Rotating shaft welding jig, rotating shaft welding worktable and automatic rotating shaft welding system

A welding fixture and workbench technology, applied in welding accessories, welding equipment, welding equipment, etc., can solve problems such as cracks, slag inclusions, uneven welding, high labor intensity, etc., to save costs and procedures, improve work High efficiency and good welding fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

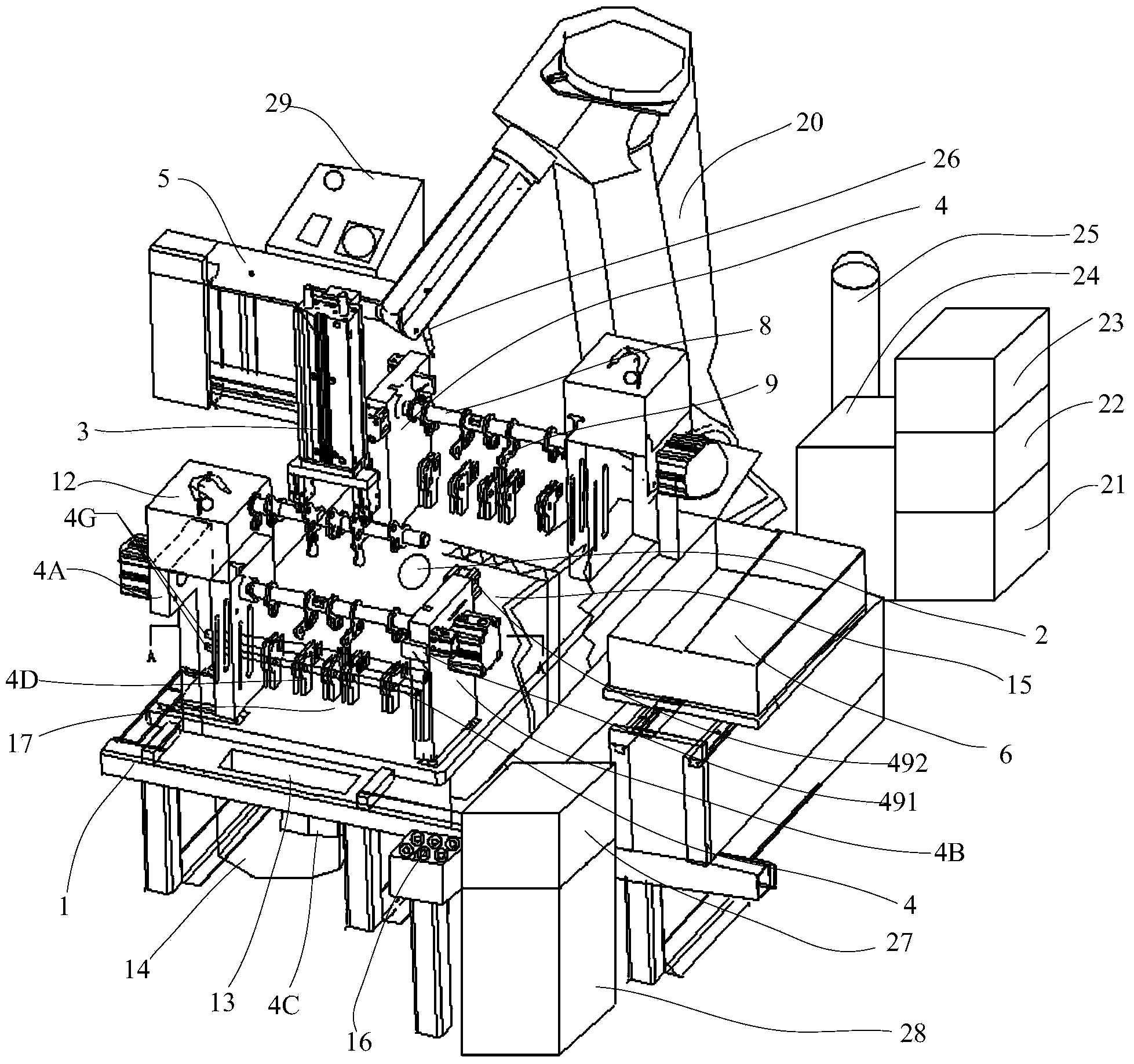

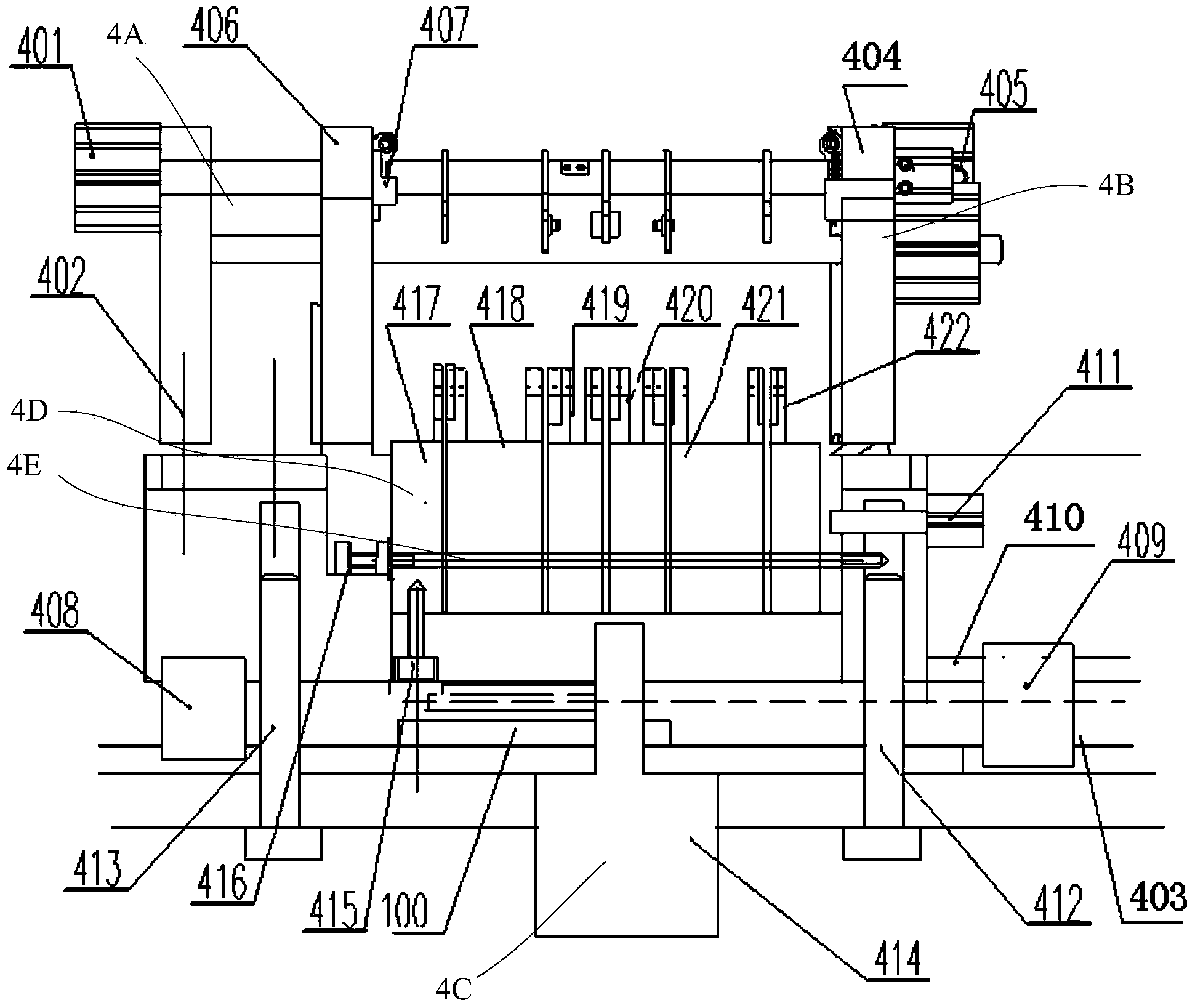

[0041] Such as figure 1 As shown, the present invention provides an automatic welding system for a rotating shaft, including a rotating shaft welding workbench and a robot welding system. The rotating shaft welding workbench and the robot welding system cooperate with each other to realize the welding of the rotating shaft and the rotating shaft components. The rotating shaft welding workbench is used for clamping and fixing the rotating shaft and rotating shaft components to be welded, and the robot welding system is used for performing welding work. The two ends of the rotating shaft welding workbench are equipped with a feeding position and a welding position, which can realize feeding and welding at the same time to improve work efficiency, wherein one end of the welding robot 20 located in the robot welding system is a welding position, and the other end is a feeding position An operation panel 16 is arranged on one side of the loading position, and the control panel 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com