Solar textile machinery recovery frame with automatic loading and unloading function

A technology for textile machinery and automatic loading and unloading, which is applied in textiles and papermaking, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of accumulated residues in sliding grooves, poor sliding, and increased cost of disassembly devices, so as to reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

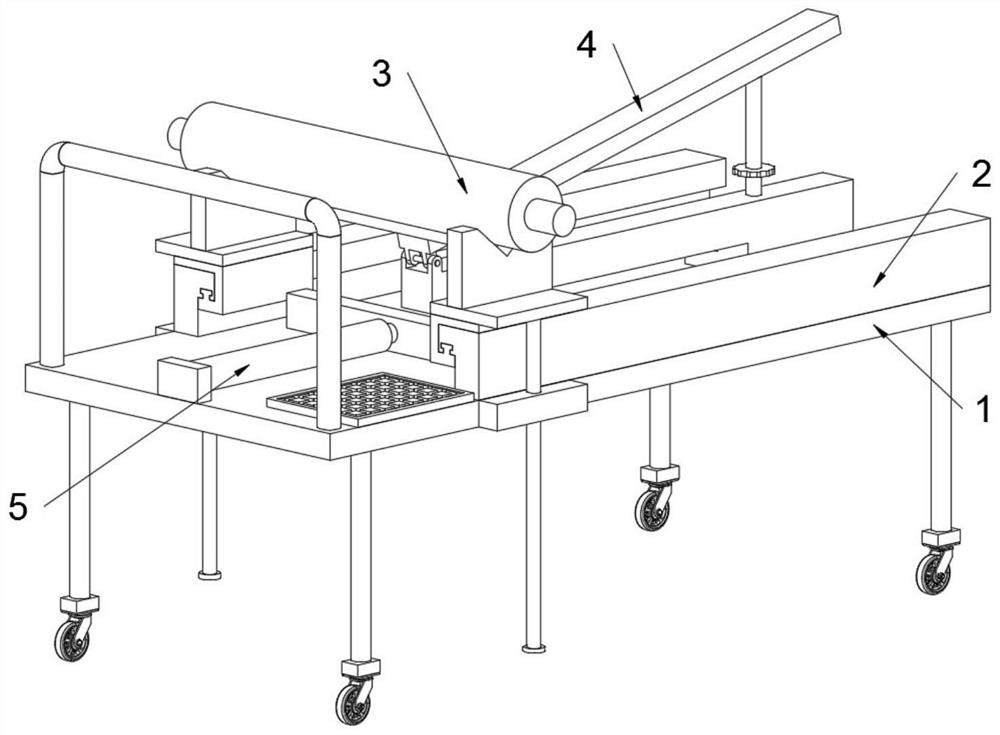

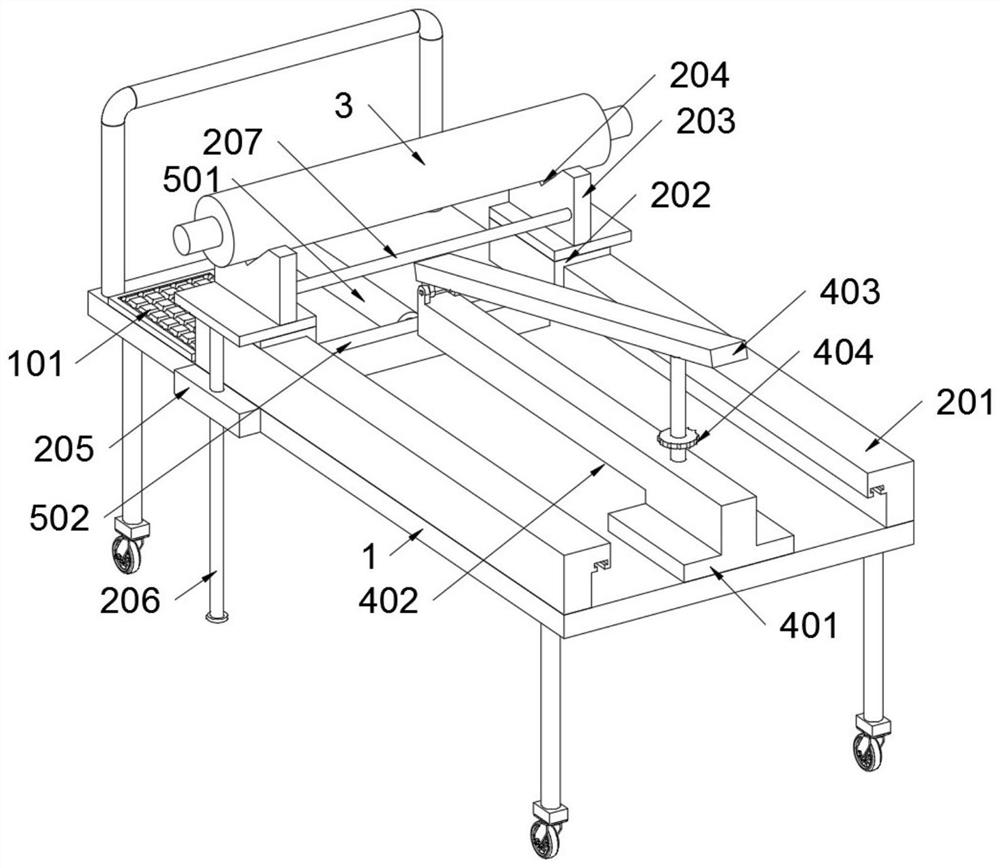

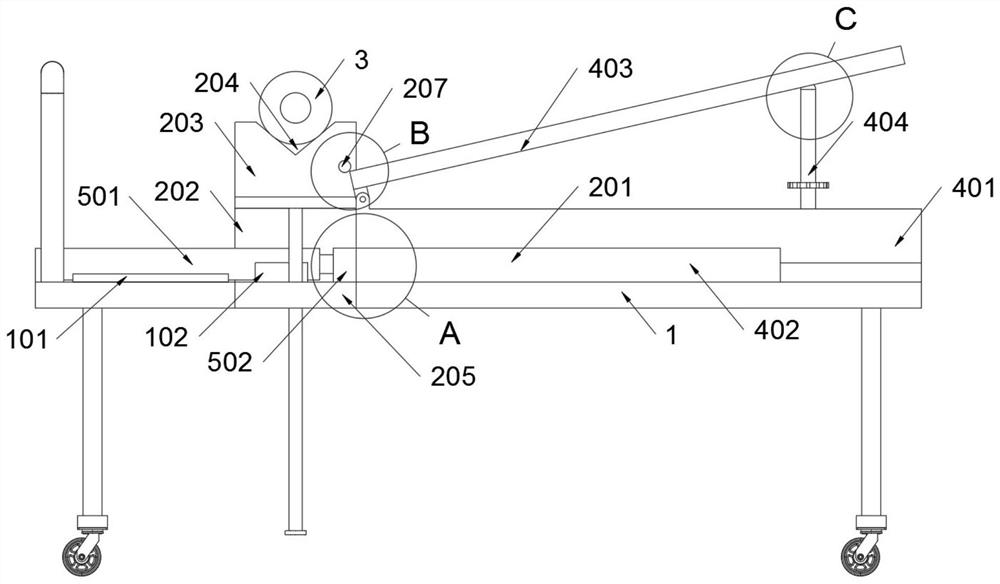

[0033] as attached figure 1 to attach Figure 7 Shown:

[0034] The invention provides a solar textile machinery recovery rack with automatic loading and unloading function, which includes a car body 1; a sliding structure 2 is installed on the car body 1, and a roller 3 is installed on the sliding structure 2; a lifting structure is installed on the car body 1 4, and the car body 1 is also equipped with an electric telescopic rod 501; refer to as image 3, the sliding structure 2 includes a cylindrical rod 207, the cylindrical rod 207 is welded between two placement seats 203, and the cylindrical rod 207 is a cylindrical rod-shaped structure; the lifting structure 4 also includes a force rod 403, and the force rod 403 Rotationally connected to the main body seat 401, and the force rod 403 is arranged obliquely, and the inclination angle is 35 degrees; the position of the force rod 403 is aligned with the cylindrical rod 207, and the top surface of the force rod 403 is polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com