Narrow channel two-element working wheel for turbocompressor and manufacturing method of working wheel

A technology of turbo compressor and narrow flow channel, which is applied to the components, pump components, mechanical equipment, etc. of the pumping device for elastic fluid, can solve problems such as safety and hidden dangers, achieve small unbalance and improve Product efficiency and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

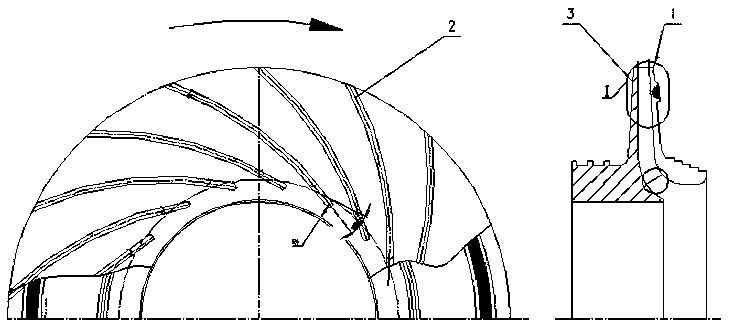

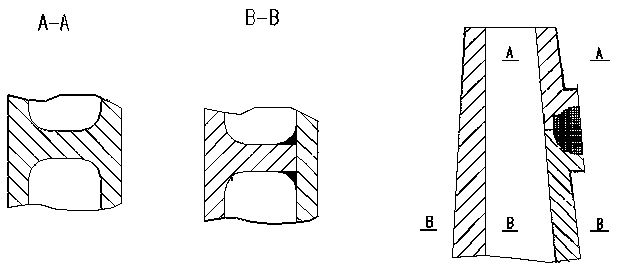

[0021] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-2 Shown: a narrow channel binary working wheel used on a turbo compressor, which includes a plurality of blades 2, and the blades 2 are arranged on a disc 3, and the disc 3 is connected to the wheel cover 1 by welding , the shown wheel cover 1 and the blade 2 are connected together by welding, and the blade 2 is milled on the wheel disc 3, wherein the blade 2 is semi-open and milled on the wheel disc 3, and the wheel disc 3 and the wheel cover 1 Ring connection by manual sub-arc welding. The wheel cover 1 and the blade 2 are connected together by brazing.

[0022] A kind of manufacturing method of the narrow channel binary impeller used on the turbocompressor of the present invention comprises the following steps:

[0023] 1) Part of the flow channel at the outlet is milled as a whole by a closed impeller to ensure that the outlet size fully meets the design req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com