Welding process of large-sized liquefied natural gas storage tank

A technology of liquid natural gas and welding process, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as welding difficulties, and achieve the effect of improving welding efficiency, speeding up construction progress, and saving welding materials and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

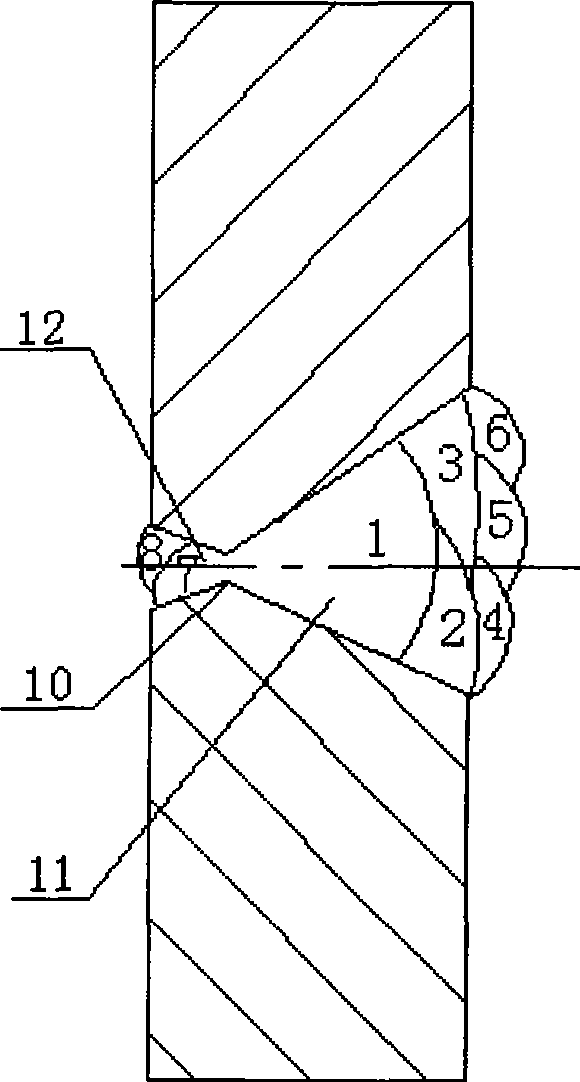

Image

Examples

Embodiment 1

[0033] 1. Using AC square wave power supply:

[0034] There are two kinds of power sources for submerged arc automatic welding, DC and AC. With DC power supply, the weld bead can be spread out and the fusion is good. However, when the DC power supply is used for welding, the current is applied in the same direction, and a directional magnetic field will be formed. For 9 The magnetization-sensitive material of %Ni steel is not easy to eliminate once the magnetization is generated. If the residual magnetism exceeds 50 gauss, it will produce arc magnetic deflection and seriously affect the welding quality. In order to solve the magnetization problem of 9% Ni steel, an AC power supply should be selected. .

[0035] However, if the AC power supply uses a sine wave, the width of the arc will be narrowed, the fusion on the upper side of the weld bead will be worse, and the molten pool will be shallower, so the AC sine wave is considered inappropriate.

[0036] Therefore, the AC squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com