A DC circuit breaker magnetic blowing device

A DC circuit breaker, magnetic blowing technology, applied in the direction of circuit breaker parts, circuits, electrical components, etc., can solve the problems of circuit breaker failure, low magnetic permeability, reducing the environmental applicability of the device, safety and reliability, etc., to achieve High safety and reliability, and the effect of improving breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

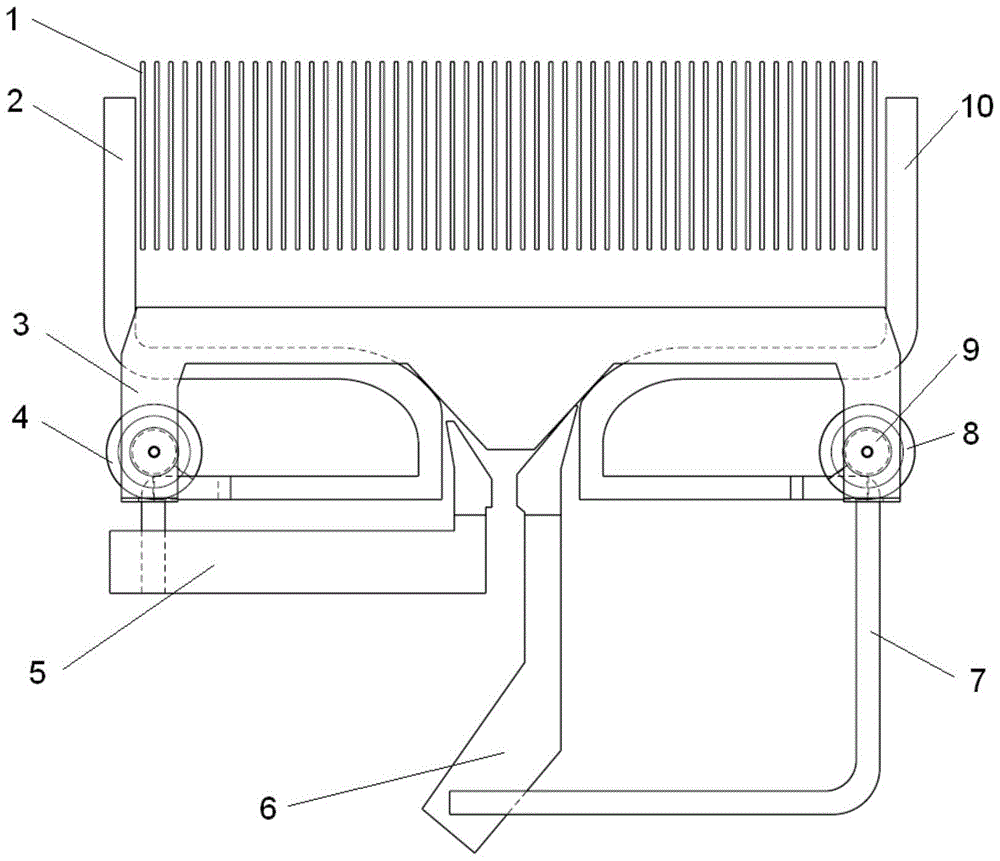

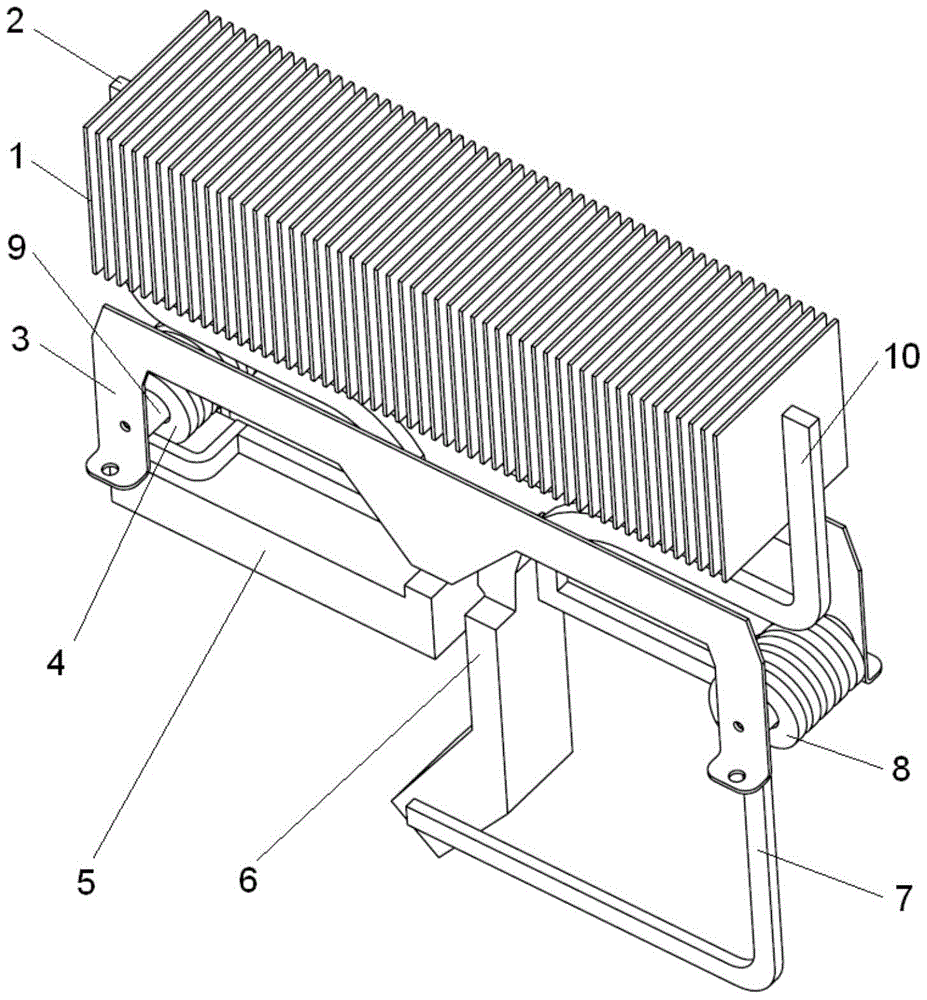

[0025] 1. First, introduce the structure of the present invention. A DC circuit breaker magnetic blowing device of the present invention includes a static end arc striking angle 2 and a moving end arc striking angle 10 arranged at both ends of the arc extinguishing chamber 1; two symmetrically arranged guide magnets The plate 3 is located between the arc striking angle 2 of the static end and the arc striking angle 10 of the moving end, and is arranged under the arc extinguishing chamber; a magnetic blowing coil 4 of the static end is respectively connected with the arc striking angle 2 of the static end and the static contact 5 at both ends , the inner cavity of the static end magnetic blowing coil 4 is coaxially placed with an iron core 9; a moving end magnetic blowing coil 8 connected to the moving end arc striking angle 10 and the moving contact through a wire 7 at both ends, the described An iron core 9 is coaxially placed in the inner cavity of the magnetic blowing coil 8...

Embodiment 2

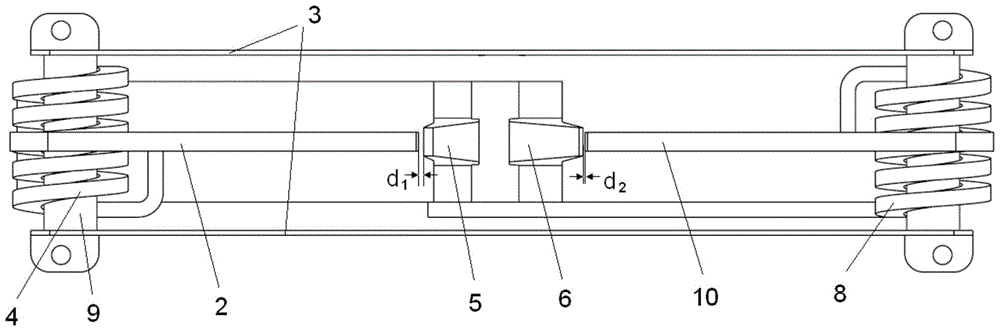

[0029] Example 2: Figure 1~3 The magnetic guide plate 3 in can also be Figure 6 In the structure shown, the structure is to separate the magnet-conducting plate 3 from the symmetrical plane in the middle, and keep a certain distance therebetween. Other structures are the same as in Embodiment 1, and will not be repeated here.

[0030] When working, when the arc is transferred to the dynamic (static) end arc ignition angle 10 (2), the arc will connect the dynamic (static) end arc ignition angle 10 (2) and the dynamic (static) end magnetic blowing coil 8 (4) in series Together, according to Ampere's law, it can be seen that the iron core 9 installed in the cavity of the dynamic (static) end magnetic blowing coil 8 (4) will induce a magnetic field, due to the winding of the static end magnetic blowing coil 4 and the moving end magnetic blowing coil 8 Therefore, the direction of the induced magnetic field in the iron core 9 is the same, and the winding direction of the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com