Rotor of drive motor of new energy automobile

A technology for new energy vehicles and driving motors, which is applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing the difficulty of calibrating dynamic balance, long glue filling process time, and increased rotor weight, etc., and it is easier to achieve the glue filling amount. Control, improve NVH performance, improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

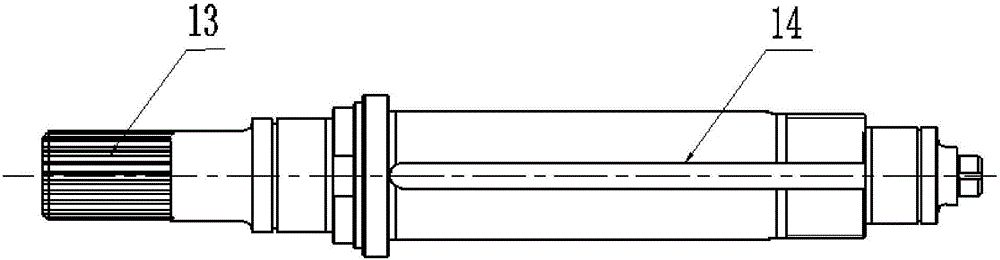

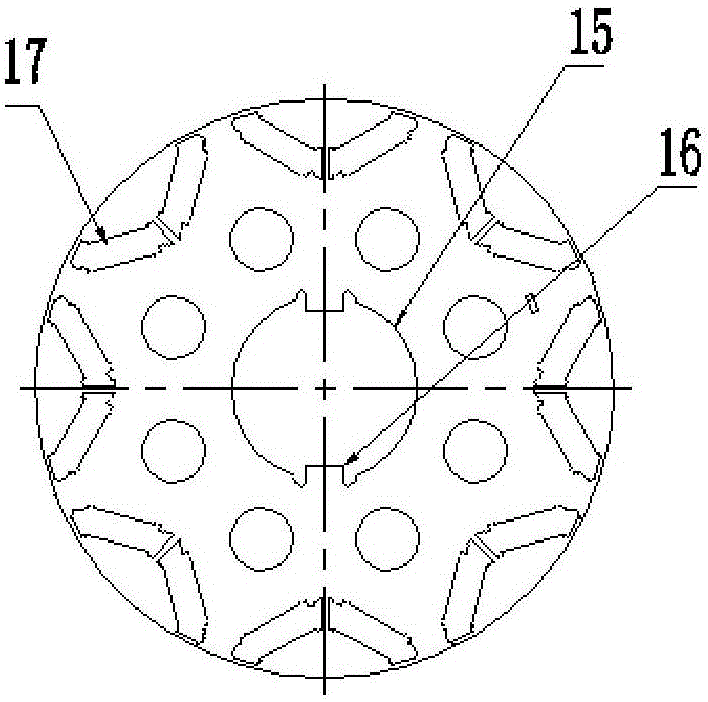

[0031] see Figure 1-9 , a new energy vehicle drive motor rotor, has:

[0032] The rotor core is provided with a permanent magnet slot extending from the upper end surface of the iron core to the lower end surface of the iron core. The middle part of the rotor iron core is provided with an axial inner circular hole of the rotor iron core. The inner wall of the inner circular hole of the rotor iron core is provided with There is a boss; the rotor shaft is provided with a plurality of keyway-shaped open slots in the rotor iron core matching section. The inner circular hole of the rotor iron core is provided with a plurality of flat key-shaped bosses. The rotor shaft is provided with a plurality of keyway-shaped open slots in the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com