Surrounding type welding device for water conservancy pipeline machining and welding technology of surrounding type welding device

A technology of welding device and welding process, which is applied in the field of surrounding welding device and its welding process, which can solve the problems that welding slag is easy to affect sliding, the welding quality is difficult to observe due to heavy smoke, and welding slag splashes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

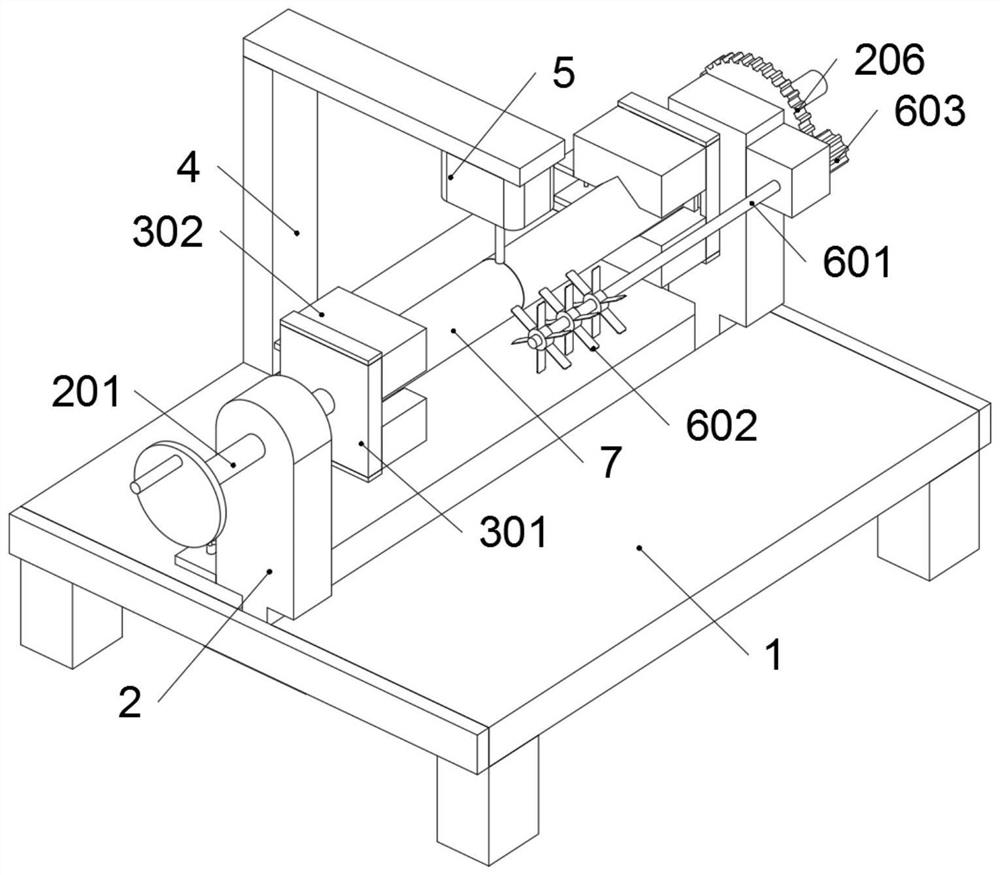

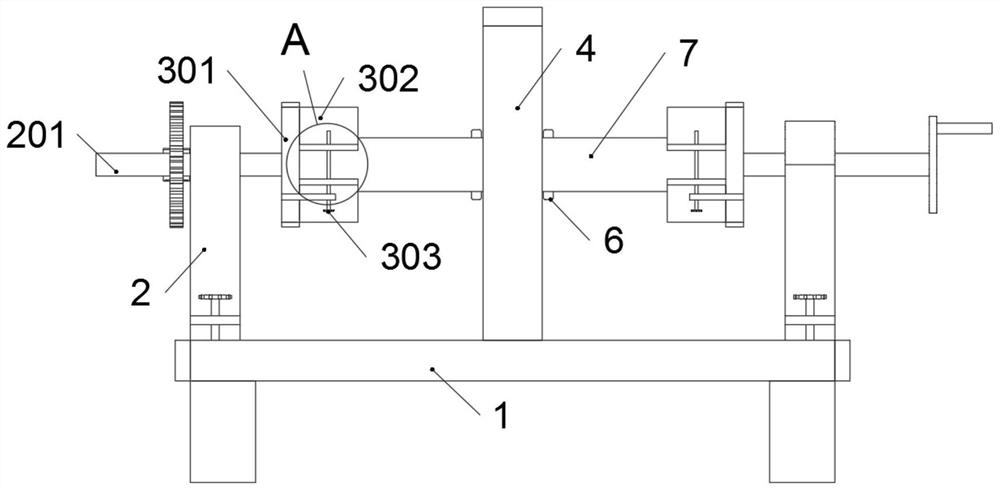

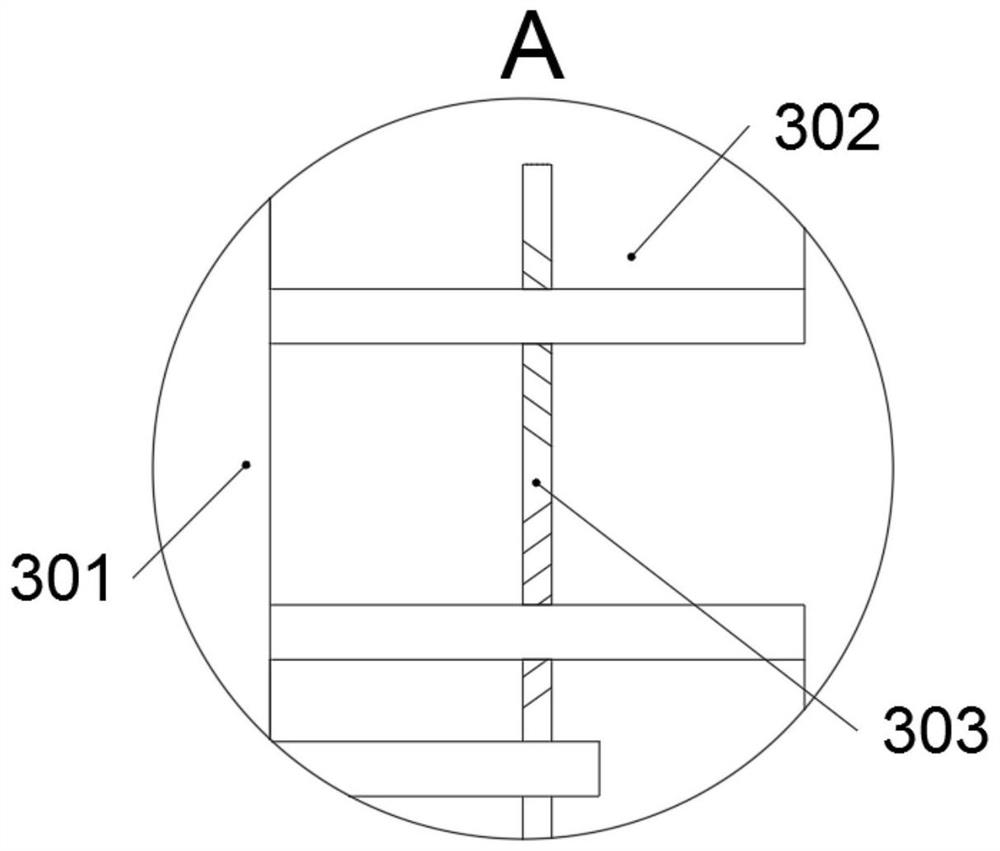

[0045] as attached figure 1 to attach Figure 8 Shown:

[0046] The present invention provides an encircling welding device and welding process for water conservancy pipeline processing, including a base 1; the base 1 is placed on the ground, and two bases 2 are installed on the base 1; refer to Figure 6 , the seat body 2 includes: a rotating shaft 201, which is rotatably connected to the seat body 2, and a handle is installed on the rotating shaft 201, and the rotating shaft 201 is connected to the clamping seat 301 by welding, so that the axial rotation of the pipe material 7 can be realized when the handle is turned , and then meet the requirements of annular welding; two sleeves 202, two sleeves 202 are provided, and the two sleeves 202 are respectively sleeved on the two rotating shafts 201, and the two sleeves 202 are threadedly connected with a fixing bolt 203, so that the fixing of the extension length of the sleeve 202 can be realized; a groove 204 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com