Aluminum electrolysis simulation practical training operating system and operating method thereof

An operating system, aluminum electrolysis technology, applied in educational appliances, instruments, teaching models, etc., can solve the problems of single simulation project, high risk, poor training effect, etc., to achieve convenient use, improve stability, and reduce load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

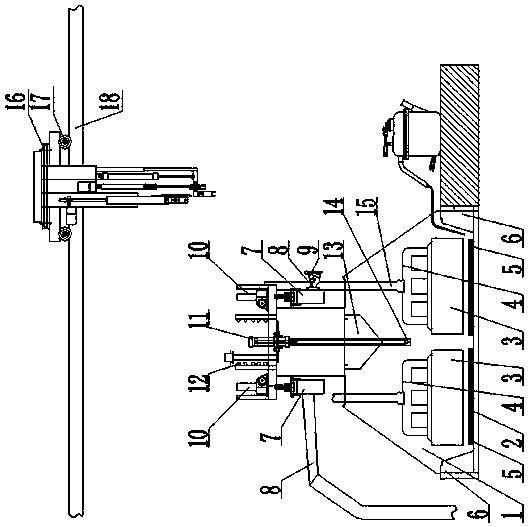

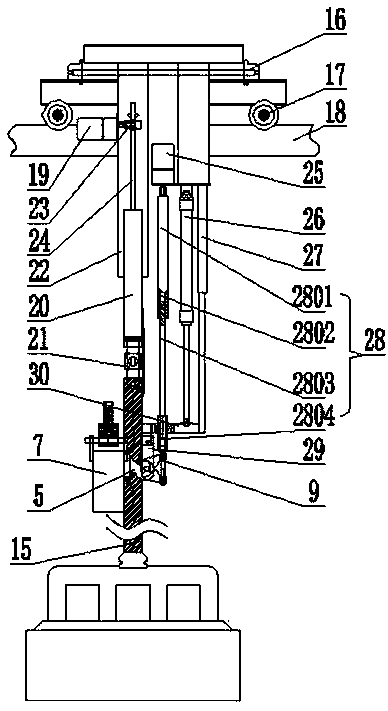

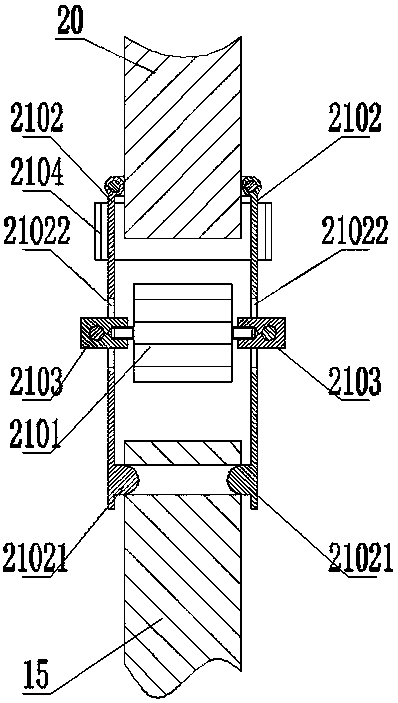

[0072] Such as figure 1 Said, an aluminum electrolysis simulation training operating system of the present invention includes an aluminum electrolysis cell 1, an anode replacement device and an aluminum-clad aluminum extraction device. The aluminum electrolysis cell 1 is provided with a cathode carbon block 2 which is connected to the aluminum The bottom of the electrolytic cell 1. The aluminum electrolytic cell 1 is provided with an aluminum electrolytic cell bank 6, which is located on both sides of the bottom of the aluminum electrolytic cell 1, and the aluminum electrolytic cell 1 is provided with an anode carbon block 3 and an anode steel claw 4. The bus bar 7 and the anode conductive rod 15, the anode steel claw 4 is connected to the top of the anode carbon block 3, the anode conductive rod 15 is connected to the top of the anode steel claw 4, the bus bar 7 is connected to the anode conductive rod 15, and the bus bar 7 is provided with a bus bar Hook 5, the bus bar hook 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com