LaserTRACER-based method for detecting and identifying geometrical errors of translational shafts of numerical control machine tool

A geometric error, CNC machine tool technology, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems that have not yet been found, and achieve the effect of rapid calibration and good identification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0024] like figure 1 As shown, the LaserTRACER-based CNC machine tool translational axis geometric error detection and identification method provided by the present invention includes the following steps in order:

[0025] 1) Construct a measurement system composed of CNC machine tools and LaserTRACER, and use the measurement system to measure the end pose error of the machine tool;

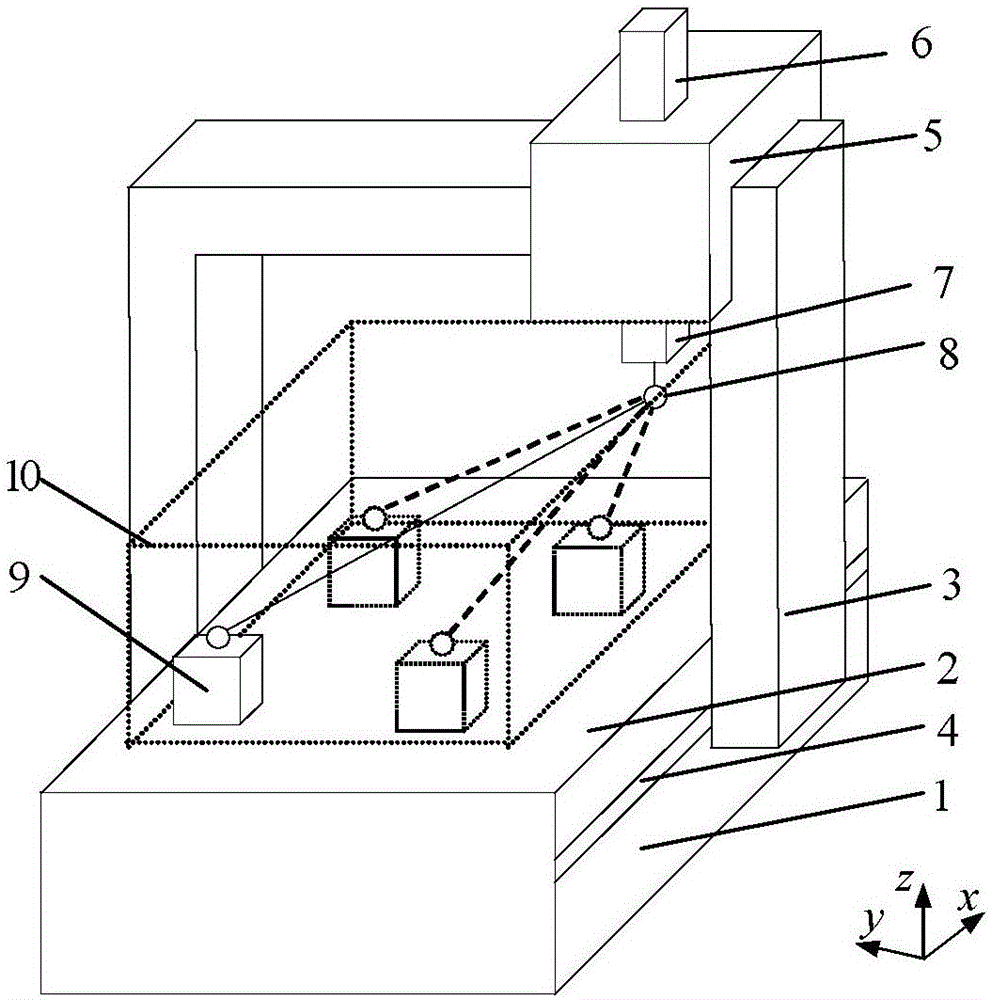

[0026] like figure 2 As shown, in the measurement system, the CNC machine tool mainly includes a bed 1, a column 3, an X guide rail 4, a Y guide rail, a Y slide table 5, a Z guide rail, a Z slide table 6, and a spindle 7; The upper end surface is the workbench 2, and the X guide rail 4 is installed in the X-axis (front and back) direction on both sides of the bed 1, and the inner side of the lower end of the door-shaped column 3 forms a moving pair with the X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com