Hot wire TIG welding gun with three tungsten electrodes

A welding torch and tungsten electrode technology, which is applied in the field of three tungsten electrode hot wire TIG welding torches, can solve the problems such as the limitation of the ability to melt the base metal, the accurate positioning of the unfavorable arc, and the fluctuation of the feeding position of the hot wire, so as to achieve a uniform preheating effect and improve the Welding efficiency, the effect of slender gun body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

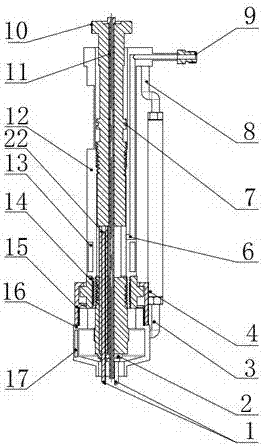

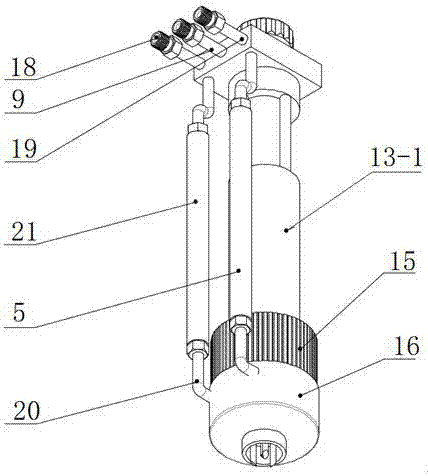

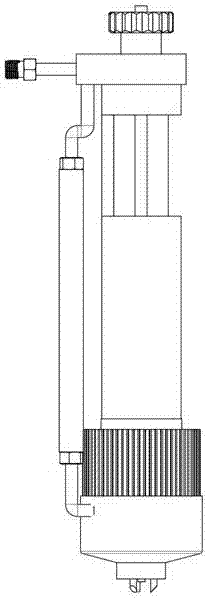

[0021] A kind of three tungsten electrode 1 hot wire TIG welding torch of the present embodiment comprises the gun body 12 of internal hollow, as figure 1 As shown, the lower end of the gun body 12 is the gun head, and the upper end is the gun tail. The tip of the gun is provided with a conductive tip 2. The outer wall of the conductive tip 2 establishes an insulating and sealed connection with the inner wall of the gun body 12 through the insulating bakelite 14 surrounding its exterior in the circumferential direction. , the outer wall of the contact tip 2 is provided with external threads, the inner wall of the rubber wood is provided with matching internal threads, and the rubber wood is fixedly connected to the contact tip 2 through the internal and external threads that cooperate with each other,

[0022] The rear part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com