Robot joint rotating hydraulic cylinder with torque and angle feedback functions

A technology of robot joints and rotary hydraulic cylinders, applied in manipulators, fluid pressure actuation devices, manufacturing tools, etc., can solve the problems of small torque density ratio, large space occupation, large overall size, etc., and achieve high torque density and power density. , The effect of balanced force and small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

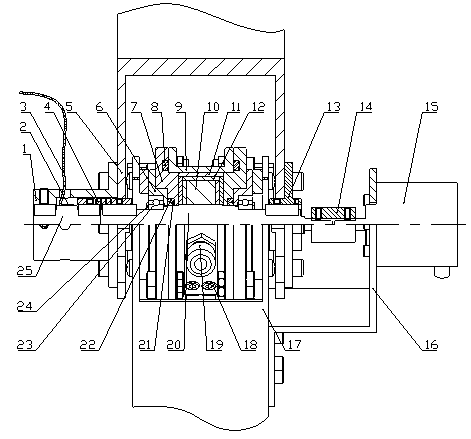

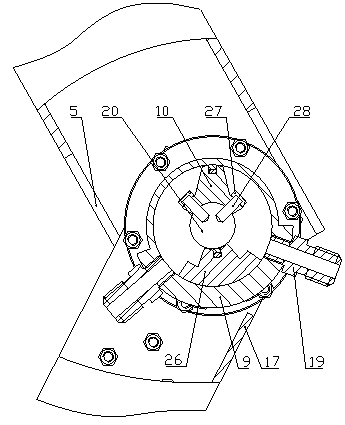

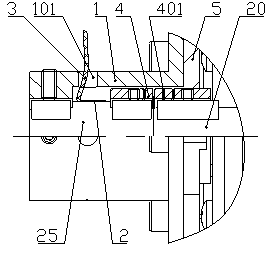

[0027] Such as Figure 1 to Figure 5 As shown, the present invention is a robot joint rotary hydraulic cylinder with torque and angle feedback, including an open-type sealed hydraulic swing cylinder, a torque sensing module and an angular displacement sensing module. The open-type sealed hydraulic swing cylinder includes the swing cylinder output shaft 20, the elastic retaining ring 24, the bearing 23, the shaft sleeve 6, the leak radial O-ring 22, the leak O-type PTFE ring 21, the open cylinder Cover 7, external leakage axial O-ring 8, cylinder body 9, fixed blade 26, moving blade 10, internal leakage PTFE strip 11, internal leakage sealing strip 12 and oil inlet and outlet passage connector 19. The moving blade 10 and the swing cylinder output shaft 20 are placed inside the cylinder body 9, and the moving blade 10 is fixedly connected to the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com