Assembly process of safety belt and safety belt winder

An assembly process and technology for seat belts, which are applied in the field of assembly technology of seat belts and seat belt retractors, can solve problems such as difficulty in assembling seat belts and seat belt retractors, improve working environment and working methods, and improve assembly. Difficulty, the effect of meeting the requirements of the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

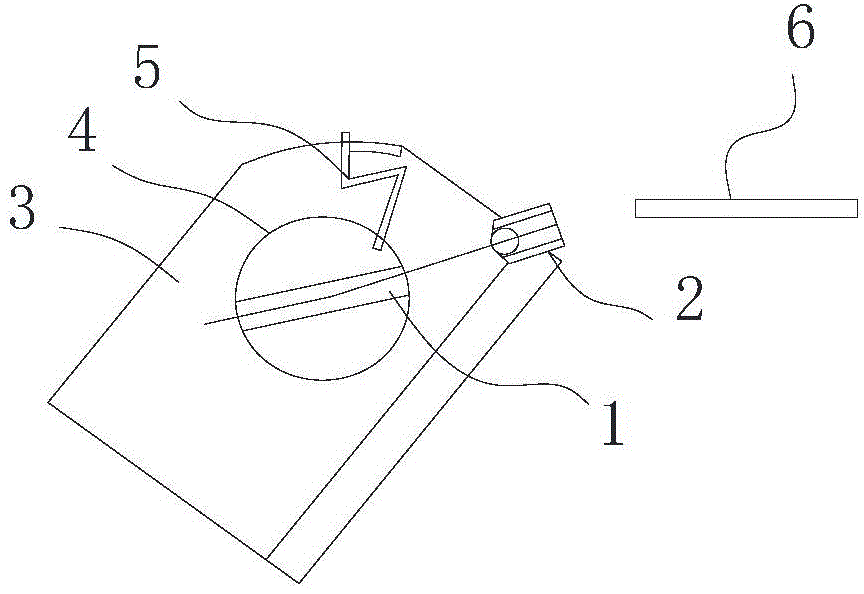

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The assembly process of the safety belt and the safety belt retractor is characterized in that it comprises the following steps:

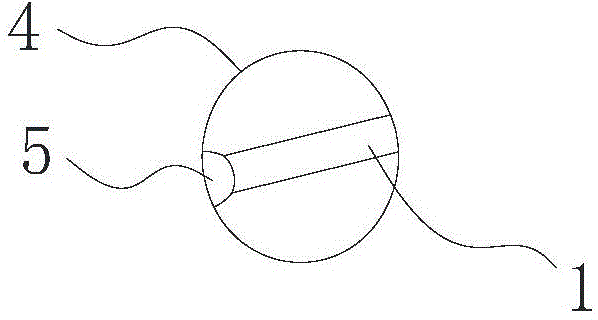

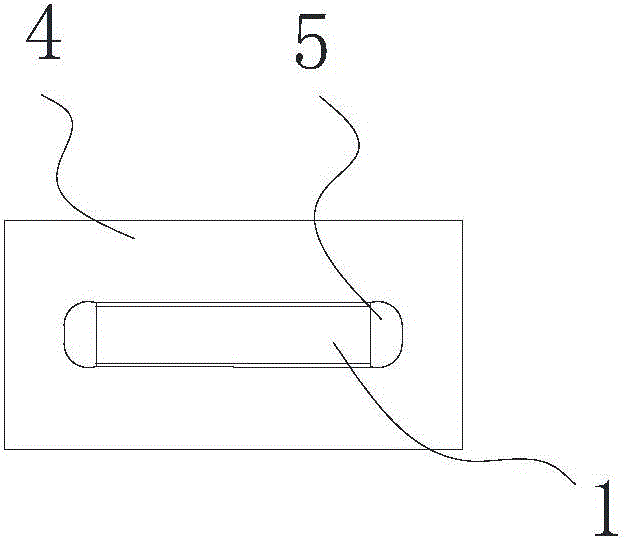

[0027] Step 1. Fix the seat belt retractor on the auxiliary tooling, so that the included angle between the axis of the movable guide of the seat belt retractor and the axis of the mandrel through hole is an obtuse angle; the included angle described in the present invention is 150 °-179°.

[0028] Step 2, passing the end of the safety belt through the movable guide and the through hole of the mandrel in turn;

[0029] Step 3, bending the end of the safety belt to form a folded portion;

[0030] Step 4. Sew the end of the folded part to the safety belt to form a piercing part;

[0031] Step 5. Insert the locking rod into the piercing part, and withdraw the safety belt, so that the locking rod and the end of the through hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com