Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Avoid swiping again" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

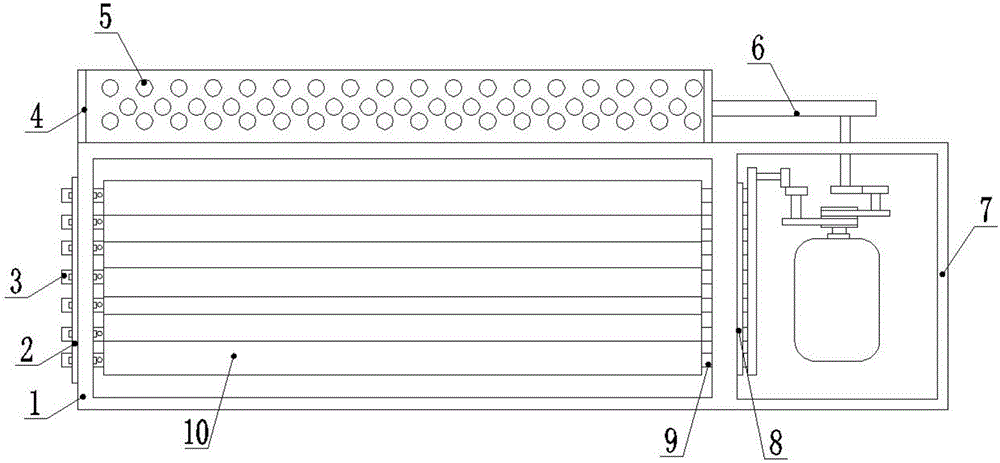

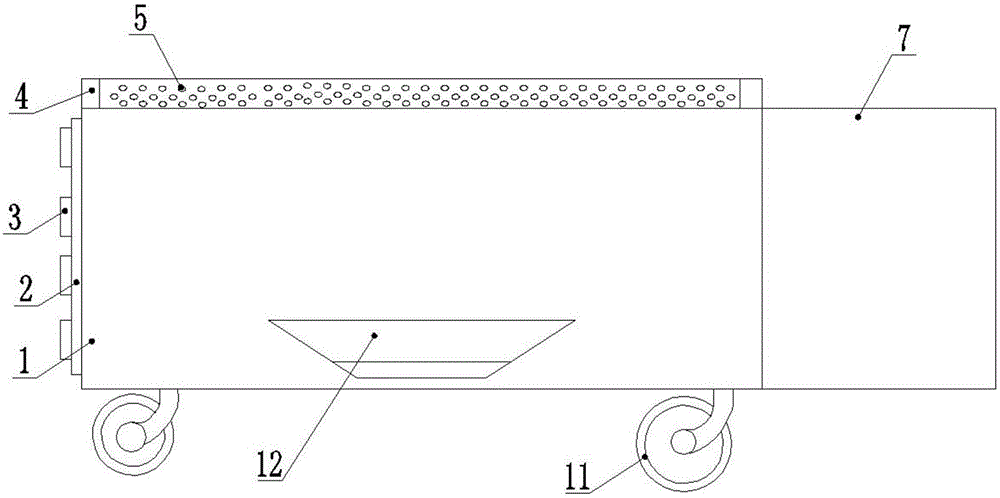

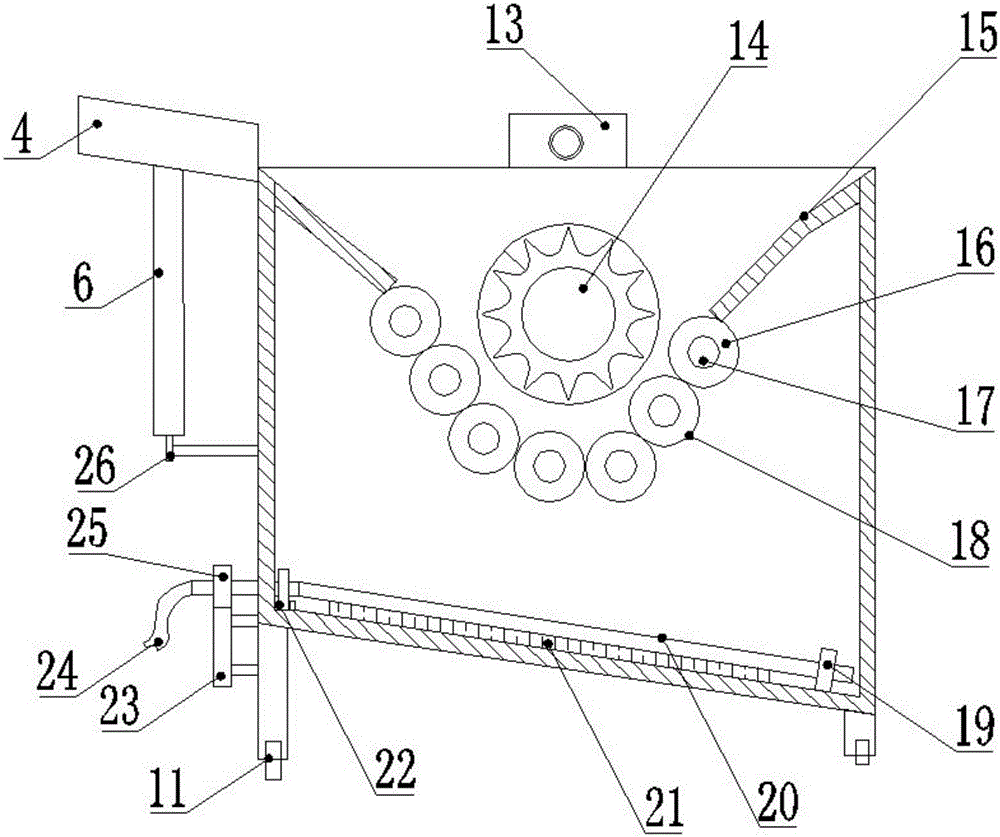

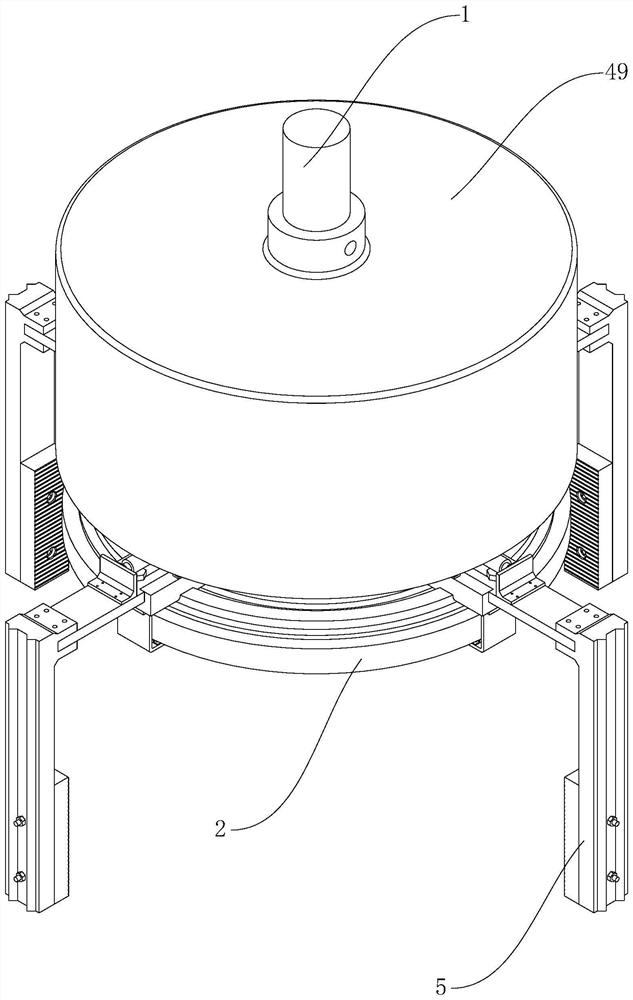

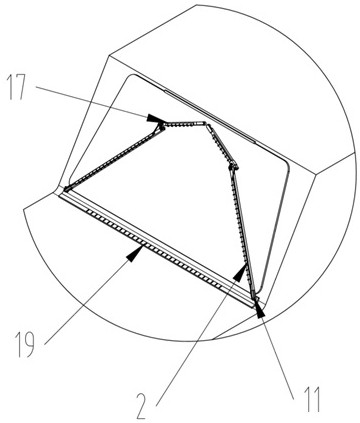

Walnut cleaning machine

The invention relates to a walnut cleaning machine. The walnut cleaning machine comprises a cleaning box and a transmission box, a fixation device is arranged on the opposite side walls of the cleaning box, the fixation device comprises first bearing seats and second bearing seats, a first bearing is installed in each first bearing seat, a sliding key is fixed on the inner wall of each first bearing, a key groove is formed in each first rotating shaft in the axial direction, and the sliding keys are installed in the corresponding key grooves in a sliding mode; a first core hole is formed in one end of each first rotating shaft, a second rotating shaft is rotatably installed in each second bearing seat, a second core hole is formed in one end of each second rotating shaft, and the first core holes and the second core holes are all regular polygon holes; a brush roller is installed in each first core hole and the corresponding second core hole; a cleaning device is arranged on the lower sides of the brush rollers, a locking device is arranged between each first rotating shaft and the corresponding roller body, and a screening device is arranged in the cleaning box. According to the walnut cleaning machine, replacing of brush rollers is easy, the assembling precision of a machine is not affected, and the cleaning effect on walnuts is good.

Owner:李志雄

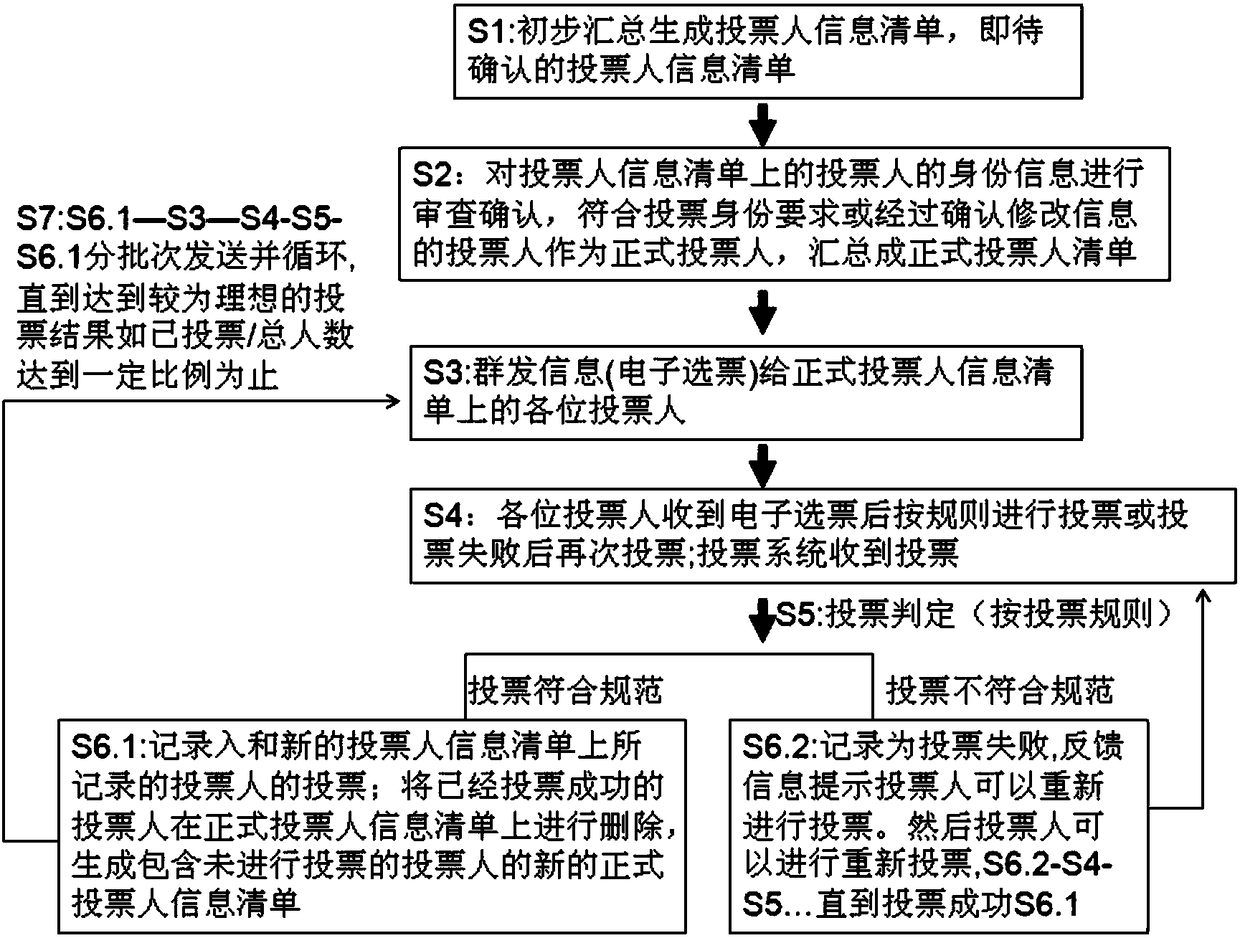

Electronic voting method

PendingCN108280921AHigh precisionIncrease credibilityVoting apparatusSensing by electromagnetic radiationTime basedStatus changed

The invention discloses an electronic voting method. The method comprises the steps of checking a list of information of voters in a certain way, and generating an official voter information list after the list is verified to be accurate; the method emphasizes the pre-checking of the identity attribute of the voters, thus avoiding the phenomenon that due to the change of the identity attribute ofthe voters in reality, the voters who should have the right to vote are unable to vote, enhancing the accuracy and credibility of voting, and avoiding the creation of invalid votes; furthermore, the method comprises the steps of automatically screening a new list of un-voted people, and performing accurate group push for a plurality of times based on the new list of the un-voted people and votingresult judgment, thus helping to correct the voting errors of the voters, and increasing the voting efficiency and the voting proportion. In addition, a closed electronic voting system with a functionof examining identity is provided; the votes of people excluded in the official voter list or the votes of people who are not subjected to identity examination are considered as invalid, so that voting for oneself is avoided, and the generation of invalid votes is also avoided.

Owner:合肥诺优信息科技有限公司

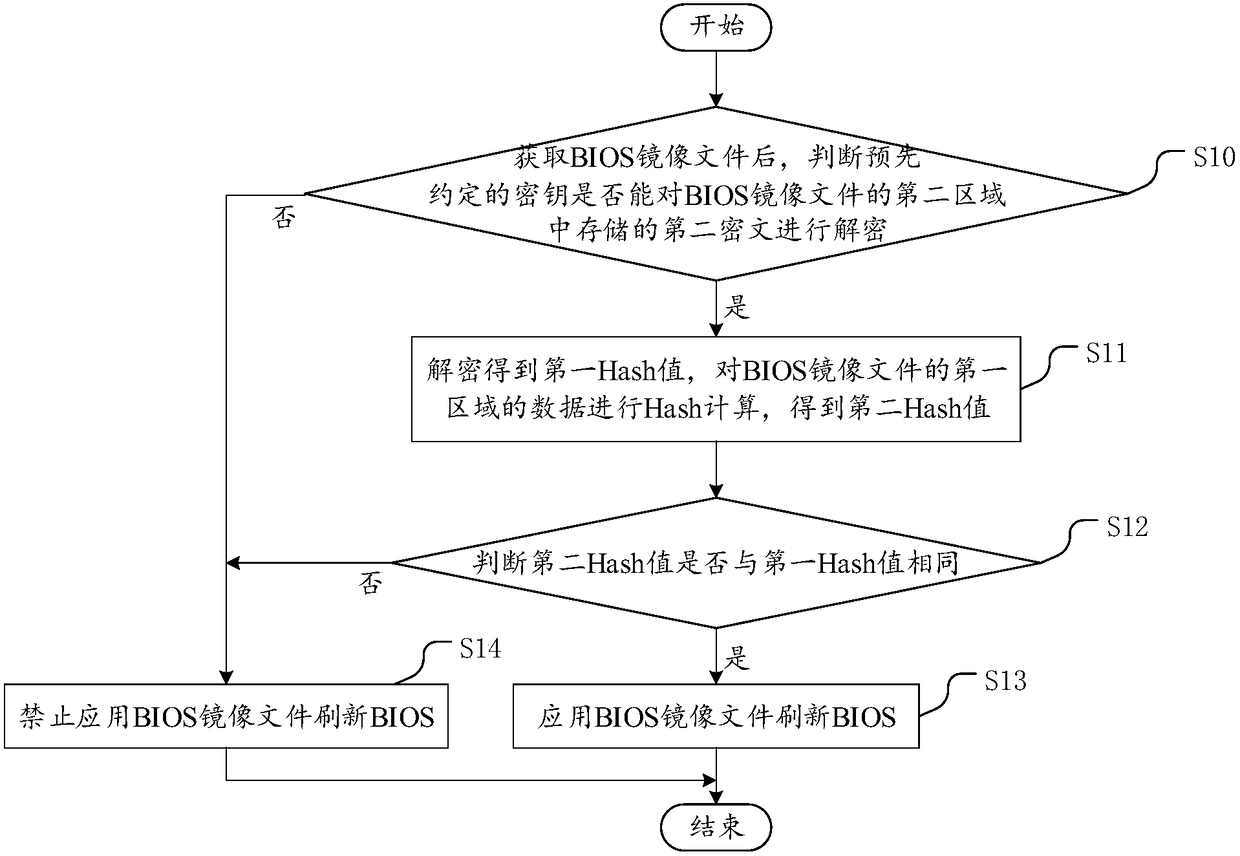

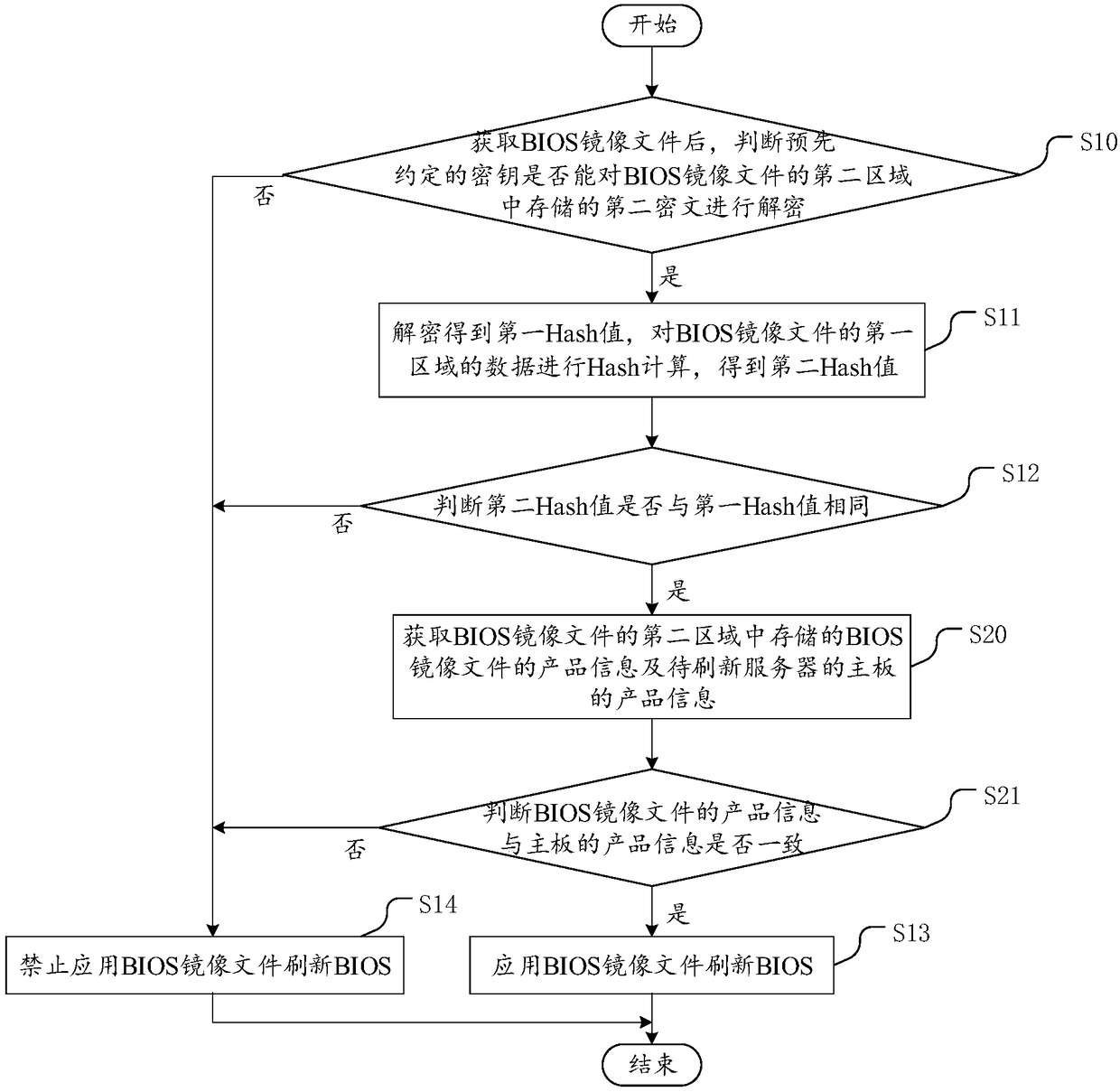

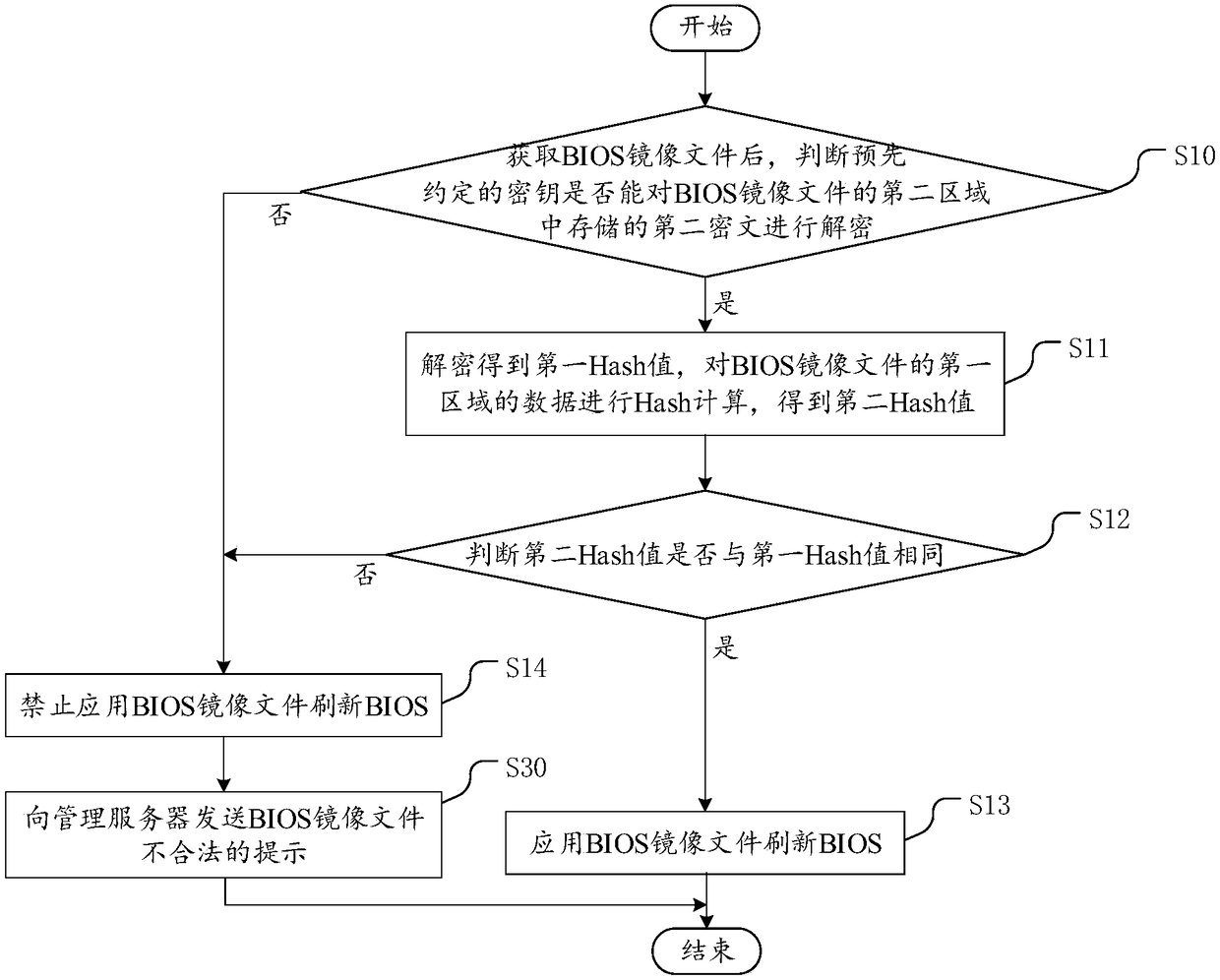

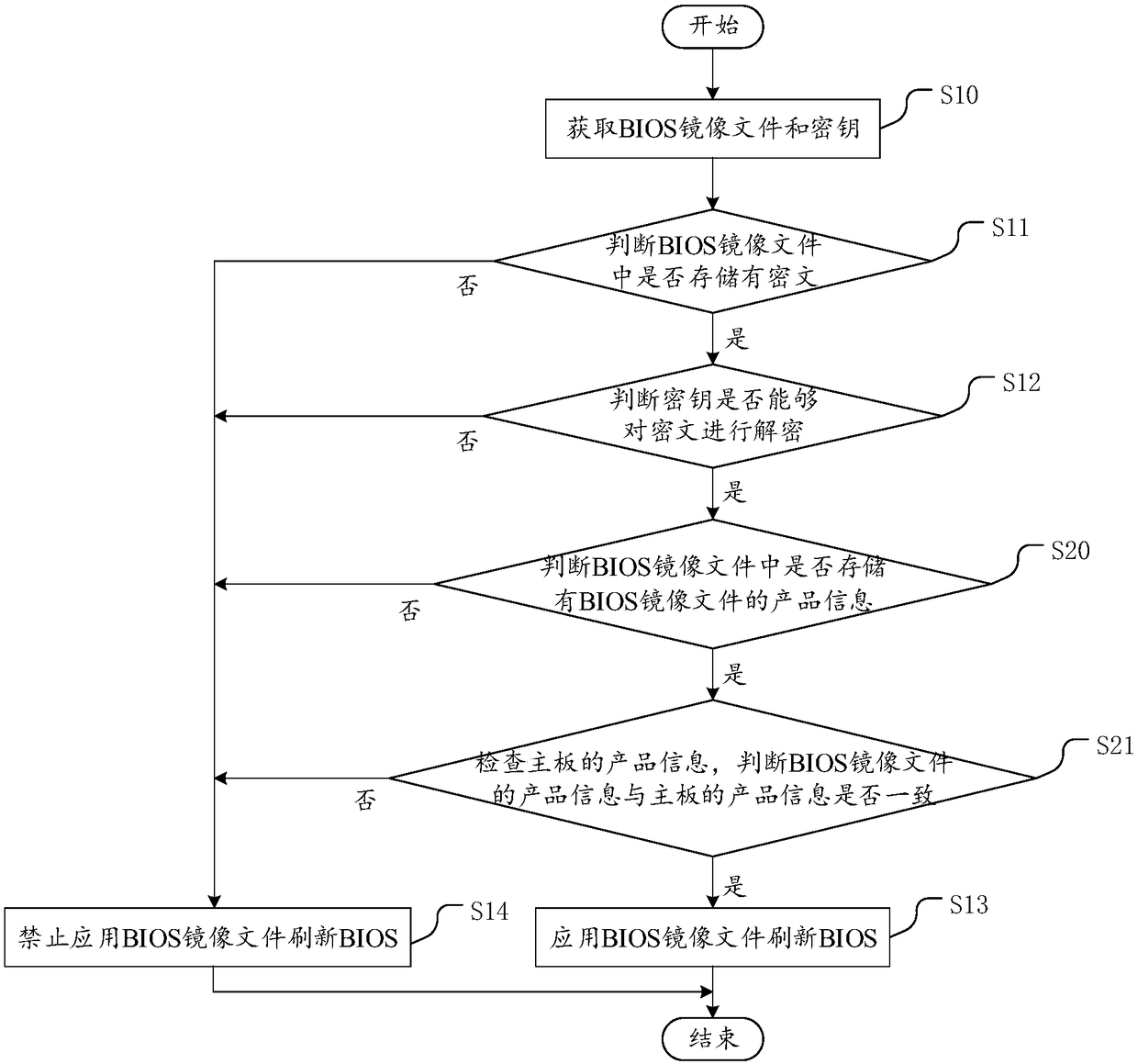

Device and method for verifying BIOS (basic input output system) integrality in out-of-band BIOS refreshing

InactiveCN108256355AAvoid swiping againImprove securityDigital data protectionBootstrappingTransfer procedureCiphertext

The invention discloses a method for verifying BIOS (basic input output system) integrality in out-of-band BIOS refreshing. The method is applied to a substrate management controller and includes: after acquiring a BIOS mirror image file, judging whether a second ciphertext stored in the BIOS mirror image file can be decrypted by a pre-determined secret key or not, and if yes, further judging whether a first Hash value obtained by decryption is identical to a second Hash value generated by data calculation in a first area of the BIOS mirror image file or not. Compared with the prior art in which whether the BIOS mirror image file is completed or not is judged only through a check code generated by an original BIOS mirror image file, the method has advantages that by twice judgment, high safety is realized, the problem of failure in server starting after refreshing of the BIOS mirror image file due to the fact that the BIOS mirror image file along with the check code is maliciously tampered in a transmission process is avoided, safety in out-of-band BIOS refreshing is improved, and smoothness in server operation is realized. The invention further provides a device for verifying BIOSintegrality in out-of-band BIOS refreshing and a computer readable storage medium.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

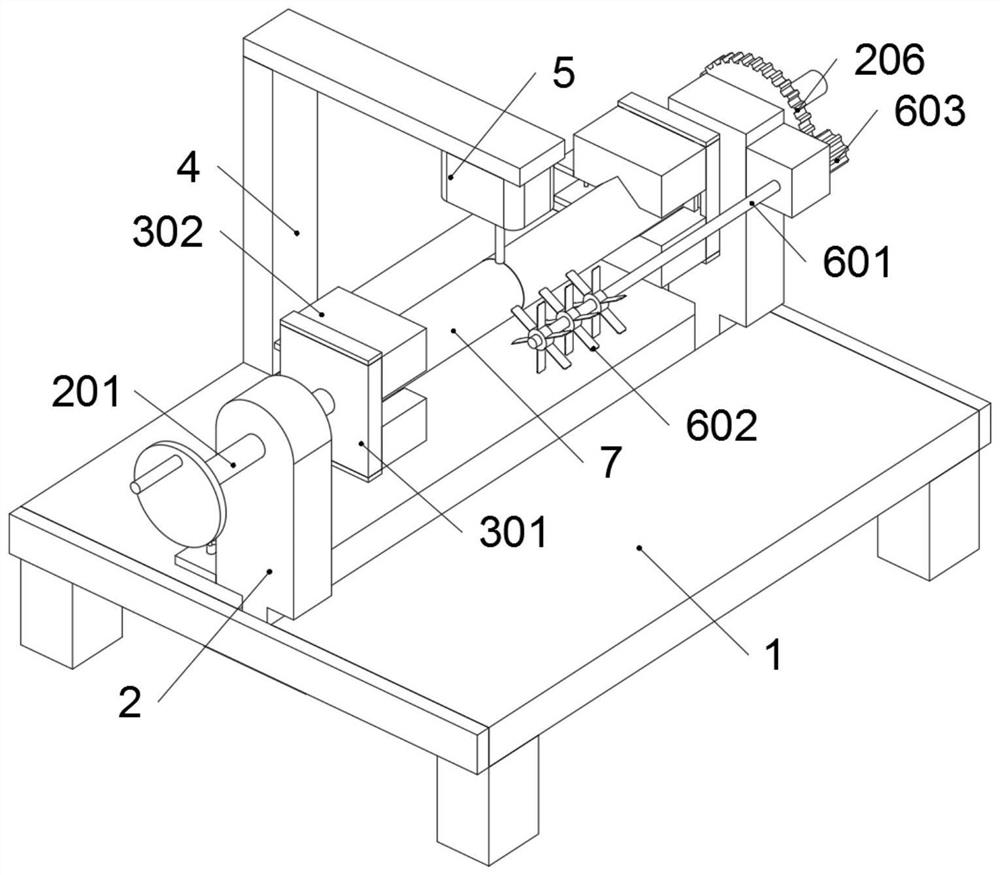

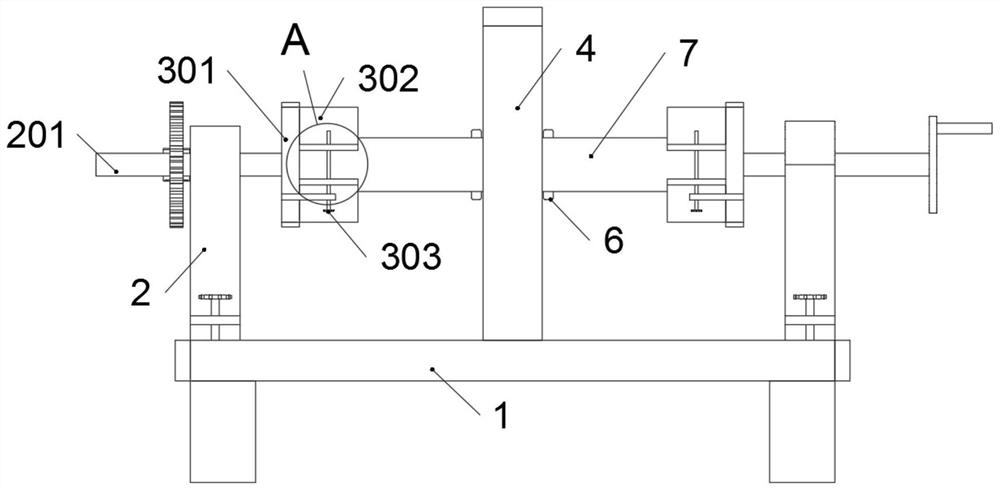

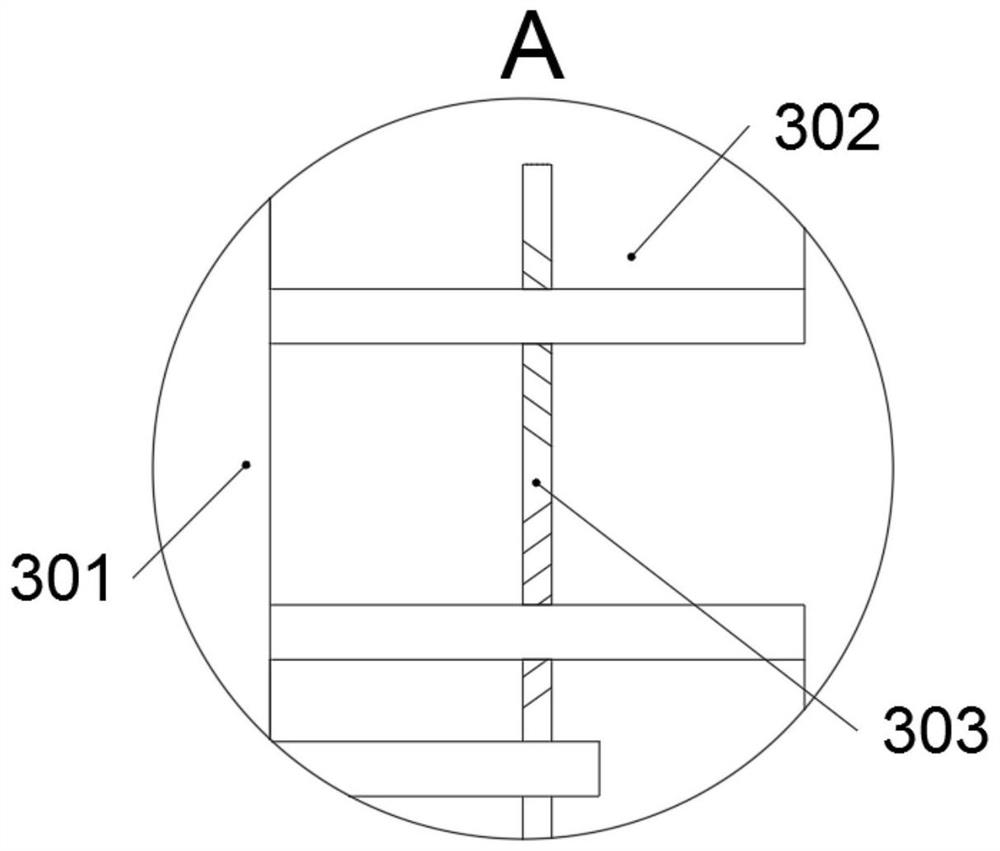

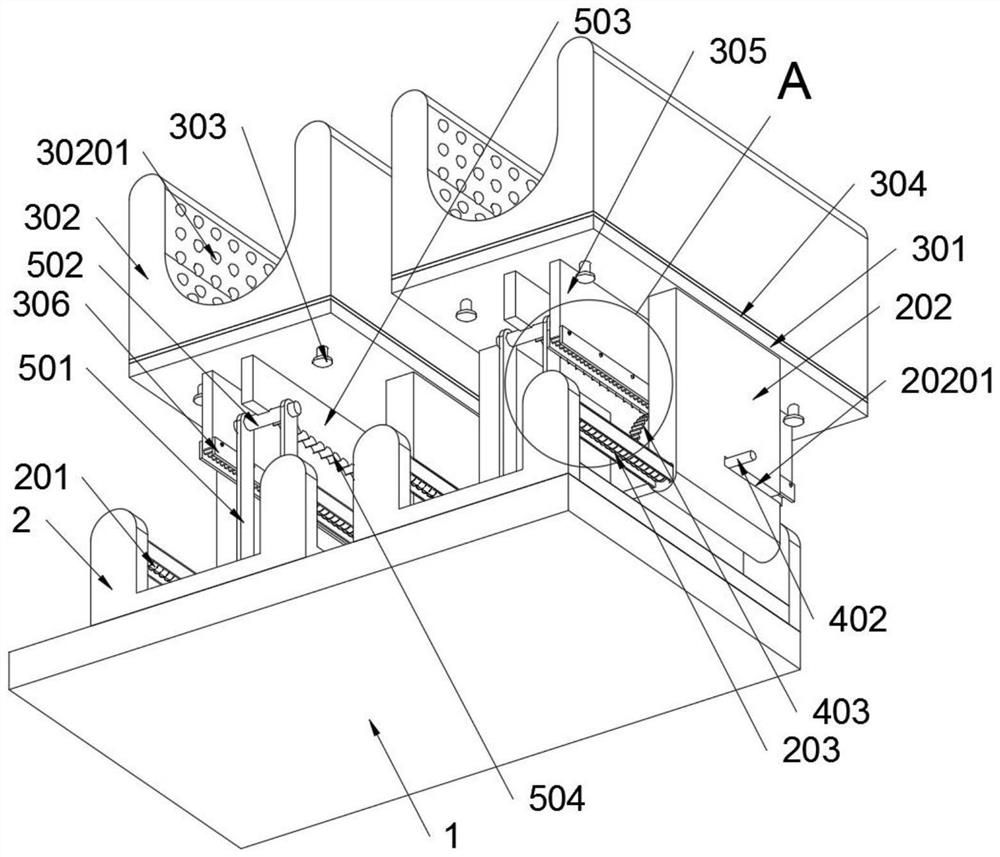

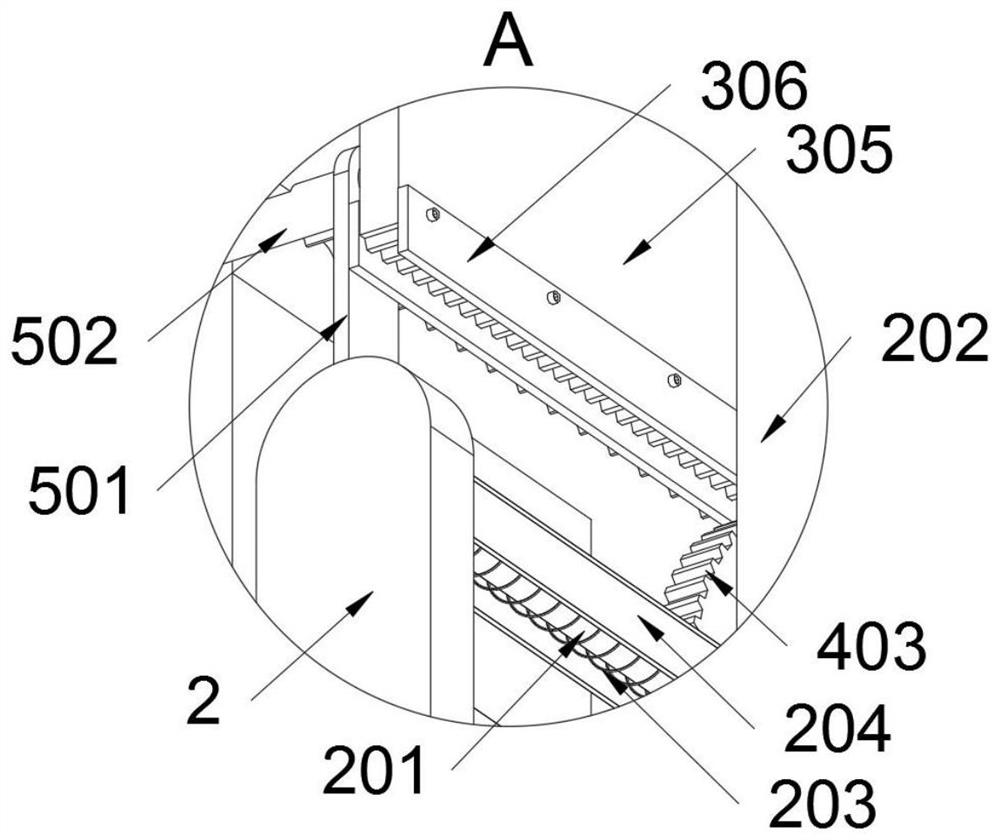

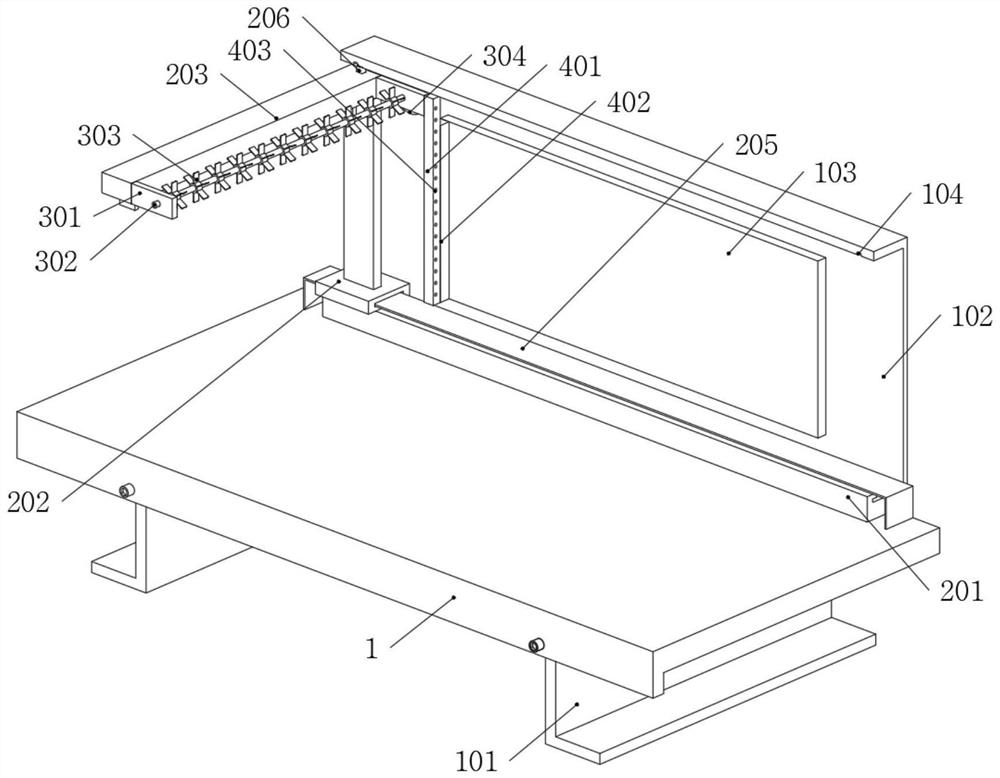

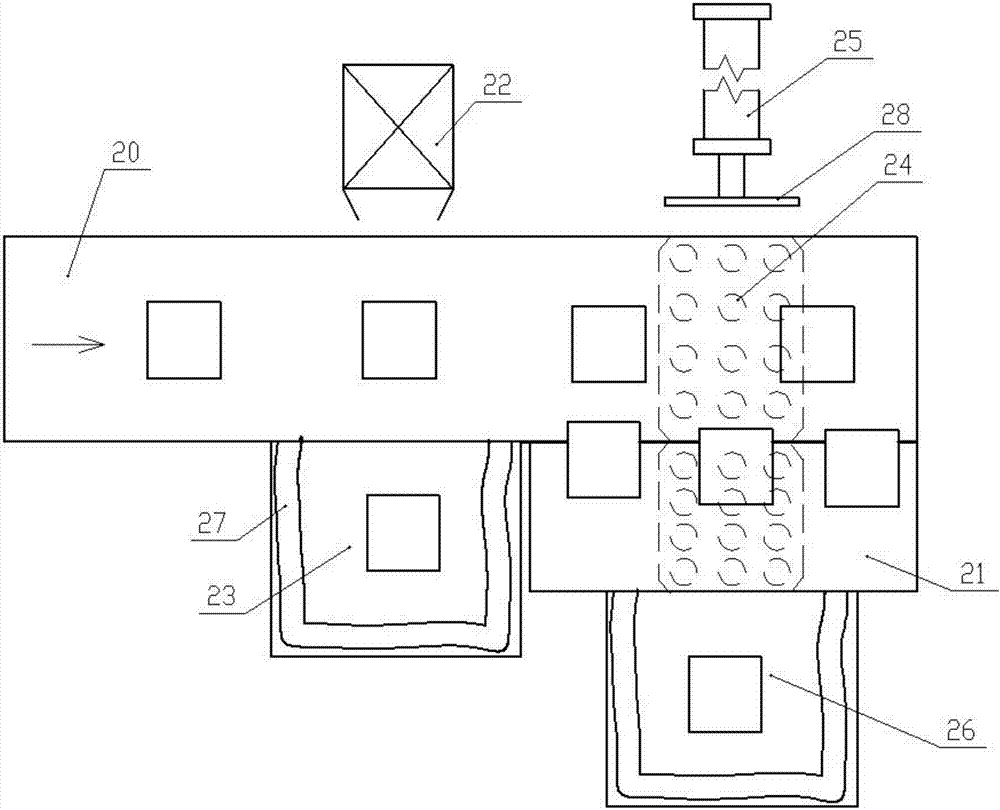

Surrounding type welding device for water conservancy pipeline machining and welding technology of surrounding type welding device

PendingCN113579591AAutomatic blowingRealize synchronous rotationWelding/cutting auxillary devicesAuxillary welding devicesButt jointGear wheel

The invention provides a surrounding type welding device for water conservancy pipeline machining and a welding process of the surrounding type welding device, and relates to the technical field of welding devices. The problems that although an existing device can achieve annular welding, the cooling effect at a welding seam position is slow, and the welding quality is difficult to observe due to large smoke in the welding process are solved. According tp the surrounding type welding device for water conservancy pipeline machining and the welding process of the surrounding type welding device, the device comprises a base, the base is placed on the ground, a rotating shaft is rotatably connected to a seat body, three blades are installed on the rotating shaft, and the blades are aligned to butt joint positions of two pipes; a gear A is mounted on the rotating shaft; and a gear B is installed on the rotating shaft and meshes with the gear A, and the gear ratio of the gear B to the gear A is 5: 1, so that cooling and smoke blowing can be automatically achieved in the annular welding process.

Owner:郭林平

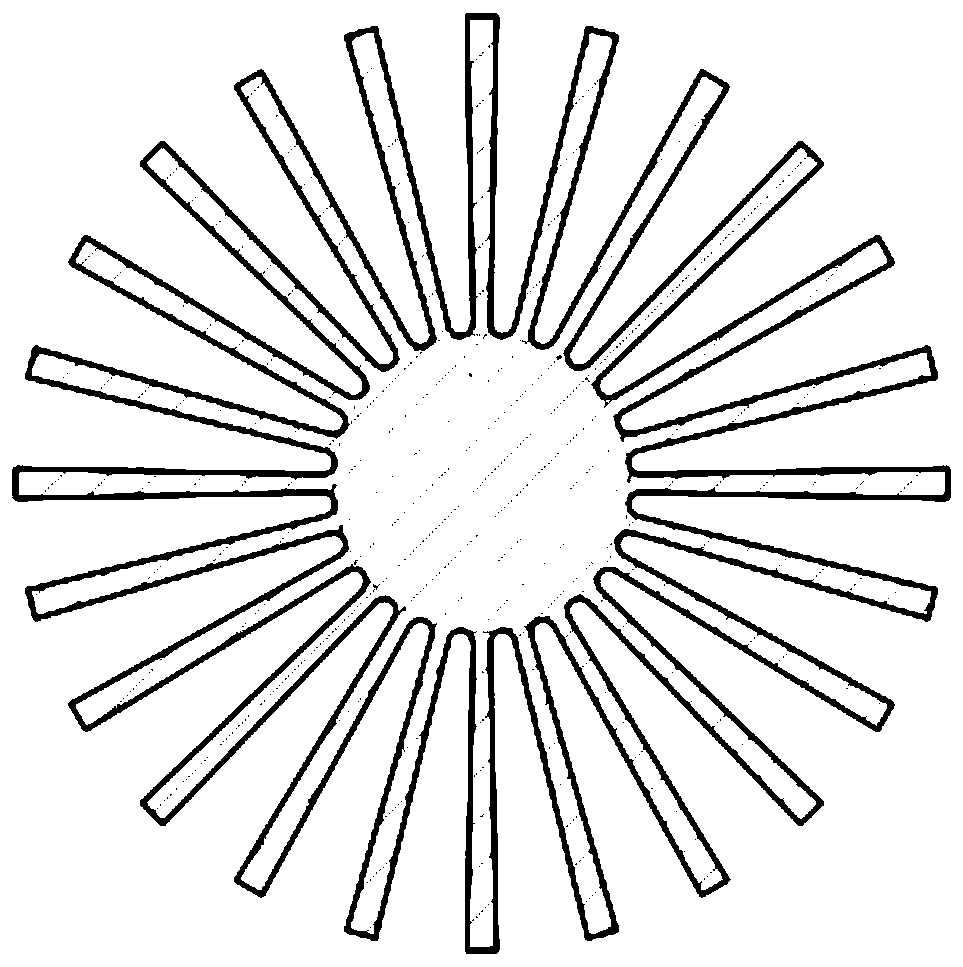

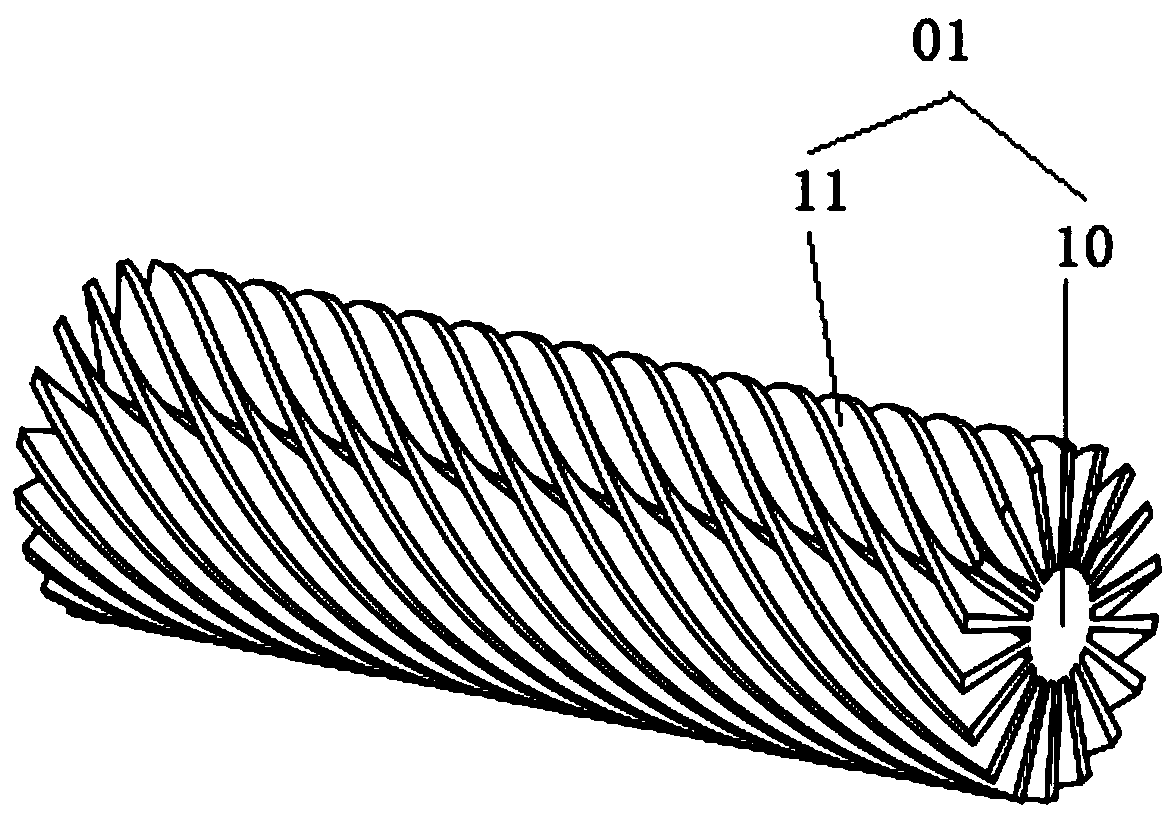

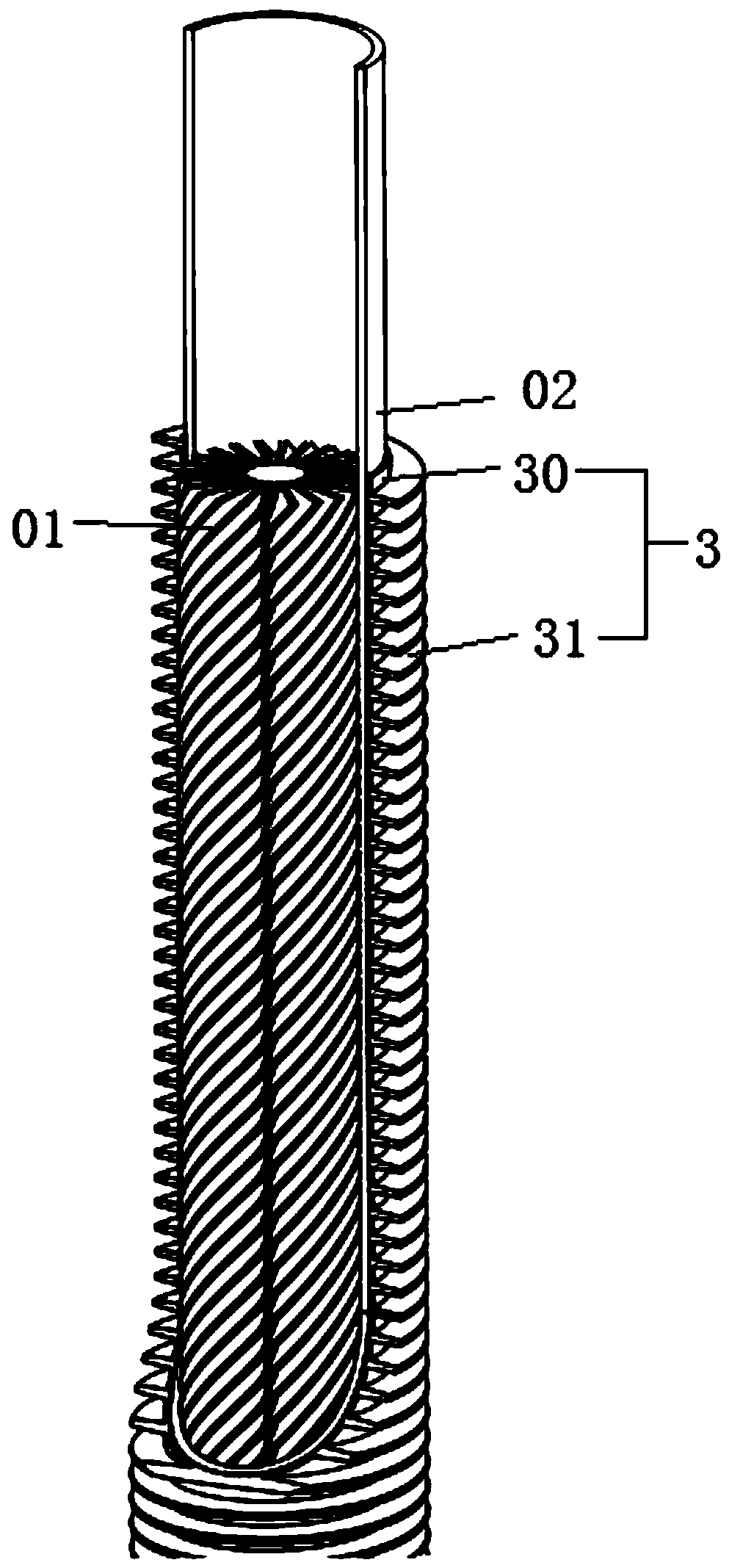

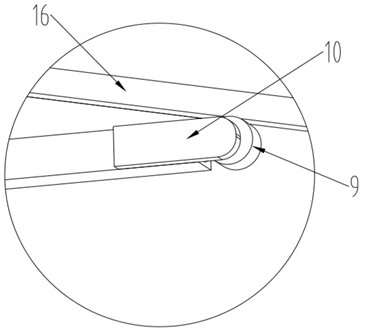

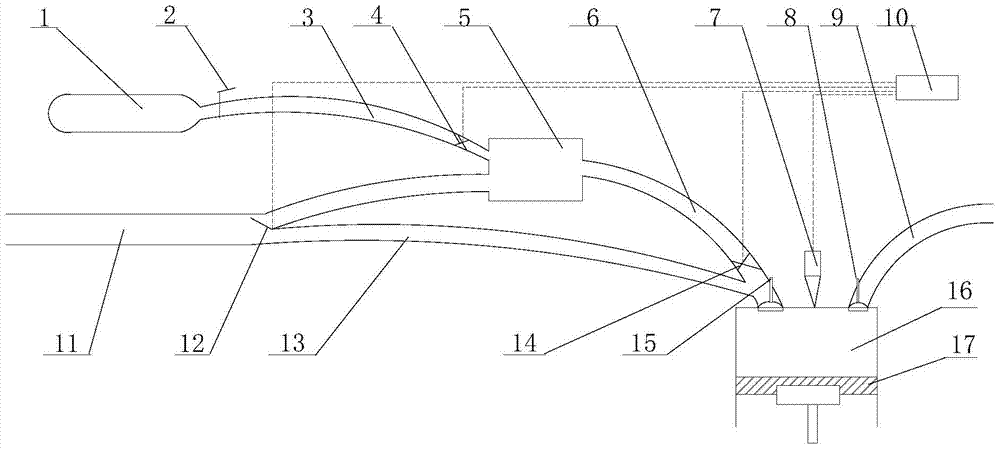

Outer fin heat exchange tube with spiral inner core and manufacturing method of outer fin heat exchange tube

InactiveCN111322899ATube length unlimitedAvoid swipingTubular elementsEngineeringMechanical engineering

The invention provides an outer fin heat exchange tube with a spiral inner core, and relates to the technical field of heat exchange. The manufacturing method comprises the following steps of S1, acquiring the spiral inner core: (1) processing into a longitudinal fin profile by adopting a hot extrusion way; and (2) applying rotational torque to the profile extruded at a constant speed through a rotation-shearing tool according to a rotational speed corresponding to a designed screw pitch while the profile is relatively hot and easy to deform, so that a longitudinal fin is spirally deformed toobtain the spiral inner core; S2, compounding the spiral inner core and a base tube: (1) obtaining a cored base tube by a thermal expansion and cold contraction or rolling compounding method; and S3,compounding the cored base tube and an outer fin sleeve: (1) manufacturing an outer sleeve by adopting a hot extrusion way; (2) performing contact-type inserting of the cored base tube in the outer sleeve when the outer sleeve is relatively hot and the internal diameter of the outer sleeve is relatively large, and compounding the outer sleeve and the cored base tube when the outer sleeve is subjected to thermal expansion and cold contraction; and (3), extruding the outer fin on the outer sleeve to manufacture the outer fin heat exchange tube with the spiral inner core. The outer fin heat exchange tube with the spiral inner core overcomes the defects that in the prior art, the length of a corrugated inner fin of a heat exchange tube is limited, trash needs to be cleaned in soldering, the production cost is high, the cycle is long, and the application range is limited.

Owner:香港环能有限公司

Protective device for hot galvanizing technology

InactiveCN108772259AImprove the disadvantages of low work efficiencyShorten the timeLiquid surface applicatorsCoatingsArchitectural engineering

Owner:安徽省庐峰镀锌有限公司

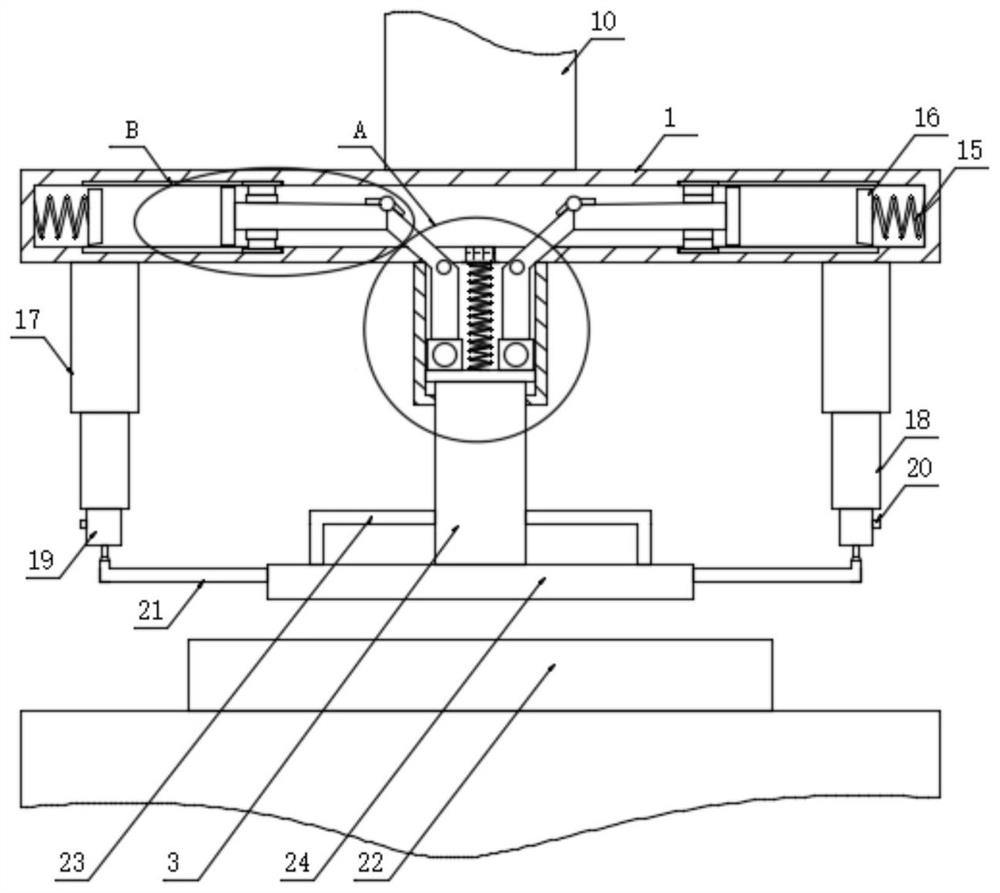

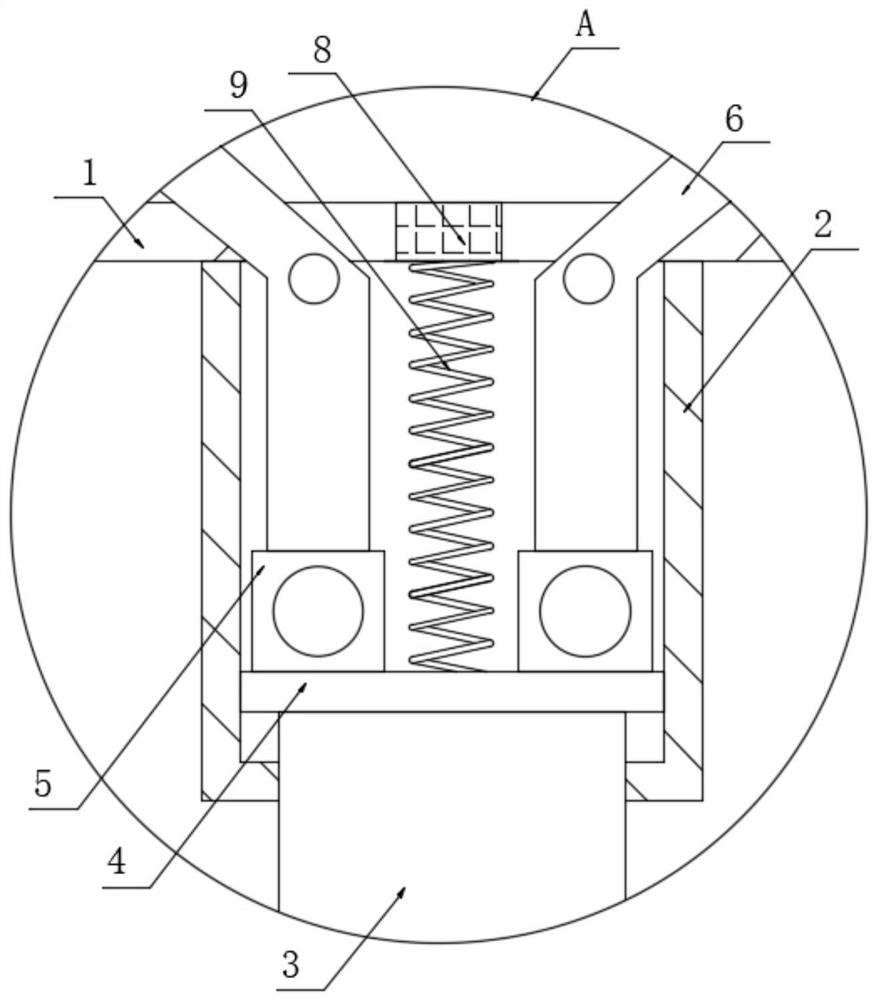

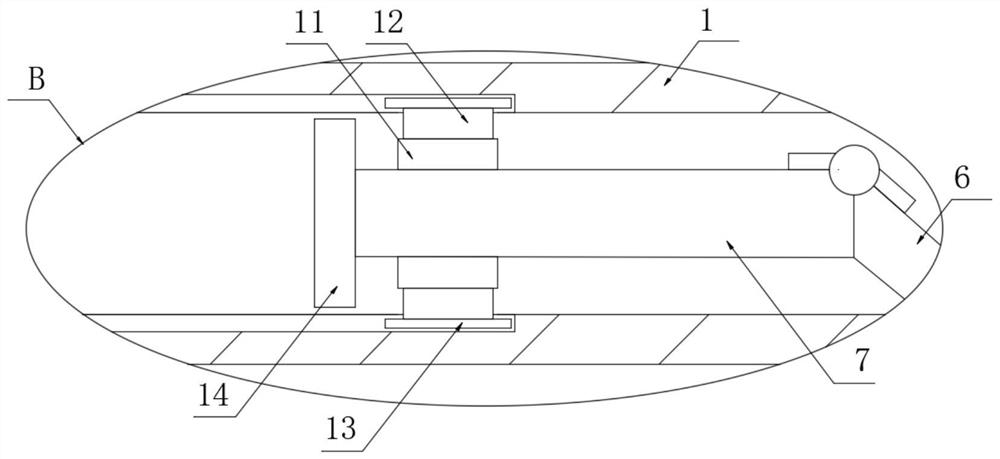

Sports training-based device for quickly relieving shank muscles after sprint

InactiveCN111743745ARealize reciprocating friction massageReduce frictional resistanceVibration massageSuction-kneading massageLeg muscleEngineering

The invention provides a sports training-based device for quickly relieving shank muscles after sprint, relates to the technical field of sports training auxiliary equipment, and solves the problem that leg muscles cannot be vibrated and relaxed in a linkage manner while a relaxing structure reciprocates to rub and relax and the problem that when a foreign object collides with a sliding rod, the sliding rod is easily deformed, so that the normal sliding is influenced. The sports training-based device for quickly relieving shank muscles after sprint comprises a base and a protective tile, the base is fixedly connected with two main body seats through bolts, and each main body seat is fixedly connected with a placement structure through a bolt. The protective tile is of a concave structure,the outer wall of the protective tile is not in contact with the inner wall of a sliding hole B, and the gap distance between the outer wall of the protective tile and the inner wall of the sliding hole B is 0.5cm, so that normal sliding of the sliding seat is not affected after the protective tile is slightly deformed due to contact between a foreign object and the outer wall of the protective tile.

Owner:徐夕丰

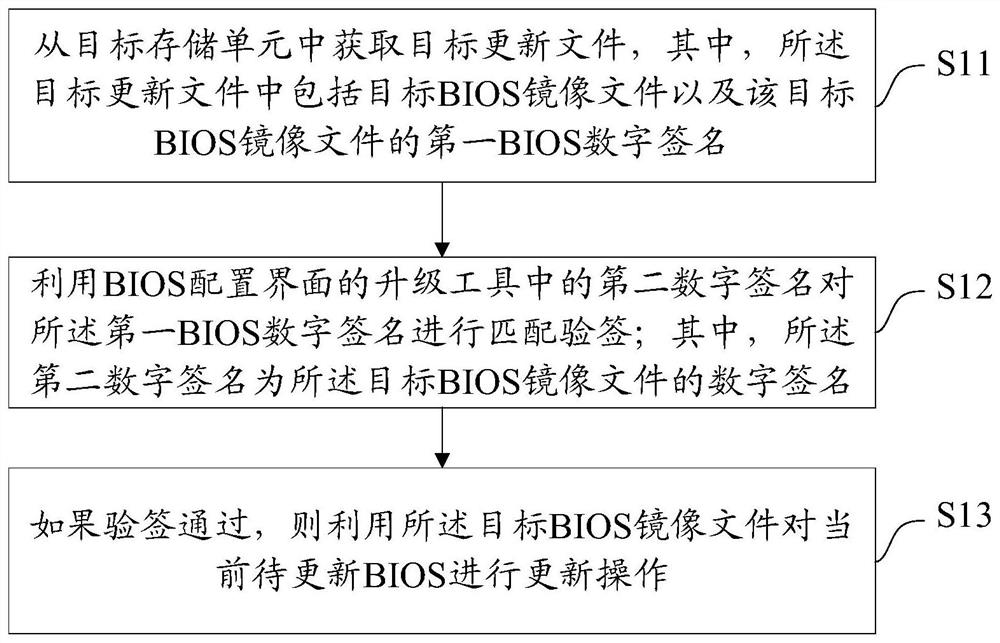

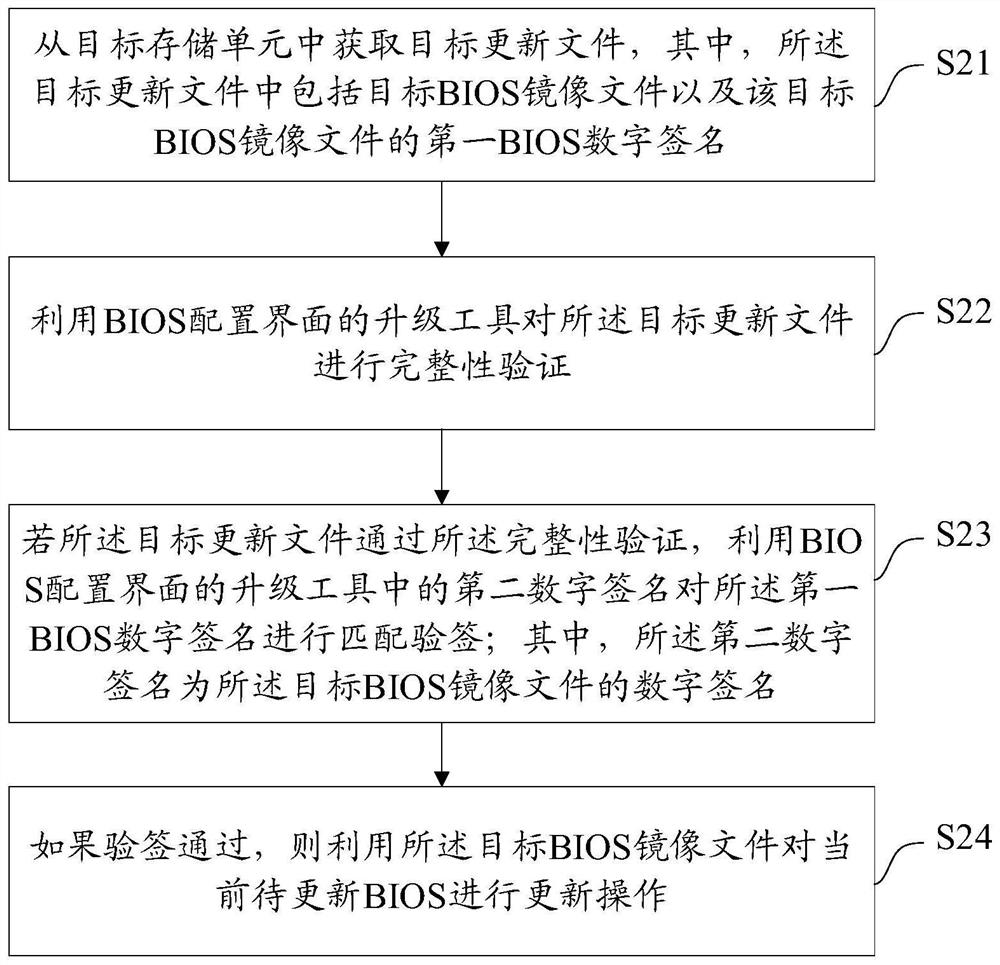

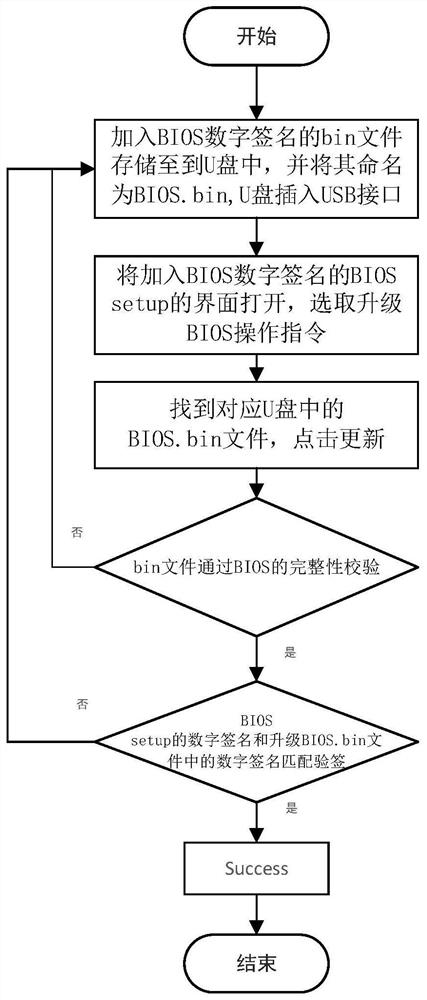

BIOS updating method and device, equipment and medium

PendingCN112507343AEnsure safetyUniqueness guaranteedPlatform integrity maintainanceDigital signatureMirror image

The invention discloses a BIOS updating method and device, equipment and a medium, and the method comprises the steps: obtaining a target updating file from a target storage unit, wherein the target updating file comprise a target BIOS mirror image file and a first BIOS digital signature of the target BIOS mirror image file; performing matching signature verification on the first BIOS digital signature by utilizing a second digital signature in an upgrading tool of a BIOS configuration interface, wherein the second digital signature is a digital signature of the target BIOS mirror image file;and if the signature verification is passed, updating the current BIOS to be updated by utilizing the target BIOS mirror image file. Thus, the second digital signature in the upgrading tool of the BIOS configuration interface is used for verifying the signature of the obtained target BIOS mirror image file, the safety and uniqueness of the obtained target BIOS mirror image file are guaranteed, other mirror image files can be prevented from being swiped in the BIOS updating process, and therefore the safety of BIOS updating is guaranteed.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

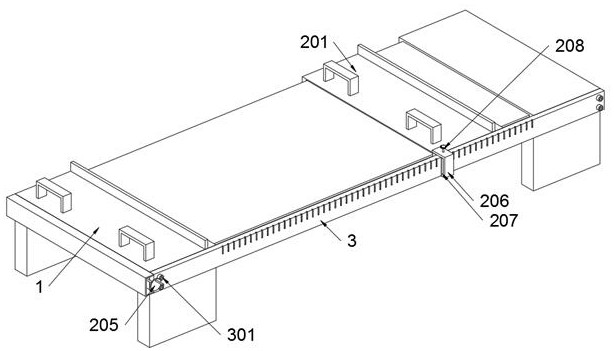

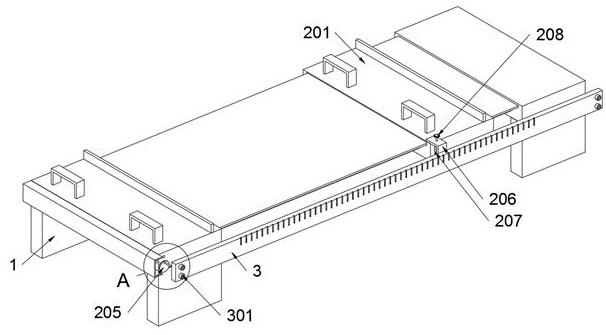

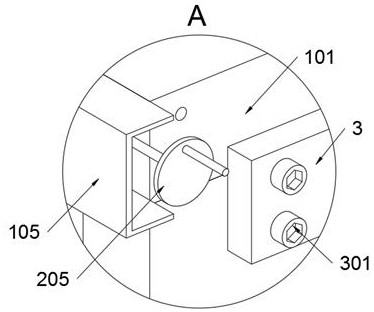

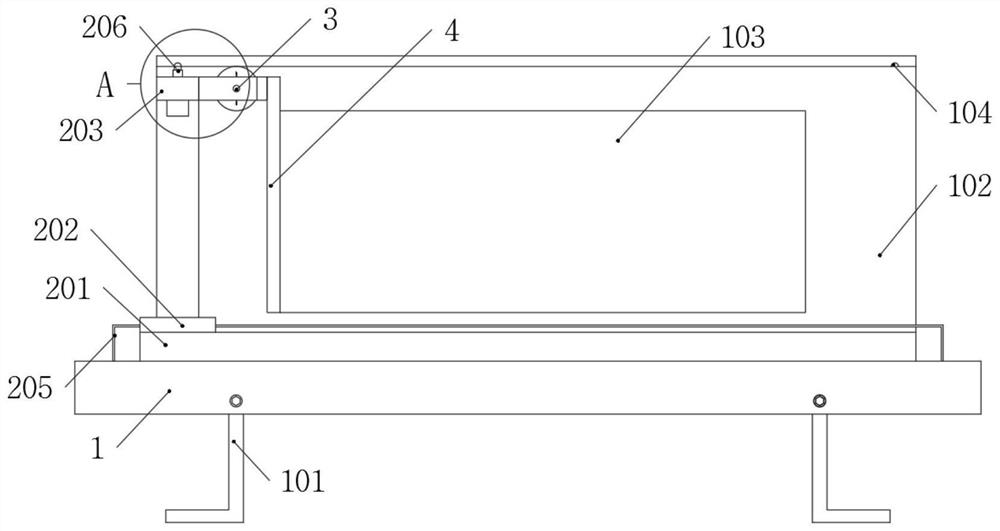

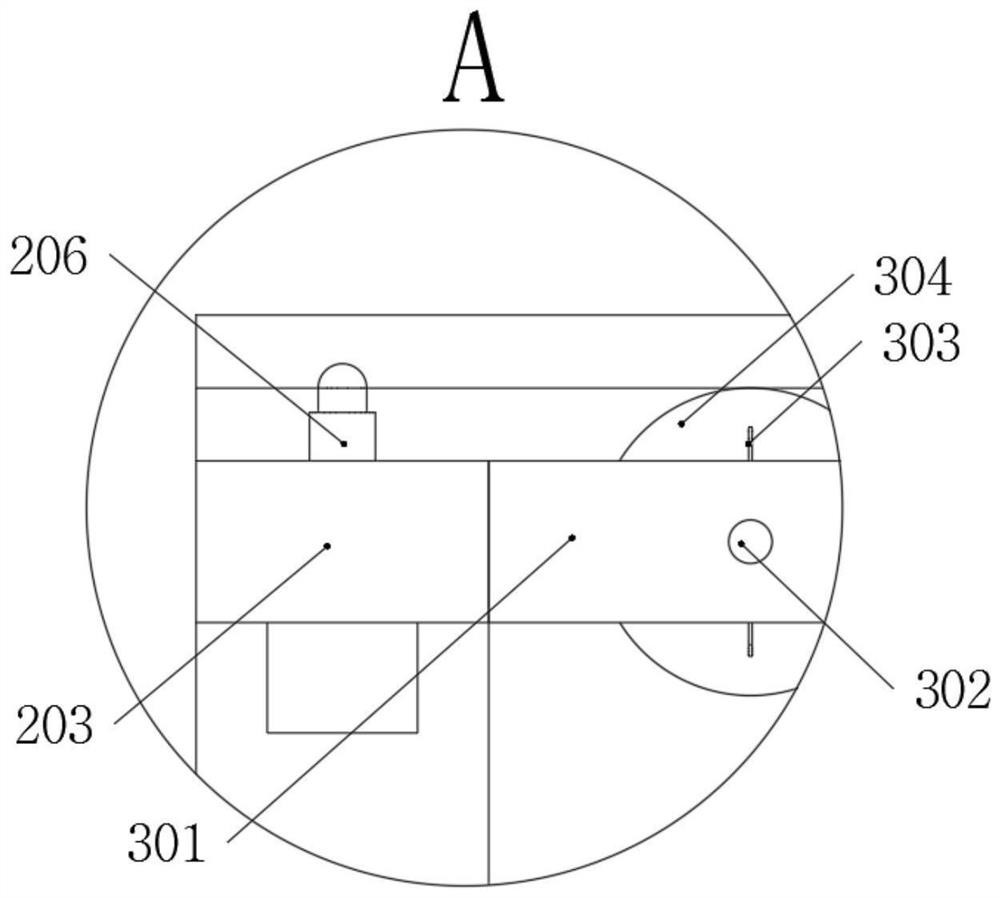

Ligament changing traction device based on track and field training

ActiveCN113144530ARealize automatic lockingClean thoroughlyGymnastic exercisingClassical mechanicsEngineering

The invention provides a ligament changing traction device based on track and field training, relates to the technical field of physical training equipment, and solves the problem that ligament stretching in various modes cannot be realized through structural improvement. The problems that a sliding structure is prone to collision, collision protection of the sliding structure cannot be achieved through structural improvement, and normal sliding of the sliding structure is not affected after the protection structure is collided are solved. The ligament changing traction device based on track and field training comprises a sliding seat structure; a stretching structure is installed on the sliding seat structure, and a graduated scale is further installed on the sliding seat structure. Through arrangement of a through hole and a baffle, the through hole is formed in a sliding plate, and the through hole is of a rectangular hole-shaped structure; and the through hole is slidably connected with the baffle and is not in contact with the top end face, the bottom end face, the left end face and the right end face of the baffle, and therefore the situation that sliding of the sliding plate is blocked due to slight deformation of the baffle can be prevented.

Owner:苏泽海

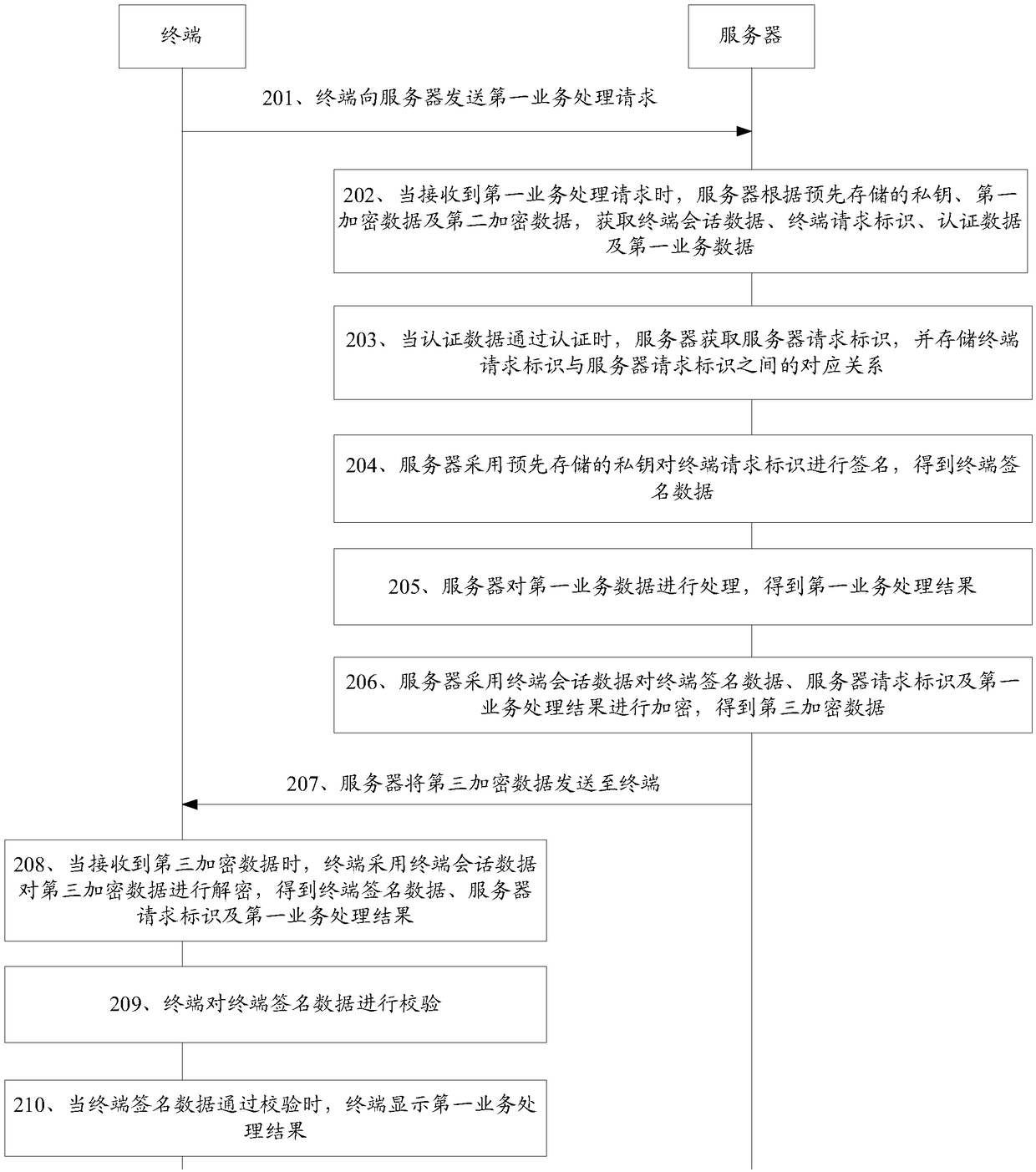

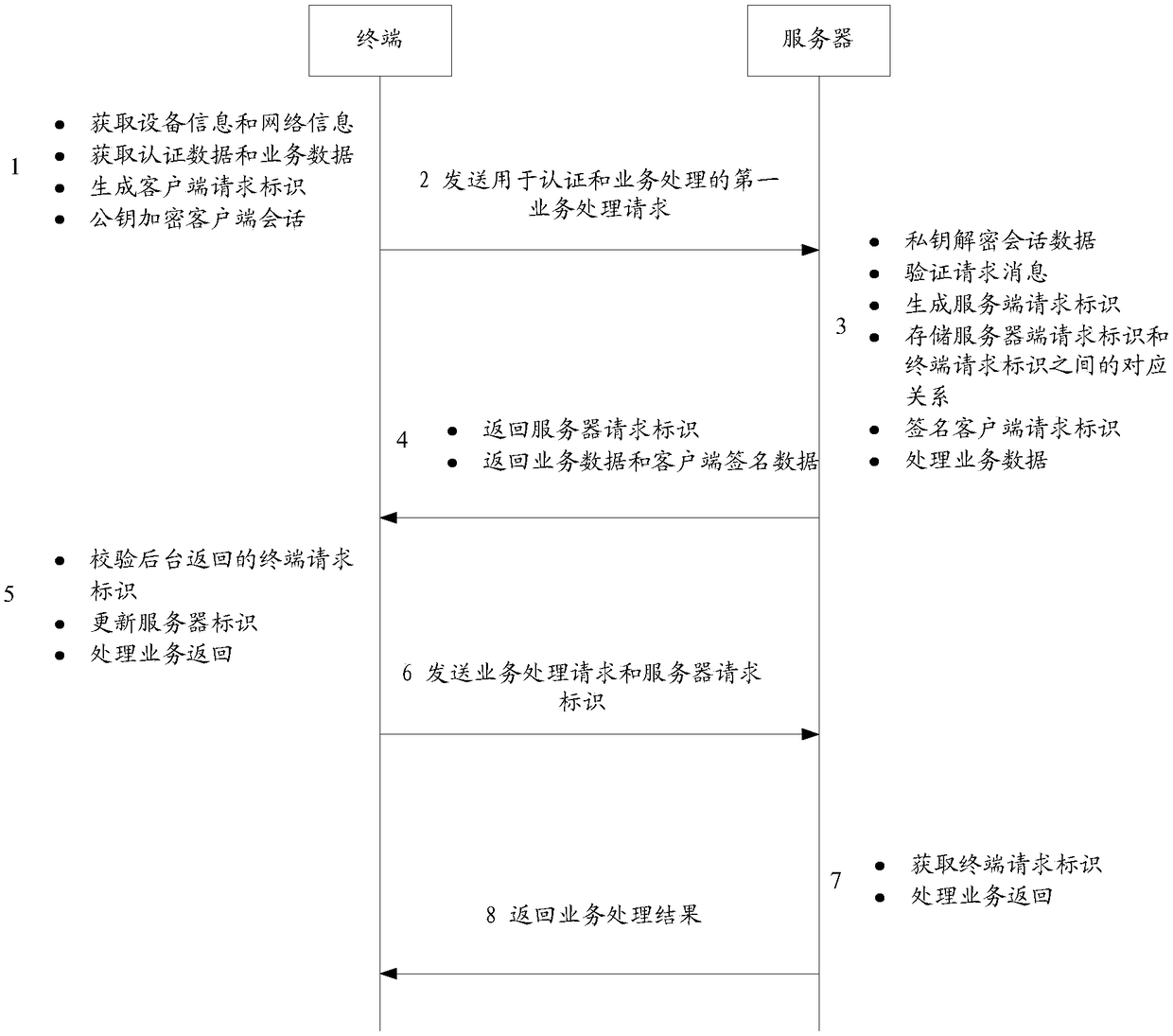

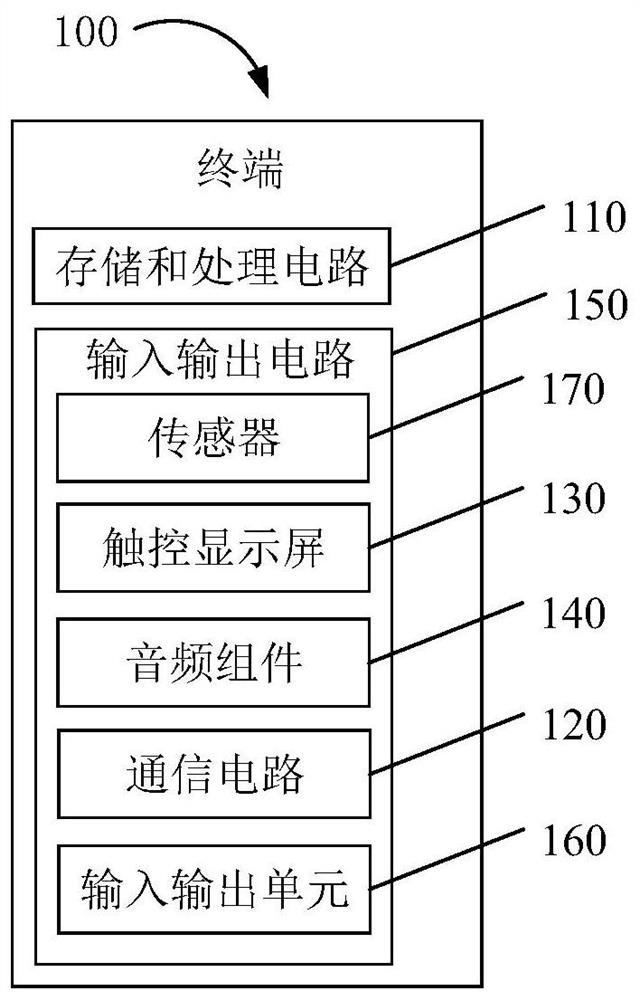

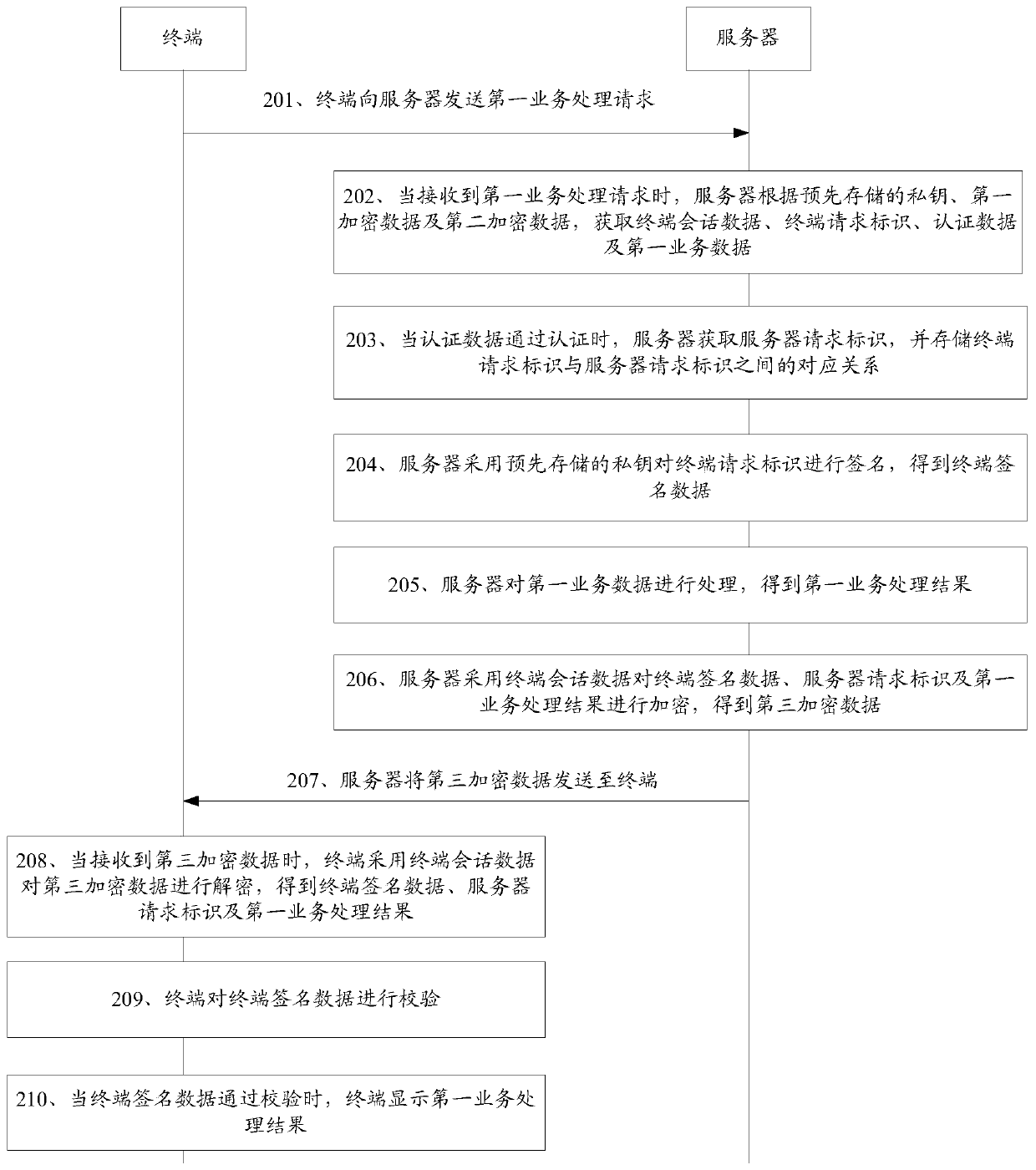

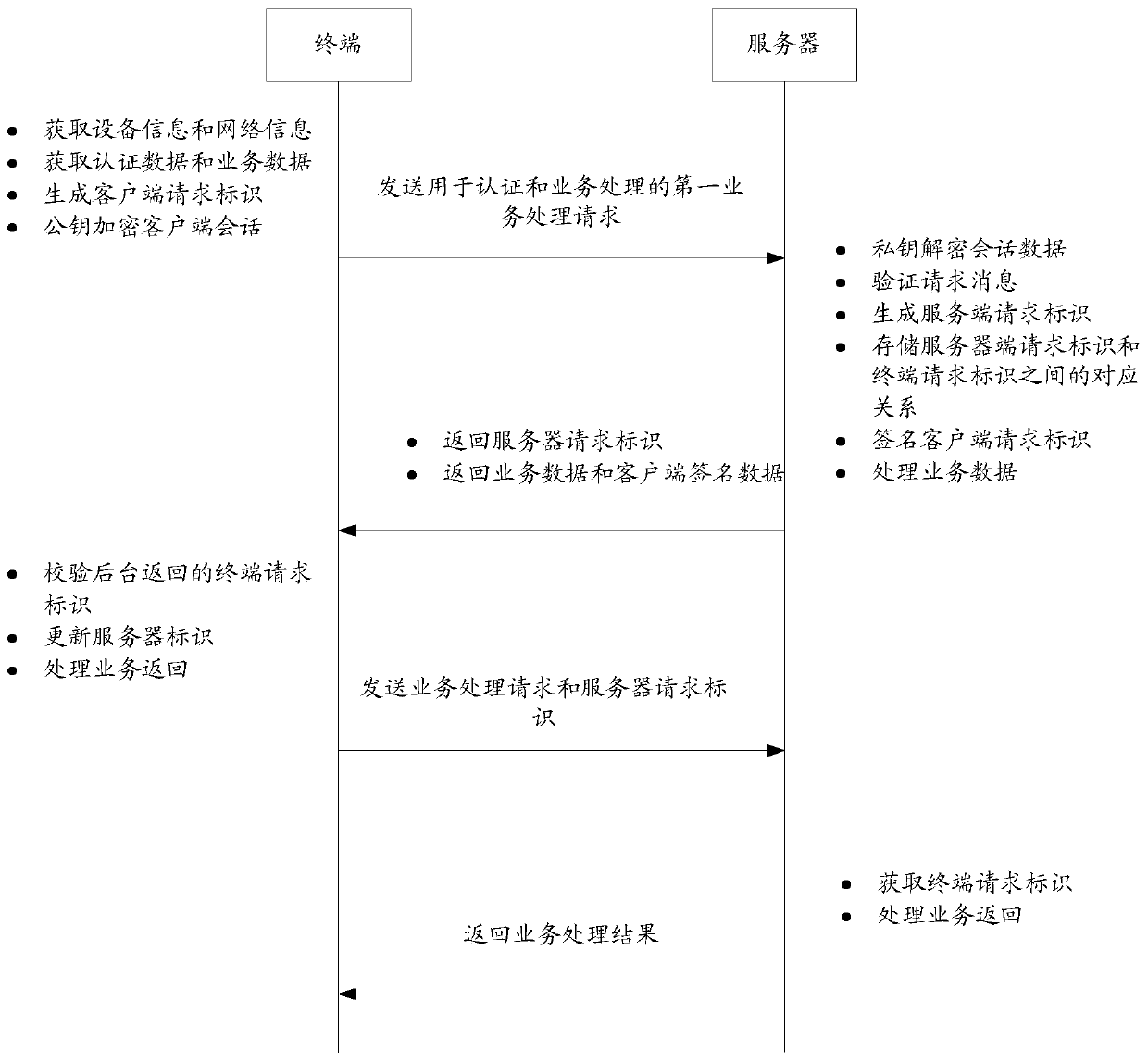

Service processing method, terminal and server

ActiveCN108737341ARelieve stressImprove securityKey distribution for secure communicationThe InternetEncryption

The invention discloses a service processing method, a terminal and a server, belonging to the technical field of internets. The terminal and the server authenticate each other in service processing,wherein the authentication process depends on not only a stored secret key or an encryption algorithm but also terminal session data, a terminal request identifier and a secret key, after authentication succeeds, the service is processed. The terminal session data and the terminal request identifier are generated by the terminal in communication with the server, therefore, even if other terminalscan acquire secrete keys stored by the terminal and the server, the terminals cannot acquire the terminal session data and the terminal request identifier, volume is prevented from increasing, the processing pressure of the server is lowered, the server is safer, and the service has better performance.

Owner:TENCENT TECH (SHENZHEN) CO LTD

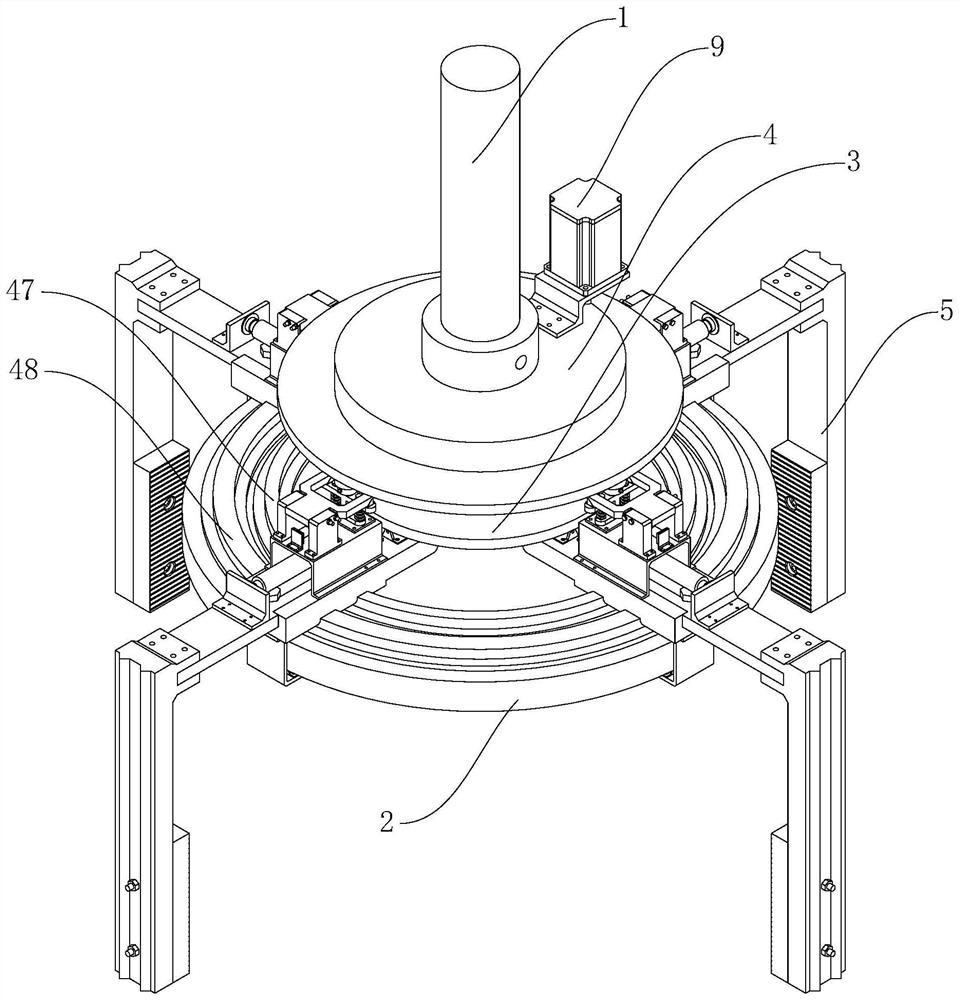

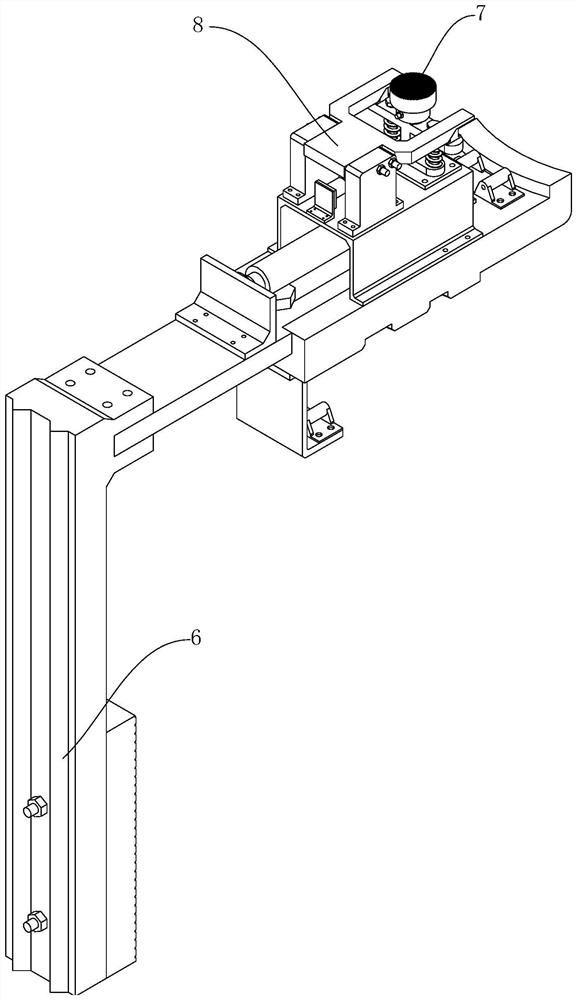

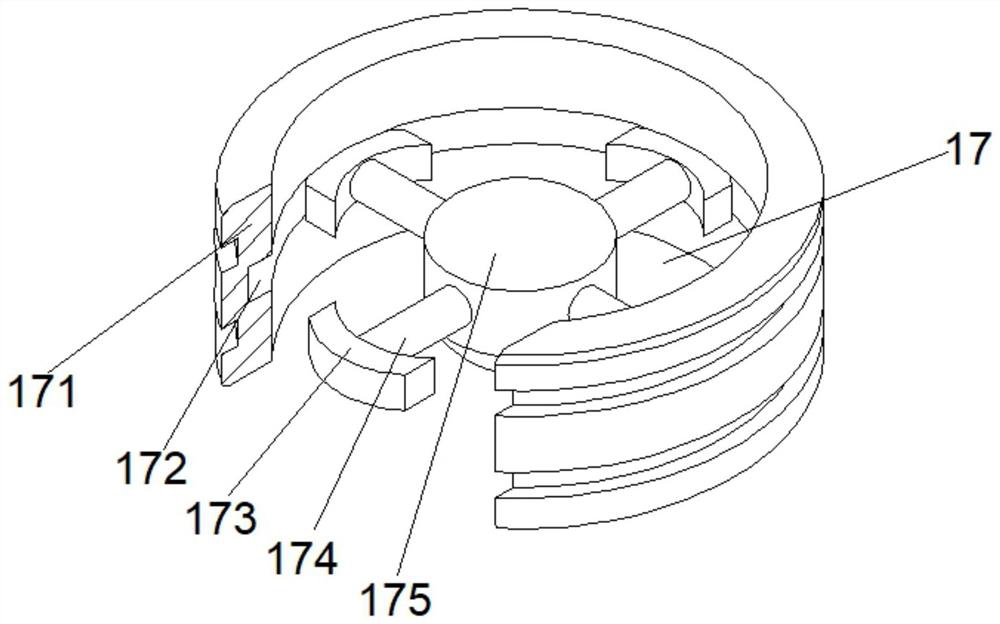

Convenient-to-adjust clamping device for intelligent manufacturing

The invention relates to the related technical field of intelligent manufacturing, in particular to a convenient-to-adjust clamping device for intelligent manufacturing, which comprises a supporting cylinder, a first connecting disc, a second connecting disc, a third connecting disc, a clamping arm assembly, a clamping arm device, a locking device, a control device, an adjusting assembly, a driving device and a trigger connecting piece, the first connecting disc, the second connecting disc and the third connecting disc are all fixedly arranged on the connecting cylinder in a sleeving mode, each clamping arm assembly comprises a clamping arm device, a locking device and a control device, the adjusting assembly comprises a driving device and a plurality of trigger connecting pieces, and a plurality of vertical clamping arms can gather towards the middle to clamp a part. The control device can drive the trigger connecting piece to be connected with the driving device while opening the locking device, so that the adjusting assembly can drive the clamping arm assembly to slide to adjust the position, and when the control device drives the trigger connecting piece to be separated from the driving device, the locking device can automatically abut against the third connecting disc to fix the clamping arm assembly.

Owner:湛宗平

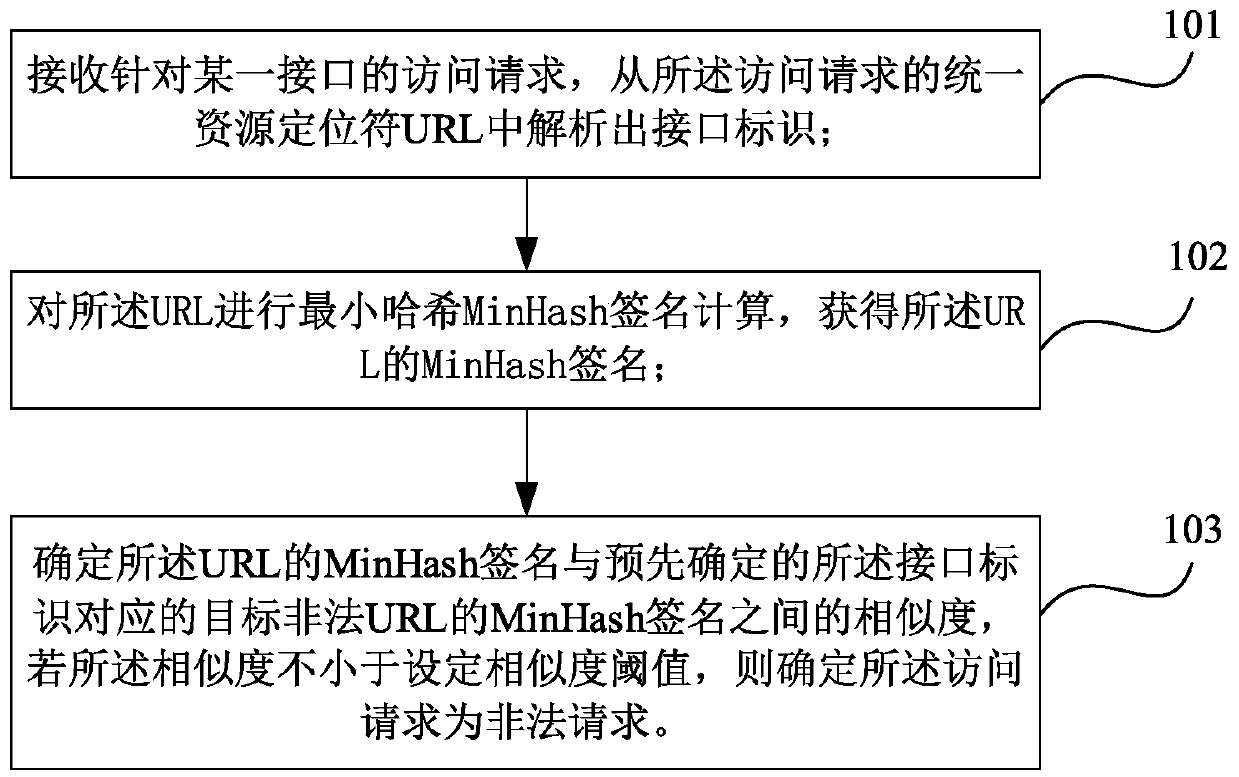

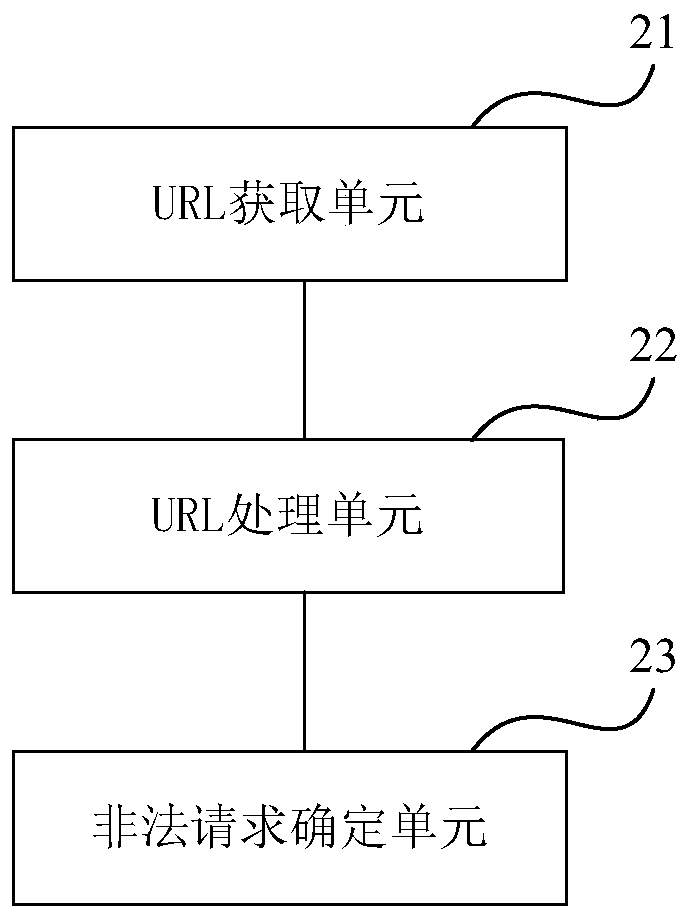

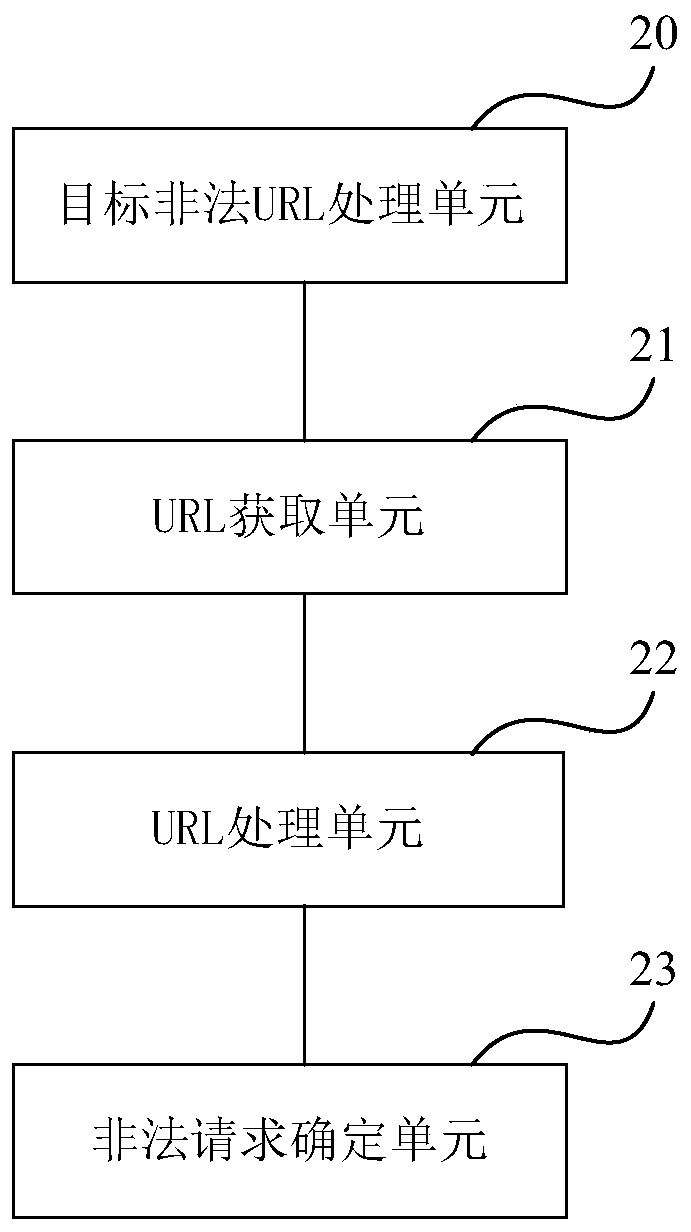

Illegal request identification method and device

InactiveCN110381017AAvoid crawlingIllegal requests are identified in a timely mannerUser identity/authority verificationSpecial data processing applicationsUniform resource locatorData mining

The embodiment of the invention provides an illegal request identification method and device, and the method comprises the steps: receiving an access request for a certain interface, and analyzing aninterface identification from a uniform resource locator URL of the access request; carrying out minimum hash signature calculation on the URL, so as to obtain a MinHash signature of the URL; and determining the similarity between the MinHash signature of the URL and the MinHash signature of the target illegal URL corresponding to the predetermined interface identifier, and if the similarity is not less than a set similarity threshold, determining that the access request is an illegal request. According to the technical scheme provided by the invention, the URLs are converted into the minimumhash signatures to compare the similarity between the URLs, so that the illegal request identification efficiency is greatly improved.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

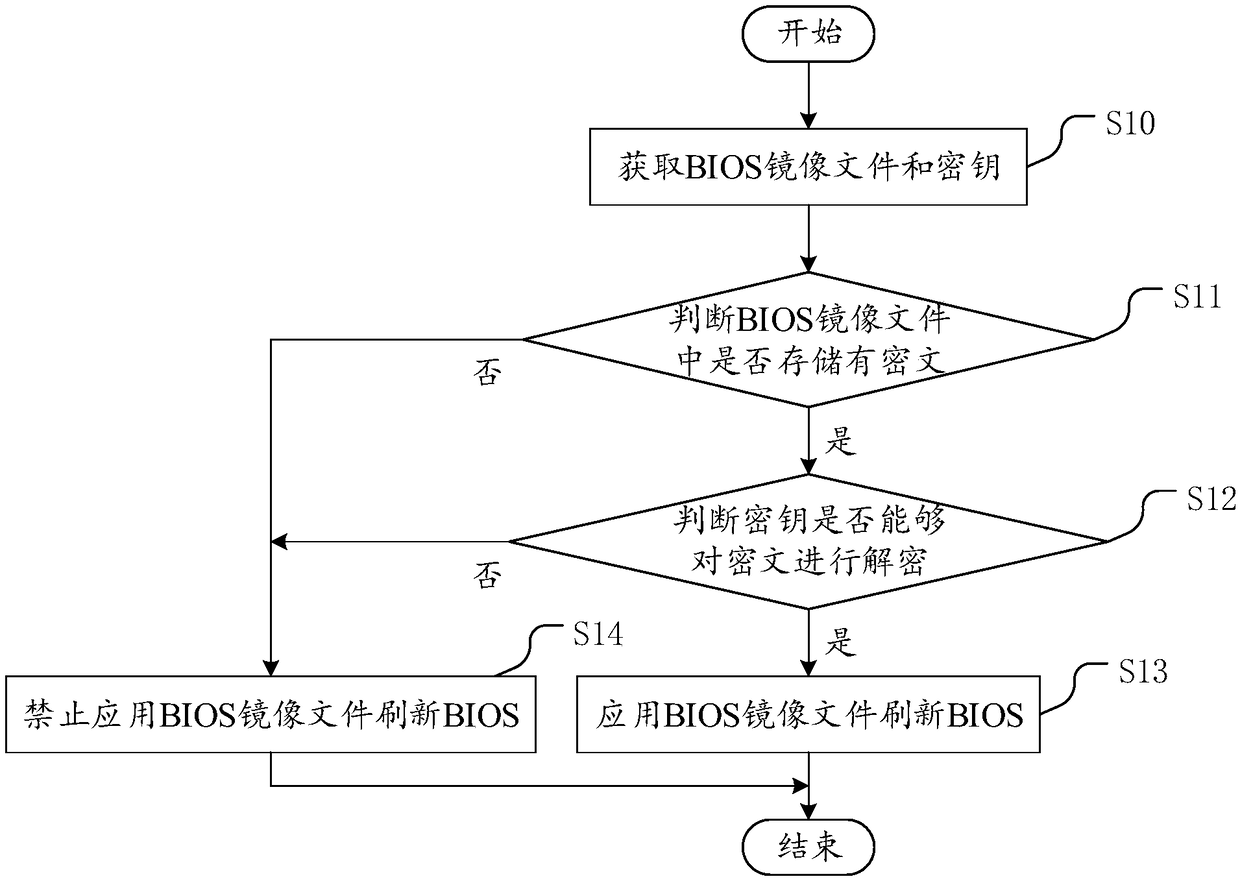

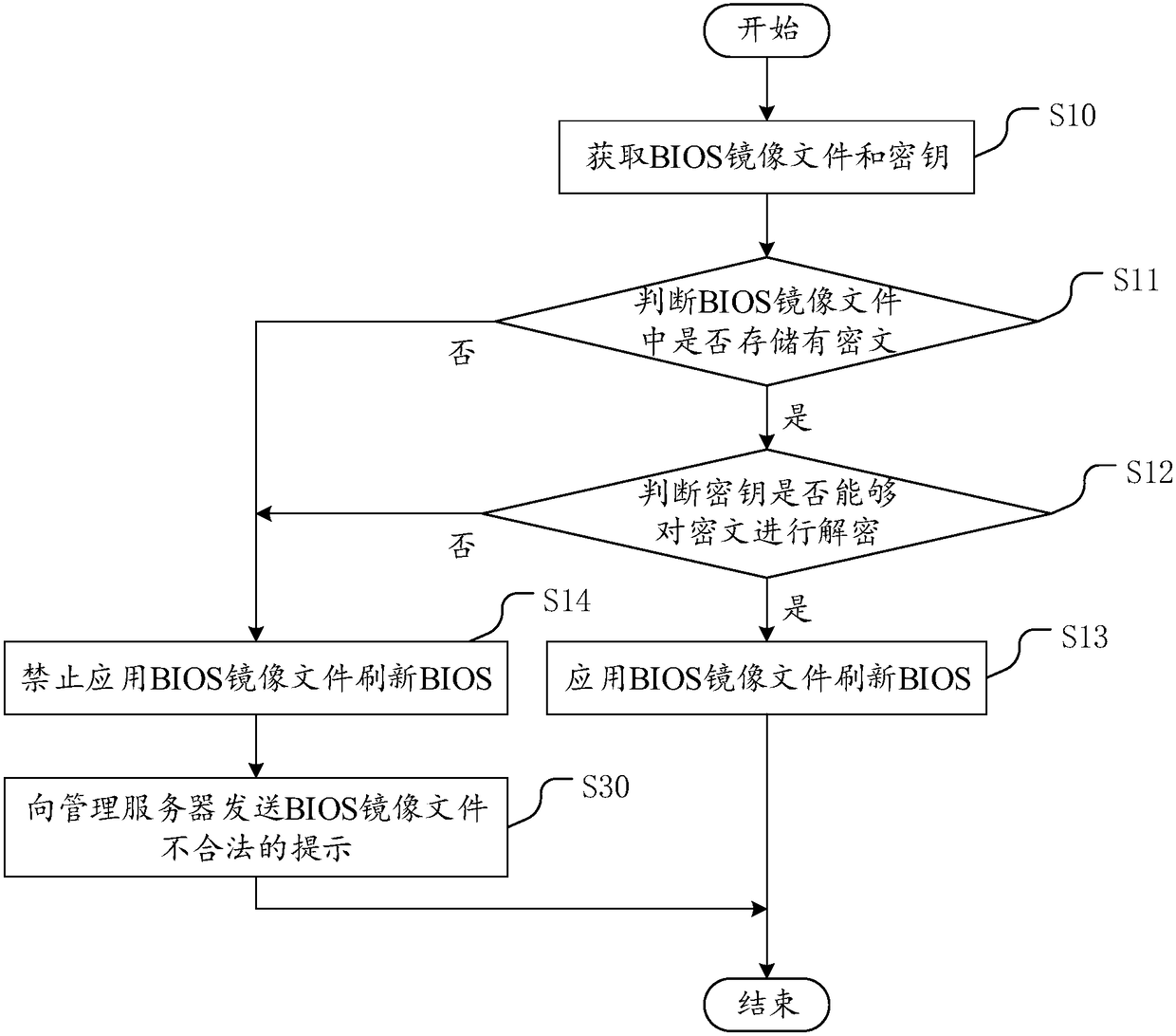

Method and device for verifying legality of BIOS during out-of-band refreshing of BIOS

ActiveCN108228219AAvoid swiping againKey distribution for secure communicationUser identity/authority verificationCiphertextMirror image

The invention discloses a method for verifying legality of a BIOS during out-of-band refreshing of the BIOS. The method is applied in a substrate management controller. The method includes: acquiringa BIOS mirror image document and a secret key; judging a ciphertext is stored in the BIOS mirror image document or not; if yes, judging whether the secret key can decipher the ciphertext or not, if yes, applying the BIOS mirror image document to refresh the BIOS, and if not, prohibiting applying the BIOS mirror image document to refresh the BIOS; if not, prohibiting applying the BIOS mirror imagedocument to refresh the BIOS. By the method, the BIOS mirror image document is ciphered before transmission and then deciphered, so that the substrate management controller is avoided flushing wrong and illegal BIOS mirror image documents, and smooth running of a server is ensured. The invention further provides a device for verifying the legality of the BIOS during out-of-band refreshing of the BIOS and a computer readable storage medium. The device has the above advantages, which will not be repeated here.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

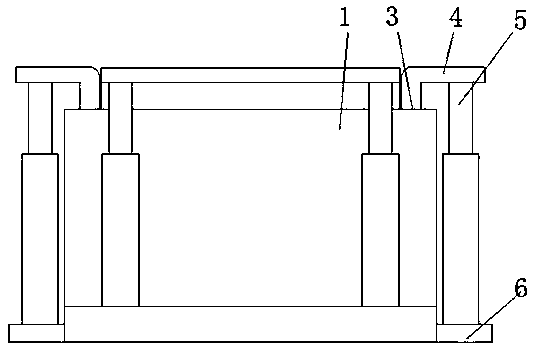

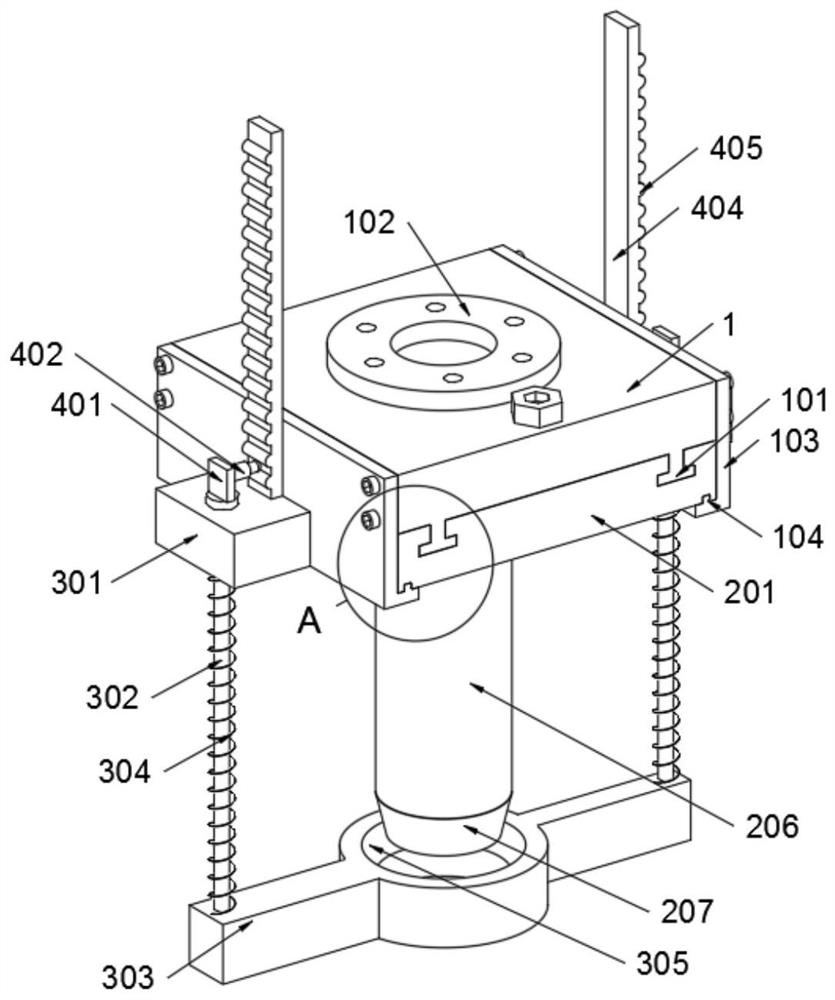

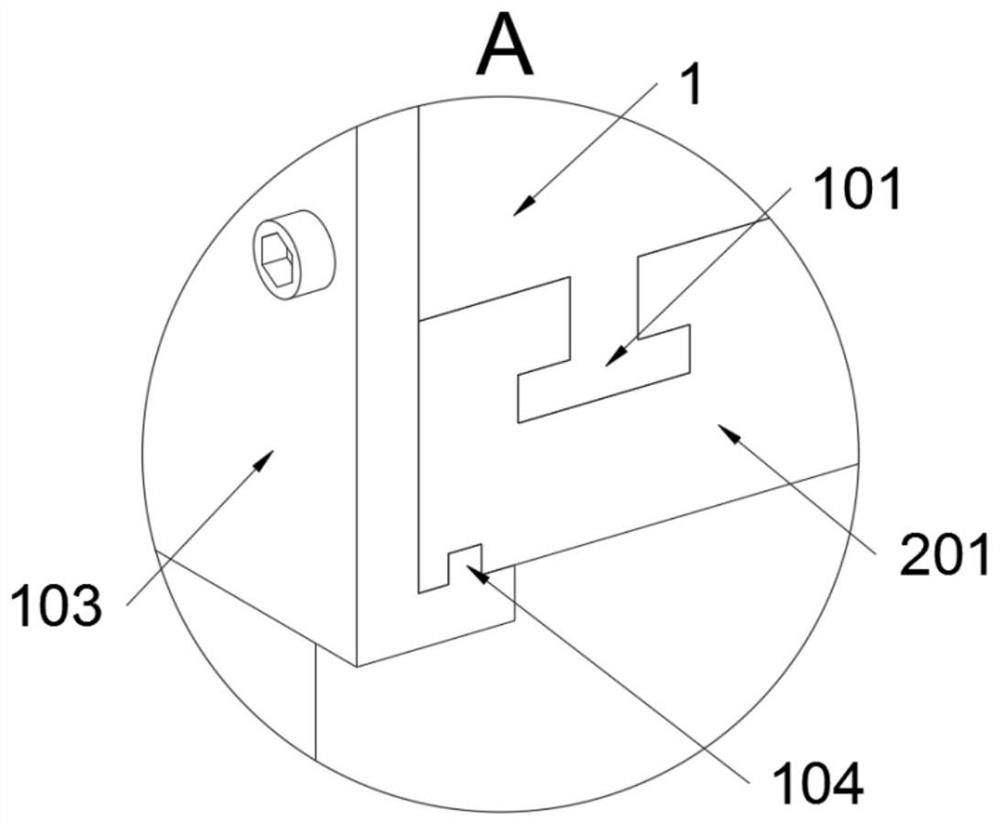

Piling device for constructional engineering and piling device connecting structure

PendingCN112726601AAvoid bump damageShake offCleaning processes and apparatusBulkheads/pilesArchitectural engineeringStructural engineering

The invention provides a piling device for constructional engineering and a piling device connecting structure, and relates to the technical field of construction machinery. The problems that automatic cleaning of soil on a pile rod cannot be synchronously realized, meanwhile, shaking-off of the soil on the pile rod cannot be realized through structural improvement, and rapid installation of the pile rod and effective protection during placement cannot be achieved through structural improvement are solved. The piling device for constructional engineering and the piling device connecting structure comprises a mounting base, wherein a pile rod structure is mounted on the mounting base, a cleaning structure is further mounted on the mounting base, and an auxiliary structure is further mounted on the mounting base. The inner walls of connecting plates are in contact with the outer side of connecting seat A, and the two connecting plates jointly form an auxiliary fixing structure of the connecting seat A; the bottom end faces of the connecting plates are lower than the bottom end faces of clamping protrusions A, the two connecting plates further form a protection structure of the clamping protrusions A, and therefore the clamping protrusions A can be prevented from being collided and damaged during placement.

Owner:叶华攀

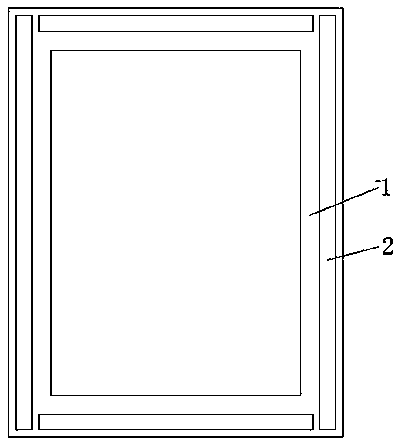

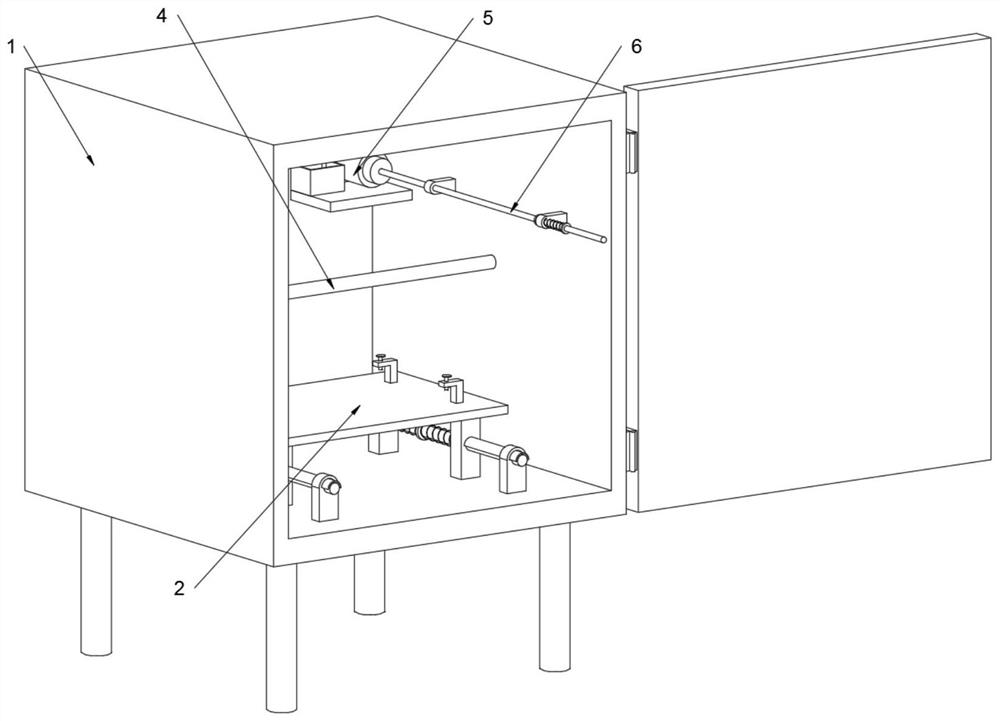

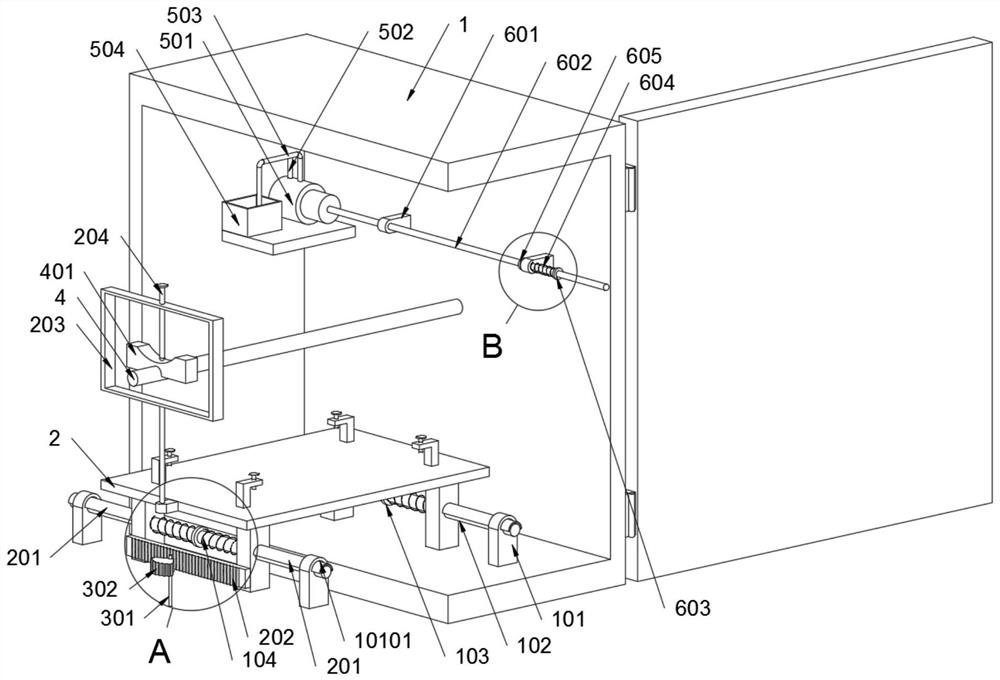

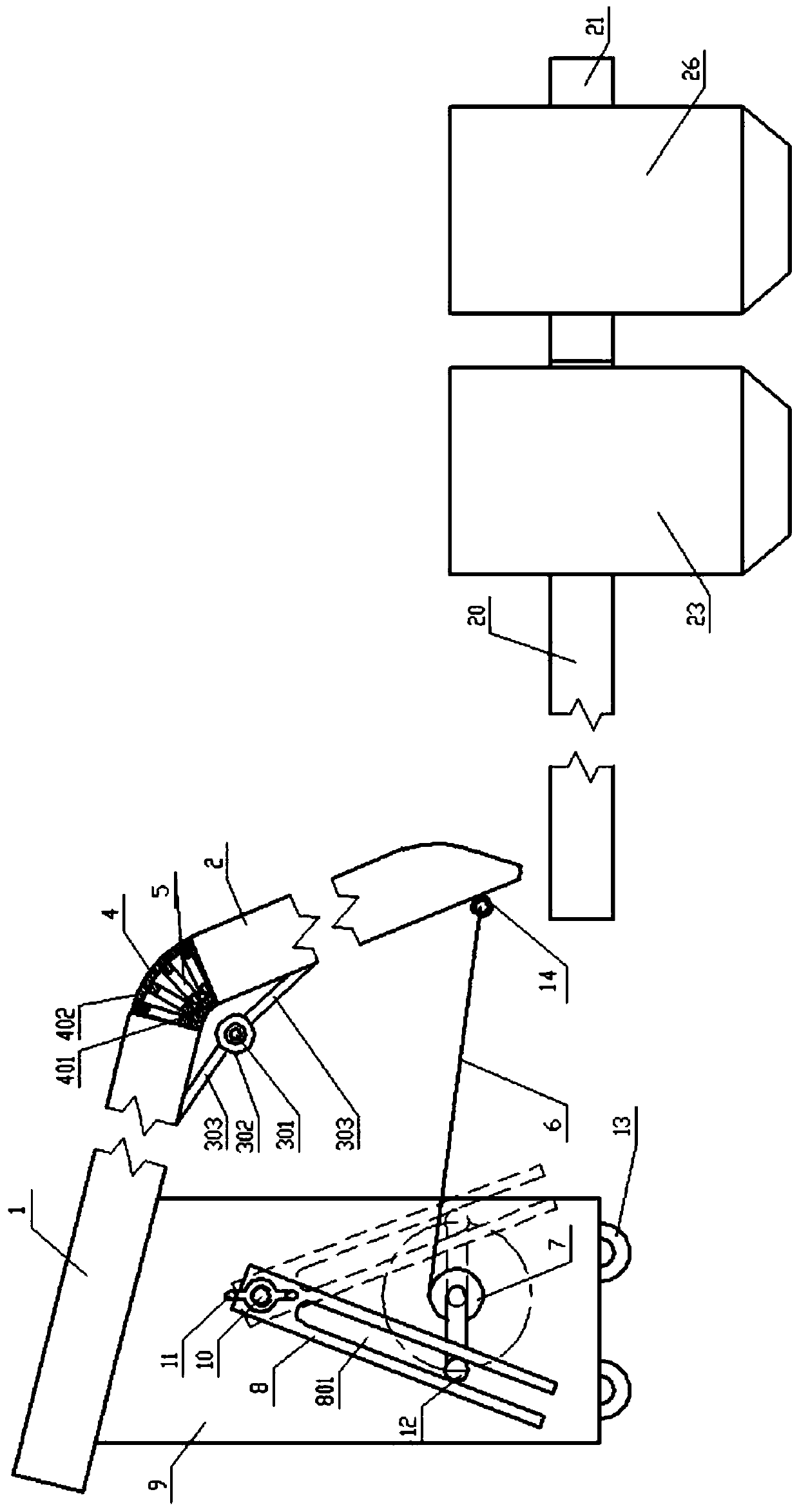

Painting device based on whole household wood set and capable of achieving angle limiting and diffusion prevention

ActiveCN111822193AAvoid swiping againExpand the spraying rangeSpraying apparatusReciprocating motionWood plank

The invention provides a painting device based on the whole household wood set and capable of achieving angle limiting and diffusion prevention and relates to the field of household board painting devices. By means of the painting device, the problems that the painting efficiency cannot be improved or the painting range cannot be widened through reciprocating motion of wood boards and limited oscillation of a spray head, and floating paint granules cannot be sucked automatically in a linked manner when a box door is opened are solved. The painting device based on the whole household wood set and capable of achieving angle limiting and diffusion prevention comprises a box body and mounting seats. A part fixing seat is connected to the box body in a sliding manner. Due to engagement of an incomplete gear and a gear set, when the incomplete gear is driven by a rotating shaft to rotate, the part fixing seat is in the reciprocating motion state, and thus, the part fixing seat can cooperatewith a painting mechanism to widen the paint spraying range; and a rectangular frame is welded to the part fixing seat, a threaded rod is in threaded connection to the rectangular frame and is in contact with the top end face of a force-bearing block, when the threaded rod performs reciprocating motion along with the part fixing seat, a painting seat is in the reciprocating swing state, and therefore, reciprocating spraying can be achieved.

Owner:台州市马马塑业有限公司

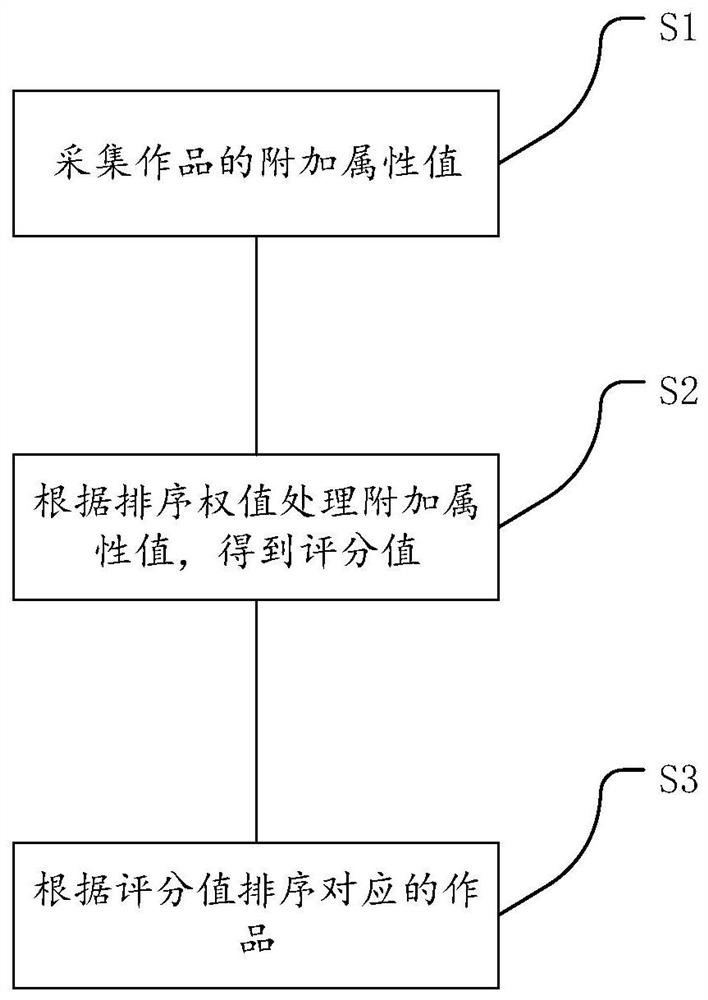

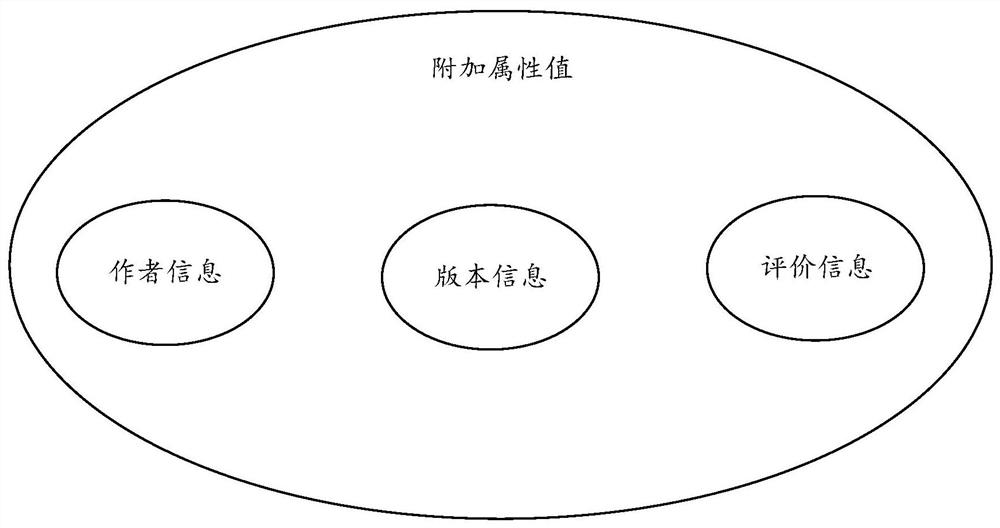

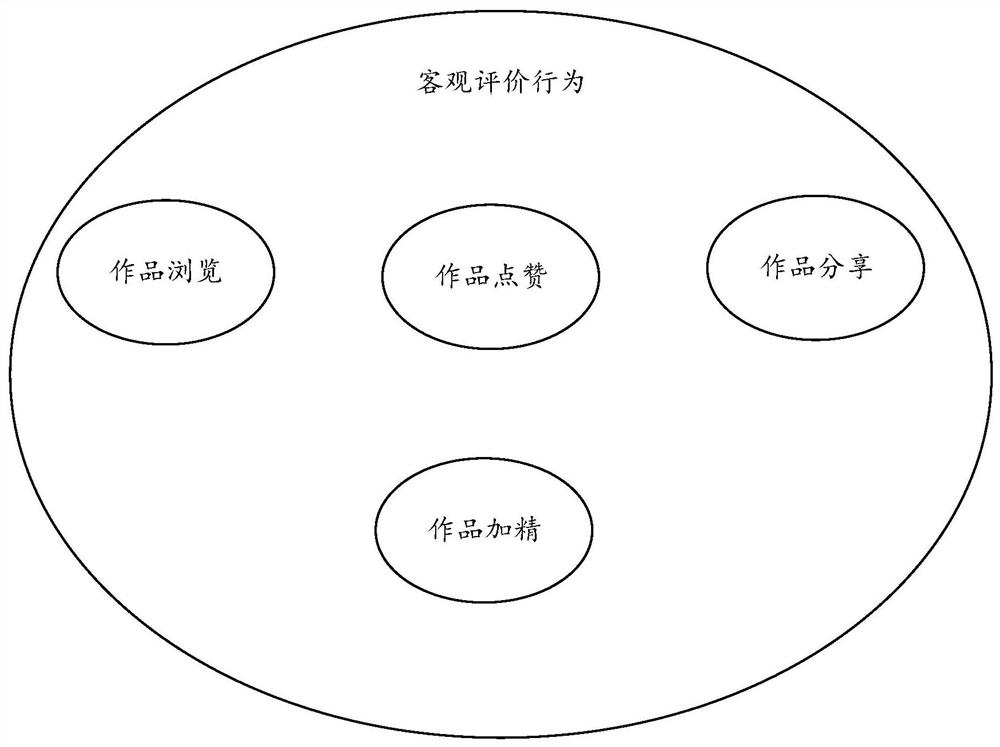

Work sorting method and device and storage medium

PendingCN111737566AImprove replacement efficiencyJudging the recommended valueDigital data information retrievalSpecial data processing applicationsEngineeringAlgorithm

The invention relates to a work sorting method and device and a storage medium. The work sorting method comprises the steps that additional attribute values of works are collected; processing the additional attribute value according to the sorting weight to obtain a score value; and sorting the corresponding works according to the score values. The device comprises an collection module used for acquiring additional attribute values of works; the calculation module is used for processing the additional attribute value according to the sorting weight to obtain a score value; and the sorting module is used for sorting the corresponding works according to the score values. According to the embodiment of the invention, the additional attribute values of the works are collected as basic data fordetermining work sorting; through the sorting weight, the proper score value can be calculated according to the importance degree of the additional attribute value, the recommendation value of the works can be judged from different angles conveniently, and the works corresponding to the sorting of the score value can be used as a basis for recommending the works.

Owner:SHENZHEN ZHANYIN TECH CO LTD

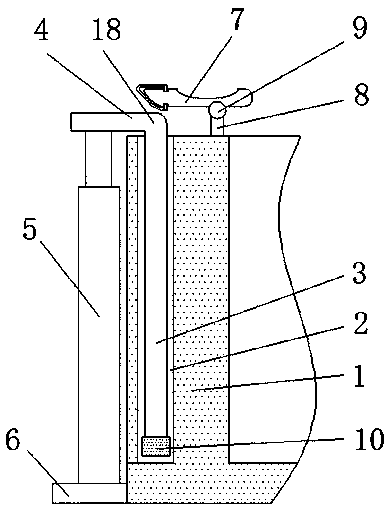

Clinical diagnosis and treatment device for general medicine

InactiveCN114225231ASimple structureImprove the fixing strengthCleaning using toolsLight therapyPhysical medicine and rehabilitationMedical equipment

The invention provides a clinical diagnosis and treatment device for general medicine, which relates to the technical field of medical equipment and comprises a bed body, a detection and treatment part, a cleaning part and an auxiliary part, the bed body is fixedly connected with two supporting seats through bolts, the two supporting seats are both in contact with the ground, and the bed body is of an L-shaped plate-shaped structure; the detection and treatment part is composed of a sliding seat, a sliding block, a mounting arm, a treatment lamp, an auxiliary seat and a contact switch, and the sliding seat is fixedly connected to the bed body through a bolt. The sliding block is provided with the sliding hole, the sliding hole is in sliding connection with the auxiliary seat, and the inner wall of the sliding hole is not in contact with the auxiliary seat, so that normal sliding of the sliding block is not influenced even if the auxiliary seat is collided, and the problems that firstly, dust is easily accumulated on the treatment lamp after an existing device is used for a period of time; and secondly, the problem that dust and residues are easily accumulated in a sliding seat of an existing device to affect sliding of a sliding block is solved.

Owner:孟聪聪

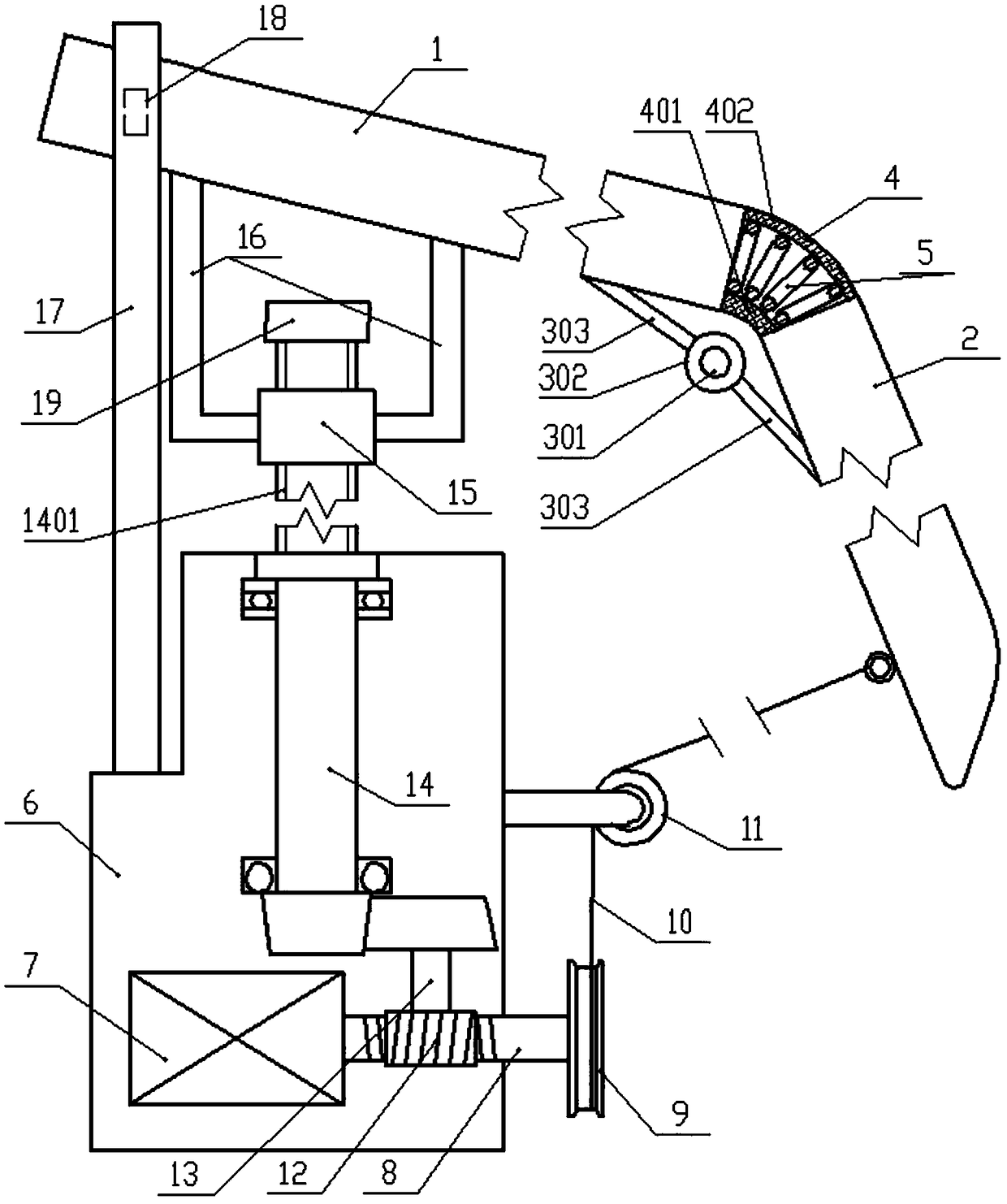

An automatic unloading device

ActiveCN107399620BImprove performanceGuaranteed StrengthLoading/unloadingChutesDrive shaftEngineering

The invention discloses an automatic demounting device which comprises conveying plates and a lifting mechanism. The conveying plates comprise the first conveying plate and the second conveying plate which are hinged to each other. The two conveying plates are connected through a telescopic pipe made of rubber, and a cylinder spring is arranged in the telescopic pipe. The lifting mechanism comprises a machine box, a motor is arranged in the machine box, a rolling wheel is arranged at the tail end of an output shaft of the motor, and after being wound around a pulley, a steel cable on the rolling wheel is connected with the second conveying plate. The part, located in the machine box, of the output shaft is of a worm structure and is in engagement transmission with a horizontally-arranged worm gear. A worm is fixed to a vertically-arranged first transmission shaft, and the first transmission shaft transmits torque to a second transmission shaft. The top end of the second transmission shaft stretches out of the top of the machine box, a thread is arranged on the stretching-out segment of the second transmission shaft, and a transmission nut is screwed on the threaded segment of the second transmission shaft and connected with the bottom face of the first conveying plate. A guide rail is further vertically arranged on the machine box. A guide wheel on the edge of one side of the first conveying plate is located in a sliding groove of the guide rail. The automatic demounting device is high in automation degree and quite high in maneuvering flexibility.

Owner:重庆旭永科技发展有限公司

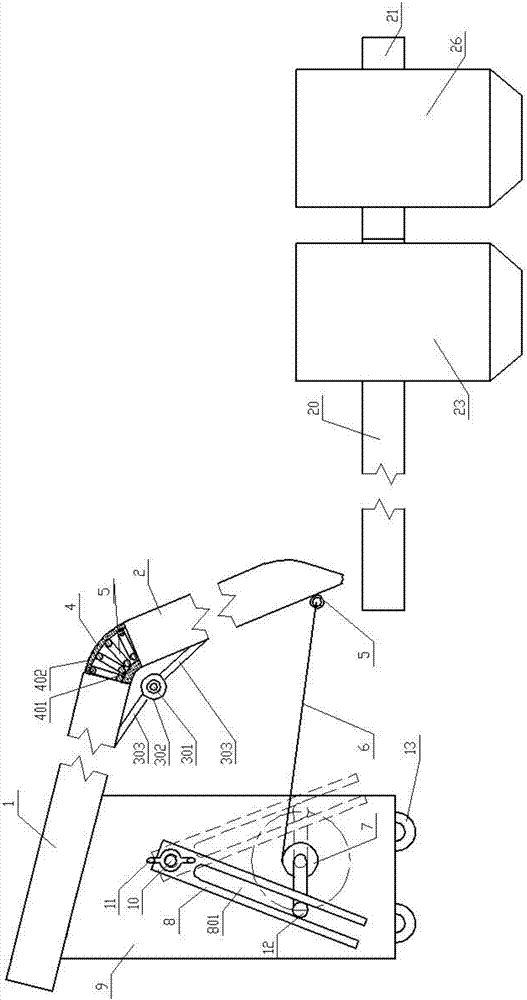

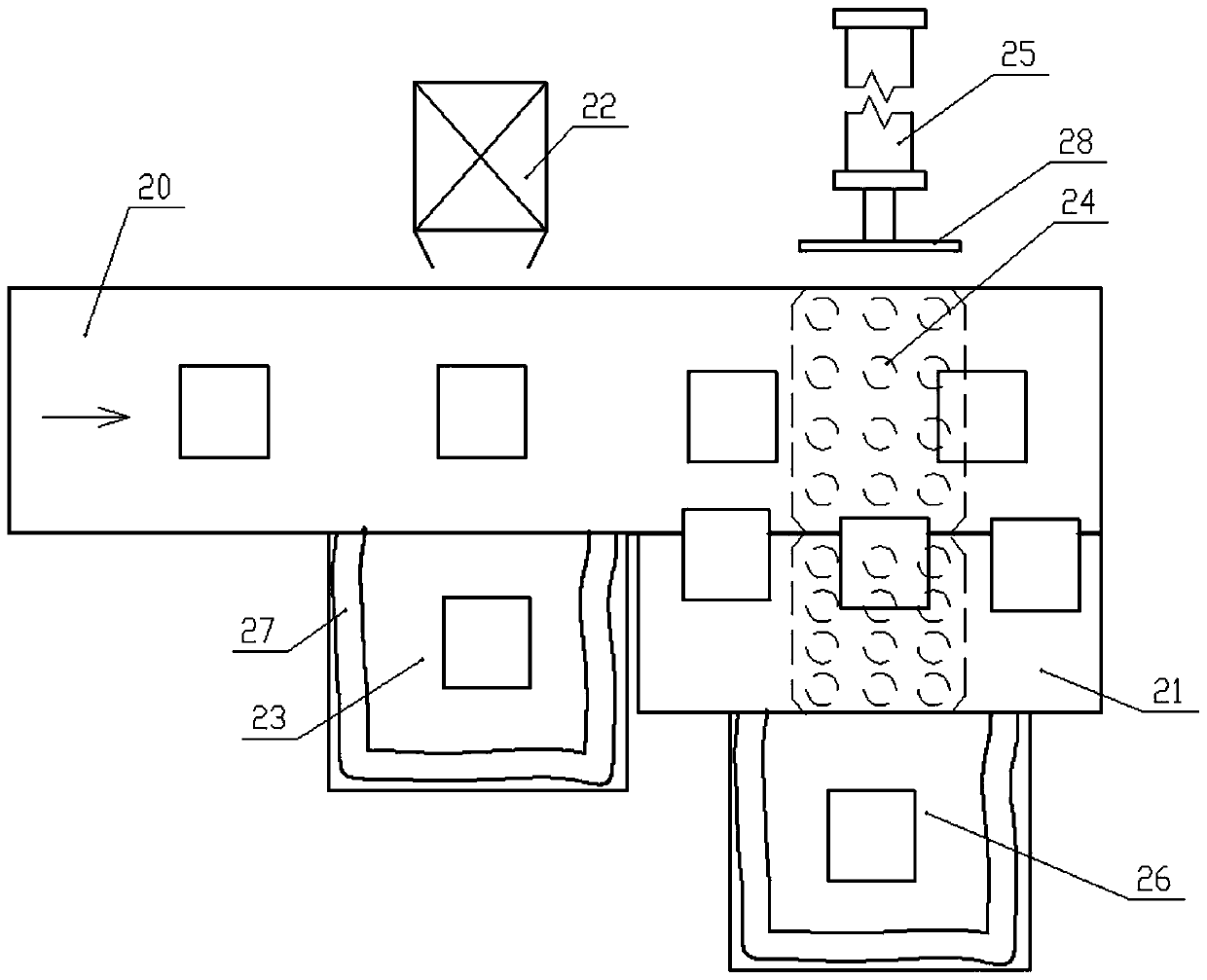

Logistics transportation automatic sorting line

The invention discloses a logistics transportation automatic sorting line. The bottom faces of the connecting positions of a first conveying plate and a second conveying plate of a conveying device of the logistics transportation automatic sorting line are hinged through a hinge, and the two conveying plates are connected through a telescopic pipe. A lifting ring is fixed to the bottom face of the output end of the second conveying plate. One end of a steel cable is tied on the lifting ring, and the other end of the steel cable is wound around a roller. A forked strip plate is further included, a U-shaped long-strip-shaped gap is arranged at one end of the forked strip plate, the other end of the forked strip plate is hinged to a machine shell, and a butterfly nut is screwed at the free end of a hinged shaft. A screening device of the logistics transportation automatic sorting line comprises a longer first conveying belt and a shorter second conveying belt, and the two conveying belts are connected in parallel. A fan is arranged on one side of the first conveying belt, and a first goods receiving bin is arranged on the other side of the first conveying belt. Pressure sensors are arranged below the first conveying belt and the second conveying belt. A hydraulic rod and a second goods receiving bin are arranged at the two ends of the straight line formed by arranging the pressure sensors below the two conveying belts. The sorting line is flexible in conveying and extremely high in sorting efficiency.

Owner:重庆旭永科技发展有限公司

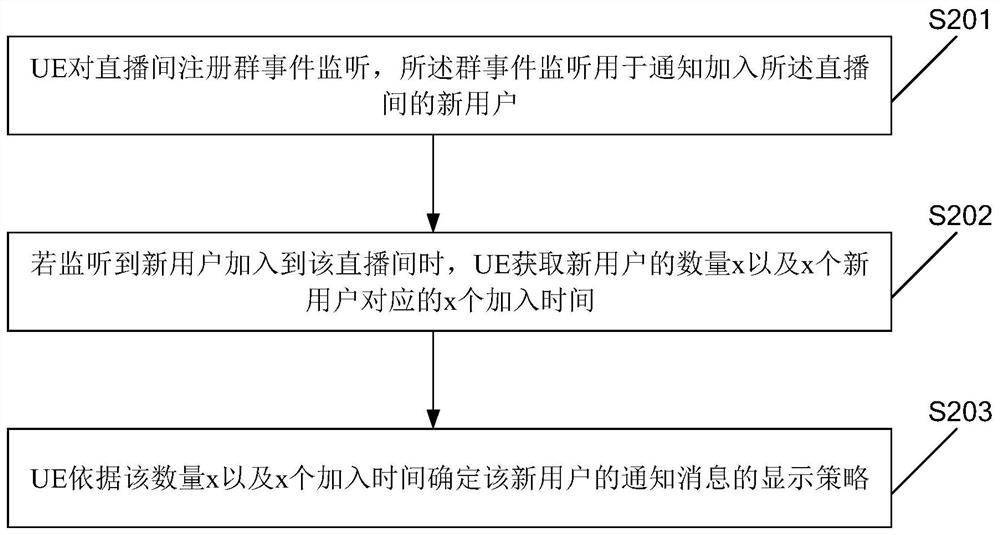

Message processing method of live broadcast room and related product

InactiveCN112399241AAvoid swiping againImprove experienceSelective content distributionTelecommunicationsMessage handling

The embodiment of the invention provides a message processing method for a live broadcast room and a related product, and the method comprises the steps that UE monitors a registered group event of alive broadcast room, and the group event monitoring is used for notifying a new user joining the live broadcast room; if monitoring that new users join the live broadcast room, the UE acquires the number x of the new users and x joining times corresponding to the x new users; and the UE determines a display strategy of the notification message of the new user according to the number x and the x joining times. The technical scheme provided by the invention has the advantage of high user experience.

Owner:SHENZHEN FUTU NETWORK TECH CO LTD

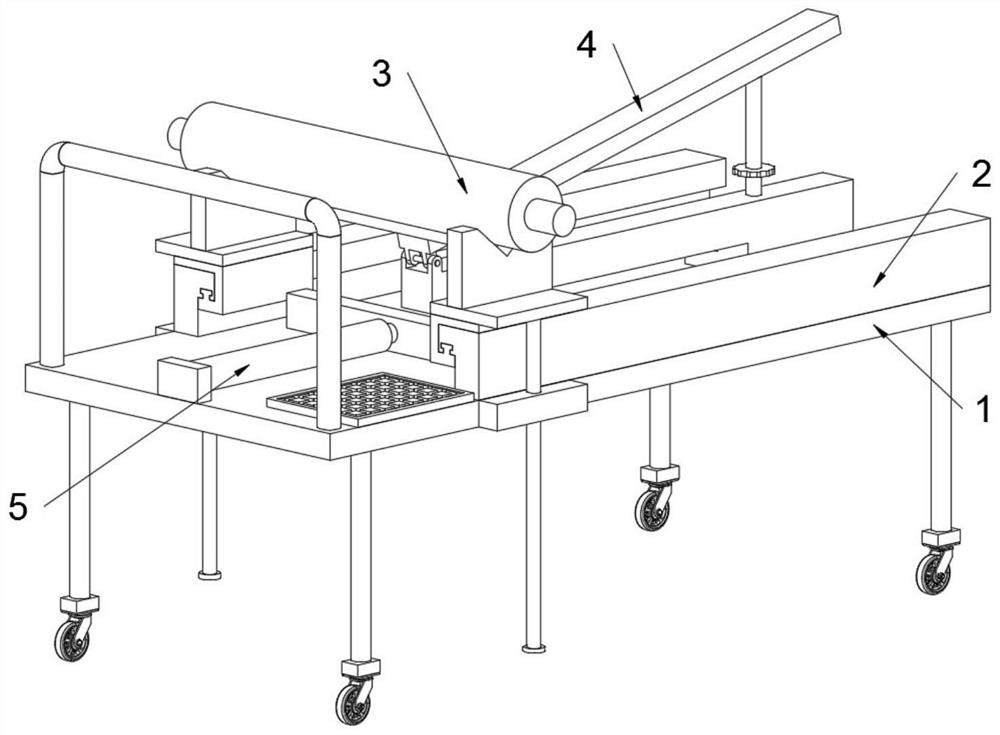

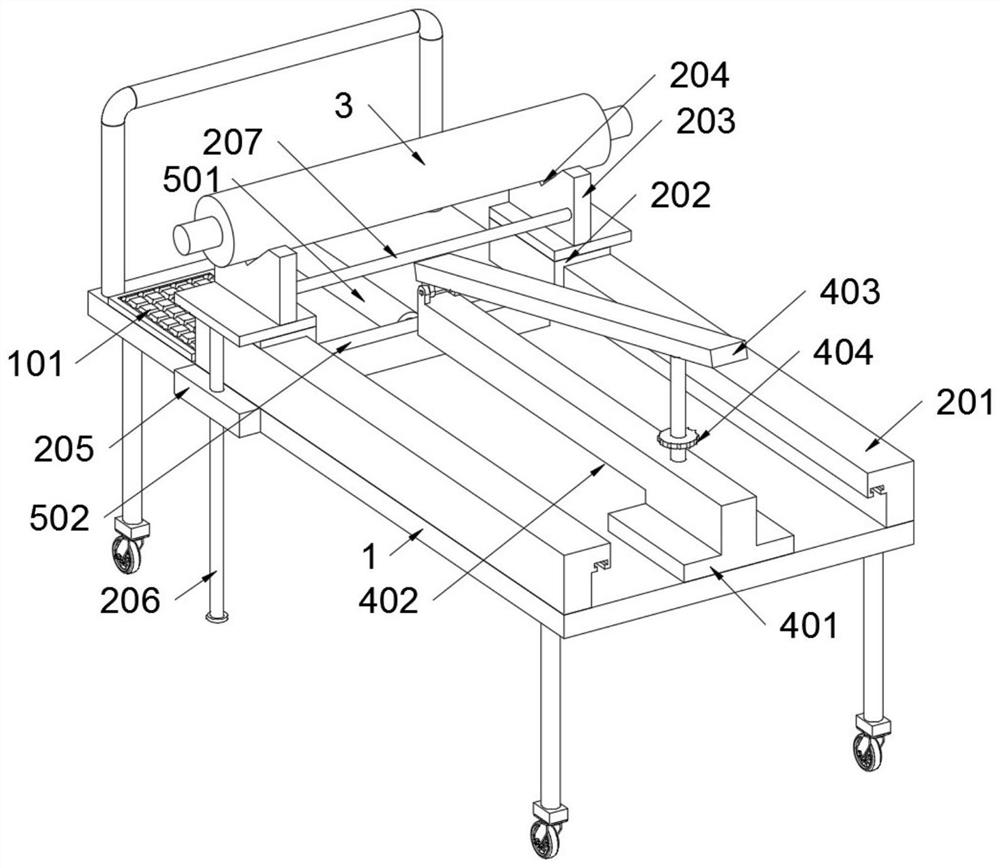

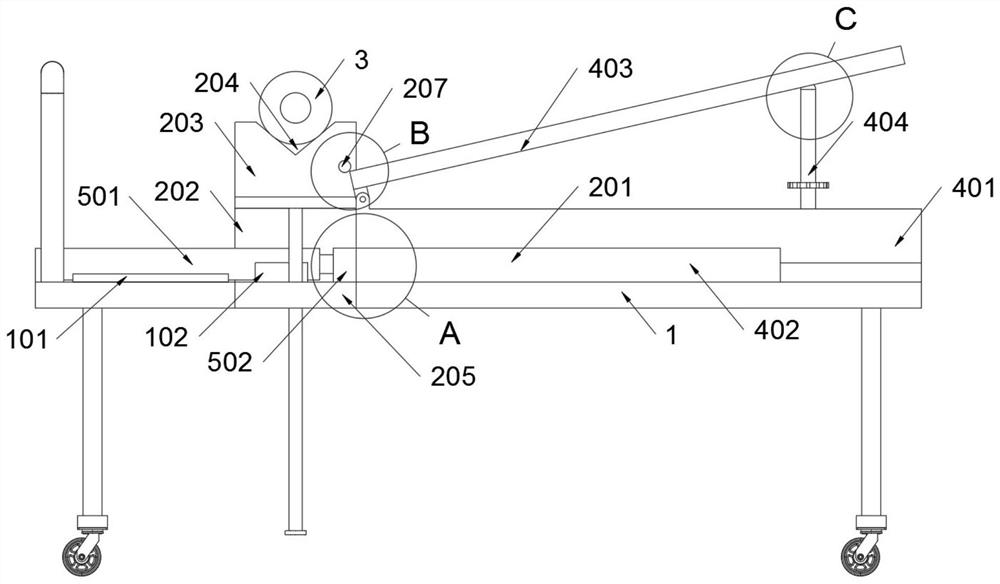

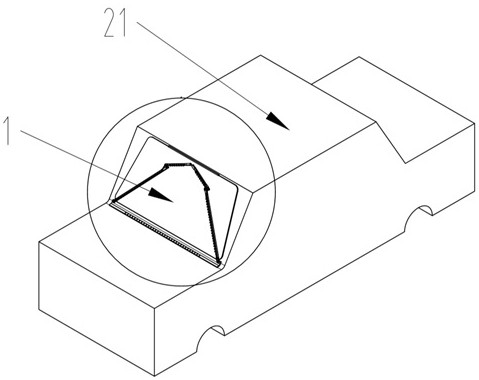

Solar textile machinery recovery frame with automatic loading and unloading function

InactiveCN112501731AReduce frictionLow costFilament handlingTextiles and paperForward slidingIndustrial engineering

The invention provides a solar textile machinery recovery frame with an automatic loading and unloading function, and relates to the technical field of textile machinery auxiliary devices. The problems that horizontal displacement and vertical displacement of a dismounting device cannot be realized under driving of one electric element through structural improvement, after being used for a periodof time, residues are prone to be accumulated in a sliding groove, and consequently sliding is not smooth are solved. The solar textile machinery recovery frame with the automatic loading and unloading function comprises a vehicle body; and a sliding structure is installed on the vehicle body, and rollers are installed on the sliding structure. A stress rod is rotationally connected to a main bodyseat and is arranged in an inclined mode, and the inclination angle is 35 degrees; and the stress rod is aligned with a cylindrical rod in position, the top end face of the stress rod is polished, the cylindrical rod makes contact with the stress rod when the cylindrical rod and a containing seat move forwards by 10 cm along with a sliding seat A, and therefore when the sliding seat A continues to slide forwards, the height of the containing seat can be increased.

Owner:温州邑品鞋业有限公司

A car wiper without dead angle with a cleaning device

A car wiper with cleaning device without dead angle, including active wiper, swing wiper, swing wiper chuck, handle, spring, roller, roller mounting plate, rotating cover, electric cylinder, wiper baffle plate, wiper mounting plate, car body , washer fluid sprayer; the plane under the front window of the car body is fixedly equipped with the wiper installation plate, and the cylindrical surface at the tail end of the rotating cover is installed in the through holes on both sides of the wiper installation plate, and the rotating cover can be rotated on the wiper installation plate The tail end of the active wiper is fixedly connected with the slot at the tail end of the swing wiper chuck, and the active wiper can swing with the rotation of the swing wiper chuck; the swing wiper chuck can rotate on the handle, The swinging wiper can swing relative to the active wiper; through the relative rotation of the main swinging wiper and the drive of the electric cylinder, the entire area of the front glass of the car can be wiped, which greatly improves the safety of the car in rainy weather.

Owner:江苏朗禾控制系统有限公司

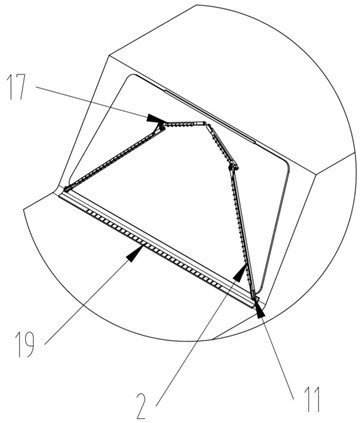

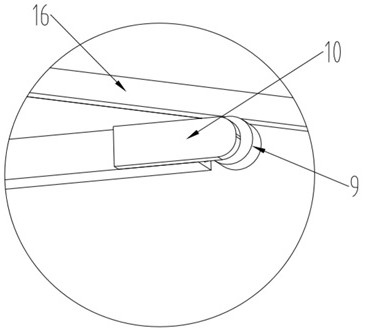

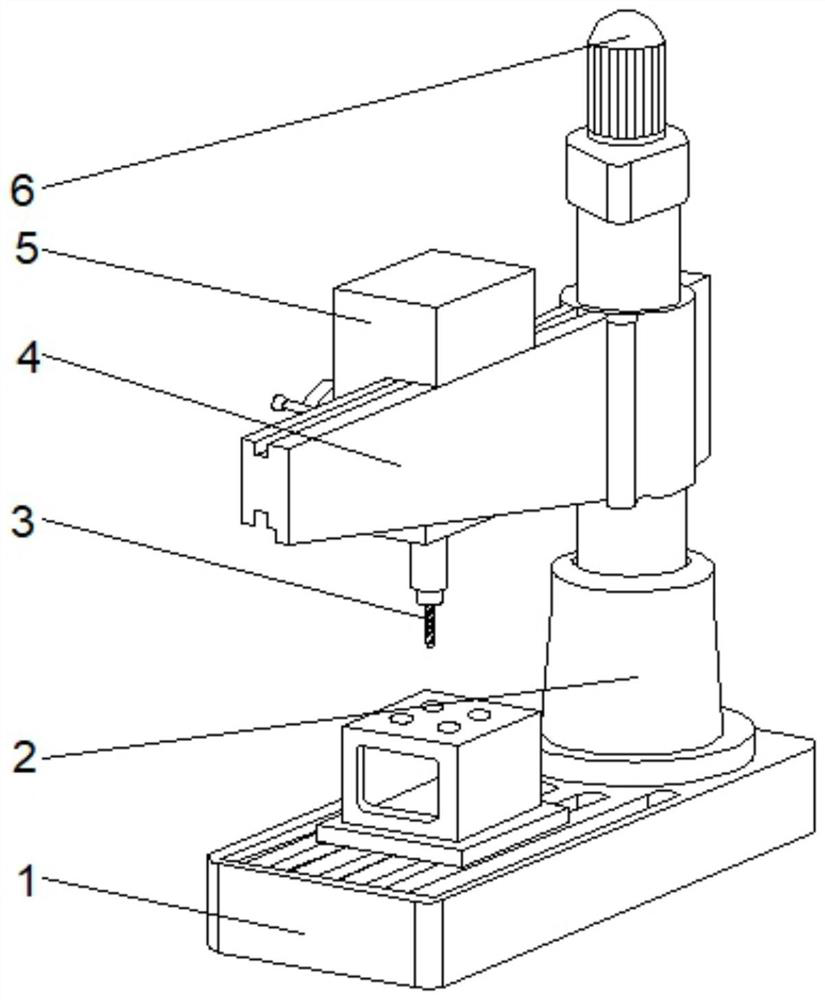

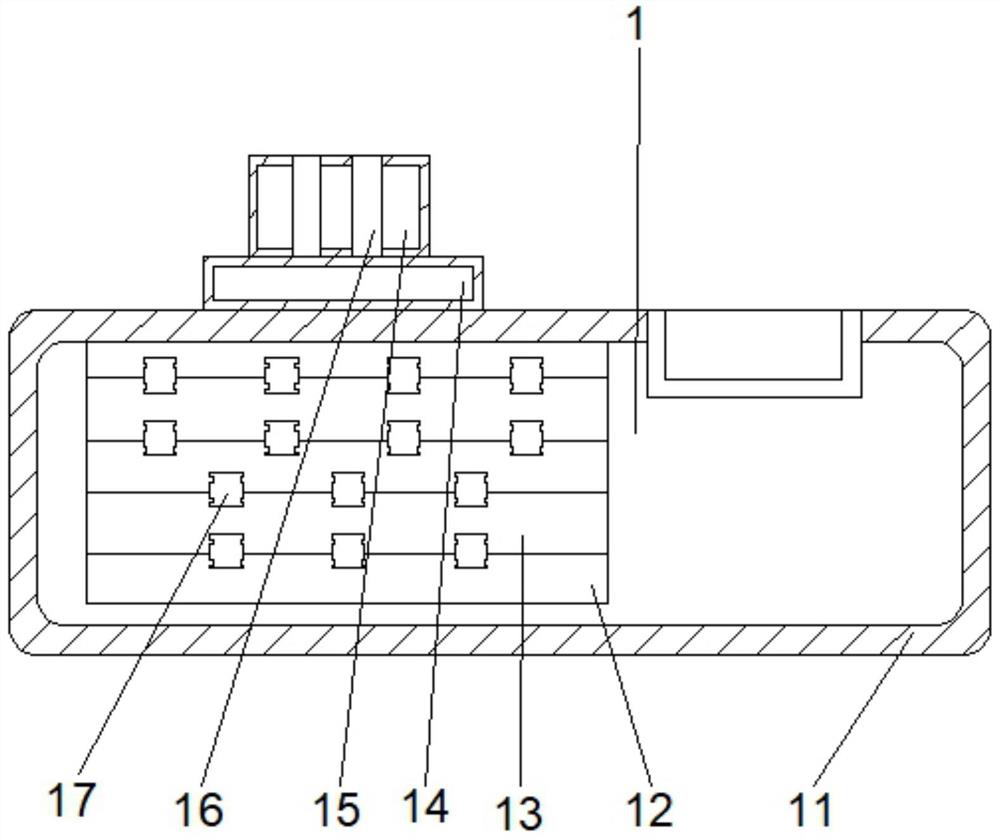

Drilling equipment for machining

PendingCN113427040AAvoid swiping againComprehensive mechanical collectionPositioning apparatusMaintainance and safety accessoriesElectric machineryStructural engineering

The invention discloses drilling equipment for machining, which comprises a stand column, wherein the bottom end of the stand column is fixedly connected with a cleaning device, a motor is arranged in the middle of the top end of the stand column, a movable frame is arranged on the outer surface of the middle of the stand column, and a fixator is arranged in the middle of the top of the back face of the movable frame; the bottom of the fixator is fixedly connected with a drill bit. The invention relates to the technical field of machining equipment. According to the drilling equipment for machining, sweeps accumulated on a workbench enter a storage groove from a circulating groove in the working process, so that the sweeps are prevented from falling and being clamped between the circulating grooves, the situation that the falling sweeps damage workers or are clamped in gaps and are not easy to clean is effectively prevented, the service life of the equipment is prolonged; and the situation that sweeps adhere to the surface of the device, and consequently deviation of a hole occurs is avoided, the stability of the device body in the drilling process is effectively guaranteed, and the situation that a drill bit is damaged in the drilling process is further avoided.

Owner:李胜强

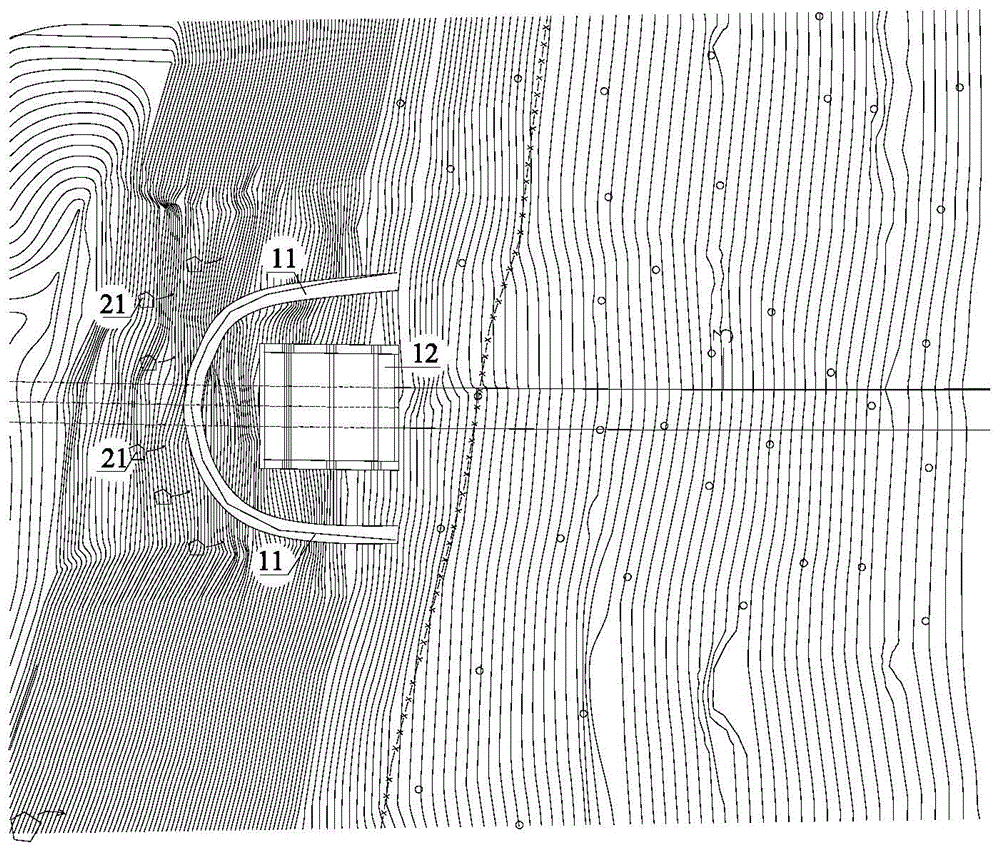

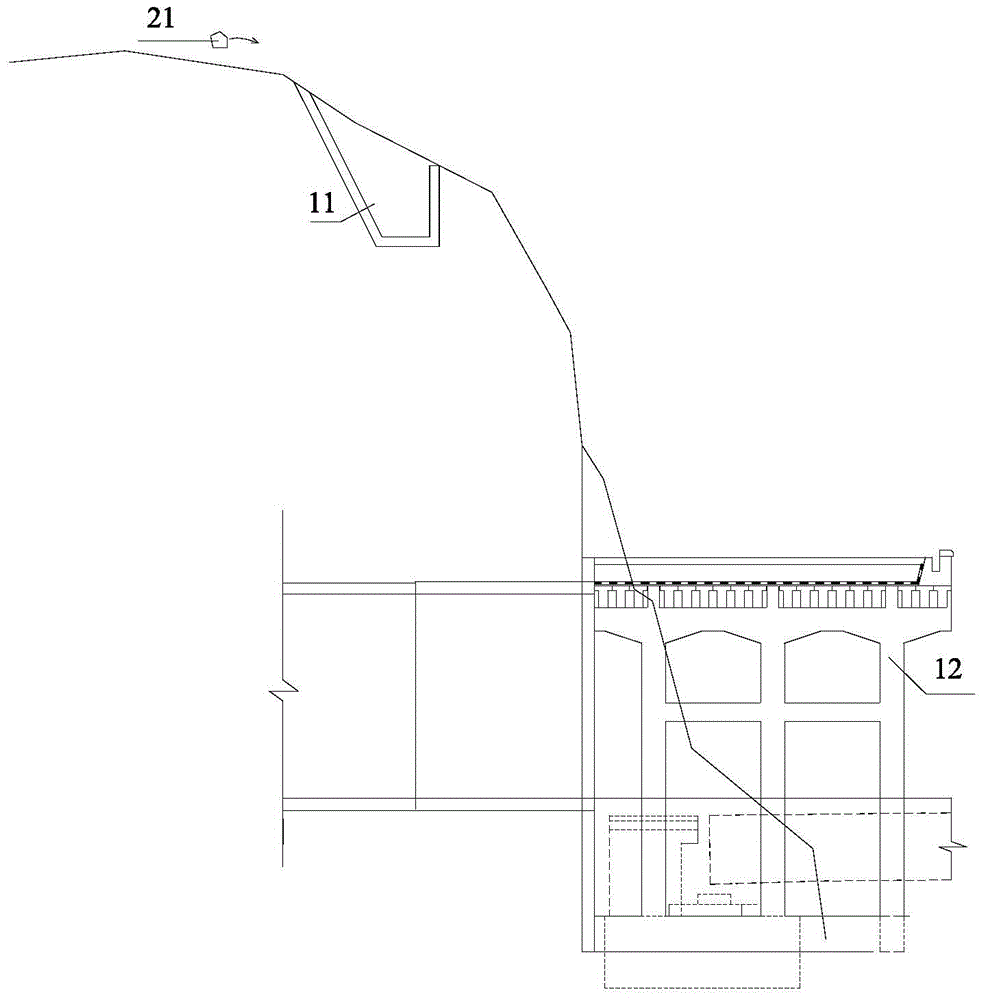

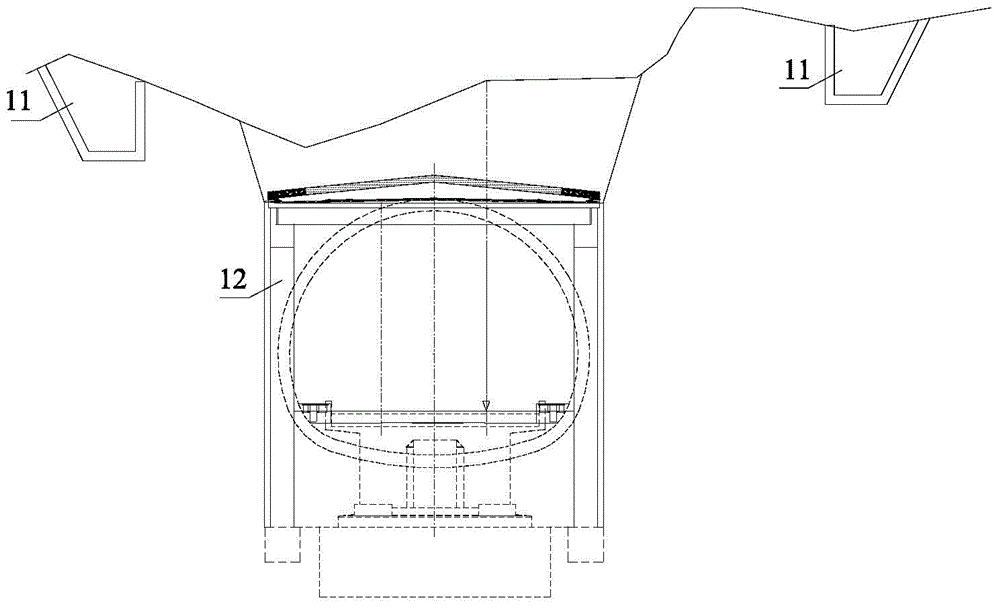

Rockfall prevention structure at tunnel entrance

The invention discloses a rockfall prevention structure for a tunnel portal. The rockfall prevention structure for the tunnel portal aims to substantially reduce the amount of moving rocks at the tunnel portal, lower the construction cost of a rockfall prevention project and reduce the construction difficulty. The rockfall prevention structure for the tunnel portal comprises a tunnel portal structure and a rockfall happening area located on a slope face above the tunnel portal structure. A falling rock induction groove is formed in the portion, between the tunnel portal structure and the rockfall happening area, of the slope face. The falling rock induction groove is provided with an arc top segment, a left side segment and a right side segment, wherein the arc top segment is close to the rockfall happening area, and the left side segment and the right side segment extend downwards along the original slope face to the portions outside the tunnel portal structure and the line.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Cake pressing device for special-shaped brush production

The invention discloses a cake pressing device for special-shaped brush production. The invention belongs to the technical field of cake pressing devices. The device is characterized by comprising a hollow plate, a pushing mechanism is fixedly connected to the center of the lower surface of the hollow plate, a driven mechanism is arranged in the hollow plate, a pressing plate is fixedly connectedto the bottom end of the pushing mechanism, and two air outlet pipes are fixedly inserted into the left side and the right side of the pressing plate correspondingly; vacuum pumps are fixedly connected to the ends, away from the pressing plate, of the two air outlet pipes, air inlet pipes are fixedly connected to the sides, opposite to each other, of the two vacuum pumps, first inner pipes are fixedly connected to the upper surfaces of the two vacuum pumps, and first outer pipes are slidably connected to the outer walls of the two first inner pipes; by arranging the vacuum pumps at the bottomsof the two first inner pipes, when a special-shaped brush is used for cake press, the special-shaped brush can be effectively prevented from being swiped in a pressure bearing plate by extracting andreleasing air, and therefore convenience is brought to workers in use.

Owner:安徽瑞洁刷业有限公司

Service processing method, terminal and server

ActiveCN108737341BRelieve stressImprove securityKey distribution for secure communicationData terminalThe Internet

The invention discloses a service processing method, a terminal and a server, belonging to the technical field of internets. The terminal and the server authenticate each other in service processing,wherein the authentication process depends on not only a stored secret key or an encryption algorithm but also terminal session data, a terminal request identifier and a secret key, after authentication succeeds, the service is processed. The terminal session data and the terminal request identifier are generated by the terminal in communication with the server, therefore, even if other terminalscan acquire secrete keys stored by the terminal and the server, the terminals cannot acquire the terminal session data and the terminal request identifier, volume is prevented from increasing, the processing pressure of the server is lowered, the server is safer, and the service has better performance.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Dead-corner-free automobile windshield wiper with cleaning device

A dead-corner-free automobile windshield wiper with a cleaning device comprises a driving windshield wiper body, a swinging windshield wiper body, a swinging windshield wiper chuck, a rotating handle,a spring, a rolling wheel, a rolling wheel mounting plate, rotating covers, an electric cylinder, a windshield wiper baffle, a windshield wiper mounting plate, an automobile body and a cleaning fluidsprayer. The windshield wiper mounting plate is fixedly installed on the plane below a front window of the automobile body, the cylindrical faces of the tail ends of the rotating covers are installedin through holes in the two sides of the windshield wiper mounting plate, and the rotating covers can rotate on the windshield wiper mounting plate. The tail end of the driving windshield wiper bodyis provided with a clamping groove fixedly connected with the clamping groove in the tail end of the swinging windshield wiper chuck, and the driving windshield wiper body can swing along with rotation of the swinging windshield wiper chuck. The swinging windshield wiper chuck can rotate on the rotating handle, and the swinging windshield wiper can swing relative to the driving windshield wiper body; through the relative rotation of the main swinging windshield wiper and the driving of the electric cylinder, the whole area of a front glass of an automobile can be wiped, and the safety of the automobile running in rainy days is greatly improved.

Owner:NANJING LONHER DATE CO LTD

A fuel supply system for marine dual-fuel engines that can avoid loss of natural gas exchange

ActiveCN105422319BAvoid swiping againAvoid wastingInternal combustion piston enginesFuel supply apparatusCombustion chamberInlet valve

The invention aims to provide a ship dual-fuel engine fuel supply system capable of preventing a natural gas change loss. The ship dual-fuel engine fuel supply system comprises a natural gas tank, a mixer, a combustion chamber and an air main pipe; an intake main pipe is arranged in an intake valve of the combustion chamber; an exhaust passage is formed in an exhaust door of the combustion chamber; a diesel nozzle is mounted in the top of the combustion chamber; the natural gas tank is communicated with an inlet of a natural gas channel; an outlet of the natural gas channel is communicated with the mixer; the mixer is communicated with the intake main pipe through a mixed gas intake passage; the tail end of the air main pipe is divided into a first branch pipe and a second branch pipe; the first branch pipe is communicated with the mixer; and the second branch pipe is communicated with the intake main pipe. The ship dual-fuel engine fuel supply system prevents mixed gas from being directly fed into air in the gas change process, so that the fuel waste and the environmental damage are prevented.

Owner:HARBIN ENG UNIV

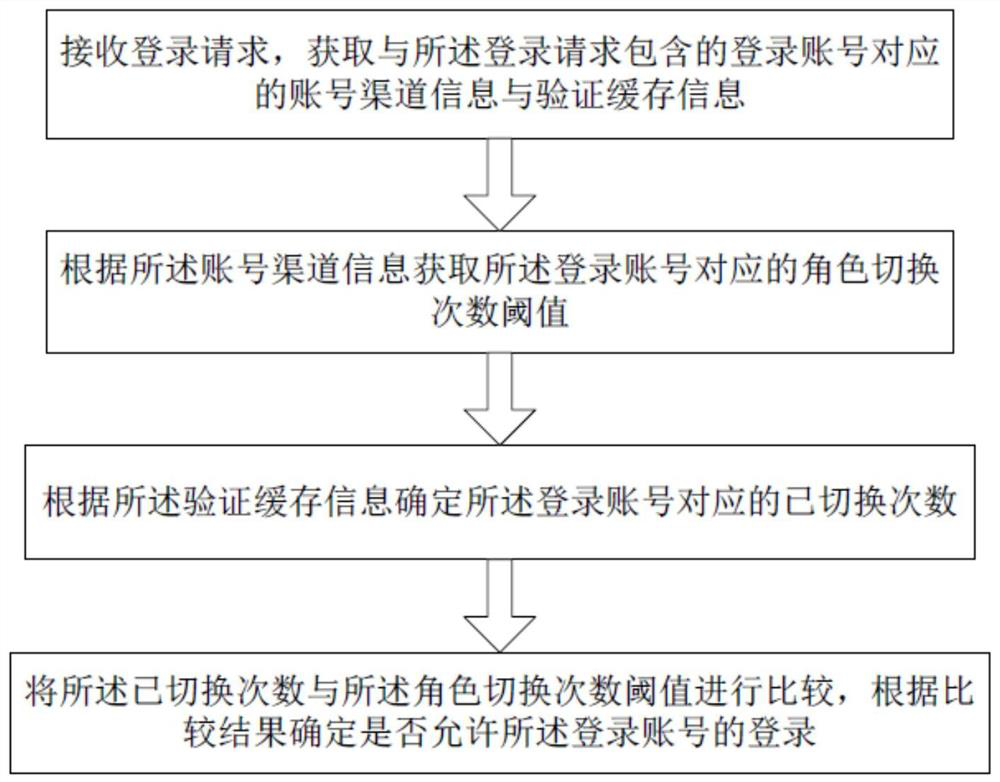

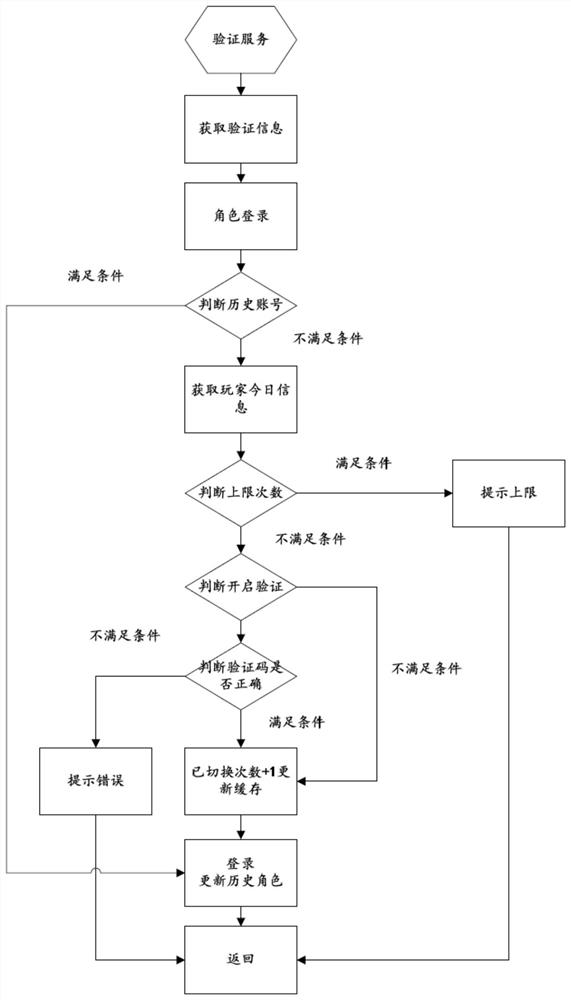

Account anti-refreshing method and terminal

PendingCN114733203AImprove stabilityAvoid swiping againDigital data authenticationVideo gamesEngineeringSwitching frequency

The invention discloses an account number anti-refreshing method and a terminal, and the method comprises the steps: obtaining role channel information and verification cache information corresponding to a login account number contained in a login request, obtaining a corresponding role switching frequency threshold value according to the account number channel information, and determining the switching frequency corresponding to the login account number according to the verification cache information. The number of switched times is compared with a role switching time threshold value, whether login of the login account is allowed or not is determined according to a comparison result, different account channels have corresponding role switching time threshold values, and whether login is allowed or not is determined by comparing the number of switched times corresponding to the login account with the role switching time threshold value. The number of times of role switching of different channel user login accounts is effectively limited, the situation that a workroom frequently switches the accounts to swipe list information rewards or frequently tests player accounts through technical means is prevented, the number swipe behavior can be prevented while normal user login accounts are not affected, and the user experience is improved. And the stability of the server is improved.

Owner:福建天晴在线互动科技有限公司

An automatic sorting line for logistics transportation

ActiveCN107442415BGuaranteed StrengthEasy to transportGas current separationLogistics managementStructural engineering

The invention discloses a logistics transportation automatic sorting line. The bottom faces of the connecting positions of a first conveying plate and a second conveying plate of a conveying device of the logistics transportation automatic sorting line are hinged through a hinge, and the two conveying plates are connected through a telescopic pipe. A lifting ring is fixed to the bottom face of the output end of the second conveying plate. One end of a steel cable is tied on the lifting ring, and the other end of the steel cable is wound around a roller. A forked strip plate is further included, a U-shaped long-strip-shaped gap is arranged at one end of the forked strip plate, the other end of the forked strip plate is hinged to a machine shell, and a butterfly nut is screwed at the free end of a hinged shaft. A screening device of the logistics transportation automatic sorting line comprises a longer first conveying belt and a shorter second conveying belt, and the two conveying belts are connected in parallel. A fan is arranged on one side of the first conveying belt, and a first goods receiving bin is arranged on the other side of the first conveying belt. Pressure sensors are arranged below the first conveying belt and the second conveying belt. A hydraulic rod and a second goods receiving bin are arranged at the two ends of the straight line formed by arranging the pressure sensors below the two conveying belts. The sorting line is flexible in conveying and extremely high in sorting efficiency.

Owner:重庆旭永科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com