Metal pin for wire harness connectors

A technology of wire harness connectors and metal pins, which is applied in the field of metal pins, can solve problems affecting the normal operation of equipment, increase production costs, and deformation of upper pins, so as to improve yield and difficulty of assembly, improve production efficiency, and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

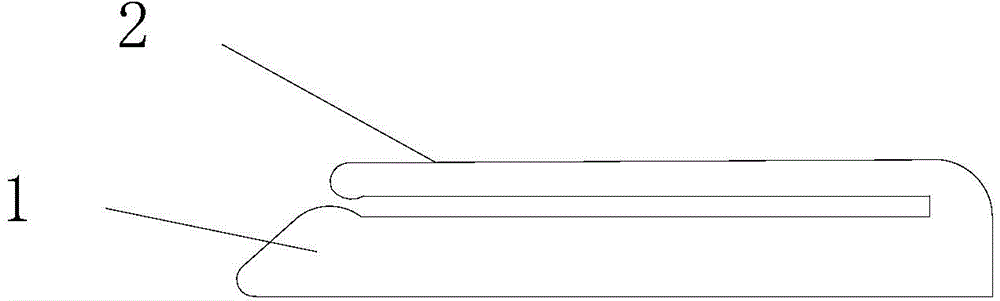

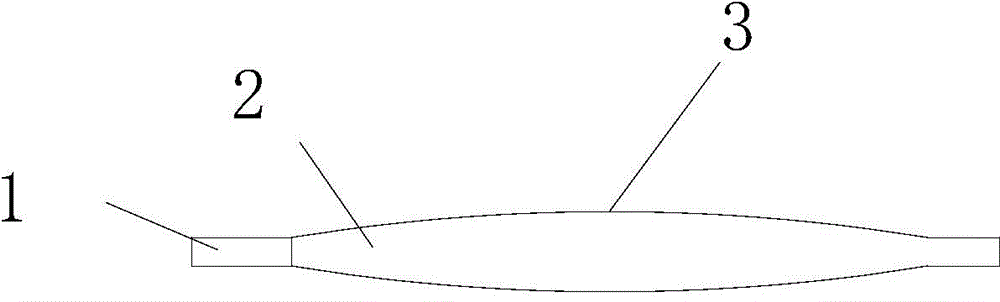

[0013] Such as figure 1 and figure 2 The metal pin of the wire harness connector shown includes a lower pin 1 connected to the wire harness connector. The tail end of the lower pin 1 is integrally provided with an upper pin 2, and the upper pin 2 is arranged in parallel with the lower pin 1. It is characterized in that: the two sides of the upper stitch 2 are extended outward with reinforcing convex shells 3 .

[0014] In summary, the present invention has the following beneficial effects:

[0015] The present invention improves the metal pin of the connector. The present invention sets reinforced convex shells on both sides of the metal pin, which effectively improves the strength of the upper pin, effectively reduces the possibility of deformation caused by external force impact, and improves the goodness of product assembly. The efficiency and the difficulty of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com