Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Reduce unbalance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotor Manufacturing Method

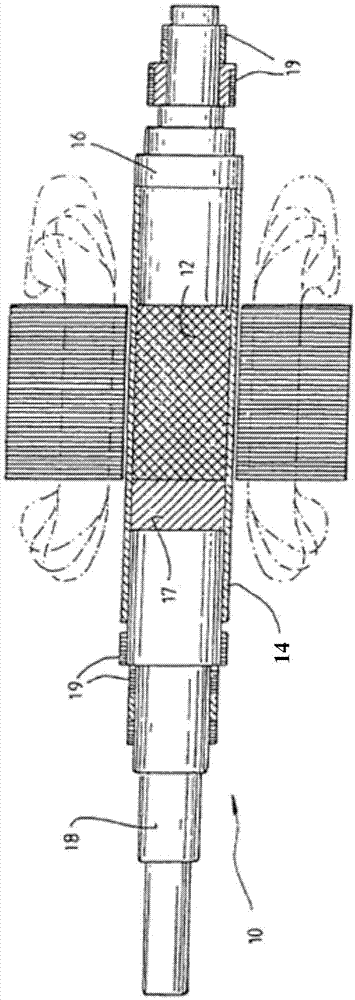

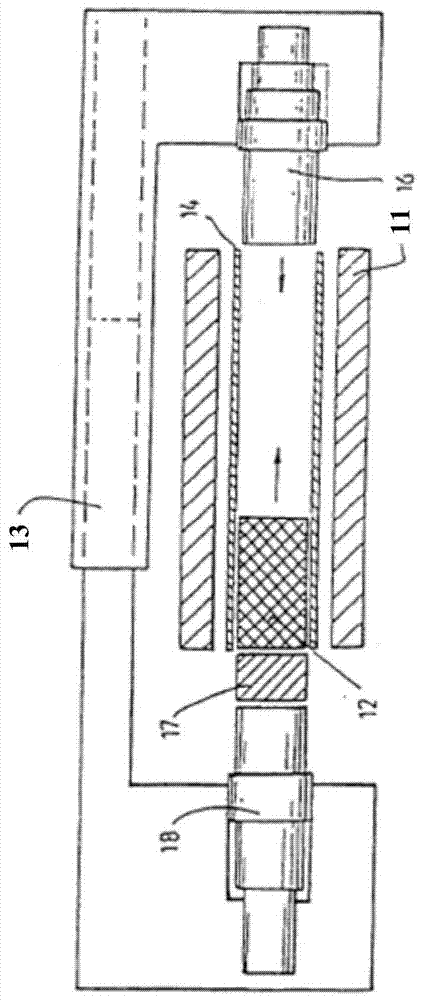

ActiveUS20110000079A1Reduce unbalanceImprove work efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMagnet

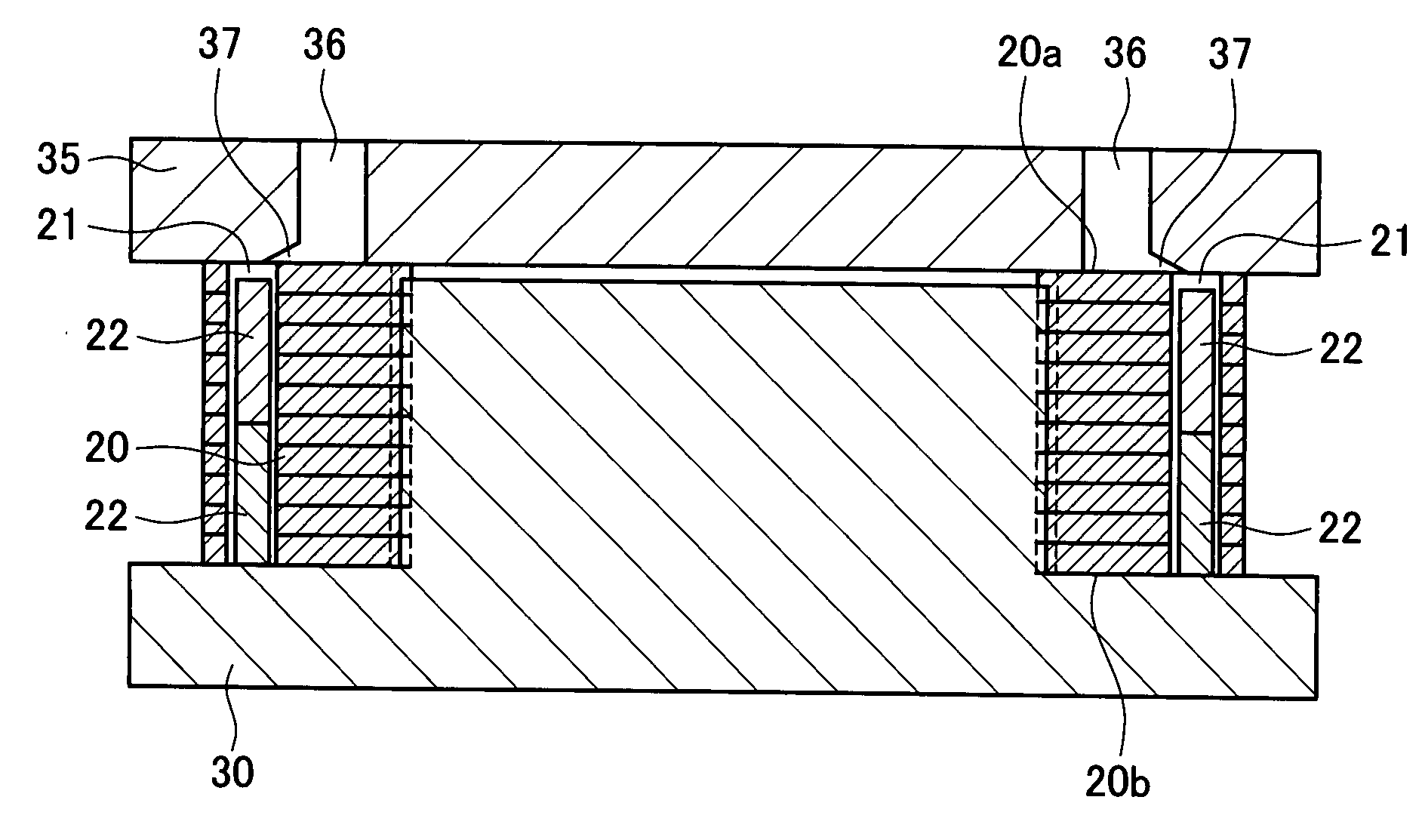

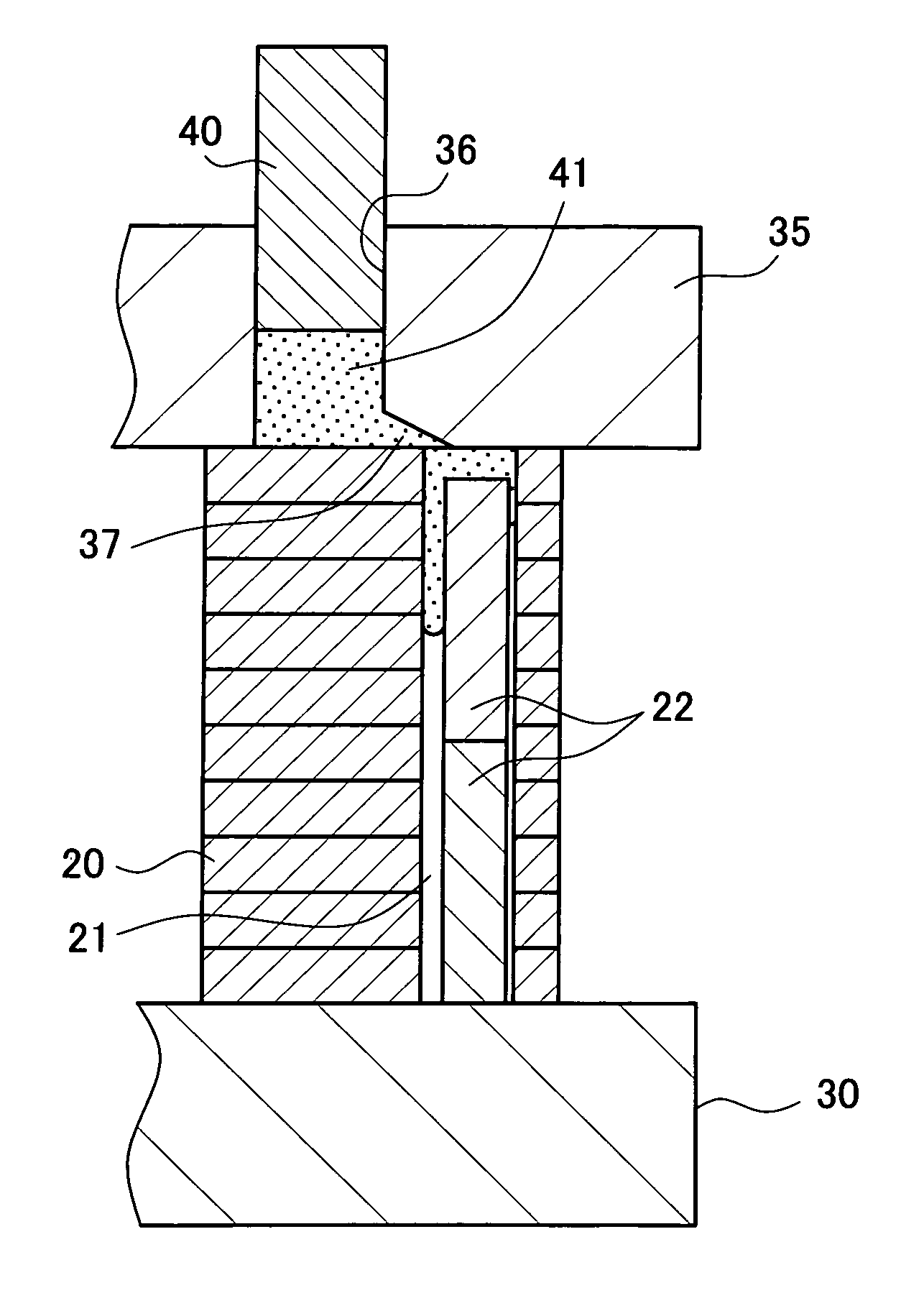

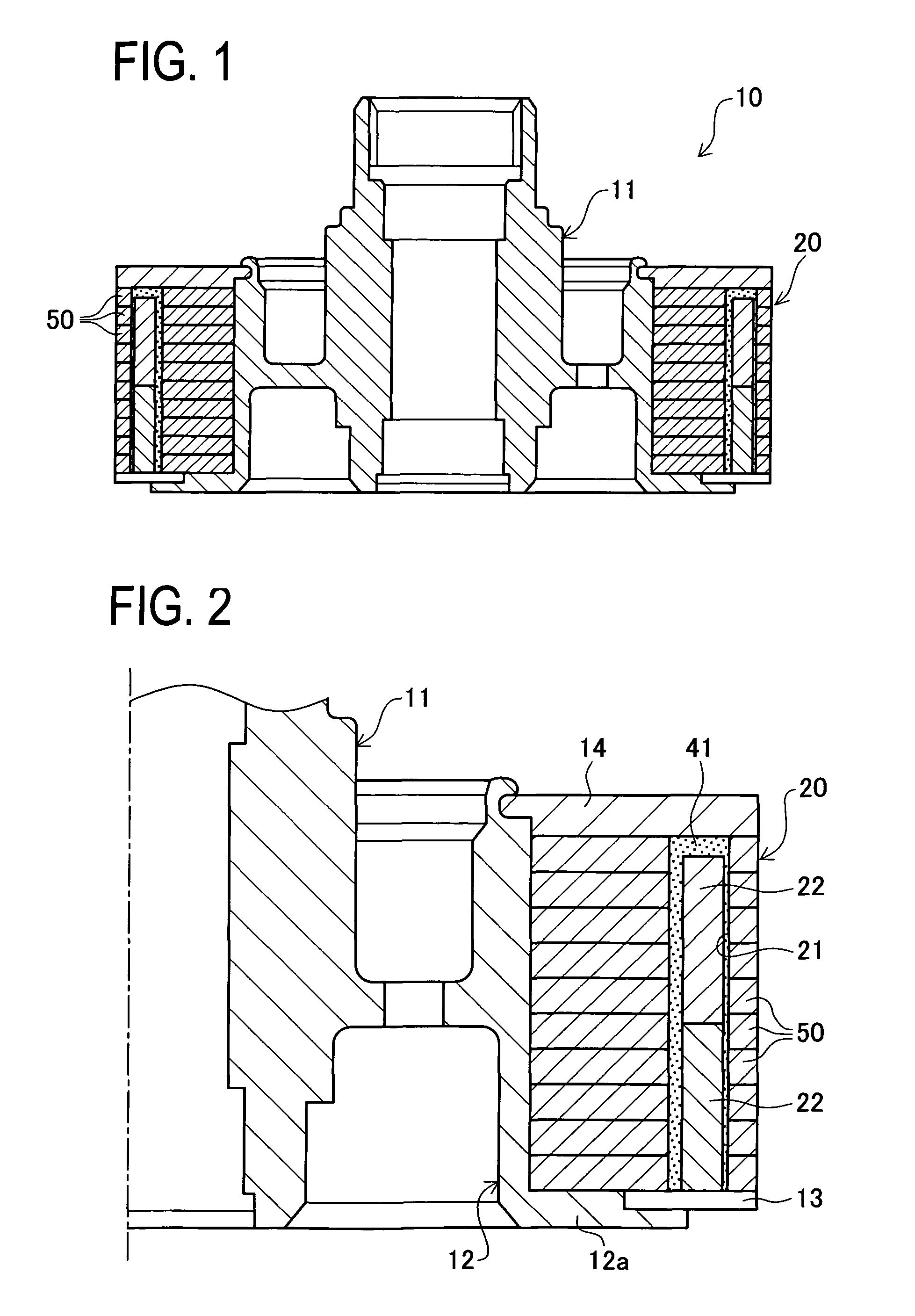

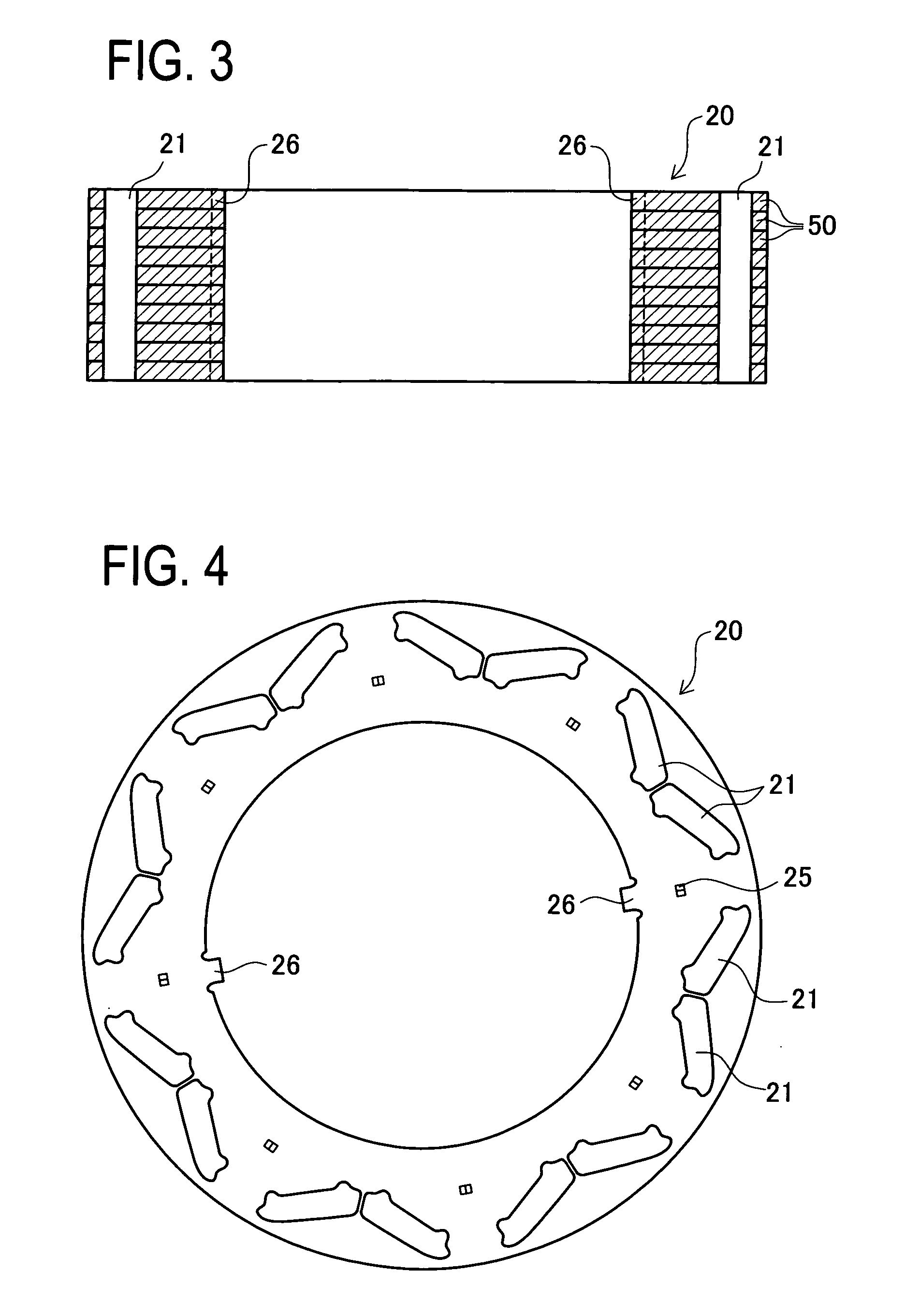

An object is to provide a rotor manufacturing method capable of reducing a rotor unbalance amount by controlling a magnet arrangement position in a rotor core and improving work efficiency when fixing a magnet to the rotor core by using resin. A lower surface of a rotor core is arranged in a lower mold. A magnet is arranged in a lower mold. A magnet is contained in each of magnet containing holes formed in the rotor core in such a manner that a predetermined space is assumed between an upper surface of the rotor core and an upper surface of the magnet. An upper mold is arranged on the upper surface of the rotor core. The upper mold and the lower mold apply a pressure to the rotor core and a molten resin is supplied with pressure from an internal diameter side via the predetermined space into the plurality of magnet containing holes from respective cylinder arranged in the upper mold. Thus, the magnets are molded by resin while pressing the magnets toward the outer diameter side of the magnet containing holes.

Owner:TOYOTA JIDOSHA KK +1

Rotor manufacturing method

ActiveUS8020280B2Reduce unbalanceImprove work efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMagnet

An object is to provide a rotor manufacturing method capable of reducing a rotor unbalance amount by controlling a magnet arrangement position in a rotor core and improving work efficiency when fixing a magnet to the rotor core by using resin. A lower surface of a rotor core is arranged in a lower mold. A magnet is arranged in a lower mold. A magnet is contained in each of magnet containing holes formed in the rotor core in such a manner that a predetermined space is assumed between an upper surface of the rotor core and an upper surface of the magnet. An upper mold is arranged on the upper surface of the rotor core. The upper mold and the lower mold apply a pressure to the rotor core and a molten resin is supplied with pressure from an internal diameter side via the predetermined space into the plurality of magnet containing holes from respective cylinder arranged in the upper mold. Thus, the magnets are molded by resin while pressing the magnets toward the outer diameter side of the magnet containing holes.

Owner:TOYOTA JIDOSHA KK +1

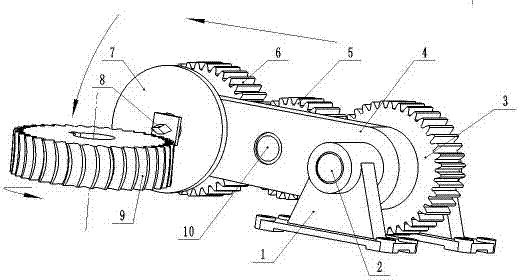

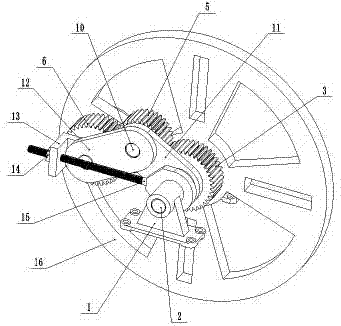

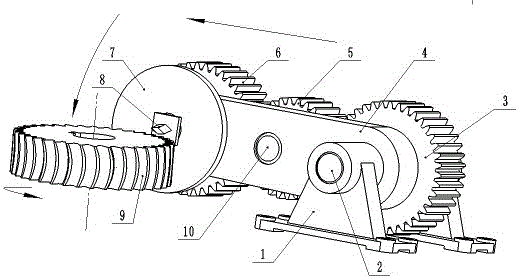

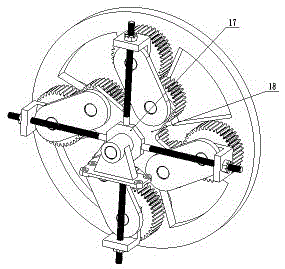

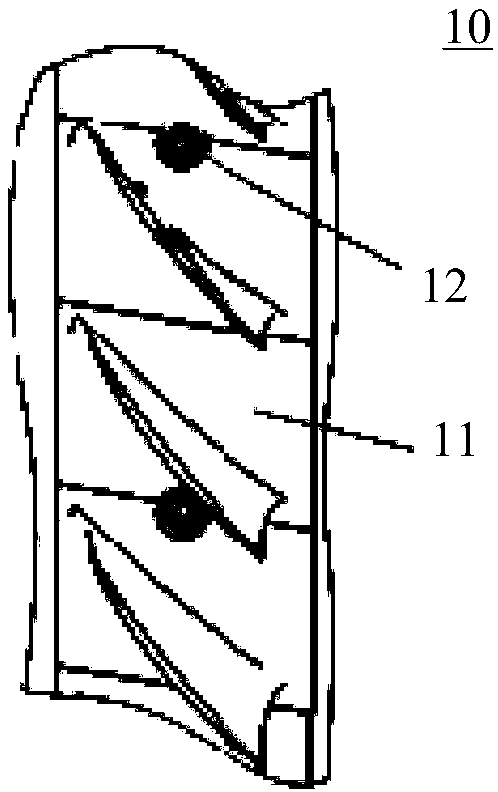

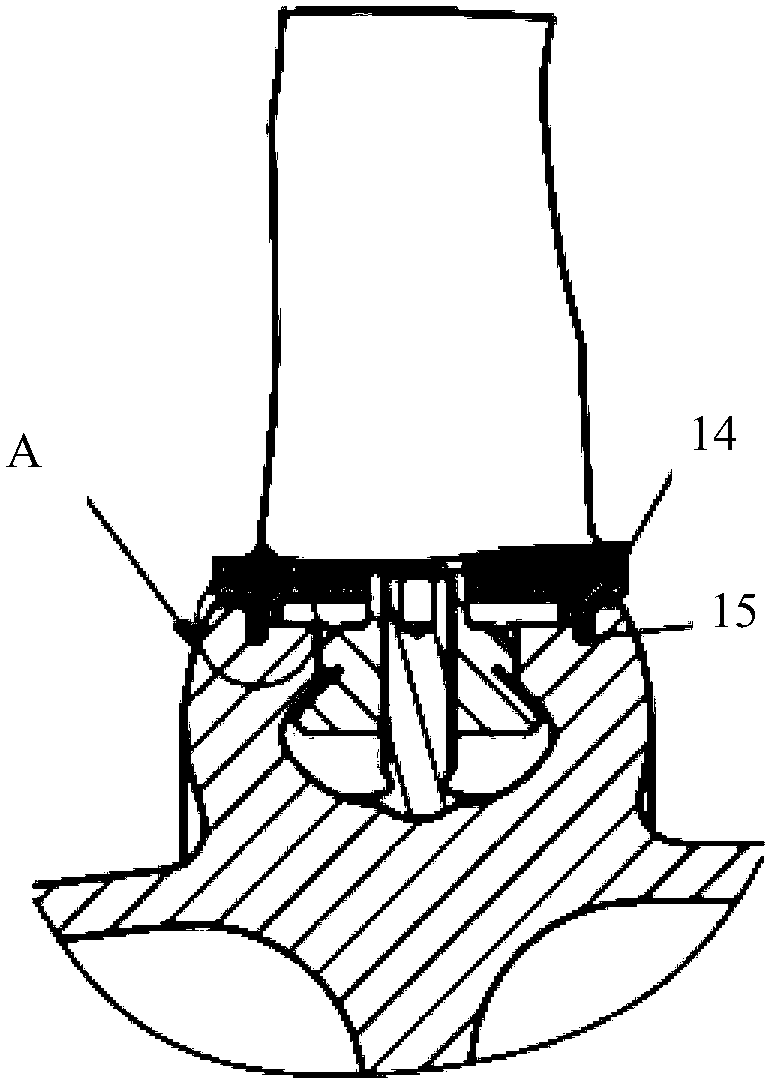

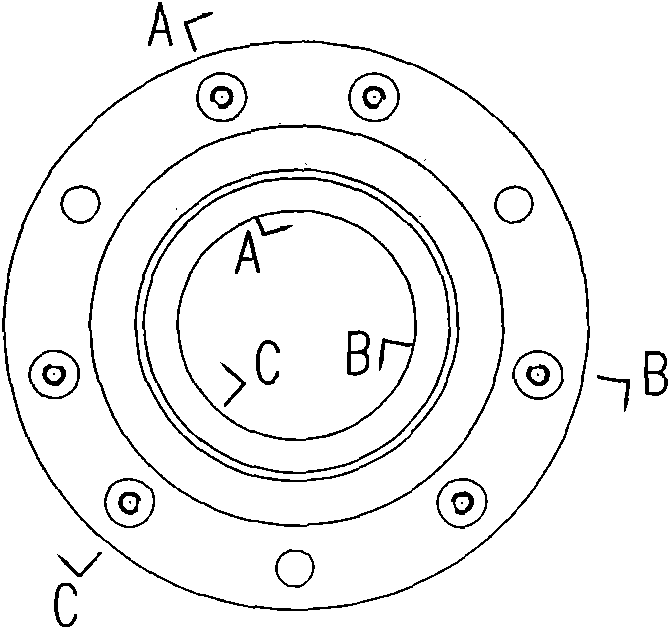

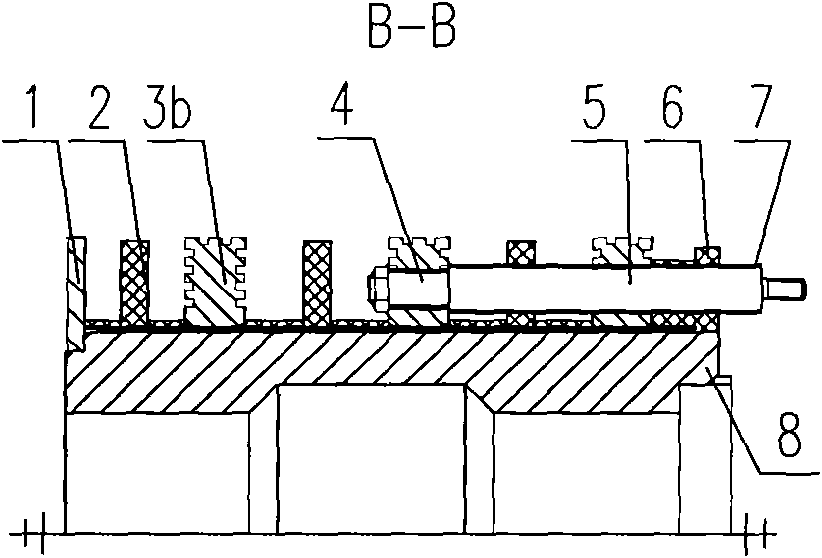

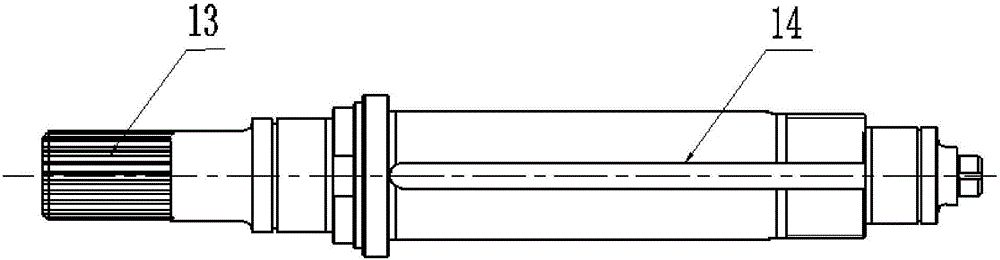

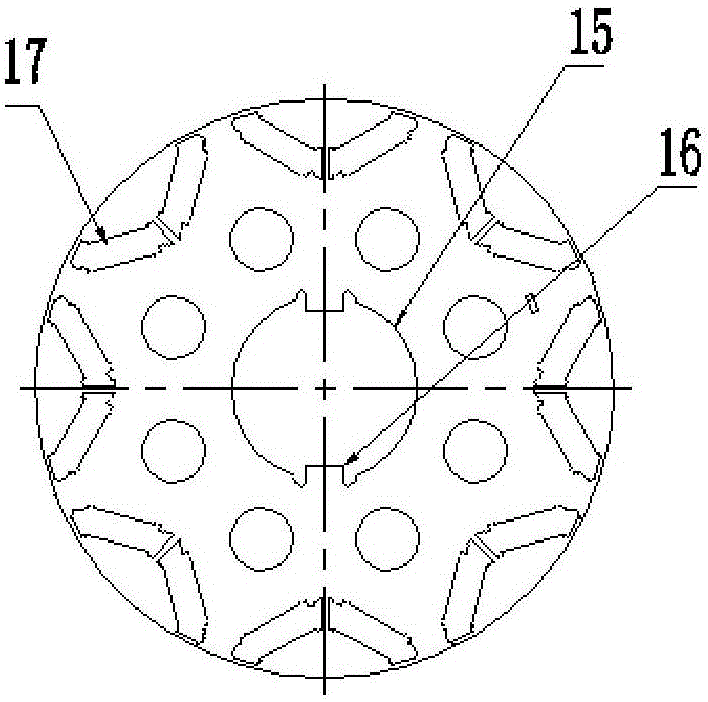

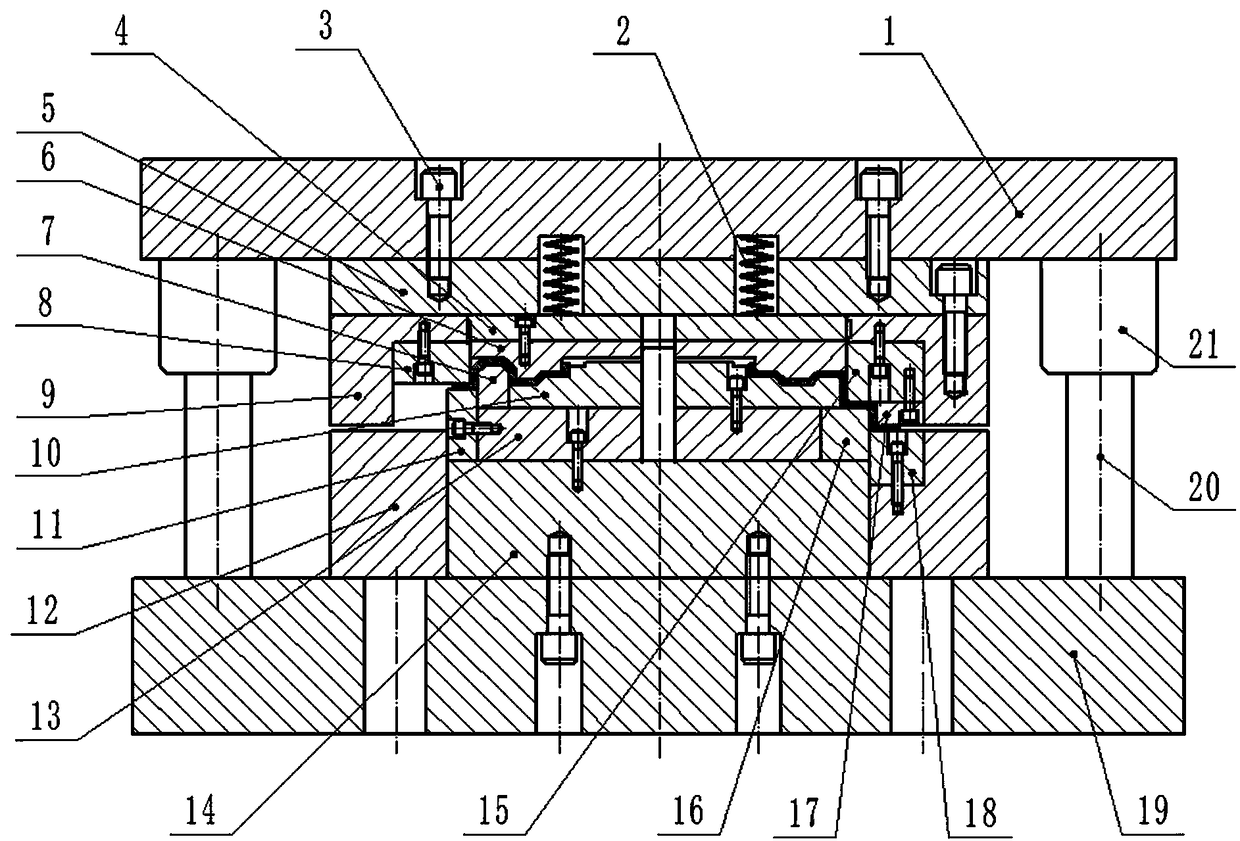

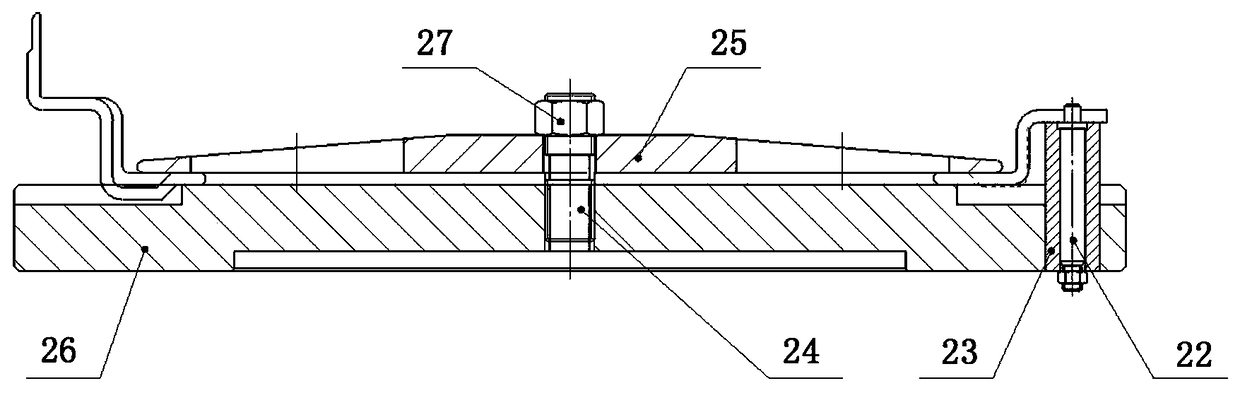

Translation processing device for arc tooth trace cylindrical gear

InactiveCN103203647AImprove processing efficiencyReduce unbalanceDriving apparatusGear teethGear transmissionKnife blades

The invention discloses a processing device for an arc tooth trace cylindrical gear in the technical field of gears. The gear which the processing device is used for is provided with an arc tooth trace, an involute or an arc tooth profile and has equal circumferential tooth thickness. A plurality of blades of the processing device are evenly distributed around a planetary gear train. When the gear is processed, the blades perform plane motion, the gear axis and sun gear rotation axis of the planetary gear train are intersected in different planes, and the gear is processed in a generating method. The arc tooth trace cylindrical gear with the equal circumferential tooth thickness can be processed through the processing device, gear manufacturing precision and efficiency can be improved, and a processed gear pair has stability in transmission and is large in bearing capability and suitable for application to a high-speed heavy-duty gear transmission device.

Owner:SICHUAN UNIV

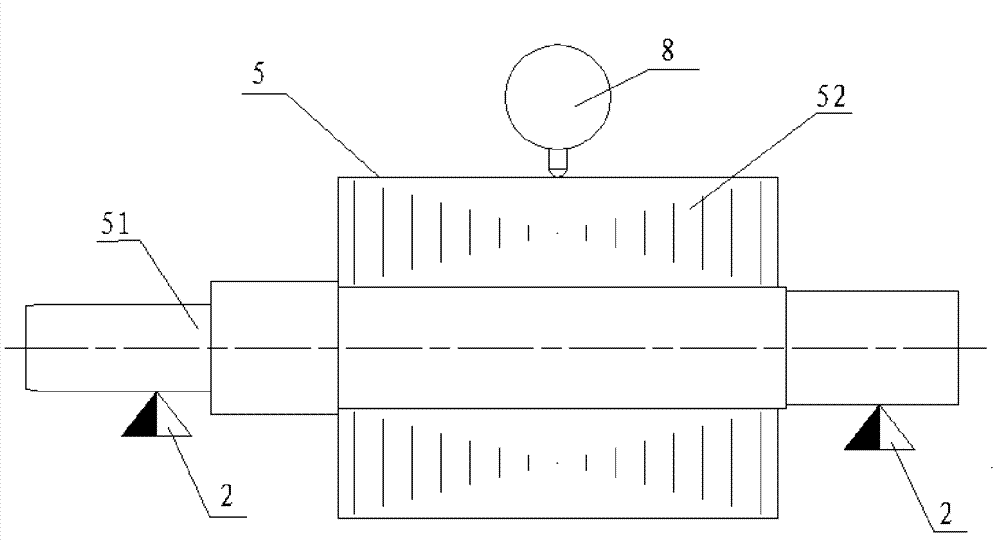

Shafting structure for motor, and assembling method

ActiveCN105449895AReduce in quantityReduce assembly coaxiality is difficult to guarantee the problemMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineryStructural engineering

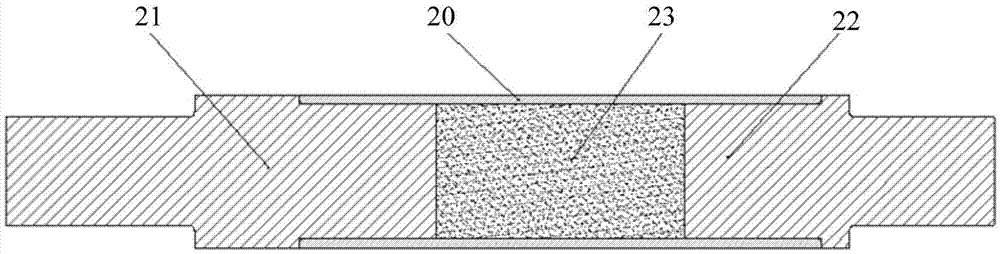

The invention discloses a shafting structure for a motor, and an assembling method. The shafting structure comprises a front-segment shaft (62), a rear-segment shaft (63), annular magnetic steel (61) and an alloy sheath (60), wherein the rear-segment shaft (63) successively comprises a first shaft joint (631) and a second shaft joint (633) from front to back, and the diameter of the first shaft joint (631) is smaller than that of the second shaft joint (633); the annular magnetic steel (61) sleeves the first shaft joint (631) of the rear-segment shaft (63); the external diameter of the rear end of the front-segment shaft (62) is the same as the external diameter of the annular magnetic steel (61); and the alloy sheath (60) sleeves the front-segment shaft (62) and the annular magnetic steel (61). According to the scheme provided by the invention, the shafting structure and the assembling method overcome the defects of complex structure, large assembling difficulty, poor safety and the like in the prior art and also have the advantages of simple structure, small assembling difficulty and good safety.

Owner:GREE ELECTRIC APPLIANCES INC +1

Method for optimizing centroid eccentricity of engine core engine rotor

ActiveCN106837426ACenter of mass eccentricity reductionReduce unbalancePump componentsBlade accessoriesMathematical modelSpin axis

The invention discloses a method for optimizing centroid eccentricity of an engine core engine rotor. The method for optimizing centroid eccentricity of the engine core engine rotor comprises a first step of taking a minimum value of a core engine rotor joint face centroid eccentricity OC as an optimization target of the method for optimizing centroid eccentricity of the engine core engine rotor; a second step of establishing a core engine rotor centroid eccentricity prediction optimization mathematic model; a third step of obtaining a theta value corresponding when the actual spin axis OC of the labyrinth disc fitting centroid O deviated from the core engine rotor, and performing high pressure turbine rotor and high pressure compressor rotor angle rotation assembly according to the theta value. According to the method for optimizing centroid eccentricity of the engine core engine rotor, before rotor assembly, by optimal calculation, the angular phasing corresponding when the OC value is minimum is selected to guide core engine rotor assembly, and the goal of reducing centroid eccentricity of the core engine rotor and an unbalanced amount of the core engine rotor and improving high voltage rotor vibration is achieved.

Owner:AECC SHENYANG ENGINE RES INST

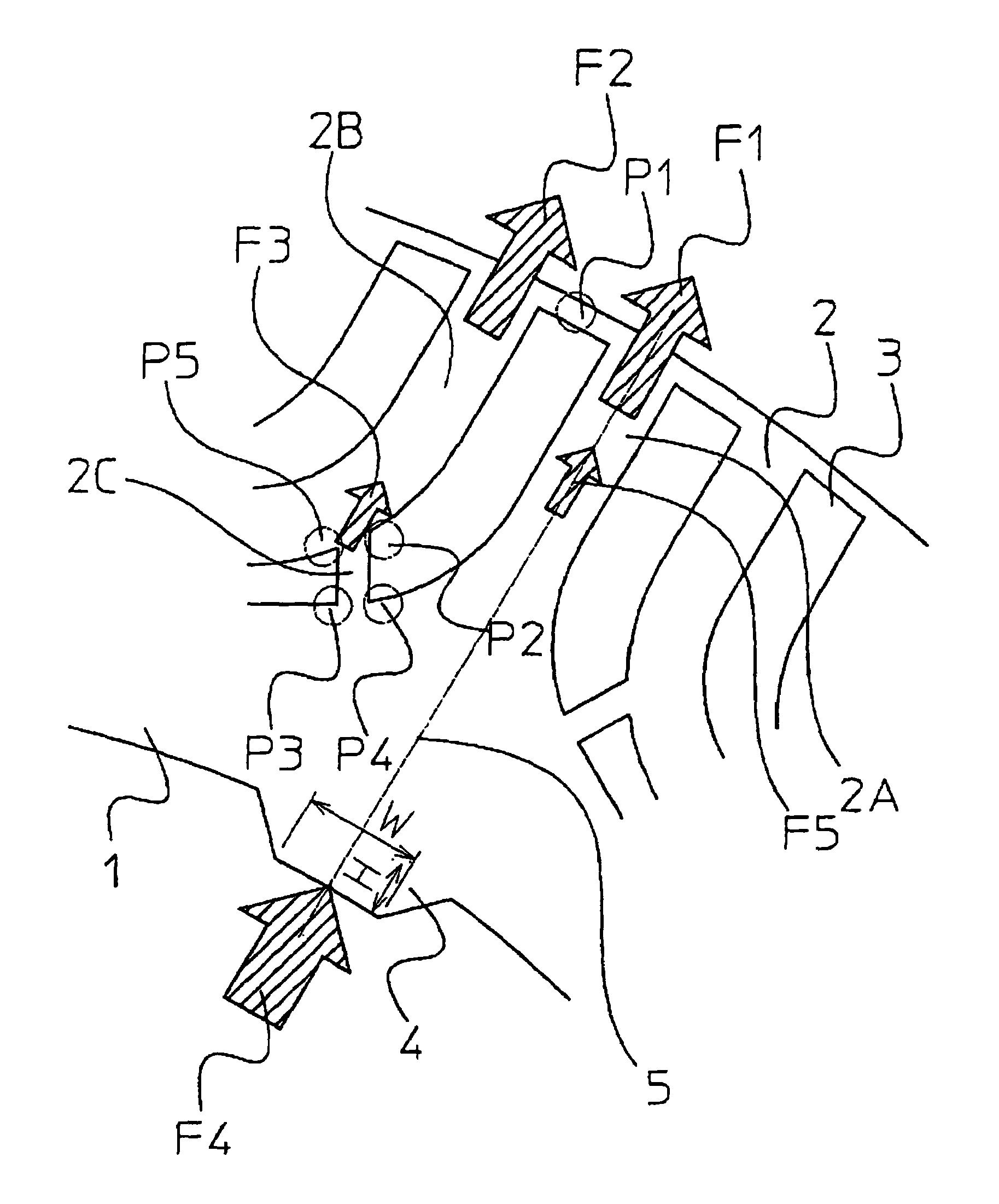

Vibration damping device

InactiveCN102822562AMinimizes changes in inertial mass balancePrevent or suppress changes in inertial mass balanceRotating vibration suppressionSlip couplingReciprocating motionTransmitted power

Provided is a vibration damping device capable of suppressing variations in the degree of reciprocating movement of a pendulum which is caused by variations in the rotational center of the vibration damping device. The vibration damping device is equipped with a pendulum vibration damping mechanism (11) that includes a mass body (10) that moves in a pendular manner in response to torsional vibrations to dampen the torsional vibrations. An inertial body (4) is provided on the drive power source side of rotation shafts (2, 3). An elastic vibration reducing mechanism (5) is capable of transmitting power to the inertial body (4) and provided more toward the transmission side than the inertial body (4). The pendulum vibration damping mechanism (11) is capable of transmitting power to the elastic vibration reducing mechanism (5) and provided more toward the transmission side than the elastic vibration reducing mechanism (5). A torque limiter mechanism (14) is capable of transmitting power to the pendulum vibration damping mechanism (11) and provided more toward the transmission side than the pendulum vibration damping mechanism (11).

Owner:TOYOTA JIDOSHA KK

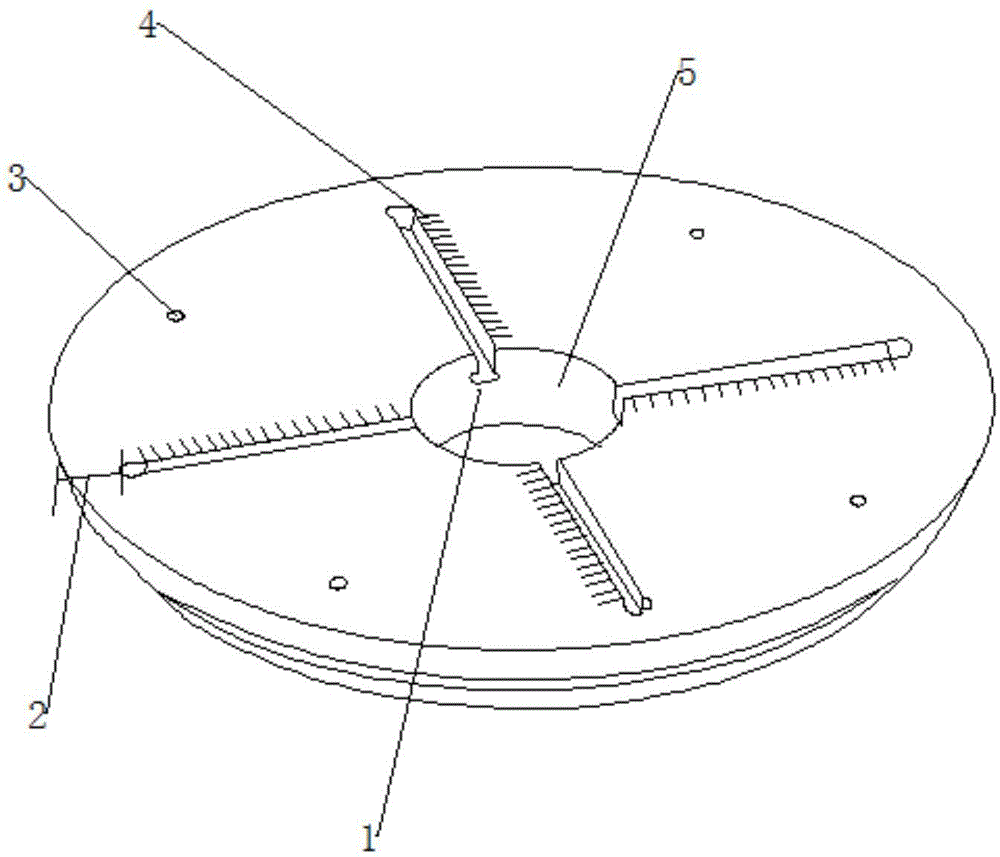

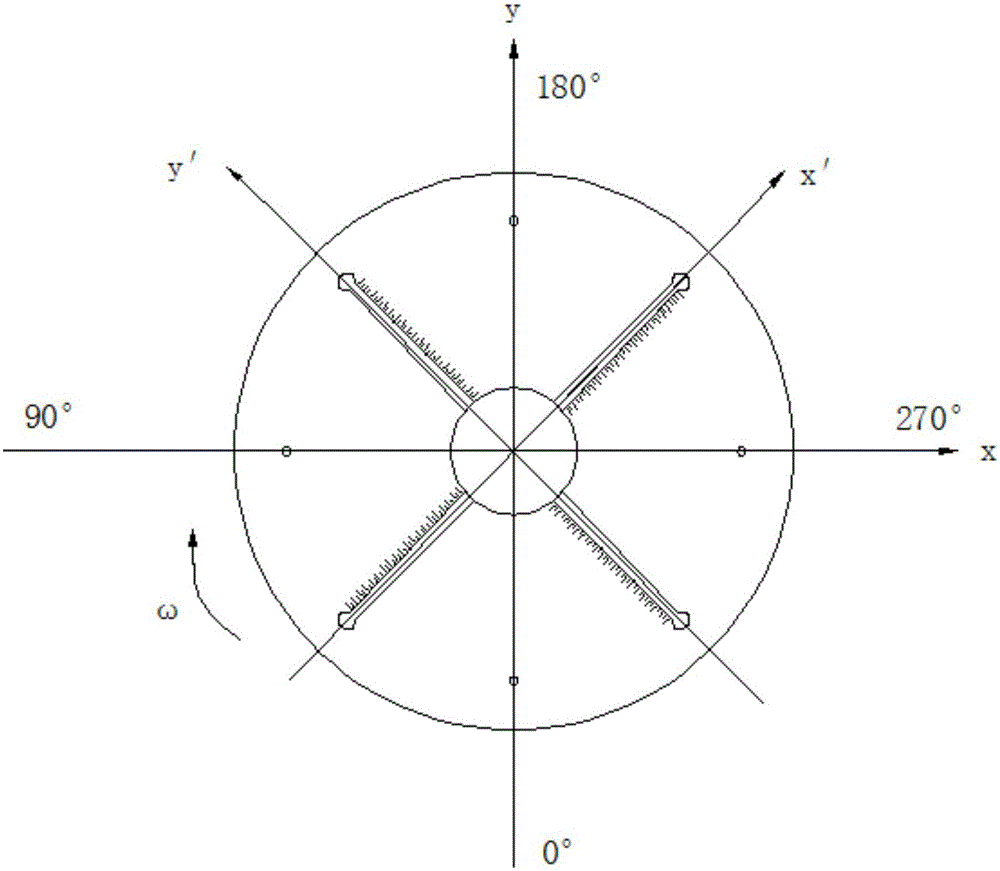

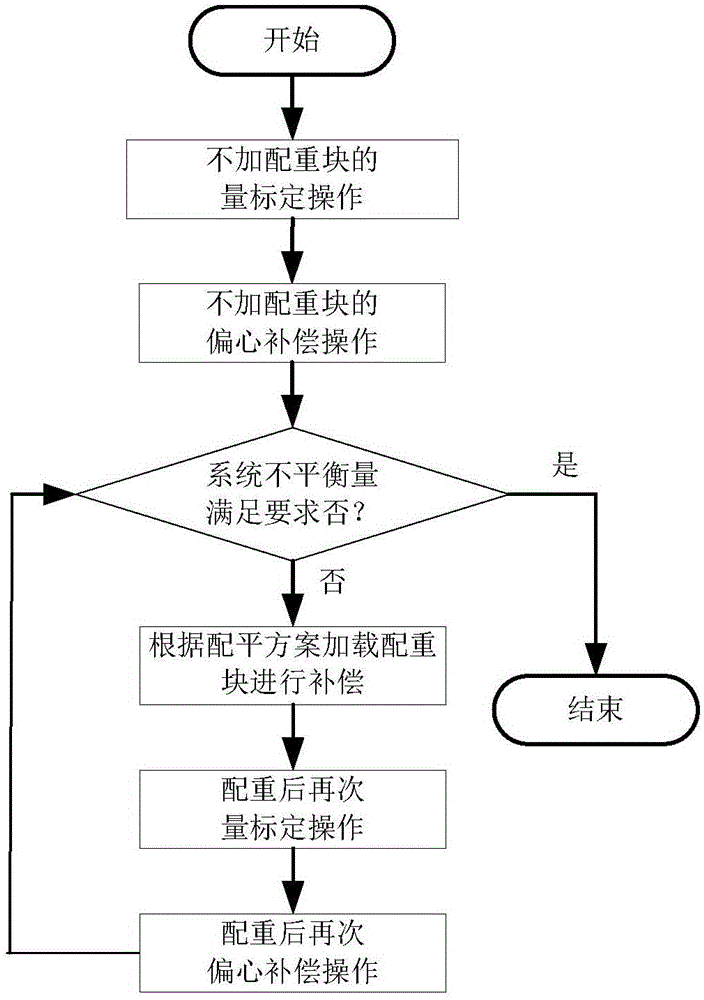

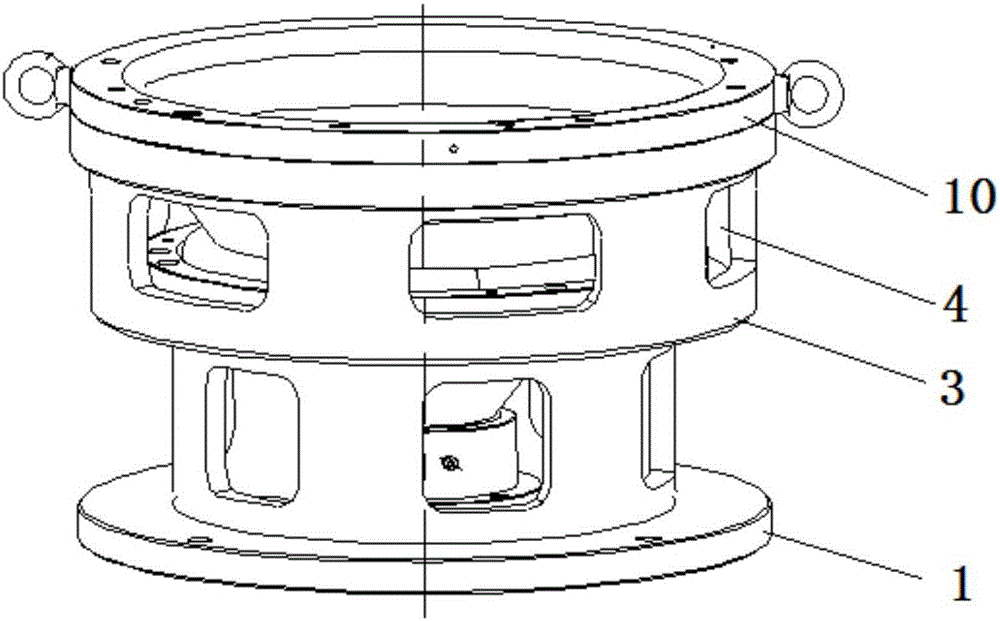

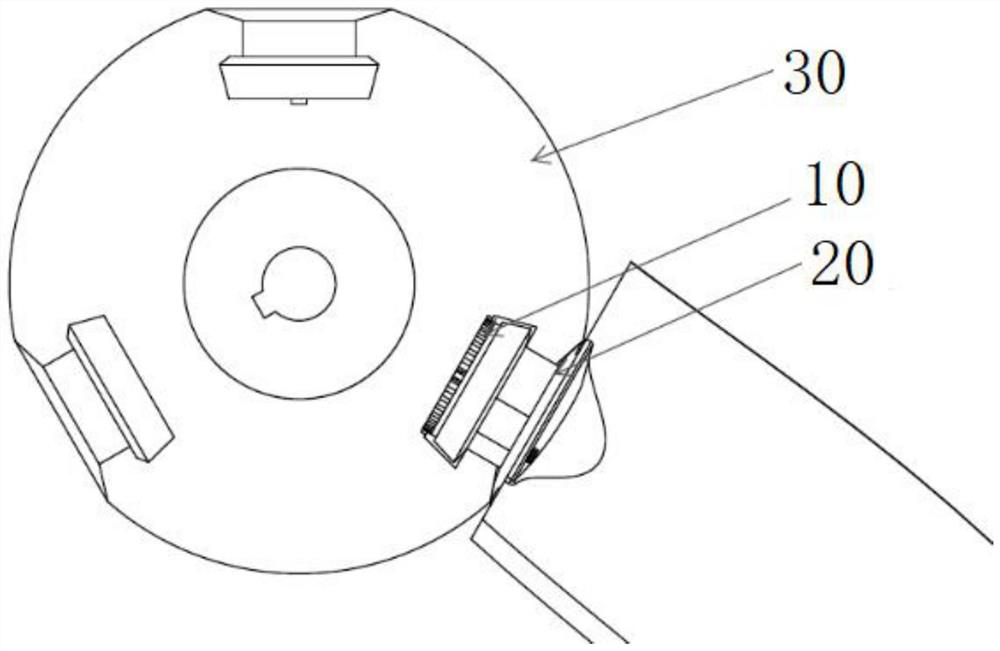

Dynamic compensation wheel rim for compensating system unbalance of tyre dynamic balancing testing machine and method

ActiveCN105115666AReduce unbalanceReduce stringent precision requirementsStatic/dynamic balance measurementDynamic balanceImage resolution

The invention discloses a dynamic compensation wheel rim for compensating system unbalance of a tyre dynamic balancing testing machine and a method. The invention aims to solve the following problems that the relatively great system unbalance of the tyre dynamic balancing testing machine affects the test precision and resolution of the system; an eccentric compensation algorithm and operations are only used for calculating the system unbalance mass and cannot achieve real compensation of the system unbalance; currently some compensating devices require great modification of a conventional structure; and a counterweight correcting face and a measurement correcting face are not consistent. Four T type grooves with scribed lines are arranged on the orthogonal direction of the wheel rim. Counterweight blocks are further arranged. Each counterweight block group is a pair of T type bolt-nut pair structure matching the orthogonal T type grooves in terms of the dimension. The system unbalance can be lowered to an ideal range through the combined movement of the counterweight blocks with a known mass. The equipment detection precision is effectively improved.

Owner:SHANDONG UNIV

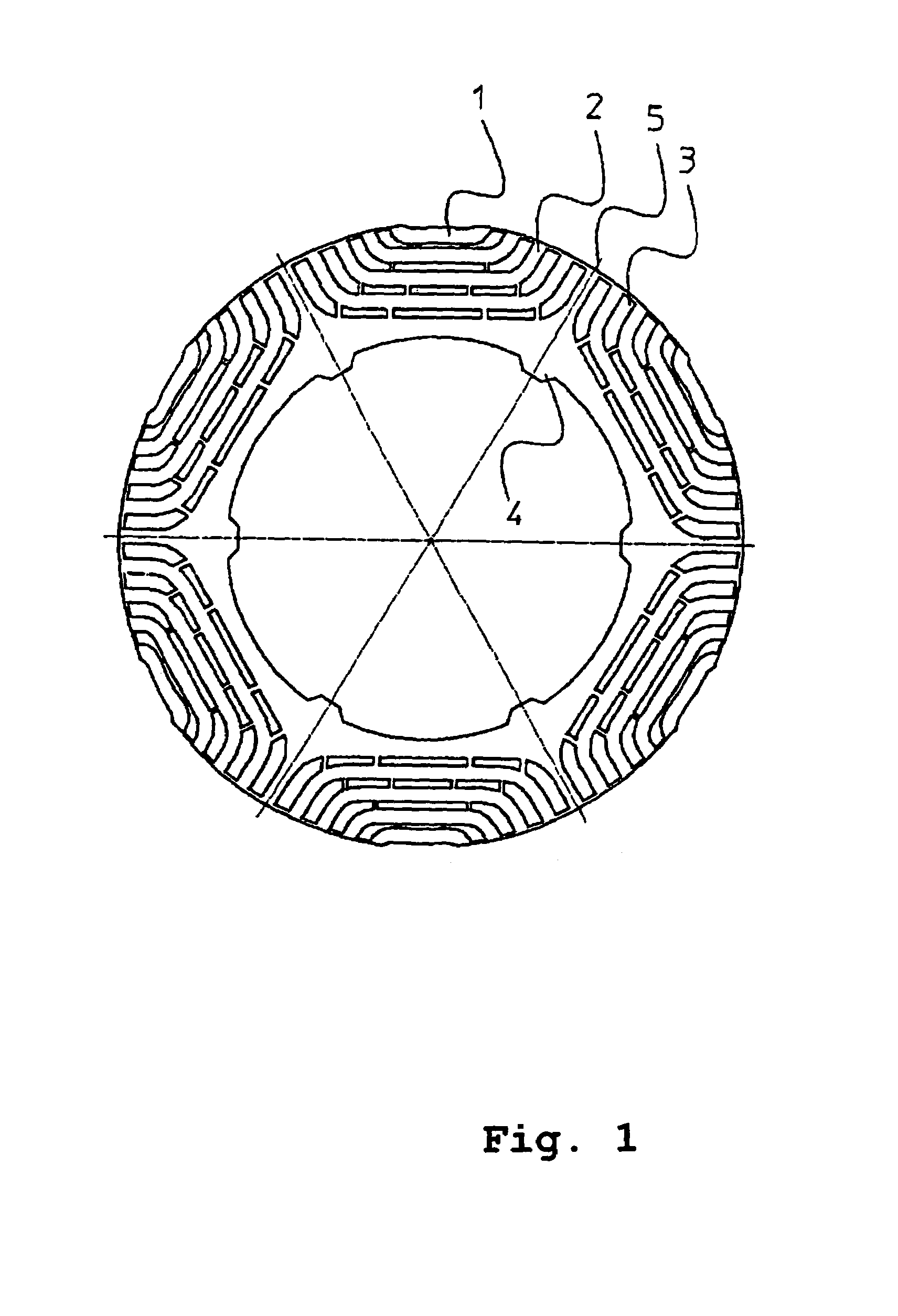

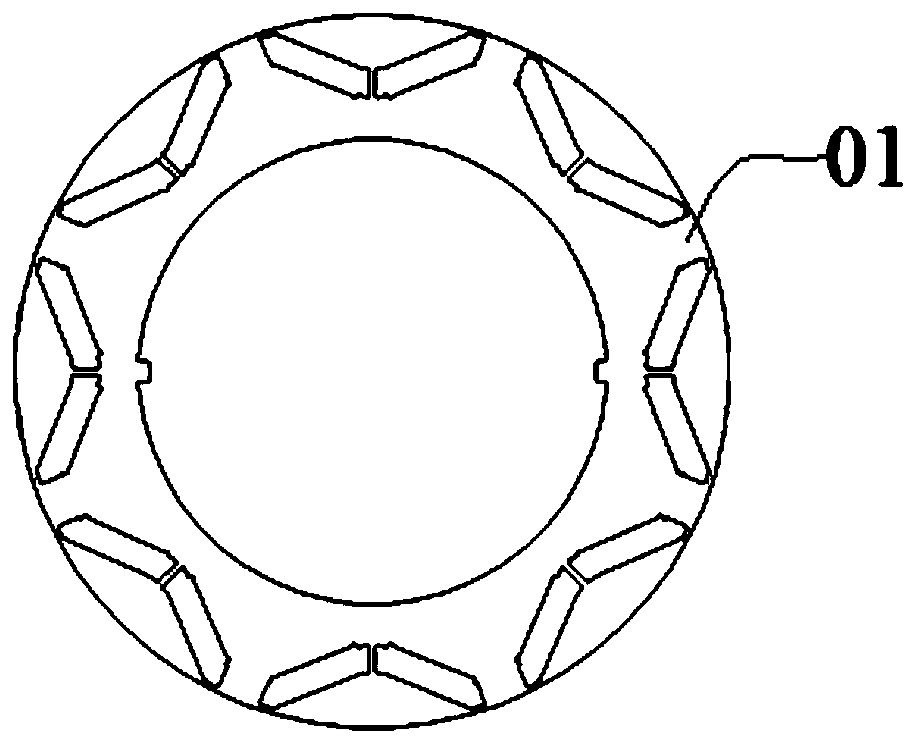

Rotor of reluctance motor

ActiveUS7151336B2Reduce displacementReduce unbalanceSynchronous generatorsMagnetic circuit rotating partsMagnetic polesReluctance motor

A plurality of projections are provided abutted with an outer circumference of a columnar axis inserted to an inner circumference of a rotor. The projections are provided in the direction of a magnetic pole in the rotor. When the rotor is fixed to the columnar axis, the projection parts are fixed by “plunge-in” and the other rotor inner circumference parts have an uniform clearance to the columnar axis. The clearance is filled with an adhesive agent, thereby fixing the rotor to the columnar axis.

Owner:OKUMA CORP

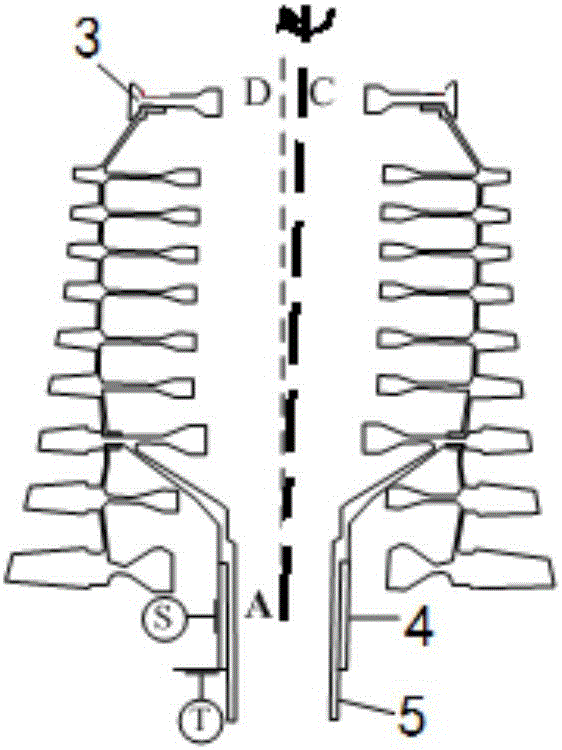

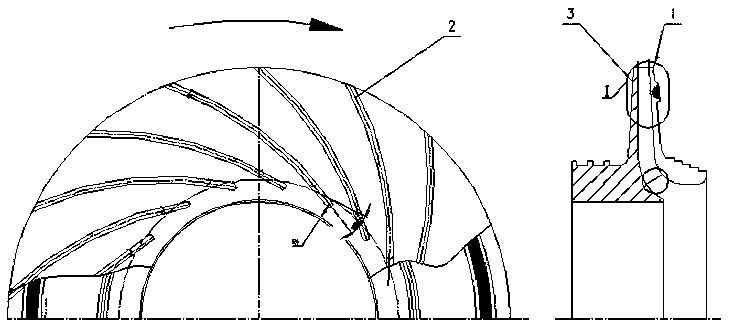

Dynamic balance emendation method of 1.5MW wind power generator with radial fan and rotor

InactiveCN102332796AGood dynamic balance indexShorten speedWind energy generationCentering/balancing rotorsCycloneDynamic balance

The invention discloses a dynamic balance emendation method of a 1.5MW wind power generator with a radial fan and a rotor. The dynamic balance emendation method comprises the following steps of: 1, primarily balancing to complete the balance of a radial fan (3); 2, secondarily balancing to complete the balance of partial rotor (4) except for the radial fan (3); and finally balancing. The dynamic balance emendation method has the beneficial effect of respectively carrying out primary balance, secondary balance and final balance on the radial fan and the partial rotor (the rotor body is provided with a left cyclone fan and a right cyclone fan) except for the radial fan, thus the vibration speed and noise of the rotor are reduced, and the unbalance amount of the radial fan and the rotor body is decreased so that the wind power generator reaches an optimal dynamic balance index.

Owner:DONGFANG ELECTRIC CORPLESHAN NEW ENERGY EQUIP

Turbine moving blade sequencing method

The invention relates to a turbine moving blade sequencing method. The turbine moving blade sequencing method comprises following steps: 1) carrying out grouping, taking all moving blades as originalsamples, and dividing the moving blades into several groups; 2) carrying out intra-group optimal sequencing, and carrying out optimization sequencing on samples in each group through an enumeration method; and 3) carrying out inter-group optimal sequencing, carrying out optimization sequencing on the groups through the enumeration method, and determining the final sequence of the original samples.The turbine moving blade sequencing method strives to determine the assembling sequence of the turbine moving blades under reasonable calculated quantity, and to control the amount of unbalance generated by the moving blades to a minimum level, through grouping, the intra-group blade sequence is first optimized, then the sequence of the groups is optimized again, the amount of unbalance is reduced, and therefore the finally-obtained total amount of unbalance is low, and the turbine moving blade sequencing method can also carry out blade sequencing in an occasion having a large number of blades and having an exact demand on the amount of unbalance.

Owner:NANJING TURBINE & ELECTRIC MASCH (GRP) CO LTD

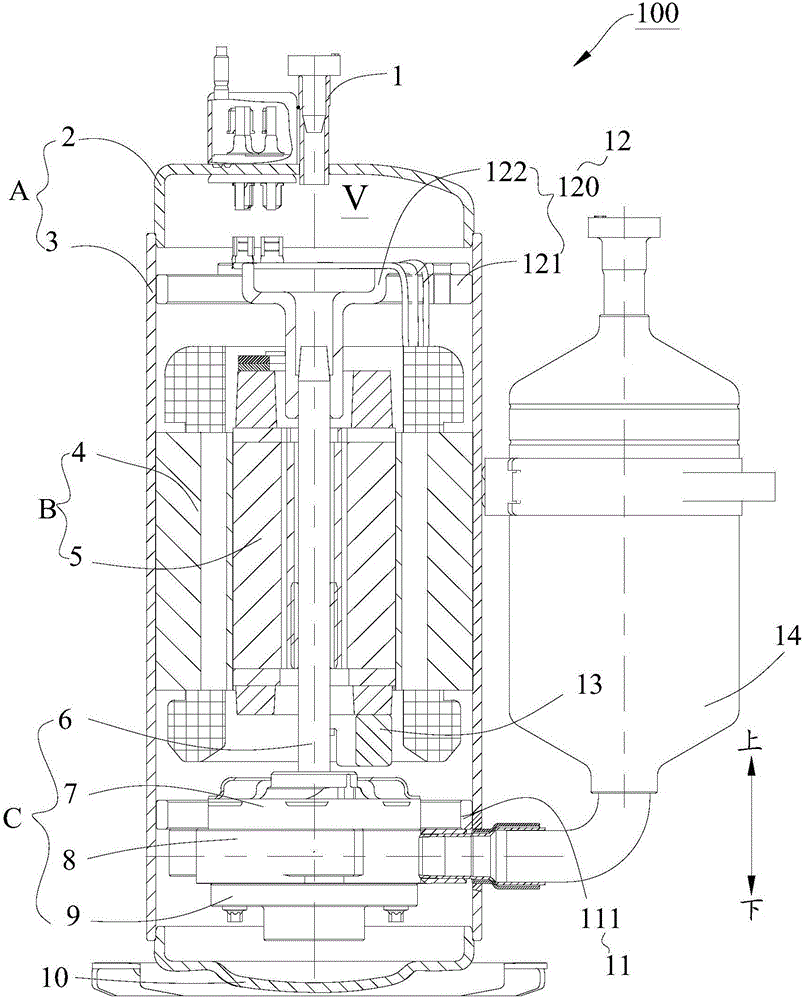

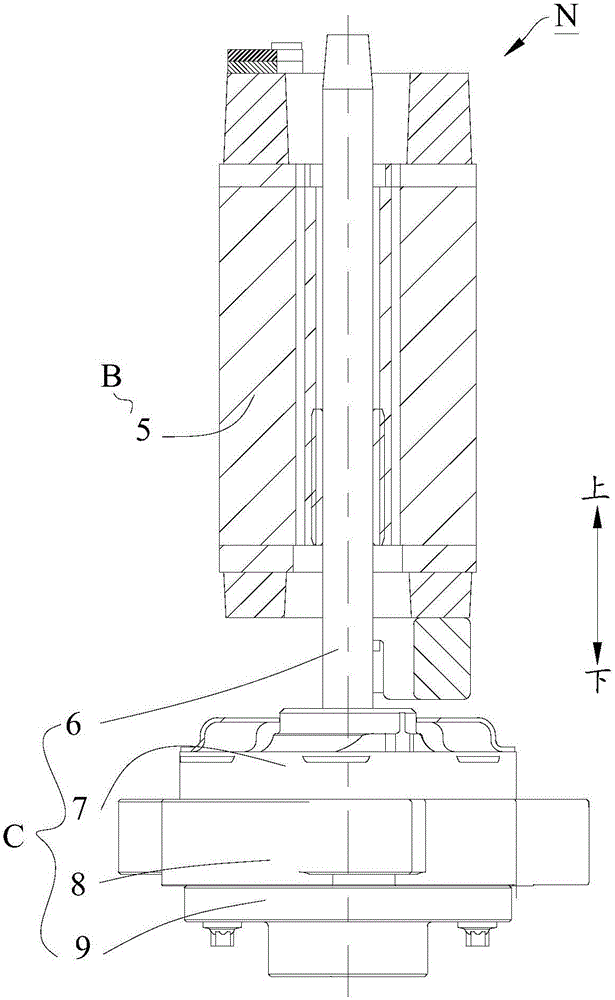

Rotary compressor

ActiveCN105041652AImprove assembly accuracySimple structureRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsMechanical engineeringCrankshaft

The invention discloses a rotary compressor. The rotary compressor comprises a shell, a compressing component, a motor component, a first machine frame and a supporting component. The peripheral wall of the first machine frame is fixed to the inner wall of the shell. A main bearing, a supplementary bearing or a cylinder or other parts such as a partition board of the compressing component are fixedly connected to the first machine frame. The supporting component comprises a second machine frame and an auxiliary bearing, wherein the peripheral wall of the second machine frame is fixed to the inner wall of the shell, and the auxiliary bearing is fixed to the upper surface of the second machine frame and arranged on the upper portion of a crankshaft in a sleeving mode. According to the rotary compressor, due to the fact that a compressing component and rotor assembly is connected to the shell in a transition mode through the first machine frame and the second machine frame, assembling precision is improved, it is guaranteed that a uniform air gap is formed between a stator and a rotor of a motor, abrasion between each bearing and the crankshaft is light, noise is low, torque power consumption caused when the crankshaft rotates is low, motor gap unbalance amount is small, and small-gap assembly of the stator and the rotor of the motor is achieved. Furthermore, the compressor is simple and reasonable in structure and high in reliability.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

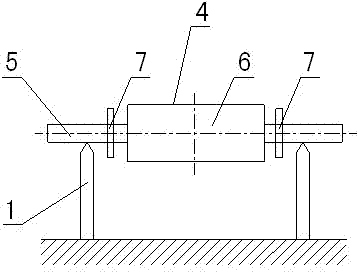

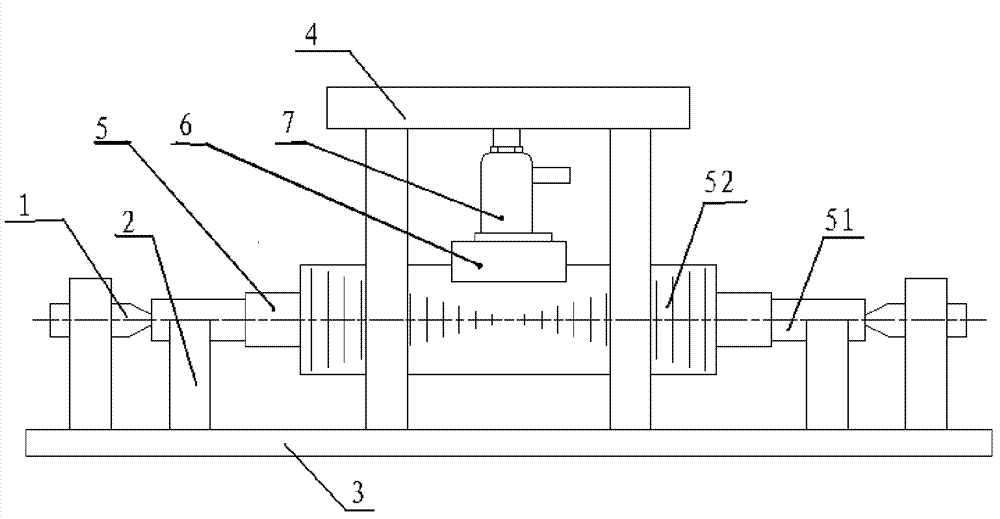

Calibration device and calibration method for armature unbalance of DC motor

InactiveCN103368343AReduce noiseImprove stabilityCentering/balancing rotorsEngineeringCorrection method

The invention discloses a calibration device for armature unbalance of a DC motor, which is used in the field of motor manufacturing. The calibration device includes a support frame part and a calibration part. The support frame part includes centers, armature supports, a substrate and a support frame. The support frame is arranged at center part of the substrate in an axial direction. The centers and the armature supports are arranged at two ends of the substrate respectively in an axial direction, wherein the armature supports are arranged between the centers and the support frames. The calibration part is arranged between the support frame and the substrate. And the calibration part includes: a pressing piece and a hydraulic jack, wherein a bottom surface of the pressing piece is a cambered surface. The invention also discloses a calibration method for the armature unbalance of the DC motor and the method includes the following steps: an unbalance testing step for determining a position of a place with the largest radial-jittering value of an iron-core of the DC motor armature, a data comparison step, an unbalance calibration step and a verification step.

Owner:SHANGHAI NANYANG ELECTRICAL MACHINERY

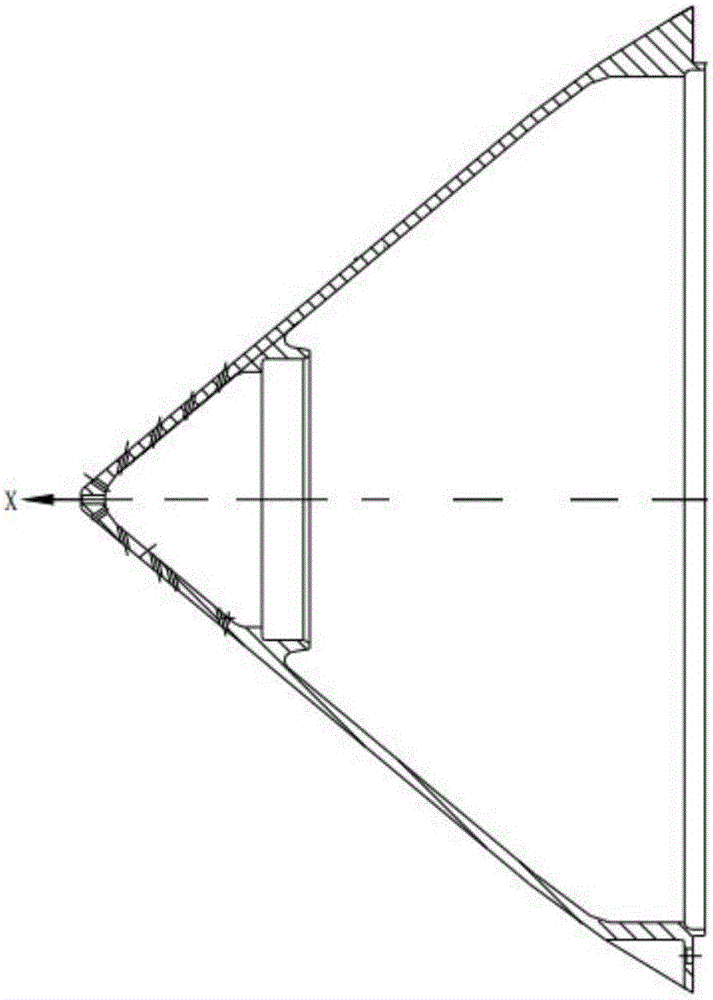

Process method of improving wall thickness uniformity of closed thin-walled rotary part

The invention discloses a process method of improving wall thickness uniformity of a closed thin-walled rotary part. The process method comprises the steps: (1) designing a finish turning clamp of a novel structure; (2) designing a following process route according to the finish turning clamp; and (3) adjusting the working allowance of a finish turning procedure. As the performance and reliability of a new generation engine are improved, a higher requirement is posed to the processing precision of a part; a designer requires the amount of unbalance of the rotary part more and more strictly. Therefore, reduction of the amount of unbalance of a cover hood part which is relatively great in processing difficulty will be widely applied by using the method. Meanwhile, the technology is suitable for both processing closed rotary parts which are different in structure and size and improving the processing precision of the part, and the process method has a wide application prospect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

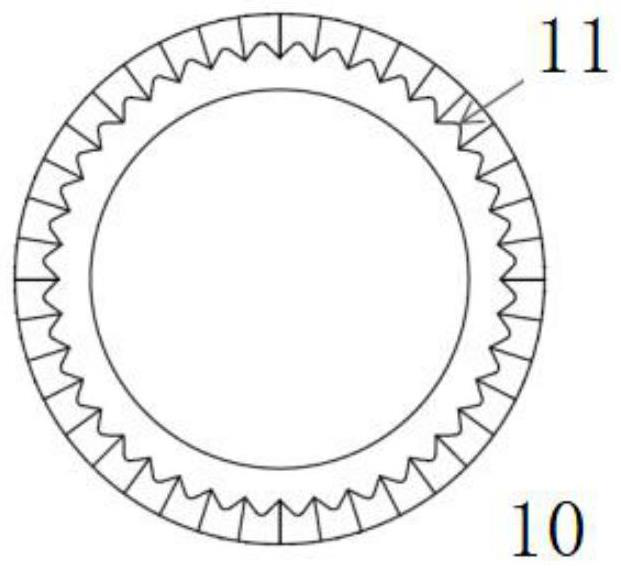

A translational processing device for arc-toothed cylindrical gears

The invention discloses a processing device for an arc tooth trace cylindrical gear in the technical field of gears. The gear which the processing device is used for is provided with an arc tooth trace, an involute or an arc tooth profile and has equal circumferential tooth thickness. A plurality of blades of the processing device are evenly distributed around a planetary gear train. When the gear is processed, the blades perform plane motion, the gear axis and sun gear rotation axis of the planetary gear train are intersected in different planes, and the gear is processed in a generating method. The arc tooth trace cylindrical gear with the equal circumferential tooth thickness can be processed through the processing device, gear manufacturing precision and efficiency can be improved, and a processed gear pair has stability in transmission and is large in bearing capability and suitable for application to a high-speed heavy-duty gear transmission device.

Owner:SICHUAN UNIV

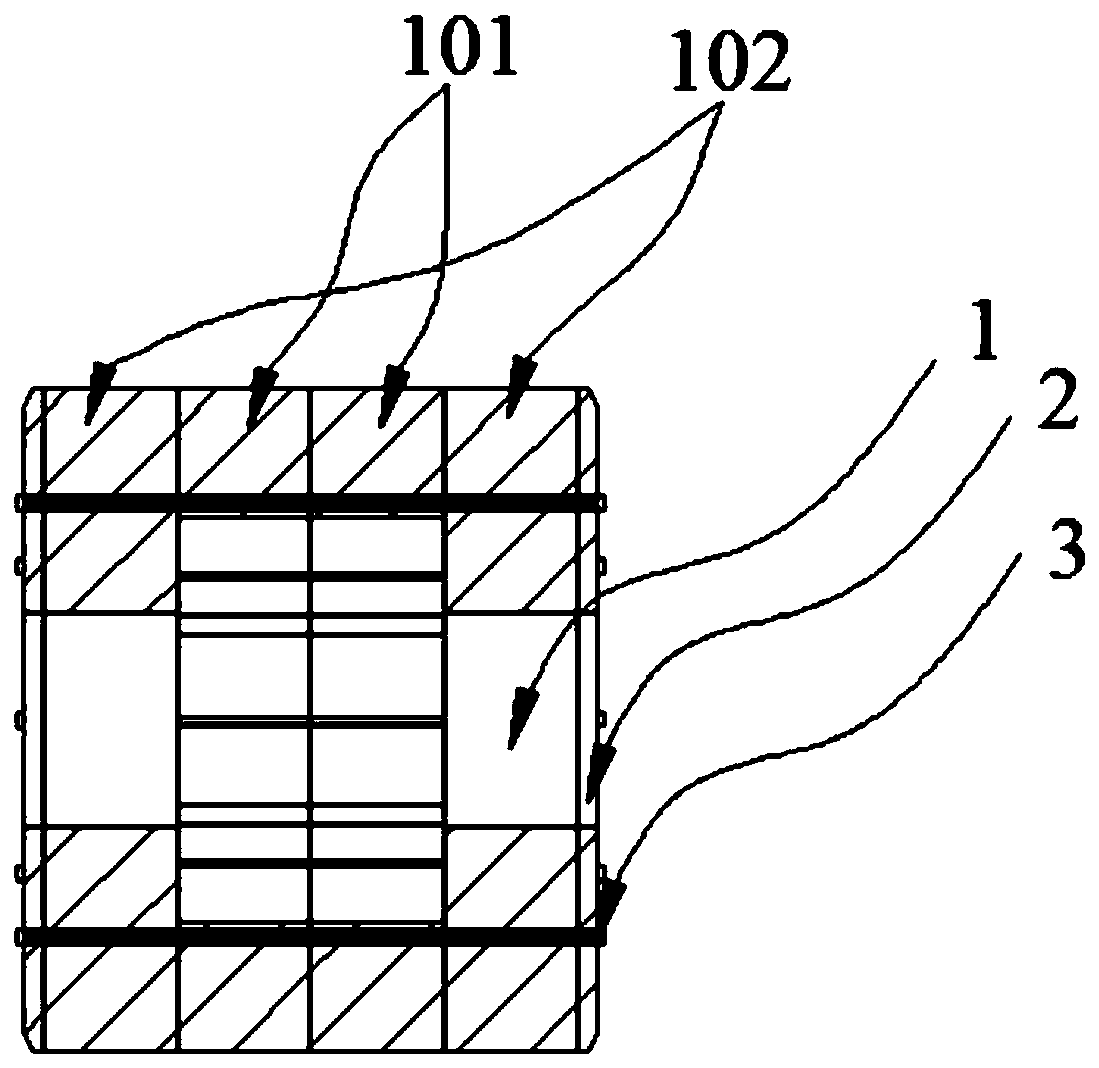

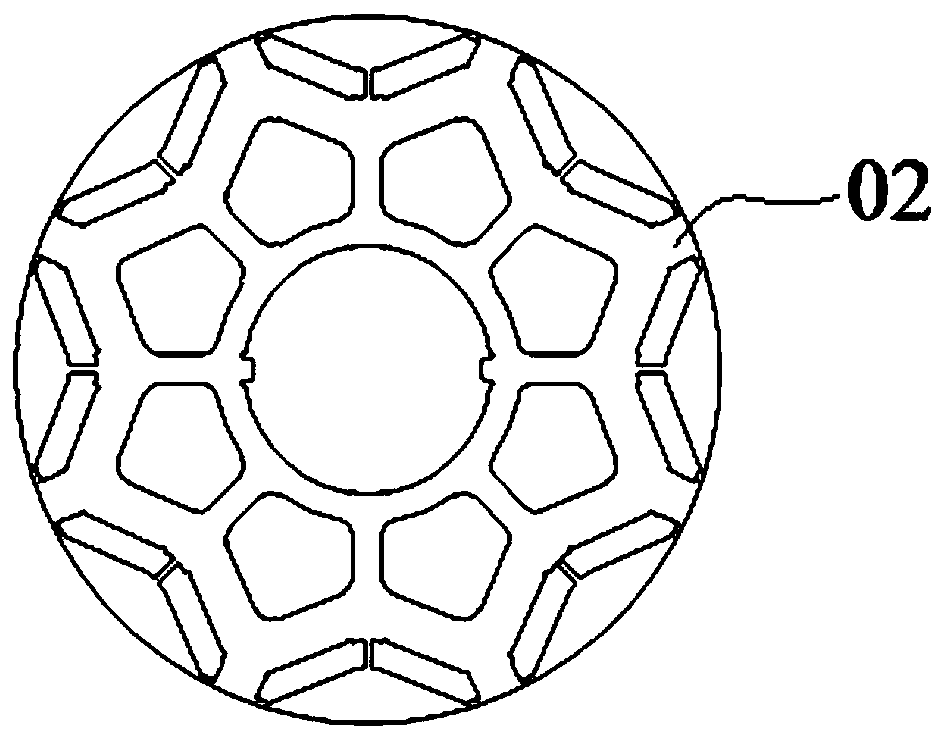

Rotor core and motor

PendingCN111600409ALose weightImprove featuresMagnetic circuit rotating partsElectric machineStructural engineering

The invention discloses a rotor core and a motor. The rotor iron core comprises magnetic steel baffles arranged at the two ends, a plurality of sections of first segmented iron cores and a plurality of sections of second segmented iron cores are fixedly arranged between the magnetic steel baffles, matching of the rotor iron core and a rotating shaft is achieved through the first segmented iron cores, and weight reduction of the rotor iron core is achieved through the second segmented iron cores. According to the rotor core, the total weight of the motor is directly reduced, the torque / power density is improved, the unbalance amount generated by a support structure is reduced, the air gap non-uniformity is reduced, and the torque pulsation and the NVH characteristic of the motor are improved; indirectly, support dies are reduced, matching of the support and the rotor core is improved, air gap non-uniformity caused by different coaxiality is reduced, the process requirement is simplified, and the production efficiency is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Axial-flow type aeroengine rotor

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

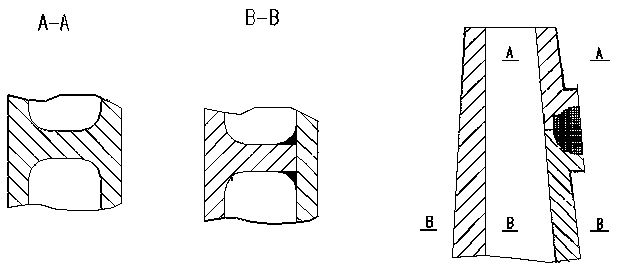

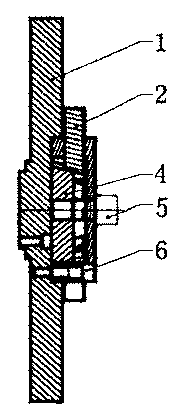

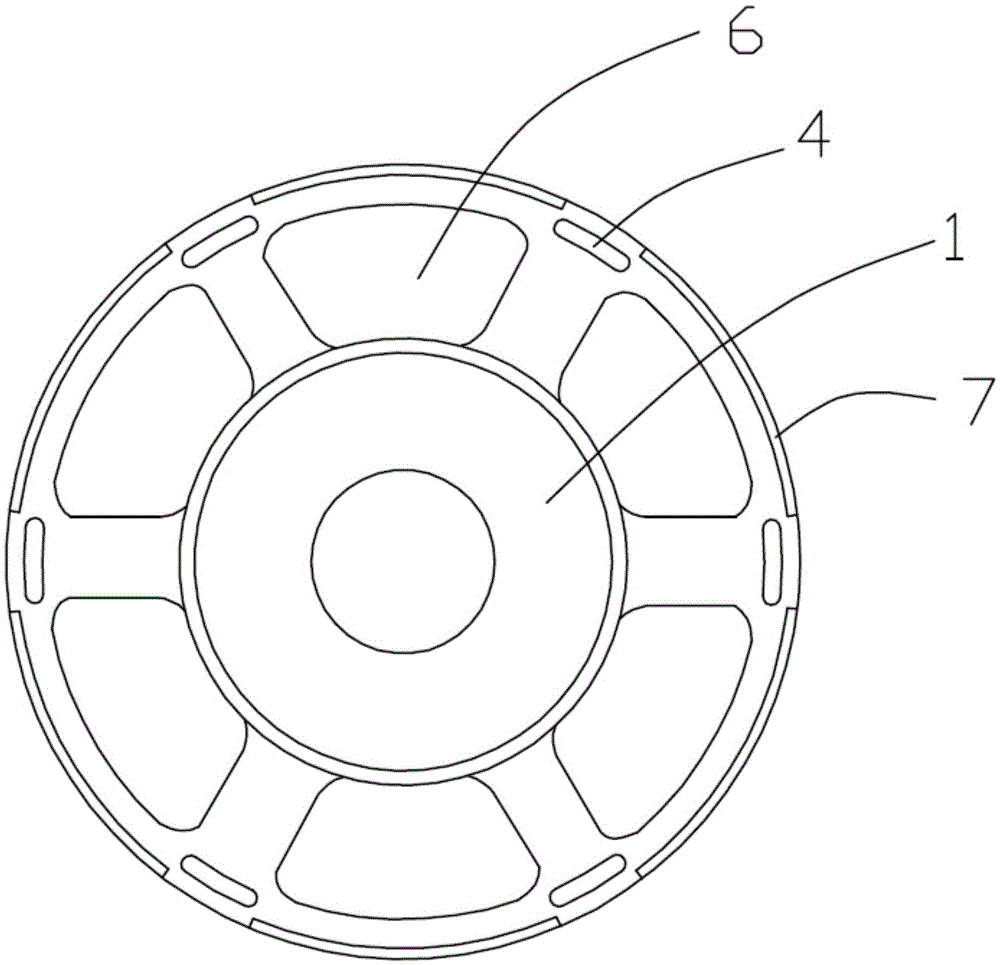

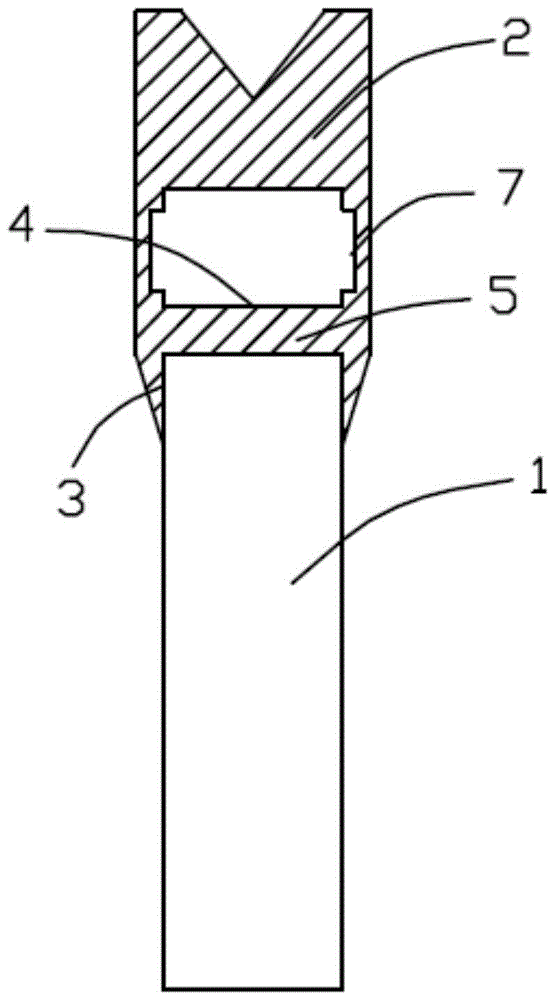

Structure for reducing unbalance of wound motor slip ring

ActiveCN102064645AEnsure safetyGuaranteed reliabilityAsynchronous induction motorsElectric machineEngineering

The invention relates to a structure for reducing the unbalance of a wound motor slip ring. The structure comprises a circular board, three insulating boards, three slip rings, six hexagonal nuts, six conducting rod, an insulating gasket, six insulating tubes and a sleeve. All the slip rings, the insulating boards, the circular board and the insulating gasket are sleeved on the sleeve; the conducting rods run through the corresponding slip rings, the insulating boards and the insulating gasket and are fixed on the slip rings by the nuts; the insulating tubes are sleeved on the corresponding conducting rods; weight reduction holes for reducing the weight are drilled at the position, near a hole for penetrating the conducting rods, of two of the three slip rings; and the number and the sizes of the weight reduction holes, near the hole for penetrating the conducting rods, on one slip ring are the same as the number and the sizes of the weight reduction holes on the other slip ring. The structure for reducing the unbalance of the wound motor slip ring is simple and compact, and is remarkable in interaction effect; under the conditions of not changing the material of the structure and guaranteeing the safety and the reliability of the motor, the unbalance of the slip rings is reduced by adding the weight reduction holes on the slip rings so as to prevent vibrations caused by the slip rings in the operation of the motor.

Owner:SEC ELECTRIC MACHINERY

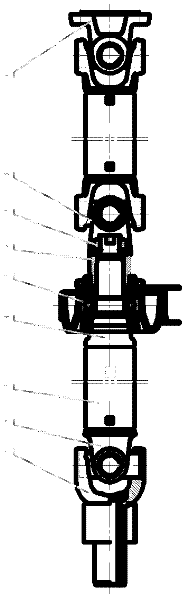

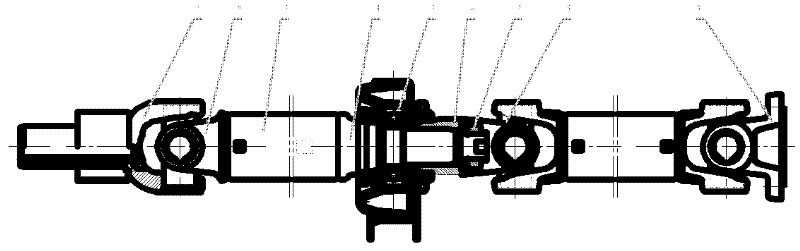

One-piece transmission shaft assembly

The invention discloses a one-piece transmission shaft assembly which is characterized that the excircle of a spline shaft and an axle tube are welded together, the other end of the axle tube and an axle tube fork are formed by welding, the axle tube fork is connected with a slip yoke through a cross axle; the spline shaft at the other end is in interference fit with a hanging assembly through the excircle and a bearing bore and is connected with the middle slip yoke by virtue of a spline; the spline shaft and the slip yoke are locked by virtue of a nut, the middle slip yoke is connected with the axle tube fork by the cross axle, the axle tube fork is connected with a flange fork through the cross axle, and a front transmission shaft and a rear transmission shaft are connected, thus forming the one-piece transmission shaft assembly; and after whole dynamic balance is achieved, the imbalance quantity of the loaded transmission shafts is reduced to the minimum.

Owner:诸城市威尔浦汽车传动轴有限公司

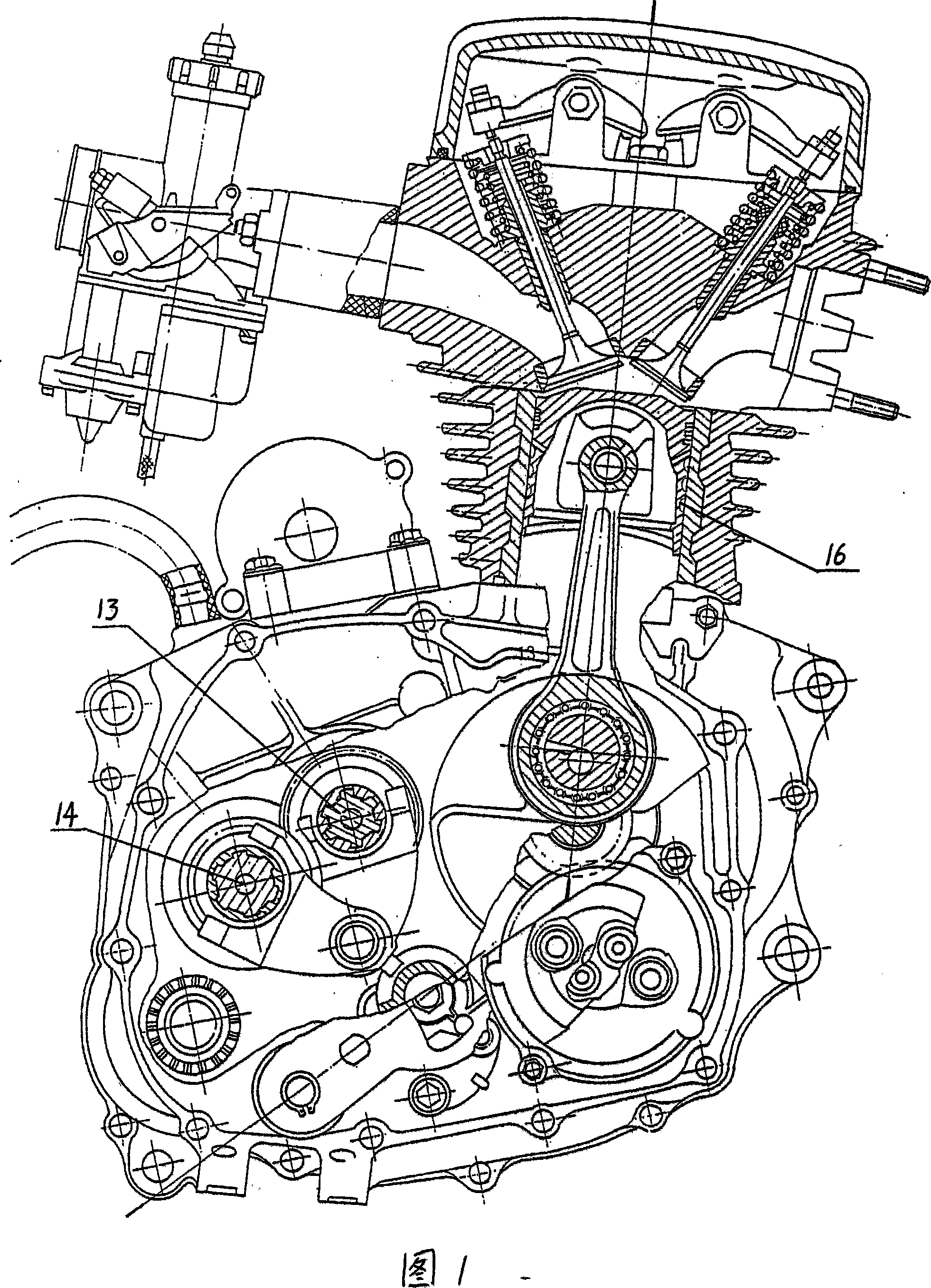

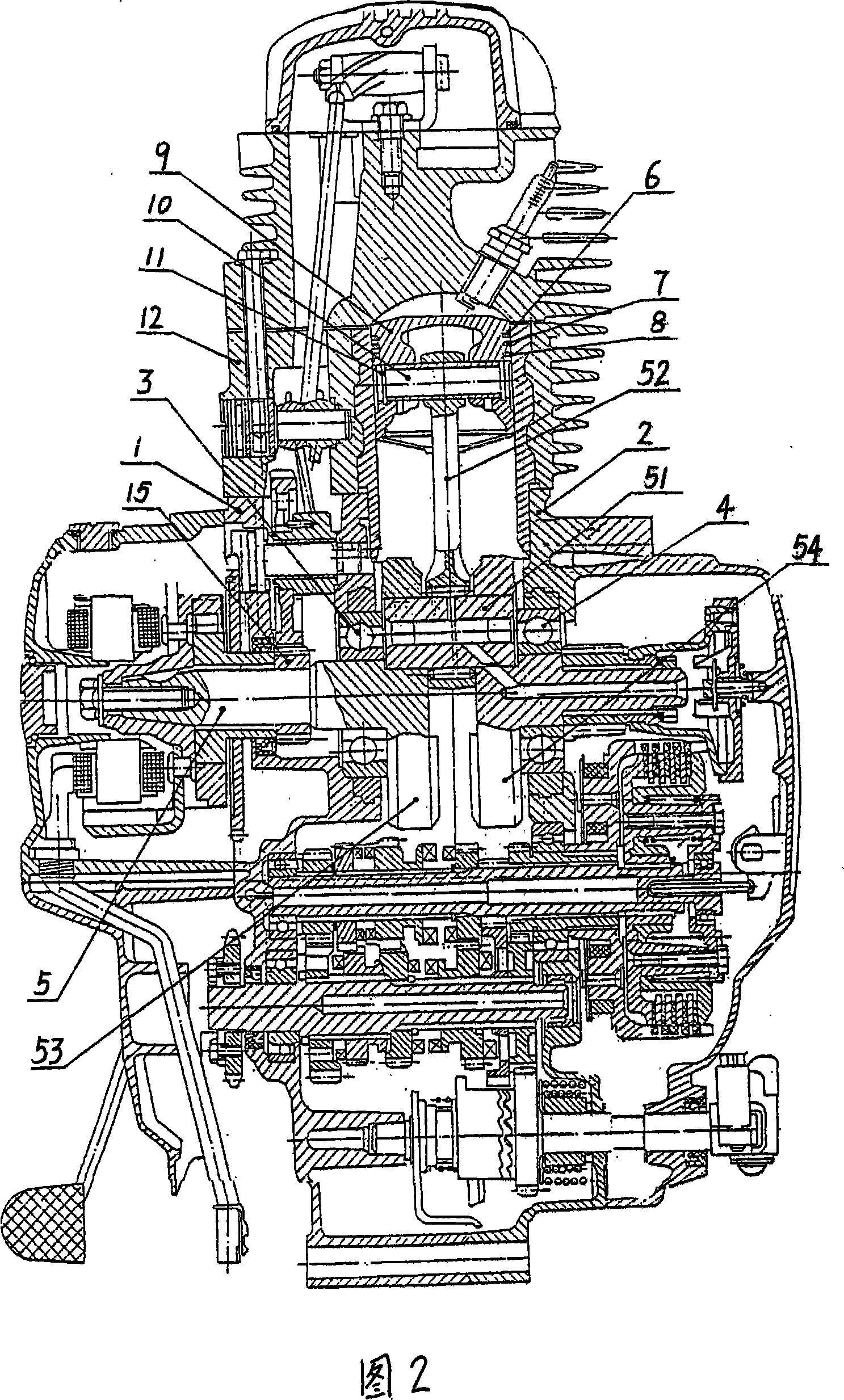

CG150 engine applying lightweight optimization and dynamic balance optimization technique

InactiveCN101078366AReduce friction lossAchieve lightweight optimizationCrankshaftsCasingsFriction lossDynamic balance

The invention relates to a CG150 engine adopting light-weight optimization and balance optimization technology, belonging to the motorcycle engine field. It mainly solves problems that the whole machine has serious vibration and outputs of power and torque are smaller because the rotational inertia is not appropriate and friction loss is larger. The optimization design not only relates to thermal parts such as piston, piston ring, piston pin, piston block joint and cylinder so on but also changes main parts such as crank-connecting rod, box, crank bearing, bearing pushing bolt and variable speed assembly so on. By decreasing frictional loss of thermal parts outputs of power and torque are improved. By optimal dynamical balance rate and main shaft angle the vibration is decreased. By changing transmission ratio the effect of comfortable riding is obtained. It is used for motorcycle engine so as to be suitable for mountain road.

Owner:济南轻骑发动机有限公司

Rotor of drive motor of new energy automobile

PendingCN106655571AReduce unbalanceAchieve direct fixationMagnetic circuit rotating partsSupports/enclosures/casingsNew energyDrive motor

The invention discloses a rotor of a drive motor of a new energy automobile. The rotor is provided with a rotor iron core, wherein the rotor iron core is provided with a permanent magnet groove extending from the upper end face of the lower end face of the iron core and, the middle part of the rotor iron core is provided with an axial iron core inner round hole and the inner wall of the inner round hole of the rotor iron core is provided with a boss; a rotor shaft fitting with the inner round hole of the rotor iron core and provided with an axial open groove fitting with the boss; an upper end board whose lower end face fits the upper end face of the iron core and is provided with a first guide groove communicating with a permanent magnet groove and also provided with an air inlet and air outlet both communicating with the first guide groove; a lower end board whose upper end face fits the lower end face of the iron core and provided with a second guide groove communicating with the permanent magnet groove. Therefore, rotor structural weight and rotation inertia are reduced; the manufacture cost is reduced; and the integral performance of the drive motor is improved.

Owner:芜湖杰诺瑞汽车电器系统有限公司

Rotor iron core convenient to produce

InactiveCN104333155AReduce manufacturing costGuaranteed uptimeMagnetic circuit rotating partsDynamic balanceMaterials science

The invention discloses a rotor iron core convenient to produce. The rotor iron core comprises a plurality of iron core sheets which are superposed together. Each iron core sheet is provided with a plurality of rivet holes convenient to run through and heat dissipation holes; the iron core sheets are uniformly distributed and superposed to form three iron core groups which are connected together. Each iron core group is formed by the plurality of same iron core sheets; each iron core sheet is provided with two groups of uniformly-distributed rivet holes; meanwhile, each iron core sheet is provided with two key grooves; and the iron core sheet is provided with a balance hole in the circumference of the heat dissipation hole. The rotor iron core has the advantages of reducing production labor hour, simplifying manufacture steps, reducing production cost wholly, being convenient for rivets to pass through, being stable in motor operation, being small in torque pulsation and motor noise, simplifying dynamic balance correction work load, and reducing manufacture cost of the motor.

Owner:HANGZHOU MOEN MOTOR

Narrow channel two-element working wheel for turbocompressor and manufacturing method of working wheel

ActiveCN110645201ASufficient welding strengthReduce unbalancePump componentsPumpsClassical mechanicsWeld strength

Provided is a narrow channel two-element working wheel for a turbocompressor. Blades are forged on a wheel disc through a semi-open type and closed type combined mode, and the wheel disc and a wheel cap are annularly connected through manual argon arc welding. The wheel cap and the blades are connected together through braze welding. The narrow channel two-element working wheel has the advantagesthat the welding strength is sufficient, a channel welding transition area is smooth, the unbalance amount is small and the appearance quality is high.

Owner:杭州杭氧透平机械有限公司

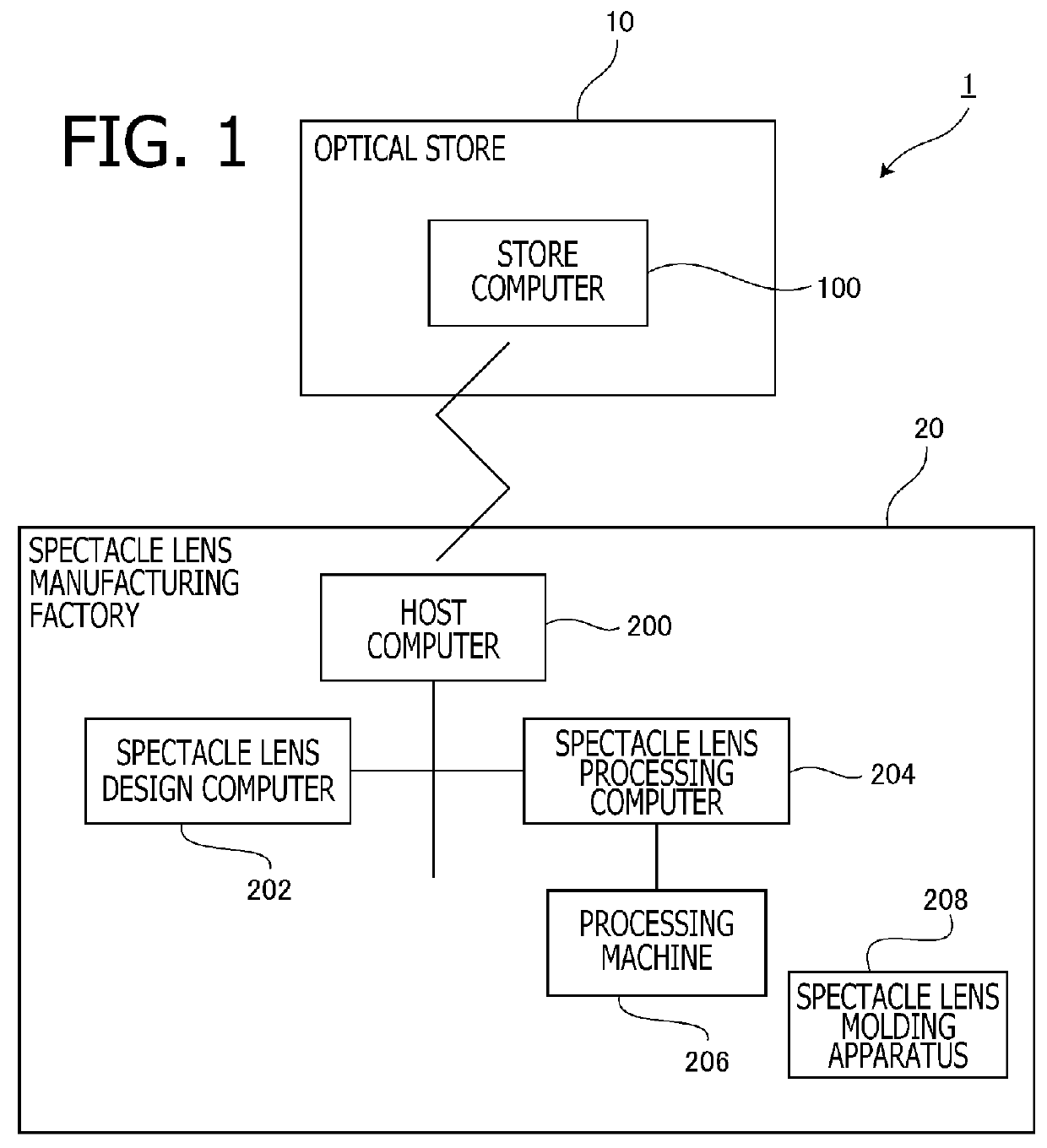

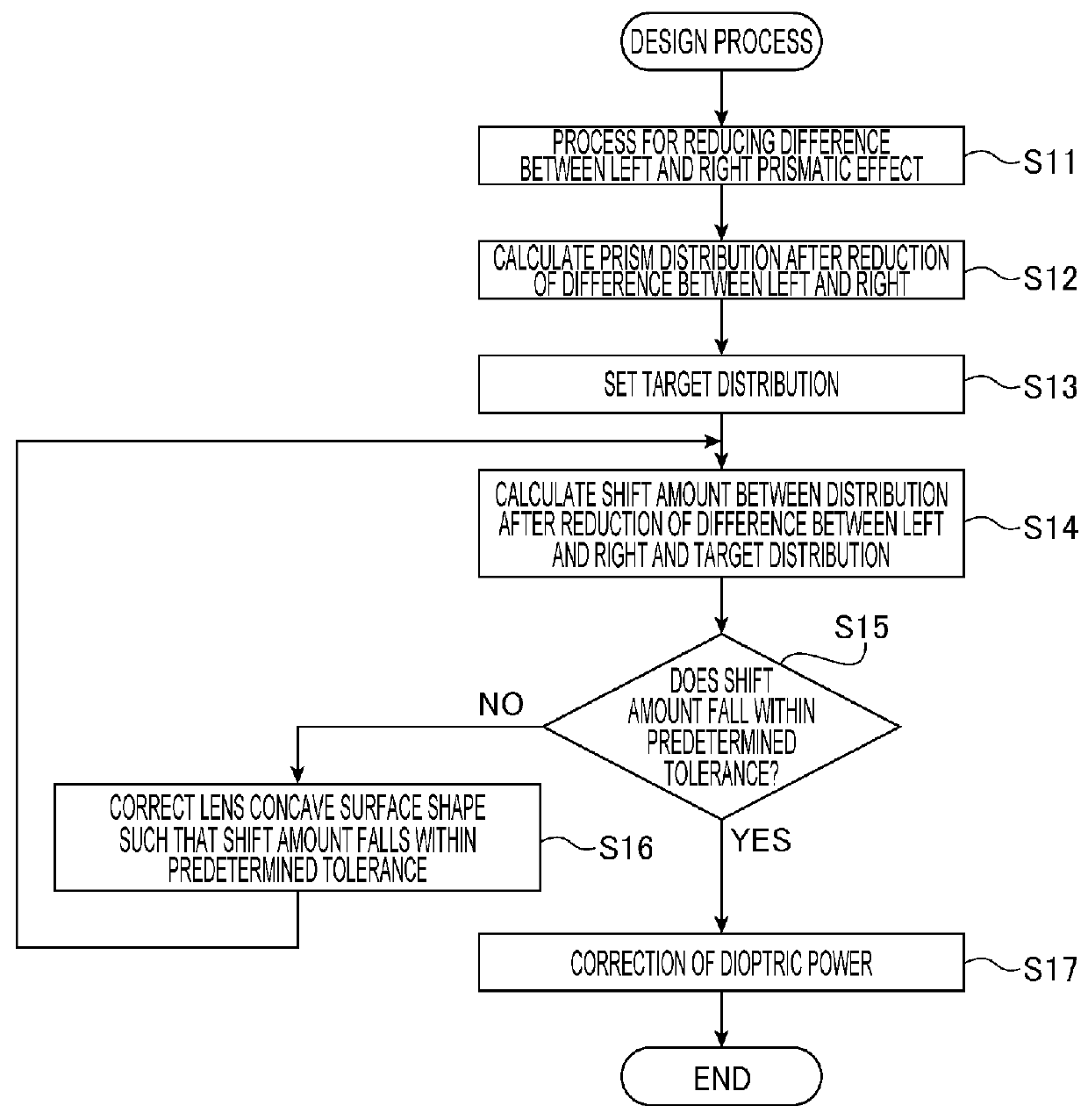

Spectacle lens, manufacturing method thereof and lens supply system

ActiveUS20160033791A1Reduce unbalanceReduce uncomfortable feelingProgramme controlComputer controlSight linePrism

A lens supply system has: an initial shape data obtaining unit that obtains initial shape data of a spectacle lens; a shape data correcting unit that corrects the initial shape data such that, when a base curve of an initial lens manufactured based on the initial shape data is defined as a first base curve, a predetermined lens having a second base curve lower than the first base curve is defined as a target spectacle lens, prismatic effects which light rays in respective visual line directions passing through a center of an eye assumed in optical design receive from the initial lens coincide with or approach prismatic effects which the light rays receive from the target spectacle lens; and a spectacle lens manufacturing unit that manufactures a spectacle lens based on the corrected initial shape data.

Owner:HOYA CORP

Optimizing method for reducing equilibrium amount of push type clutch cover

The invention discloses an optimizing method for reducing equilibrium amount of a push type clutch cover. The method comprises the steps that raw materials are placed on a mold for cover blanking andpunching a middle mold, and a cover outside shape and a middle shape are blanked at a time in a gapped manner; the shape of the cover is formed through a forming mold on a pressure machine tool; on anumerical control lathe, middle hole end face turning and middle hole diameter correcting can be achieved through a turning tool; mounting holes, transmission piece holes and gaps are punched out directly through mounting hole, transmission piece hole and gap punching die on a punching machine; finally, on the numerical control lathe, the outer circle and the depth are turned through the turning tool. The method has the beneficial effects that the number of part machining procedures is reduced, production efficiency is improved, production cost is reduced, positioning accuracy and concentricity of the transmission piece hole distribution circle and the outer circle are ensured, machining quality and precision are ensured, and the aim of reducing the unbalance amount of a cover assembly isachieved.

Owner:GUILIN FUDA

Modular cabin blower system for aircraft

PendingUS20220065171A1Arrange moreReduce overhangGas turbine type power plantsEngine fuctionsNacelleCombustor

A gas turbine engine includes an engine core including a compressor, a combustor, and a turbine, the compressor being connected to the turbines through a respective shaft; and a cabin blower system comprising: an electric variator comprising a first electrical machine connected to a first shaft arranged along a first axis, a second electrical machine connected to a second shaft arranged along a second axis, and a power management system; a cabin blower comprising a compressor driven by a third shaft arranged along a third axis, the compressor comprising an air inlet and an air outlet; and a differential gearbox. The gas turbine engine further includes an accessory gearbox arranged within an accessory gearbox casing and adapted to drive the cabin blower system.

Owner:ROLLS ROYCE PLC

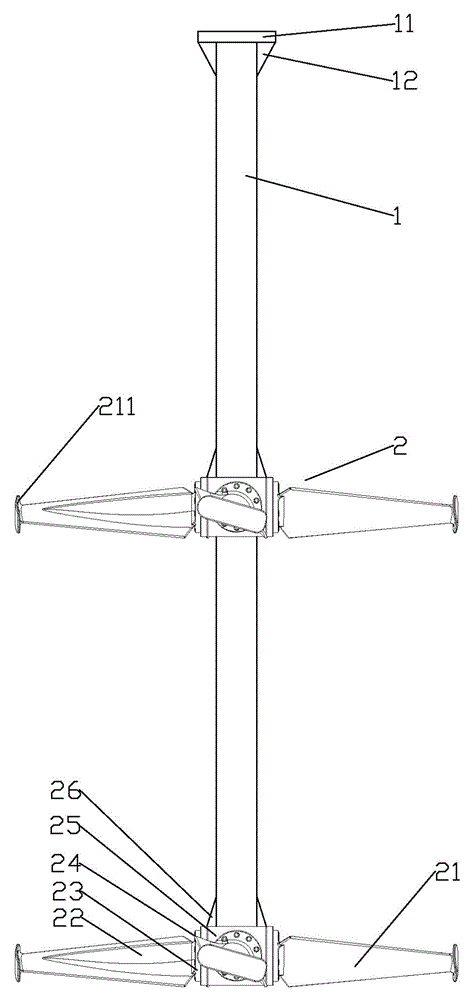

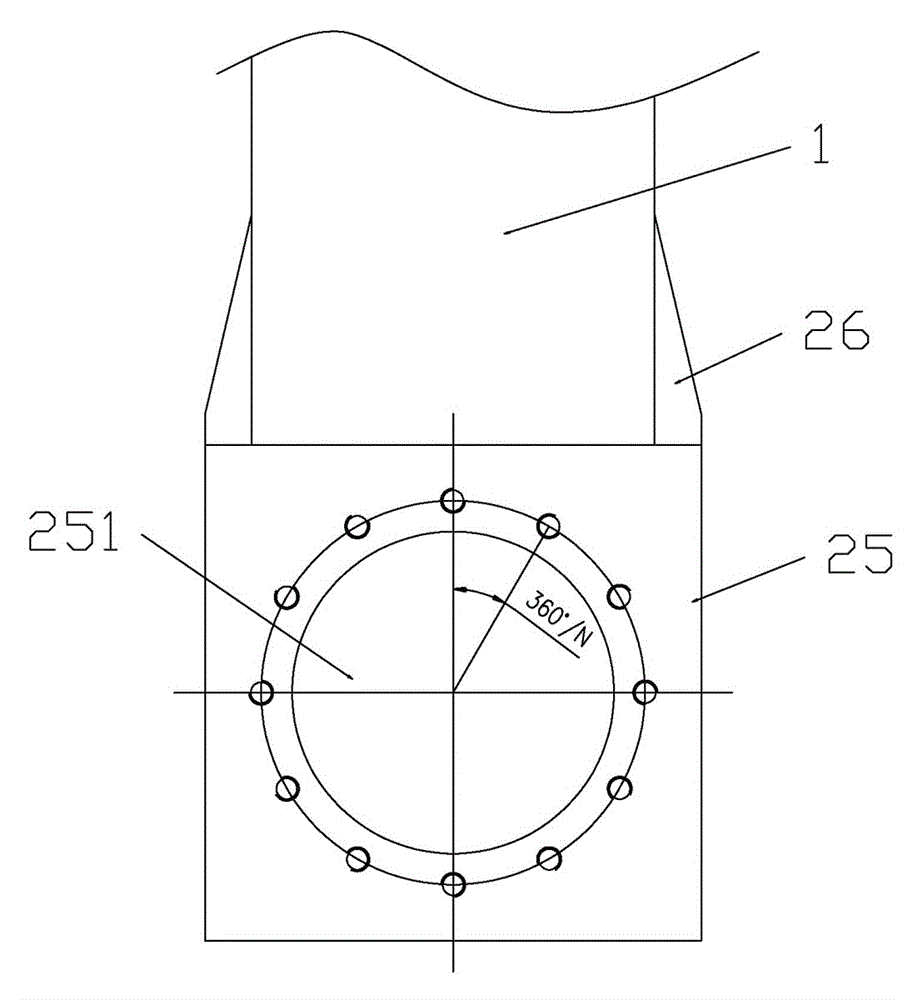

Extraction tank stirrer

InactiveCN105056826AReduce deflectionReduce unbalanceSolvent extractionMixer accessoriesSquare wheelImpeller

The invention discloses an extraction tank stirrer. The stirrer comprises a stirring shaft (1) and is characterized in that the upper layer of the stirring shaft (1) is provided with an impeller (2), the impeller (2) comprises a square wheel hub (25), which is fixed on the stirring shaft (1) and a blade (21); the blade (21) is fixed on the square wheel hub (25) through a connection flange (23); the upstream face of the blade (21) is a streamline curved surface, so that the stirrer can push fluid to a longer distance under a same push force; and the tail end of the blade (21) is provided with a cylindrical current stabilizing ring (211), which can reduce the deflection of the stirring shaft (1) and improve the stirring stability. The provided extraction tank stirrer has the advantages that the materials are overturned for many times during the rotation process of the stirring shaft, the stirring is table, the stirring effect is good, and the extraction tank stirrer is especially suitable for materials with a high solid content. Moreover, the blade angle can be adjusted, and the parts can be changed easily, so the extraction tank stirrer can be promoted and used.

Owner:江苏胜开尓工业技术有限公司

Adjustable connecting device and fan using same

PendingCN114321009ASolve the problems of high cost of mold opening and low degree of generalizationEnsure consistencyPump componentsPump installationsAir volumeCustomer attrition

The invention provides an adjustable connecting device and a fan using the same, the adjustable connecting device comprises a connecting piece, a fan blade and a wheel disc, the connecting piece is arranged between the fan blade and the wheel disc, and the connecting piece can enable the relative angle between the connecting piece and the fan blade to be adjustable; and / or the relative angle between the wheel disc and the connecting piece can be adjusted; the problems that the angle of the fan blade cannot be adjusted, different performance requirements (including but not limited to static pressure, air volume and the like) of different customers cannot be met at the same time, the project development period is too long, and customer loss is caused due to the influence on the project development progress are solved; and meanwhile, the problems of too high mold opening cost and low generalization degree caused by a large amount of mold opening due to demand change are solved, the product generalization is improved, the new cost input is reduced, and extremely high practical value and cost benefit are achieved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Clutch assembly and clutch pressure plate balancing tool

InactiveCN103792043AGuaranteed coaxialityEnsure safetyStatic/dynamic balance measurementControl engineeringEngineering

The invention discloses a clutch assembly and clutch pressure plate balancing tool. The balancing tool comprises a fixed plate and a movable plate. The movable plate is installed in the middle of the fixed plate. The fixed plate is connected with a fixed sleeve through the movable plate. The bottom part of the movable plate is equipped with a mobile block. By adopting the technical scheme of the invention, generation of the unbalanced amount is reduced, and coaxiality and safety of a clutch assembly during the balancing process are ensured.

Owner:SUZHOU RUNKAI AUTO PARTS MFG

Guide wire wheel for polycrystalline silicon cutting wires and preparation process thereof

The invention discloses a guide wire wheel for polycrystalline silicon cutting wires. The guide wire wheel comprises a wire wheel body, wherein the wire wheel body is manufactured by carbon fibers; and guide wire groove rings are fixed at the outer periphery of the wire wheel body. The preparation process comprises the steps of: 1) shape cutting; 2) compression molding; 3) accurate cutting; 4) molding of the guide wire groove rings; and 5) balance testing. The guide wire wheel is high in accuracy, low in error, small in weight and high in hardness, and largely prolongs the service life.

Owner:ZHANGJIAGANG BAOHUALI HIGH POLYMER PROD CO LTD

A wire pulley for polysilicon cutting wire and its preparation process

Owner:ZHANGJIAGANG BAOHUALI HIGH POLYMER PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com