Built-in permanent magnet synchronous motor

A permanent magnet synchronous motor, built-in technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the comprehensive quality of permanent magnet synchronous motors Poor, affecting motor efficiency, wide speed regulation and other issues, to achieve the effect of optimizing the orientation of the magnetic steel, improving the waveform of the air gap flux density, and reducing the torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

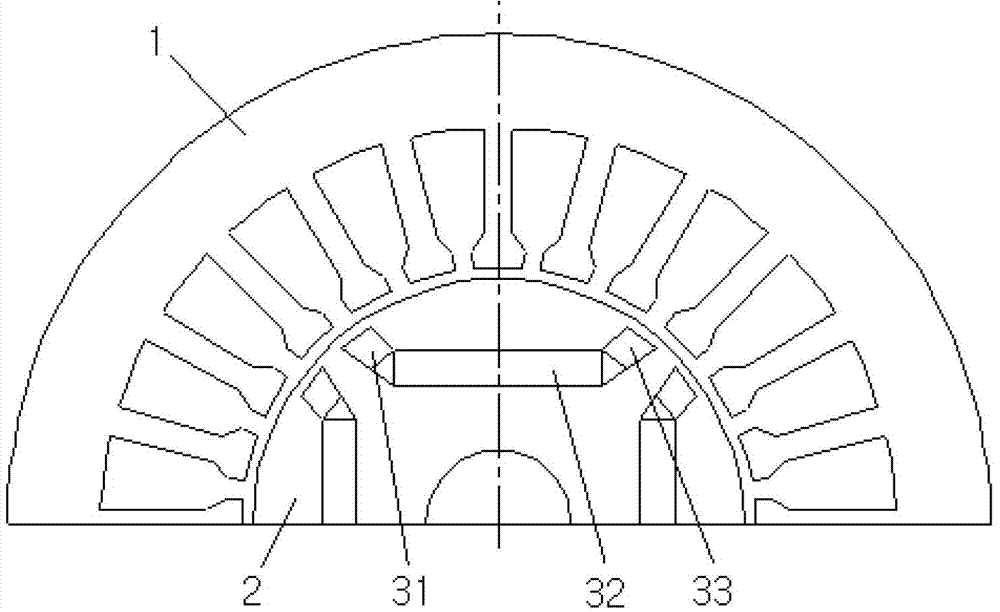

[0024] Such as figure 1 As shown, a built-in permanent magnet synchronous motor provided by the first embodiment of the present invention includes a stator 1 and a rotor 2, and an air gap is left between the inner peripheral surface of the stator 1 and the outer peripheral surface of the rotor 2;

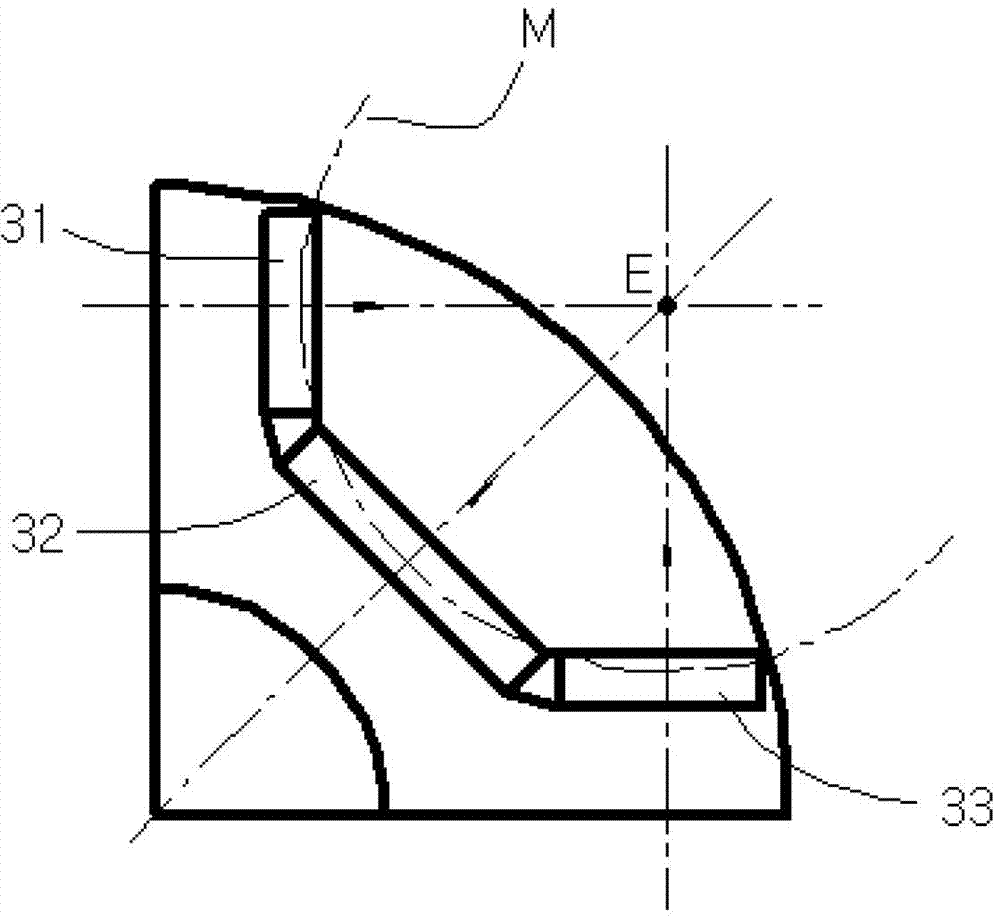

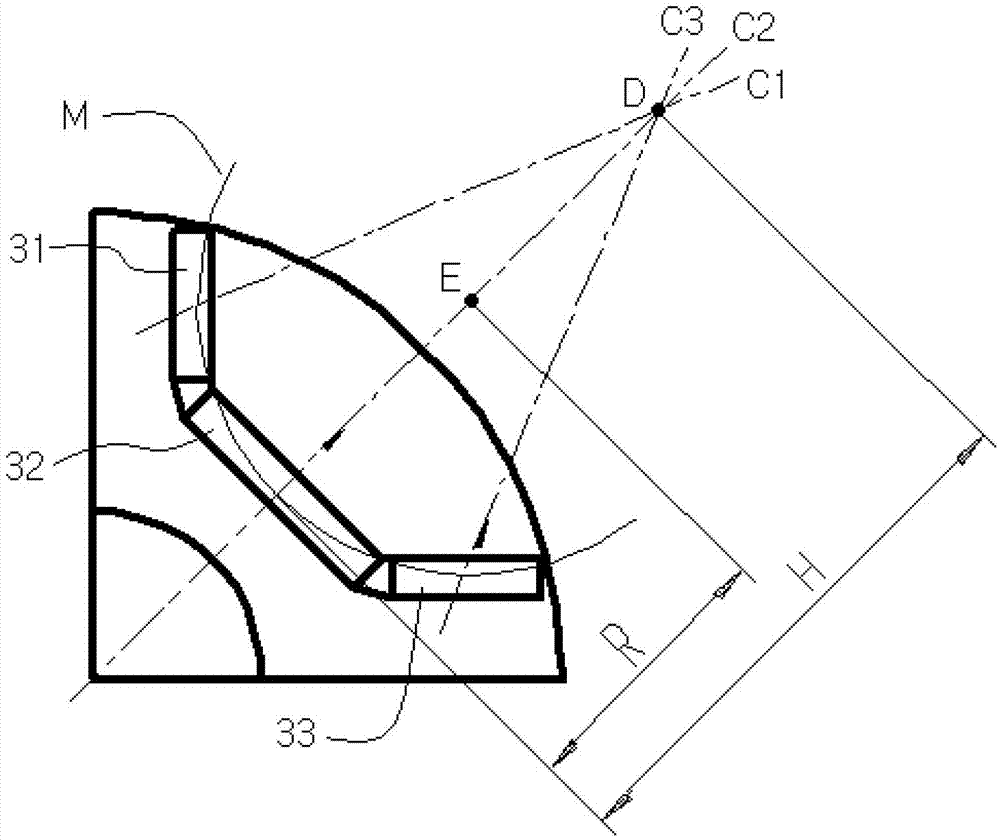

[0025] The rotor 2 is provided with a plurality of permanent magnet slots at axially symmetrical intervals around the central axis of the rotor 2, and three permanent magnets 31, 32, 33 are arranged in each permanent magnet slot, and three permanent magnets 31, 32, 33 are arranged in each permanent magnet slot. Among the magnets, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com