Low noise fast response permanent magnet DC brushless motor for constant wind control

A permanent magnet DC, brushless motor technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems that affect the smooth and low-noise operation of the motor, the difficulty of industrialization, and the small starting torque, etc., to achieve Improve air gap magnetic field waveform, overcome electromagnetic noise and rotor loss, and reduce torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention adopts a permanent magnet brushless DC motor fan with DC frequency conversion, and its working principle is: the stator produces a rotating magnetic field that directly interacts with the rotor permanent magnetic field to make the motor run, and the motor speed can be adjusted by changing the DC voltage.

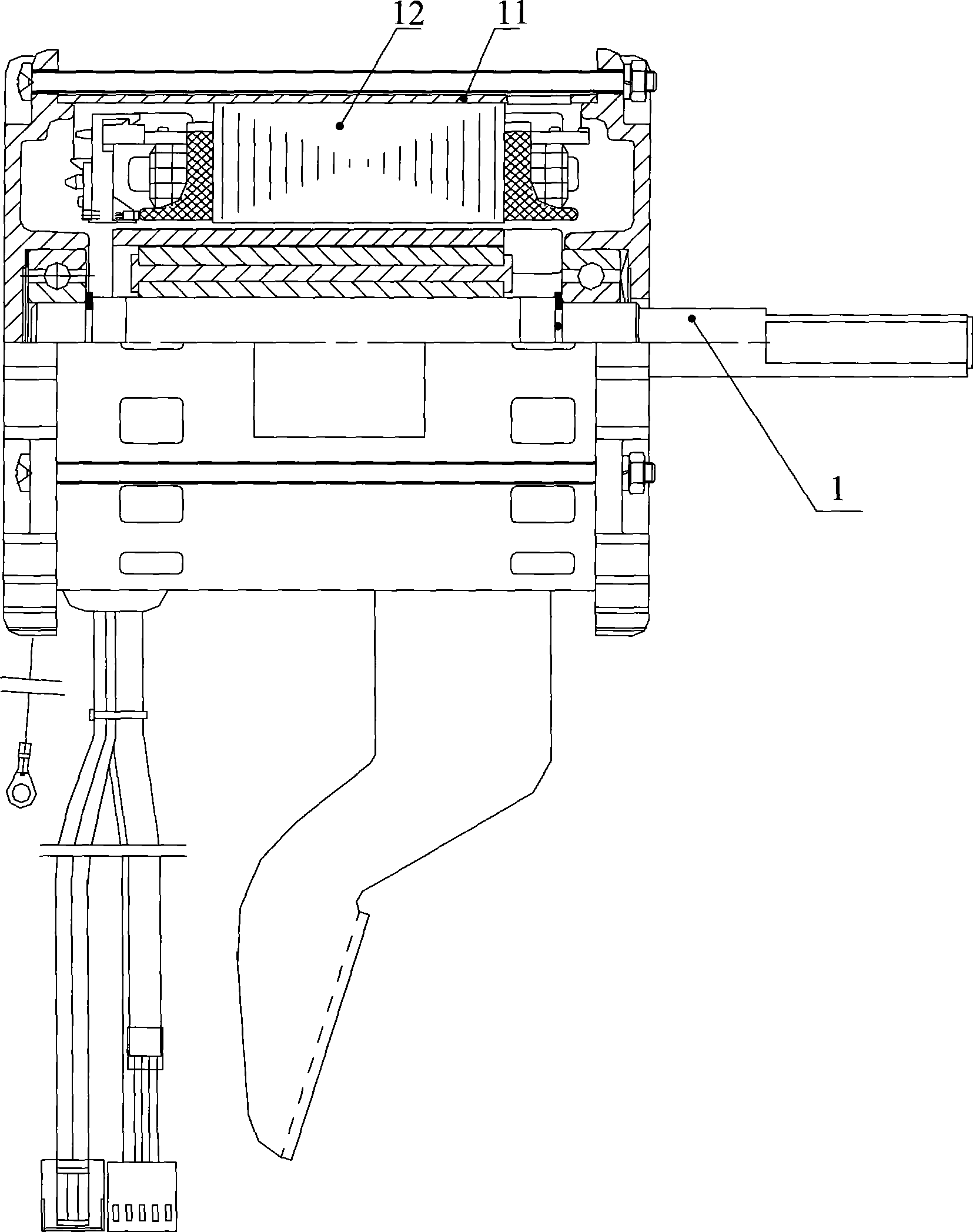

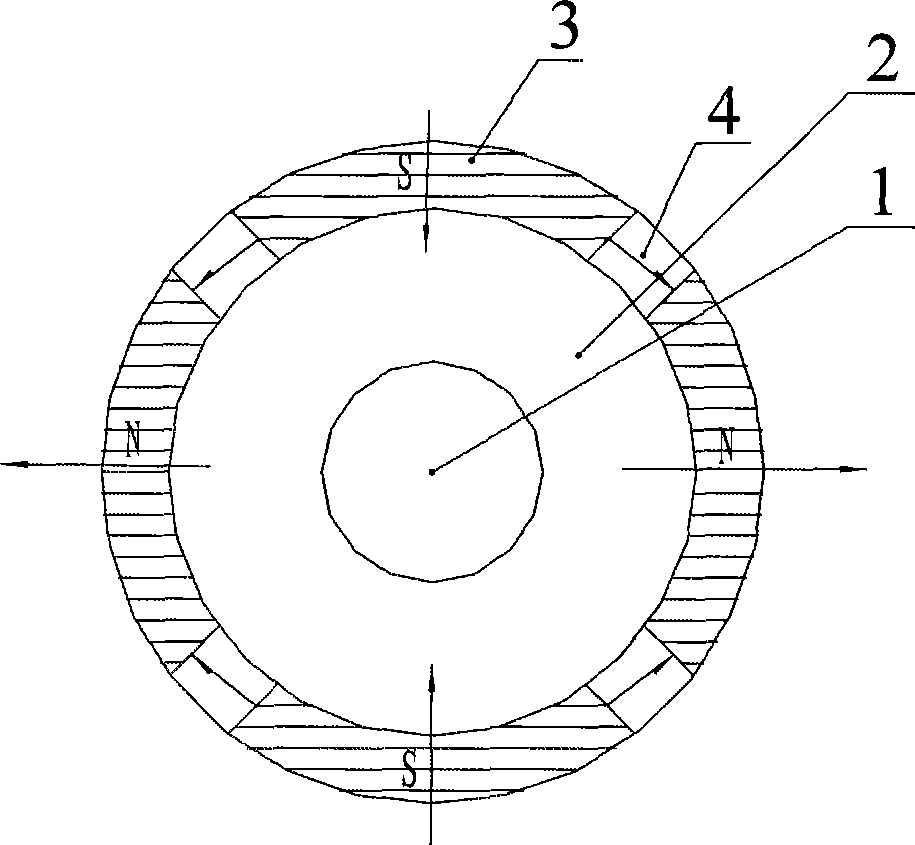

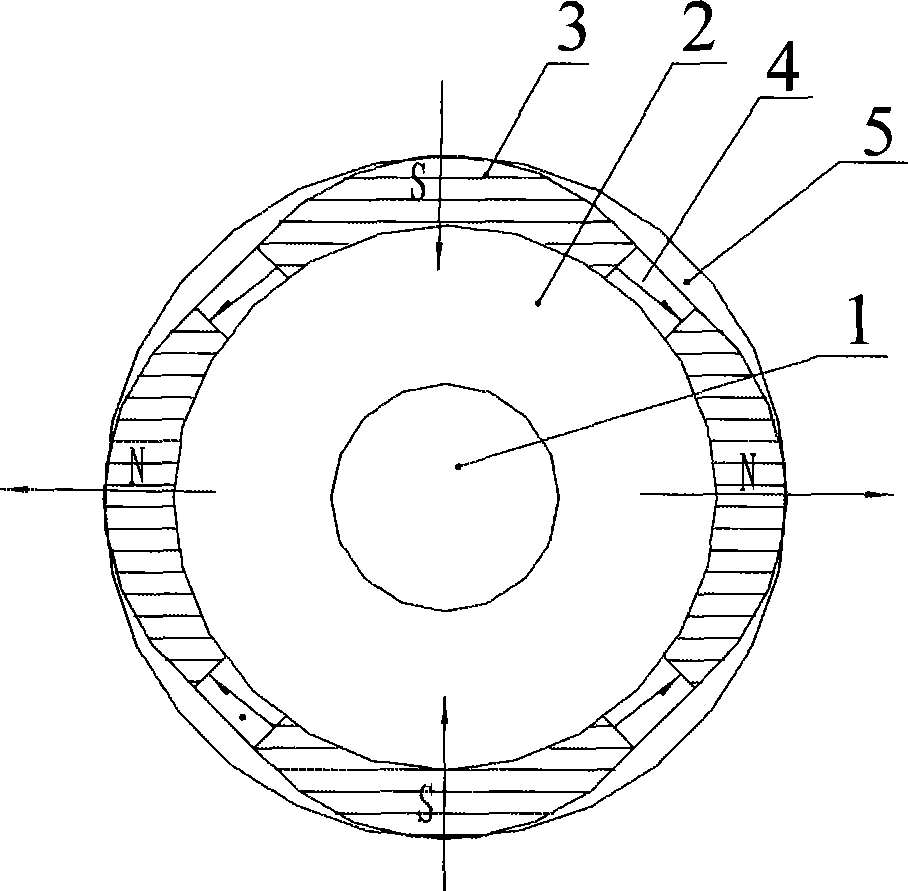

[0030] figure 1 As shown, a low-noise and quick-response permanent magnet brushless DC motor for constant air volume control includes a casing 11, a stator 12 and a rotor inside the casing, and the stator includes a stator core and a stator winding fixed on the inner wall of the casing. The shell doubles as the stator magnetically permeable yoke. Permanent magnet rotors with mixed poles of radially and tangentially magnetized steel magnets, such as figure 2 , 3 , 4 shows: the permanent magnet rotor includes the main shaft 1, the rotor iron core 2 and the outer circumference direction of the rotor iron core are uniformly fixed with magnetic pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com