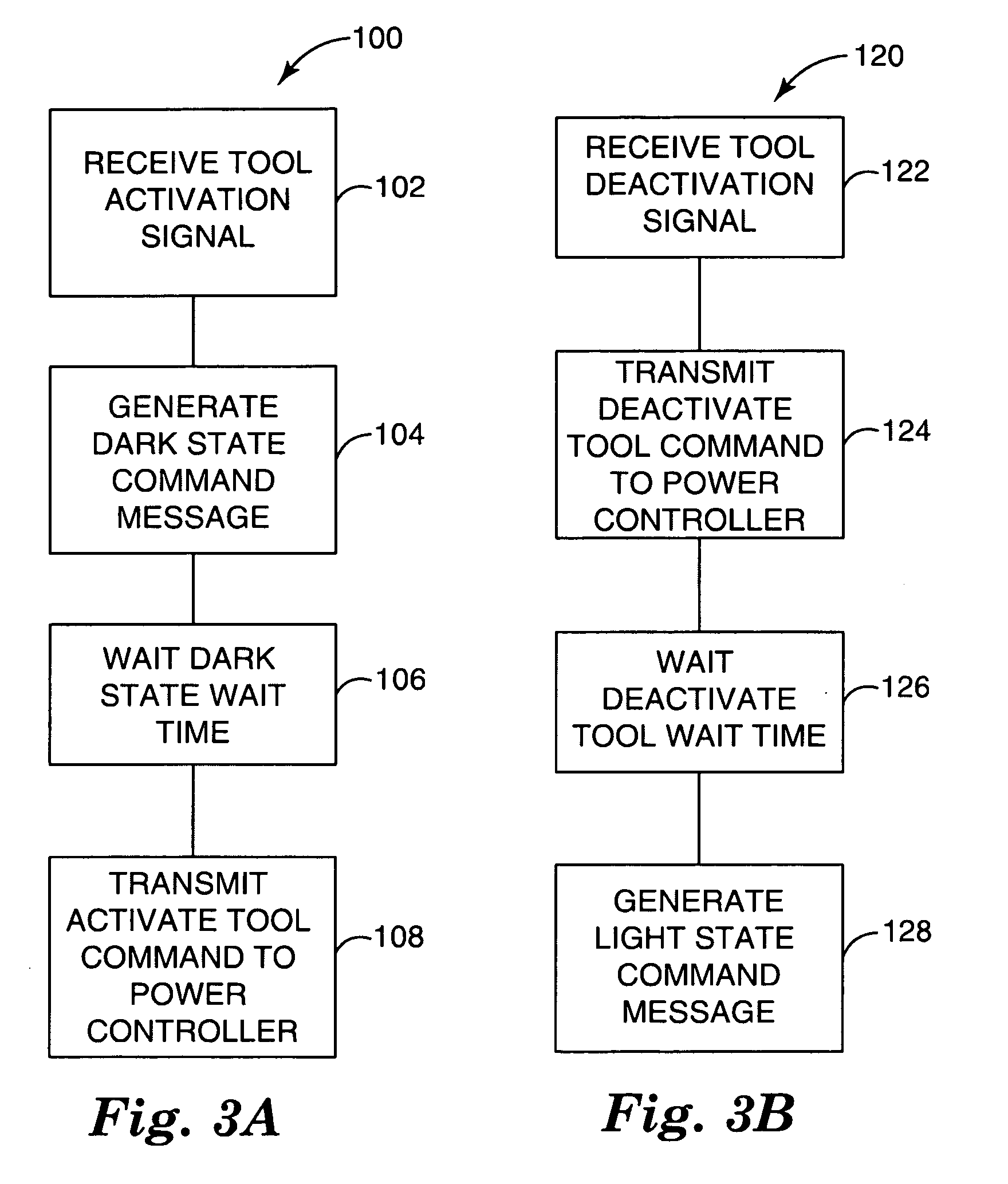

Control of an automatic darkening filter

A protective automatic darkening filter (ADF) and an associated tool, such as a welding torch, are controlled by a corresponding communication unit. The invention helps to ensure that the tool is not activated before the ADF has reached its dark state. A communication channel between the communication unit and the ADF may be established using a wired or wireless medium.

Owner:3M INNOVATIVE PROPERTIES CO

Electric-arc resistant face shield or lens including ir-blocking inorganic nanoparticles

A transparent electric-arc resistant composition is produced by preparing crystalline tungsten bronze nanoparticles and homogenously dispersing the nanoparticles in a transparent plastic matrix. The crystalline tungsten bronze nanoparticles are prepared by homogeneously mixing an aqueous solution of soluble tungsten and cesium salts and then drying the solution. The dried solution is then heated in a reducing gas or inert gas atmosphere to form crystalline tungsten bronze nanoparticles. Thereafter, a dispersion agent is added and the nanoparticles are dispersed in a liquid solvent medium by wet milling to form a dispersion mixture. The dispersion mixture is then mixed with polymer pellets to form a polymer mixture, and the polymer mixture is then extruded to yield polymer pellets containing highly homogeneously dispersed inorganic nanoparticles. During or after dispersion, additional particles, dyes, heat stabilizers or UV absorbers, may be added. A lens or shield is then molded from the polymer pellets.

Owner:HONEYWELL INT INC

System and method for welding system cable management

ActiveUS20140069904A1Restrict movementWelding electric supplyCouplings bases/casesManagement systemCable management

Embodiments of the present disclosure include a cable management system with a housing comprising a first shell and a second shell configured to couple together about welding system cabling such that a portion of the welding system cabling is contained by the housing. The first and second shells form openings at ends of the housing such that the welding system cabling is capable of extending through the openings and such that edges of the openings enclose a perimeter of the welding system cabling when the first and second shells are coupled together about the welding system cabling. A cradle receives a weld cable of the welding system cabling. A cable clamp engages the weld cable and cooperates with the cradle to restrict movement of the weld cable when the weld cable is disposed in the cradle and the cable clamp is engaged.

Owner:ILLINOIS TOOL WORKS INC +1

Real-time monitoring device for welding robot welding process

The invention discloses a real-time monitoring device for a welding robot welding process. The device comprises a welding gun, an image collection mechanism, a laser transmitting mechanism and a temperature collection mechanism. The image collection mechanism and the laser transmitting mechanism are fixedly arranged on the welding gun. The image collection mechanism comprises a U-shaped support and a charge coupled device (CCD) camera, an aluminum sleeve is arranged on the outside of a machine body of the CCD camera, and a copper foil is coated on the inner lateral wall of the aluminum sleeve. A copper sleeve is arranged on the outside of a lens, and a plastic filler is arranged between the lens and the copper sleeve. The laser transmitting mechanism comprises an aluminum column and an end cover. A laser light-emitting diode is arranged in the aluminum column. The temperature collection mechanism comprises a plurality of thermocouples arranged evenly at intervals and a data collection module. The data collection module and the CCD camera are connected onto an industrial personal computer through universal serial bus (USB) transmission lines respectively. By means of a laser beam transmitted by the laser light-emitting diode and the CCD camera, active vision sensing can be achieved, and fusion processing and monitoring of collection data of temperature and subjective vision are achieved through the industrial personal computer.

Owner:SHANGHAI UNIV OF ENG SCI

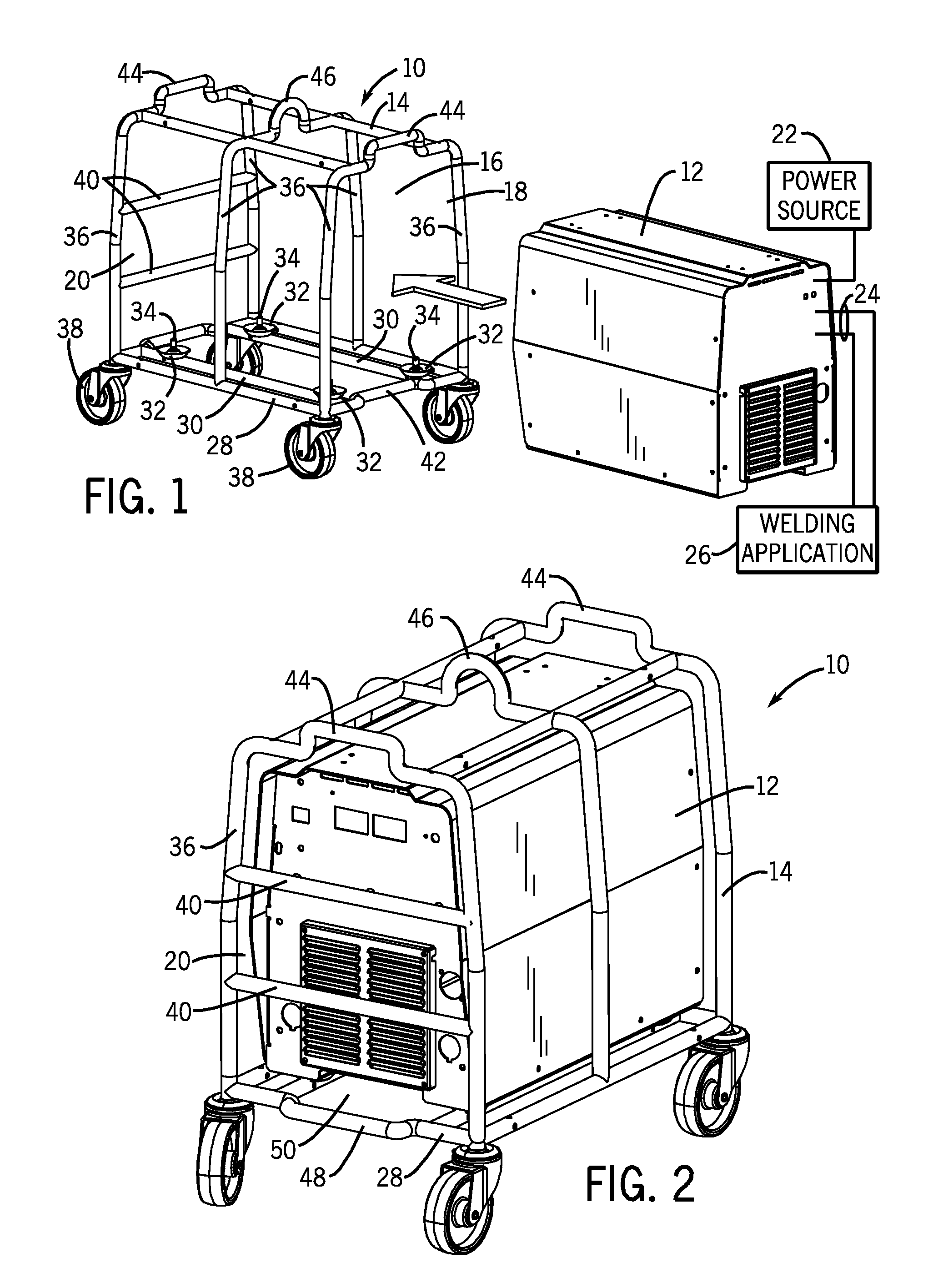

Welding Power Supply External Protective Support Structure

InactiveUS20110204013A1Welding/cutting auxillary devicesMachines/enginesWelding power supplyElectrical and Electronics engineering

An external support structure for a welding power supply includes a cage-like assembly that is configured to receive and at least partially surround the welding power supply. The cage-like assembly includes fastening points allowing for securement of the welding power supply within the assembly. The assembly further includes stacking members to permit stacking of the assembly with a self-similar structure.

Owner:ILLINOIS TOOL WORKS INC

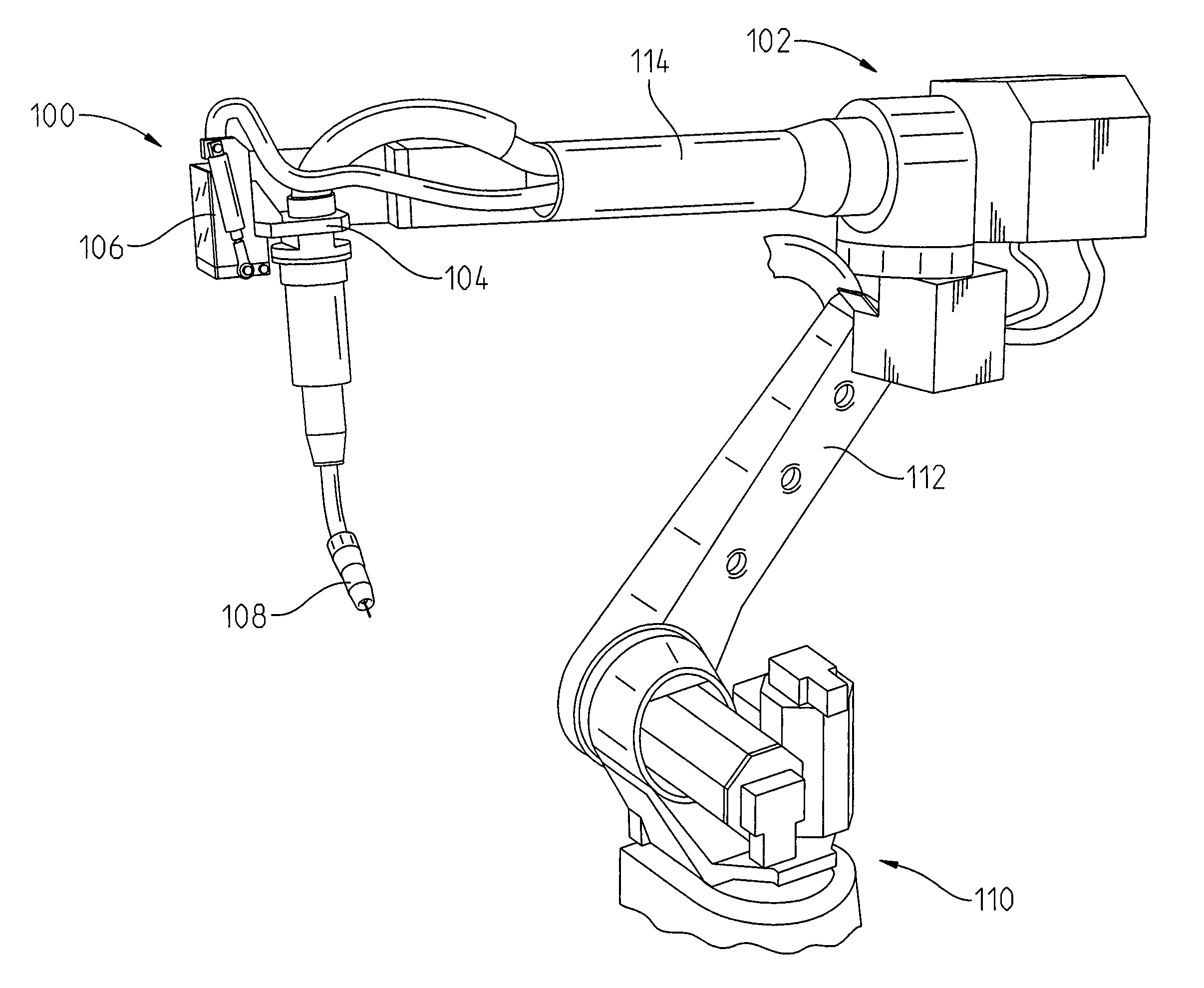

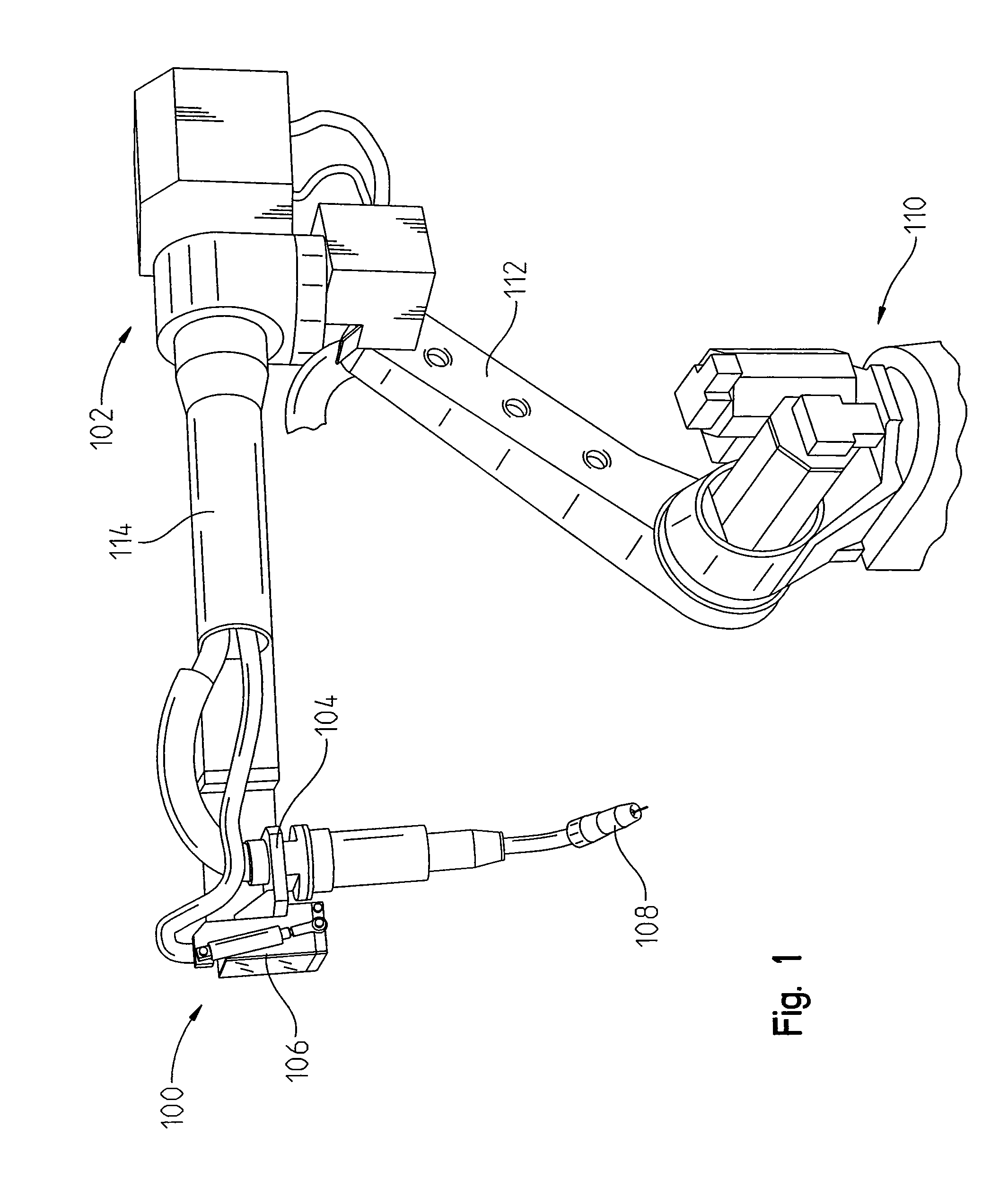

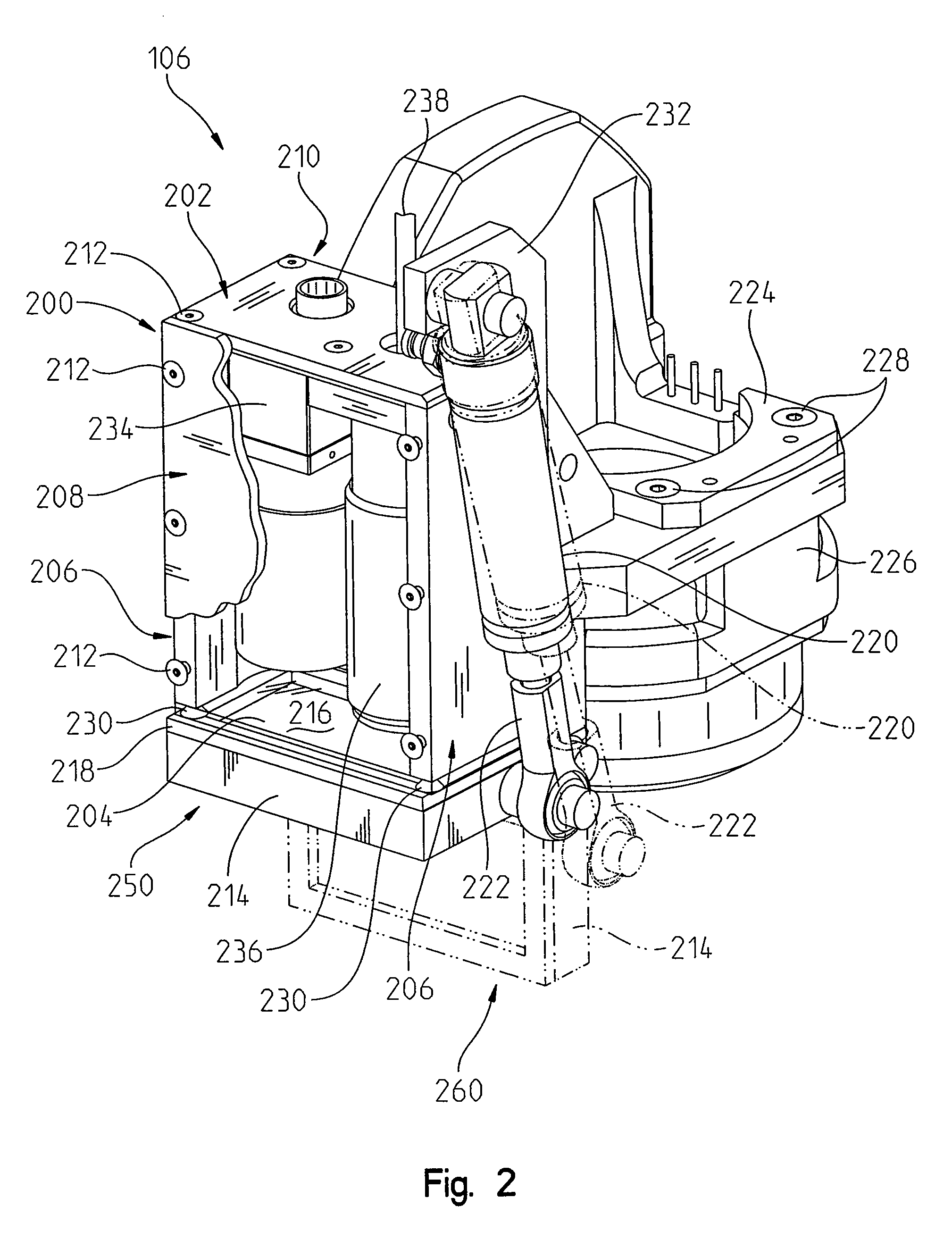

Protective enclosure

InactiveUS20120325781A1Enhance the imageConveniently mountedWelding/cutting auxillary devicesContainer/bottle contructionRobotic armEngineering

The present disclosure provides a system for carrying out a welding process. The system includes a controllable robot having a robotic arm and a welding device coupled to the robotic arm. The welding device is configured to perform the welding process. The system also includes a housing coupled to the robotic arm adjacent the welding device and a closure member pivotably coupled to one end of the housing. The closure member is adapted to pivot between an open position and a closed position. A camera is disposed in the housing and removably coupled thereto. The camera has a lens oriented towards the closure member. The system further includes a light source disposed in the housing and removably coupled thereto such that the light source is disposed adjacent to the camera. During the welding process, the camera and light source are enclosed by the housing and closure member.

Owner:DEERE & CO

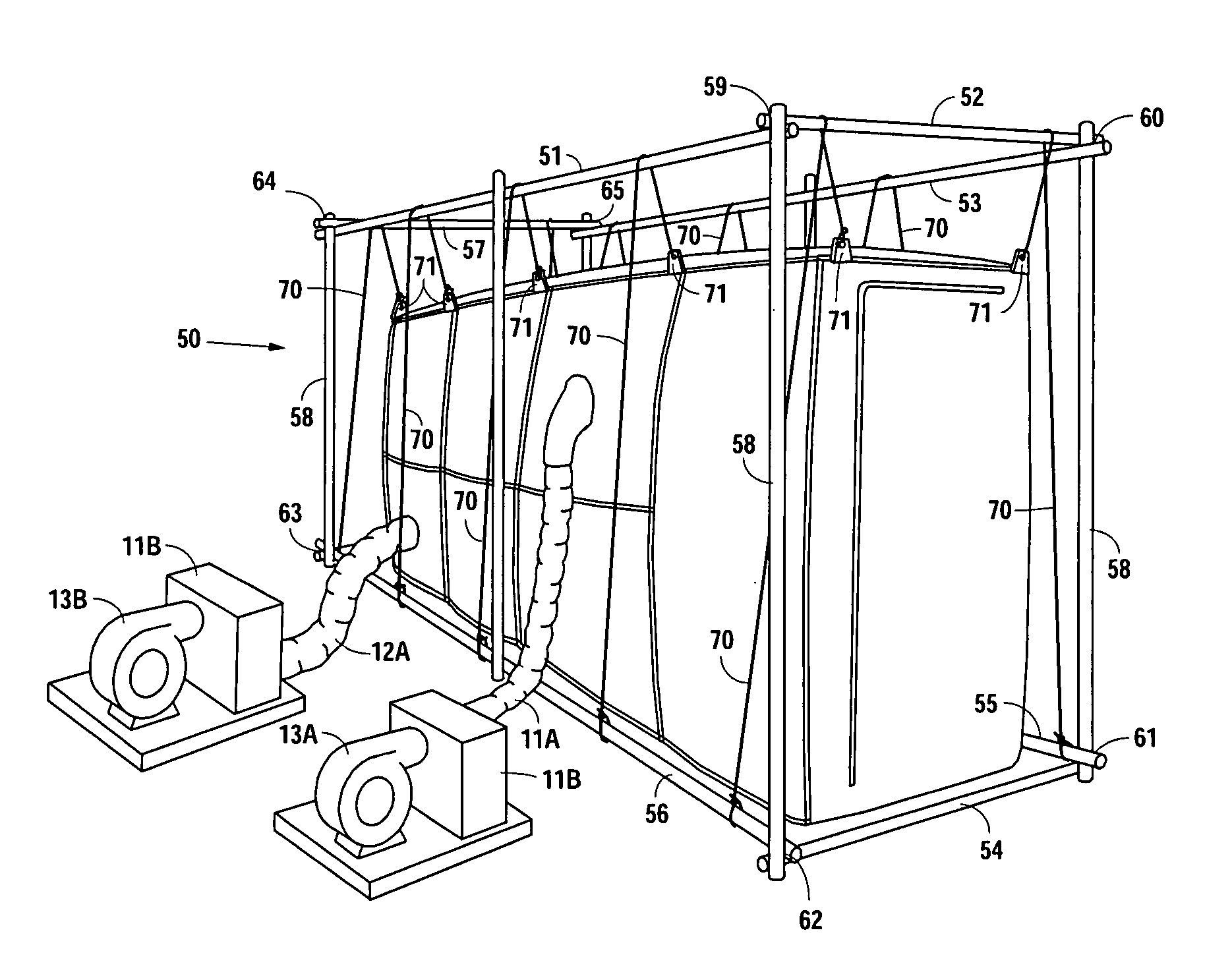

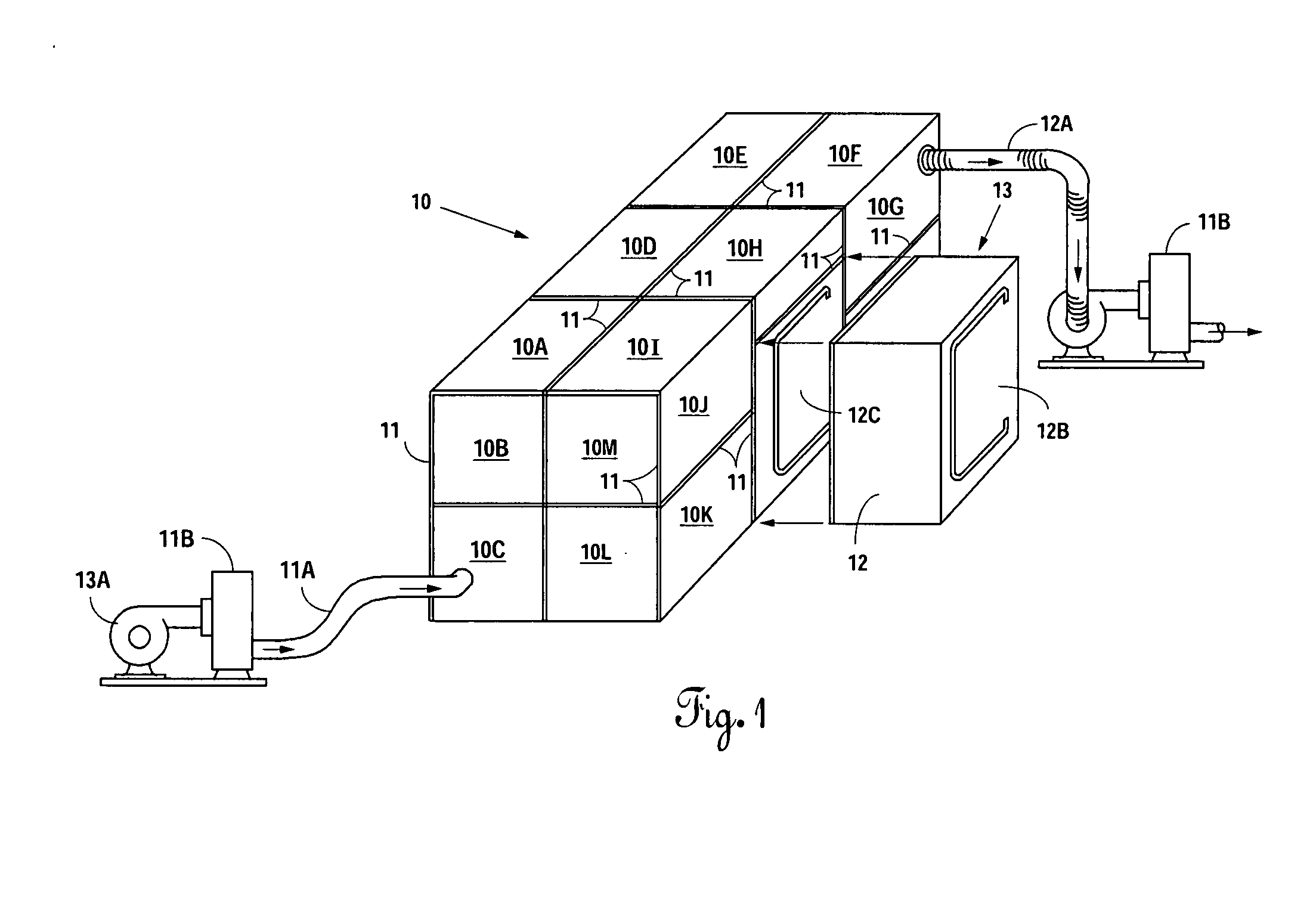

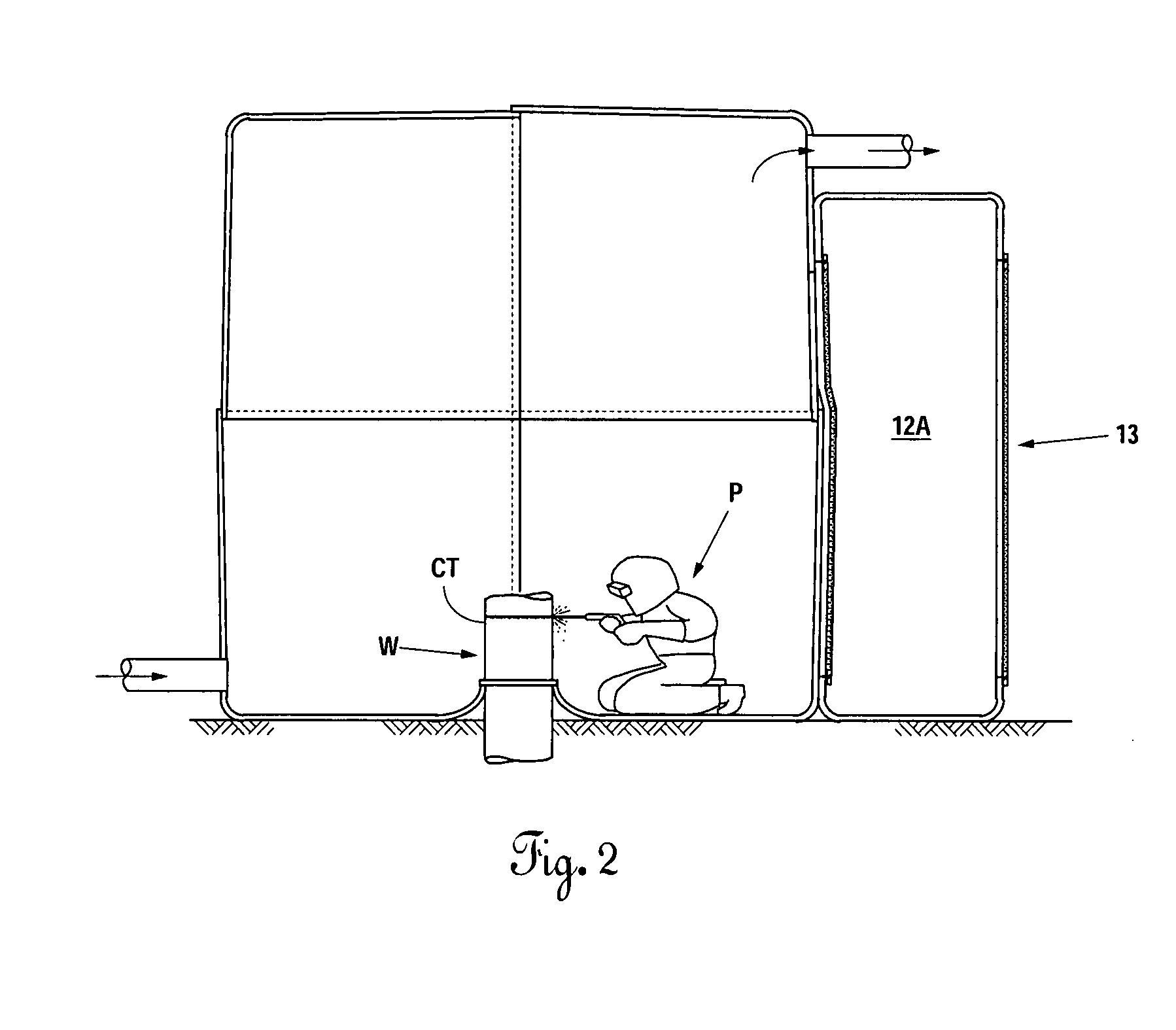

Modular welding or like operation conduit enclosure abstract of the disclosure

An inflatable modularly constructed for use over cites near welding or other operations upon, for example, one or more conduit members, in order to retain within the interior structure unwanted gases, flake, slags, sparks and other debris. The modules may be shaped and provided in such numbers as to provide a specific contour with each member being re-usable in combination with other members for subsequent operations. The modular members are selectively secured together so as to be substantially air tight to provide effective inflation of the unit. A framework may also be provided to assist in enhancing effective inflation during work operations. Fans and filter units may be provided for continuous inflation and to filter the intake inflation gas.

Owner:CINARUCO INT

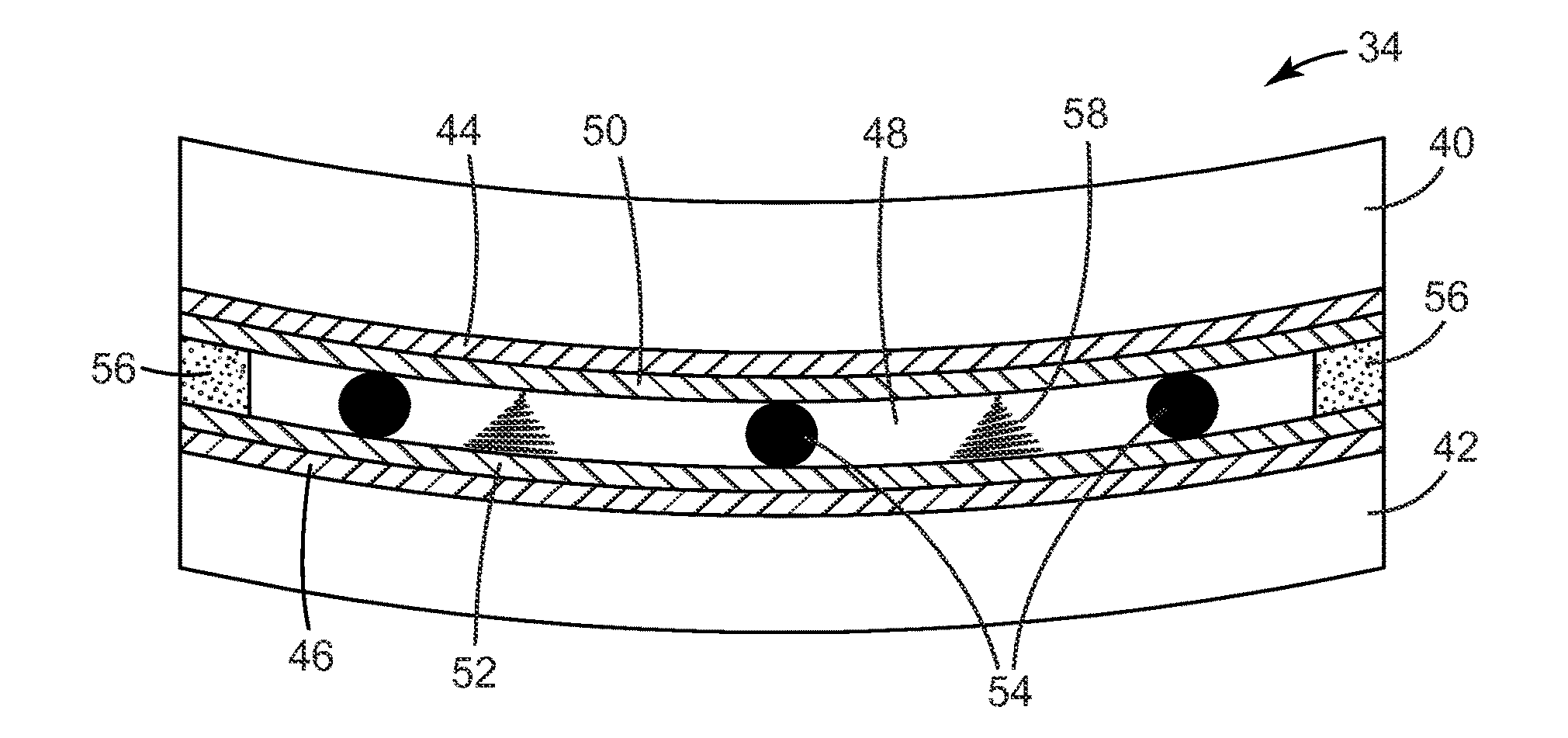

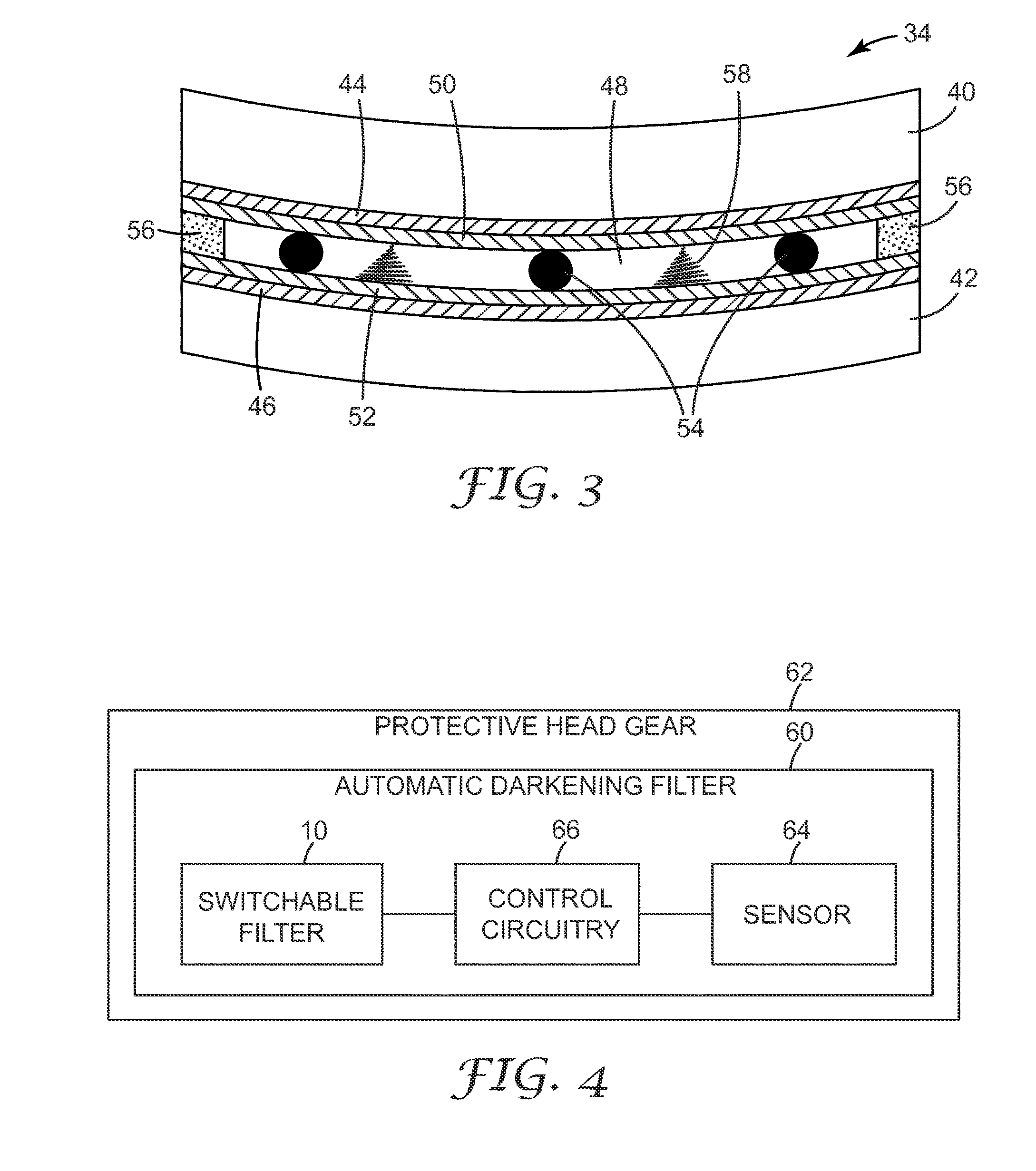

Curved Automatic-Darkening Filter

ActiveUS20160262467A1Expand field of viewReduce weightLamination ancillary operationsGogglesPolarizerLight filter

An automatic-darkening filter 10, 10′ that comprises a first polarizer 14, a second polarizer 18, a first liquid-crystal cell 16, and a sensor 64. The first polarizer 14 has a first polarization direction, and the second polarizer 18 has a second polarization direction. The liquid crystal cell 16 is disposed between the first and second polarizers 14, 18 and contains first and second optically-transparent, flexible, glass layers 40 and 42 with the liquid crystal layer 48 being located between these layers. The sensor 64 detects incident light and causes a signal to be sent, which causes molecular rotation within the liquid crystal layer. The inventive automatic-darkening filter is beneficial in that overall product weight can be reduced and the view field can be increased.

Owner:3M INNOVATIVE PROPERTIES CO

Welding system providing visual and audio cues to a welding helmet with a display

A system for aiding a user in at least one of welding, cutting, joining, and cladding operations is provided. The system includes a welding tool and a welding helmet with a face-mounted display. The system also includes a spatial tracker configured to track the welding helmet and the welding tool in 3-D space relative to an object to be worked on. A processor based subsystem is configured to generate visual cues based on information from the spatial tracker and transmit the visual cues to a predetermined location on the face-mounted display.

Owner:LINCOLN GLOBAL INC

Multi-function face protector

Disclosed herein is a face protector having a protective shade that enables the worker to perform welding as well as grinding while wearing the multi-function face protector and that can be used with safety glasses, goggles and a mask. The multi-function face protector includes a head band, a forehead cover, and a face shield. The face shield comprises resilient hooks formed at its upper central portion, and engaging portions formed at its opposite ends respectively. The forehead cover comprises shield couplings formed at the central portion of its inner surface, and projections formed at the opposite ends of its inner surface respectively. The resilient hooks of the face shield are engaged with the respective shield couplings of the forehead cover.

Owner:OTOS TECH

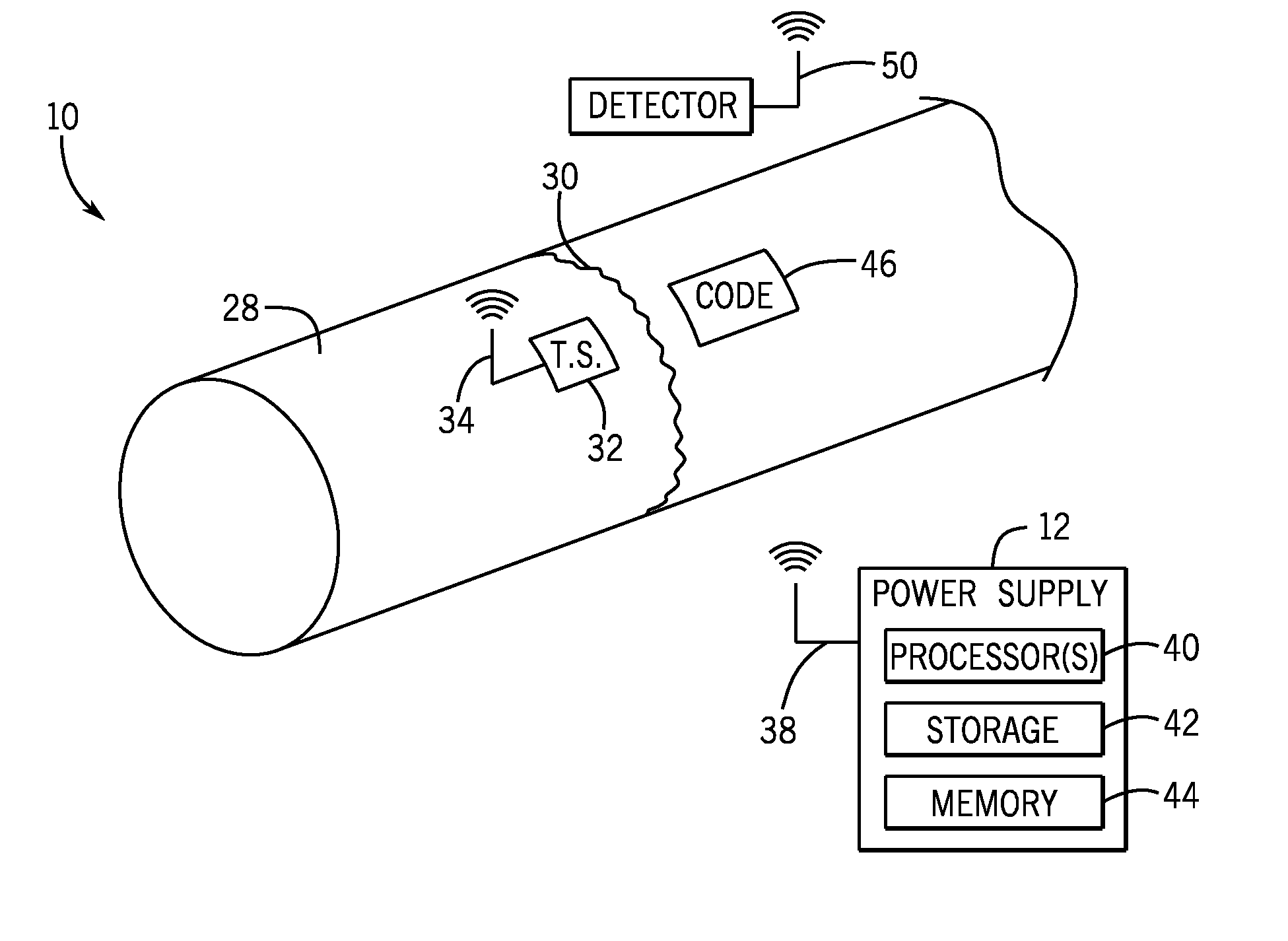

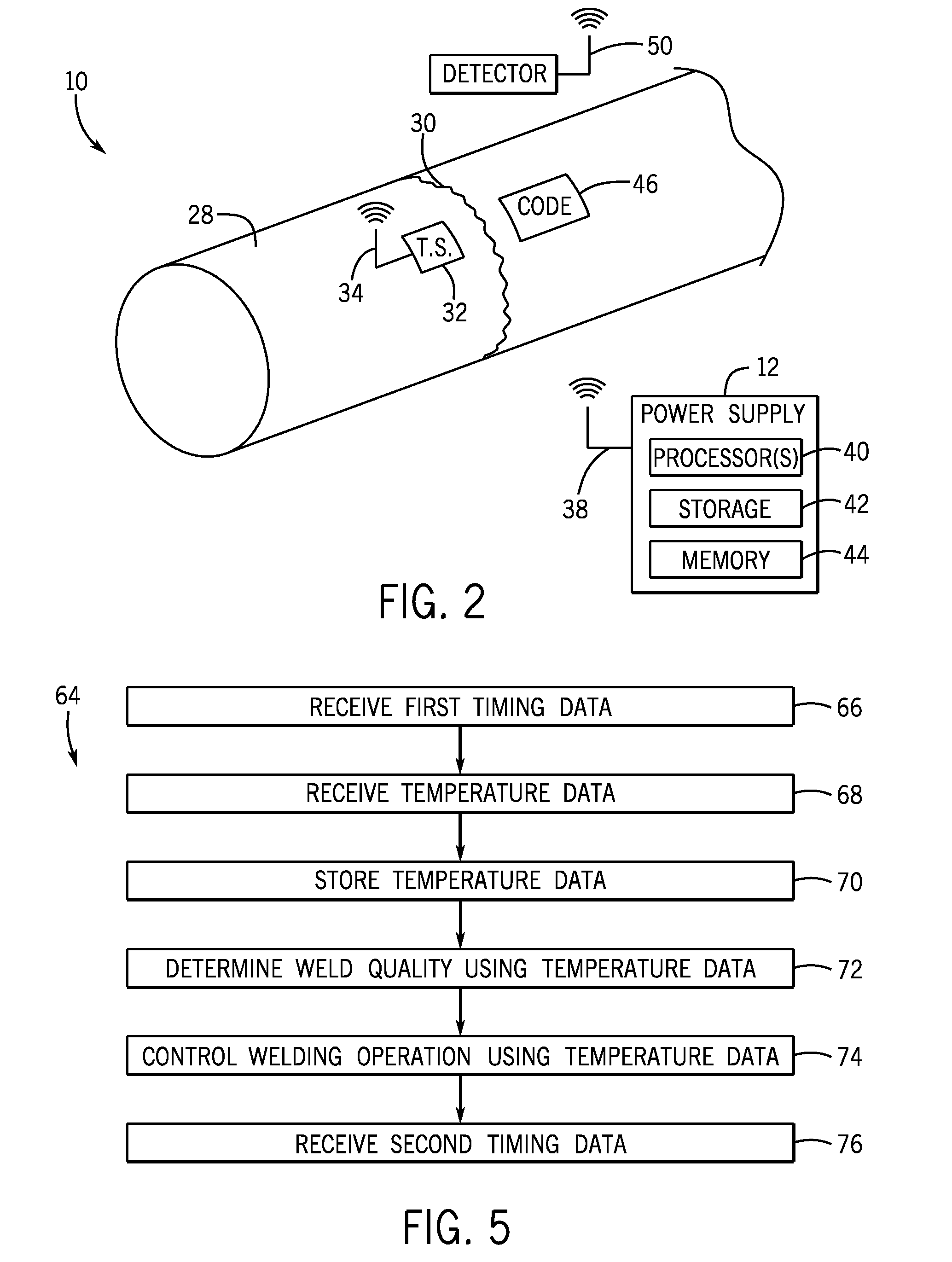

Welding system for determining a quality of a welding operation

ActiveUS20140332514A1Determining of operationPlasma welding apparatusMetal working apparatusEngineeringElectrical and Electronics engineering

A welding system includes a repositionable temperature sensor. The repositionable temperature sensor is configured to detect temperatures corresponding to a workpiece and to provide temperature data corresponding to the detected temperatures. The welding system also includes a power supply configured to receive the temperature data from the temperature sensor. The power supply is configured to modify control of an output of the power supply based on the detected temperature.

Owner:ILLINOIS TOOL WORKS INC

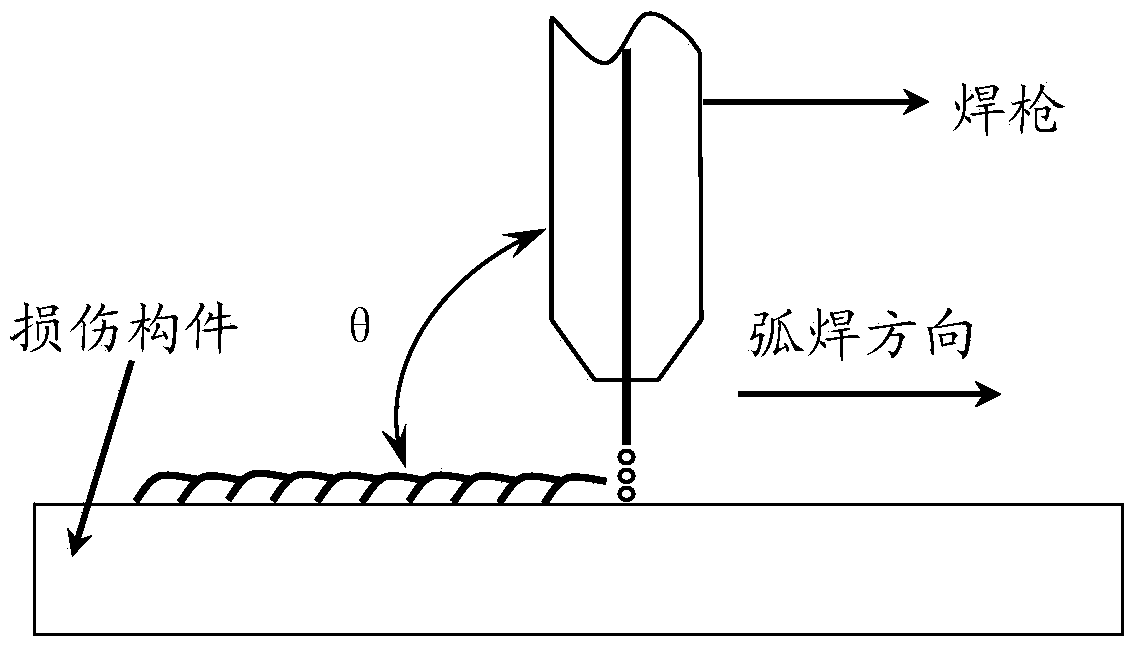

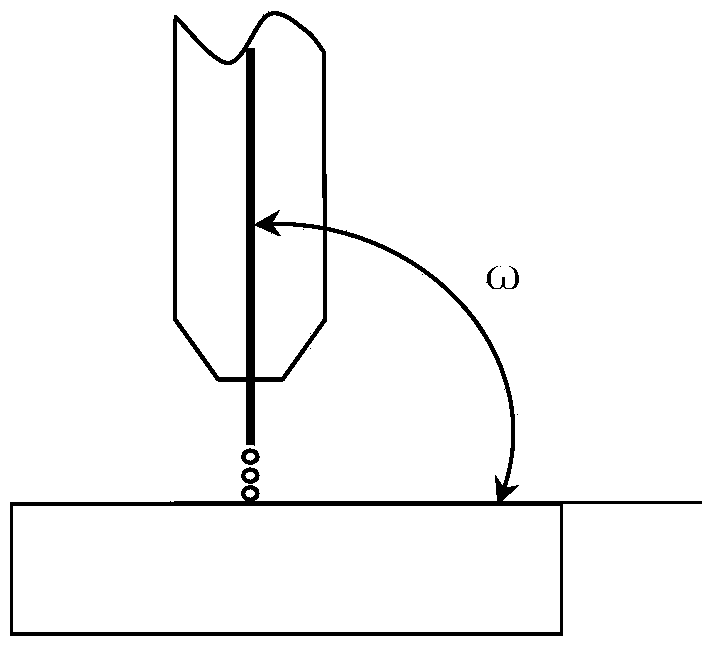

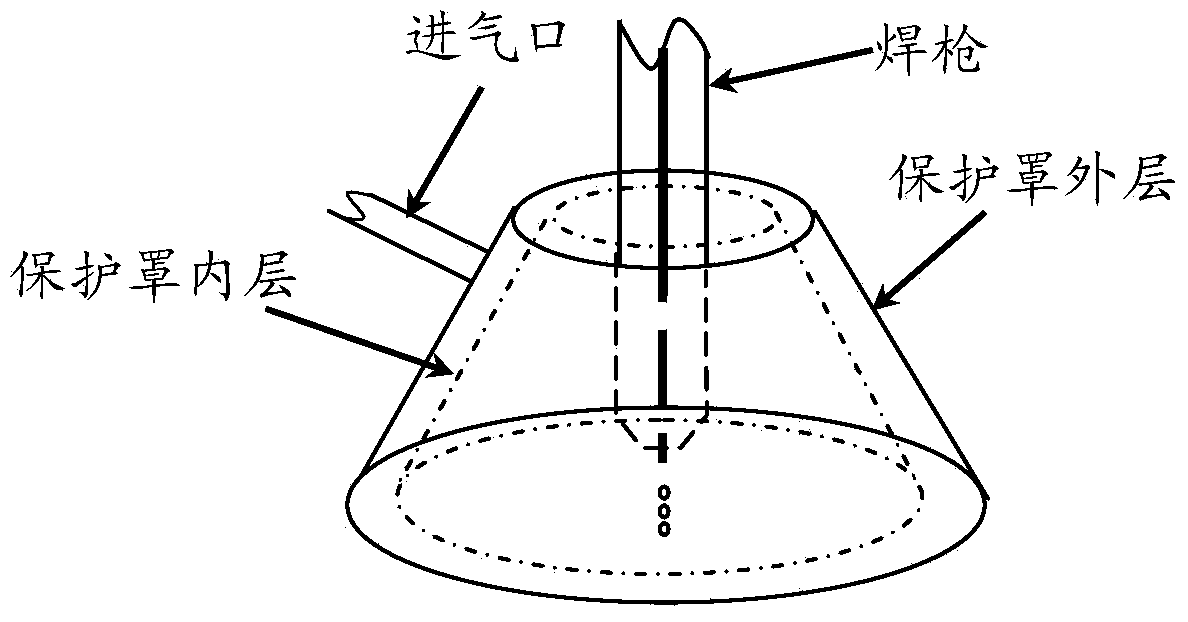

Titanium and titanium alloy component arc welding adding material remanufacturing method

ActiveCN104014912ASmall sizeImprove performanceWelding/cutting media/materialsWelding/soldering/cutting articlesAttitude controlShielding gas

The invention discloses a titanium and titanium alloy component arc welding adding material remanufacturing method. In the arc welding adding material remanufacturing process, the pulse MIG welding technology is adopted, the mode of metal transfer is spray transfer, a double-microdomain adjusting mode is adopted in gas protection, the appearance structure is a bell jar type or a ship type, and a front stretching and back extending mode is adopted in protection gas supplying and non-supplying; the inclination angle theta and the inclination angle omega of opposite welding lines of a welding gun are controlled; argon or argon-helium or helium-argon or helium is adopted as the double-microdomain protection gas; an arc welding robot is adopted to control the moving speed and posture of the welding gun. The titanium and titanium alloy component arc welding adding material remanufacturing method solves the problems of gas protection, technology optimization and quality control in the titanium and titanium alloy component MIG arc welding adding material remanufacturing, adding material remanufacturing of abraded or broken titanium and titanium alloy components is achieved, the gas protection structure is simple, easy to use and good in protection effect, a sealing gas chamber is not needed, more than 40 percent of materials can be saved, the thermal input can be reduced by more than 20 percent, and the titanium and titanium alloy component arc welding adding material remanufacturing quality is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

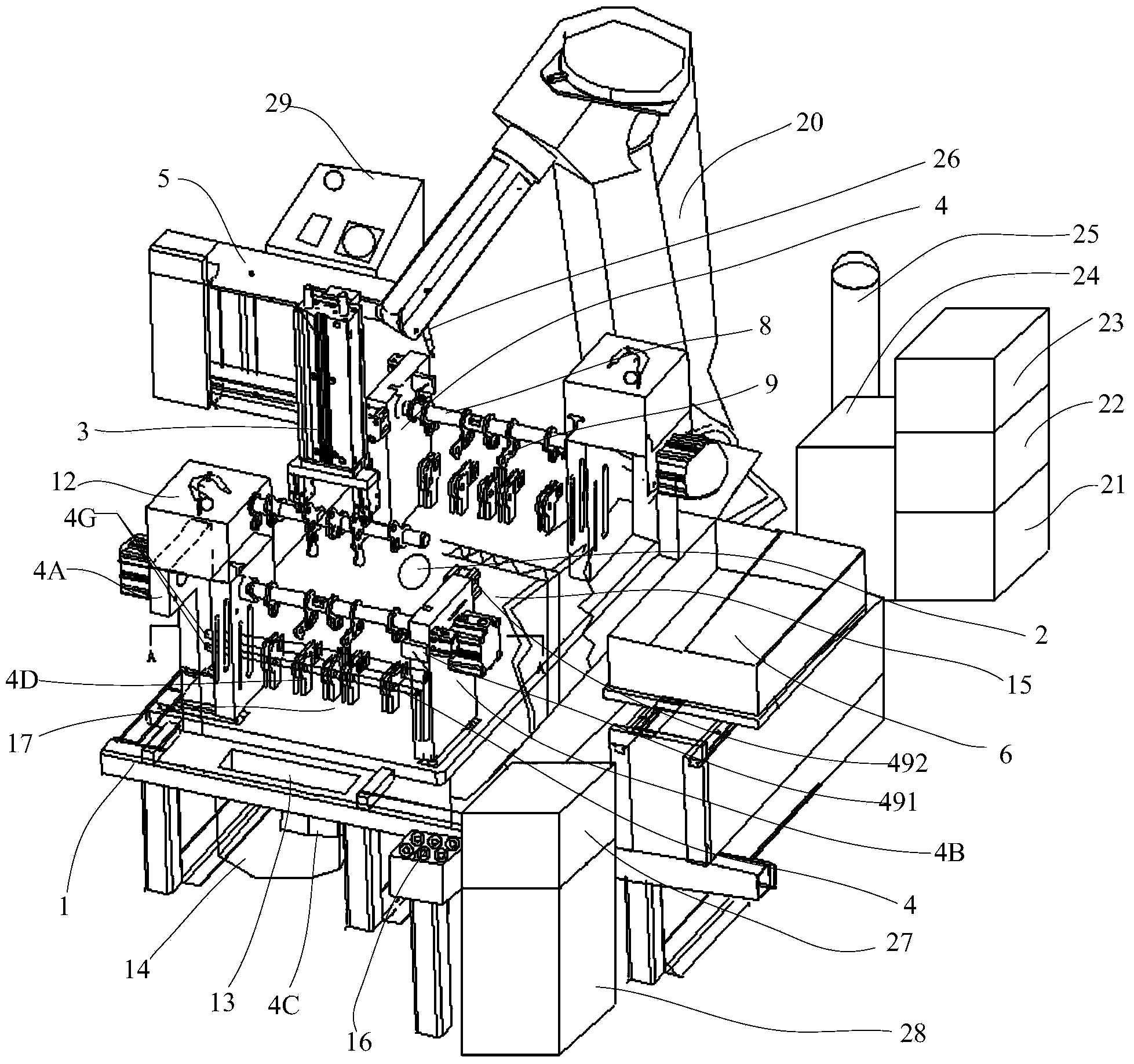

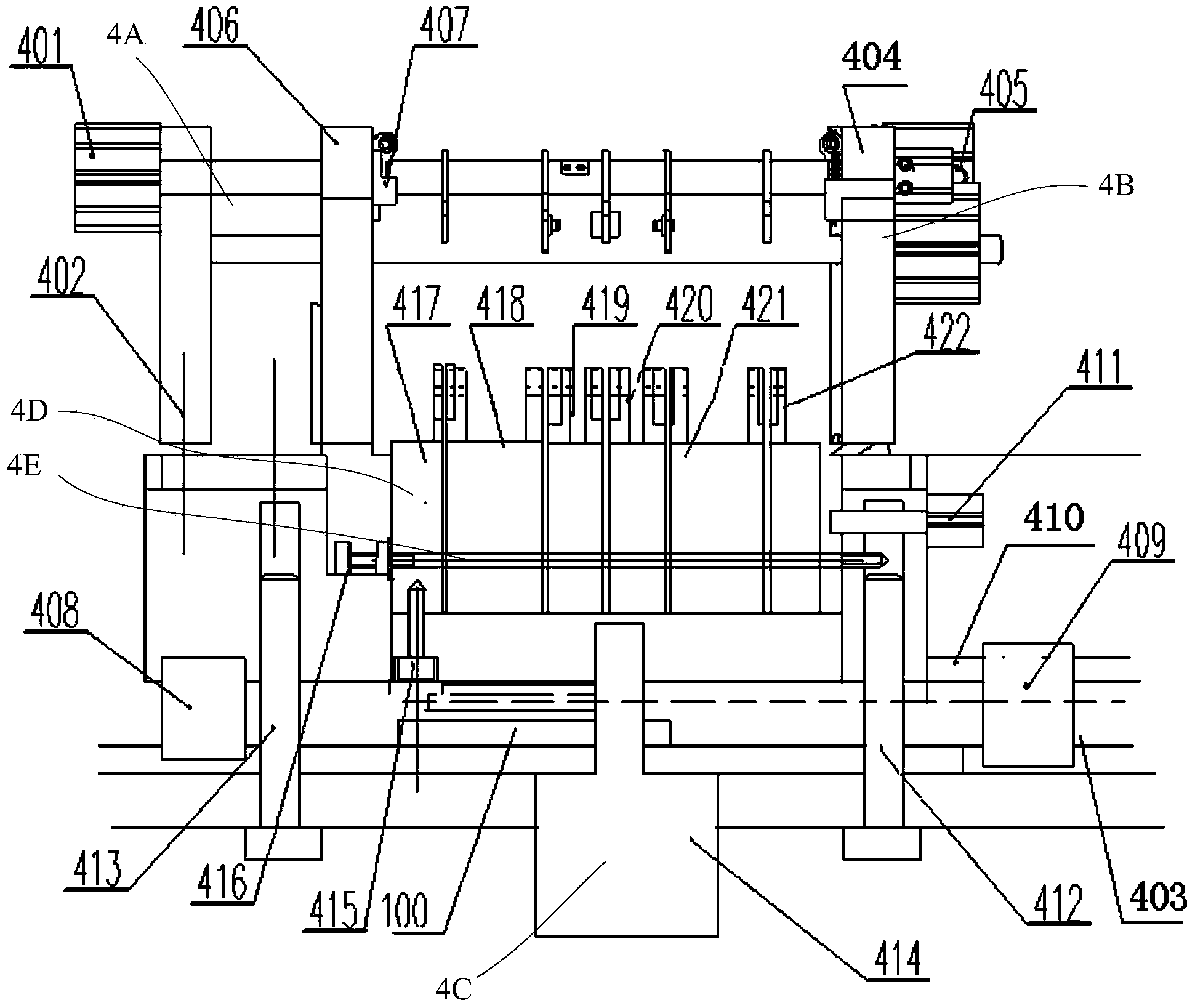

Rotating shaft welding jig, rotating shaft welding worktable and automatic rotating shaft welding system

ActiveCN103506797ASimple structurePrecise control of shape and positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a rotating shaft welding jig, a rotating shaft welding worktable and an automatic rotating shaft welding system. The rotating shaft welding jig comprises a rotating shaft clamp and a component fixing device, wherein the rotating shaft clamp is used for clamping a rotating shaft, and the component fixing device is used for fixing a rotating shaft component which needs to be welded to the rotating shaft. The rotating shaft clamp comprises a rotating shaft supporting and rotating mechanism and a rotating shaft supporting and clamping mechanism, wherein the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism are used for clamping the two ends of the rotating shaft respectively. The component fixing device is arranged between the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism and comprises a rotating shaft component clamping part and a clamping driving part. The rotating shaft component clamping part comprises a plurality of bases which are arranged on a base plate side by side, wherein the bases include at least one fixed locating base and a plurality of sliding bases. The clamping driving part is connected with the rotating shaft component clamping part and can drive the sliding bases to slide towards the locating base so that the adjacent bases can clamp and loosen the rotating shaft component. The rotating shaft welding jig can clamp the rotating shaft and the rotating shaft component at a time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

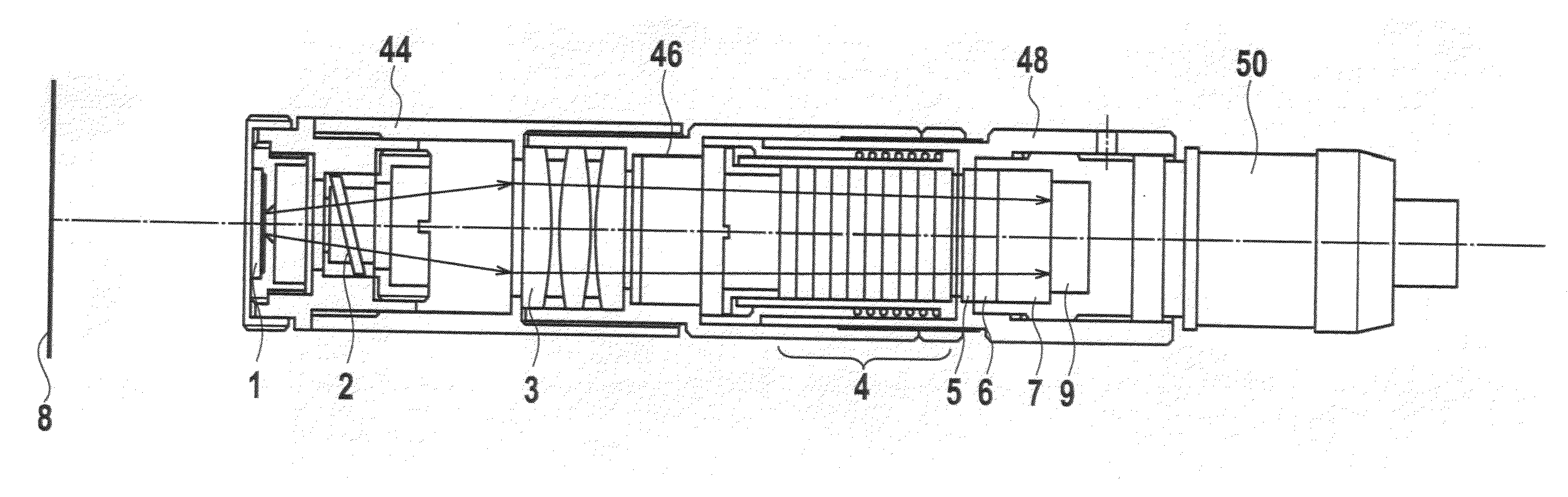

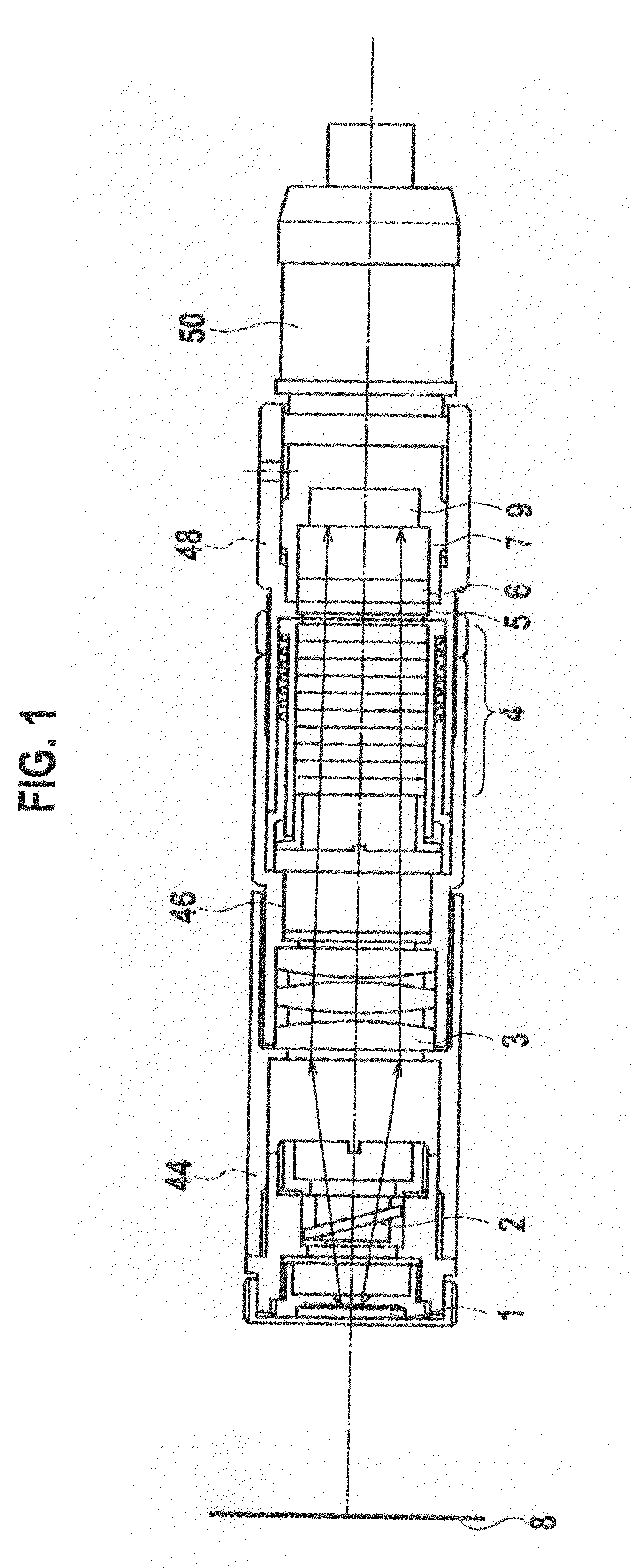

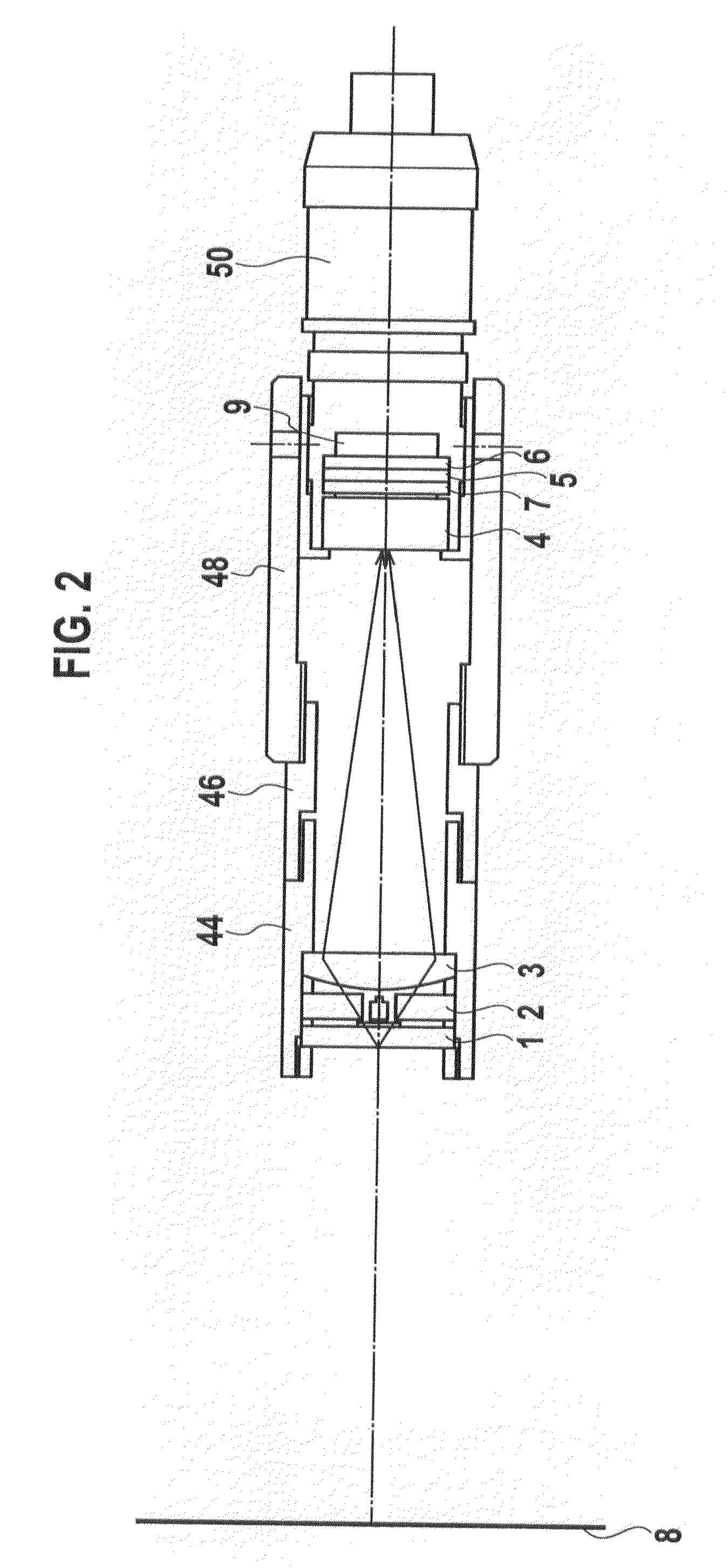

Welding observation device

InactiveUS20100206851A1Analysis by electrical excitationAnalysis by thermal excitationLight guideEngineering

A welding observation apparatus is provided to use partial darkening by a telecentric optical system and a photochromic filter (PCF) as an optical system for filtering light emission from arc discharge in order to verify the welding condition under the welding arc discharge, without forming an image on the PCF, so that light reducing performance can be secured even if a focus shifts from on the PCF, with satisfactory monitoring of welding condition.The welding observation apparatus comprises: an arc welding unit 8; an objective optical system (1, 2) for concentrating light from the arc welding unit 8; a telecentric optical system 3 for guiding the light concentrated by the objective optical system (1, 2); a PCF 4 for illuminating with the light guided by the telecentric optical system 3; and a solid state imaging device 9 for receiving the light passing through the PCF 4, wherein the light from the arc welding unit 8 is partial-darkened by the PCF 4.

Owner:THE FUJIKURA CABLE WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com