A translational processing device for arc-toothed cylindrical gears

A technology for cylindrical gears and processing devices, which is applied in the direction of driving devices, components with teeth, metal processing equipment, etc., can solve the problems of low gear precision, reduced load-bearing capacity, and insufficient rigidity, so as to improve the processing accuracy of gears and reduce the The effect of unbalance and improving the rigidity of members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

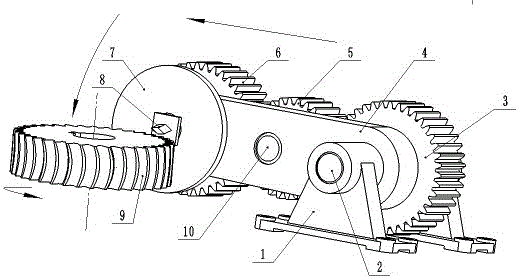

[0020] Such as figure 1 As shown, a single-cutter, single-blade constant-tooth-line-radius processing device for processing circumferentially equal-tooth-thick circular-arc tooth-line cylindrical gears is a processing device designed according to the principle of cutter translational processing of circumferentially equal-tooth-thickness, including a sun The wheel 3 is fixed on the supporting base 1, the planetary carrier 4 is movably connected to the supporting base 1 by the central shaft 2, the idler gear 5 and the planetary gear 6 mesh with each other, and are respectively movably connected to the planetary carrier 4 by a connecting column 10, and at the same time The idler gear 5 meshes with the sun gear 3, the cutter head 7 is fixed on the planetary wheel 6, and the blade 8 is fixed on the cutter head 7. Since the sun gear 3 and the planetary gear 6 have the same modulus and number of teeth, when the planet carrier 4 rotates around the central axis 2, the normal direction ...

Embodiment 2

[0022] Such as figure 2 Shown is a single-cutter, single-blade variable-tooth-tooth-tooth-tooth-tooth-tooth-thick arc-tooth-toothed cylindrical gear processing device in the circumferential direction, including a sun gear 3 fixed on a support seat 1, an idler gear 5 and an adjustment connecting rod through a connecting column 10 11 and the connecting rod 12 are movably connected, and the adjusting connecting rod 11 is movably connected to the center of the idler 5 and the sun gear 3, and the connecting rod 12 is movably connected to the centers of the idler 5 and the planetary gear 6, and the idler 5 is respectively connected to the sun gear 3 and the sun gear 3. The planetary gear 6 is engaged, and the multi-purpose planetary carrier 16 is movably connected on the support seat 1 through the central shaft 2. The planetary wheel is installed in the chute of the multi-purpose planetary carrier 16 through another connecting column 10, and the connecting block 13 is movably connec...

Embodiment 3

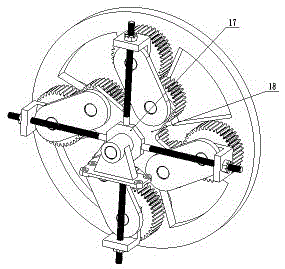

[0024] Such as image 3 Shown is a multi-cutter, single blade variable tooth line radius arc tooth line cylindrical gear processing device. On the basis of Example 2, the adjusting bolt 15 is changed to a multi-purpose adjusting bolt 17, and the adjusting connecting rod 11 is changed to a multi-purpose connecting rod 18. A gear pair consisting of a plurality of idler gears 5 and planetary gears 6 is added, which are evenly distributed around the sun gear 3. This device can reduce the unbalance of the planetary gear system, which is conducive to improving rigidity and processing accuracy; at the same time, each planet A cutter head 7 can be fixed at the center of the gear 6, so the planetary carrier 16 can be used for one revolution, and the tooth blank workpiece 9 can be processed many times, which improves the processing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com