Structure for reducing unbalance of wound motor slip ring

A winding type, balanced technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of uneven weight distribution of conductive rods, hidden dangers of motor operation, etc., to achieve simple structure, reduce unbalance, and effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

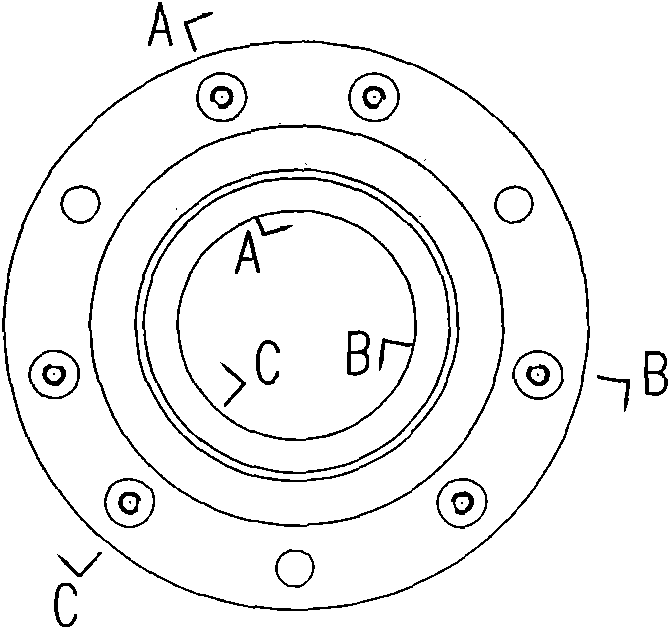

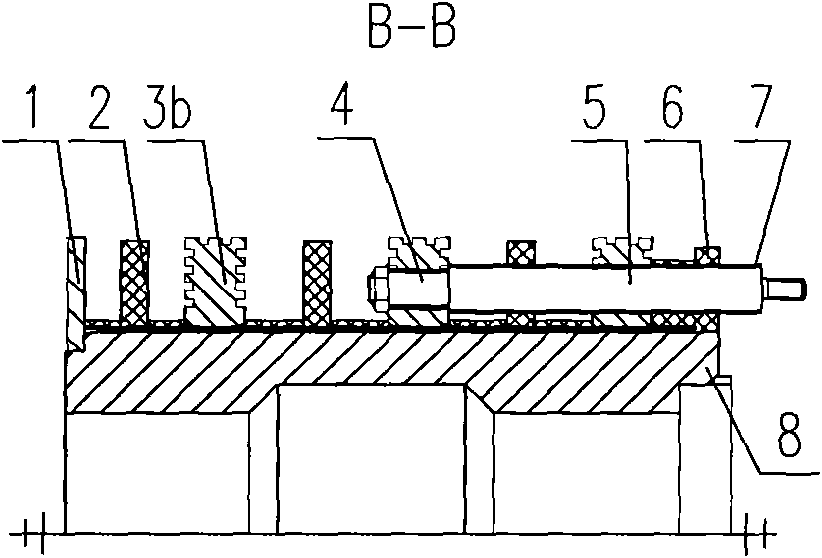

[0017] Such as Figure 1~4 As shown, the present invention includes a circular plate 1, three insulating plates 2, three slip rings 3a, 3b, 3c, six hexagon nuts 4, three conductive rods 5, an insulating washer 6, six insulating tubes 7 and A sleeve 8. The circular plate 1, the insulating plate 2, the slip rings 3a, 3b, 3c and the insulating washer 6 are sequentially sleeved on the sleeve 8. The three conductive rods 5 pass through the corresponding insulating washer 6, the insulating plate 2 and the slip rings 3a, 3b, 3c: Use hexagon nuts 4 to fix the three slip rings 3a, 3b, 3c, respectively, and sleeve the insulating tube 7 on the corresponding conductive rod 5.

[0018] Such as Figure 5-7 As shown, in the three slip rings 3a, 3b, 3c, two of the slip rings 3a, 3b are drilled in the vicinity of each pair of holes 9 for conducting rods, and three additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com