Logistics transportation automatic sorting line

An automatic sorting and logistics technology, which is applied in the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc. The effect of improving mobility and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

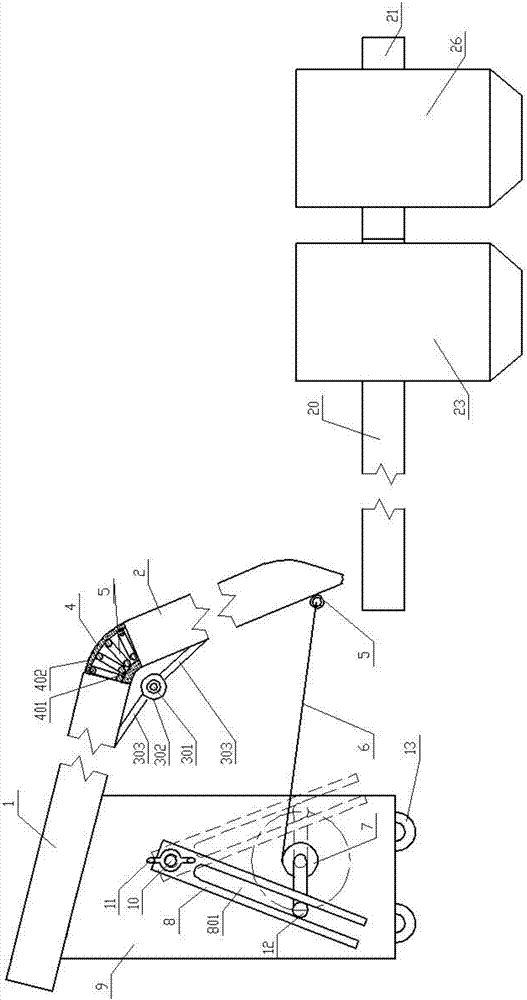

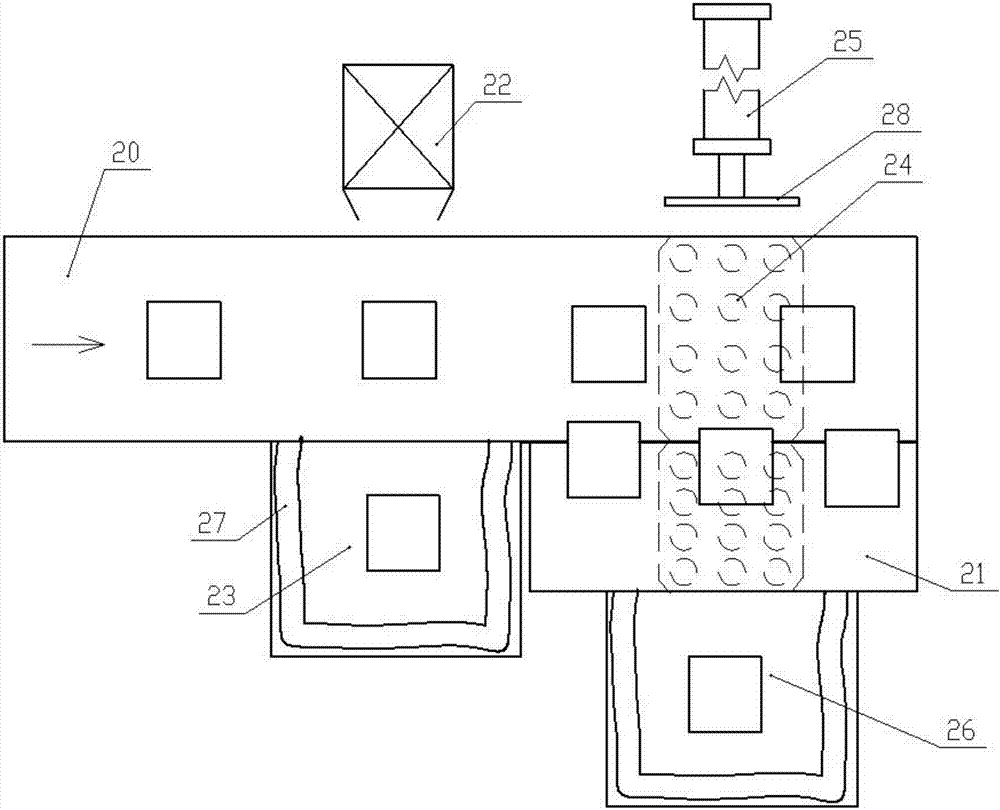

[0015] Such as figure 1 As shown, an automatic sorting line for logistics transportation includes a conveying device and an automatic screening device; the conveying device includes a conveying plate fixed on the top of the casing; the conveying plate includes a first conveying plate 1 and a second conveying plate 2 , wherein the bottom surface of the junction of the first conveying plate 1 and the second conveying plate 2 is hinged by a hinge, and the two conveying plates are connected by a telescopic tube 4, and the telescopic tube 4 is a hollow rectangular tube structure made of elastic rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com