Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194results about How to "Realize synchronous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

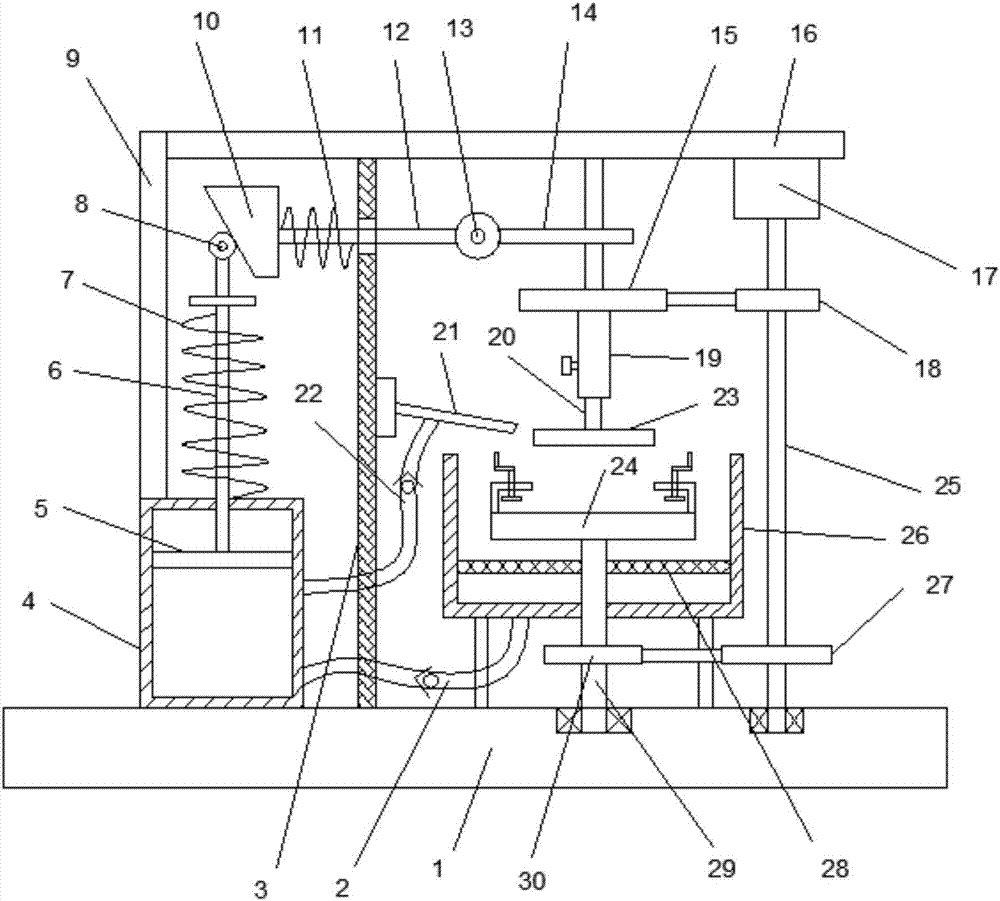

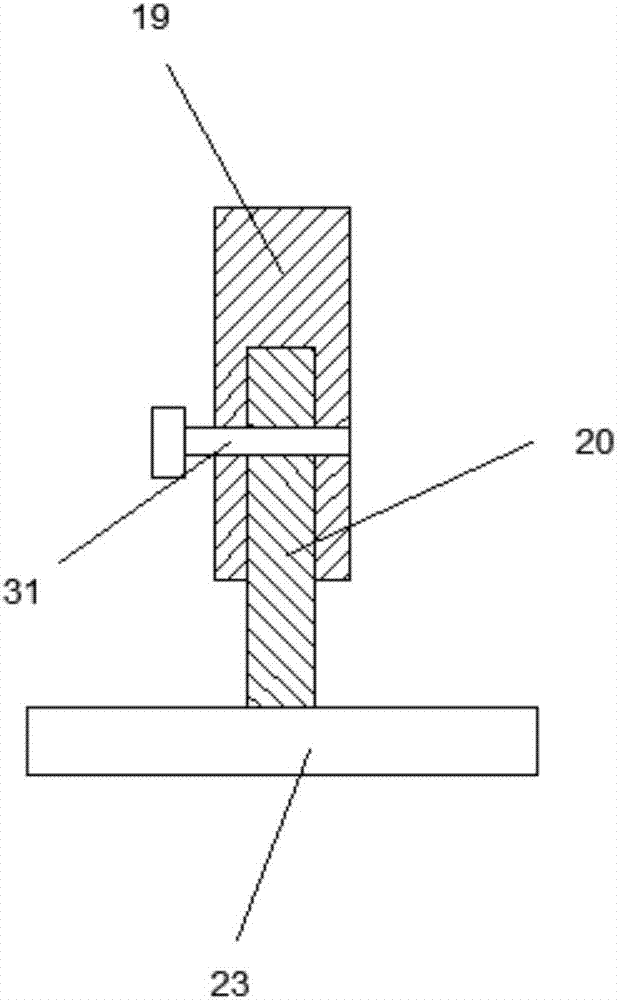

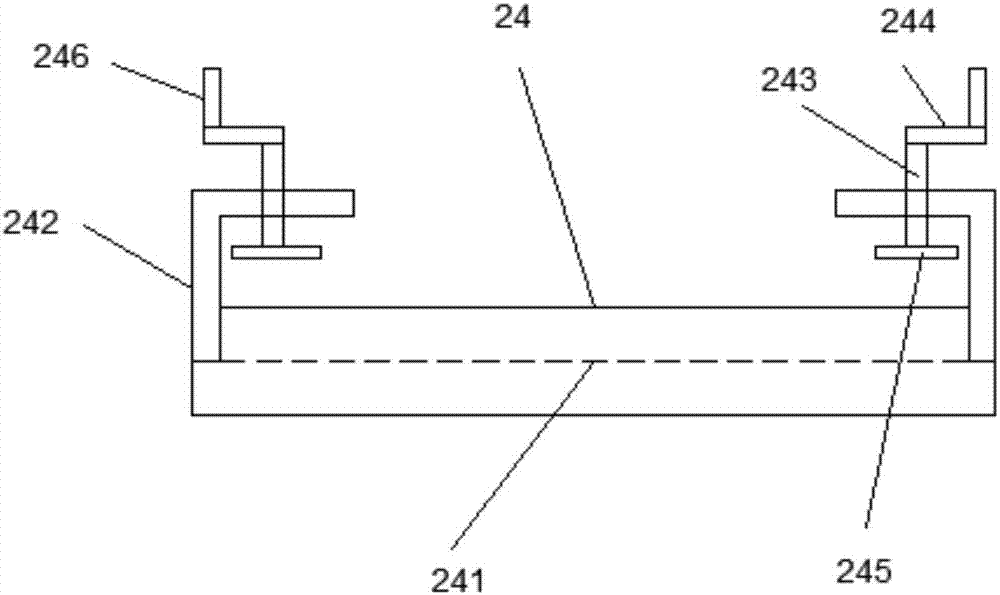

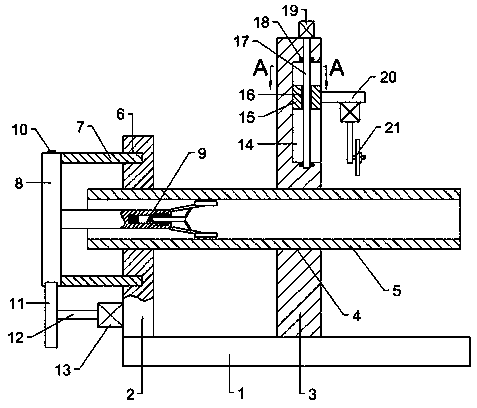

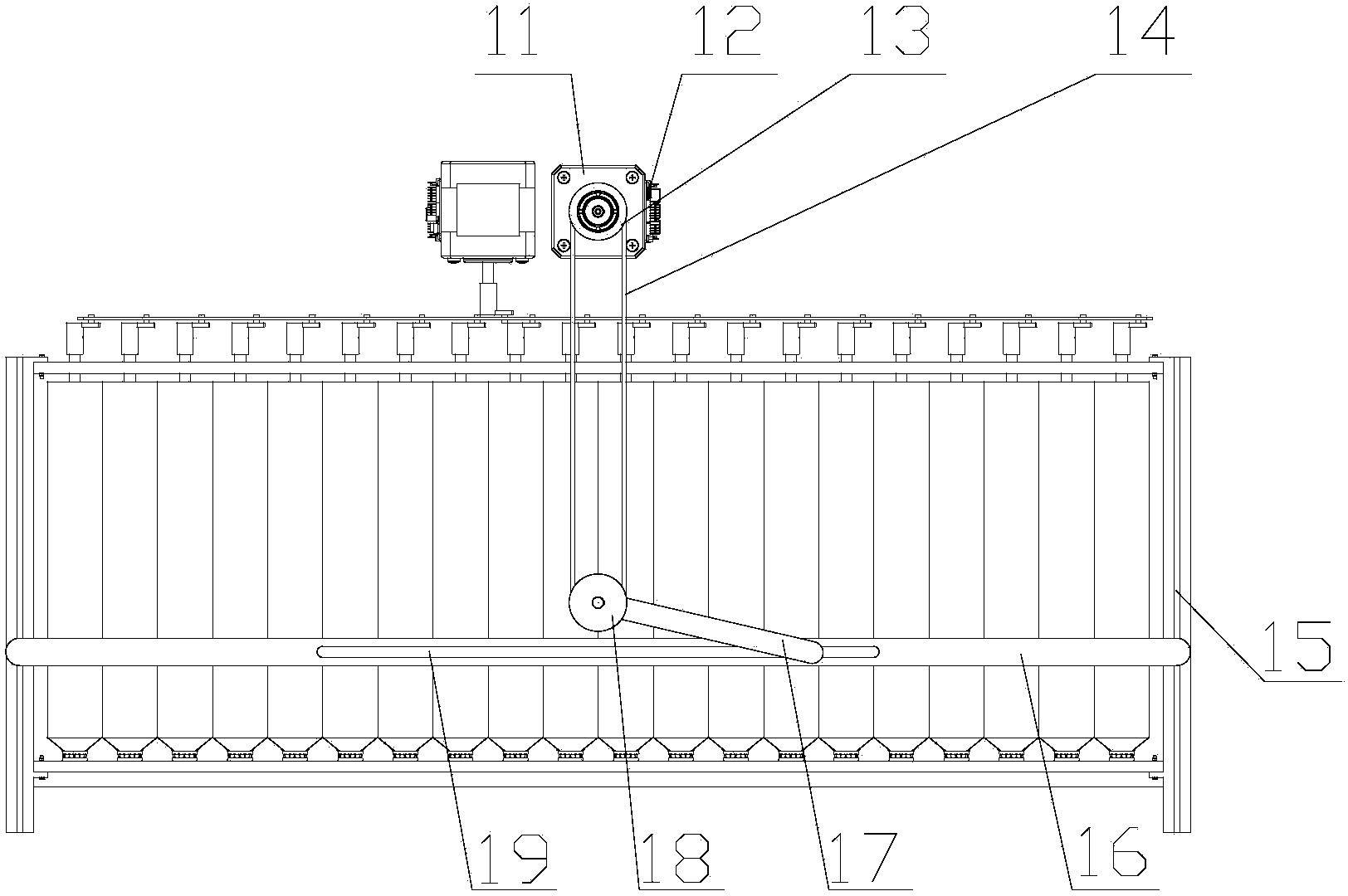

Building aluminum plate grinding device with cooling and dust removal function

InactiveCN107160246AImprove grinding efficiencyImprove sanding qualityPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftCooling effect

The invention discloses a building aluminum plate grinding device with the function of cooling and dust removal, which comprises a base and a top plate, a driving motor is connected to the right side of the lower end of the top plate, a driving shaft is connected to the lower end of the driving motor, and an upper driving belt is connected to the middle part of the upper end of the driving shaft The left end of the upper driving pulley is connected with the upper driven pulley through a belt, the upper end of the upper driven pulley is connected with a rotating cam at the coaxial position, the left end of the rotating cam is provided with a guide wheel, the left end of the guide wheel is connected with a guide rod, and the left end of the guide rod A wedge-shaped block is connected, the left end of the wedge-shaped block is in contact with a lifting wheel, the lower end of the lifting wheel is connected with a lifting shaft, the middle part of the lower end of the driving shaft is connected with a lower driving pulley, and the left end of the lower driving pulley is connected with a lower driven pulley through a belt. The middle part of the driven pulley is connected with a driven shaft. The invention realizes the synchronous rotation of the grinding wheel and the workbench, realizes the cooling effect on the grinding wheel, and takes away the aluminum dust produced during grinding.

Owner:苏锦忠

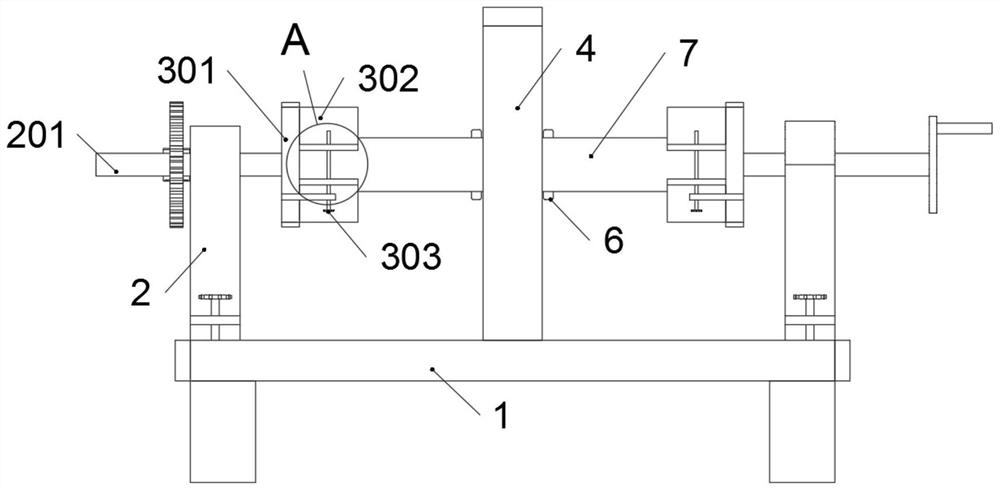

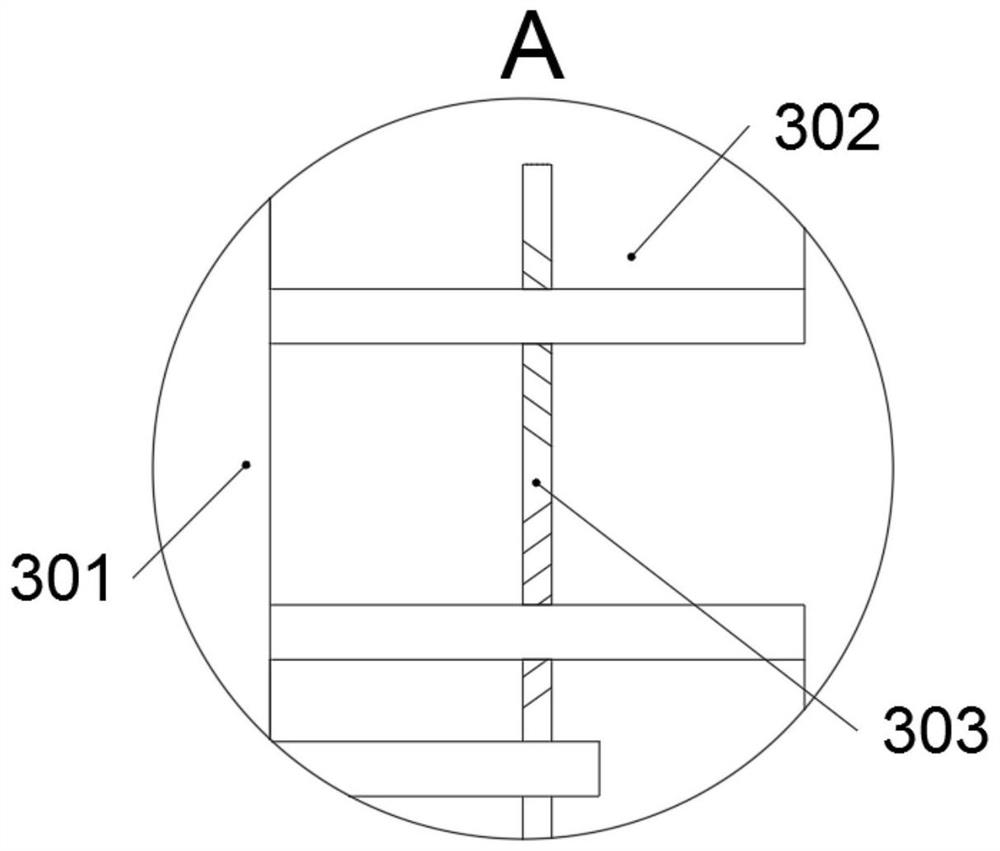

Building steel pipe cutting-off equipment with steel pipe synchronous rotation function

The invention discloses building steel pipe cutting-off equipment with a steel pipe synchronous rotation function. The equipment comprises a base, wherein the left part of the base is fixedly connected with a first supporting plate, and a movable through hole is formed in the first supporting plate; a second supporting plate is fixedly connected to the position, located on the right side of the first supporting plate, of the base, another movable through hole is formed in the second supporting plate, and a steel pipe is jointly erected in the two movable through holes; annular grooves are formed in the left side wall of the first supporting plate, and sleeves are arranged in the annular grooves; a disc is fixedly connected to the left ends of the sleeves, a steel pipe clamping device is fixedly connected to the right side wall of the disc, a gear ring is fixedly connected to the edge of the disc, and a gear is meshed with the lower side of the gear ring. The building steel pipe cutting-off equipment with the steel pipe synchronous rotation function has the beneficial effects that a rotating shaft drives the gear to rotate, the gear drives the gear ring to rotate, and the gear ringcan drive the steel pipe to rotate through the disc and the steel pipe clamping device, so that the large-diameter steel pipe is conveniently cut, furthermore, a notch is flat, subsequent trimming does not need to be carried out, and operation safety performance is higher.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

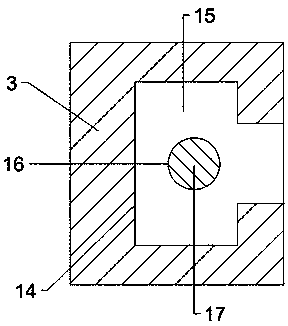

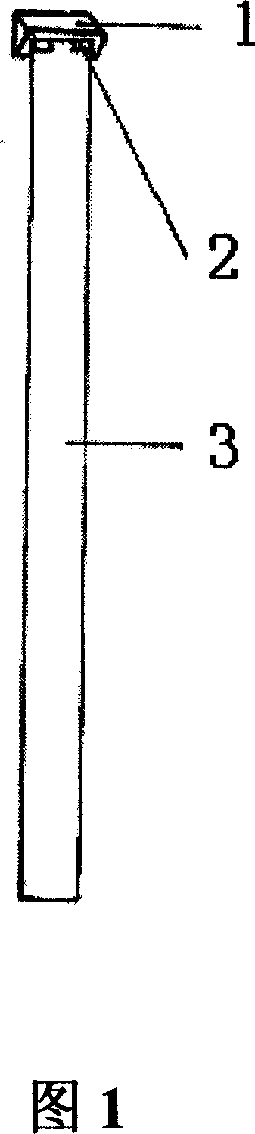

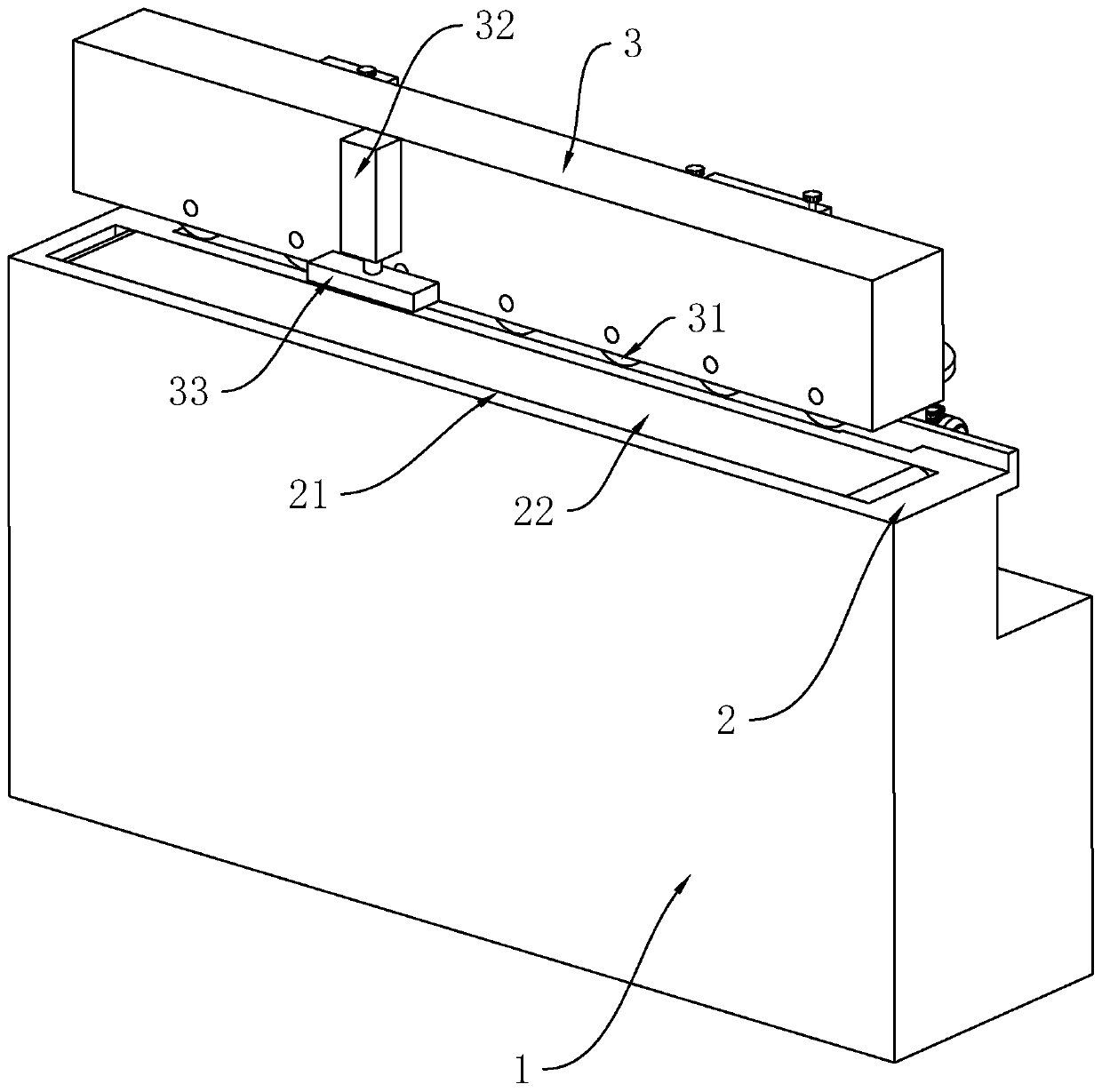

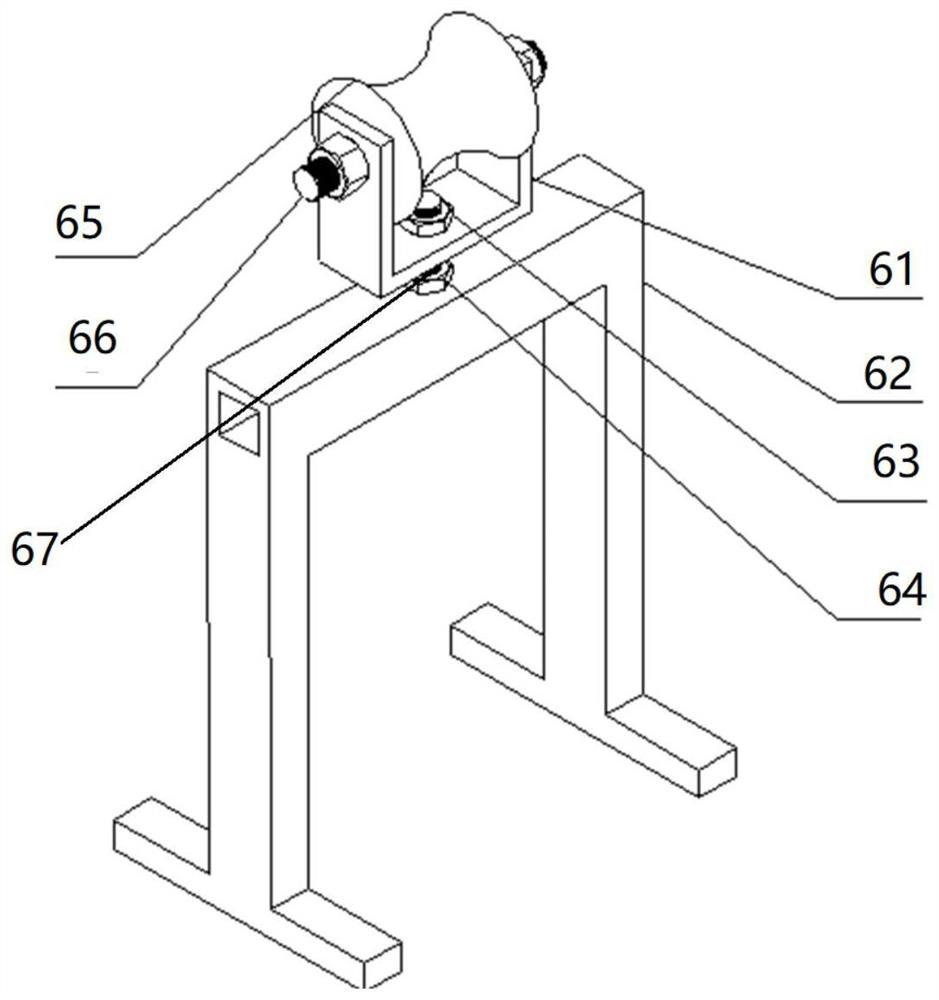

Supporting device having adjusting function

InactiveCN107035945AImprove practicalityRealize synchronous rotationAngles/taper measurementsStands/trestlesHydraulic cylinderEngineering

The invention belongs to the mechanical field and particularly relates to a supporting device having the adjusting function. The supporting device having the adjusting function aims to solve the problems that an existing supporting device cannot support an inclined face, and the angle of the inclined face cannot be adjusted. The supporting device having the adjusting function comprises a base. The base is of a cuboid structure. Two parallel sliding rails are welded to the upper side of the base. The cross section of each sliding rail is in an I shape. Four sleeves are arranged on the upper side of the base and arranged in rectangle. The bottoms of the four sleeves are each provided with a sliding groove with a T-shaped cross section. The sliding rails are movably installed in the sliding grooves. The four sleeves are connected with the sliding rails in a sliding manner. A base plate is welded among the bottoms of the side edges of the four sleeves. A hydraulic cylinder is installed on the upper side of the base plate. The tail end of a piston rod of the hydraulic cylinder is provided with a push plate. The upper side of the push plate is provided with four guide holes arranged in a rectangle. The supporting device having the adjusting function can support an object with an inclined face, the rotation angle of a supporting plate can be quite conveniently known, the precision is quite high, and the trouble caused by repeated adjustment in the debugging process is avoided.

Owner:HUANGHE S & T COLLEGE

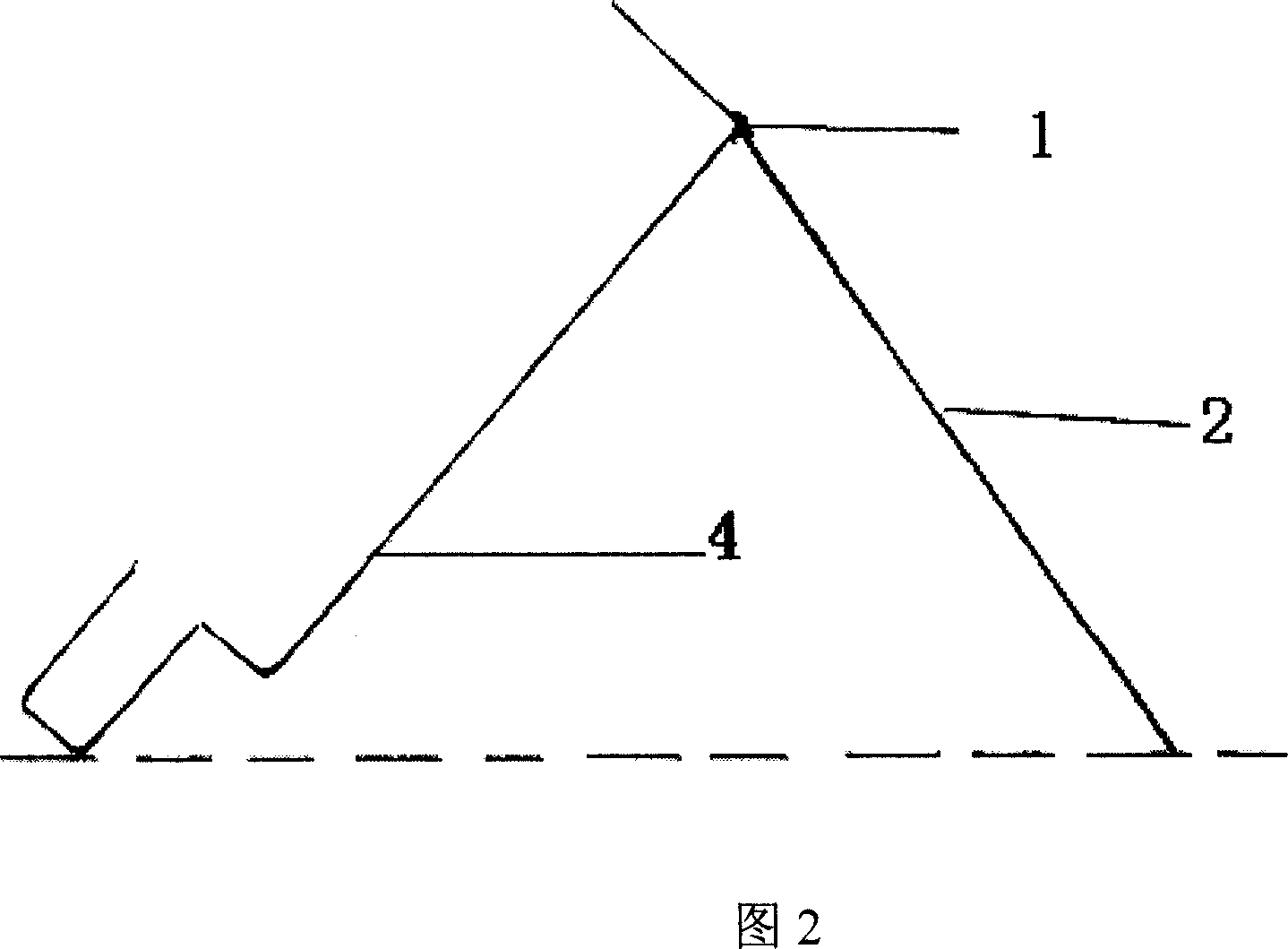

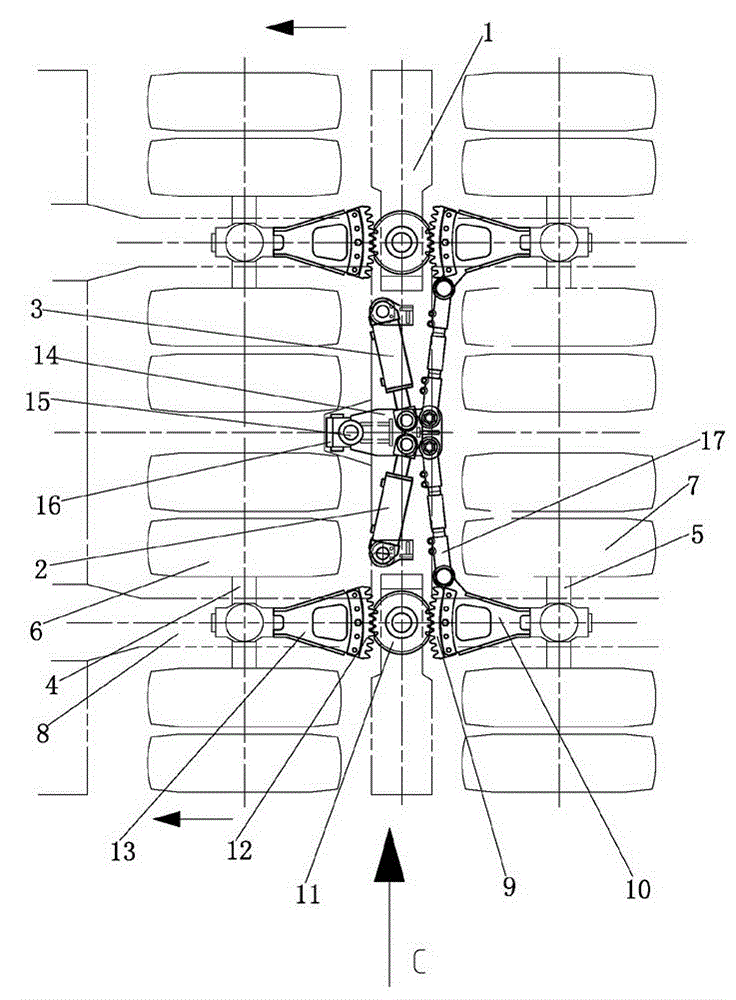

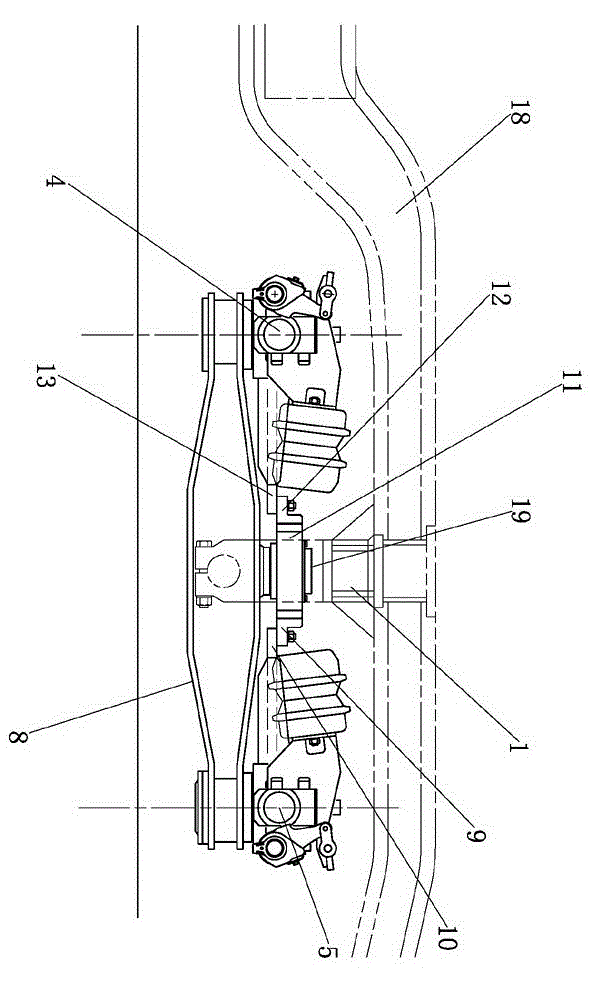

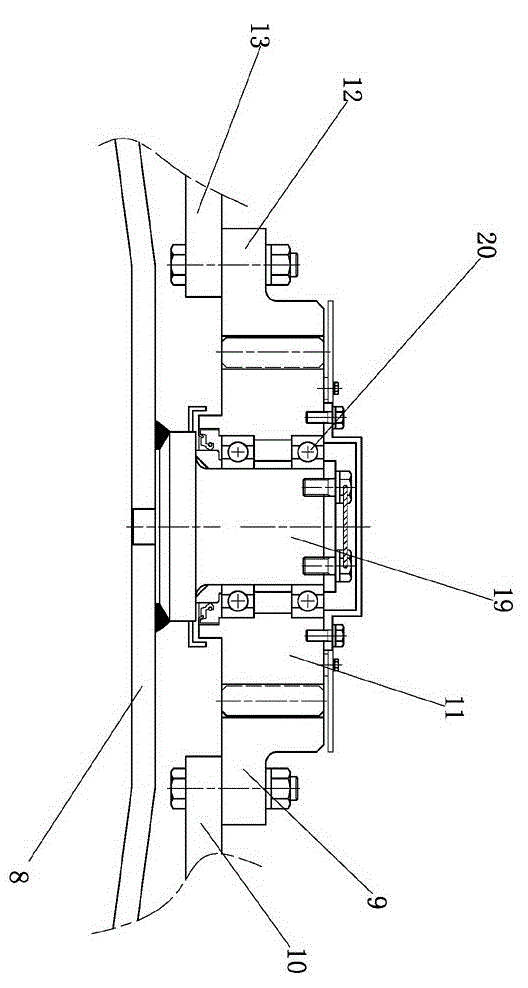

Installation of car for guarding against side turned over

InactiveCN1958356ARealize synchronous rotationReduce supportPedestrian/occupant safety arrangementVehicle fittings for liftingEngineeringCentrifugal force

A mechanism for preventing lateral turn-over of car features that a lateral turn-over resisting assemblage is installed to the side of car close to the top of car. Said lateral turn-over resisting assemblage is composed of a limiting lug installed to the side of car close to the top of car, and steel leaf spring linked with said lug via hinge.

Owner:谭建

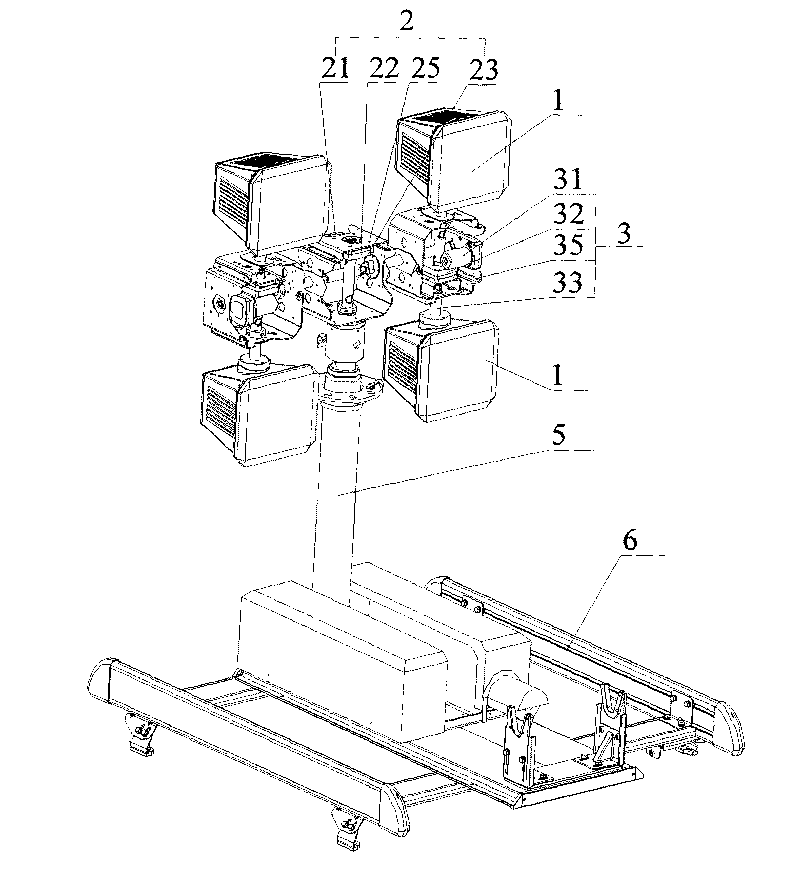

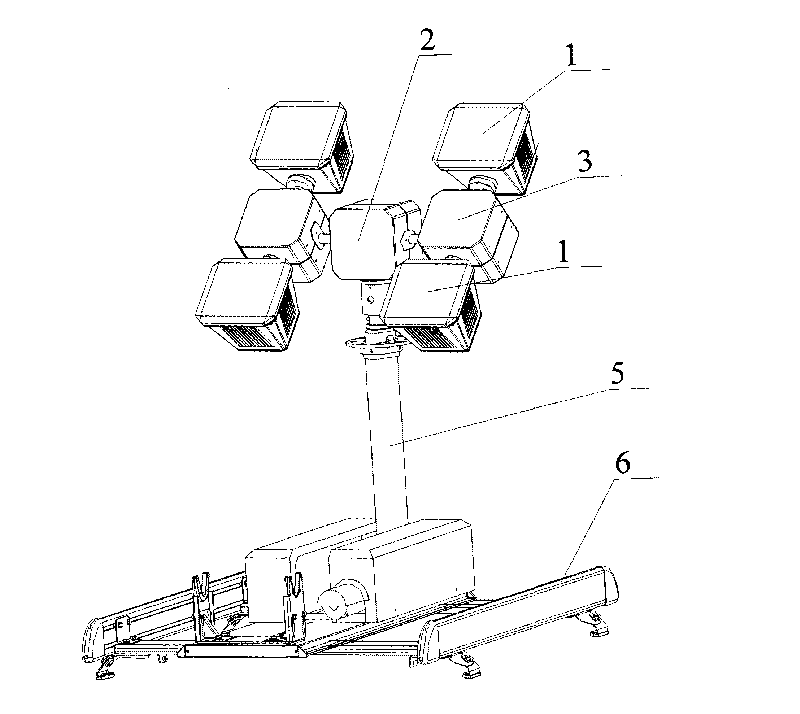

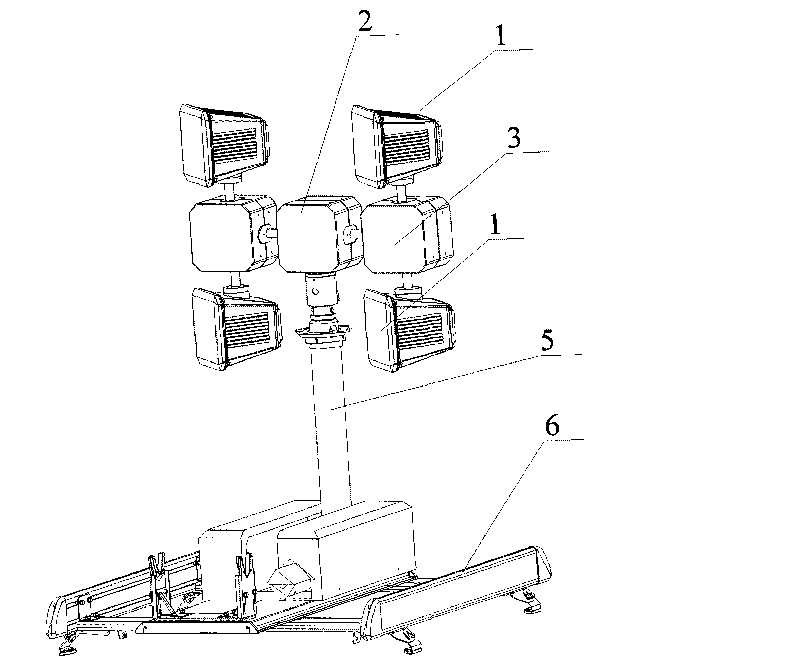

Omnidirectional rotating lamp

InactiveCN101761889AFull range of rotationFull rotationElectric circuit arrangementsElectric lightingIrradiationTripod head

The invention discloses an omindirectional rotating lamp which comprises a lamp main body connected with a holder mechanism. The holder mechanism which drives the lamp main body to realize omindirectional rotation comprises a control device and at least two holders, wherein the two holders are connected together in a rotating manner, one is a main holder, and the other is an auxiliary holder. The auxiliary holder is connected with the lamp main body in a rotating manner to drive the lamp main body to rotate at 360 DEG, and the main holder is connected with the auxiliary holder in a rotating manner to drive the auxiliary holder to rotate at 360 DEG. Both the main holder and the auxiliary holder are connected with the control device which respectively controls rotating angles of the lamp main body and the auxiliary holder in two vertical directions. The provided omindirectional rotating lamp has the advantages of simple structure, small volume, simple as well as convenient operation, no dead corners for irradiation and omindirectional adjustment.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

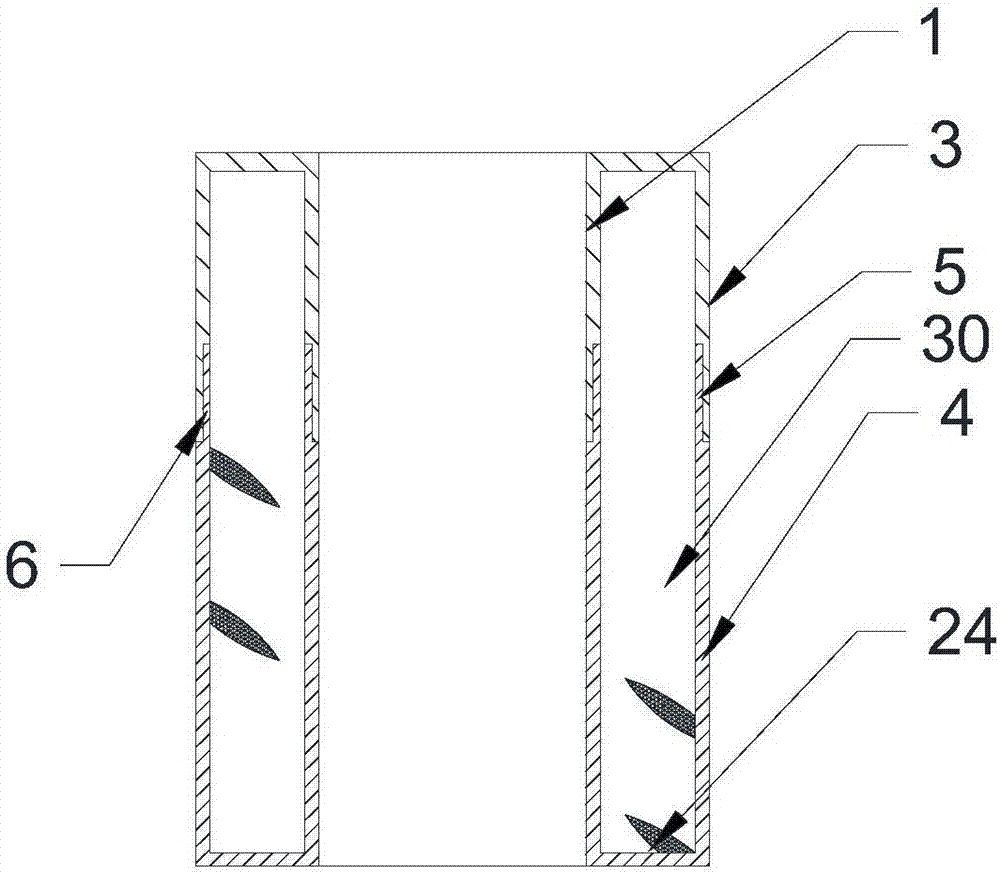

Novel three-side-reversible blackboard

InactiveCN103625173AIncrease the usable areaRealize synchronous rotationWriting boardsMotor controllerEngineering

Owner:ANHUI UNIV OF SCI & TECH

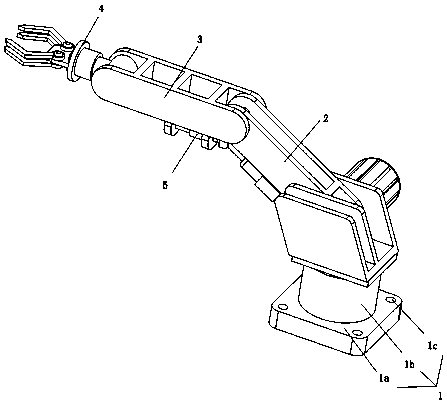

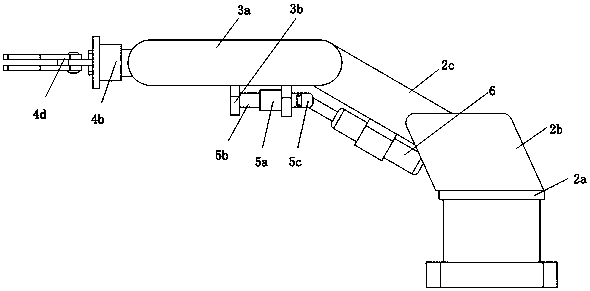

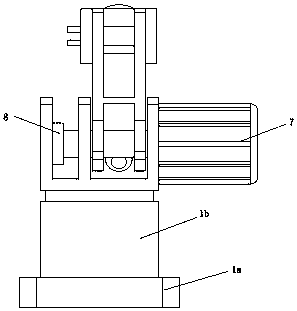

Industrial foldable manipulator

InactiveCN108555948ARealize synchronous rotationEasy to installGripping headsArmsMechanical equipmentDrive motor

The invention relates to the field of mechanical equipment, in particular to an industrial foldable manipulator which comprises a drive mechanism, a first supporting mechanism, a second supporting mechanism and a grasping mechanism; the side wall of the bottom of the second supporting mechanism is provided with a telescopic component; the first supporting mechanism comprises a cushion plate, a first mounting seat which is fixedly connected with the top of the cushion plate and a first supporting arm which is hinged to the first mounting seat; the side wall of the bottom of the first supportingarm is provided with a drive cylinder; the output end of the drive cylinder is fixedly connected with the back end of the telescopic component; the side wall of the first mounting seat is provided with a first drive motor; the output end of the first drive motor penetrates through one side of the first mounting seat and extends toward the other side of the first mounting seat; the first mountingseat is provided with a fixed seat which is fixed at the output end of the first drive motor; and the bottom end of the first supporting arm is fixed on the output end of the first drive motor. The industrial foldable manipulator provided by the invention is simple in structure and less in occupying space and meet the production demands of a modern enterprise.

Owner:镇江鑫邦瑞机械有限公司

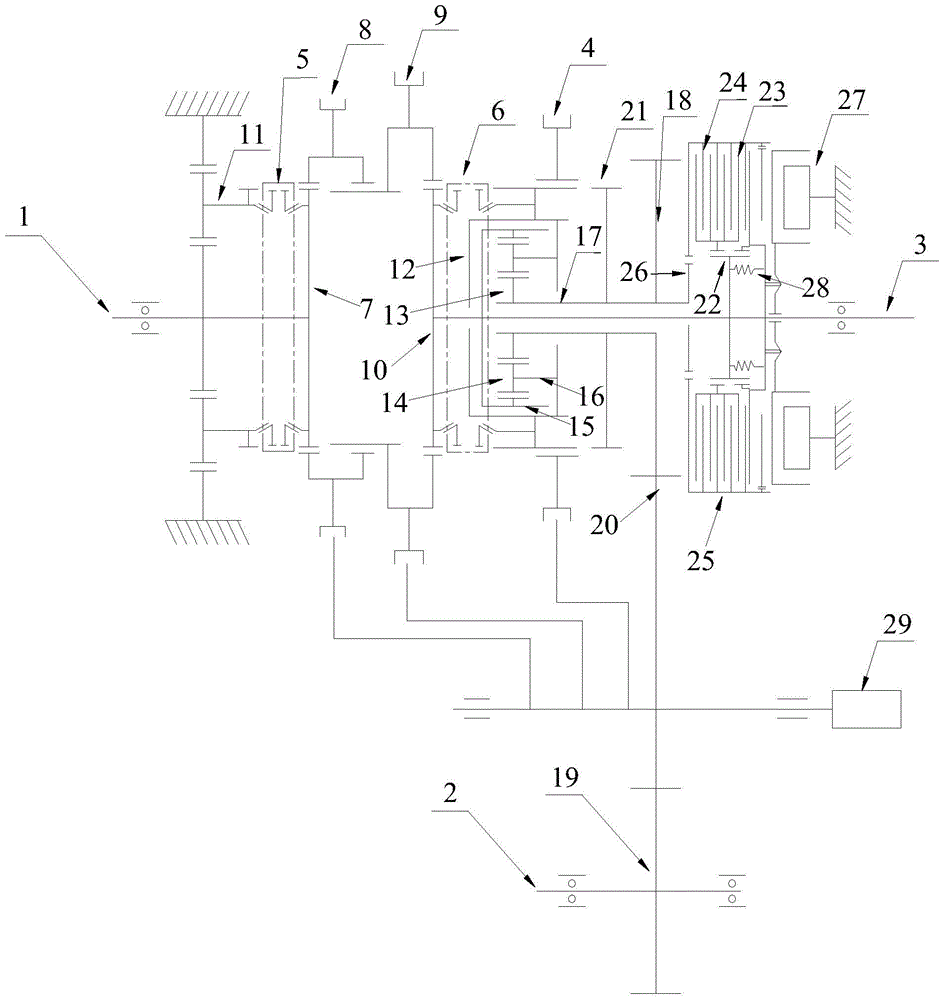

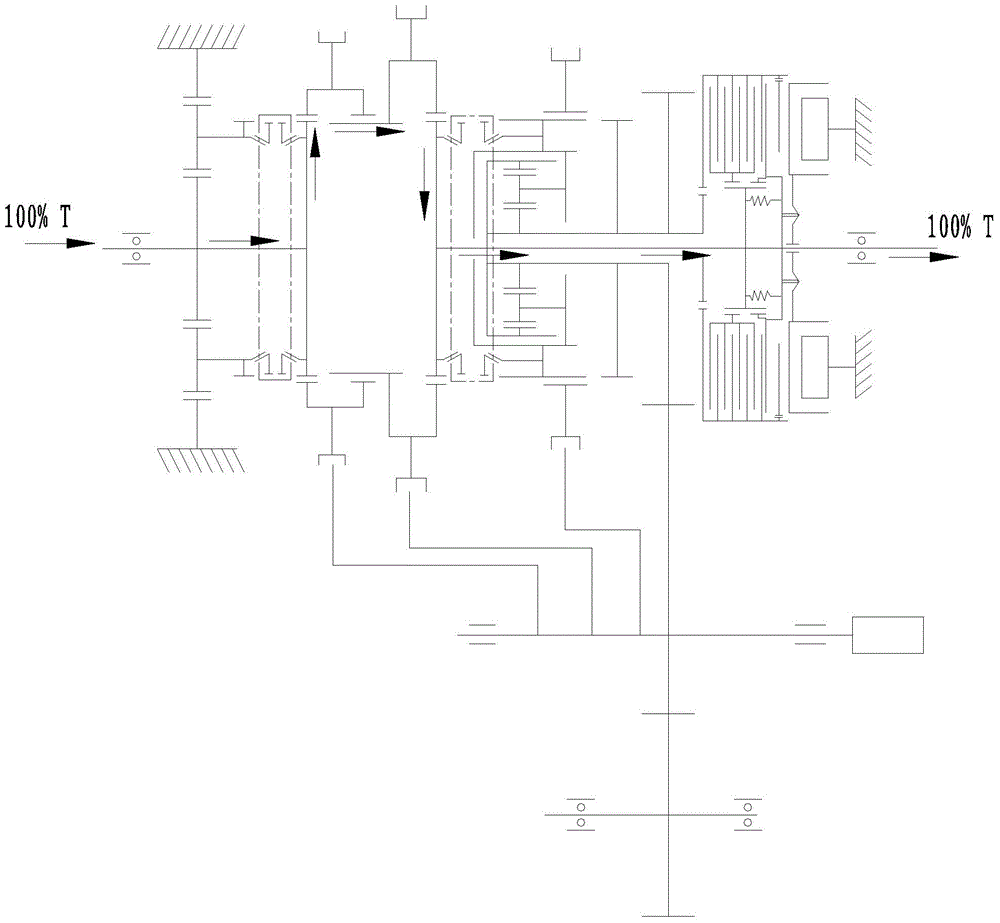

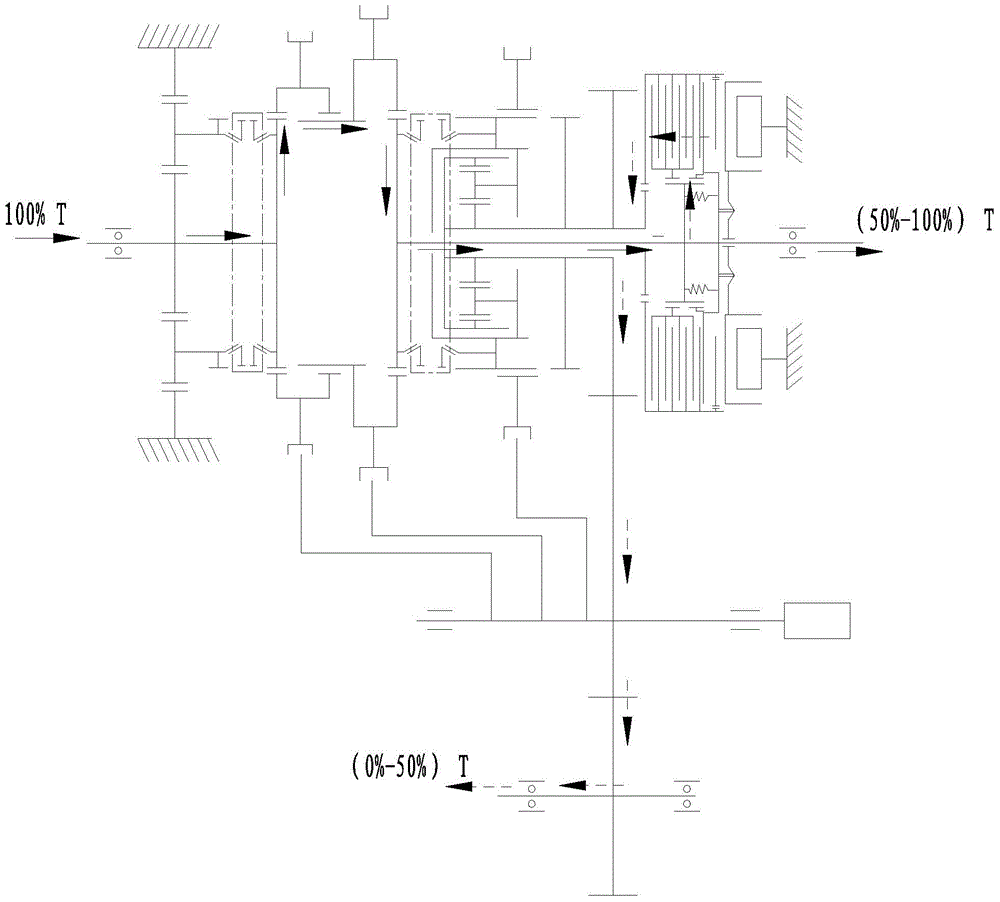

Automobile and transfer case thereof

The invention discloses an automobile and a transfer case thereof. The transfer case comprises an input shaft, a front output shaft and a rear output shaft, and further comprises a planetary gear mechanism arranged on the front input shaft, a first power switching part, a central differential mechanism, a second power switching part, a locking part and a clutch assembly, wherein the first power switching part can be connected with the power output end and the front input shaft of the planetary gear mechanism in a switching mode; the central differential mechanism is arranged on the rear output shaft; the second power switching part can be connected with the central differential mechanism and the rear output shaft; the locking part is connected with the power input end of the central differential mechanism and the power input end of a front shaft transmission mechanism so that the central differential mechanism and the front shaft transmission mechanism can synchronously rotate; the clutch assembly is arranged on the rear output shaft and can transmit power on the rear output shaft to the front output shaft. The transfer case is a full-mode transfer case and has a plurality of working modes, the different working modes can be selected at will according to the operation intention of a driver and changes of road conditions, functions of the transfer case are increased, and the transfer case can meet drive requirements of the automobile more sufficiently.

Owner:GREAT WALL MOTOR CO LTD

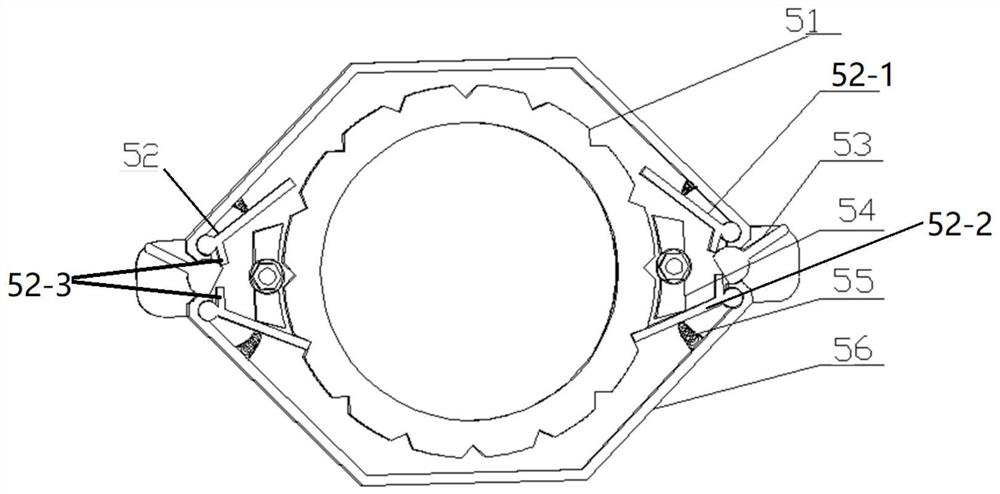

Guide blade adjustment device and compressor

ActiveCN106194843AReduce stuckReduce faults such as reverse rotationPump componentsPump controlEngineeringSpare part

The invention discloses a guide blade adjustment device and a compressor. The guide blade adjustment device comprises a base, guide blades rotationally arranged on the base, a driving ring rotationally arranged on the base in a sleeving manner, first connecting pieces capable of rotating with the guide blades synchronously, and second connecting pieces fixedly connected with the first connecting pieces, wherein the first connecting pieces are movably arranged at the guide blades along the rotating axis directions of the guide blades; one second connecting piece is connected with the driving ring through a universal connecting piece; and the driving ring is movably arranged at the base along the axial direction of the base. The guide blade adjustment device simply adopts one universal connecting piece. Compared with a guide blade adjustment device adopting two universal connecting pieces in the prior art, the probability of failures such as sticking and negative rotation of the guide blades is reduced effectively, and the operating reliability of the compressor is improved; in addition, the spare parts are reduced effectively, the structure is simplified, and the processing difficulty, the assembly difficulty and the cost are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

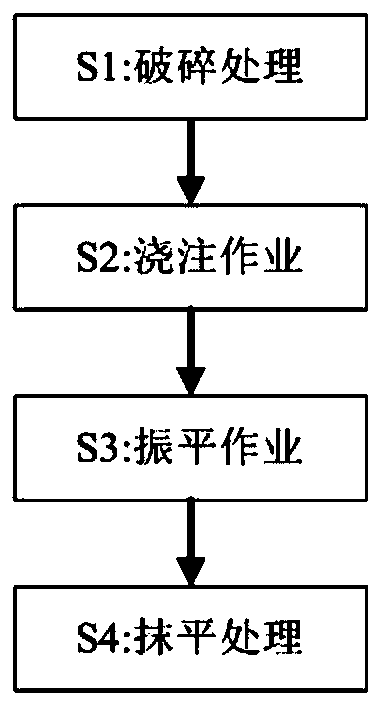

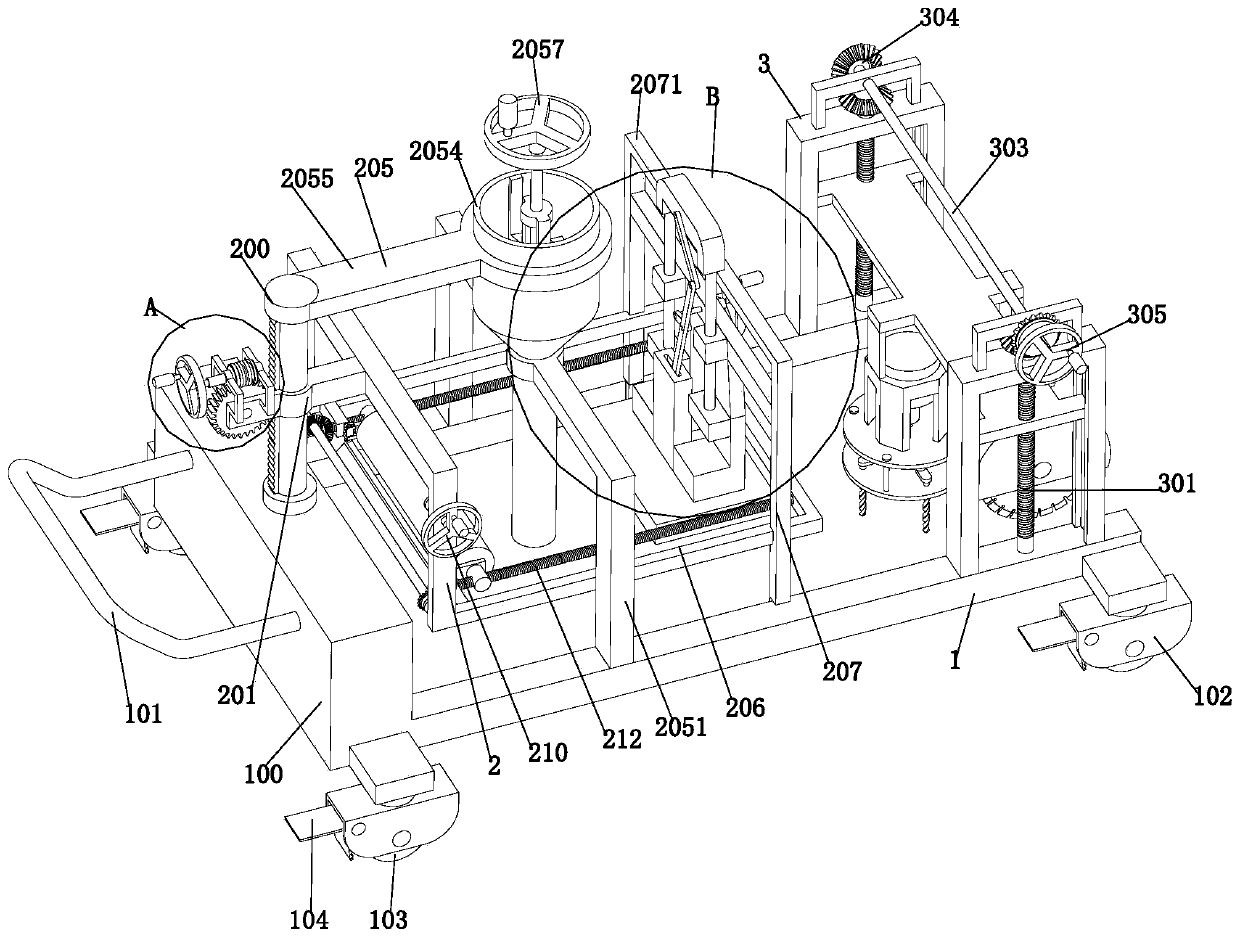

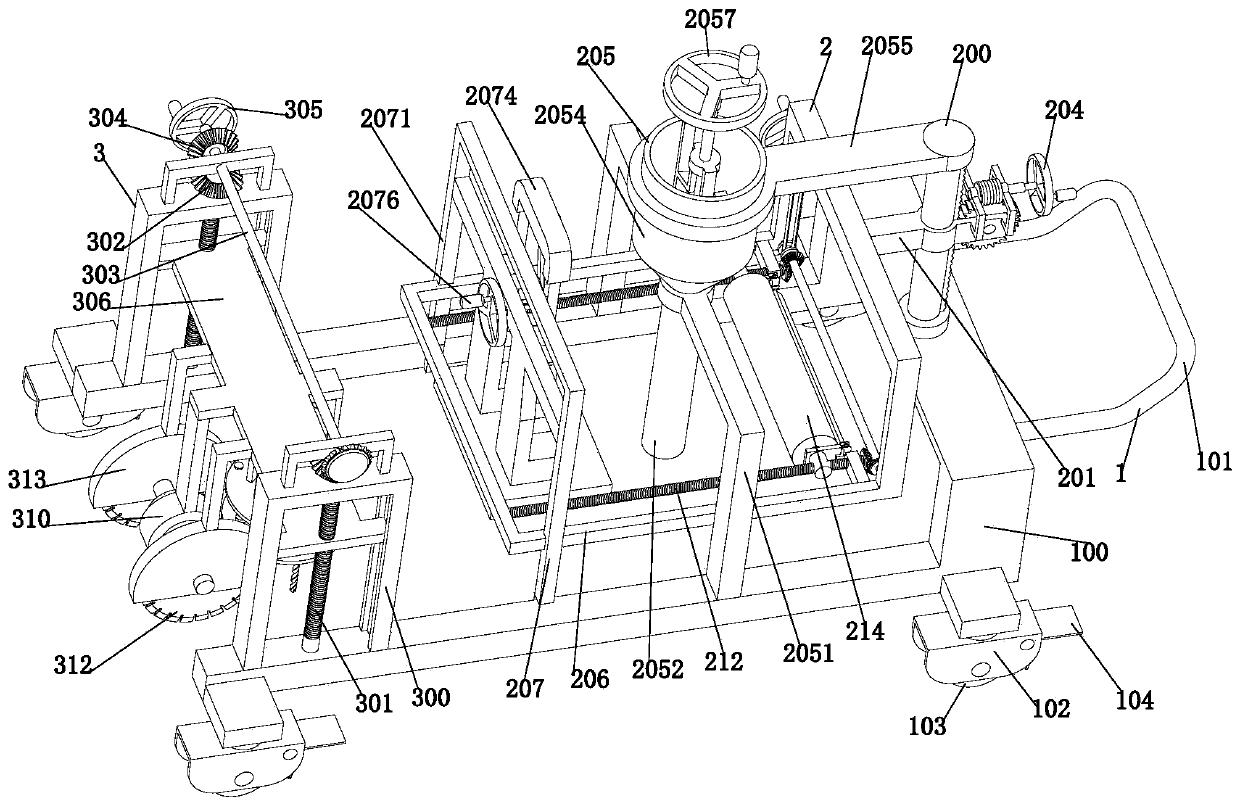

Concrete road pavement crack quick repairing method

ActiveCN111287063AImprove work efficiencyEliminate uneven thicknessRoads maintainenceStructural engineeringArchitectural engineering

The invention provides a concrete road pavement crack quick repairing method which comprises a stepping mechanism, a pouring mechanism and a crushing mechanism, the crushing mechanism is installed onthe stepping mechanism, the pouring mechanism is arranged right behind the crushing mechanism, and the pouring mechanism is installed on the stepping mechanism; the problems that in the using processof a concrete road, pits are formed in the road surface due to damage caused by long-term rolling compaction of vehicles, and local transverse and longitudinal cracks, missing edges and falling corners occur to many road sections, so that the road surface driving comfort and safety are seriously affected, and the road surface needs to be repaired are solved; however, when the existing concrete highway pavement is repaired; generally, new concrete is manually stirred on site, then the new concrete is directly poured into a pit slot, and the pavement is leveled to finish repairing, so that the mode has the defects of long construction time, low bonding force to the original cement concrete, easiness in falling, high manual labor intensity, low efficiency and high construction cost.

Owner:山西同创建筑工程有限公司

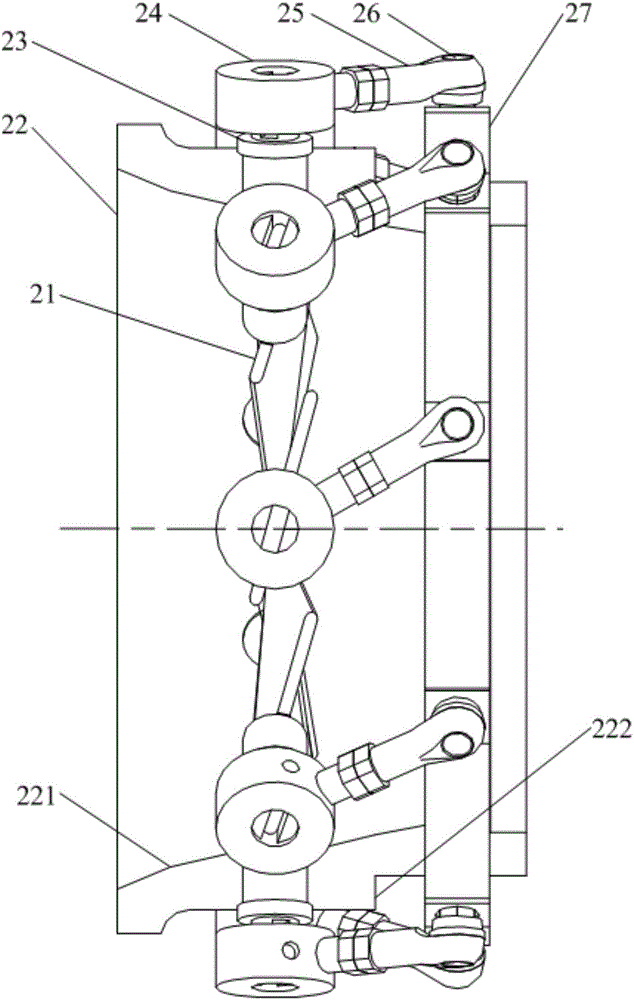

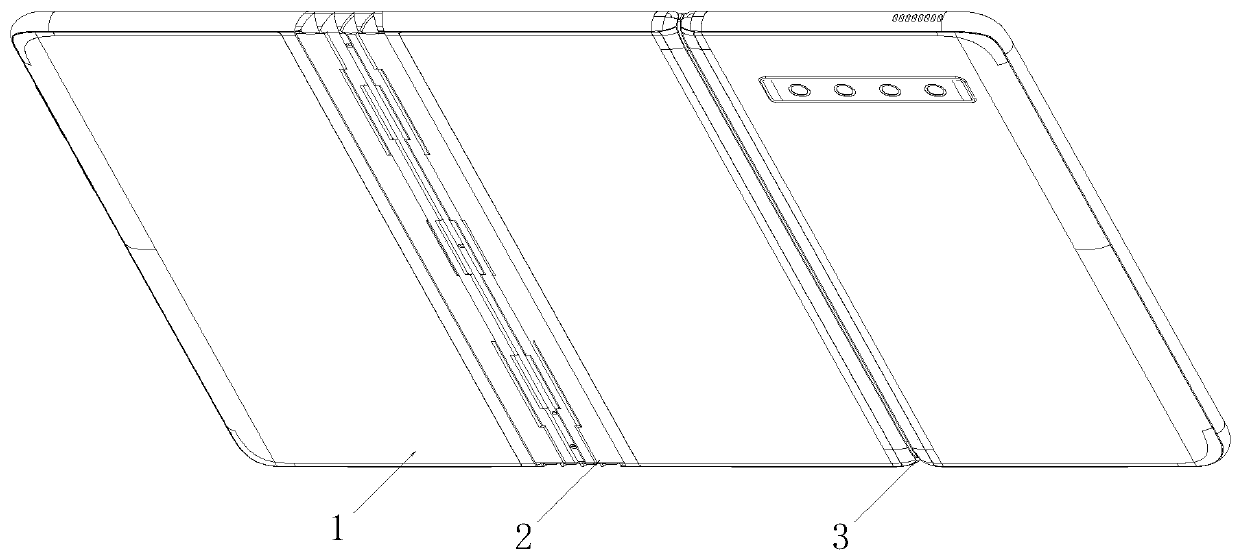

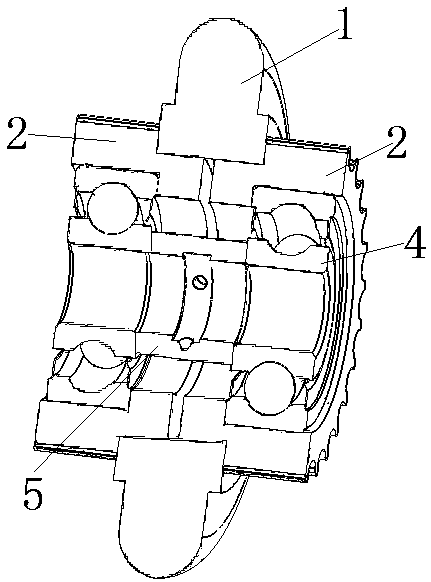

Synchronous rotating mechanism for inward and outward folding of flexible screen

PendingCN110131299AMeet the double-fold functionPrevent top screenPivotal connectionsIdentification meansSelf lockingEngineering

The invention discloses a synchronous rotating mechanism for inward and outward folding of a flexible screen. The mechanism comprises three rotationally connected cases and rotary mechanisms for connecting the cases, wherein the rotary mechanisms include an outward-folding rotary mechanism and an inward-folding rotary mechanism; the inward-folding rotary mechanism comprises an inward-folding package body and an inward-folding rotary shaft; the inward-folding rotary shaft comprises an inward-folding moving frame, a sliding moving frame and a compensation moving frame, and the sliding moving frame and the compensation moving frame are bilaterally symmetrically arranged, combined and connected; the sliding moving frame comprises a first sliding moving frame body and a second sliding moving frame body; two slots are formed in the inward-folding moving frame; a sliding groove, a sliding block and a sliding post are arranged on each of the first sliding moving frame body and the second sliding moving frame body; each sliding post can slide in the corresponding slot, the corresponding sliding groove and the corresponding sliding block; the sliding posts can rotate in the corresponding slots to be flattened, upward and downward movement is realized, and accordingly, the condition that the mechanism jacks the screen is avoided; clamping point grooves are combined with corresponding positioning pins, so that a clamping point self-locking function is available in both 0-degree and 180-degree states; each sliding groove and the corresponding sliding post are in sliding connection and achieve semi-arc locking synchronization, and a compensation function is achieved in a screen unfolding state.

Owner:DONGGUAN JINFENG ELECTRONICS

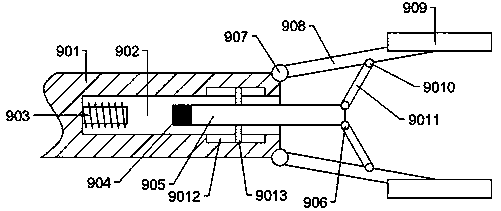

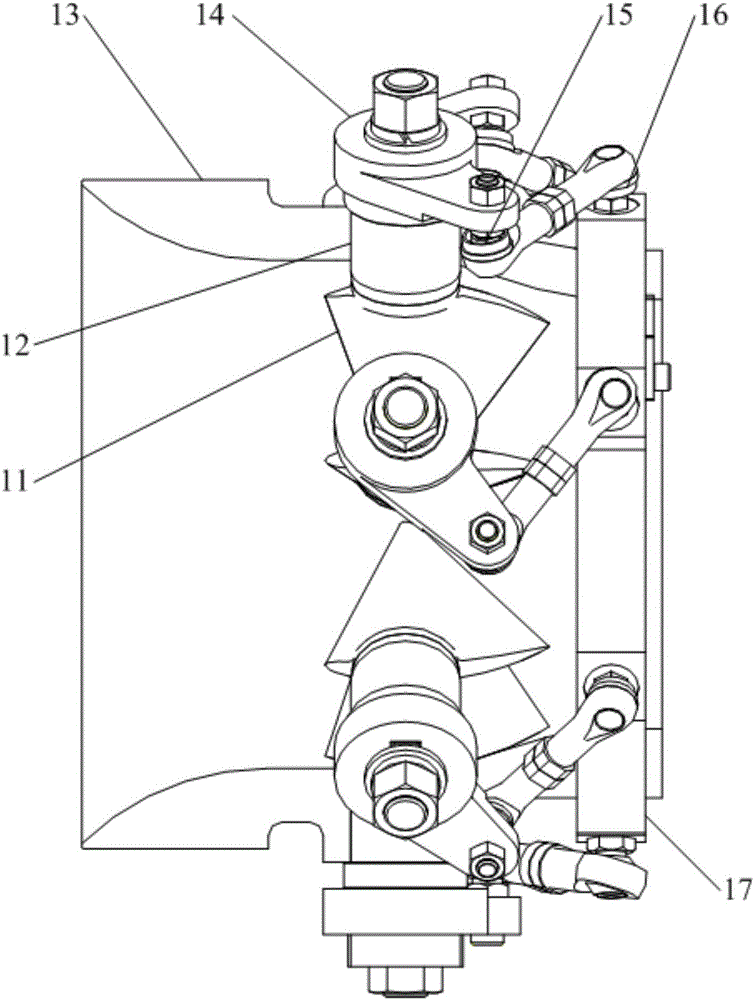

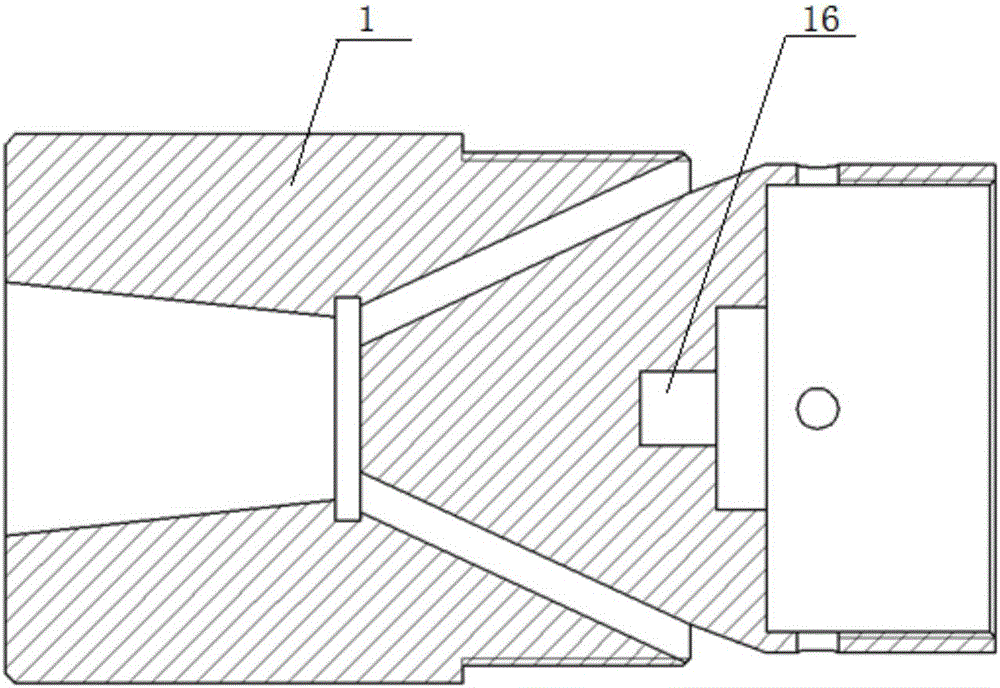

Tool deviation correcting device for cutting machine head

ActiveCN103112039ARealize synchronous rotationThe detection value is accurateMetal working apparatusEngineeringMechanical engineering

The invention relates to a cutter deviation correcting device for a cutting machine head and belongs to the field of cutting machines. The cutter deviation correcting device for the cutting machine head comprises a pressure plate and a cutter apron and further comprises a guide wheel support, pressure wheels and a position sensor arranged on an elastic arm. The guide wheel support is arranged on the pressure plate. The pressure wheel and a rear pressure wheel are arranged on the guide wheel support. The guide wheel support is connected with the pressure plate through the elastic arm. The guide wheel support, the elastic arm and the pressure plate are combined as a whole. The cutter apron comprises a pressure block, a cutter fixing square core, a rotary core and an elastic connecting rod. The rotary core is movably arranged between the pressure block and the cutter fixing square core. The rotary core is connected with the elastic connecting rod. The cutter deviation correcting device solves the problem of torsion of a cutter caused by extrusion of the cutter by a material in the process of cutting so that the cutter is prevented from being broken, deviation is reduced, a gap is adjusted in real time and quality of a product is guaranteed.

Owner:HANGZHOU ECHO SCI TECH

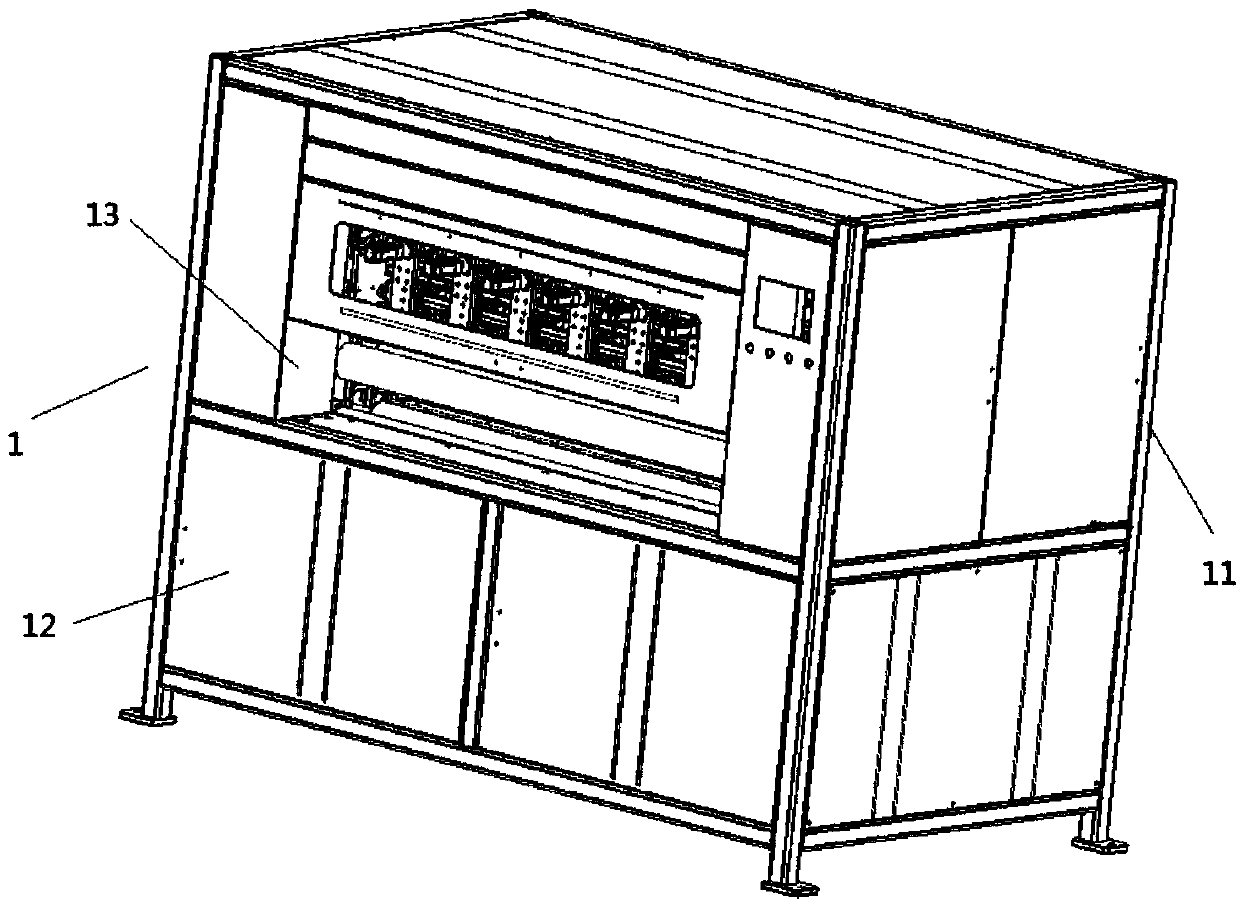

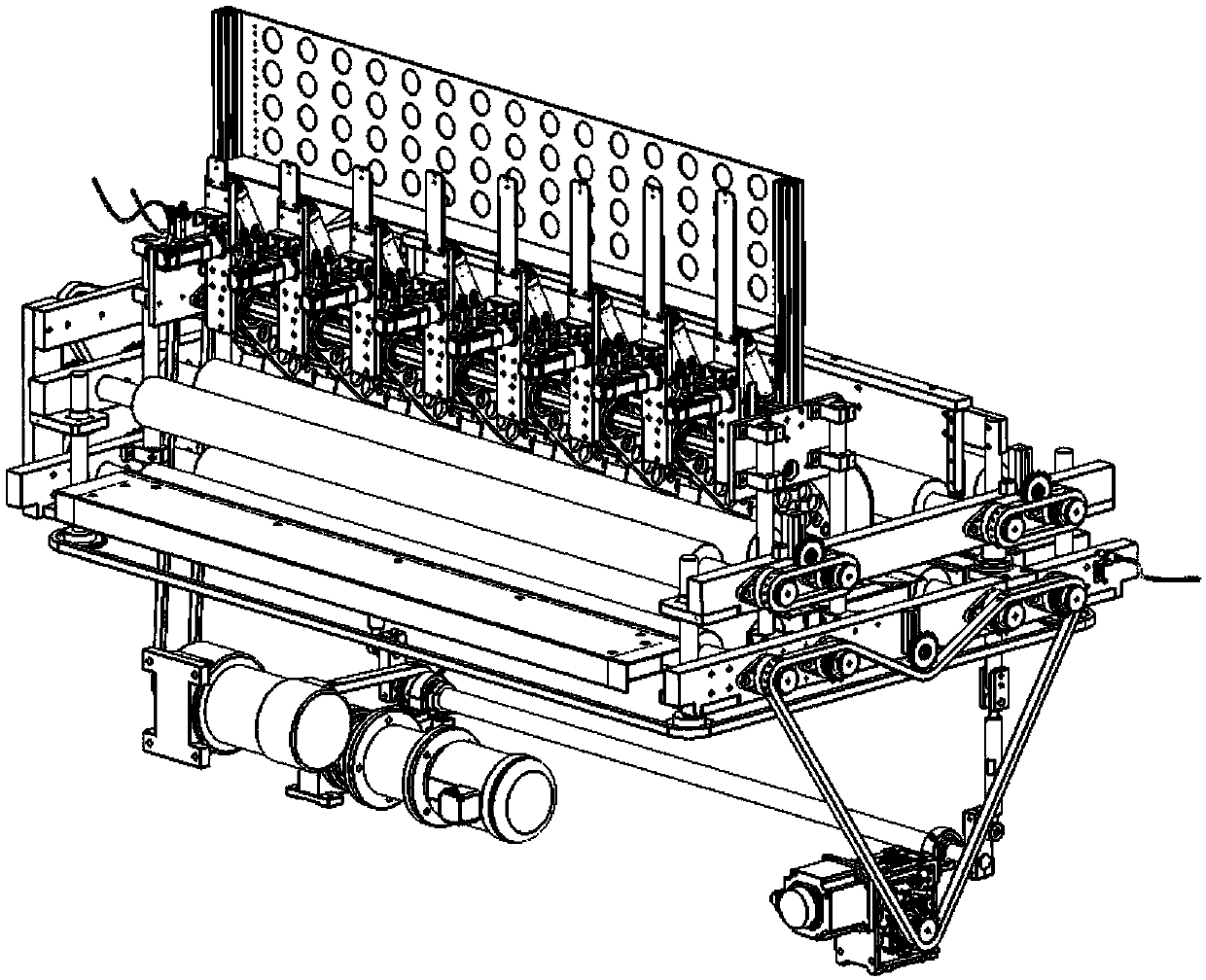

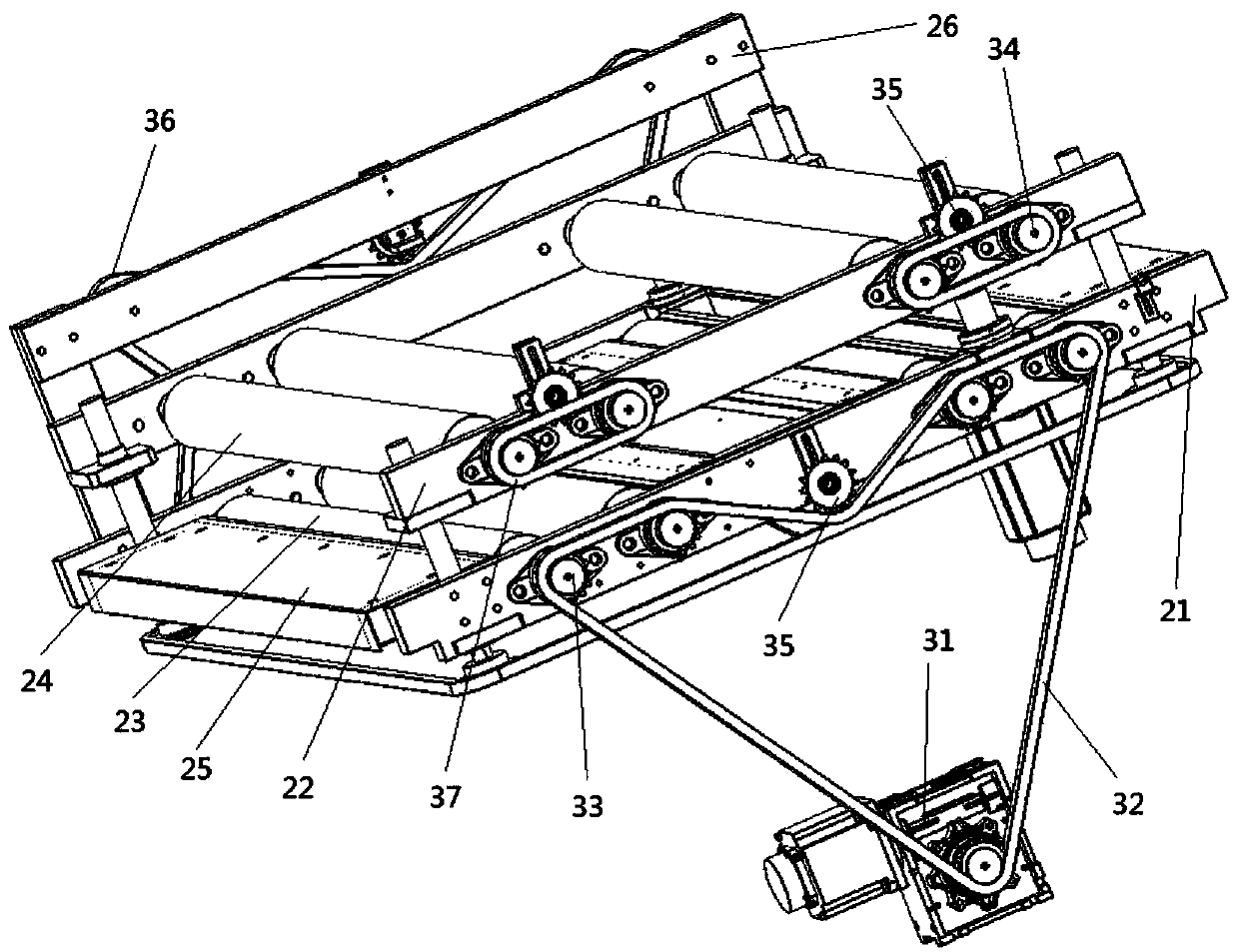

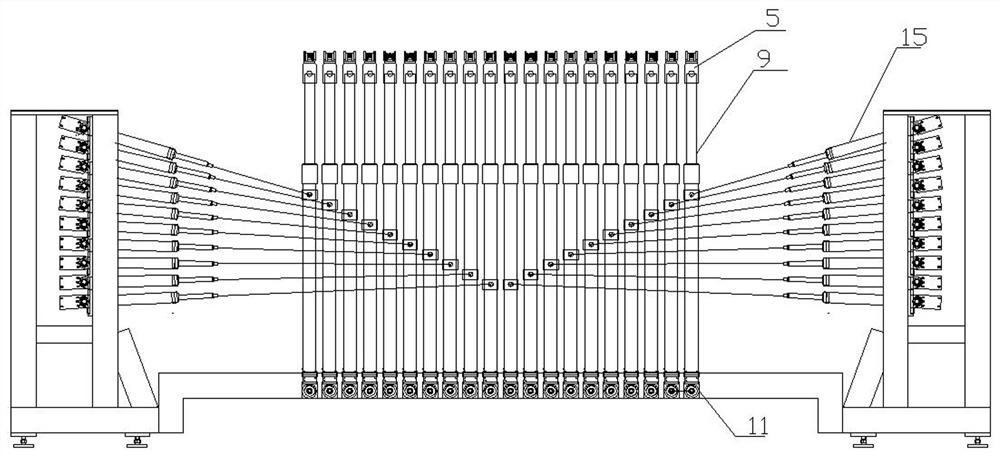

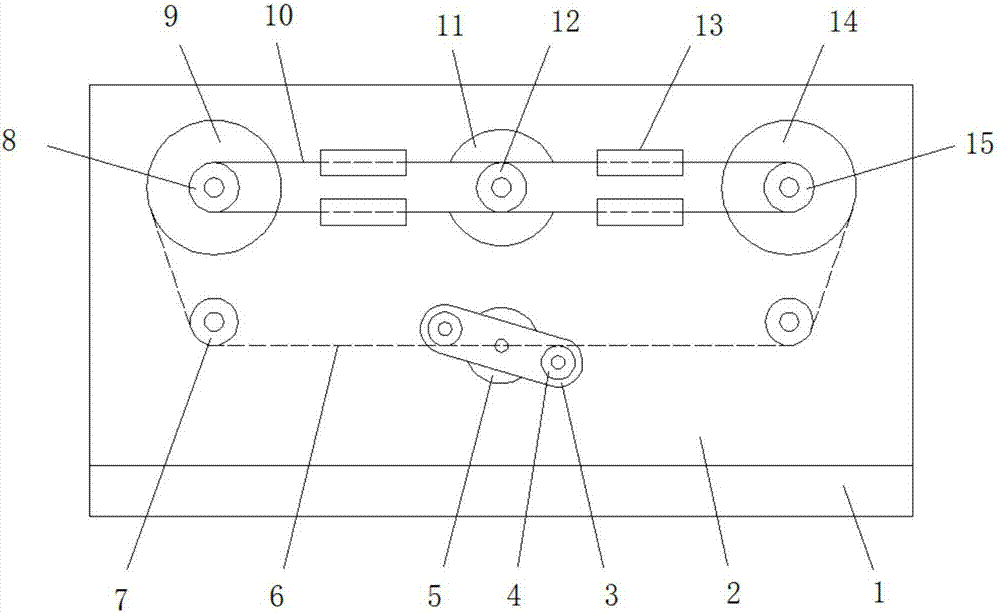

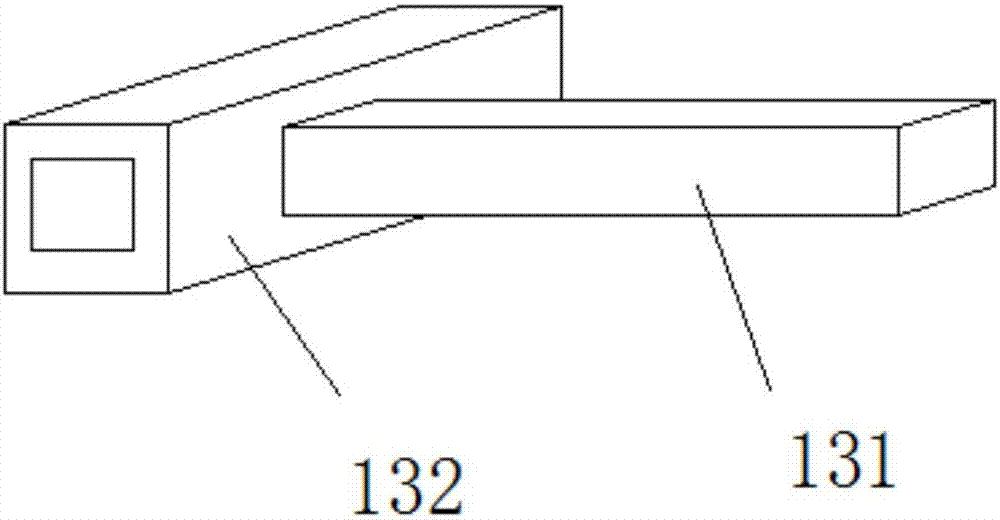

Automatic slitter

InactiveCN107777434AHigh degree of automationImprove the efficiency of feedingArticle deliveryWebs handlingEngineeringAutomation

The invention discloses an automatic slitting machine, which comprises a casing, a slitting mechanism and a feeding mechanism arranged inside the casing; the casing includes a frame and a plurality of door panels; the feeding mechanism includes a first driver, and a pair of upper rollers are fixed plate and a pair of lower roller fixing plates, the two ends are respectively connected to the upper feeding roller group between the upper roller fixing plates, and the two ends are respectively rotating and connected to the lower feeding roller group between the lower roller fixing plates; the cutting mechanism includes Transverse cutting mechanism and slitting mechanism. The slitting mechanism includes a support frame, a mounting frame, a driving shaft, multiple hob mechanisms, a sliding mechanism and a second driver. The cutting knife and a pair of connection assemblies respectively connected between the end of the power shaft of the cross-cutting knife and the end of the cross-cutting knife. The automatic slitting machine of the present invention has high degree of automation and high cutting precision, and can realize cross-cutting and longitudinal cutting of materials, thereby improving cutting efficiency.

Owner:JIANGSU BAIYIDA INTELLIGENT TECH CO LTD

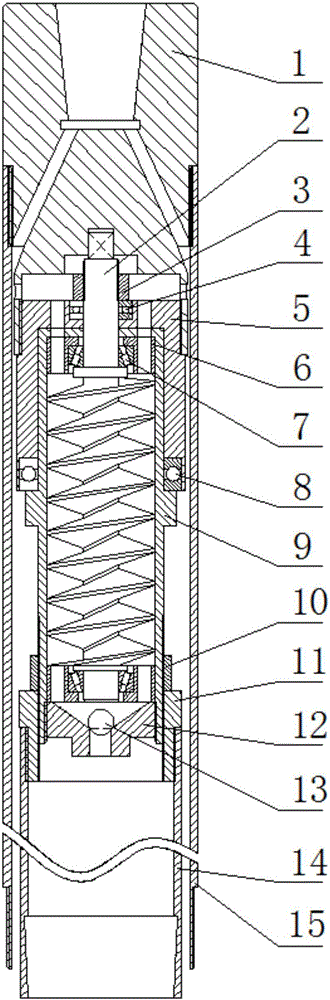

Spiral rotating shaft type local reverse circulation core drill bit

The invention discloses a spiral rotating shaft type local reverse circulation core drill bit. The spiral rotating shaft type local reverse circulation core drill bit at least comprises a connector, a transition element, a communication element, an inner pipe and an outer pipe. The upper end of the connector is connected with a drill rod. The middle section of the connector is connected with the outer pipe. The lower end of the connector is connected with the transition element. The hollow transition element is internally provided with the communication element. The outer portion of the lower end of the communication element is connected with the inner pipe through an inner pipe connector. The inner pipe is arranged in the outer pipe in a sleeved mode. The outer pipe is connected with a reamer and a core drill head. The spiral rotating shaft type local reverse circulation core drill bit further comprises a spiral rotating shaft. The spiral rotating shaft is installed in the hollow communication element after being supported through a pair of conical roller bearings and two bearing bases. Meanwhile, the upper end of the spiral rotating shaft is connected into the connector, the interior of the lower end of the communication element leads to the inner pipe after being in threaded connection with a one-way part base, a large thrust bearing is arranged between the transition element and the communication element, a small thrust bearing is arranged between the transition element and the spiral rotating shaft, and the 'two-pipe single-rotating' effect in the drilling process of the drill bit is achieved. According to the spiral rotating shaft type local reverse circulation core drill bit, the spiral blade and two-pipe single-rotating reverse circulation working principles are combined, and the collecting rate of drill cores is effectively improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

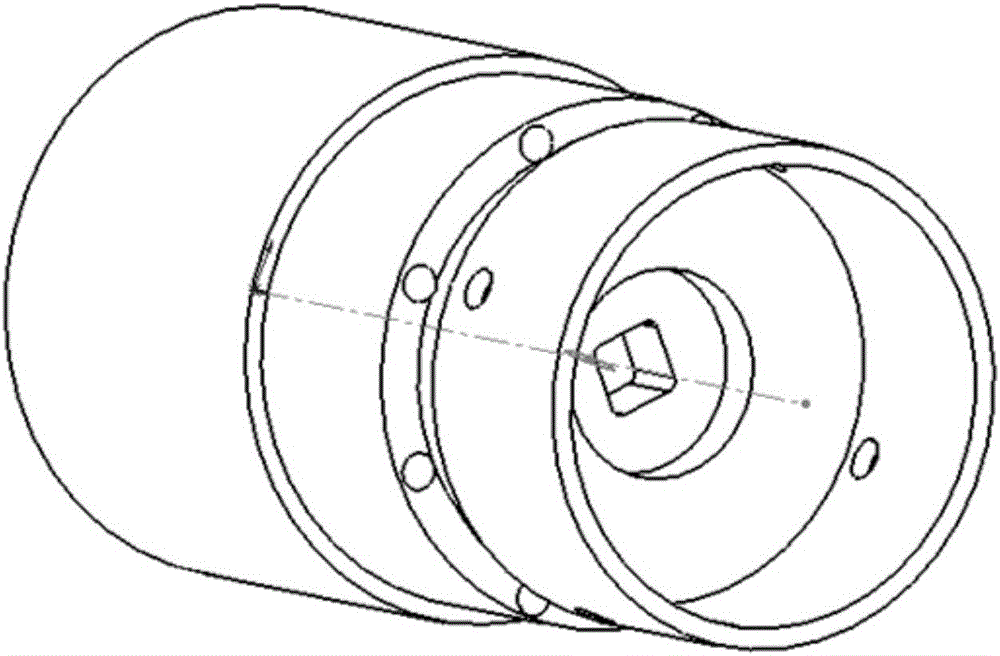

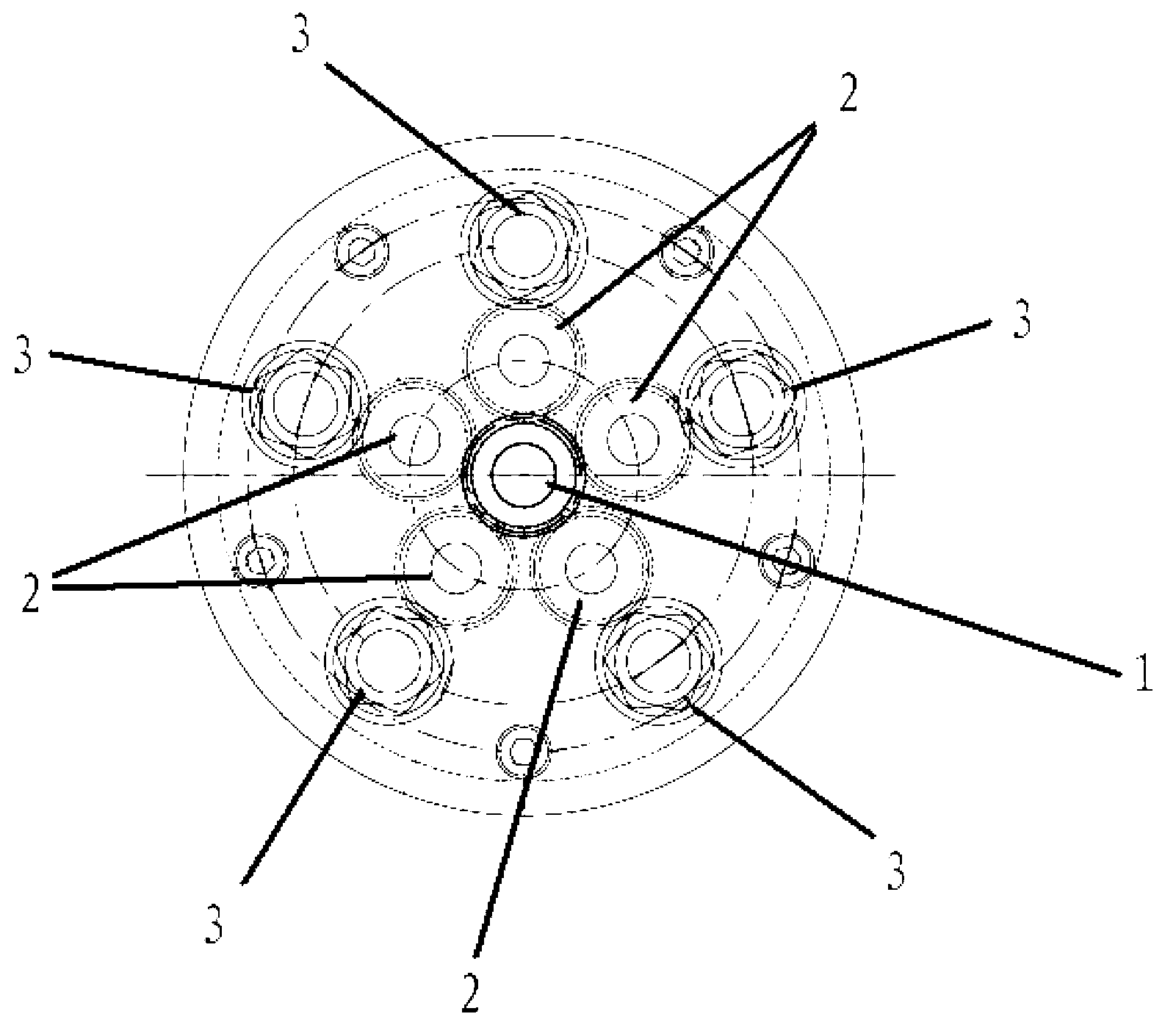

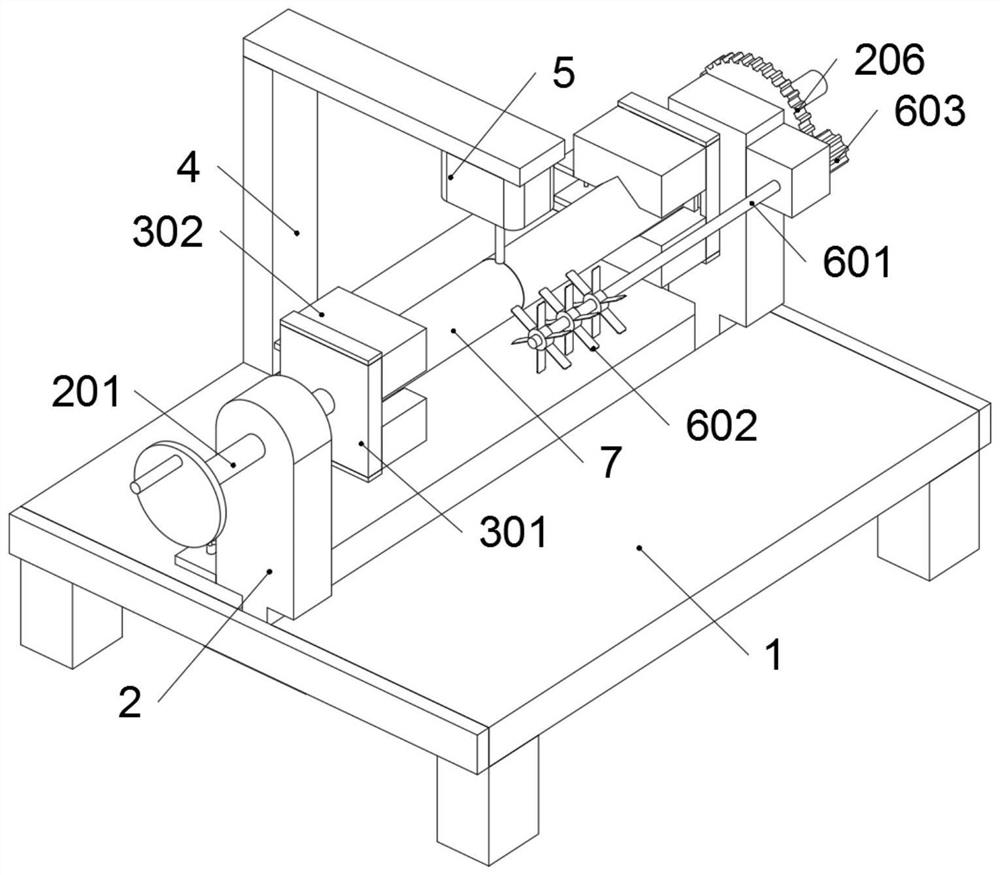

Tire fast pretightening device for passenger car

InactiveCN103286741ASimple structureRealize synchronous rotationMetal-working hand toolsTorque transmissionDrive shaft

The invention discloses a tire fast pretightening device for a passenger car. The tire fast pretightening device comprises a shell, a plurality of driven shafts and a torque transmission part. A drive shaft is rotatably connected to the shell. each driven shaft is connected with a nut sleeve. The torque transmission part is used for transmitting torque of the drive shaft to the driven shafts. The pretightening device is simple in structure, the driven shafts distributed on the periphery of the drive shaft can be driven by the drive shaft to rotate synchronously, synchronous rotation of the nut sleeves is achieved, and pretightening efficiency of nuts on a tire is increased.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

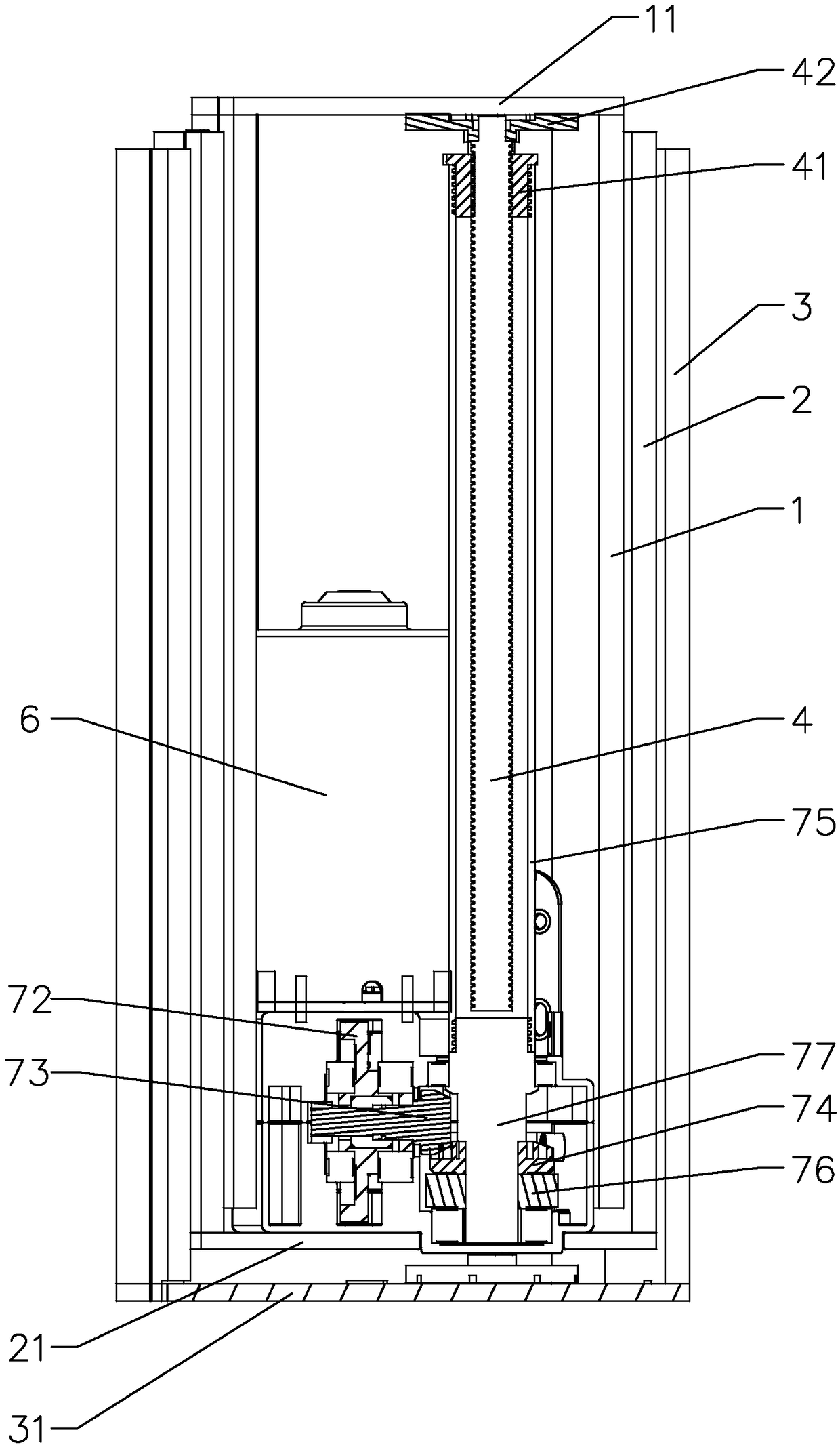

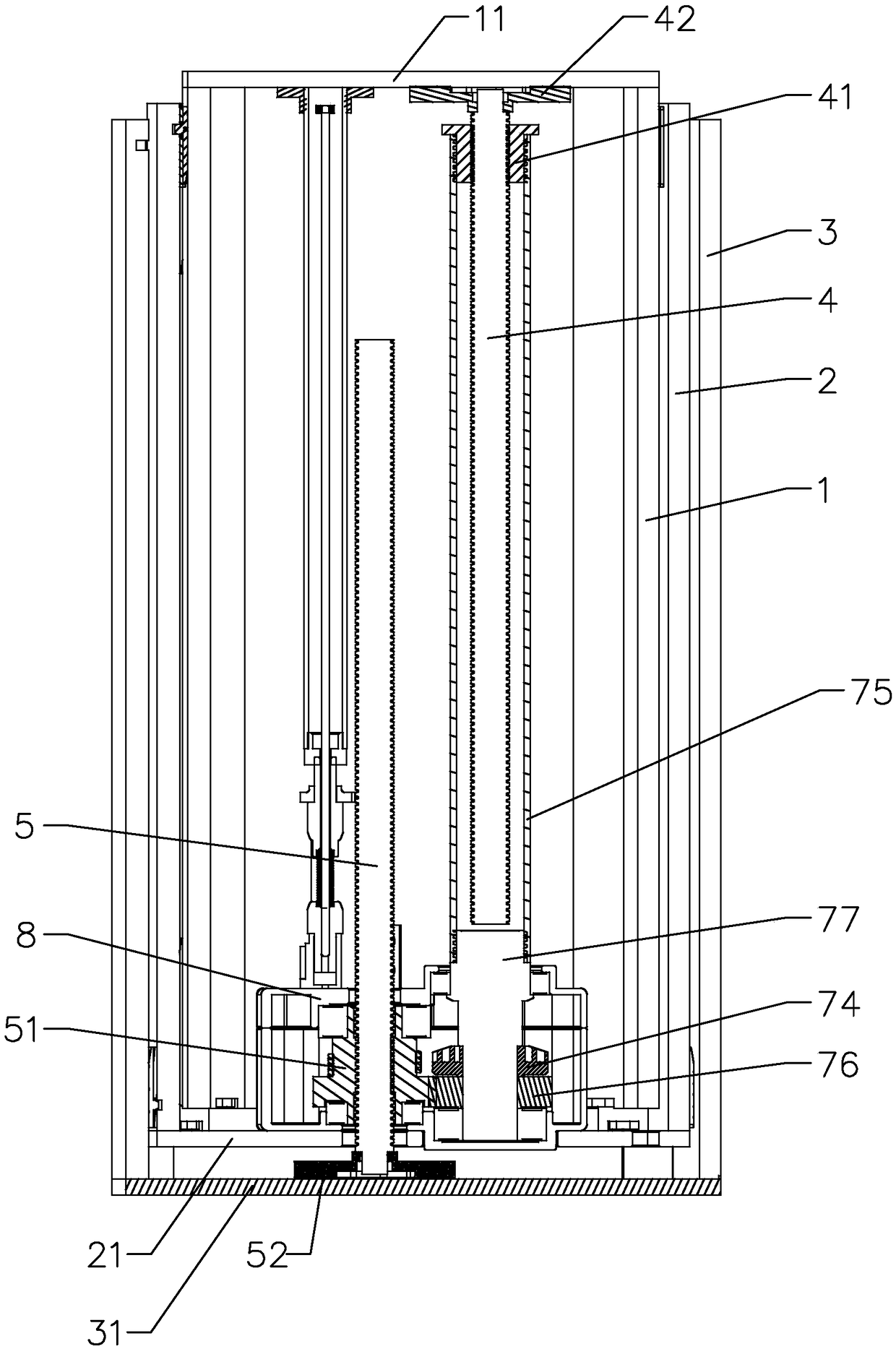

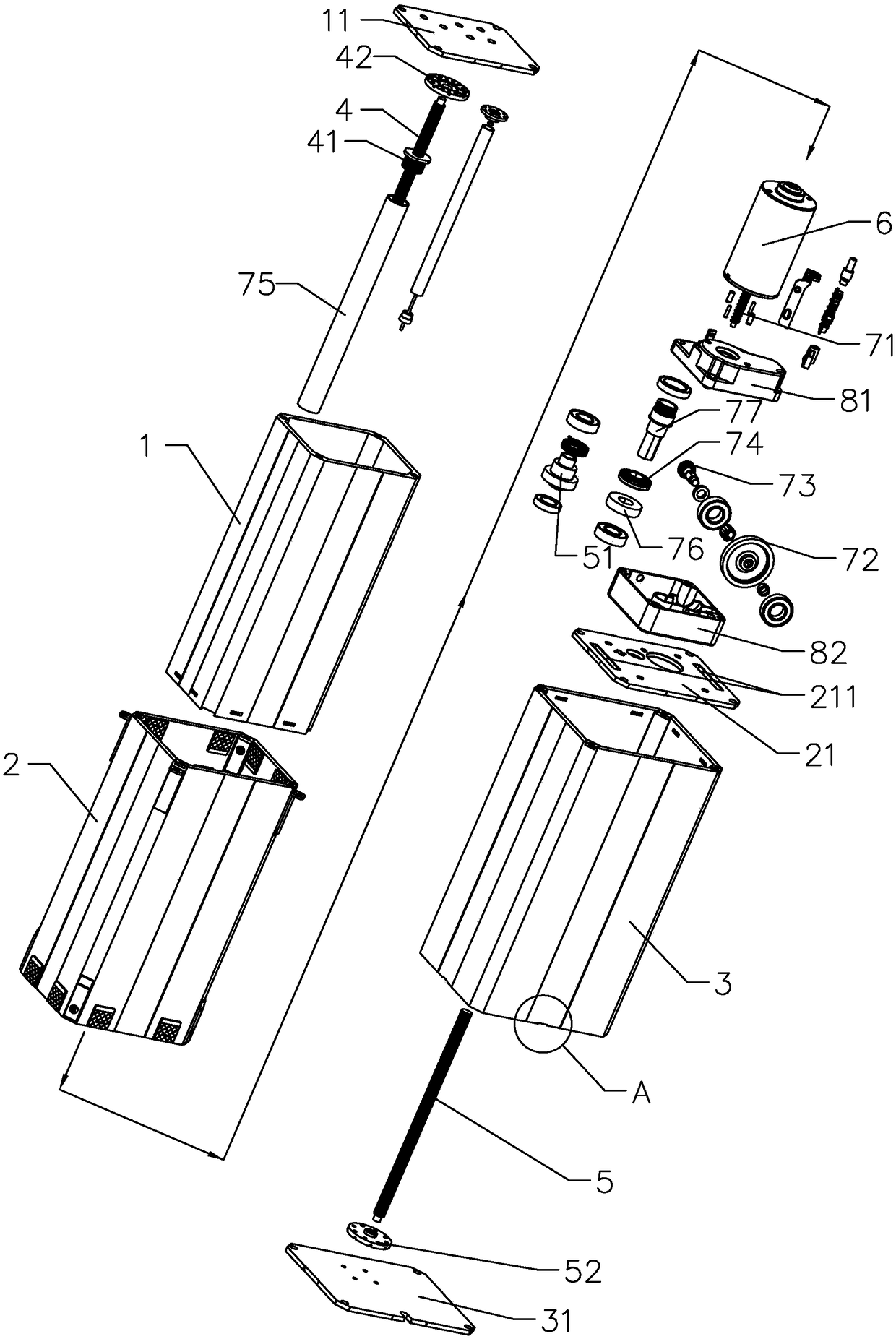

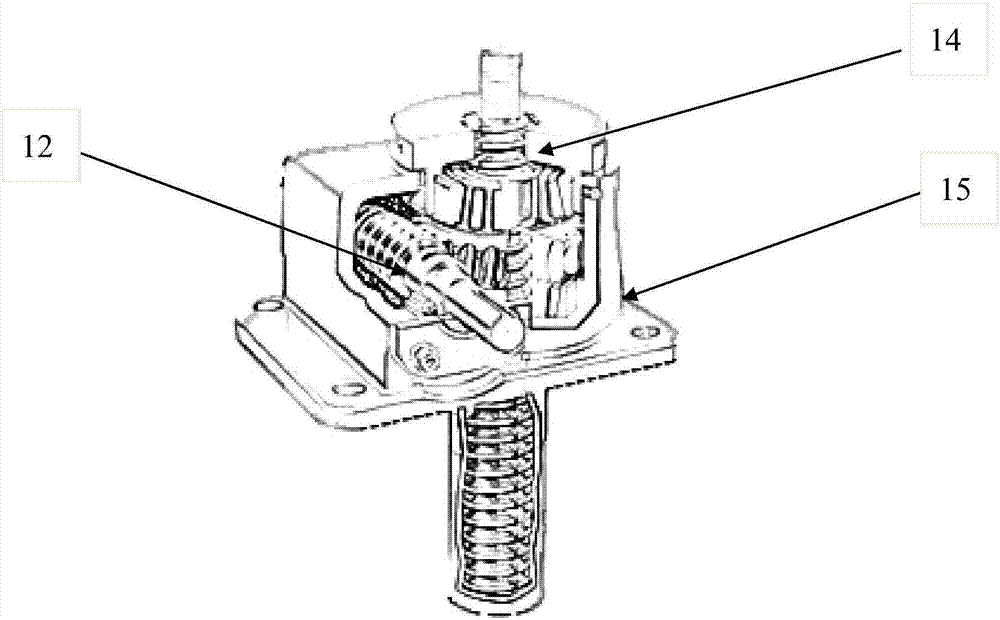

Lifting stand column

PendingCN108662109ACompact structureSimple structureGearingLifting framesReciprocating motionIndustrial engineering

The invention discloses a lifting stand column. The lifting stand column comprises an inner pipe, a middle pipe, an outer pipe, a first screw rod, a second screw rod and a driving mechanism; the innerpipe is arranged in the middle pipe in a sleeved mode and can move in the axial direction of the middle pipe in a reciprocating mode, the outer pipe is arranged outside the middle pipe in a sleeved mode and can move in the axial direction of the middle pipe in a reciprocating mode, a middle plate is arranged at the bottom end of the middle pipe, and the driving mechanism is arranged on the middleplate; the first screw rod is fixedly connected to the inner pipe, the second screw rod is fixedly connected to the outer pipe, the first screw rod is in threaded transmission connection with a firstoutput nut, the second screw rod is in threaded transmission connection with a second output nut, and the driving mechanism drives the first output nut and the second output nut rotate to enable thatthe first screw rod and the second screw rod to drive the inner pipe and the outer pipe to move in the axial direction of the middle pipe respectively; and the first output nut and the second outputnut work independently, so that the transmission stages of the first screw rod and the second screw rod are the same, and therefore the problem that the transmission efficiency is reduced due to the increase of the transmission stage is avoided.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

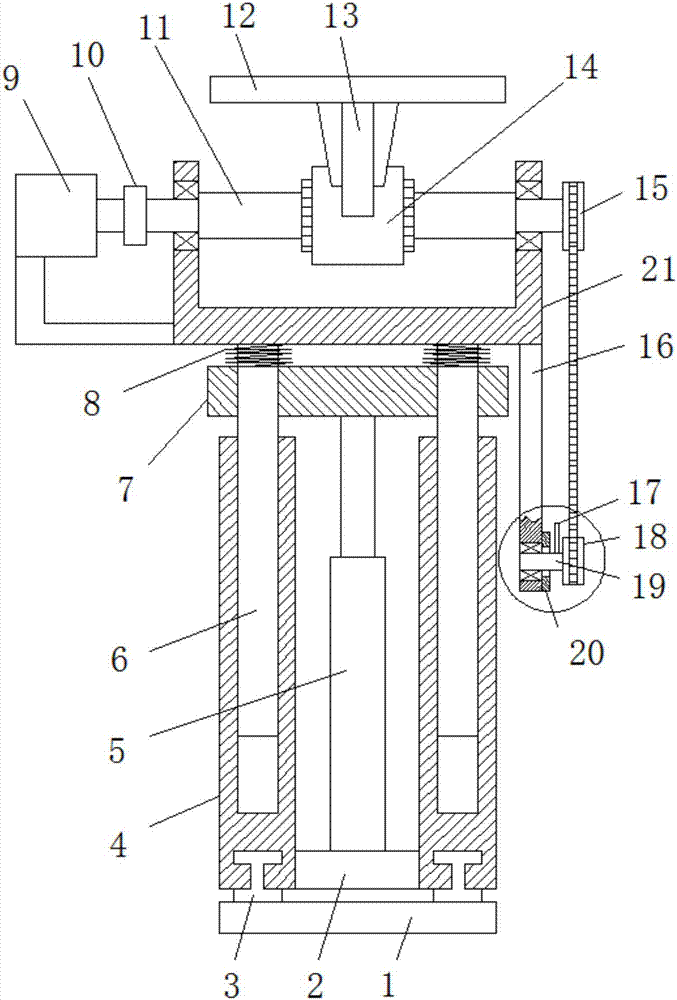

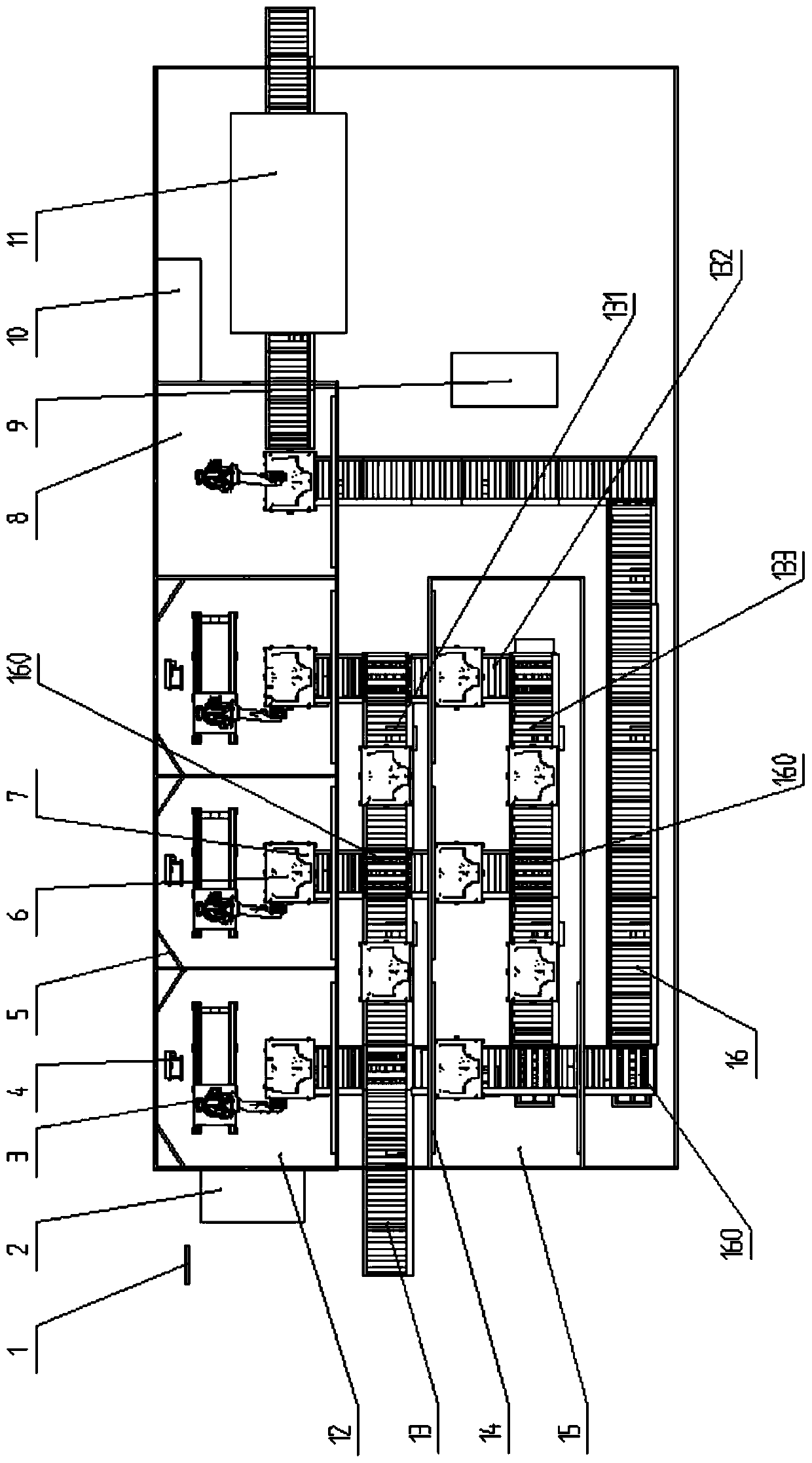

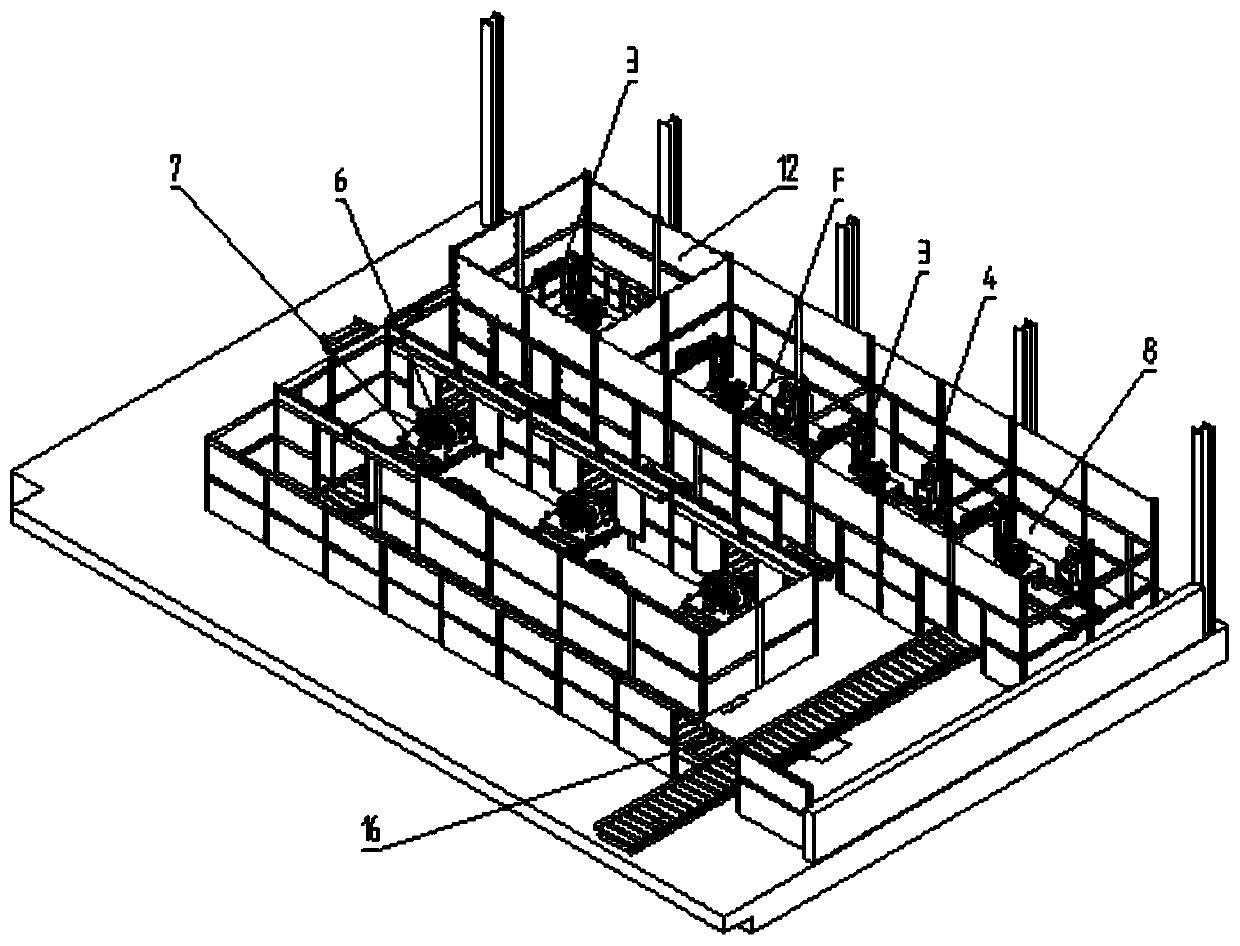

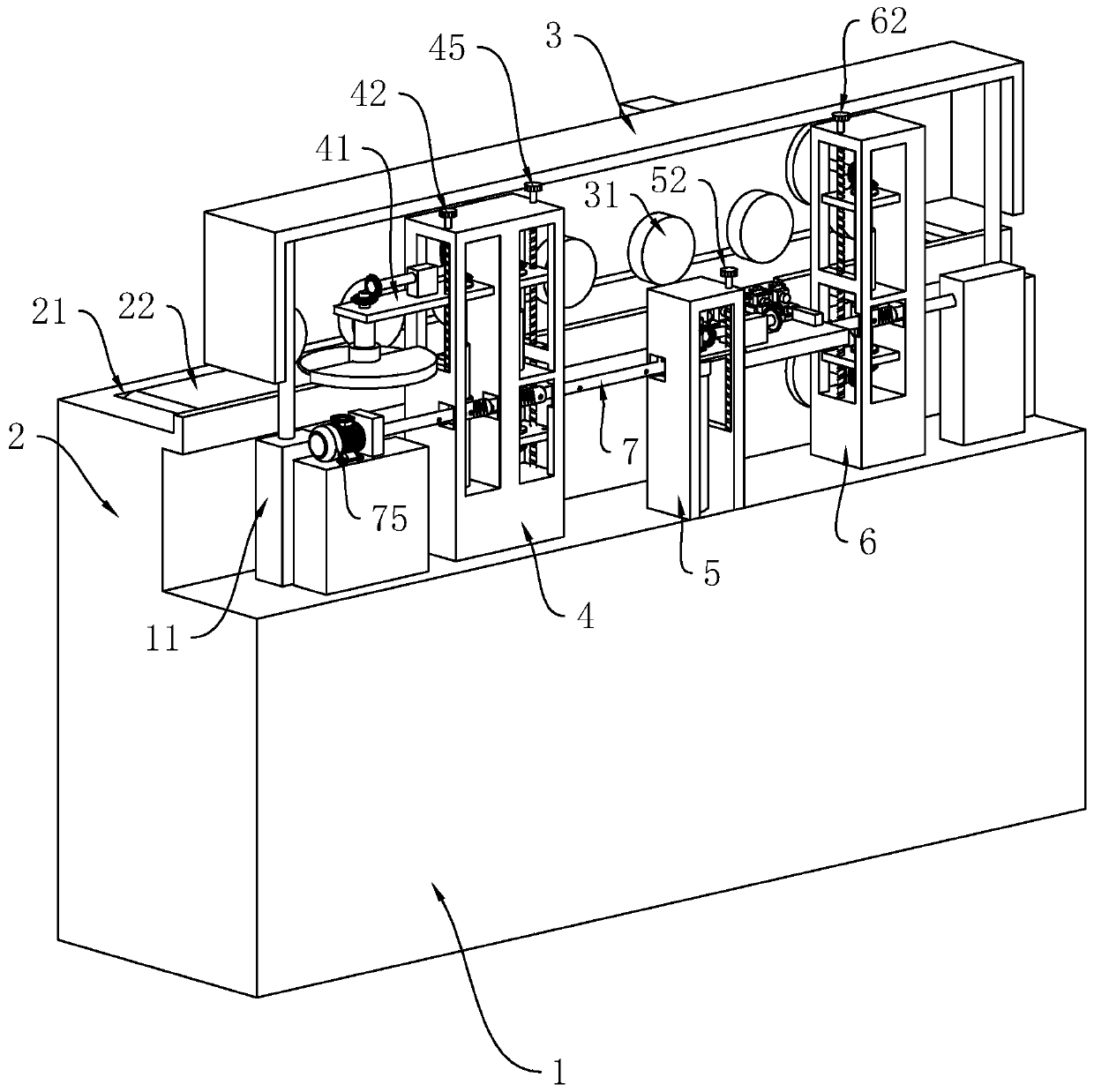

Intelligent polishing production line for putty on surface of casting

PendingCN111347316AImprove work efficiencyReduce labor intensityEdge grinding machinesGrinding wheel securing apparatusProduction lineGrating

The invention discloses an intelligent polishing production line for putty on the surface of a casting, and belongs to the field of machining. The intelligent polishing production line comprises a robot polishing chamber, a manual finishing chamber, a spraying chamber and a drying chamber which are sequentially arranged in an assembly line, the robot polishing chamber communicates with the manualfinishing chamber through a roller type conveying line to realize material transferring, the manual trimming chamber and the spraying chamber communicate with an accumulation line through the roller type conveying line and realize material transferring, the spraying chamber communicates with the drying chamber through the roller type conveying line, a polishing robot is arranged in the robot polishing chamber and used for performing polishing on a plurality of to-be-ground positions of a workpiece, a safety optical grating for monitoring the working range of the polishing robot is further arranged in the robot polishing chamber, and an abrasive paper replacing mechanism is arranged in the robot polishing chamber and used for replacing abrasive paper on the polishing robot. According to theintelligent polishing production line for the putty on the surface of the casting, the assembly line type automatic polishing is achieved, the manpower is saved, the working efficiency is improved and the intelligent polishing production line is more environmentally friendly.

Owner:天津三合智能装备制造有限公司

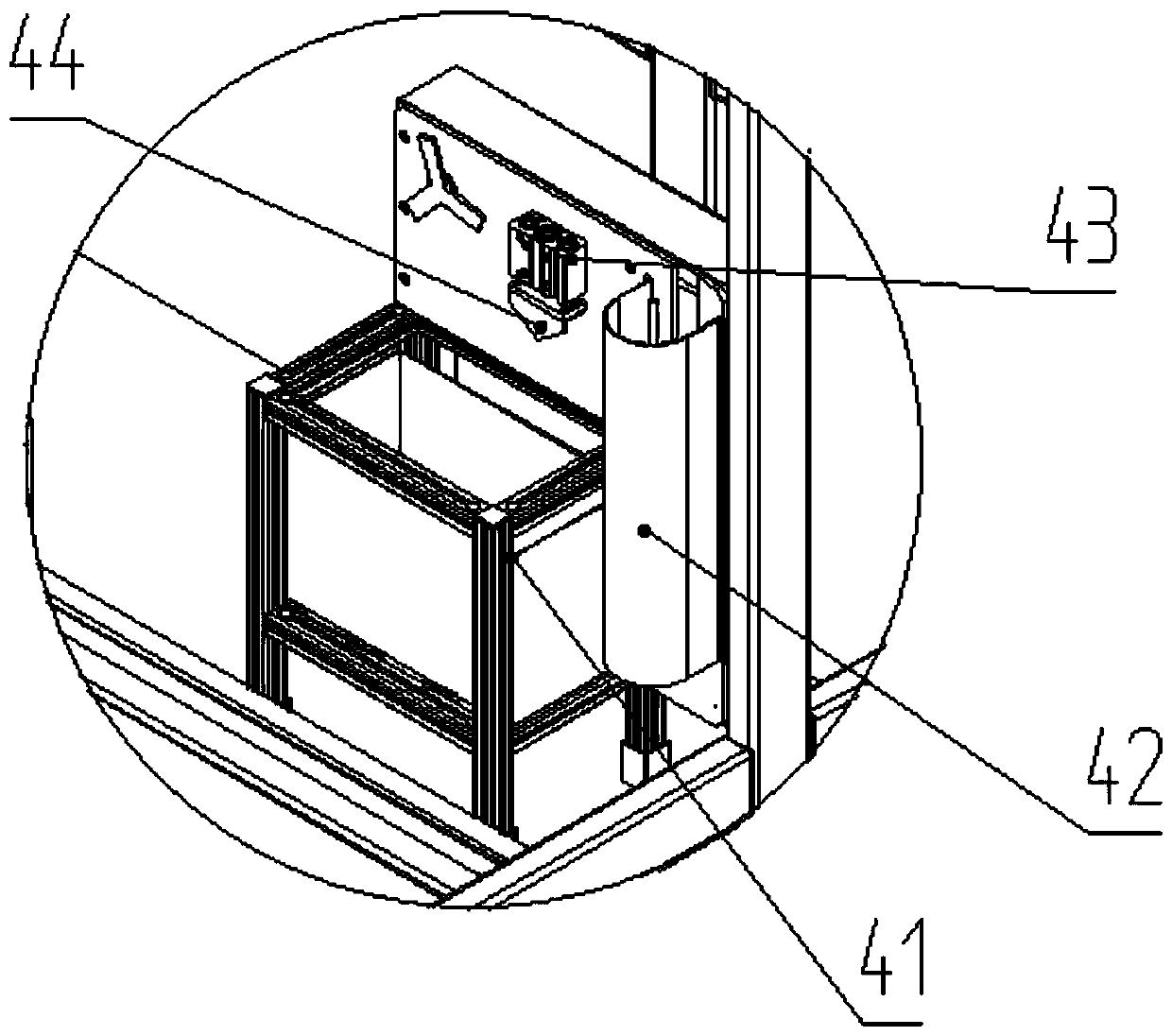

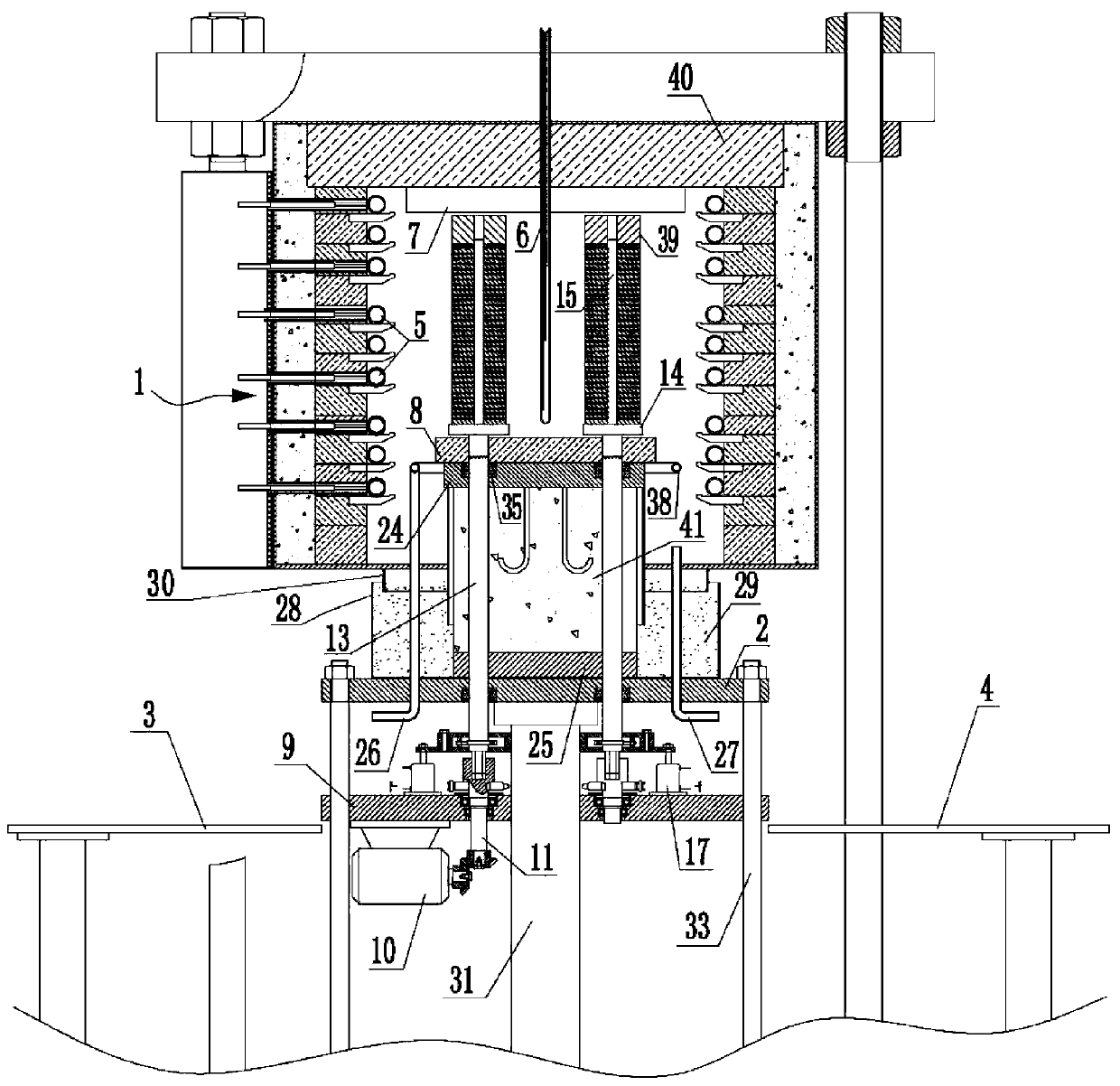

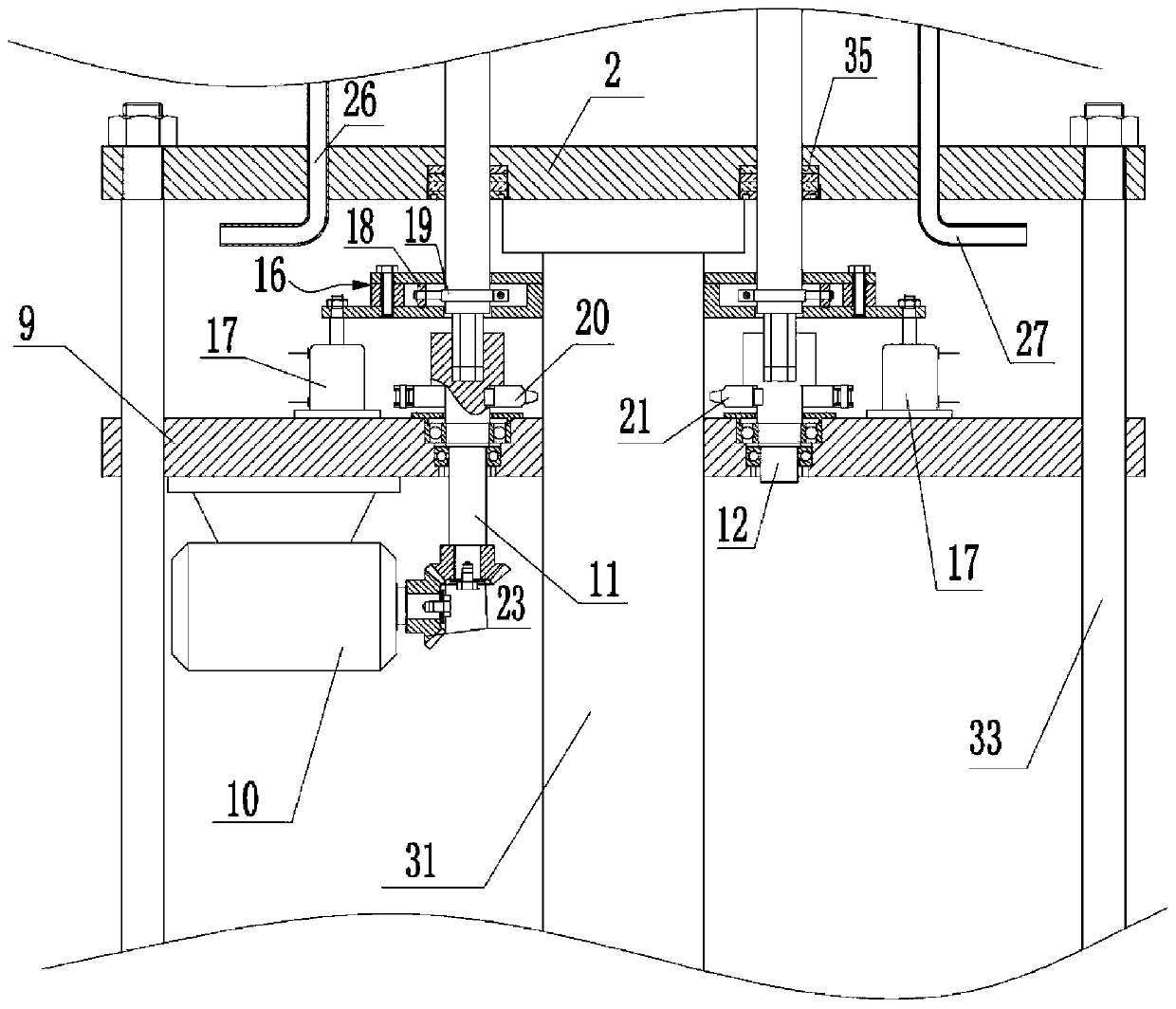

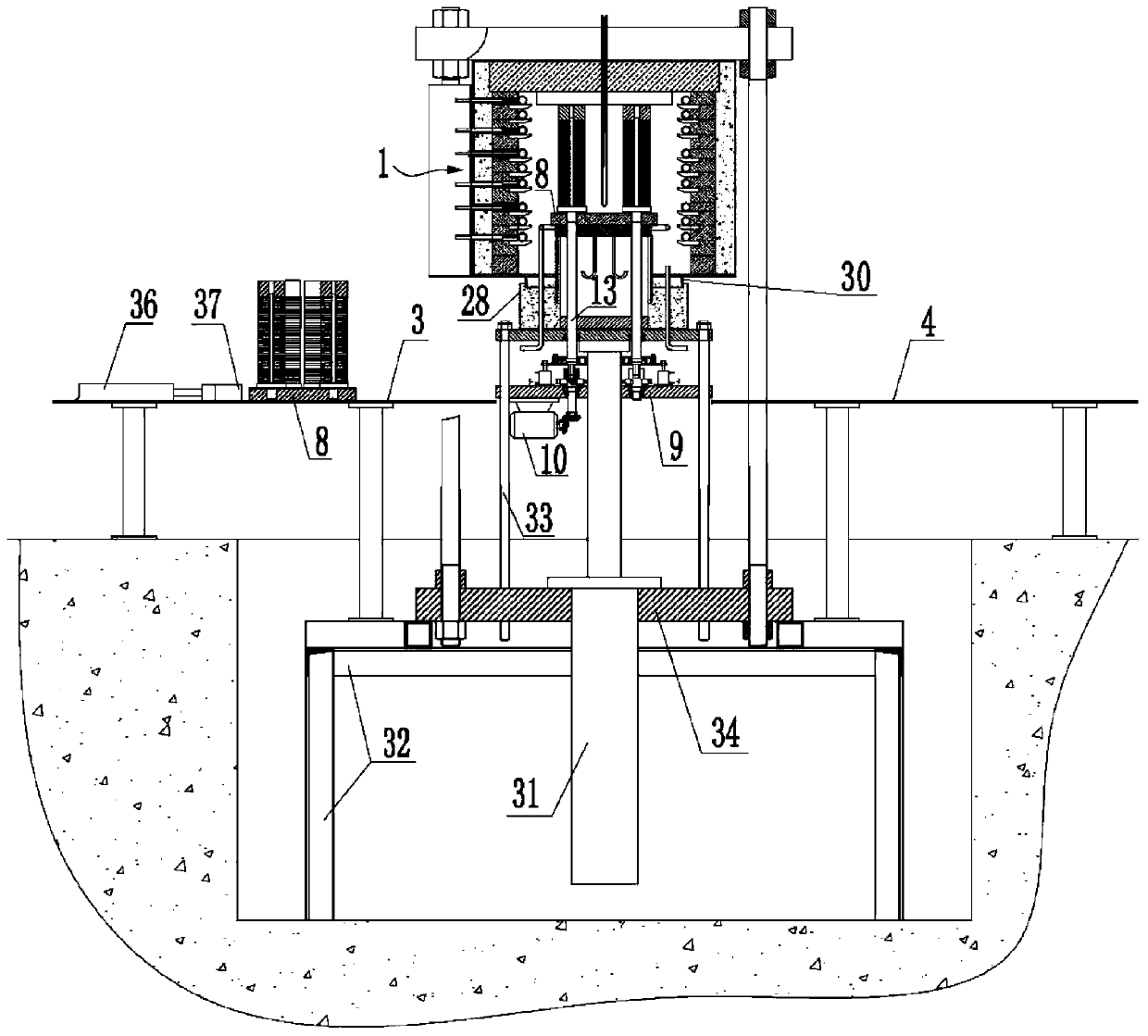

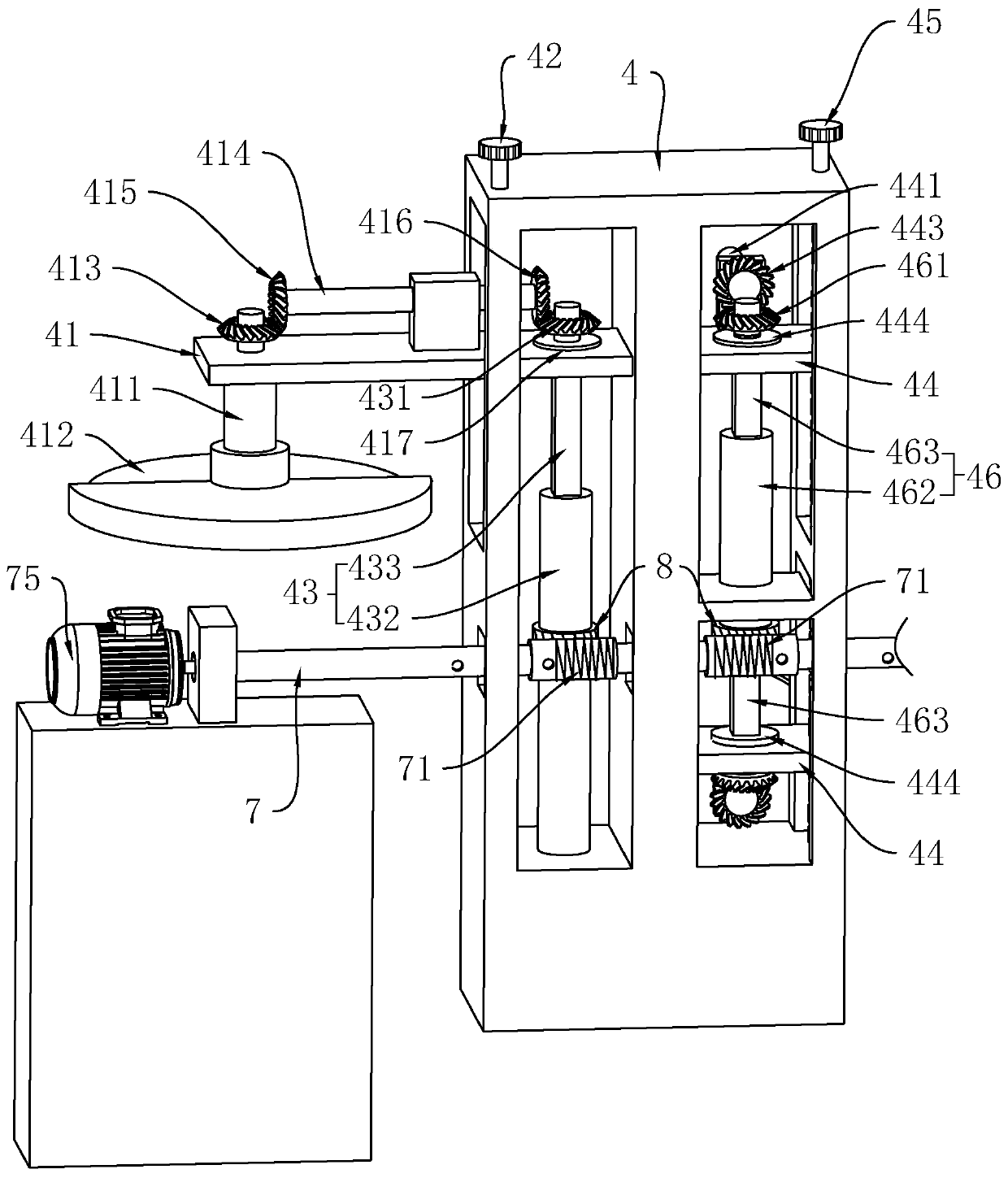

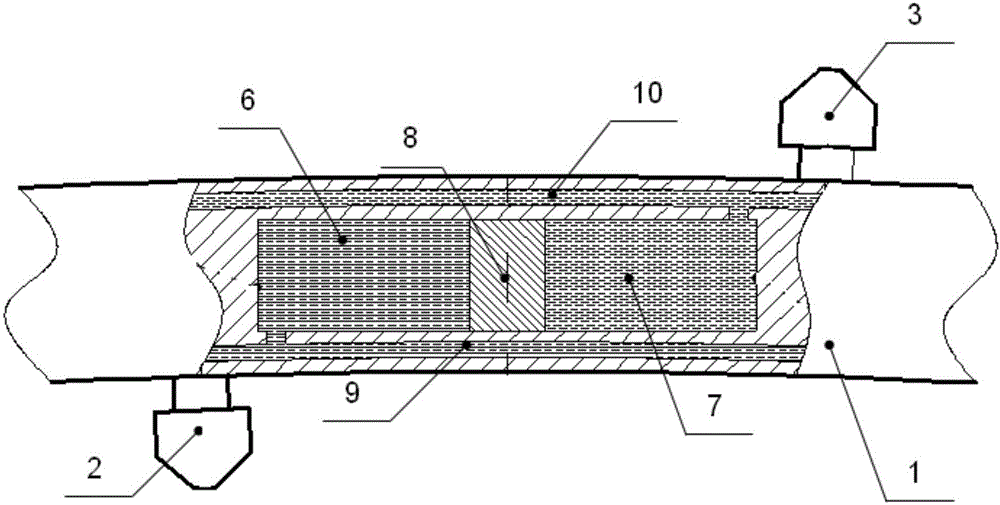

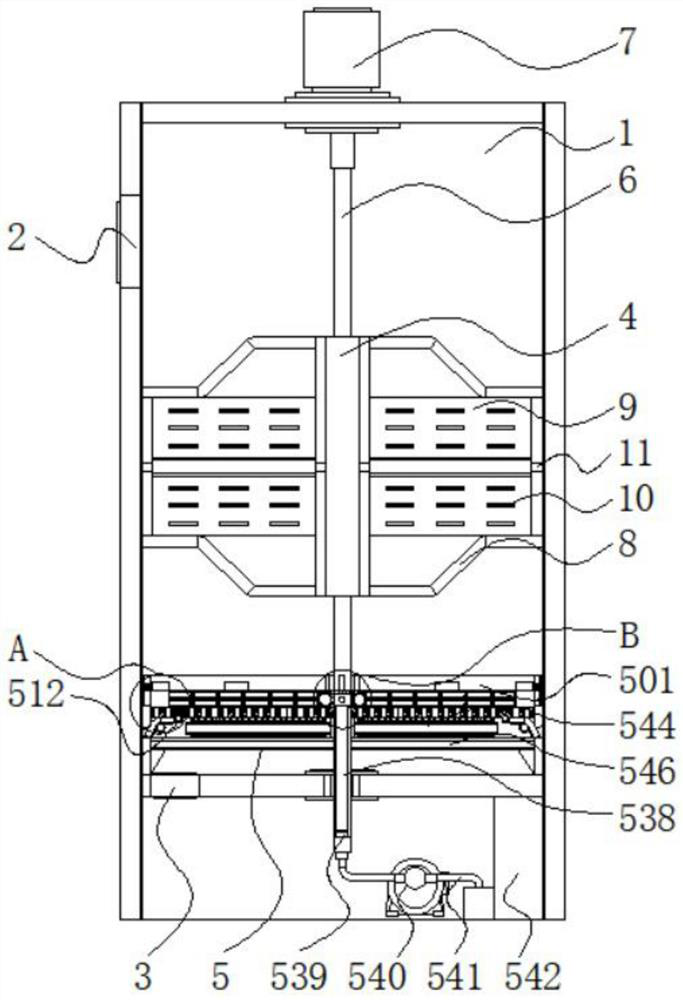

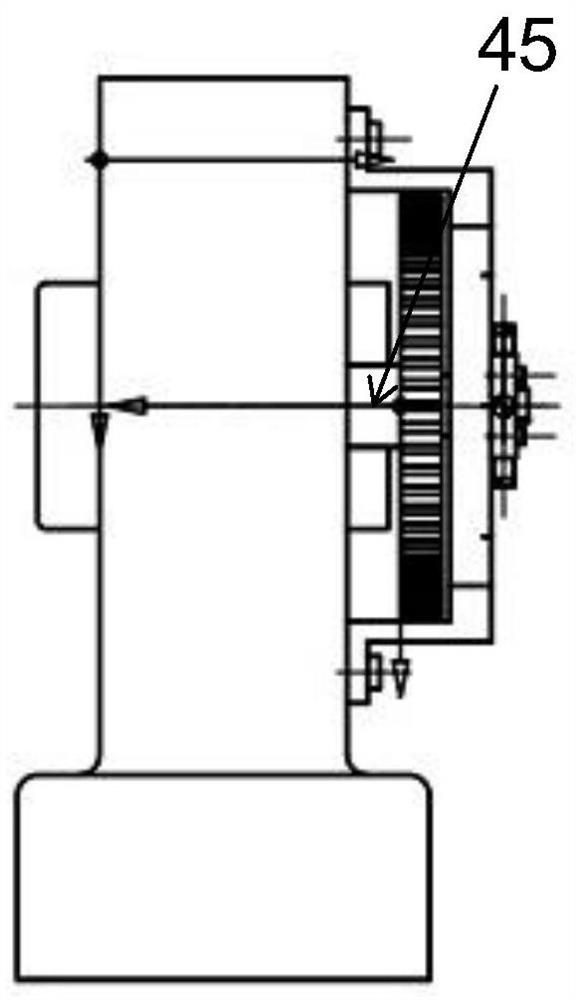

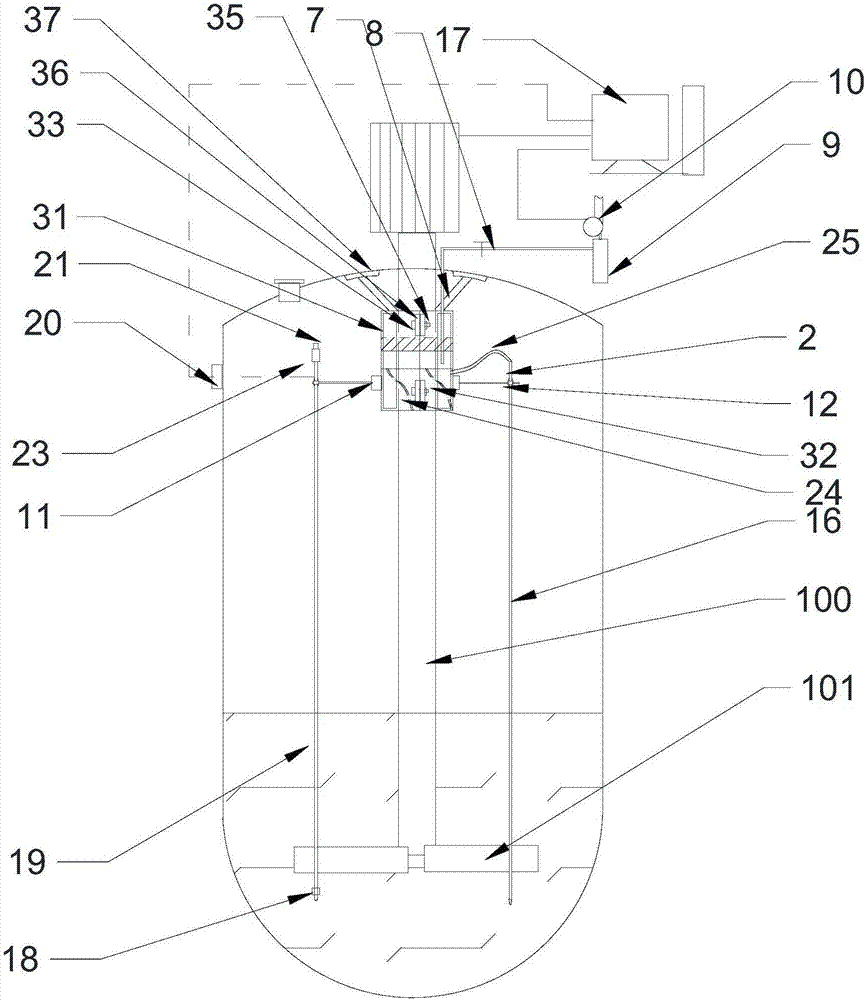

Diamond saw blade rotary sintering furnace and rotary sintering process

ActiveCN111238221AEnsure consistencyIncrease heat radiation conductionFurnace componentsRotary drum furnacesHeating efficiencyHeating cooling

The invention relates to a diamond saw blade rotary sintering furnace and a rotary sintering process, and belongs to the technical field of diamond saw blade machining. The diamond saw blade rotary sintering furnace comprises a sintering furnace body, a lifting base which is correspondingly arranged on the lower side of the sintering furnace body, and a furnace loading workbench and a furnace unloading workbench which are located on the two sides of the lifting base. A thermocouple for temperature measuring is arranged in the sintering furnace body. An upper pressure head is fixedly arranged on the upper top face in the sintering furnace body. The diamond saw blade rotary sintering furnace further comprises an overall base plate for conveying saw blades to be loaded and unloaded. A furnacepillar part is arranged on the upper end face of the lifting base, and a rotating assembly for driving the saw blades to rotate during machining is fixedly arranged on the lower side of the lifting base. The rotating assembly is arranged on the diamond saw blade rotary sintering furnace, saw blade columns can be at a rotating state in the heating and cooling process, and therefore the saw bladesare evenly heated, and the heating and cooling consistency of the hot-pressed and sintered saw blades is improved, and heating efficiency is improved.

Owner:许世祥

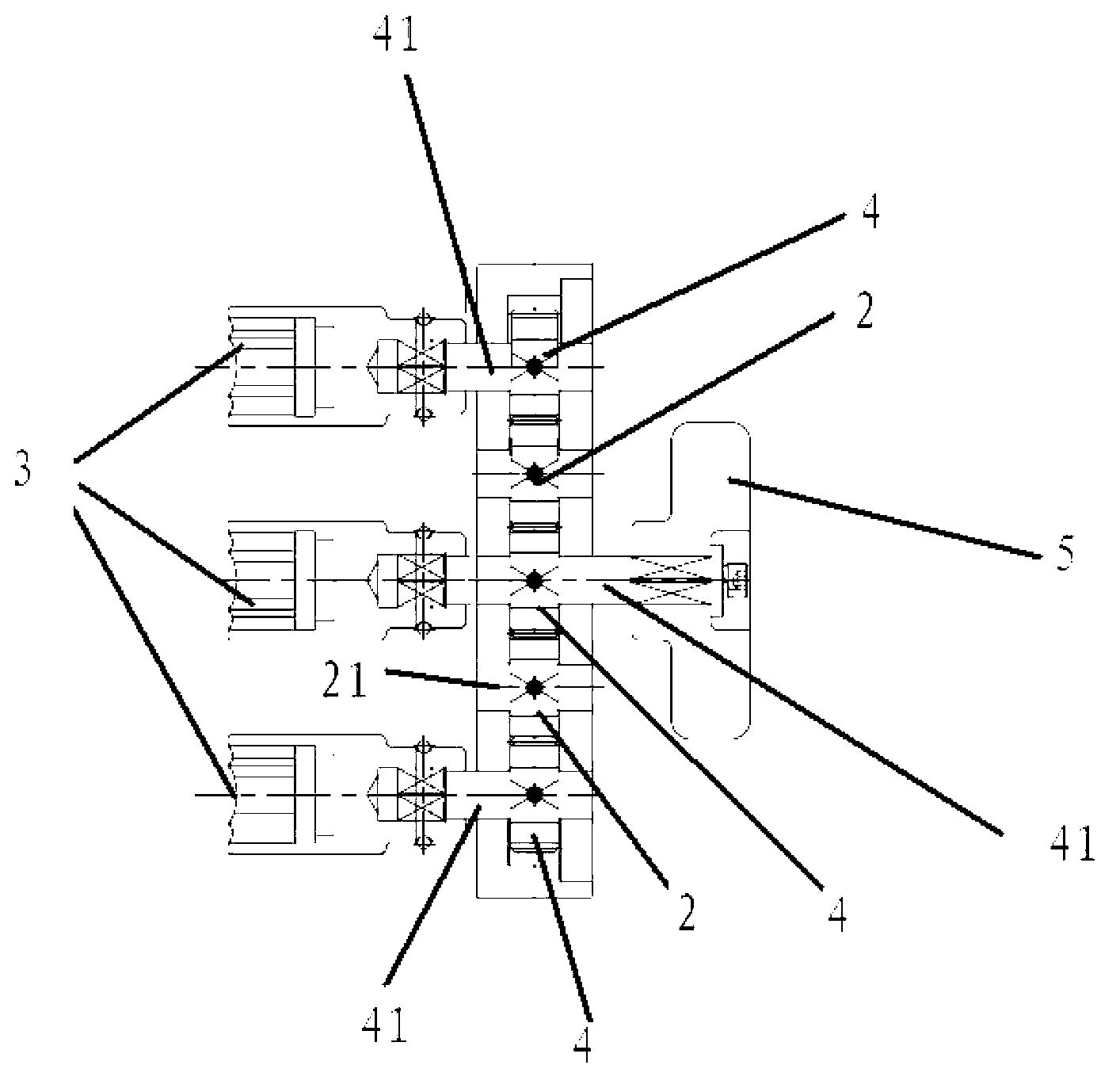

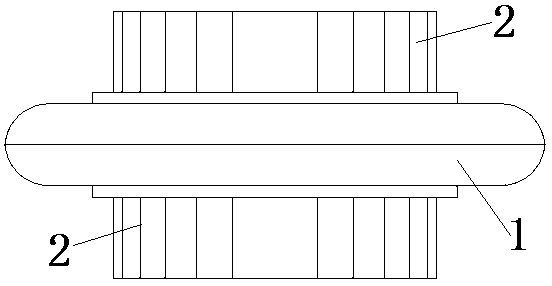

Grinding wheel grinding device, machine tool and inner hole groove machining method

PendingCN110026861ARealize synchronous rotationHigh precisionGrinding drivesGrinding machinesEngineeringGrinding wheel

The invention relates to a grinding wheel grinding device, a machine tool and an inner hole groove machining method. The grinding wheel grinding device comprises a grinding arm which is used for suspending in a to-be-machined hole in an axial direction, a grinding wheel is rotationally assembled on the overhanging end of the grinding arm, a transmission structure used for being in transmission connection with a corresponding power mechanism is arranged on the grinding wheel, and the grinding wheel is provided with an outer peripheral surface used for grinding the inner wall of the to-be-machined hole. According to the grinding wheel grinding device, power is transmitted to the grinding wheel through two transmission wheels, the grinding wheel is clamped between the two transmission wheels,synchronous rotation of the grinding wheel and the two transmission wheels is realized, so that the groove on the hole wall of the to-be-machined hole is machined, the machining efficiency is high, the machined groove has higher contour precision, and the technical requirements of the high-precision groove are met.

Owner:ZHENGZHOU DIAMOND PRECISION MFG

Multifunctional woodwork processing equipment

InactiveCN111251386AEasy to useImprove processing efficiencyEdge grinding machinesStationary drilling machinesProcess equipmentEngineering

The invention relates to multifunctional woodwork processing equipment which comprises a base. A conveying platform is arranged on one side of the base, and the side, corresponding to the conveying platform, of the base is vertically and fixedly connected with a vertical frame I, a vertical frame II and a vertical frame III. A driving frame I is arranged on one side of the vertical frame I and isprovided with a saw web with a vertical axis. Two driving frames II are arranged on the other side of the vertical frame I and are provided with saw webs II of which the axial directions are perpendicular to the length direction of the conveying platform. A driving frame III is arranged on one side of the vertical frame II, and a plurality of drill bits III are arranged on the driving frame III. The axial directions of the drill bits III are same with the axial directions of the saw webs II, and the drill bits III can drive the conveying platform to move. Two driving frames IV are arranged onone side of the vertical frame III on the vertical direction, and polishing wheels same with the axial directions of the saw webs II are arranged on the driving frames IV. The multifunctional woodworkprocessing equipment can overcome the defect of single function of existing woodwork processing equipment and realize the effect of finishing multiple processes with one equipment.

Owner:青岛泽禾木业股份有限公司

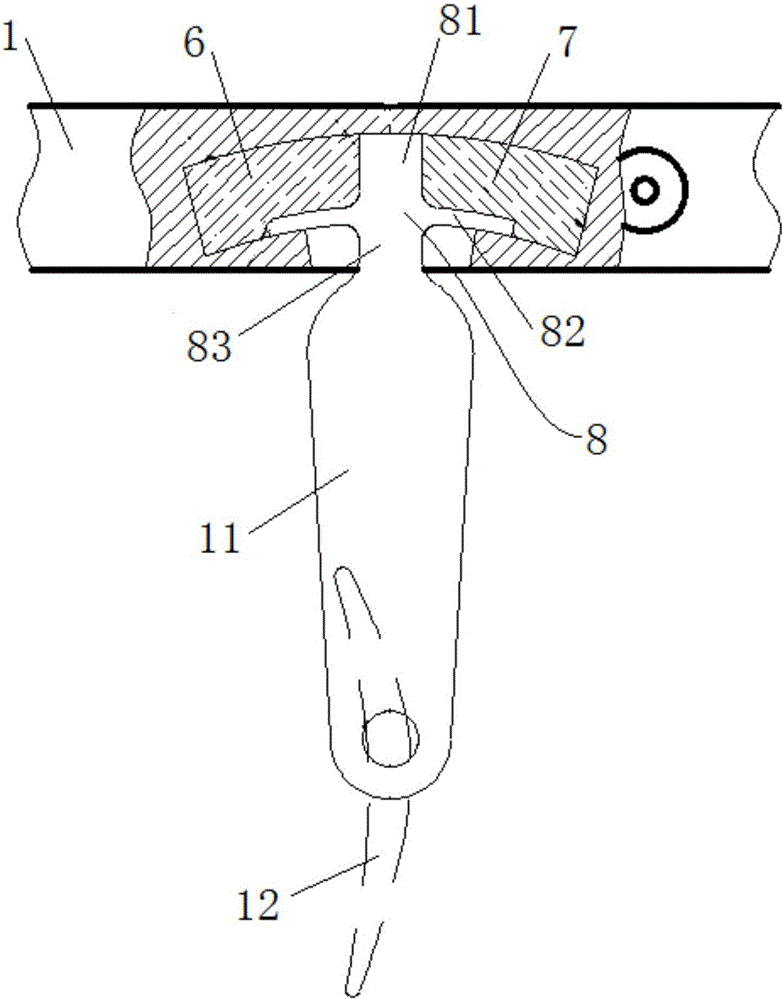

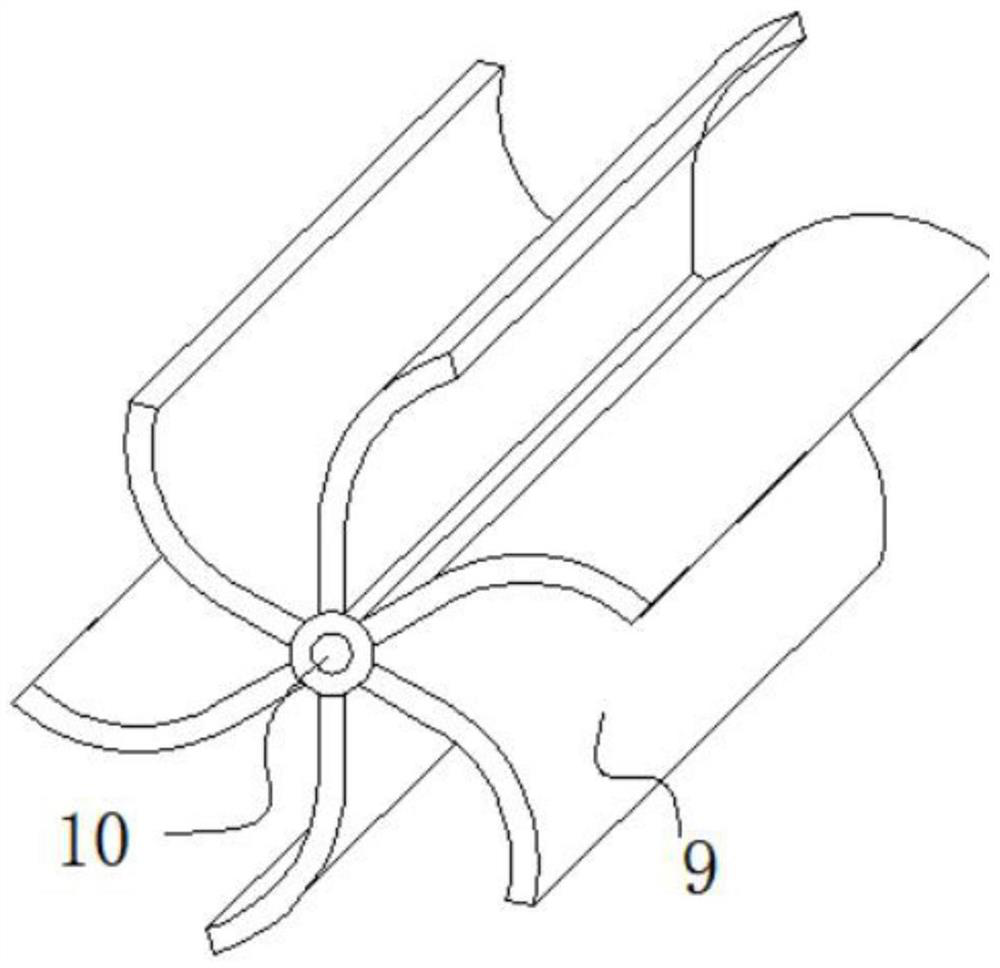

Surrounding type welding device for water conservancy pipeline machining and welding technology of surrounding type welding device

PendingCN113579591AAutomatic blowingRealize synchronous rotationWelding/cutting auxillary devicesAuxillary welding devicesButt jointGear wheel

The invention provides a surrounding type welding device for water conservancy pipeline machining and a welding process of the surrounding type welding device, and relates to the technical field of welding devices. The problems that although an existing device can achieve annular welding, the cooling effect at a welding seam position is slow, and the welding quality is difficult to observe due to large smoke in the welding process are solved. According tp the surrounding type welding device for water conservancy pipeline machining and the welding process of the surrounding type welding device, the device comprises a base, the base is placed on the ground, a rotating shaft is rotatably connected to a seat body, three blades are installed on the rotating shaft, and the blades are aligned to butt joint positions of two pipes; a gear A is mounted on the rotating shaft; and a gear B is installed on the rotating shaft and meshes with the gear A, and the gear ratio of the gear B to the gear A is 5: 1, so that cooling and smoke blowing can be automatically achieved in the annular welding process.

Owner:郭林平

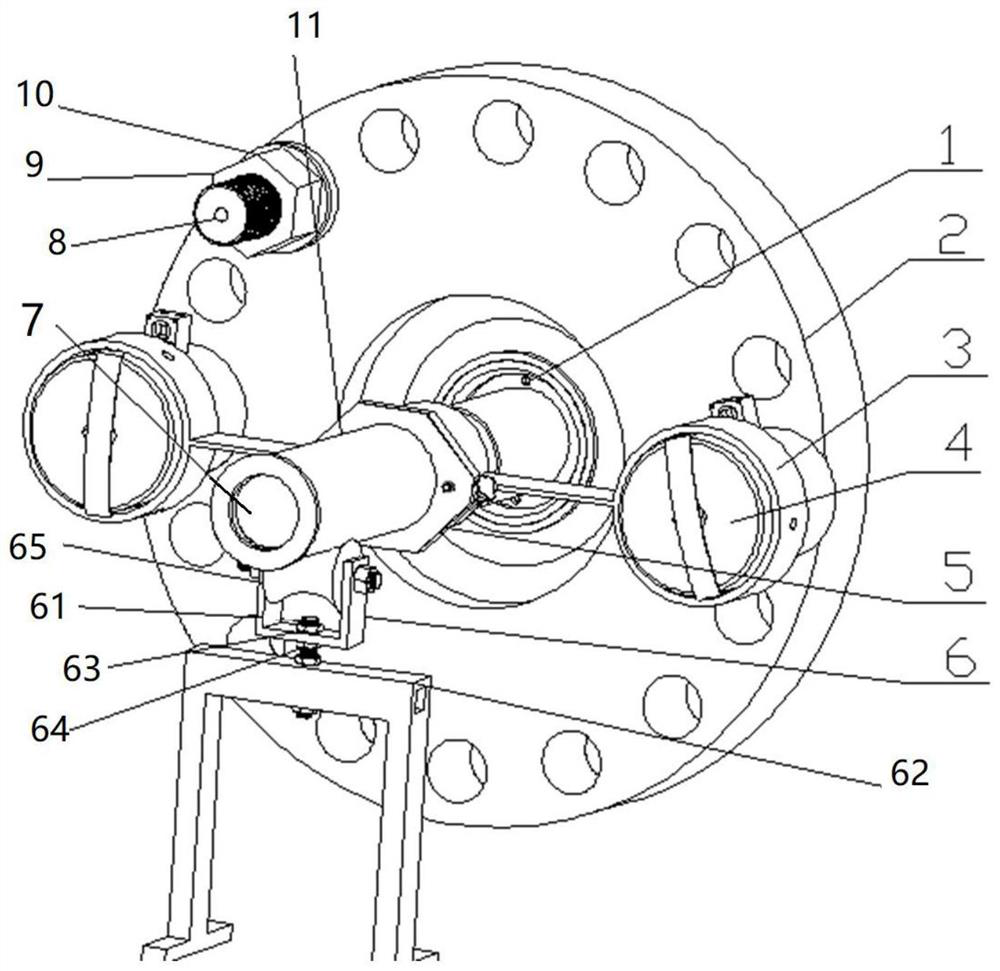

Stator blade driving device

ActiveCN106089809AWill not deformRealize synchronous rotationPump componentsPumpsPressure differenceTurbine

The invention discloses a stator blade driving device and relates to the technical field of turbine engines. The stator blade driving device is used for adjusting the installation angle of a blade and comprises a support and a rocker arm. The support is of an annular structure and is fixedly installed on a casing. An oil cavity is formed in the support. The oil cavity is an arc-shaped section. A piston is arranged in the oil cavity. The oil cavity is divided into a first oil cavity body and a second oil cavity body by the piston. The first oil cavity body is provided with a first oil nozzle. The second oil cavity body is provided with a second oil nozzle. One end of the piston stretches out of the oil cavity and is connected with one end of the rocker arm. The other end of the rocker arm is connected with the blade. The stator blade driving device has the beneficial effects that the driving rocker arm of the blade moves in the oil cavity in the support according to a preset path, the rocker arm is driven by the piston, the piston is driven by the pressure difference of the first oil cavity body and the second oil cavity body, the rocker arm is not affected by outside resistance, and the rocker arm is prevented from being deformed in the rotation process.

Owner:AECC SHENYANG ENGINE RES INST

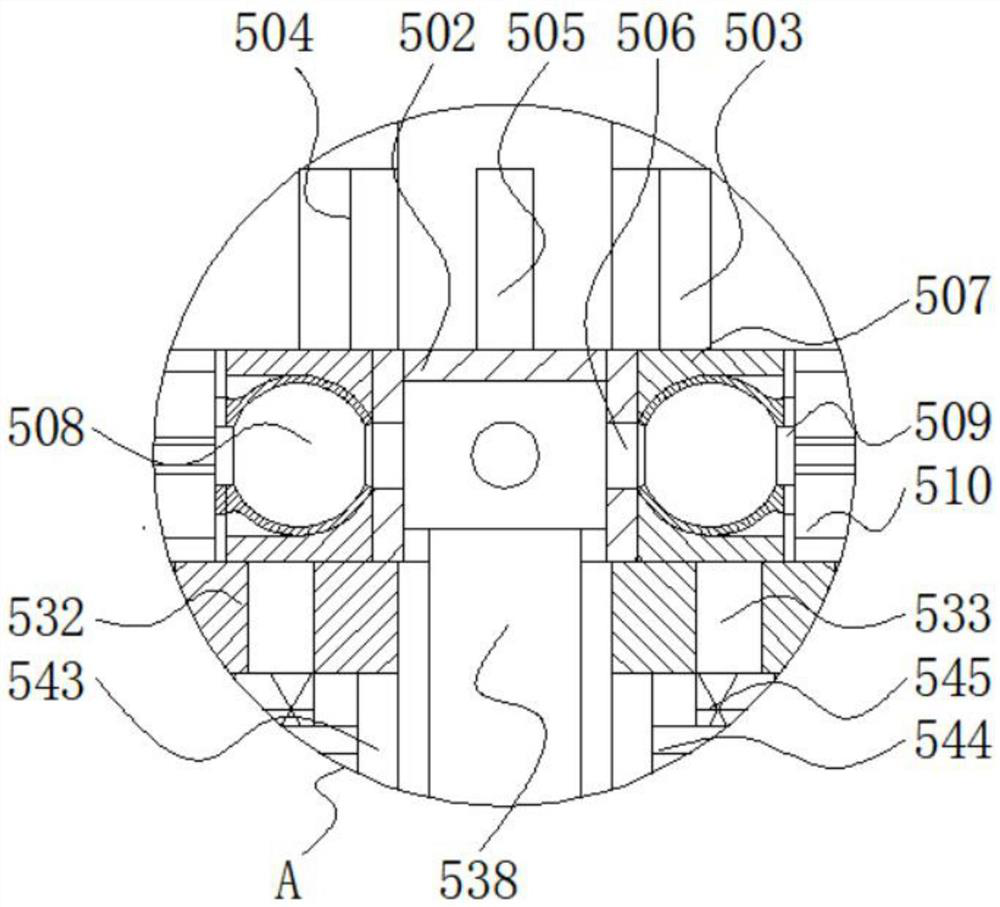

Natural enzyme soap containing fruit enzyme and production equipment of natural enzyme soap

ActiveCN114471313AImprove the mixing effectRealize synchronous rotationRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention discloses natural enzyme soap of fruit enzyme and production equipment thereof, and relates to the technical field of natural enzyme soap production, in particular to natural enzyme soap of fruit enzyme and production equipment thereof, which comprises an enzyme production tank body, and a feeding notch and a discharging notch formed in the enzyme production tank body, a fixed column sleeve and an auxiliary filtering mechanism are arranged in the enzyme production tank body, a fixed shaft rod penetrating out of the fixed column sleeve extends to a driving motor, and the driving motor is fixed to the enzyme production tank body through threads. Under the action of the driving motor, the fixing frame can be driven to rotate through the fixing column sleeve, and the fixing frame is movably connected with the blades through the cooperation of the transverse sleeve and the transverse shaft, so that the blades are subjected to the action of raw materials and rotate along the outside of the transverse shaft through the transverse sleeve, and the raw materials can be stirred again through the blades; the blades can revolve along the fixed shaft rod and can rotate along the transverse shaft, so that the raw material mixing effect can be effectively improved.

Owner:浙江永金生物科技有限公司

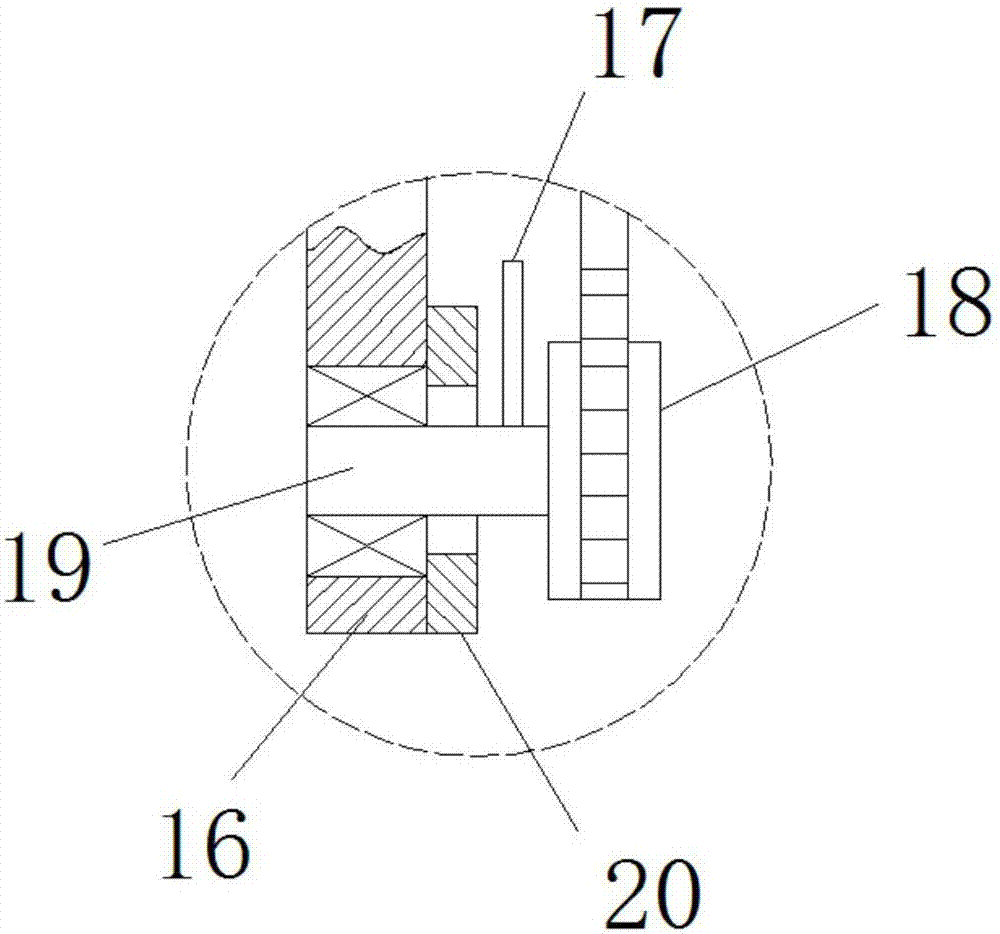

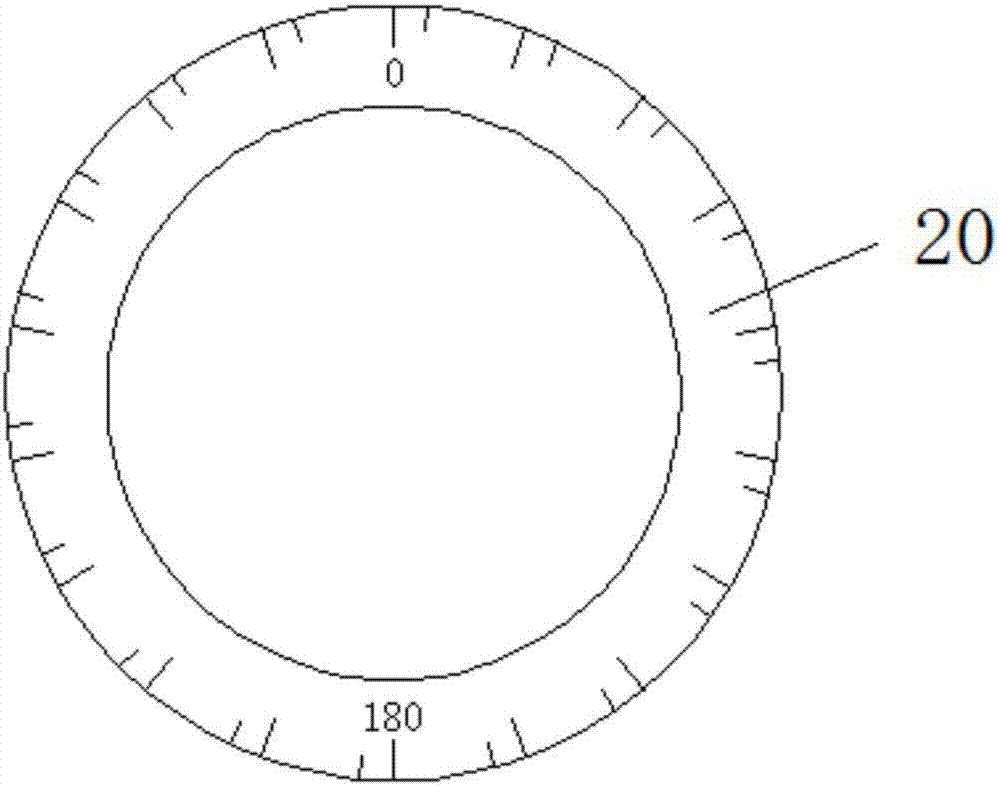

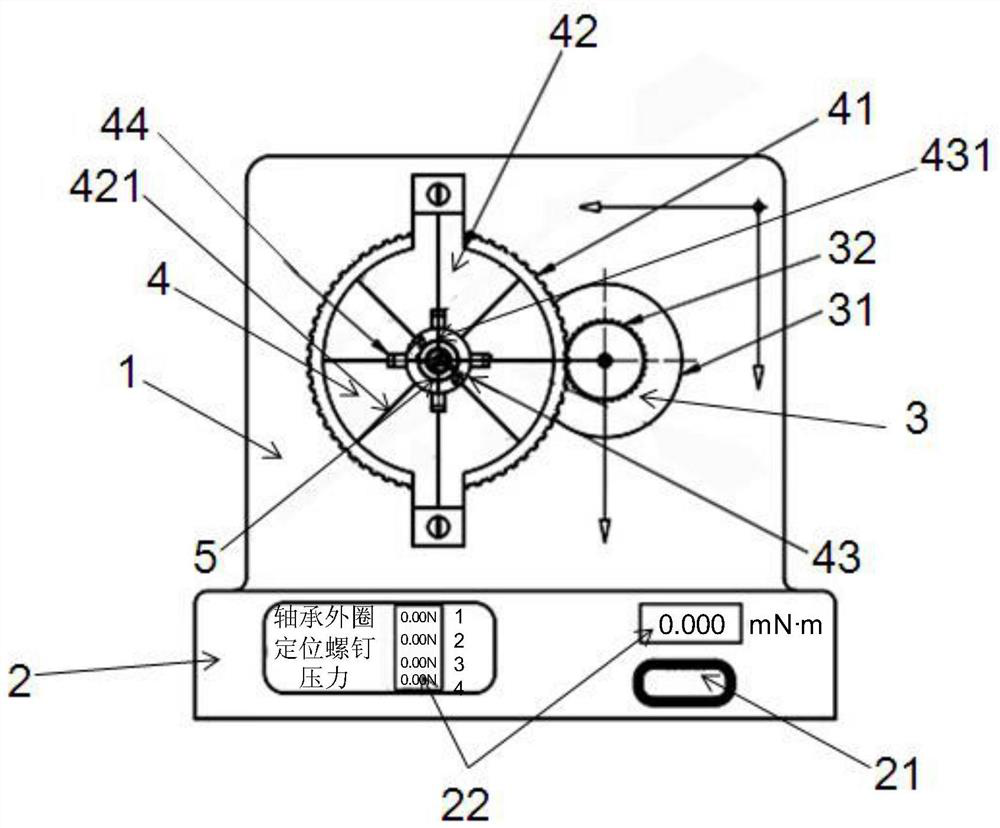

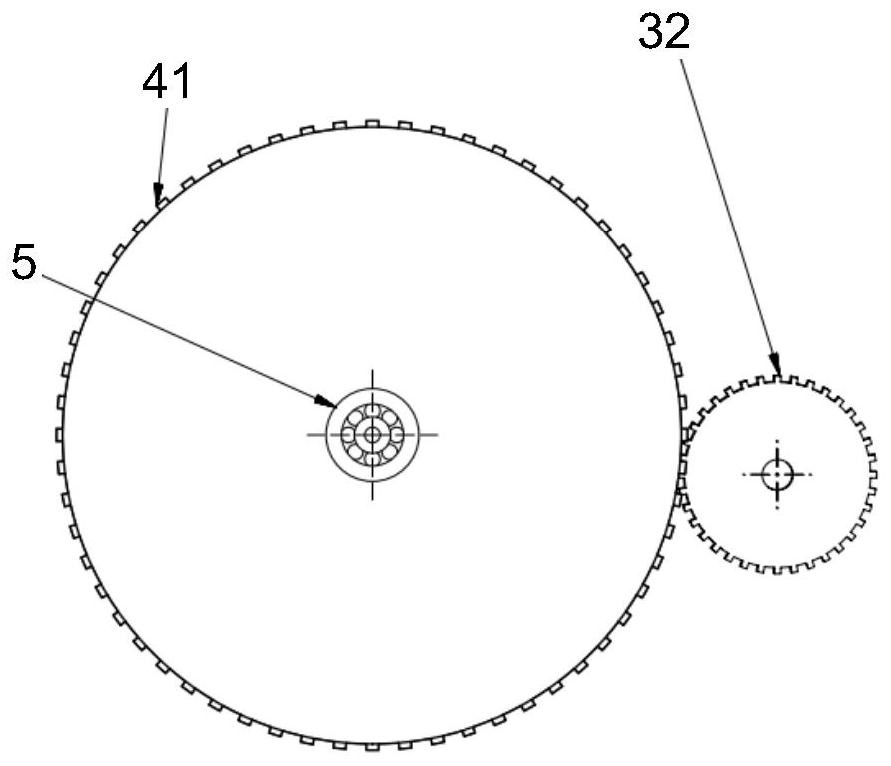

High-precision rolling bearing friction torque testing device and method

ActiveCN111947925APrecise positioningHigh resolutionMachine bearings testingForce sensorsDrive wheelFriction torque

The invention relates to a high-precision rolling bearing friction torque testing device and method. The invention aims to solve the technical problems that in the prior art, the rolling testing errorof extremely small friction torque is large, the testing stability of the same point is poor, and it is difficult to achieve friction torque testing of multiple points evenly distributed on a rollingbearing, and provides a high-precision rolling bearing friction torque testing device and method. A motor of a power assembly of the device is installed on a rack; a driving wheel is mounted on the motor; the diameter of a driven wheel of a testing assembly is greater than that of the driving wheel; the driven wheel is arranged on the rack and is meshed with the driving wheel; a scale compass isgreater than a fixing ring in diameter; the scale compass is arranged in front of the driven wheel in parallel and is fixed on the rack; the scale compass is provided with a plurality of scale lines and a plurality of fixing ring positioning holes; scale marks are also arranged on the fixing ring; a radial through hole and an axial through hole are formed in the fixing ring. The method is carriedout by using the device.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

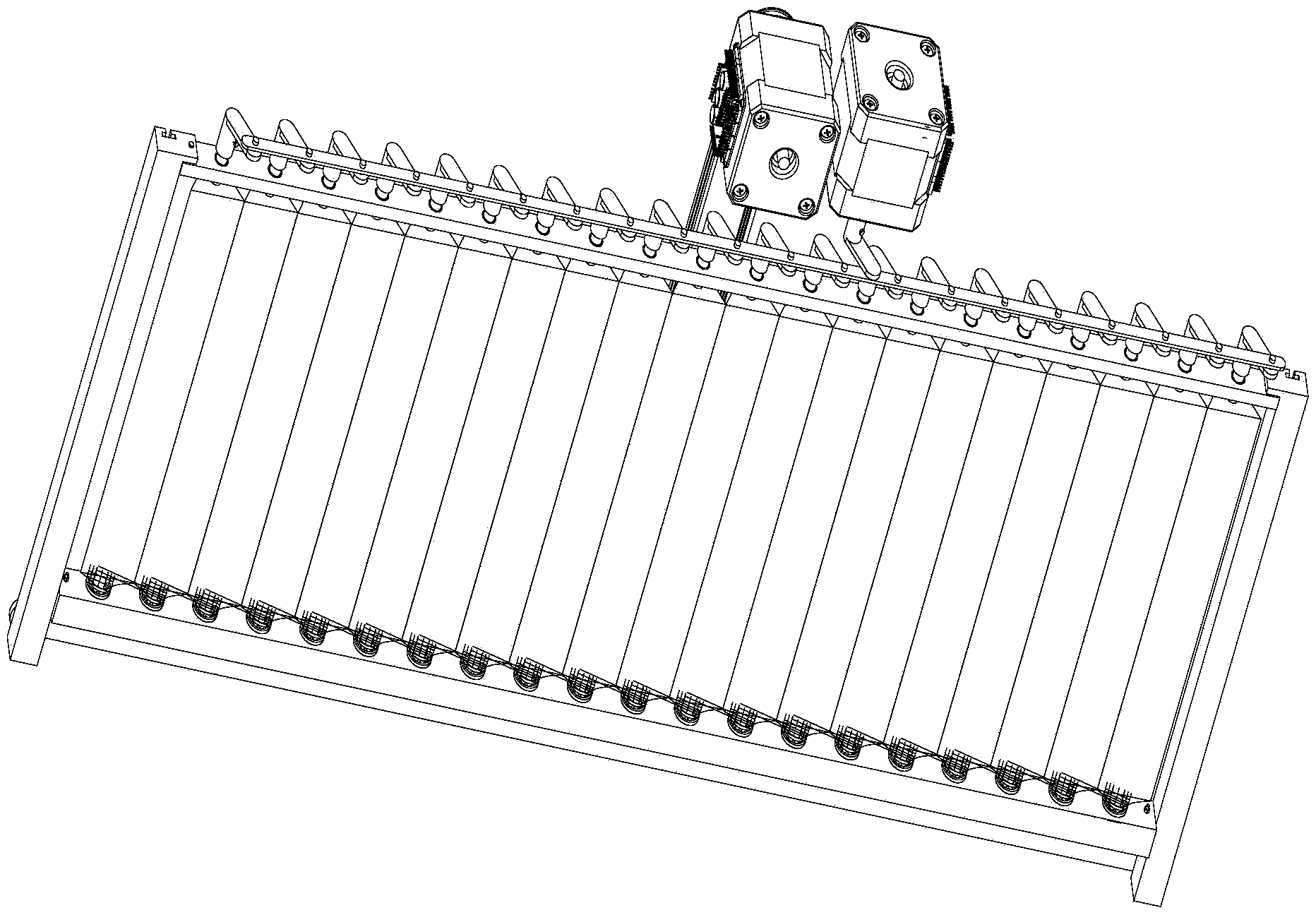

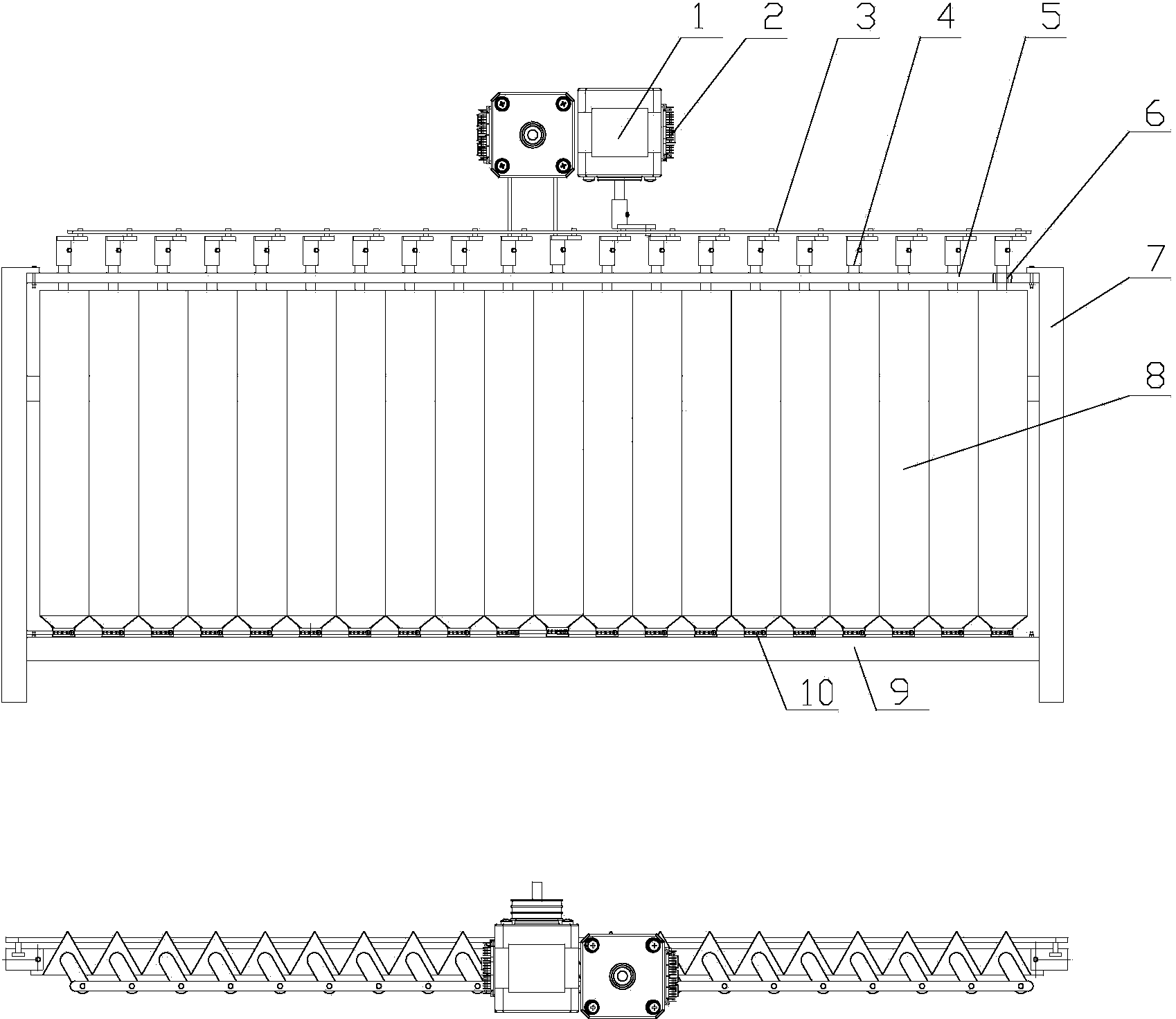

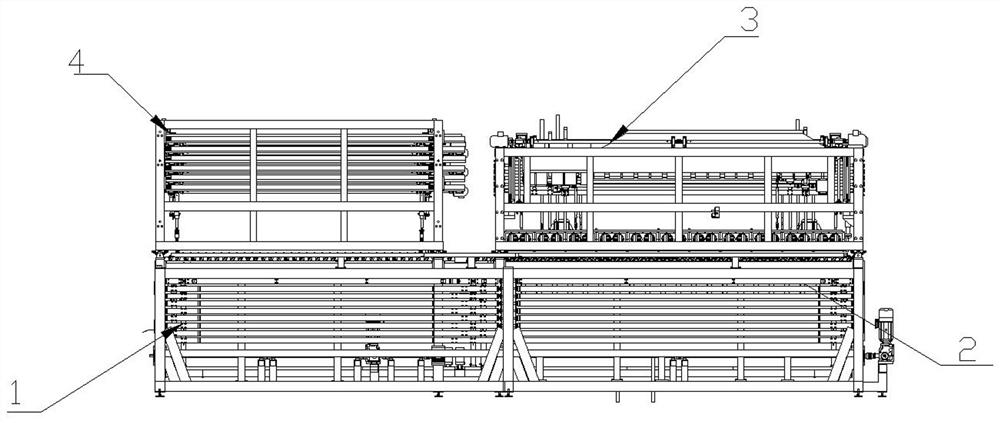

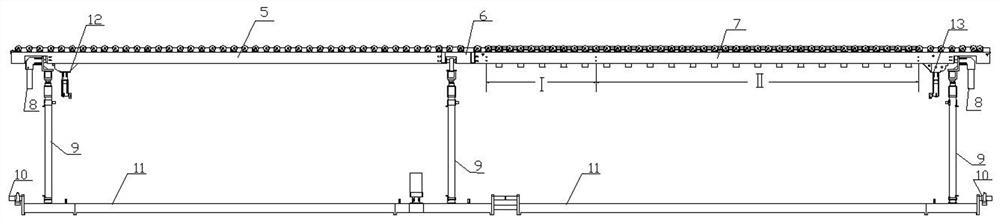

Forming and tempering method and forming and tempering equipment of tempered glass

ActiveCN111977947AReduce usageReduce manufacturing costGlass reforming apparatusGlass tempering apparatusElectric machineryToughened glass

The invention relates to a forming and tempering method and forming and tempering equipment of tempered glass. In the method, forming requirements of a variety of glass are satisfied through lifting,horizontal swinging and self torsion of forming section beams and tempering section beams; in the equipment, multiple forming section beams and tempering section beams are respectively arranged at thelower part of a forming section and the lower part of a tempering section; the forming section beams and the tempering section beams are arranged at intervals along the direction vertical to the glass conveying direction; the forming section beams and the tempering section beams are respectively provided with a first roller conveying mechanism and a second roller conveying mechanism; a wind box is also arranged on the tempering section beams; the forming section beams and the tempering section beams are rotatably connected with a lifting mechanism respectively; the lifting mechanism is connected with a side pushing mechanism; the bottom of the lifting mechanism is rotatably connected with a machine frame of the equipment; and the forming section beams and the tempering section beams are also connected with a torsion motor. The forming and tempering method and the forming and tempering equipment in the invention not only can be used for producing single curved glass and hyperbolic glass, but also can be used for producing a variety of specially-shaped glass; and thus, the adaptation is very high.

Owner:LUOYANG LANDGLASS TECH CO LTD

Cone yarn automatic conveying mechanism

The invention discloses a cone yarn automatic conveying mechanism. The cone yarn automatic conveying mechanism comprises a bottom plate. A fixing plate is mounted at the top of the bottom plate. A first rotary shaft, a second rotary shaft, two third rotary shafts, four guiders, a first motor and a second motor are mounted on the side edge of the fixing plate. A pay-off roller and a second driven chain wheel are mounted on the second rotary shaft. A take-up roller and a first driven chain wheel are mounted on the first rotary shaft. A driving chain wheel is mounted on an output shaft of the first motor. A chain is connected among the driving chain wheel, the first driven chain wheel and the second driven chain wheel. Each guider comprises a fixing rod and a guide sleeve; one end of each fixing rod is mounted on the fixing plate; each guide sleeve is mounted at the other end of the corresponding fixing rod; and the chain is connected with the guide sleeves in a sleeving mode. Guiding wheels are mounted on the third rotary shafts. The spinning efficiency is improved, the structure is quite compact, transmission is stable, and the system operation stability is quite high.

Owner:嘉兴正联纺织股份有限公司

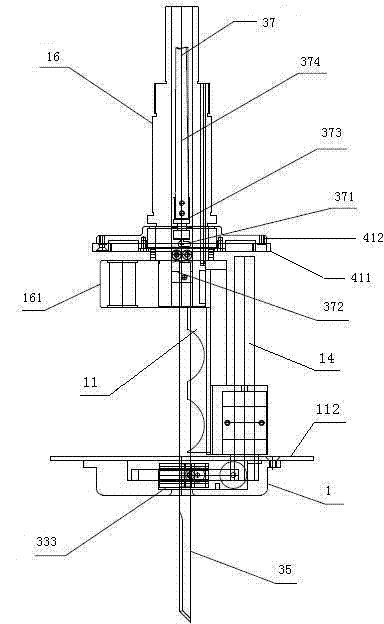

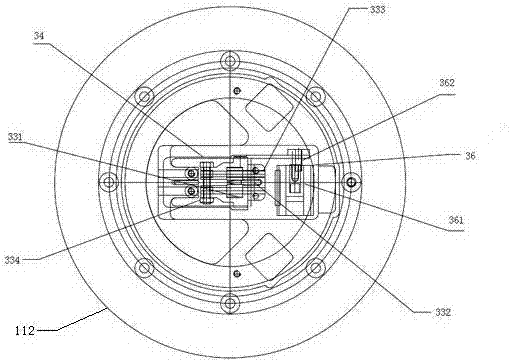

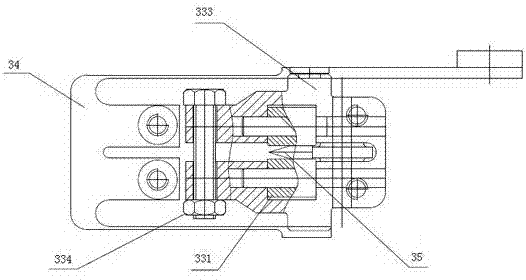

Automatic sampling device

ActiveCN107014641AEasy to installEasy to disassembleWithdrawing sample devicesControl engineeringElectric machinery

The invention discloses an automatic sampling device. The automatic sampling device comprises a sleeve and a sampling assembly, wherein the sleeve is internally provided with a liquid storage cavity and comprises an annular fixing assembly located at the upper part and an annular rotating assembly located at the lower part; an annular inward-sinking chute is formed in the inner wall of the bottom of the annular fixing assembly; an annular slide block is arranged on the outer wall of the top of the annular rotating assembly; a sample conveying pipe is arranged at the top of the annular fixing assembly, an exhausting assembly is further mounted on a sample storage device, multiple groups of driving motors are mounted on the outer wall of the annular rotating assembly, each group of the driving motors are connected with a lead screw elevator through threaded horizontal rotating rods, and a vertical lifting assembly is mounted on the lead screw elevator along the vertical direction; and the sampling assembly comprises a sampling pipe. By arranging the annular fixing assembly and the annular rotating assembly, the synchronous rotation of the sleeve, the sampling assembly and a stirring rotating shaft is realized, real-time sampling in a reaction process is realized, and the sampling efficiency is improved.

Owner:杭州鸿利机械制造有限公司

Nuclear power station large horizontal centrifugal pump king bolt stretching labor-saving device

PendingCN111702716AReliable disassemblyPrecise positioning and manipulationMetal-working hand toolsCentrifugal pumpRatchet

The invention belongs to the field of nuclear power station rotating equipment maintenance, and particularly relates to a nuclear power station large horizontal centrifugal pump king bolt stretching labor-saving device. The device comprises a sleeve arranged outside a pump shaft in a sleeving mode and a rotating support connected with the sleeve, wherein the rotating support rotates along with rotation of the sleeve, a ratchet structure is arranged outside the sleeve and fixedly connected with the rotating support, stretching cylinders are arranged at the two ends of the rotating support, whenthe sleeve rotates, the stretching cylinders can rotate along the circumference where a king bolt is arranged, rolling wheel supporting assemblies are arranged below the sleeve, the concentricity ofthe stretching cylinders at the ends of the rotating support and the king bolt is achieved by controlling the rotating position of a gear, and it is guaranteed that the king bolt is accurately alignedduring dismounting. According to the device, the device is simple in structure and convenient to operate for personnel, the labor intensity of maintenance personnel can be effectively reduced, the safety is improved, the irradiation time of the personnel is shortened, and the maintenance efficiency is improved.

Owner:JIANGSU NUCLEAR POWER CORP

Semi-trailer with accurate steering function

ActiveCN105059387ARealize synchronous rotationLow costSteering linkagesMechanical steering gearsVehicle frameEngineering

The invention belongs to the technical field of transport vehicles, and discloses a semi-trailer with an accurate steering function. The torque of a front-row wheel group and a back-row wheel group which are at the back part of a vehicle frame is transmitted in a gear transmission manner, synchronous rotation of the front-row wheel group and the back-row wheel group is realized, the synchronicity of the rotation of the front-row wheel group and the rotation of the back-row wheel group is ensured through the smoothness and the reliability of gear transmission and the accuracy of the torque, and the passing rate of steering is greatly increased; a driving arc rack and a driven arc rack are arranged, so that the semi-trailer is convenient to manufacture, the transmission effect can be ensured through rack structures, besides material cost can be reduced, a cumbersome gear structure is omitted, and the practicality is greatly improved.

Owner:YANG ZHOU VULCAN MACHINERY MFG CO LTD

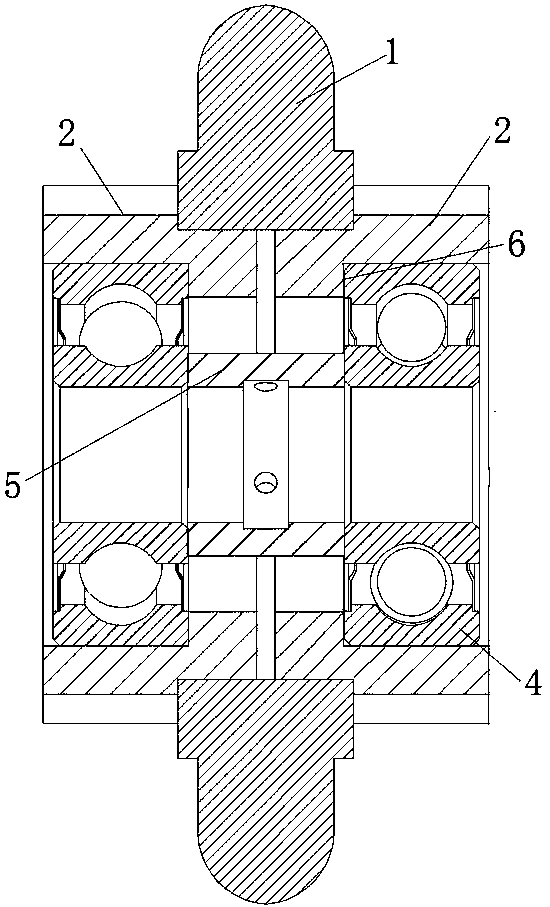

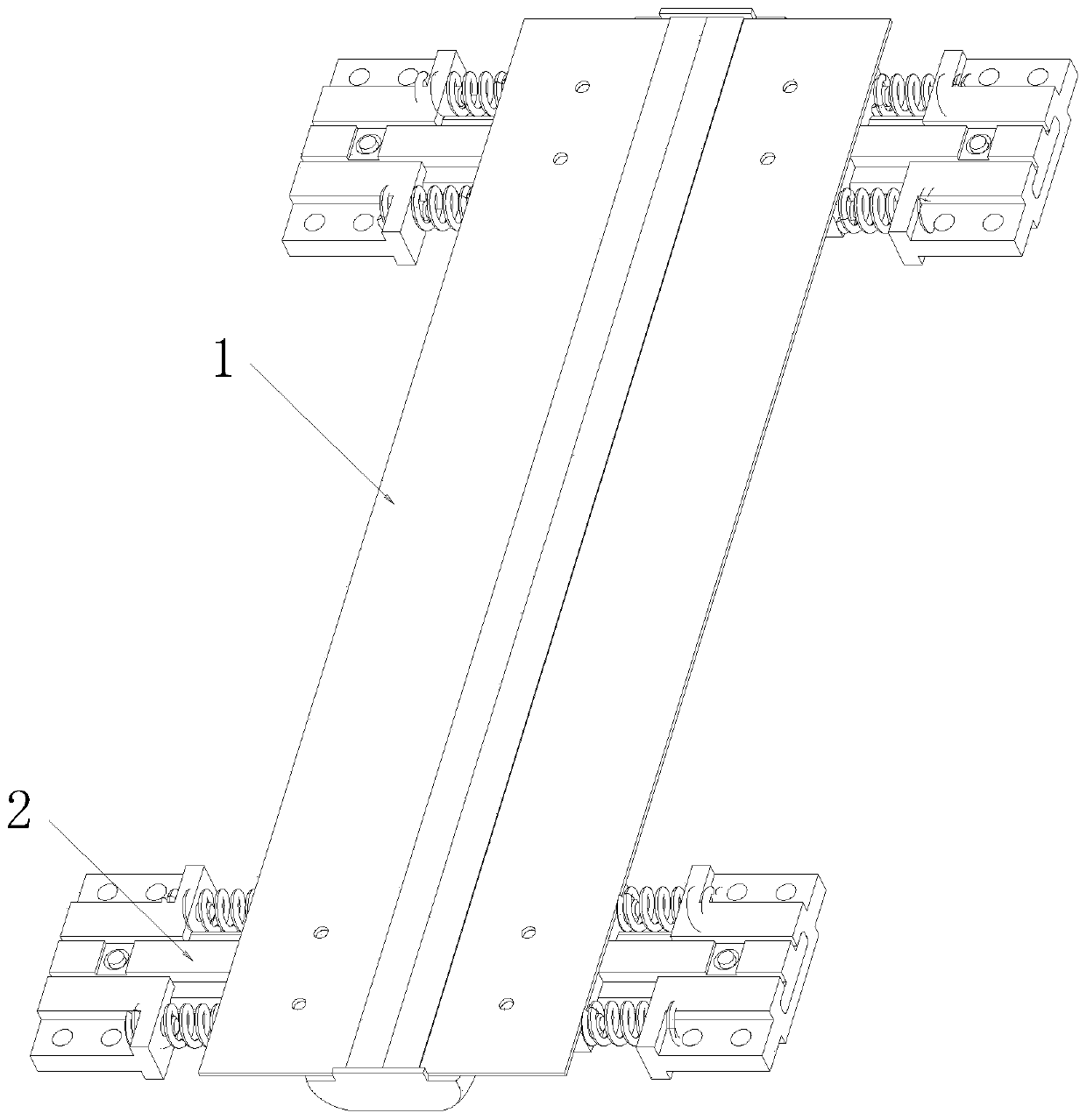

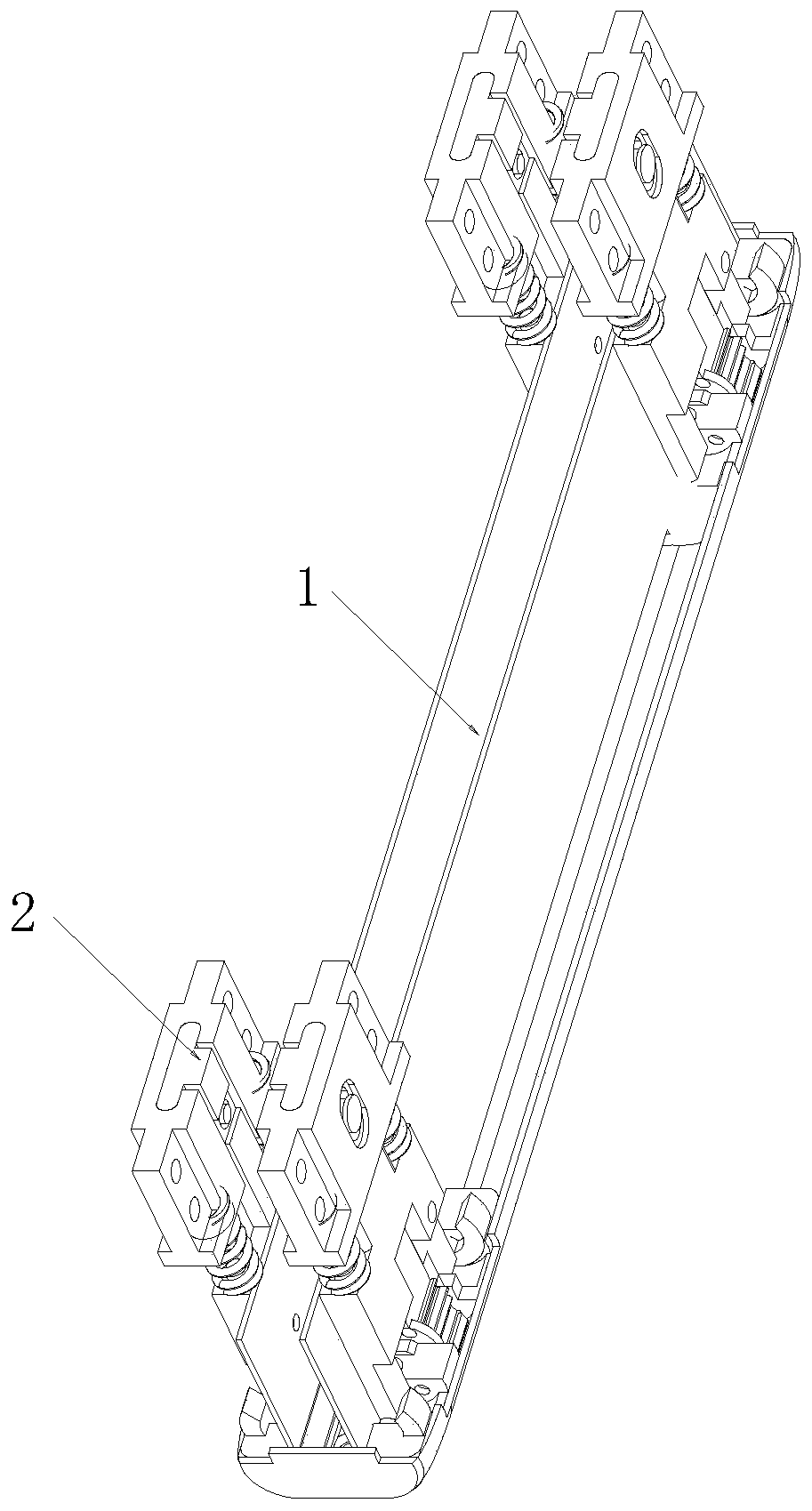

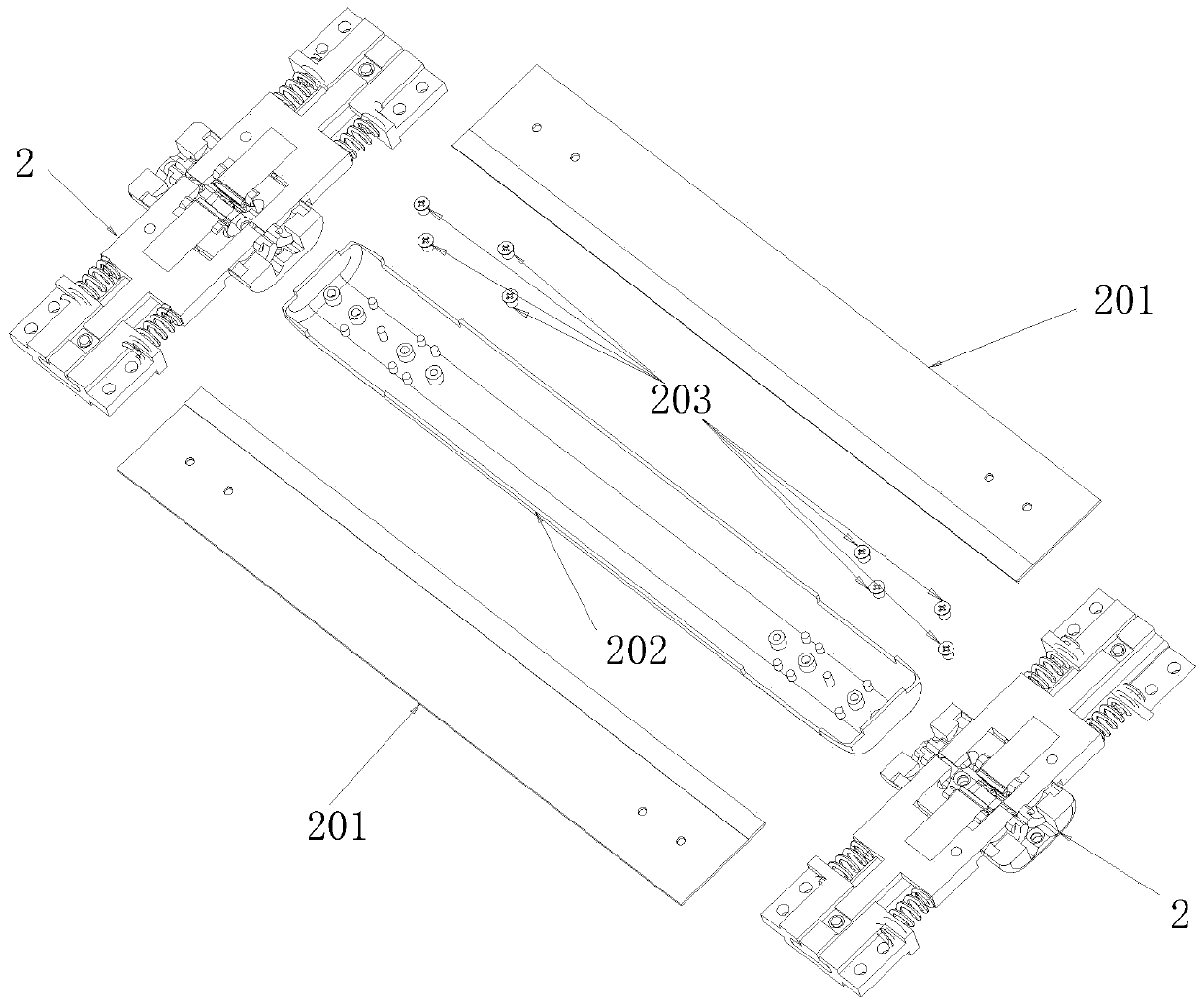

Wedge-shaped inward folding synchronous rotating mechanism

PendingCN109915475ASatisfy validityRealize buffer compensationPivotal connectionsGear wheelEngineering

The invention discloses a wedge-shaped inward folding synchronous rotating mechanism which comprises a packaging body and rotary shafts connected with the two ends of the packaging body respectively;each rotary shaft comprises a rotating shaft and compensating mechanisms arranged on the two sides of the rotating shaft respectively; each compensating mechanism comprises a sliding rail seat and a slider; each rotating shaft is composed of a middle gear group and rotating mechanisms at the two ends of middle gear group respectively; each rotating mechanism comprises a first rotating mechanism and a second rotating mechanism; each of the first rotating mechanisms and the second rotating mechanisms is provided with multiple semi-circular arc moving blocks; each first rotating mechanism furthercomprises an elastic block; each second rotating mechanism further comprises two groups of positioning pins for realizing positioning and clamping of 0-degree and 180-degree positions and finishing self-locking; each positioning pin is provided with a spring; the compensating mechanisms and the rotating mechanisms realize connection positioning through connection of semi-circular arc pipe positions and provide damping and torsion of synchronous rotation, a mechanism is bent along a spindle self, a double-side rotating circle center is arranged at the joint of the upper end of each rotary shaft and a screen, and in the rotating process, each screen sinks into the middle part of the corresponding rotating shaft to realize compensation buffering.

Owner:DONGGUAN JINFENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com