Dynamic compensation wheel rim for compensating system unbalance of tyre dynamic balancing testing machine and method

A dynamic balance testing machine and dynamic compensation technology, applied in the field of dynamic compensation rims, can solve problems such as unbalanced amount and lack of compensation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

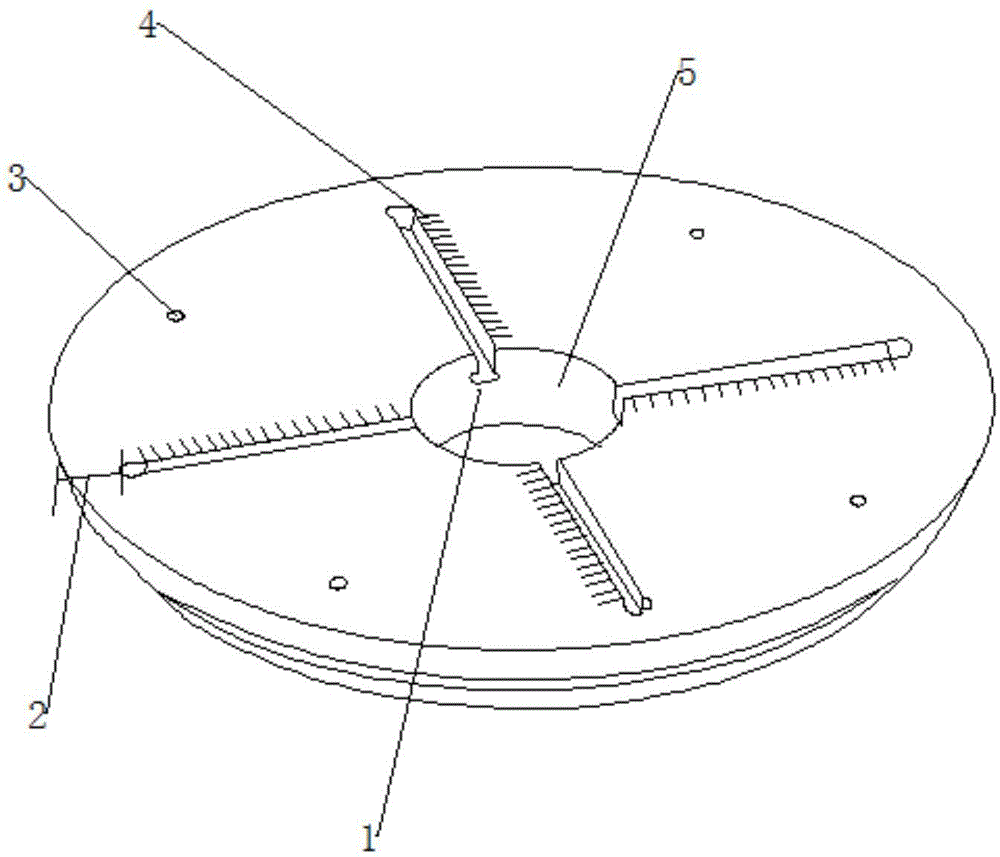

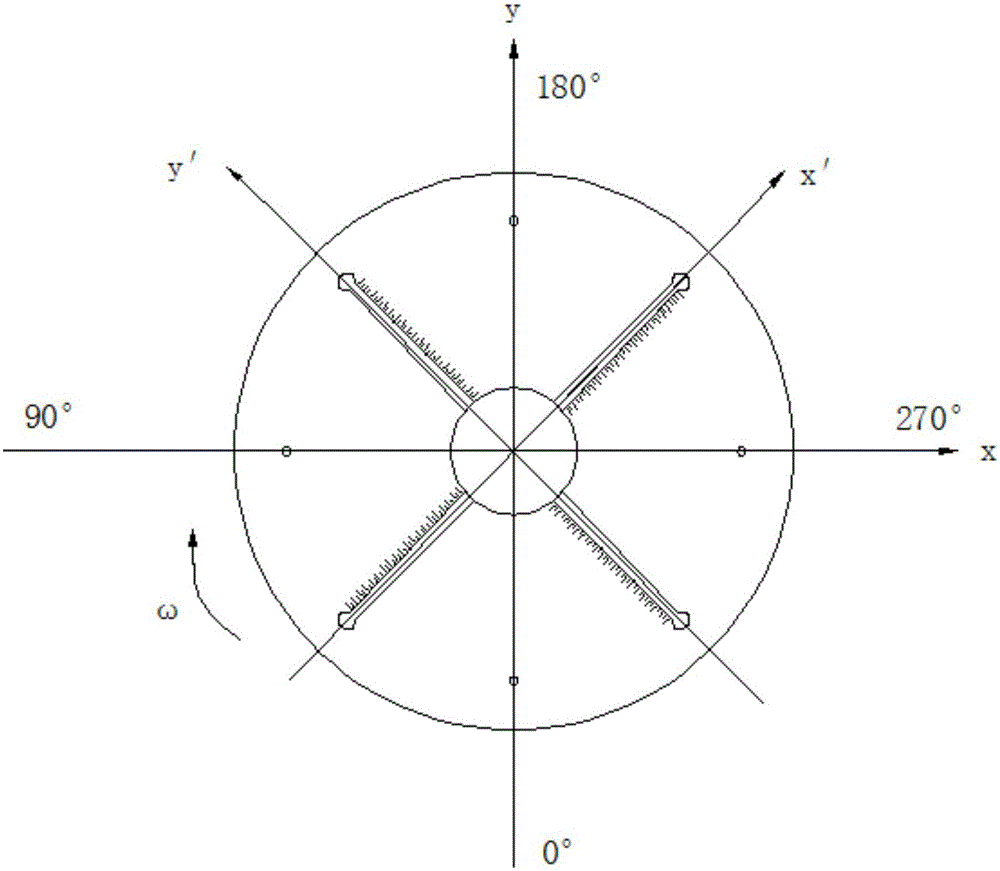

[0065] figure 1 , is the structure diagram of the rim designed in the embodiment of the present invention. The rim of the tire dynamic balancing testing machine includes an upper rim and a lower rim. In this embodiment, only the upper rim is described. Four T-shaped grooves 1 are respectively opened in the orthogonal direction on the surface of the rim, and two sets of T-shaped bolt-nut structure pairs with masses of 10g, 20g, 30g, 50g, and 100g are configured. T-bolts and matching nuts can be designed and manufactured by selecting appropriate materials according to the size of the rim and the size of the T-slot, and will not be described in detail in this embodiment. The T-shaped bolt can be moved and fixed in the T-shaped slot, and the T-shaped slot 1 can have a scale 4 to facilitate the measurement and adjustment of the T-shaped bolt. Four threaded holes 3 for loading weights during the calibration process are provided at specific positions on the edge of the rim.

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com