Forming and tempering method and forming and tempering equipment of tempered glass

A tempered glass and equipment technology, which is applied in glass forming, glass tempering, glass reshaping, etc., can solve the problems of affecting the quality of tempering, large deformation range, and the air grid structure cannot adapt to various special-shaped glass, etc., to achieve blowing Uniform, guaranteed tempering quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Embodiment 1: Regarding the description of the flexible pressing mechanism, take the production of V-shaped glass and corrugated glass (or corrugated glass) as an example. The V-shaped glass means that the cross-section of the glass is V-shaped, and the corrugated glass is Refers to the wavy cross-section of the glass, and the same is true for the definition of other special-shaped glasses.

[0106] (1) Figure 16 Indicates the state of the flexible pressing mechanism when producing V-shaped glass. During production, the press-down frame 401 of the flexible press-down mechanism is raised at the initial position as a whole. In this example, the press-down frame 401 is raised by 500mm to facilitate the forming of the crossbeams of each forming section below. Then, according to the shape of the upper surface of the target glass, the vertical telescopic mechanism 403 and the lateral telescopic mechanism 402 act, so that the spatial position of each pressing beam 407 is adj...

Embodiment 2

[0108]Embodiment 2: Regarding the description of the upper air grid mechanism of the tempering section, the production of V-shaped glass and √-shaped glass is taken as an example.

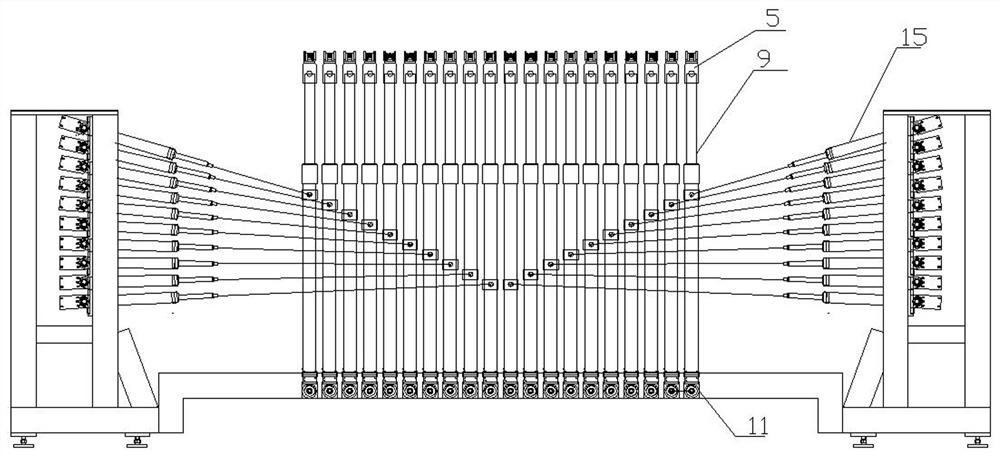

[0109] (1) After the V-shaped glass is formed in the forming section, it is sent to the tempering section. Before that, the upper air grille needs to be preformed in advance. Please refer to here Figure 18 shown. First, raise the upper air grid frame 301 from the initial position, 1000mm in this example, then the vertical lifting rod 304 shrinks to raise the center of the entire upper air grid (that is, the two air grid units), and then the air package The lifting mechanism and the air grid adjustment mechanism work to adjust the angle, horizontal and vertical positions of each hard air box 310, and finally make the lower surface of each hard air box 310 in the upper air grid fit to form a V-shaped blower that matches the shape of the glass. noodle. Figure 18 It can also be seen in the matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com